automatic transmission FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 303 of 413

07-01-12

General Transmission Service

07-01-12

the transmission,

any

metal particles

or clutch plate

or

band material that

may have been carried into

the

cooler

should

be

removed from

the

system

by

flushing

the

cooler

and

lines before

the transmission

is put

back into serv-

ice.

In no

case should

an

automatic

transmission having

a

clutch

or

band

failure

or

other internal trouble result-

ing

in

fluid contamination,

be put

back into service without first flushing

the transmission

oil

cooler.

To flush

the oil

cooler, follow

the

instruct!

on >

provided with

the

Rotun-

da Automatic Transmission Torque

Converter

and

Cooler Cleaner

LRE-

60081.

INSPECTION

TURBINE

AND

STATOR

END

PLAY CHECK

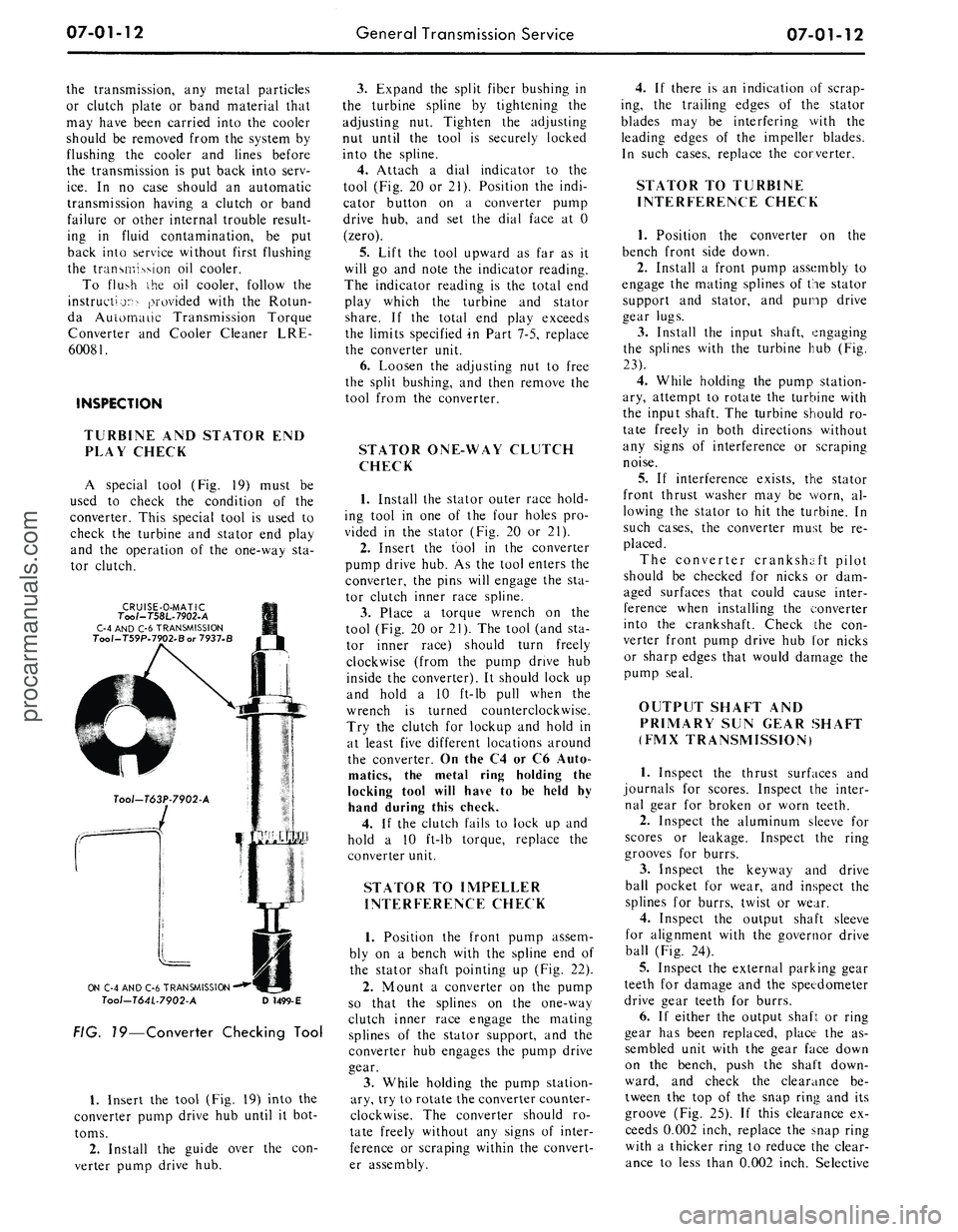

A special tool

(Fig. 19)

must

be

used

to

check

the

condition

of the

converter. This special tool

is

used

to

check

the

turbine

and

stator

end

play

and

the

operation

of the

one-way

sta-

tor clutch.

CRUISE-O-MATIC

Too/-T58L-7902-A

C-4 AND C-6 TRANSMISSION

Tool-T59P.7902.Bor 7937-B

ON C-4 AND C-6 TRANSMISSION

Tool-T64L-7902-A

D

1499-E

FIG. 19—Converter Checking Tool

1.

Insert

the

tool (Fig.

19)

into

the

converter pump drive

hub

until

it

bot-

toms.

2.

Install

the

guide over

the con-

verter pump drive

hub.

3.

Expand

the

split fiber bushing

in

the turbine spline

by

tightening

the

adjusting

nut.

Tighten

the

adjusting

nut until

the

tool

is

securely locked

into

the

spline.

4.

Attach

a

dial indicator

to the

tool (Fig.

20 or

21). Position

the

indi-

cator button

on a

converter pump

drive

hub, and set the

dial face

at 0

(zero).

5.

Lift

the

tool upward

as far as it

will

go and

note

the

indicator reading.

The indicator reading

is the

total

end

play which

the

turbine

and

stator

share.

If the

total

end

play exceeds

the limits specified

in

Part 7-5, replace

the converter unit.

6. Loosen

the

adjusting

nut to

free

the split bushing,

and

then remove

the

tool from

the

converter.

STATOR ONE-WAY CLUTCH

CHECK

1.

Install

the

stator outer race hold-

ing tool

in one of the

four holes

pro-

vided

in the

stator (Fig.

20 or 21).

2.

Insert

the

tool

in the

converter

pump drive hub.

As the

tool enters

the

converter,

the

pins will engage

the sta-

tor clutch inner race spline.

3.

Place

a

torque wrench

on the

tool (Fig.

20 or

21).

The

tool (and

sta-

tor inner race) should turn freely

clockwise (from

the

pump drive

hub

inside

the

converter).

It

should lock

up

and hold

a 10

ft-lb pull when

the

wrench

is

turned counterclockwise.

Try

the

clutch

for

lockup

and

hold

in

at least five different locations around

the converter.

On

the

C4

or C6

Auto-

matics,

the

metal ring holding

the

locking tool will have

to be

held

by

hand during this check.

4.

If the

clutch fails

to

lock

up and

hold

a 10

ft-lb torque, replace

the

converter unit.

STATOR

TO

IMPELLER

INTERFERENCE CHECK

1.

Position

the

front pump assem-

bly

on a

bench with

the

spline

end of

the stator shaft pointing

up

(Fig.

22).

2.

Mount

a

converter

on the

pump

so that

the

splines

on the

one-way

clutch inner race engage

the

mating

splines

of the

stator support,

and the

converter

hub

engages

the

pump drive

gear.

3.

While holding

the

pump station-

ary, try

to

rotate the converter counter-

clockwise.

The

converter should

ro-

tate freely without

any

signs

of

inter-

ference

or

scraping within

the

convert-

er assembly.

4.

If

there

is an

indication

of

scrap-

ing,

the

trailing edges

of the

stator

blades

may be

interfering with

the

leading edges

of the

impeller blades.

In such cases, replace

the

converter.

STATOR

TO

TURBINE

INTERFERENCE CHECK

1.

Position

the

converter

on the

bench front side down.

2.

Install

a

front pump assembly

to

engage

the

mating splines

of

the

stator

support

and

stator,

and

pump drive

gear lugs.

3.

Install

the

input shaft, engaging

the splines with

the

turbine

hub (Fig.

23).

4.

While holding

the

pump station-

ary, attempt

to

rotate

the

turbine with

the input shaft.

The

turbine should

ro-

tate freely

in

both directions without

any signs

of

interference

or

scraping

noise.

5.

