trans FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 61 of 413

02-02-42

Brake System

02-02-42

CALIPER

ABUTMENTS

OUTBOARD

CALIPER HOUSING

DUST

BOOT RETAINING GROOVE

DUST

BOOT (4)

PISTON

SEAL (4)

EXTERNAL

TRANSFER

TUBE

SCREW

INBOARD

CALIPER HOUSING

FLEXIBLE

HOSE-^

H1367-C

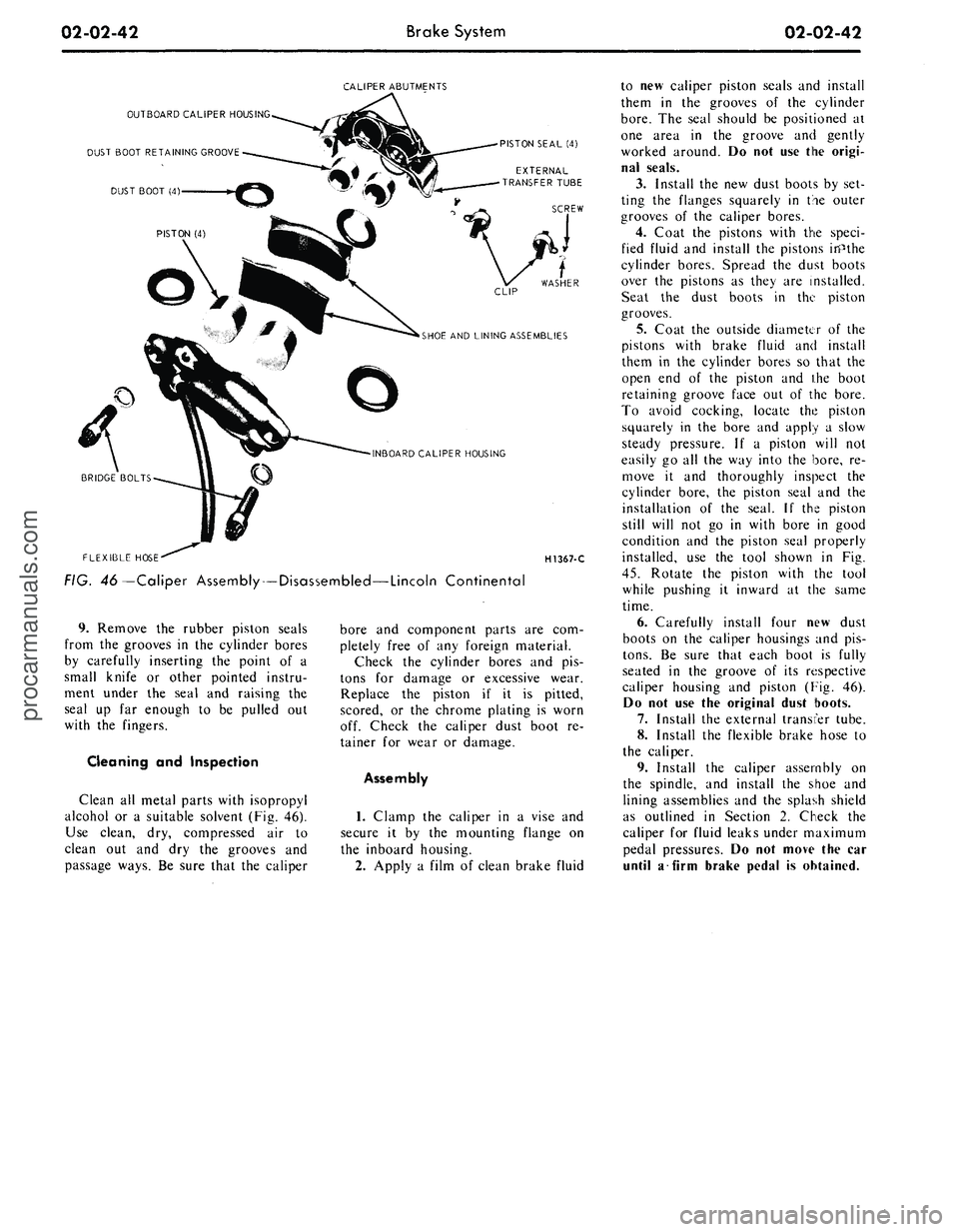

FIG. 46—Caliper Assembly — Disassembled—Lincoln Continental

9. Remove the rubber piston seals

from the grooves in the cylinder bores

by carefully inserting the point of a

small knife or other pointed instru-

ment under the seal and raising the

seal up far enough to be pulled out

with the fingers.

Cleaning and Inspection

Clean all metal parts with isopropyl

alcohol or a suitable solvent (Fig. 46).

Use clean, dry, compressed air to

clean out and dry the grooves and

passage ways. Be sure that the caliper

bore and component parts are com-

pletely free of any foreign material.

Check the cylinder bores and pis-

tons for damage or excessive wear.

Replace the piston if it is pitted,

scored, or the chrome plating is worn

off. Check the caliper dust boot re-

tainer for wear or damage.

Assembly

1.

Clamp the caliper in a vise and

secure it by the mounting flange on

the inboard housing.

2.

Apply a film of clean brake fluid

to new caliper piston seals and install

them in the grooves of the cylinder

bore.

The seal should be positioned at

one area in the groove and gently

worked around. Do not use the origi-

nal seals.

3.

Install the new dust boots by set-

ting the flanges squarely in the outer

grooves of the caliper bores.

4.

Coat the pistons with the speci-

fied fluid and install the pistons inPthe

cylinder bores. Spread the dust boots

over the pistons as they are installed.

Seat the dust boots in the piston

grooves.

5.

Coat the outside diameter of the

pistons with brake fluid and install

them in the cylinder bores so that the

open end of the piston and ihe boot

retaining groove face out of the bore.

To avoid cocking, locate the piston

squarely in the bore and apply a slow

steady pressure. If a piston will not

easily go all the way into the bore, re-

move it and thoroughly inspect the

cylinder bore, the piston seal and the

installation of the seal. If the piston

still will not go in with bore in good

condition and the piston seal properly

installed, use the tool shown in Fig.

45.

Rotate the piston with the tool

while pushing it inward at the same

time.

6. Carefully install four new dust

boots on the caliper housings and pis-

tons.

Be sure that each boot is fully

seated in the groove of its respective

caliper housing and piston (Fig. 46).

Do not use the original dust boots.

7.

Install the external transfer tube.

8. Install the flexible brake hose to

the caliper.

9. Install the caliper assembly on

the spindle, and install the shoe and

lining assemblies and the splash shield

as outlined in Section 2. Check the

caliper for fluid leaks under maximum

pedal pressures. Do not move the car

until a firm brake pedal is obtained.procarmanuals.com

Page 67 of 413

03-01-02

Suspension — Steering, Wheels And Tires — General Service

03-01-02

1 TESTING

POWER STEERING-

PRELIMINARY TESTS

The following preliminary checks

should always be made before per-

forming any operations.

AIR BLEEDING

Air in the power steering system

(shown by bubbles in the fluid) should

be bled. After making sure that the

reservoir is filled to specification (the

fluid must be at normal operating

temperature when the check is made),

turn the steering wheel through its full

travel three or four times. Do not hold

the wheels against their stops. Re-

check the fluid level.

