trans FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 36 of 413

02-02-17

Brake System

02-02-17

CALIPER PARTS

2B120 R.H.

2B121 L.H.

CALIPER ASS'Y

2B118 R.H.

2BU9L.H.

INSULATOR

CUP

2B2"

2B164

STABILIZER

2B295

FAIRLANE, MONTEGO, FALCON,

MUSTANG AND COUGAR

SEAL

2B115

2207

BOOT

20310-S

34806 S \ INNER BEARING

w CONE AND ROLLER

1201

CUP

ANCHOR PLATE

2B293 L.H.

2B292 R.H.

CONE AND ROLLER

1216

GREASE SEAL

1190

ADJUSTING NUT

374504-S

3105-R.H.

3106-L.H.

ROTOR SPLASH SHI

2K004-R.H.

2K005-L.H.

COVER-1130

1102

H 1670-A

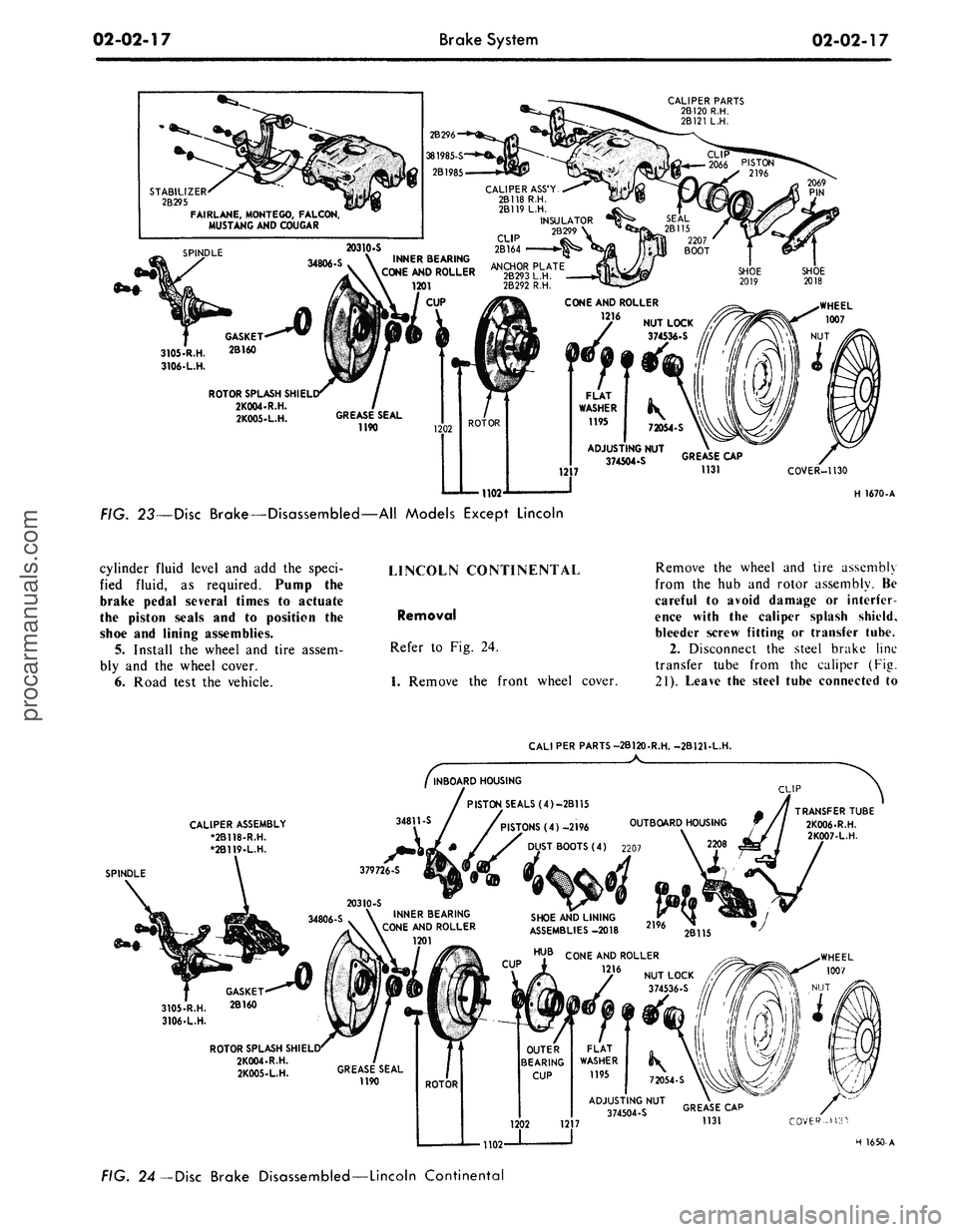

FIG. 23—Disc Brake—Disassembled—All Models Except Lincoln

cylinder fluid level and add the speci-

fied fluid, as required. Pump the

brake pedal several times to actuate

the piston seals and to position the

shoe and lining assemblies.

5. Install the wheel and tire assem-

bly and the wheel cover.