If

interference exists,

the

stator

front thrust washer

may be

worn,

al-

lowing

the

stator

to hit the

turbine.

In

such cases,

the

converter must

be re-

placed.

The converter crankshaft pilot

should

be

checked

for

nicks

or dam-

aged surfaces that could cause inter-

ference when installing

the

converter

into

the

crankshaft. Check

the con-

verter front pump drive

hub for

nicks

or sharp edges that would damage

the

pump seal.

OUTPUT SHAFT

AND

PRIMARY

SUN

GEAR SHAFT

(FMX TRANSMISSION)

1.

Inspect

the

thrust surfaces

and

journals

for

scores. Inspect

the

inter-

nal gear

for

broken

or

worn teeth.

2.

Inspect

the

aluminum sleeve

for

scores

or

leakage. Inspect

the

ring

grooves

for

burrs.

3.

Inspect

the

keyway

and

drive

ball pocket

for

wear,

and

inspect

the

splines

for

burrs, twist

or

wear.

4.

Inspect

the

output shaft sleeve

for alignment with

the

governor drive

ball (Fig.

24).

5.

Inspect

the

external parking gear

teeth

for

damage

and the

speedometer

drive gear teeth

for

burrs.

6.

If

either

the

output shaft

or

ring

gear

has

been replaced, place

the as-

sembled unit with

the

gear face down

on

the

bench, push

the

shaft down-

ward,

and

check

the

clearance

be-

tween

the top of the

snap ring

and its

groove

(Fig. 25).

If

this clearance

ex-

ceeds 0.002 inch, replace

the

snap ring

with

a

thicker ring

to

reduce

the

clear-

ance

to

less than 0.002 inch. Selectiveprocarmanuals.com

Page 307 of 413

07-01-16

General Transmission bervice

07-01-16

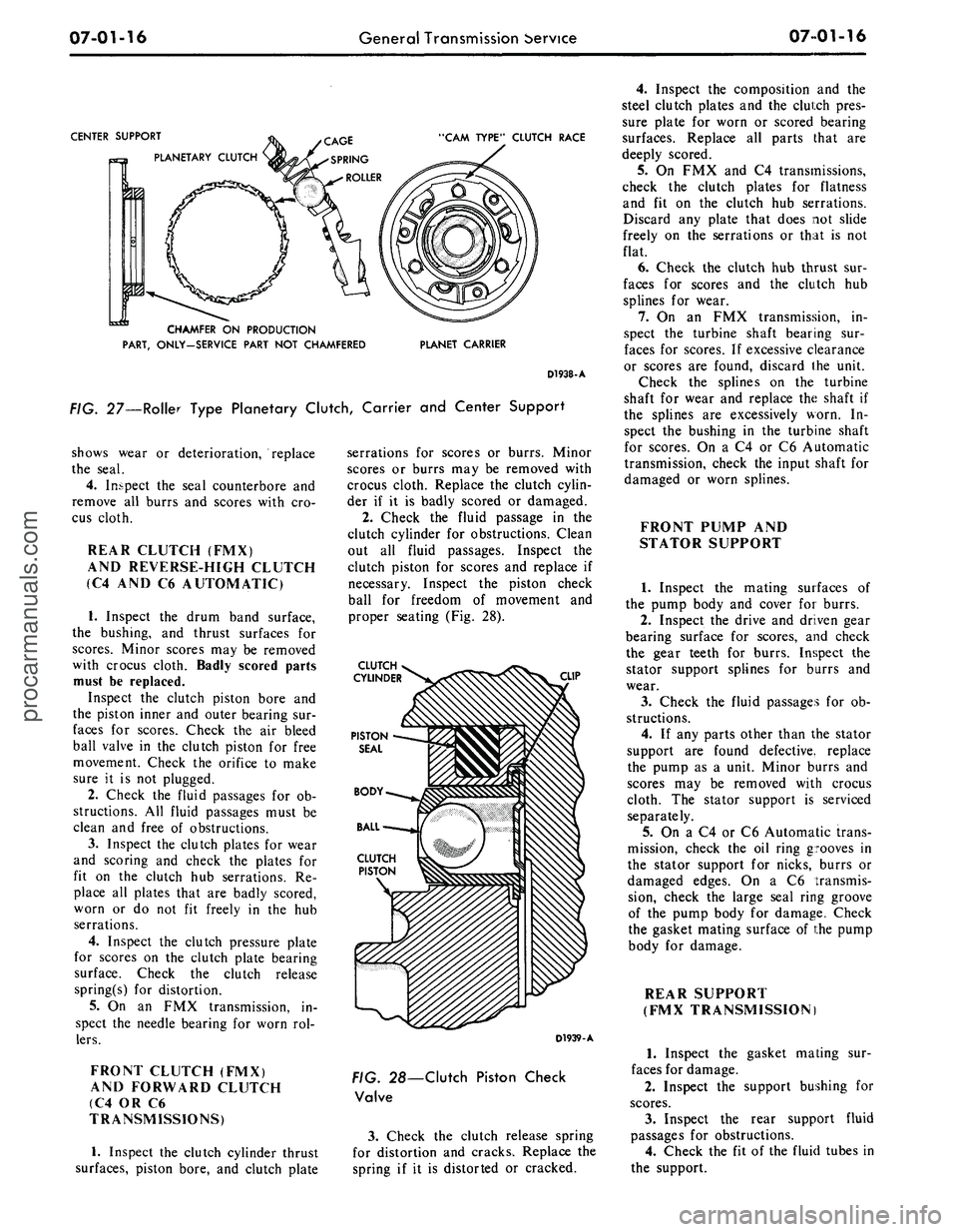

CENTER SUPPORT

PLANETARY CLUTCH

"CAM TYPE" CLUTCH RACE

CHAMFER ON PRODUCTION

PART, ONLY-SERVICE PART NOT CHAMFERED

PLANET CARRIER

D1938-A

FIG. 27—Roller Type Planetary Clutch, Carrier and Center Support

shows wear or deterioration, replace

the seal.

4.

Inspect the seal counterbore and

remove all burrs and scores with cro-

cus cloth.

REAR CLUTCH (FMX)

AND REVERSE-HIGH CLUTCH

(C4 AND C6 AUTOMATIC)

1.

Inspect the drum band surface,

the bushing, and thrust surfaces for

scores. Minor scores may be removed

with crocus cloth. Badly scored parts

must be replaced.

Inspect the clutch piston bore and

the piston inner and outer bearing sur-

faces for scores. Check the air bleed

ball valve in the clutch piston for free

movement. Check the orifice to make

sure it is not plugged.

2.

Check the fluid passages for ob-

structions. All fluid passages must be

clean and free of obstructions.

3.

Inspect the clutch plates for wear

and scoring and check the plates for

fit on the clutch hub serrations. Re-

place all plates that are badly scored,

worn or do not fit freely in the hub

serrations.

4.

Inspect the clutch pressure plate

for scores on the clutch plate bearing

surface. Check the clutch release

spring(s) for distortion.

5.

On an FMX transmission, in-

spect the needle bearing for worn rol-

lers.

FRONT CLUTCH (FMX)

AND FORWARD CLUTCH

(C4 OR C6

TRANSMISSIONS)