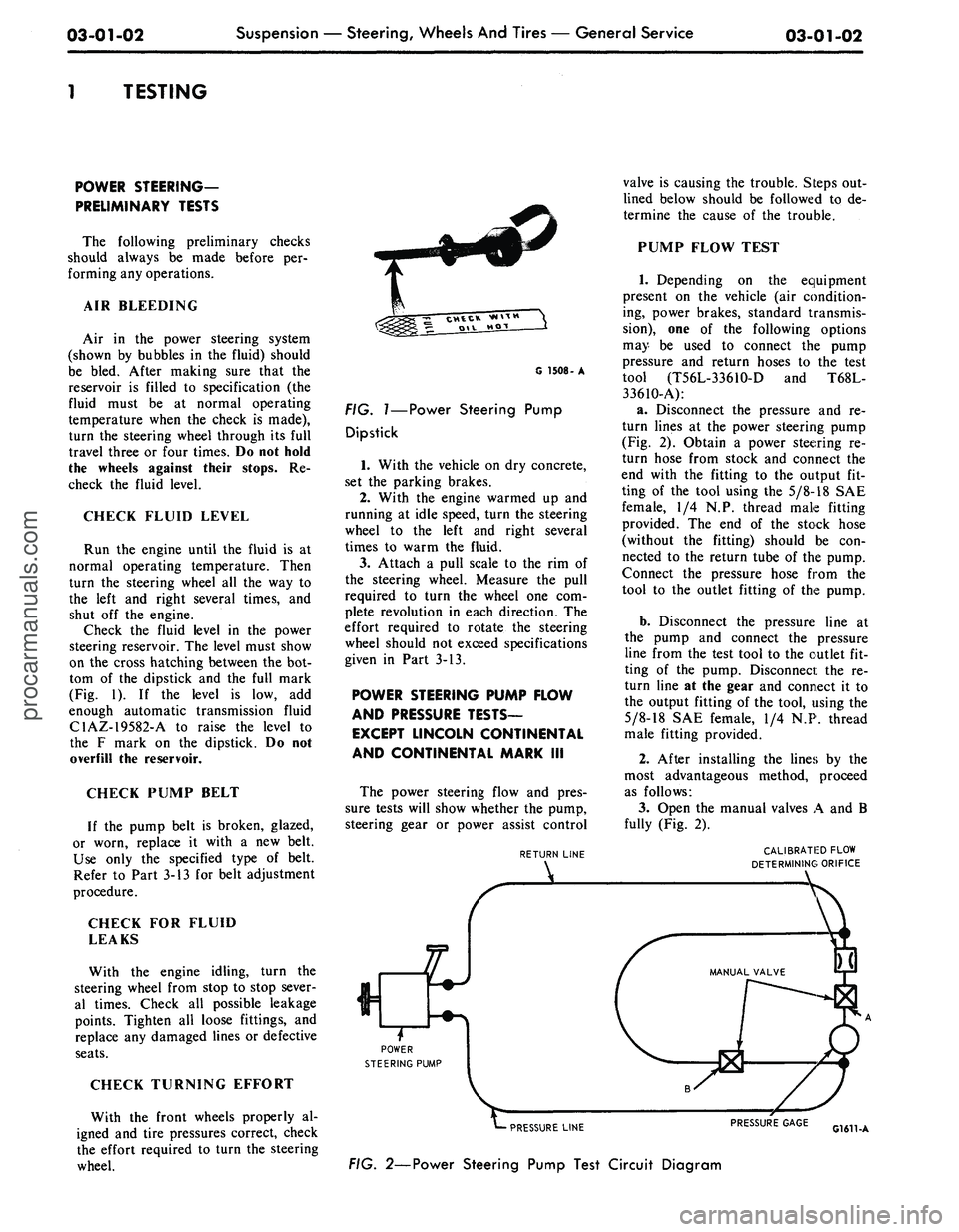

CHECK FLUID LEVEL

Run the engine until the fluid is at

normal operating temperature. Then

turn the steering wheel all the way to

the left and right several times, and

shut off the engine.

Check the fluid level in the power

steering reservoir. The level must show

on the cross hatching between the bot-

tom of the dipstick and the full mark

(Fig. 1). If the level is low, add

enough automatic transmission fluid

C1AZ-19582-A to raise the level to

the F mark on the dipstick. Do not

overfill the reservoir.

CHECK PUMP BELT

If the pump belt is broken, glazed,

or worn, replace it with a new belt.

Use only the specified type of belt.

Refer to Part 3-13 for belt adjustment

procedure.

CHECK FOR FLUID

LEAKS

With the engine idling, turn the

steering wheel from stop to stop sever-

al times. Check all possible leakage

points. Tighten all loose fittings, and

replace any damaged lines or defective

seats.

CHECK TURNING EFFORT

With the front wheels properly al-

igned and tire pressures correct, check

the effort required to turn the steering

wheel.

G 1508- A

FIG.

1—Power

Steering Pump

Dipstick

1.

With the vehicle on dry concrete,

set the parking brakes.

2.

With the engine warmed up and

running at idle speed, turn the steering

wheel to the left and right several

times to warm the fluid.

3.

Attach a pull scale to the rim of

the steering wheel. Measure the pull

required to turn the wheel one com-

plete revolution in each direction. The

effort required to rotate the steering

wheel should not exceed specifications

given in Part 3-13.

POWER STEERING PUMP FLOW

AND PRESSURE TESTS—

EXCEPT LINCOLN CONTINENTAL

AND CONTINENTAL MARK III

The power steering flow and pres-

sure tests will show whether the pump,

steering gear or power assist control

RETURN LINE

POWER

STEERING PUMP

Sr

valve is causing the trouble. Steps out-

lined below should be followed to de-

termine the cause of the trouble.

PUMP FLOW TEST

1.

Depending on the equipment

present on the vehicle (air condition-

ing, power brakes, standard transmis-

sion),

one of the following options

may be used to connect the pump

pressure and return hoses to the test

tool (T56L-3361O-D and T68L-

33610-A):

a. Disconnect the pressure and re-

turn lines at the power steering pump

(Fig. 2). Obtain a power steering re-

turn hose from stock and connect the

end with the fitting to the output fit-

ting of the tool using the

5/8-18

SAE

female, 1/4 N.P. thread male fitting

provided. The end of the stock hose

(without the fitting) should be con-

nected to the return tube of the pump.

Connect the pressure hose from the

tool to the outlet fitting of the pump.

b.

Disconnect the pressure line at

the pump and connect the pressure

line from the test tool to the outlet fit-

ting of the pump. Disconnect the re-

turn line at the gear and connect it to

the output fitting of the tool, using the

5/8-18

SAE female, 1/4 N.P. thread

male fitting provided.

2.

After installing the lines by the

most advantageous method, proceed

as follows:

3.

Open the manual valves A and B

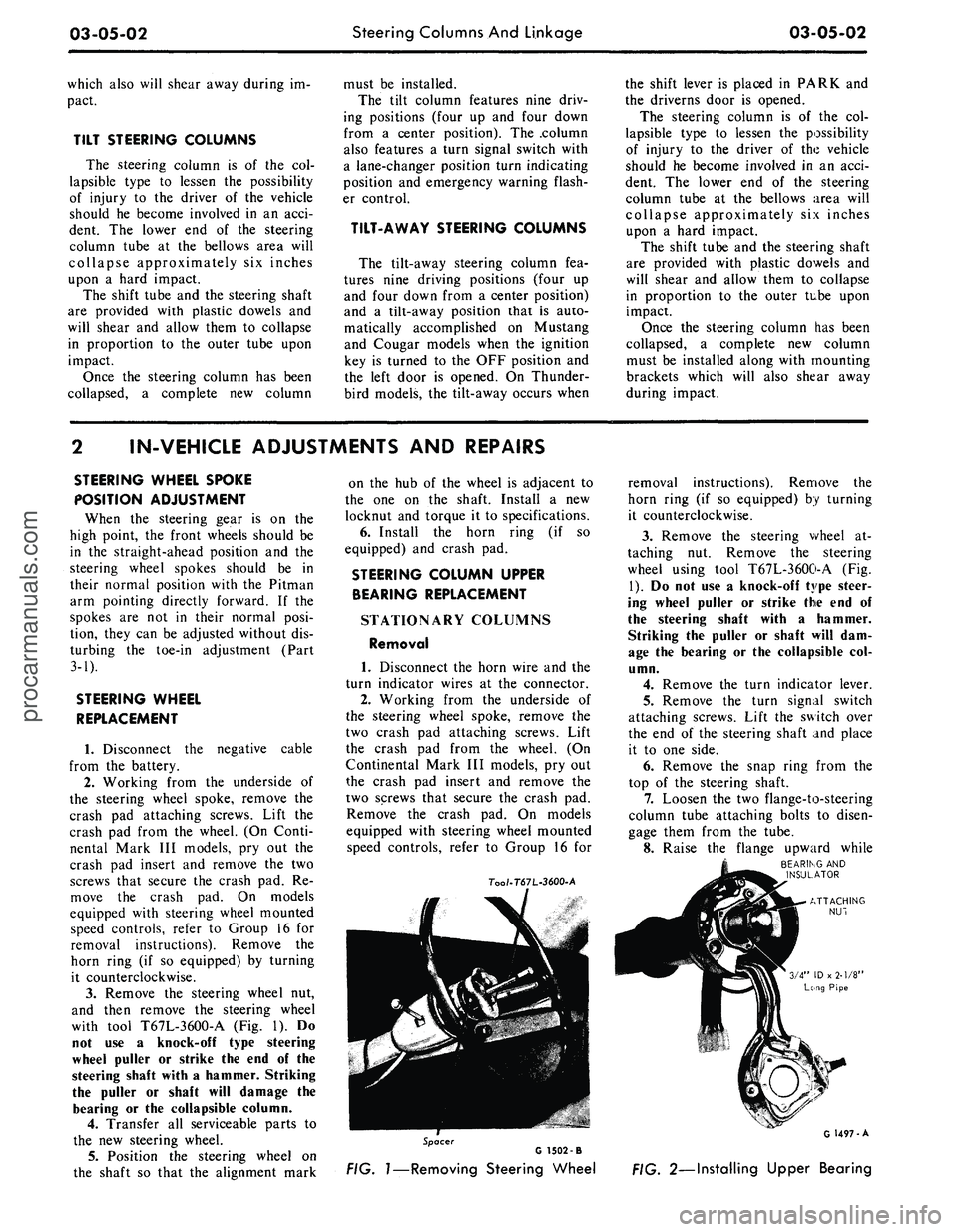

fully (Fig. 2).

CALIBRATED FLOW

DETERMINING ORIFICE

PRESSURE LINE

FIG. 2—Power Steering Pump Test Circuit Diagram

PRESSURE GAGE

G1611-Aprocarmanuals.com

Page 115 of 413

03-05-02

Steering Columns

And

Linkage

03-05-02

which also will shear away during

im-

pact.

TILT STEERING COLUMNS

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed.

The tilt column features nine driv-

ing positions (four

up and

four down

from

a

center position).

The

.column

also features

a

turn signal switch with

a lane-changer position turn indicating

position

and

emergency warning flash-

er control.