6. Road test the vehicle.

LINCOLN CONTINENTAL

Removal

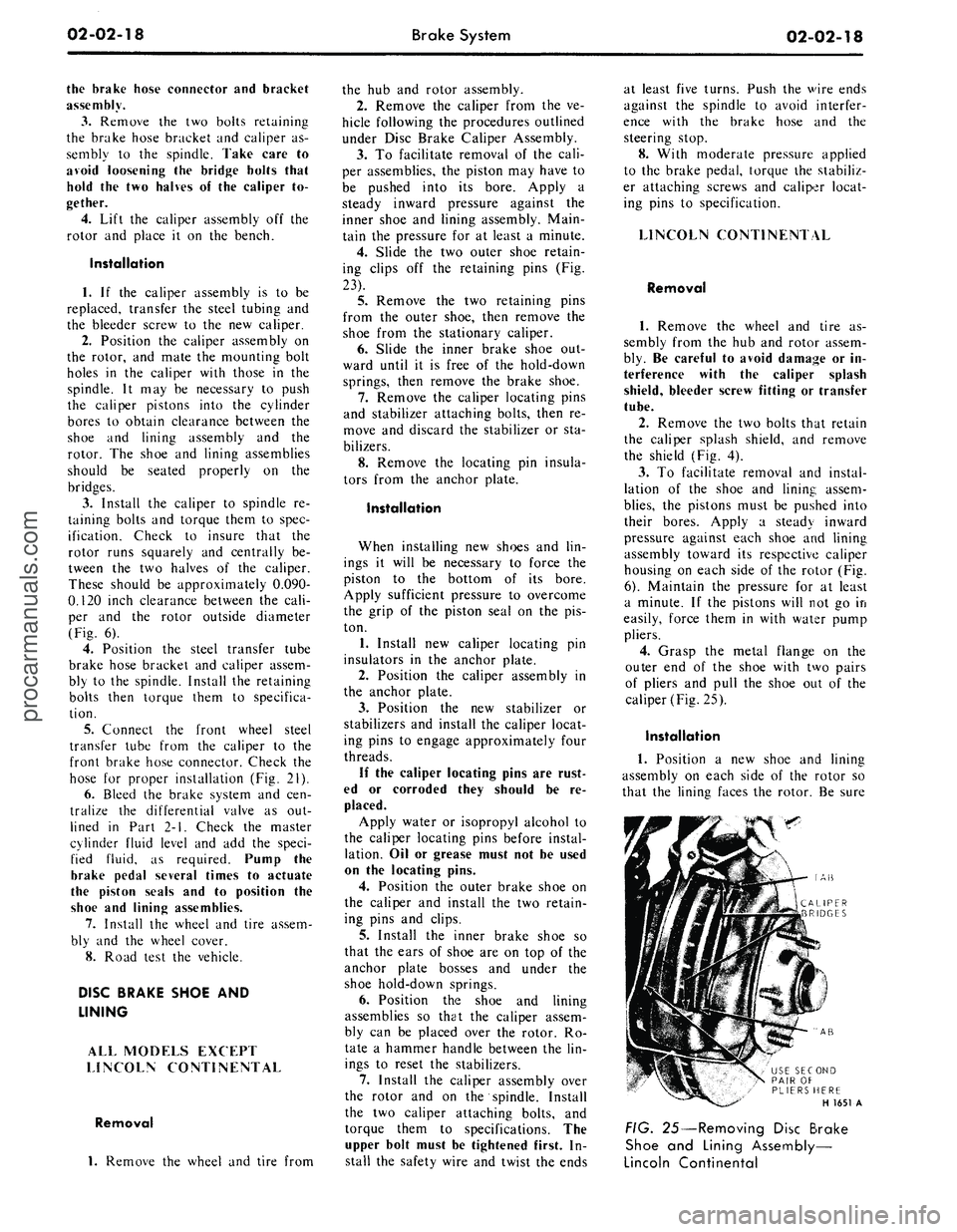

Refer to Fig. 24.

1.

Remove the front wheel cover.

Remove the wheel and tire assembly

from the hub and rotor assembly. Be

careful to avoid damage or interfer-

ence with the caliper splash shield,

bleeder screw fitting or transfer tube.

2.

Disconnect the steel brake line

transfer tube from the caliper (Fig.

21).

Leave the steel tube connected to

CALI PER PARTS-2B120-R.H. -2B121-L.H.

CALIPER ASSEMBLY

*2B118-R.H.

•2B119-L.H.

34811-S

SPINDLE

379726-S

INBOARD HOUSING

PISTON SEALS (4)-2B115

/PISTONS (4) -2196 OUTBOARD HOUSING

T BOOTS (4) 2207

CLIP

34806-S

INNER BEARING

CONE AND ROLLER

1201

GASKET

3105-R.H.

2B16°

3106-L.H.

ROTOR SPLASH

SHI

EL

1102

SHOE AND LINING

ASSEMBLIES -2018

COVER-US'!

H 1650-A

FIG. 24—Disc Brake Disassembled—Lincoln Continentalprocarmanuals.com

Page 37 of 413

02-02-18

Brake System

02-02-18

the brake hose connector

and

bracket

assembly.