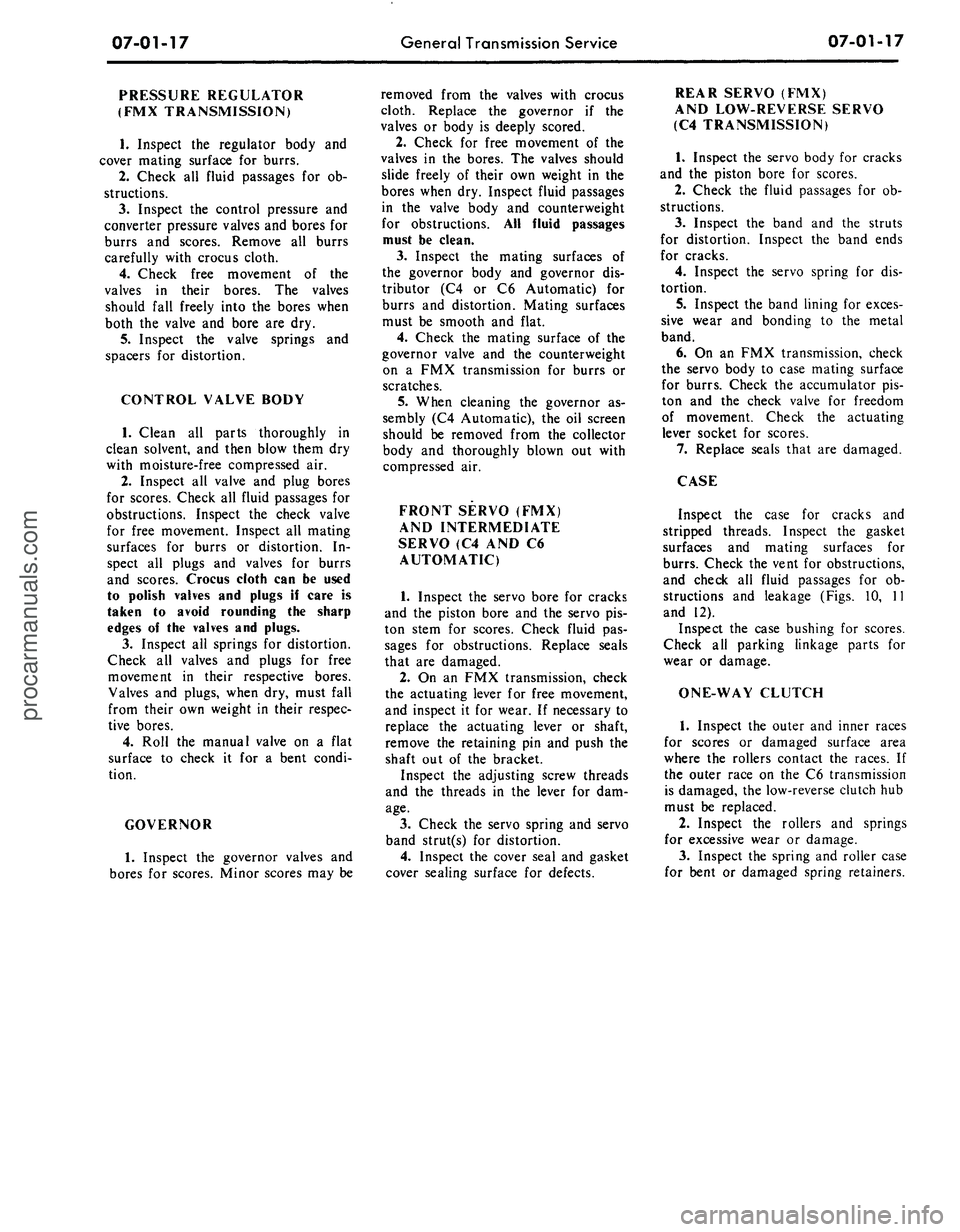

1.

Inspect the clutch cylinder thrust

surfaces, piston bore, and clutch plate

serrations for scores or burrs. Minor

scores or burrs may be removed with

crocus cloth. Replace the clutch cylin-

der if it is badly scored or damaged.

2.

Check the fluid passage in the

clutch cylinder for obstructions. Clean

out all fluid passages. Inspect the

clutch piston for scores and replace if

necessary. Inspect the piston check

ball for freedom of movement and

proper seating (Fig. 28).

CLUTCH

CYLINDER

PISTON

SEAL

CLIP

D1939-A

. 28—Clutch Piston Check

Valve

3.

Check the clutch release spring

for distortion and cracks. Replace the

spring if it is distorted or cracked.

4.

Inspect the composition and the

steel clutch plates and the clutch pres-

sure plate for worn or scored bearing

surfaces. Replace all parts that are

deeply scored.

5.

On FMX and C4 transmissions,

check the clutch plates for flatness

and fit on the clutch hub serrations.

Discard any plate that does not slide

freely on the serrations or that is not

flat.

6. Check the clutch hub thrust sur-

faces for scores and the clutch hub

splines for wear.

7.

On an FMX transmission, in-

spect the turbine shaft bearing sur-

faces for scores. If excessive clearance

or scores are found, discard the unit.

Check the splines on the turbine

shaft for wear and replace the shaft if

the splines are excessively worn. In-

spect the bushing in the turbine shaft

for scores. On a C4 or C6 Automatic

transmission, check the input shaft for

damaged or worn splines.

FRONT PUMP AND

STATOR SUPPORT

1.

Inspect the mating surfaces of

the pump body and cover for burrs.

2.

Inspect the drive and driven gear

bearing surface for scores, and check

the gear teeth for burrs. Inspect the

stator support splines for burrs and

wear.

3.

Check the fluid passages for ob-

structions.

4.

If any parts other than the stator

support are found defective, replace

the pump as a unit. Minor burrs and

scores may be removed with crocus

cloth. The stator support is serviced

separately.

5.

On a C4 or C6 Automatic trans-

mission, check the oil ring grooves in

the stator support for nicks, burrs or

damaged edges. On a C6 transmis-

sion, check the large seal ring groove

of the pump body for damage. Check

the gasket mating surface of the pump

body for damage.

REAR SUPPORT

(FMX TRANSMISSION)

1.

Inspect the gasket mating sur-

faces for damage.

2.

Inspect the support bushing for

scores.

3.

Inspect the rear support fluid

passages for obstructions.

4.

Check the fit of the fluid tubes in

the support.procarmanuals.com

Page 308 of 413

07-01-17

General Transmission Service

07-01-17

PRESSURE REGULATOR

(FMX TRANSMISSION)

1.

Inspect the regulator body and

cover mating surface for burrs.

2.

Check all fluid passages for ob-

structions.

3.

Inspect the control pressure and

converter pressure valves and bores for

burrs and scores. Remove all burrs

carefully with crocus cloth.

4.

Check free movement of the

valves in their bores. The valves

should fall freely into the bores when

both the valve and bore are dry.

5.

Inspect the valve springs and

spacers for distortion.

CONTROL VALVE BODY

1.

Clean all parts thoroughly in

clean solvent, and then blow them dry

with moisture-free compressed air.

2.

Inspect all valve and plug bores

for scores. Check all fluid passages for

obstructions. Inspect the check valve

for free movement. Inspect all mating

surfaces for burrs or distortion. In-

spect all plugs and valves for burrs

and scores. Crocus cloth can be used

to polish valves and plugs if care is

taken to avoid rounding the sharp

edges of the valves and plugs.

3.

Inspect all springs for distortion.

Check all valves and plugs for free

movement in their respective bores.

Valves and plugs, when dry, must fall

from their own weight in their respec-

tive bores.

4.

Roll the manual valve on a flat

surface to check it for a bent condi-

tion.

GOVERNOR

1.

Inspect the governor valves and

bores for scores. Minor scores may be

removed from the valves with crocus

cloth. Replace the governor if the

valves or body is deeply scored.

2.

Check for free movement of the

valves in the bores. The valves should

slide freely of their own weight in the

bores when dry. Inspect fluid passages

in the valve body and counterweight

for obstructions. All fluid passages

must be clean.

3.

Inspect the mating surfaces of

the governor body and governor dis-

tributor (C4 or C6 Automatic) for

burrs and distortion. Mating surfaces

must be smooth and flat.

4.

Check the mating surface of the

governor valve and the counterweight

on a FMX transmission for burrs or

scratches.

5.

When cleaning the governor as-

sembly (C4 Automatic), the oil screen

should be removed from the collector

body and thoroughly blown out with

compressed air.

FRONT SERVO (FMX)

AND INTERMEDIATE

SERVO (C4 AND C6

AUTOMATIC)

1.

Inspect the servo bore for cracks

and the piston bore and the servo pis-

ton stem for scores. Check fluid pas-

sages for obstructions. Replace seals

that are damaged.

2.

On an FMX transmission, check

the actuating lever for free movement,

and inspect it for wear. If necessary to

replace the actuating lever or shaft,

remove the retaining pin and push the

shaft out of the bracket.

Inspect the adjusting screw threads

and the threads in the lever for dam-

age.

3.

Check the servo spring and servo

band strut(s) for distortion.

4.

Inspect the cover seal and gasket

cover sealing surface for defects.

REAR SERVO (FMX)

AND LOW-REVERSE SERVO

(C4 TRANSMISSION)

1.

Inspect the servo body for cracks

and the piston bore for scores.

2.

Check the fluid passages for ob-

structions.

3.

Inspect the band and the struts

for distortion. Inspect the band ends

for cracks.

4.

Inspect the servo spring for dis-

tortion.

5.

Inspect the band lining for exces-

sive wear and bonding to the metal

band.

6. On an FMX transmission, check

the servo body to case mating surface

for burrs. Check the accumulator pis-

ton and the check valve for freedom

of movement. Check the actuating

lever socket for scores.