TILT-AWAY STEERING COLUMNS

The tilt-away steering column

fea-

tures nine driving positions (four

up

and four down from

a

center position)

and

a

tilt-away position that

is

auto-

matically accomplished

on

Mustang

and Cougar models when

the

ignition

key

is

turned

to the

OFF

position

and

the left door

is

opened.

On

Thunder-

bird models,

the

tilt-away occurs when

the shift lever

is

placed

in

PARK

and

the driverns door

is

opened.

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed along with mounting

brackets which will also shear away

during impact.

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

STEERING WHEEL SPOKE

POSITION ADJUSTMENT

When

the

steering gear

is on the

high point,

the

front wheels should

be

in

the

straight-ahead position

and the

steering wheel spokes should

be in

their normal position with

the

Pitman

arm pointing directly forward.

If the

spokes

are not in

their normal posi-

tion, they

can be

adjusted without

dis-

turbing

the

toe-in adjustment (Part

3-1).

STEERING WHEEL

REPLACEMENT

1.

Disconnect

the

negative cable

from

the

battery.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

crash

pad

attaching screws. Lift

the

crash

pad

from

the

wheel.

(On

Conti-

nental Mark

III

models,

pry out the

crash

pad

insert

and

remove

the two

screws that secure

the

crash

pad. Re-

move

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

nut,

and then remove

the

steering wheel

with tool T67L-3600-A

(Fig. 1). Do

not

use a

knock-off type steering

wheel puller

or

strike

the end of the

steering shaft with

a

hammer. Striking

the puller

or

shaft will damage

the

bearing

or the

collapsible column.

4.

Transfer

all

serviceable parts

to

the

new

steering wheel.

5.

Position

the

steering wheel

on

the shaft

so

that

the

alignment mark

on

the hub of the

wheel

is

adjacent

to

the

one on the

shaft. Install

a new

locknut

and

torque

it to

specifications.

6. Install

the

horn ring

(if so

equipped)

and

crash

pad.

STEERING COLUMN UPPER

BEARING REPLACEMENT

STATIONARY COLUMNS

Removal

1. Disconnect

the

horn wire

and the

turn indicator wires

at the

connector.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

two crash

pad

attaching screws. Lift

the crash

pad

from

the

wheel.

(On

Continental Mark

III

models,

pry out

the crash

pad

insert

and

remove

the

two screws that secure

the

crash

pad.

Remove

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

7oo/-T67L-3600-A

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

at-

taching

nut.

Remove

the

steering

wheel using tool T67L-3600-A

(Fig.

1).

Do not use a

knock-off type steer-

ing wheel puller

or

strike

the end of

the steering shaft with

a

hammer.

Striking

the

puller

or

shaft will

dam-

age

the

bearing

or the

collapsible

col-

umn.

4.

Remove

the

turn indicator lever.

5.

Remove

the

turn signal switch

attaching screws. Lift

the

switch over

the

end of the

steering shaft

and

place

it

to one

side.

6. Remove

the

snap ring from

the

top

of the

steering shaft.

7.

Loosen

the two

flange-to-steering

column tube attaching bolts

to

disen-

gage them from

the

tube.

8. Raise

the

flange upward while

BEARING

AND

INSULATOR

Spacer

G 1502 -B

FIG.

1—Removing

Steering Wheel

G 1497-A

FIG. 2—Installing Upper Bearingprocarmanuals.com

Page 120 of 413

03-05-07

Steering Columns And Linkage

03-05-07

the steering column

(F in Fig. 8).

7.

Disconnect

the

transmission shift

rod

at the

shift tube.

8. Working under

the

hood, install

the aligning spacer (Fig.

9)

around

the

visible portion

of the

steering shaft

and slide

it up the

shaft into

the

steer-

ing column.

It may be

necessary

to

move

the

shaft back

and

forth

to

com-

pletely install

the

spacer.

9.

At

this point

the

steering column

assembly, being loose,

may

have

dropped toward

the

steering gear

grounding

the

steering shaft

on the

steering gear input shaft.

To

properly

establish

the

steering shaft

to

steering

gear clearance, insert

a 1/8

diameter

rod

or

drill through

the

opening

in the

upper half

of the

flex coupling.

10.

Tighten

to a

snug

fit

(approxi-

mately

2-3

ft-lb)

the

nuts retaining

the

toe plates

to the

dash panel

(B in Fig.

8).

11.

If the

aligning spacer cannot

be

rotated freely,

the

dash panel holes

must

be

filed

or

reamed

for

greater

travel

(as

mentioned

in the

second

paragraph

at the

beginning

of

this

procedure).

12.

Tighten

all

nuts

and

bolts

(noted

as C, D and E in

Fig.

8) in the

passenger compartment

to a

snug

fit

(approximately 2-3 ft-lb). Again check

aligning spacer

for

looseness. Perform

these tightening operations

in

alpha-

betical order.

13.

Tighten

the

lateral adjustment

bolt

(F in Fig. 8) to

snug

fit.

Again

check

the

aligning spacer

for

loose-

ness.

14.

Tighten

all

bolts and nuts

to the

proper torque value (listed

in Fig. 8)

in alphabetical order.

15.

Remove

the

steering shaft

al-

igning spacer.

16.

Remove

the 1/8

diameter

rod or

drill previously inserted

in the

flex

coupling.

17.

Reinstall

the

trim

at the

instru-

ment panel

to

steering column mount-

ing.

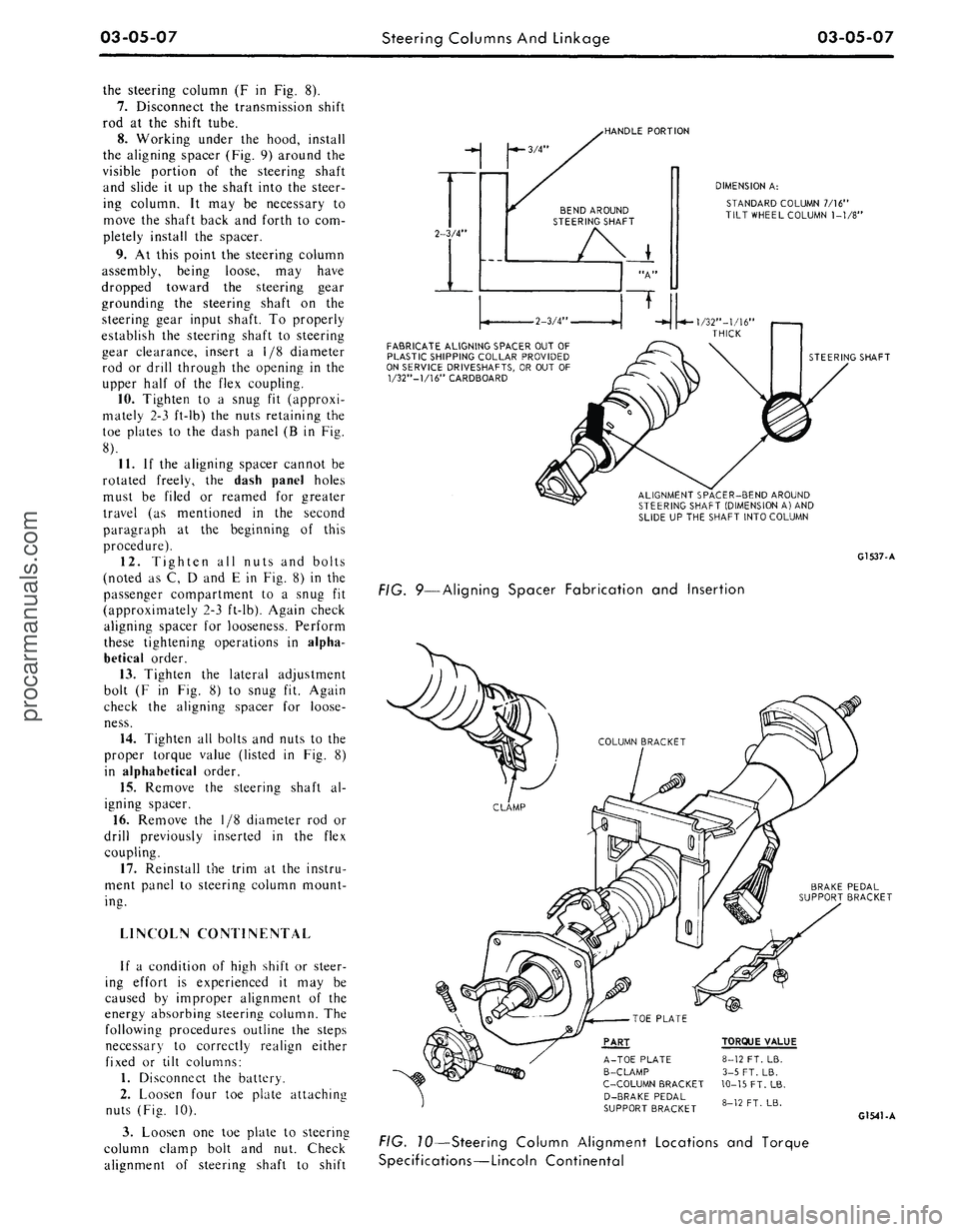

LINCOLN CONTINENTAL

If

a

condition

of

high shift

or

steer-

ing effort

is

experienced

it may be

caused

by

improper alignment

of the

energy absorbing steering column.