7.

Replace seals that are damaged.

CASE

Inspect the case for cracks and

stripped threads. Inspect the gasket

surfaces and mating surfaces for

burrs.

Check the vent for obstructions,

and check all fluid passages for ob-

structions and leakage (Figs. 10, 11

and 12).

Inspect the case bushing for scores.

Check all parking linkage parts for

wear or damage.

ONE-WAY CLUTCH

1.

Inspect the outer and inner races

for scores or damaged surface area

where the rollers contact the races. If

the outer race on the C6 transmission

is damaged, the low-reverse clutch hub

must be replaced.

2.

Inspect the rollers and springs

for excessive wear or damage.

3.

Inspect the spring and roller case

for bent or damaged spring retainers.procarmanuals.com

Page 309 of 413

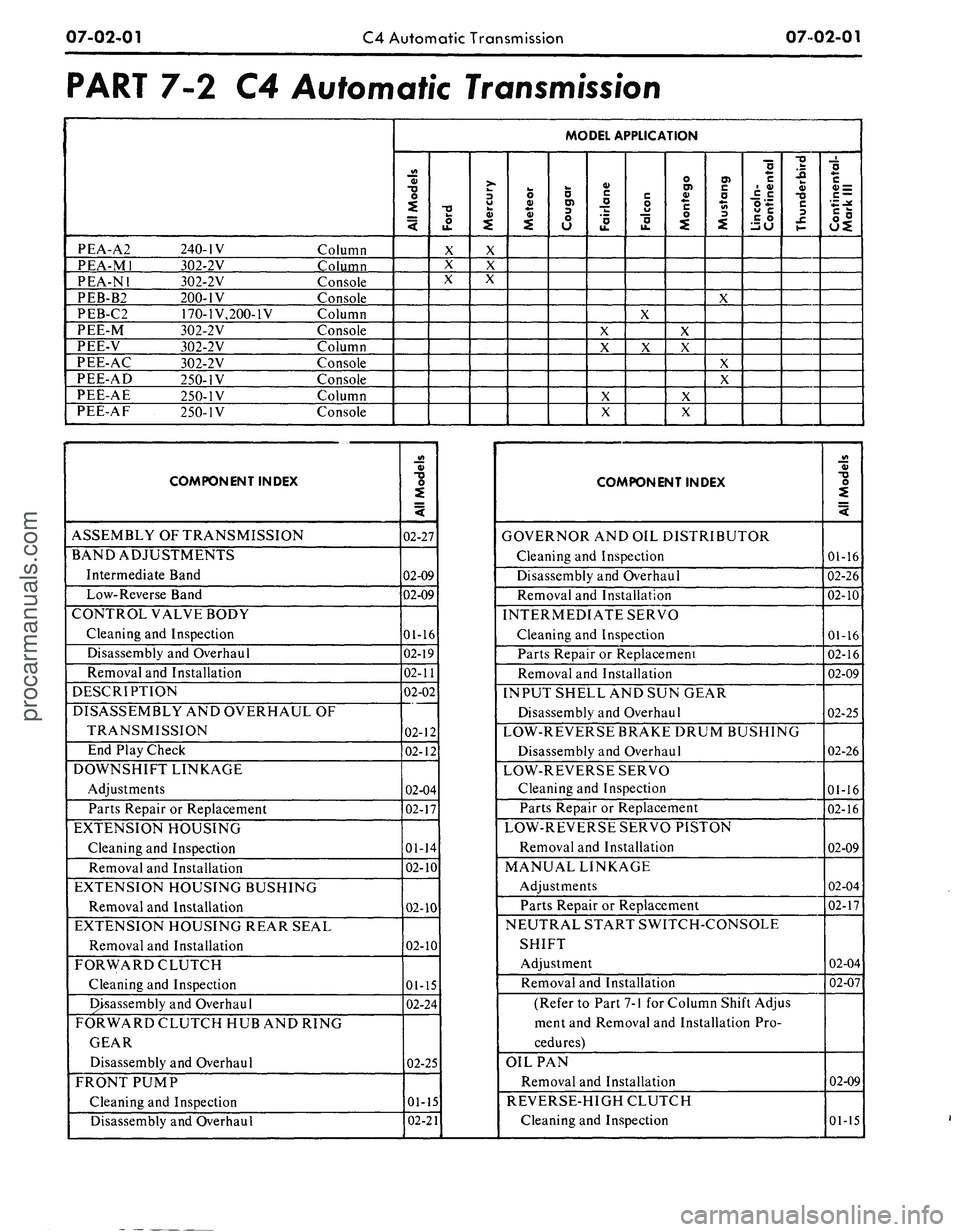

07-02^01

C4 Automatic Transmission

0702-01

PART 7-2 C4 Automatic

Transmission

PEA-A2 240-1V Column

PEA-MI 302-2V Column

PEA-N1 3O2-2V Console

PEB-B2 200-1V Console

PEB-C2 17O-1V,2OO-1V Column

PEE-M 302-2V Console

PEE-V 302-2V Column

PEE-AC 302-2V Console

PEE-AD 250-1V Console

PEE-AE 250-1V Column

PEE-AF 250-1V Console

MODEL APPLICATION

All

Models

Ford

X

X

X

Mercury

X

X

X

Meteor

Cougar

Fairiane

X

X

X

X

Falcon

X

X

Montego

X

X

X

X

Mustang

X

X

X

Lincoln-

Continental

Thunderbird

Continental-

Mark

III

COMPONENT INDEX

ASSEMBLY OF TRANSMISSION

BAND ADJUSTMENTS

Intermediate Band

Low-Reverse Band

CONTROL VALVE BODY

Cleaning and Inspection

Disassembly and Overhaul

Removal and Installation

DESCRIPTION

DISASSEMBLY AND OVERHAUL OF

TRANSMISSION

End Play Check

DOWNSHIFT LINKAGE

Adjustments

Parts Repair or Replacement

EXTENSION HOUSING

Cleaning and Inspection

Removal and Installation

EXTENSION HOUSING BUSHING

Removal and Installation

EXTENSION HOUSING REAR SEAL

Removal and Installation

FORWARD CLUTCH

Cleaning and Inspection

Disassembly and Overhaul

FORWARD CLUTCH HUB AND RING

GEAR

Disassembly and Overhaul

FRONT PUMP

Cleaning and Inspection

Disassembly and Overhaul

All

Models

02-27

02-09

02-09

01-16

02-19

02-11

02-02

02-12

02-12

02-04

02-17

01-14

02-10

02-10

02-10

01-15

02-24

02-25

01-15

02-21

COMPONENT INDEX

GOVERNOR AND OIL DISTRIBUTOR

Cleaning and Inspection

Disassembly and Overhaul

Removal and Installation

INTERMEDIATE SERVO

Cleaning and Inspection

Parts Repair or Replacement

Removal and Installation

INPUT SHELL AND SUN GEAR

Disassembly and Overhaul

LOW-REVERSE BRAKE DRUM BUSHING

Disassembly and Overhaul

LOW-REVERSE SERVO

Cleaning and Inspection

Parts Repair or Replacement

LOW-REVERSE SERVO PISTON

Removal and Installation

MANUAL LINKAGE

Adjustments

Parts Repair or Replacement

NEUTRAL START SWITCH-CONSOLE

SHIFT

Adjustment

Removal and Installation

(Refer to Part 7-1 for Column Shift Adjus

ment and Removal and Installation Pro-

cedures)

OIL PAN

Removal and Installation

REVERSE-HIGH CLUTCH

Cleaning and Inspection

All

Models

01-16

02-26

02-10

01-16

02-16

02-09

02-25

02-26

01-16

02-16

02-09

02-04

02-17

02-04

02-07

02-09

01-15

procarmanuals.com

Page 310 of 413

J7-02-02

C4 Automatic Transmission

07-02-02

COMPONENT INDEX

Disassembly and Overhaul

REVERSE RING GEAR AND HUB

Disassembly and Overhaul

SELECTOR LEVER-CONSOLE SHIFT

Removal and Installation

THROTTLE LINKAGE

All

Models

02-22

02-26

02-08

COMPONENT INDEX

Adjustments

TRANSMISSION (Complete)