The

following procedures outline

the

steps

necessary

to

correctly realign either

fixed

or

tilt columns:

1.

Disconnect

the

battery.

2.

Loosen four

toe

plate attaching

nuts (Fig.

10).

3.

Loosen

one toe

plate

to

steering

column clamp bolt

and nut.

Check

alignment

of

steering shaft

to

shift

-HANDLE PORTION

2-3/4"

-*- 3/4"

BEND AROUND

STEERING SHAFT

DIMENSION

A:

STANDARD COLUMN 7/16"

TILT WHEEL COLUMN

1-1/8"

•2-3/4

FABRICATE ALIGNING SPACER OUT OF

PLASTIC SHIPPING COLLAR PROVIDED

ON SERVICE DRIVESHAFTS, OR OUT

OF

1/32"—1/16" CARDBOARD

STEERING SHAFT

ALIGNMENT SPACER-BEND AROUND

STEERING SHAFT (DIMENSION

A)

AND

SLIDE UP THE SHAFT INTO COLUMN

G1537-A

FIG. 9—Aligning Spacer Fabrication

and

Insertion

BRAKE PEDAL

SUPPORT BRACKET

PART

A-TOE PLATE

B-CLAMP

C-C0LUMN BRACKET

D-BRAKE PEDAL

SUPPORT BRACKET

TORQUE VALUE

8-12 FT. LB.

3-5 FT. LB.

10-15

FT.

LB.

8-12 FT. LB.

G1541-A

FIG. 10—Steering Column Alignment Locations

and

Torque

Specifications—Lincoln Continentalprocarmanuals.com

Page 121 of 413

03-05-08

Steering Columns And Linkage

03-05-08

tube.

In some instances the column

will shift into proper alignment when

the toe plate attaching nuts are loos-

ened. (Alignment is acceptable if a

.010 inch feeler blade can be passed

freely, completely around the area be-

tween the outer diameter of the steer-

ing shaft and the shift tube.) if the

misalignment condition can be attrib-

uted to this area, file or ream the dash

panel holes for greater clearance. If

the alignment is maintained after the

toe plate nuts and toe plate to column

clamp bolt and nut are torqued to the

8-12 ft-lb specification, no further ad-

justment is necessary.

4.

Remove instrument panel lower

trim panel. Vehicles equipped with a

combination radio stereo tape player

will require removal of the radio and

tape player assembly in order to gain

access to the upper R.H. steering col-

umn support bracket bolt.

5.

Loosen the seven bolts at the

steering column support bracket and

brake pedal support bracket.

6. Install a 3/16 inch diameter rod

spacer in the flex coupling to assure

proper clearance between upper and

lower steering shaft.

7.

Raise the vehicle, remove the

transmission splash shield, and visual-

ly align the column to center the

steering shaft in the column. Tighten

two toe plate attaching nuts sufficient-

ly to hold the column alignment (two

persons may be required for this oper-

ation).

8. Lower the vehicle.

9. Check the clearance between the

steering column support bracket and

the instrument panel bracket. It may

be necessary to add shims (Part Num-

ber MK-3054-A .060 inch thick, or

C3AZ-3054-A, .113 inch thick) be-

tween the support bracket and the in-

strument panel bracket to prevent

movement of the column when the

support bracket bolts are tightened.

10.

Loosen the two toe plate at-

taching nuts previously tightened. Re-

check steering column alignment. In

some instances it may be necessary to

enlarge the holes in the dash panel in

order to obtain proper column align-

ment.

11.

With the column properly al-

igned, torque the four toe plate at-

taching nuts to 4-9 ft-lbs.

12.

Torque the toe plate to steering

column clamp bolt to 3-5 ft-lbs.

13.

Recheck steering shaft to shift

tube alignment. A 0.10 inch feeler

blade should pass freely, completely

around the area between the outer di-

ameter of the steering shaft and shift-

er tube.

14.

Raise the vehicle.

15.

Adjust transmission shift link-

age.

16.

Install transmission splash

shield.

17.

Lower the vehicle.

18.

Install the radio stereo tape

player if so equipped.

19.

Install instrument panel lower

trim panel.

20.

Connect the battery.

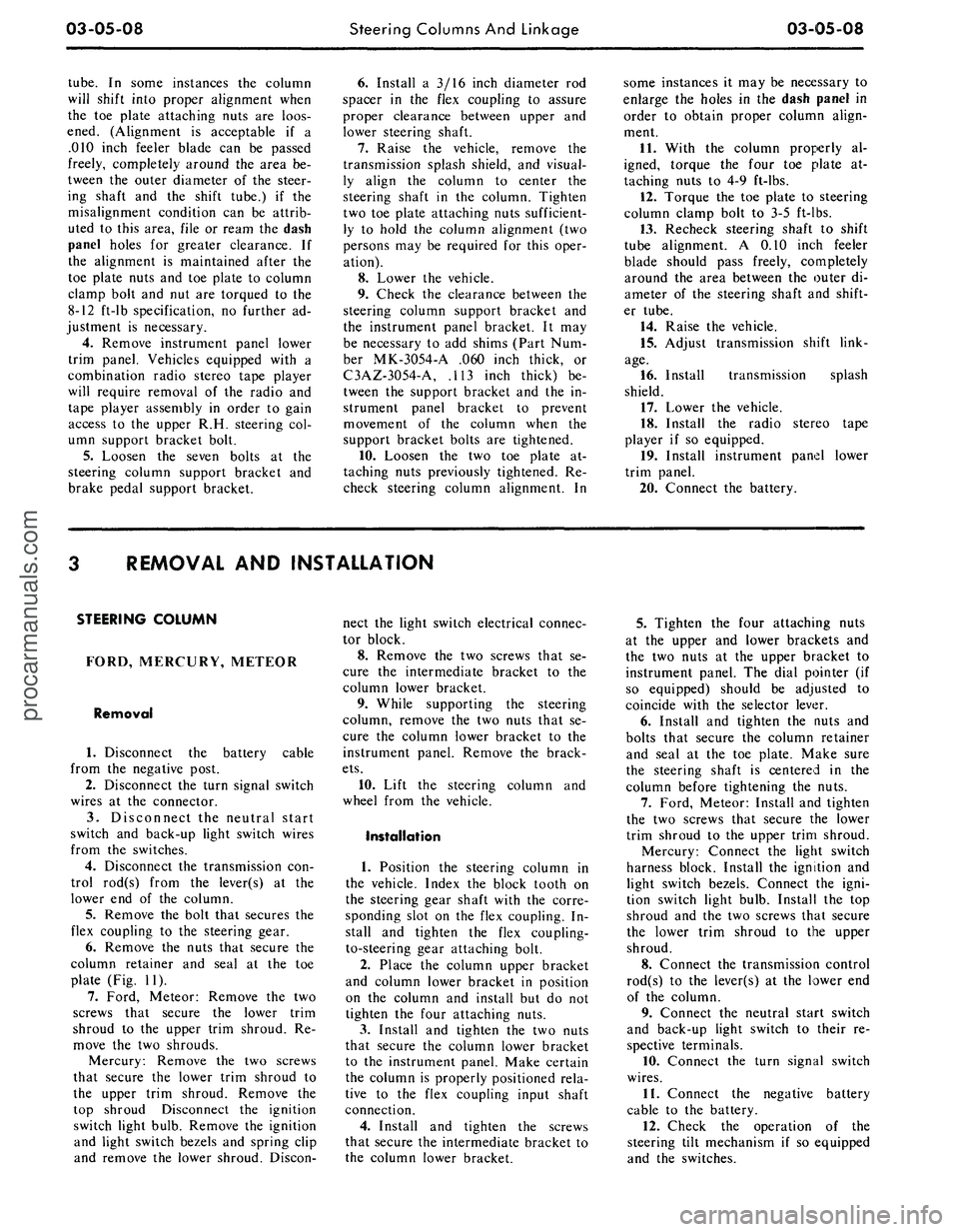

REMOVAL AND INSTALLATION

STEERING COLUMN

FORD, MERCURY, METEOR

Removal

1.

Disconnect the battery cable

from the negative post.

2.

Disconnect the turn signal switch

wires at the connector.

3.

Disconnect the neutral start

switch and back-up light switch wires

from the switches.

4.

Disconnect the transmission con-

trol rod(s) from the lever(s) at the

lower end of the column.

5.

Remove the bolt that secures the

flex coupling to the steering gear.

6. Remove the nuts that secure the

column retainer and seal at the toe

plate (Fig. 11).

7.

Ford, Meteor: Remove the two

screws that secure the lower trim

shroud to the upper trim shroud. Re-

move the two shrouds.

Mercury: Remove the two screws

that secure the lower trim shroud to

the upper trim shroud. Remove the

top shroud Disconnect the ignition

switch light bulb. Remove the ignition

and light switch bezels and spring clip

and remove the lower shroud. Discon-

nect the light switch electrical connec-

tor block.

8. Remove the two screws that se-

cure the intermediate bracket to the

column lower bracket.

9. While supporting the steering

column, remove the two nuts that se-

cure the column lower bracket to the

instrument panel. Remove the brack-

ets.

10.

Lift the steering column and

wheel from the vehicle.

Installation

1.

Position the steering column in

the vehicle. Index the block tooth on

the steering gear shaft with the corre-

sponding slot on the flex coupling. In-

stall and tighten the flex coupling-

to-steering gear attaching bolt.

2.

Place the column upper bracket

and column lower bracket in position

on the column and install but do not

tighten the four attaching nuts.

3.

Install and tighten the two nuts

that secure the column lower bracket

to the instrument panel. Make certain

the column is properly positioned rela-

tive to the flex coupling input shaft

connection.

4.

Install and tighten the screws

that secure the intermediate bracket to

the column lower bracket.

5.

Tighten the four attaching nuts

at the upper and lower brackets and

the two nuts at the upper bracket to

instrument panel. The dial pointer (if

so equipped) should be adjusted to

coincide with the selector lever.

6. Install and tighten the nuts and

bolts that secure the column retainer

and seal at the toe plate. Make sure

the steering shaft is centered in the

column before tightening the nuts.

7.

Ford, Meteor: Install and tighten

the two screws that secure the lower

trim shroud to the upper trim shroud.

Mercury: Connect the light switch

harness block. Install the ignition and

light switch bezels. Connect the igni-

tion switch light bulb. Install the top

shroud and the two screws that secure

the lower trim shroud to the upper

shroud.

8. Connect the transmission control

rod(s) to the lever(s) at the lower end

of the column.

9. Connect the neutral start switch

and back-up light switch to their re-

spective terminals.

10.

Connect the turn signal switch

wires.

11.

Connect the negative battery

cable to the battery.

12.

Check the operation of the

steering tilt mechanism if so equipped

and the switches.procarmanuals.com

Page 122 of 413

03-05-09

Steering Columns And Linkage

03-05-09

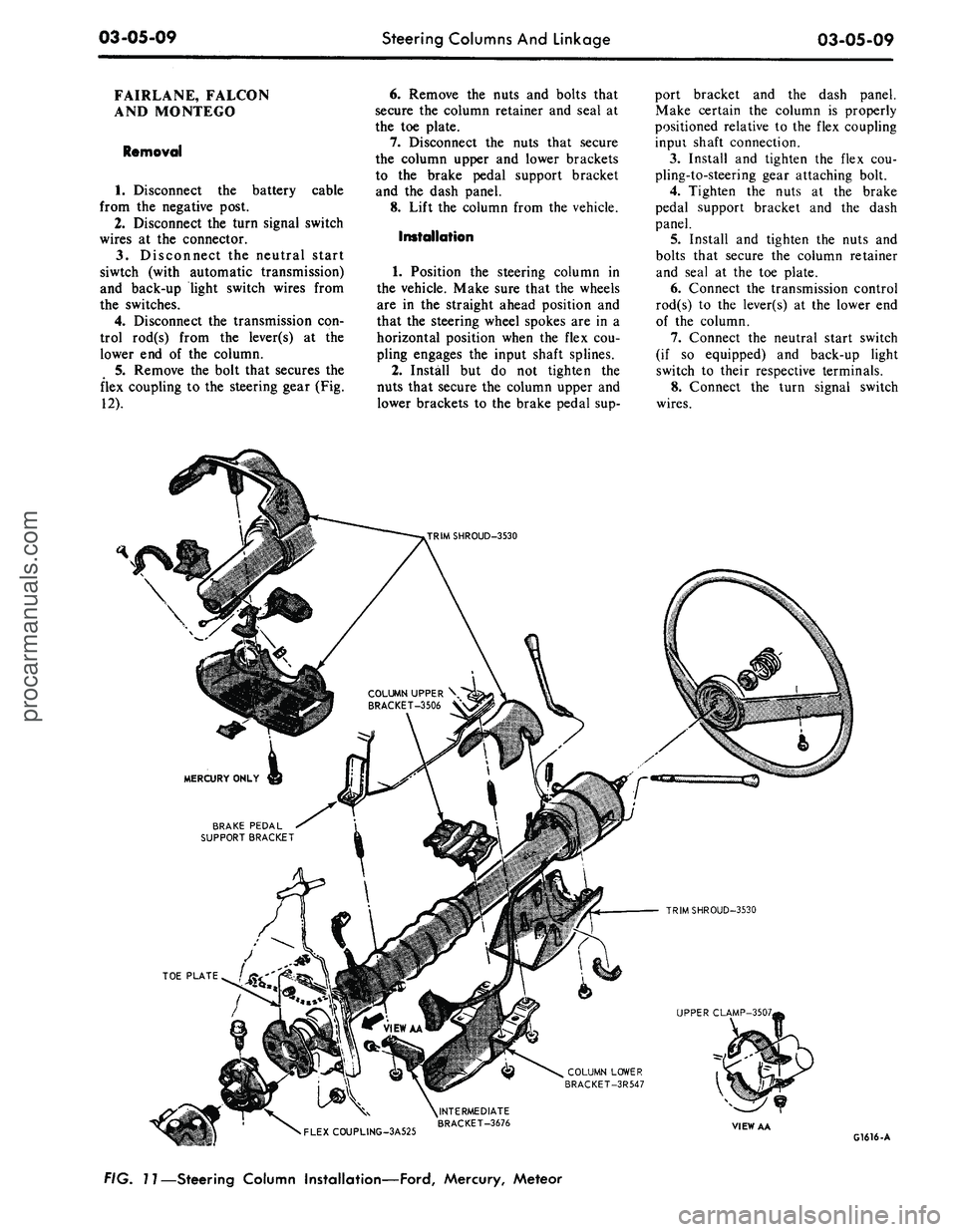

FAIRLANE, FALCON

AND MONTEGO

Removal

1.

Disconnect the battery cable

from the negative post.

2.

Disconnect the turn signal switch

wires at the connector.

3.

Disconnect the neutral start

siwtch (with automatic transmission)

and back-up light switch wires from

the switches.

4.

Disconnect the transmission con-

trol rod(s) from the lever(s) at the

lower end of the column.

5.

Remove the bolt that secures the

flex coupling to the steering gear (Fig.

12).

6. Remove the nuts and bolts that

secure the column retainer and seal at

the toe plate.

7.

Disconnect the nuts that secure

the column upper and lower brackets

to the brake pedal support bracket

and the dash panel.

8. Lift the column from the vehicle.

Installation

1.

Position the steering column in

the vehicle. Make sure that the wheels

are in the straight ahead position and

that the steering wheel spokes are in a

horizontal position when the flex cou-

pling engages the input shaft splines.

2.

Install but do not tighten the

nuts that secure the column upper and

lower brackets to the brake pedal sup-

port bracket and the dash panel.

Make certain the column is properly

positioned relative to the flex coupling

inpui shaft connection.

3.

Install and tighten the flex cou-

pling-to-steering gear attaching bolt.

4.

Tighten the nuts at the brake

pedal support bracket and the dash

panel.

5.

Install and tighten the nuts and

bolts that secure the column retainer

and seal at the toe plate.

6. Connect the transmission control

rod(s) to the lever(s) at the lower end

of the column.

7.

Connect the neutral start switch

(if so equipped) and back-up light

switch to their respective terminals.

8. Connect the turn signal switch

wires.

COLUMN UPPER \

BRACKET-3506 V

BRAKE PEDAL

SUPPORT BRACKET

TRIMSHROUD-3530

UPPER CLAMP-3507,

COLUMN LOWER

BRACKET-3R547

•

FLEXCOUPLING-3A525

^INTERMEDIATE

BRACKET-3676

VIEW AA

G1616-A

FIG. 11—Steering Column Installation—Ford, Mercury, Meteorprocarmanuals.com

Page 127 of 413

03-05-14

Steering Columns And Linkage

03-05-14

8. Connect the turn signal and

emergency flasher switch wires at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Connect the tilt-column control

cable to the release cable retainer and

vacuum motor (if so equipped). To re-

move cable slack, loosen the bracket

attaching screw and pull it slightly

toward the column, then tighten the

screw. If difficulty in adjusting this

control is experienced, the retainer

slot may be filed to gain additional

travel.

10.

Install the instrument panel

steering column plate and cover and

the instrument panel lower outer fin-

ish panel.

11.

Connect the negative cable to

the battery.

12.

Start the engine and check the

operation of the steering column and

switches.

LINCOLN CONTINENTAL

Removal

1.

Disconnect the battery.

2.

Disconnect the rod from the

lever at the lower end of the selector

tube.

Loosen the clamp bolt that locks

the flexible coupling to the steering

shaft.

3.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. Do not use a ham-

mer or knock-off type wheel puller.

Striking the puller or shaft may cause

damage to the bearings and/or col-

lapsible column. Remove the steering

wheel as shown in Fig. 15.

4.

Remove the instrument panel

steering column finish plate.

5.

Remove the four screws that at-

tach the lower retainer to the dash

panel.

6. Disconnect the turn signal switch

and emergency flasher wires at the

connectors. Disconnect the wires from

the neutral start switch.

7.

While supporting the steering

column, remove the bolts that attach

the lower clamp to the upper bracket

(Fig. 15). Lift the column from the ve-

hicle.

Installation

1.

Position the column in the vehi-

cle,

making sure that the steering

shaft engages the flex coupling.

2.

Install the column retainer-

to-dash panel attaching screws, but do

not tighten them.

3.

Install the lower clamp and the

attaching nuts. Tighten the nuts fing-

ertight.

4.