Removal and Installation

TRANSMISSION CASE BUSHING

Parts Repair or Replacement

TRANSMISSION CASE THREAD REPAIR

All

Models

02-04

02-11

02-18

02-18

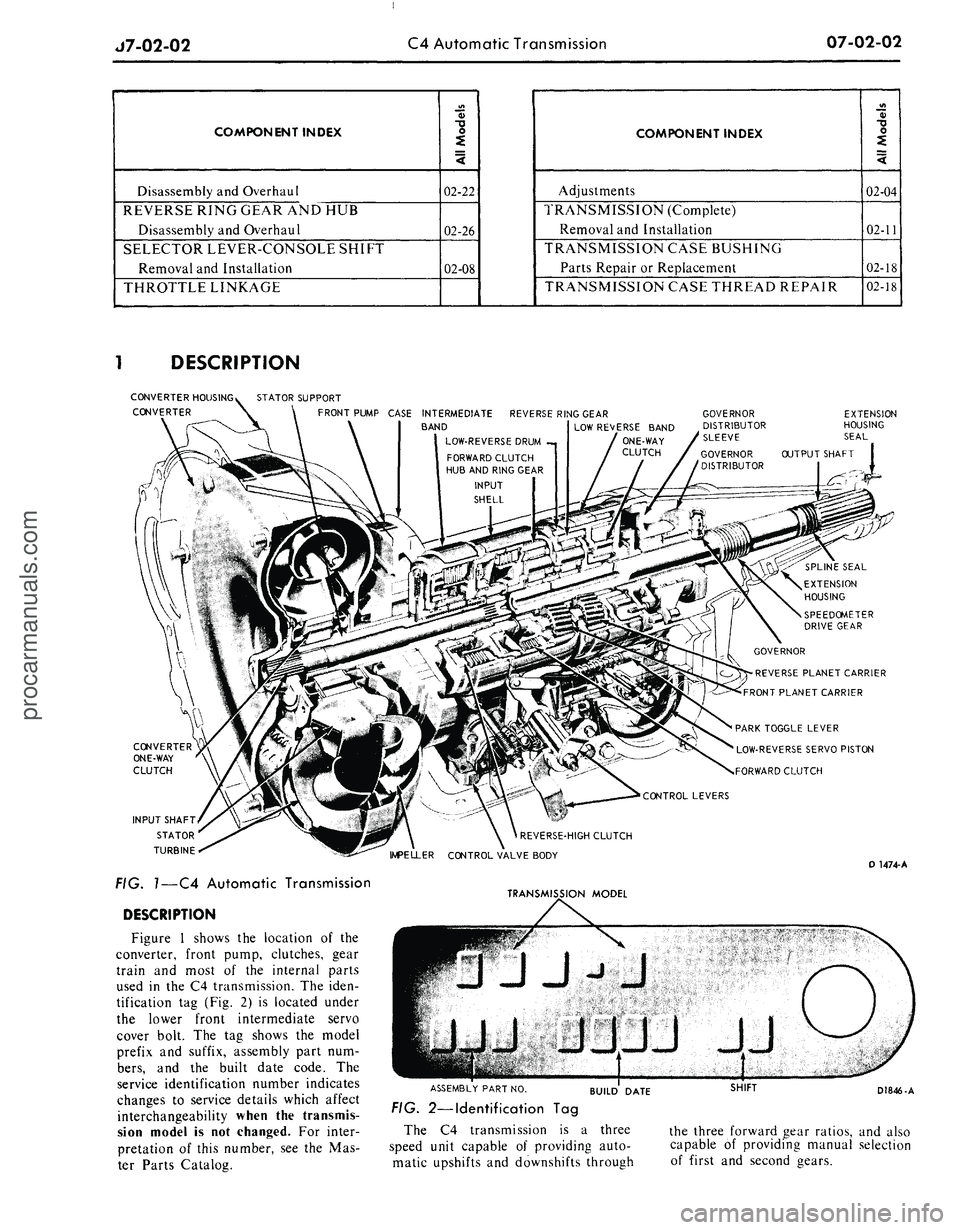

DESCRIPTION

CONVERTER HOUSING,

CONVERTER

STATOR SUPPORT

FRONT PUMP CASE

INTERMEDIATE

BAND

LOW-REVERSE DRUM

-,

FORWARD CLUTCH

HUB AND RING GEAR

INPUT

SHELL

REVERSE RING GEAR

LOW REVERSE BAND

ONE-WAY

CLUTCH

GOVERNOR

DISTRIBUTOR

SLEEVE

GOVERNOR

DISTRIBUTOR

SPLINE SEAL

EXTENSION

HOUSING

SPEEDOMETER

DRIVE GEAR

GOVERNOR

REVERSE PLANET CARRIER

FRONT PLANET CARRIER

PARK TOGGLE LEVER

LOW-REVERSE SERVO PISTON

FORWARD CLUTCH

CONTROL LEVERS

FIG.

1—C4

Automatic Transmission

DESCRIPTION

Figure

1

shows

the

location

of the

converter, front pump, clutches, gear

train

and

most

of the

internal parts

used

in

the C4 transmission. The iden-

tification

tag

(Fig.

2) is

located under

the lower front intermediate servo

cover bolt.

The tag

shows

the

model

prefix

and

suffix, assembly part num-

bers,

and the

built date code.

The

service identification number indicates

changes

to

service details which affect

interchangeability when

the

transmis-

sion model

is not

changed.

For

inter-

pretation

of

this number, see the Mas-

ter Parts Catalog.

REVERSE-HIGH CLUTCH

IMPELLER CONTROL VALVE BODY

TRANSMISSION MODEL

D 1474-A

ASSEMBLY PART NO. BUILD DATE

FIG.

2—Identification

Tag

The

C4

transmission

is a

three

speed unit capable

of

providing auto-

matic upshifts

and

downshifts through

SHIFT

D1846-A

the three forward gear ratios,

and

also

capable

of

providing manual selection

of first

and

second gears.

procarmanuals.com

Page 311 of 413

07-02-03

C4 Automatic Transmission

07-02-03

CONVERTER

FORWARD CLUTCH

PRIMARY GOVERNOR

CONVERTER

CHECK VALVE

ONE-WAY

CLUTCH

DRAIN-BACK

VALVE

FRONT LUBE

CONVERTER

PRESSURE

RELIEF VALVE

LOW AND

REVERSE

SERVO

AND DIRECT

CLUTCH

L

SECONDARY

GOVERNOR

INTERMEDIATE

BAND

ACCUMULATOR

VALVE

CUT-BACK

VALVE

2-3

BACK-OUT

VALVE

MAIN

REGU-

LATOR

VALVE

MANUAL

LOW

VALVE

1-2 SHIFT

VALVE

D2

VALVE

THROTTLE

MODULATOR

VALVE

THROTTLE

BOOST VALVE

PRESSURE

BOOSTER

VALVE

DOWNSHIFT VALVE

LINE

COASTING

BOOST

VALVE

ENGINE

MANIFOLD

VACUUM

LESS THAN

20

INCHES

PRIMARY

THROTTLE

VALVE

(CASE)

VACUUM

DIAPHRAGM

OIL

SCREEN

I) 1724-E

FIG. 3—Hydraulic Control Systemprocarmanuals.com

Page 312 of 413

07-02-04

C4 Automatic Transmission

07-02-04

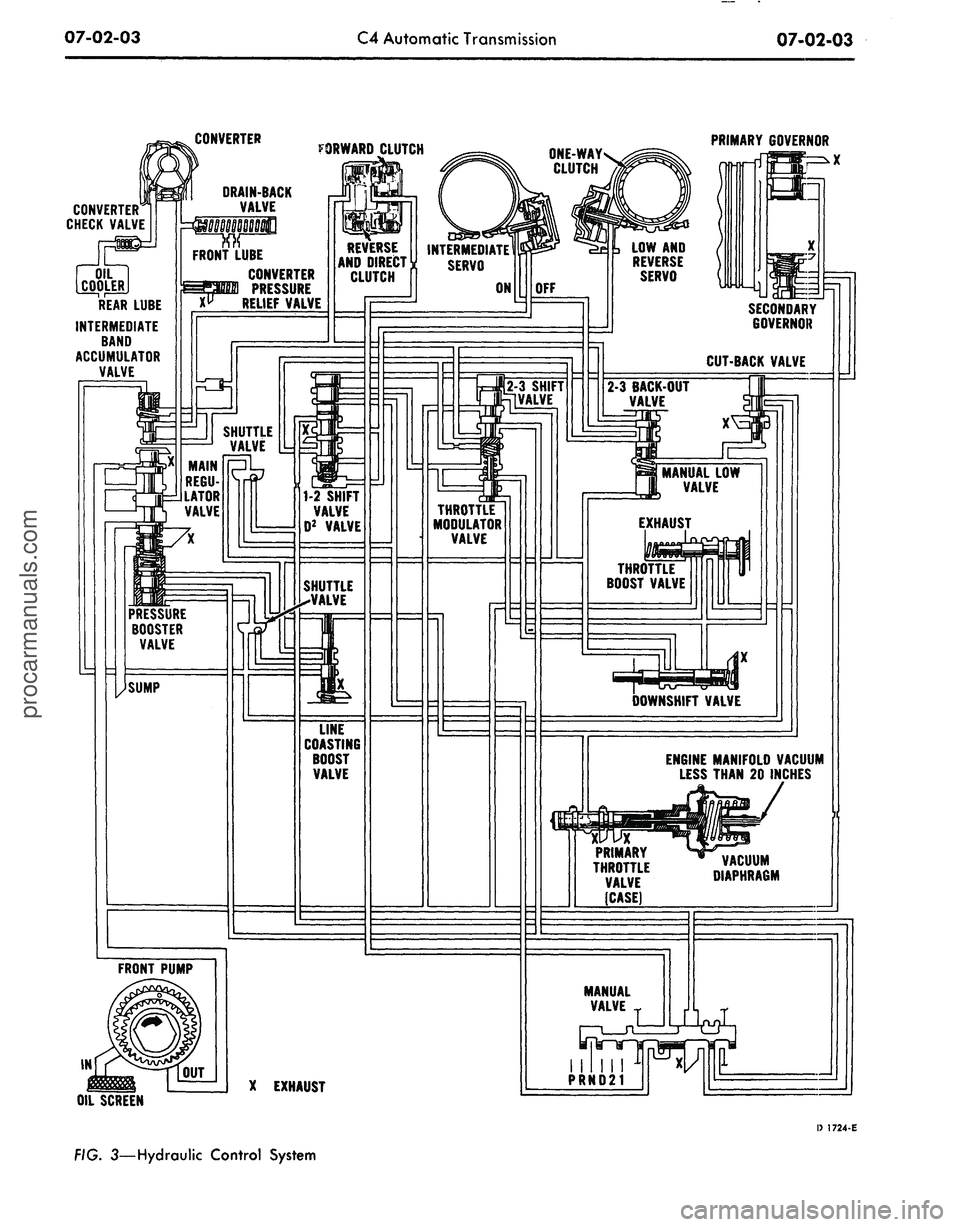

The transmission consists essentially

of a torque converter, planetary gear

train, two multiple disc clutches, a

one-way clutch and a hydraulic con-

trol system (Fig. 3).

The only adjustments on the trans-

mission proper are the intermediate

and low-reverse bands.

TRANSMISSION

MANUAL LEVER

2 IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

CONTROL LINKAGE ADJUSTMENTS

The transmission control linkage

adjustments should be performed in

the order in which they appear in this

section of the manual.

THROTTLE AND DOWNSHIFT

LINKAGE ADJUSTMENTS

Adjusting the throttle linkage is im-

portant to be certain the throttle and

kickdown systems are properly adjust-

ed. The kickdown system should come

in when the accelerator is pressed

through detent, and not before detent.

Refer to Group 10 for detailed

throttle and downshift linkage adjust-

ment procedures.

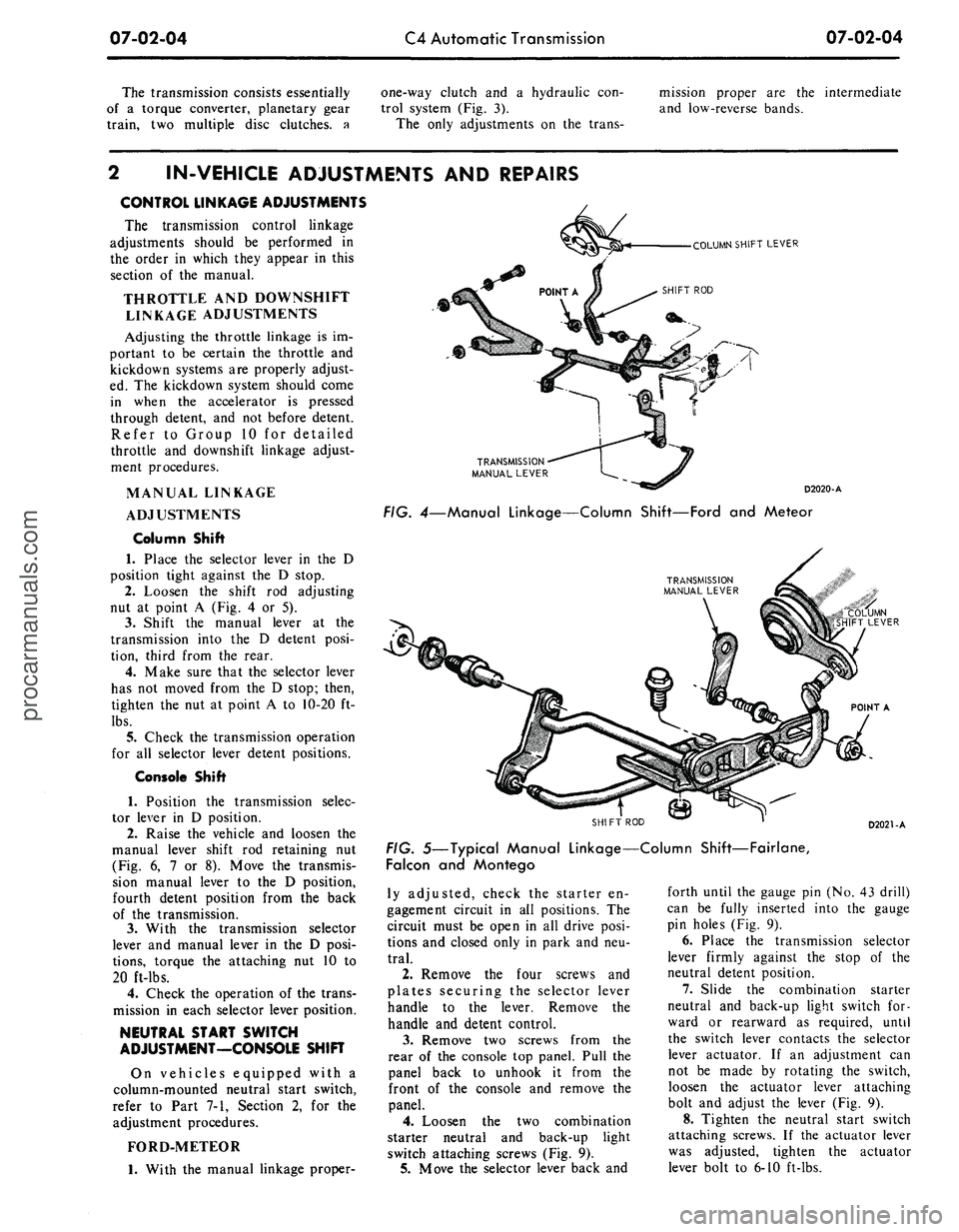

MANUAL LINKAGE

ADJUSTMENTS

Column Shift

1.

Place the selector lever in the D

position tight against the D stop.

2.

Loosen the shift rod adjusting

nut at point A (Fig. 4 or 5).

3.

Shift the manual lever at the

transmission into the D detent posi-

tion, third from the rear.

4.

Make sure that the selector lever

has not moved from the D stop; then,

tighten the nut at point A to 10-20 ft-

lbs.

5.

Check the transmission operation

for all selector lever detent positions.