Move the lower flange as re-

quired to center the steering shaft in

the tube. Aligning procedures are de-

tailed in Part 3-1. Tighten the lower

flange attaching nuts when the shaft is

centered.

5.

Connect the shift rod to the shift

lever at the lower end of the column.

6. Install and tighten the flex cou-

pling attaching bolt.

7.

Tighten the instrument panel-

to-clamp attaching nuts.

8. Connect the turn signal and

emergency flasher switch wirss at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Install the instrument panel

steering column finish plate.

10.

Install the steering wheel and

crash pad.

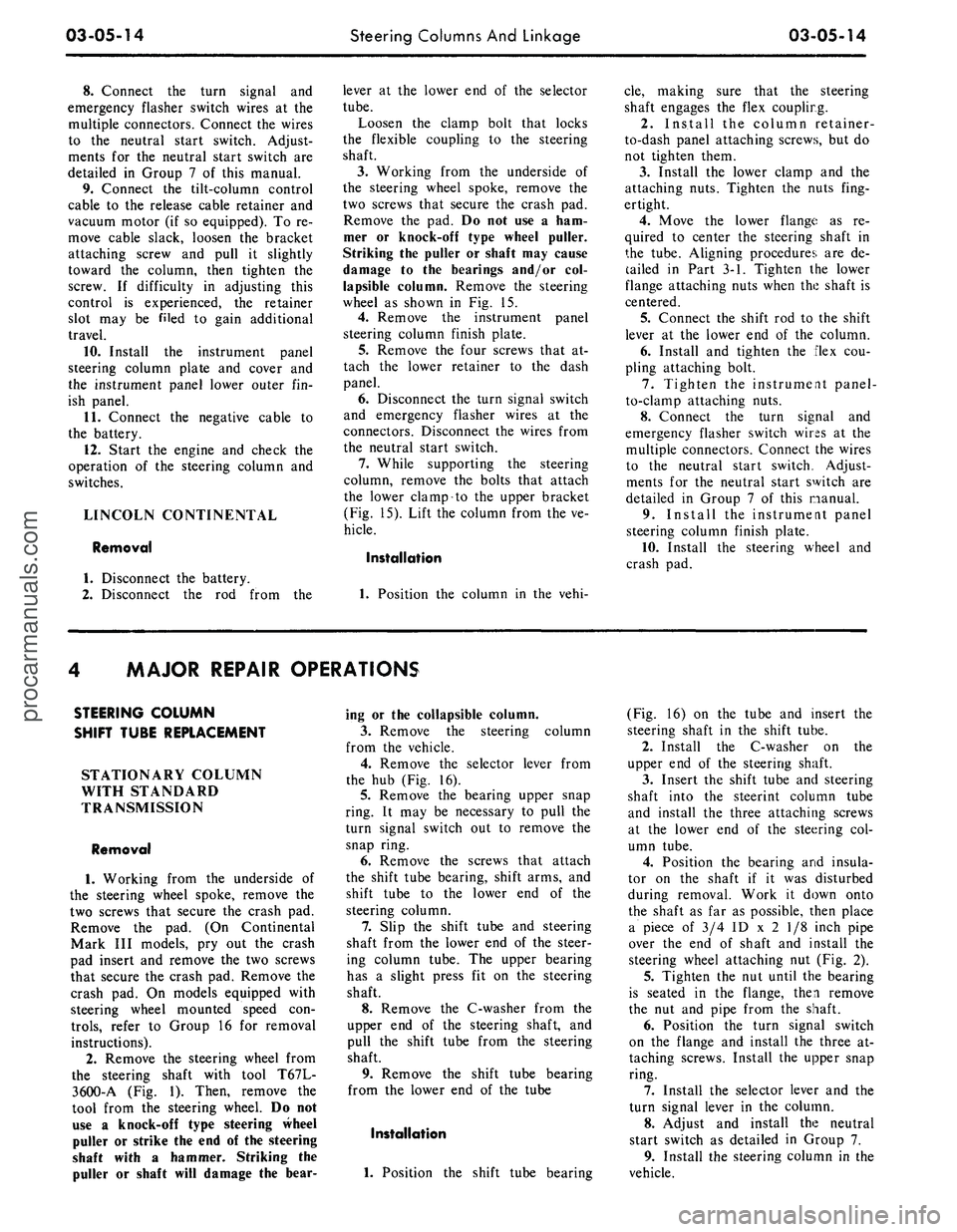

MAJOR REPAIR OPERATIONS

STEERING COLUMN

SHIFT TUBE REPLACEMENT

STATIONARY COLUMN

WITH STANDARD

TRANSMISSION

Removal

1.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. (On Continental

Mark III models, pry out the crash

pad insert and remove the two screws

that secure the crash pad. Remove the

crash pad. On models equipped with

steering wheel mounted speed con-

trols,

refer to Group 16 for removal

instructions).

2.

Remove the steering wheel from

the steering shaft with tool T67L-

3600-A (Fig. 1). Then, remove the

tool from the steering wheel. Do not

use a knock-off type steering Wheel

puller or strike the end of the steering

shaft with a hammer. Striking the

puller or shaft will damage the bear-

ing or the collapsible column.

3.

Remove the steering column

from the vehicle.

4.

Remove the selector lever from

the hub (Fig. 16).

5.

Remove the bearing upper snap

ring. It may be necessary to pull the

turn signal switch out to remove the

snap ring.

6. Remove the screws that attach

the shift tube bearing, shift arms, and

shift tube to the lower end of the

steering column.

7.

Slip the shift tube and steering

shaft from the lower end of the steer-

ing column tube. The upper bearing

has a slight press fit on the steering

shaft.

8. Remove the C-washer from the

upper end of the steering shaft, and

pull the shift tube from the steering

shaft.

9. Remove the shift tube bearing

from the lower end of the tube

Installation

1.

Position the shift tube bearing

(Fig. 16) on the tube and insert the

steering shaft in the shift tube.

2.

Install the C-washer on the

upper end of the steering shaft.

3.

Insert the shift tube and steering

shaft into the steerint column tube

and install the three attaching screws

at the lower end of the steering col-

umn tube.

4.

Position the bearing and insula-

tor on the shaft if it was disturbed

during removal. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of shaft and install the

steering wheel attaching nut (Fig. 2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws. Install the upper snap

ring.

7.

Install the selector lever and the

turn signal lever in the column.

8. Adjust and install the neutral

start switch as detailed in Group 7.

9. Install the steering column in the

vehicle.procarmanuals.com

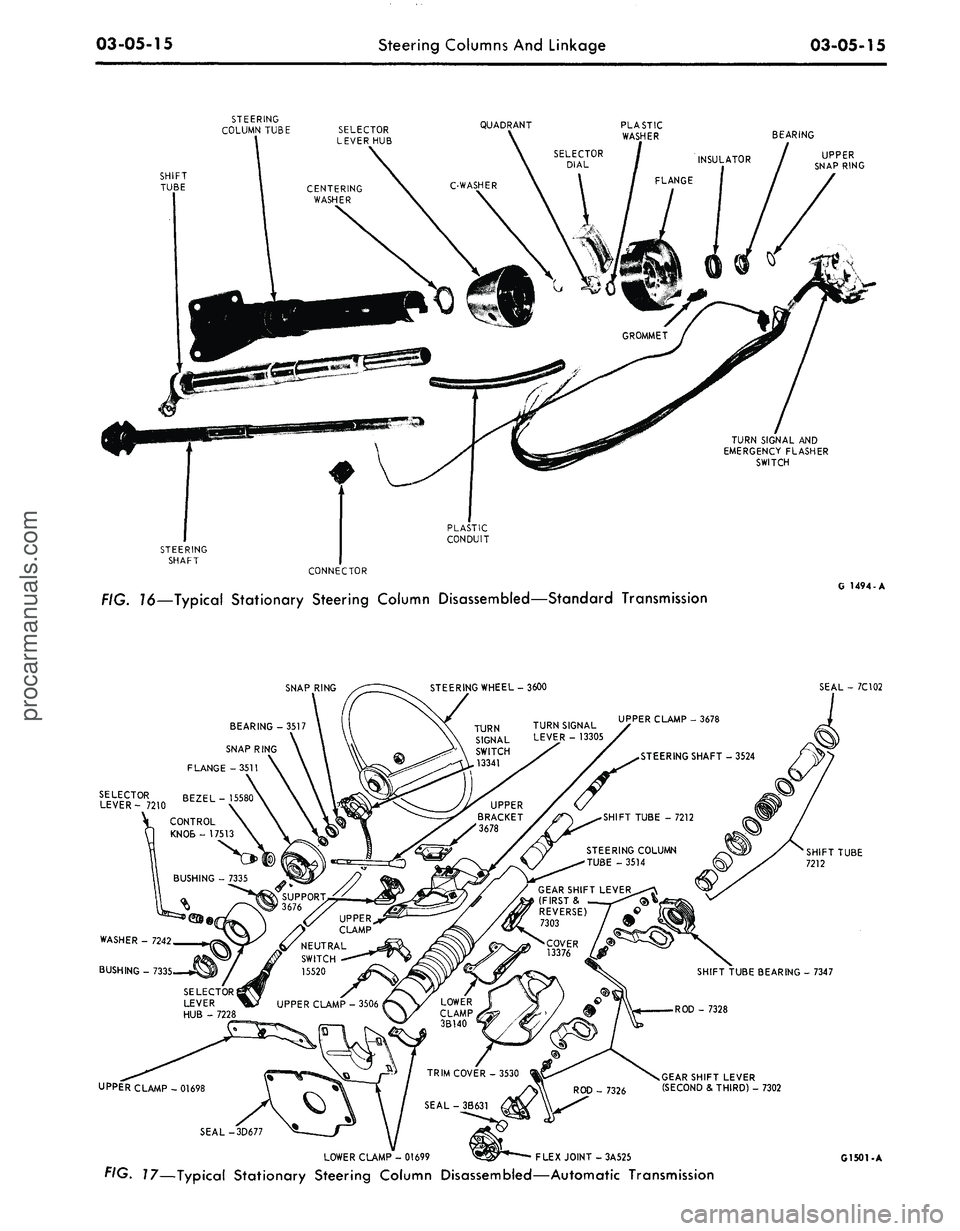

Page 128 of 413

03-05-15

Steering Columns And Linkage

03-05-15

SHIFT

TUBE

STEERING

COLUMN

TUBE

SELECTOR

I

LEVER

HUB

\

CENTERING

I

WASHER

QUADRANT

BEARING

UPPER

SNAP RING

TURN SIGNAL AND

EMERGENCY FLASHER

SWITCH

PLASTIC

CONDUIT

STEERING

SHAFT

CONNECTOR

FIG. 16—Typical Stationary Steering Column Disassembled—Standard Transmission

G 1494-A

SNAP RING

STEERING WHEEL-3600

SEAL - 7C102

BEARING -3517

SNAP RING

FLANGE -3511

SELECTOR BEZEL-

LEVER- 7210 ZtL

GEAR SHIFT LEVER

(FIRST

&

REVERSE)

/

7303

/ 9

WASHER - 7242

BUSHING - 733

- 7347

UPPER CLAMP-01698

GEARSHIFT LEVER

(SECOND & THIRD) - 7302

SEAL-

LOWER CLAMP - 01699

^^r**——

FLEX JOINT - 3A525

FIG. 17—Typical Stationary Steering Column Disassembled—Automatic Transmission

G1501-Aprocarmanuals.com

Page 136 of 413

03-06-02

Manual Steering

03-06-02

IN-VEHICLE ADJUSTMENTS AND REPAIRS

STEERING WORM AND

SECTOR

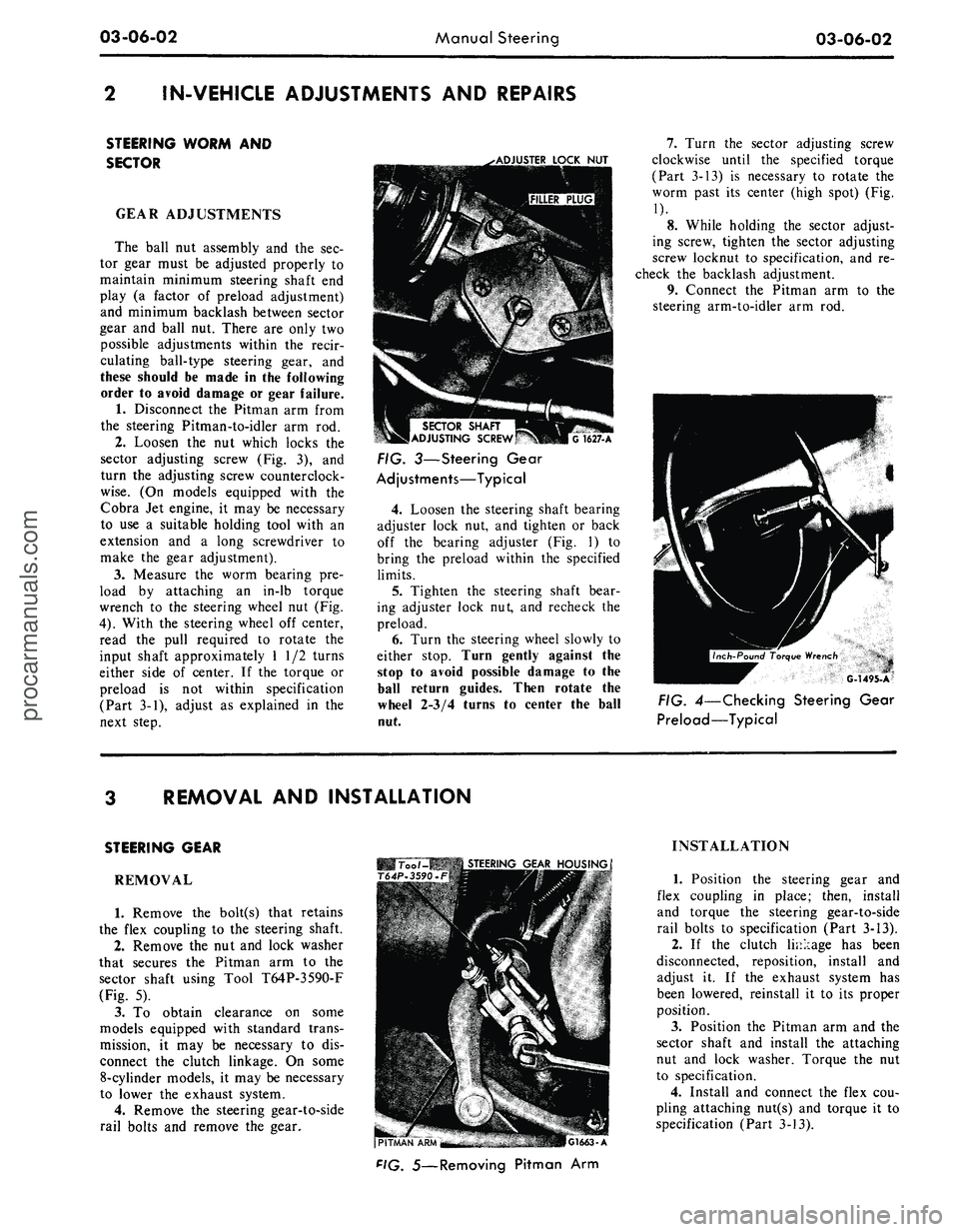

GEAR ADJUSTMENTS

The ball nut assembly and the sec-

tor gear must be adjusted properly to

maintain minimum steering shaft end

play (a factor of preload adjustment)

and minimum backlash between sector

gear and ball nut. There are only two

possible adjustments within the recir-

culating ball-type steering gear, and

these should be made in the following

order to avoid damage or gear failure.

1.

Disconnect the Pitman arm from

the steering Pitman-to-idler arm rod.

2.

Loosen the nut which locks the

sector adjusting screw (Fig. 3), and

turn the adjusting screw counterclock-

wise.

(On models equipped with the

Cobra Jet engine, it may be necessary

to use a suitable holding tool with an

extension and a long screwdriver to

make the gear adjustment).

3.

Measure the worm bearing pre-

load by attaching an in-lb torque

wrench to the steering wheel nut (Fig.

4).

With the steering wheel off center,

read the pull required to rotate the

input shaft approximately 1 1/2 turns

either side of center. If the torque or

preload is not within specification

(Part 3-1), adjust as explained in the

next step.

.•ADJUSTER

LOCK

NUT

SECTOR

SHAFT

ADJUSTING

SCREW

G

1627-A

FIG. 3—Steering Gear

Adjustments—Typical

4.

Loosen the steering shaft bearing

adjuster lock nut, and tighten or back

off the bearing adjuster (Fig. 1) to

bring the preload within the specified

limits.

5.

Tighten the steering shaft bear-

ing adjuster lock nut, and recheck the

preload.

6. Turn the steering wheel slowly to

either stop. Turn gently against the

stop to avoid possible damage to the

ball return guides. Then rotate the

wheel 2-3/4 turns to center the ball

nut.

7.

Turn the sector adjusting screw

clockwise until the specified torque

(Part 3-13) is necessary to rotate the

worm past its center (high spot) (Fig.

1).

8. While holding the sector adjust-

ing screw, tighten the sector adjusting

screw locknut to specification, and re-

check the backlash adjustment.

9. Connect the Pitman arm to the

steering arm-to-idler arm rod.

G-1495-A

FIG. 4—Checking Steering Gear

Preload—Typical

REMOVAL AND INSTALLATION

STEERING GEAR

REMOVAL

1.

Remove the bolt(s) that retains

the flex coupling to the steering shaft.

2.

Remove the nut and lock washer

that secures the Pitman arm to the

sector shaft using Tool T64P-3590-F

(Fig. 5).

3.

To obtain clearance on some

models equipped with standard trans-

mission, it may be necessary to dis-

connect the clutch linkage. On some

8-cylinder models, it may be necessary

to lower the exhaust system.

4.

Remove the steering gear-to-side

rail bolts and remove the gear.

Too /-MB

STEERING

GEAR

HOUSING

T64P-3590.F

(PITMAN

"APU'^M

-

.-. •

-"

•.:,.17''i.a—

r.iMI.

A

F'G.

5—Removing Pitman Arm

INSTALLATION

1.

Position the steering gear and

flex coupling in place; then, install

and torque the steering gear-to-side

rail bolts to specification (Part 3-13).

2.