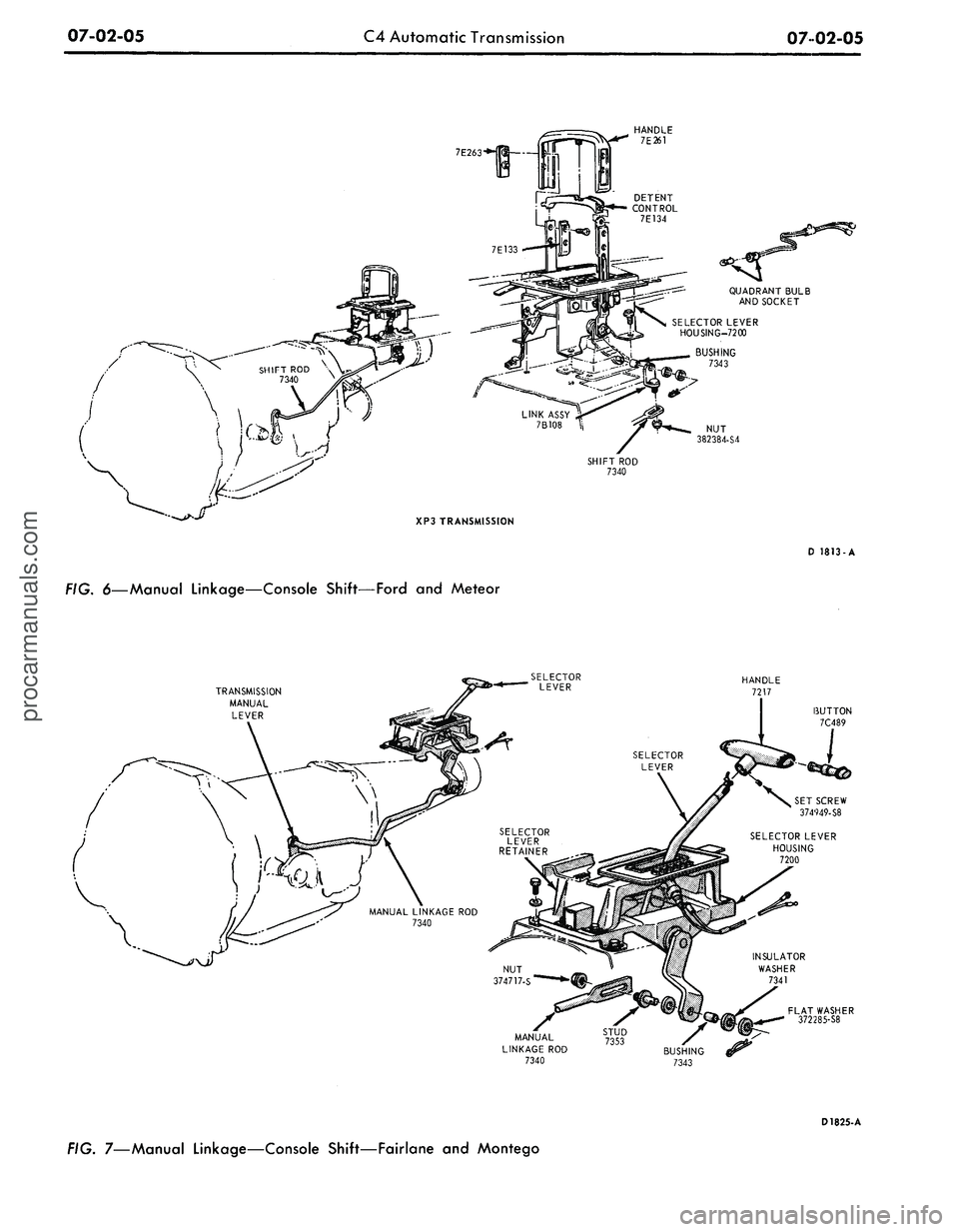

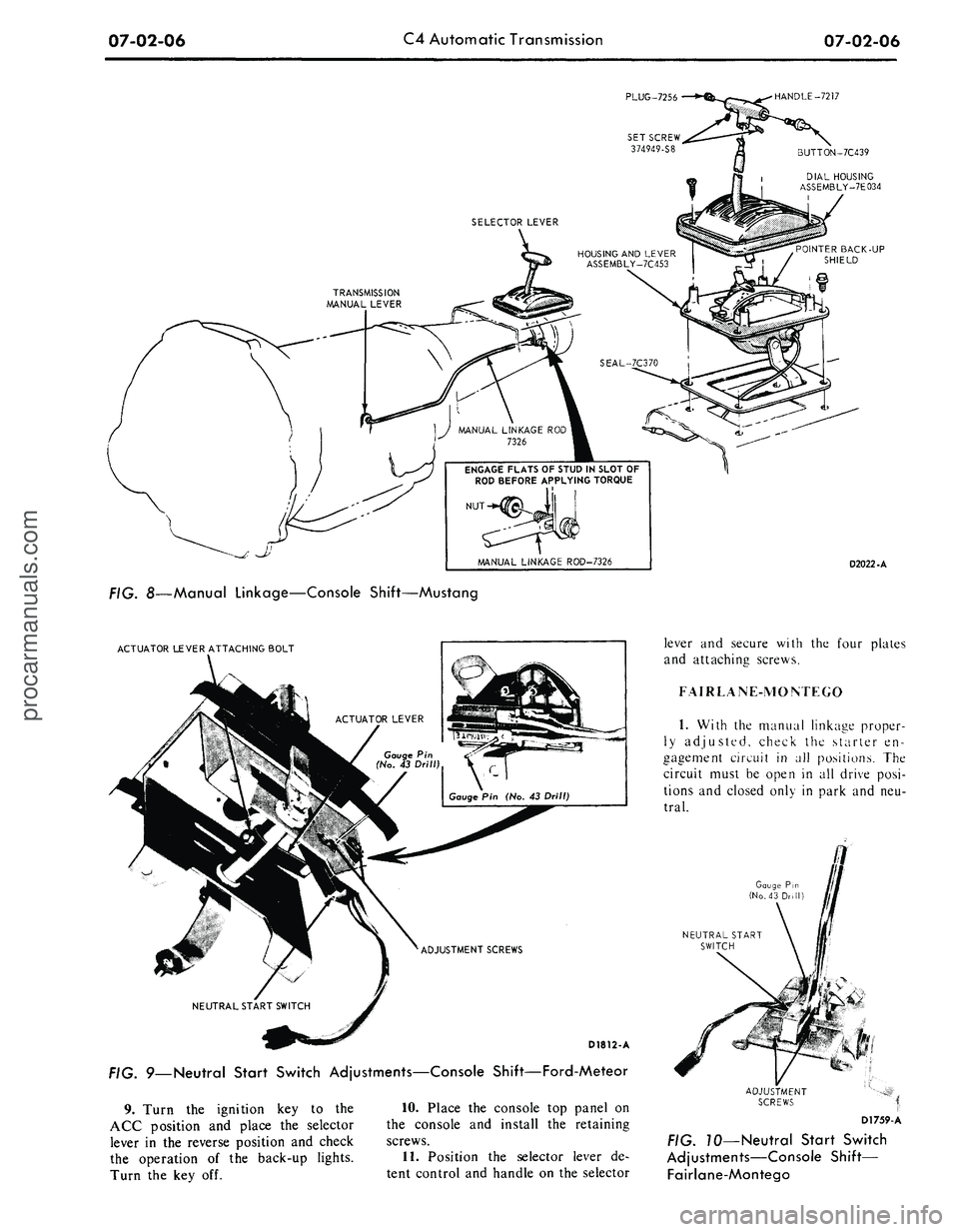

Console Shift

1.

Position the transmission selec-

tor lever in D position.

2.

Raise the vehicle and loosen the

manual lever shift rod retaining nut

(Fig. 6, 7 or 8). Move the transmis-

sion manual lever to the D position,

fourth detent position from the back

of the transmission.

3.

With the transmission selector

lever and manual lever in the D posi-

tions,

torque the attaching nut 10 to

20 ft-lbs.

4.

Check the operation of the trans-

mission in each selector lever position.

NEUTRAL START SWITCH

ADJUSTMENT—CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

adjustment procedures.