If the clutch linkage has been

disconnected, reposition, install and

adjust it. If the exhaust system has

been lowered, reinstall it to its proper

position.

3.

Position the Pitman arm and the

sector shaft and install the attaching

nut and lock washer. Torque the nut

to specification.

4.

Install and connect the flex cou-

pling attaching nut(s) and torque it to

specification (Part 3-13).procarmanuals.com

Page 142 of 413

03-07-04

Ford Design Non-Integral Power Steering System

03-07-04

12.

Stop the engine, and check the

control valve and hose connections for

fluid leaks. Correct the cause of any

leaks.

13.

Check the fluid level, and refill

the reservoir if necessary.

14.

With the engine running check

the position of the steering wheel

when the front wheels are in the

straight-ahead position.Do not make

any adjustments until toe-in is

checked.

15.

Keep the engine running, and

check toe-in. If either toe-in or steer-

ing wheel position is not correct make

all necessary adjustments (Part 3-1) at

the spindle connecting rod sleeves.

16.

Check the effort to turn the

wheels in both directions. The effort

should be about equal in both direc-

tions.

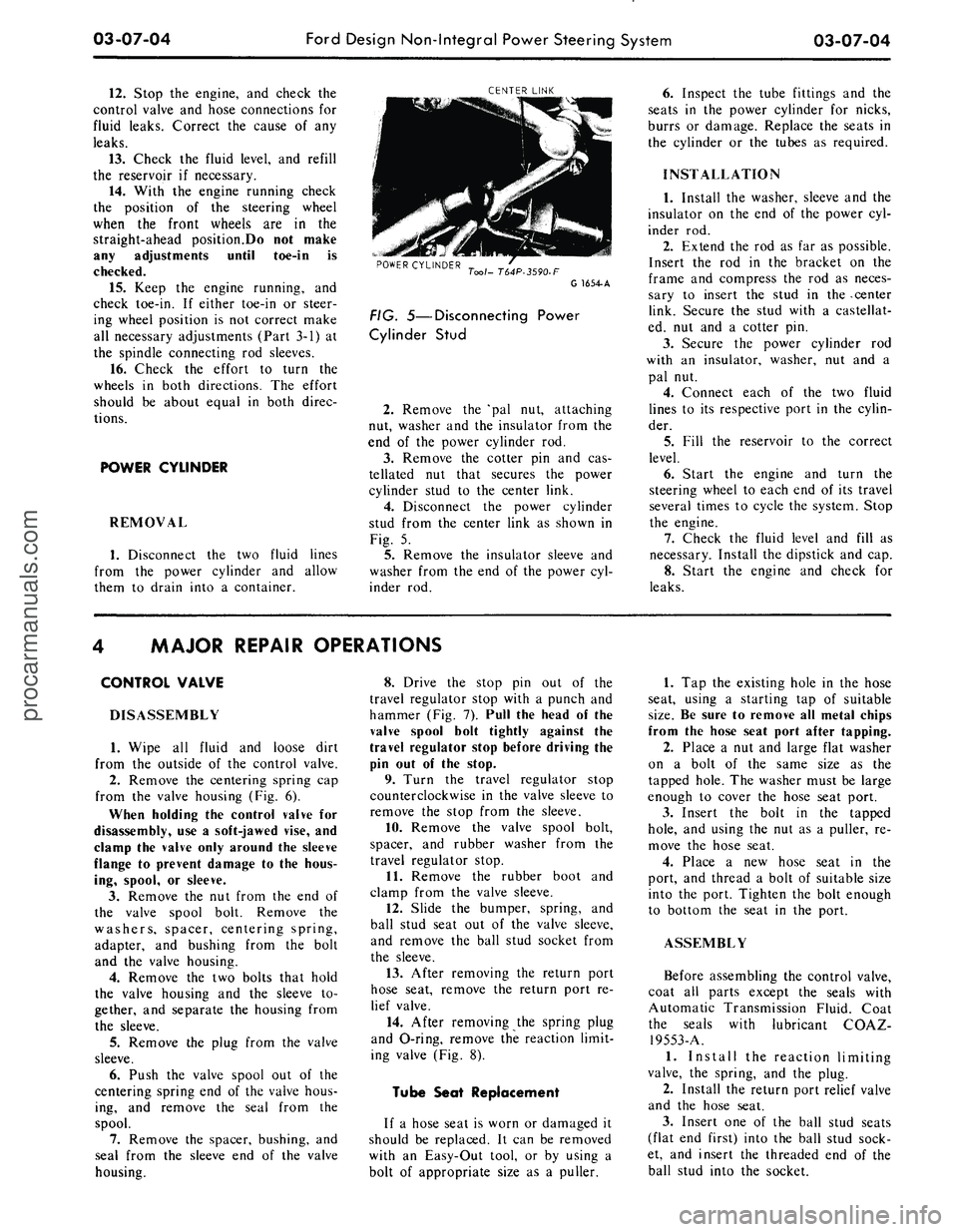

POWER CYLINDER

REMOVAL

1.

Disconnect the two fluid lines

from the power cylinder and allow

them to drain into a container.

CENTER LINK

POWER CYLINDER

Tool- T64P-3590-F

G 1654-A

FIG. 5—Disconnecting Power

Cylinder Stud

2.

Remove the 'pal nut, attaching

nut, washer and the insulator from the

end of the power cylinder rod.

3.

Remove the cotter pin and cas-

tellated nut that secures the power

cylinder stud to the center link.

4.

Disconnect the power cylinder

stud from the center link as shown in

Fig. 5.

5.

Remove the insulator sleeve and

washer from the end of the power cyl-

inder rod.

6. Inspect the tube fittings and the

seats in the power cylinder for nicks,

burrs or damage. Replace the seats in

the cylinder or the tubes as required.

INSTALLATION

1.

Install the washer, sleeve and the

insulator on the end of the power cyl-

inder rod.

2.

Extend the rod as far as possible.

Insert the rod in the bracket on the

frame and compress the rod as neces-

sary to insert the stud in the -center

link. Secure the stud with a castellat-

ed, nut and a cotter pin.

3.

Secure the power cylinder rod

with an insulator, washer, nut and a

pal nut.

4.

Connect each of the two fluid

lines to its respective port in the cylin-

der.

5.

Fill the reservoir to the correct

level.

6. Start the engine and turn the

steering wheel to each end of its travel

several times to cycle the system. Stop

the engine.

7.

Check the fluid level and fill as

necessary. Install the dipstick and cap.

8. Start the engine and check for

leaks.

MAJOR REPAIR OPERATIONS

CONTROL VALVE

DISASSEMBLY

1.

Wipe all fluid and loose dirt

from the outside of the control valve.

2.

Remove the centering spring cap

from the valve housing (Fig. 6).

When holding the control valve for

disassembly, use a soft-jawed vise, and

clamp the valve only around the sleeve

flange to prevent damage to the hous-

ing, spool, or sleeve.

3.

Remove the nut from the end of

the valve spool bolt. Remove the

washers, spacer, centering spring,

adapter, and bushing from the bolt

and the valve housing.

4.

Remove the two bolts that hold

the valve housing and the sleeve to-

gether, and separate the housing from

the sleeve.

5.

Remove the plug from the valve

sleeve.

6. Push the valve spool out of the

centering spring end of the valve hous-

ing, and remove the seal from the

spool.

7.

Remove the spacer, bushing, and

seal from the sleeve end of the valve

housing.

8. Drive the stop pin out of the

travel regulator stop with a punch and

hammer (Fig. 7). Pull the head of the

valve spool bolt tightly against the

travel regulator stop before driving the

pin out of the stop.

9. Turn the travel regulator stop

counterclockwise in the valve sleeve to

remove the stop from the sleeve.

10.

Remove the valve spool bolt,

spacer, and rubber washer from the

travel regulator stop.

11.

Remove the rubber boot and

clamp from the valve sleeve.

12.

Slide the bumper, spring, and

ball stud seat out of the valve sleeve,

and remove the ball stud socket from

the sleeve.

13.

After removing the return port

hose seat, remove the return port re-

lief valve.

14.

After removing the spring plug

and O-ring, remove the reaction limit-

ing valve (Fig. 8).

Tube Seat Replacement

If a hose seat is worn or damaged it

should be replaced. It can be removed

with an Easy-Out tool, or by using a

bolt of appropriate size as a puller.

1.

Tap the existing hole in the hose

seat, using a starting tap of suitable

size.

Be sure to remove all metal chips

from the hose seat port after tapping.

2.

Place a nut and large flat washer

on a bolt of the same size as the

tapped hole. The washer must be large

enough to cover the hose seat port.

3.

Insert the bolt in the tapped

hole,

and using the nut as a puller, re-

move the hose seat.

4.

Place a new hose seat in the

port, and thread a bolt of suitable size

into the port. Tighten the bolt enough

to bottom the seat in the port.

ASSEMBLY

Before assembling the control valve,

coat all parts except the seals with

Automatic Transmission Fluid. Coat

the seals with lubricant COAZ-

19553-A.

1.

Install the reaction limiting

valve, the spring, and the plug.

2.

Install the return port relief valve

and the hose seat.

3.

Insert one of the ball stud seats

(flat end first) into the ball stud sock-

et, and insert the threaded end of the

ball stud into the socket.procarmanuals.com