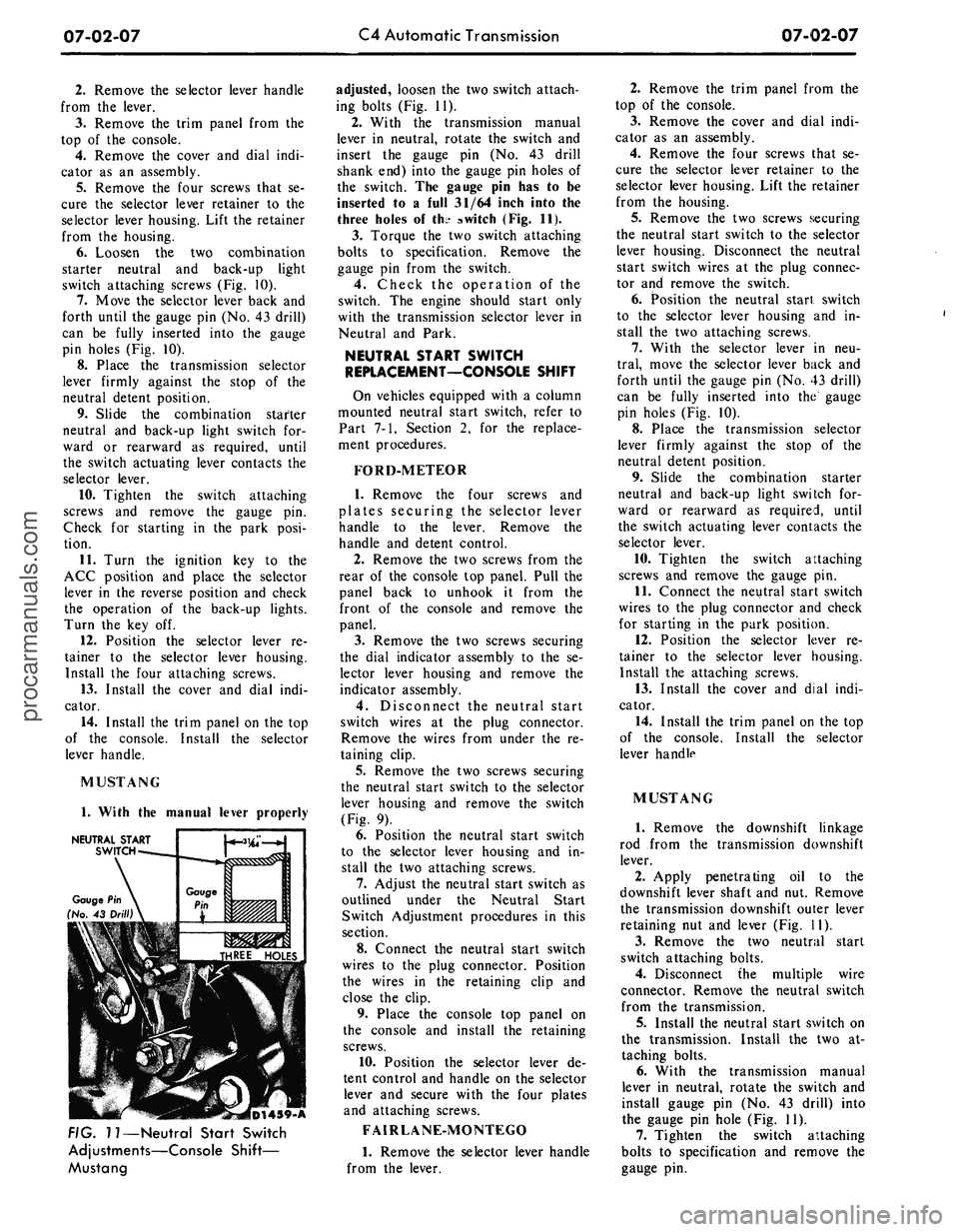

FORD-METEOR

1.

With the manual linkage proper-

COLUMN SHIFT LEVER

D2020-A

FIG.

4—Manual

Linkage—Column Shift—Ford

and

Meteor

"COLUMN

SHIFT LEVER

POINT

A

SHIFT

ROD

D2021-A

FIG.

5—Typical

Manual Linkage—Column

Shift—Fairlane,

Falcon

and

Montego

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

2.

Remove the four screws and

plates securing the selector lever

handle to the lever. Remove the

handle and detent control.

3.

Remove two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

4.

Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 9).

5.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 9).

6. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

7.

Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch lever contacts the selector

lever actuator. If an adjustment can

not be made by rotating the switch,

loosen the actuator lever attaching

bolt and adjust the lever (Fig. 9).

8. Tighten the neutral start switch

attaching screws. If the actuator lever

was adjusted, tighten the actuator

lever bolt to 6-10 ft-lbs.procarmanuals.com

Page 313 of 413

07-02-05

C4 Automatic Transmission

07 02-05

7E263

NUT

382384-S4

XP3 TRANSMISSION

D 1813-A

FIG.

6—Manual

Linkage—Console Shift—Ford and Meteor

TRANSMISSION

MANUAL

LEVER

MANUAL S™D

LINKAGE ROD

7340

FLAT WASHER

372285-S8

D1825-A

FIG. 7—Manual Linkage—Console Shift—Fairlane and Montegoprocarmanuals.com

Page 314 of 413

07-02-06

C4 Automatic Transmission

07-02-06

PLUG-7256

•HANDLE-7217

BUTTON-7C439

DIAL HOUSING

ASSEMBLY-7E034

POINTER BACK-UP

SHIELD

ENGAGE FLATS OF STUD IN SLOT OF

ROD BEFORE APPLYING TORQUE

D2022-A

FIG. 8—Manual Linkage—Console Shift—Mustang

ACTUATOR LEVER ATTACHING BOLT

D1812-A

FIG. 9—Neutral Start Switch Adjustments—Console Shift—Ford-Meteor

9. Turn the ignition key to the

ACC position and place the selector

lever in the reverse position and check

the operation of the back-up lights.

Turn the key off.

10.

Place the console top panel on

the console and install the retaining

screws.

11.

Position the selector lever de-

tent control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE-MONTEGO

1.

With the manual linkage proper-

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

Gauge Pin

(No.43 Drill)

NEUTRAL START

SWITCH

Dl759-A

70—Neutral Start Switch

Adjustments—Console Shift—

Fairlane-Montegoprocarmanuals.com

Page 315 of 413

07-02-07

C4 Automatic Transmission

07-02-07

2.

Remove the selector lever handle

from the lever.

3.

Remove the trim panel from the

top of the console.

4.

Remove the cover and dial indi-

cator as an assembly.

5.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

6. Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 10).

7.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 10).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

Check for starting in the park posi-

tion.

11.

Turn the ignition key to the

ACC position and place the selector

lever in the reverse position and check

the operation of the back-up lights.

Turn the key off.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG

1.

With the manual lever properly

NEUTRAL

START

SWITCH

(D1439-A

FIG. 11—Neutral Start Switch

Adjustments—Console Shift—

Mustang

adjusted, loosen the two switch attach-

ing bolts (Fig. 11).

2.

With the transmission manual

lever in neutral, rotate the switch and

insert the gauge pin (No. 43 drill

shank end) into the gauge pin holes of

the switch. The gauge pin has to be

inserted to a full 31/64 inch into the

three holes of the switch (Fig. 11).

3.

Torque the two switch attaching

bolts to specification. Remove the

gauge pin from the switch.

4.

Check the operation of the

switch. The engine should start only

with the transmission selector lever in

Neutral and Park.

NEUTRAL START SWITCH

REPLACEMENT—CONSOLE SHIFT

On vehicles equipped with a column

mounted neutral start switch, refer to

Part 7-1, Section 2, for the replace-

ment procedures.

FORD-METEOR

1.

Remove the four screws and

plates securing the selector lever

handle to the lever. Remove the

handle and detent control.

2.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

3.

Remove the two screws securing

the dial indicator assembly to the se-

lector lever housing and remove the

indicator assembly.

4.

Disconnect the neutral start

switch wires at the plug connector.

Remove the wires from under the re-

taining clip.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing and remove the switch

(Fig. 9).

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

Adjust the neutral start switch as

outlined under the Neutral Start

Switch Adjustment procedures in this

section.

8. Connect the neutral start switch

wires to the plug connector. Position

the wires in the retaining clip and

close the clip.

9. Place the console top panel on

the console and install the retaining

screws.

10.

Position the selector lever de-

tent control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE-MONTEGO

1.

Remove the selector lever handle

from the lever.

2.

Remove the trim panel from the

top of the console.

3.

Remove the cover and dial indi-

cator as an assembly.

4.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing. Disconnect the neutral

start switch wires at the plug connec-

tor and remove the switch.

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

With the selector lever in neu-

tral,

move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 10).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

11.

Connect the neutral start switch

wires to the plug connector and check

for starting in the park position.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle

MUSTANG

1.

Remove the downshift linkage

rod from the transmission downshift

lever.

2.

Apply penetrating oil to the

downshift lever shaft and nut. Remove

the transmission downshift outer lever

retaining nut and lever (Fig. 11).

3.

Remove the two neutral start

switch attaching bolts.

4.

Disconnect the multiple wire

connector. Remove the neutral switch

from the transmission.

5.

Install the neutral start switch on

the transmission. Install the two at-

taching bolts.

6. With the transmission manual

lever in neutral, rotate the switch and

install gauge pin (No. 43 drill) into

the gauge pin hole (Fig. 11).

7.

Tighten the switch attaching

bolts to specification and remove the

gauge pin.procarmanuals.com