3.

Remove

the two

bolts retaining

the brake hose bracket

and

caliper

as-

sembly

to the

spindle. Take care

to

avoid loosening

the

bridge bolts that

hold

the two

halves

of the

caliper

to-

gether.

4.

Lift

the

caliper assembly

off the

rotor

and

place

it on the

bench.

Installation

1.

If the

caliper assembly

is to be

replaced, transfer

the

steel tubing

and

the bleeder screw

to the new

caliper.

2.

Position

the

caliper assembly

on

the rotor,

and

mate

the

mounting bolt

holes

in the

caliper with those

in the

spindle.

It may be

necessary

to

push

the caliper pistons into

the

cylinder

bores

to

obtain clearance between

the

shoe

and

lining assembly

and the

rotor.

The

shoe

and

lining assemblies

should

be

seated properly

on the

bridges.

3.

Install

the

caliper

to

spindle

re-

taining bolts

and

torque them

to

spec-

ification. Check

to

insure that

the

rotor runs squarely

and

centrally

be-

tween

the two

halves

of the

caliper.

These should

be

approximately 0.090-

0.120 inch clearance between

the

cali-

per

and the

rotor outside diameter

(Fig.

6).

4.

Position

the

steel transfer tube

brake hose bracket

and

caliper assem-

bly

to the

spindle. Install

the

retaining

bolts then torque them

to

specifica-

tion.

5.

Connect

the

front wheel steel

transfer tube from

the

caliper

to the

front brake hose connector. Check

the

hose

for

proper installation

(Fig. 21).

6. Bleed

the

brake system

and cen-

tralize

the

differential valve

as out-

lined

in

Part

2-1.

Check

the

master

cylinder fluid level

and add the

speci-

fied fluid,

as

required. Pump

the

brake pedal several times

to

actuate

the piston seals

and to

position

the

shoe

and

lining assemblies.

7.

Install

the

wheel

and

tire assem-

bly

and the

wheel cover.

8. Road test

the

vehicle.

DISC BRAKE SHOE

AND

LINING

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire from

the

hub and

rotor assembly.

2.

Remove

the

caliper from

the ve-

hicle following

the

procedures outlined

under Disc Brake Caliper Assembly.

3.

To

facilitate removal

of the

cali-

per assemblies,

the

piston

may

have

to

be pushed into

its

bore. Apply

a

steady inward pressure against

the

inner shoe

and

lining assembly. Main-

tain

the

pressure

for at

least

a

minute.

4.

Slide

the two

outer shoe retain-

ing clips

off the

retaining pins

(Fig.

23).

5.

Remove

the two

retaining pins

from

the

outer shoe, then remove

the

shoe from

the

stationary caliper.

6. Slide

the

inner brake shoe

out-

ward until

it is

free

of the

hold-down

springs, then remove

the

brake shoe.

7.

Remove

the

caliper locating pins

and stabilizer attaching bolts, then

re-

move

and

discard

the

stabilizer

or sta-

bilizers.

8. Remove

the

locating

pin

insula-

tors from

the

anchor plate.

Installation

When installing

new

shoes

and lin-

ings

it

will

be

necessary

to

force

the

piston

to the

bottom

of its

bore.

Apply sufficient pressure

to

overcome

the grip

of the

piston seal

on the pis-

ton.

1.

Install

new

caliper locating

pin

insulators

in the

anchor plate.

2.

Position

the

caliper assembly

in

the anchor plate.

3.

Position

the new

stabilizer

or

stabilizers

and

install

the

caliper locat-

ing pins

to

engage approximately four

threads.

If

the

caliper locating pins

are

rust-

ed

or

corroded they should

be re-

placed.

Apply water

or

isopropyl alcohol

to

the caliper locating pins before instal-

lation.

Oil or

grease must

not be

used

on

the

locating pins.

4.

Position

the

outer brake shoe

on

the caliper

and

install

the two

retain-

ing pins

and

clips.

5.

Install

the

inner brake shoe

so

that

the

ears

of

shoe

are on top of the

anchor plate bosses

and

under

the

shoe hold-down springs.

6. Position

the

shoe

and

lining

assemblies

so

that

the

caliper assem-

bly

can be

placed over

the

rotor.

Ro-

tate

a

hammer handle between

the lin-

ings

to

reset

the

stabilizers.

7.

Install

the

caliper assembly over

the rotor

and on the

spindle. Install

the

two

caliper attaching bolts,

and

torque them

to

specifications.

The

upper bolt must

be

tightened first.

In-

stall

the

safety wire

and

twist

the

ends

at least five turns. Push

the

wire ends

against

the

spindle

to

avoid interfer-

ence with

the

brake hose

and the

steering stop.

8. With moderate pressure applied

to

the

brake pedal, torque

the

stabiliz-

er attaching screws

and

caliper locat-

ing pins

to

specification.

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire

as-

sembly from

the hub and

rotor assem-

bly.

Be

careful

to

avoid damage

or in-

terference with

the

caliper splash

shield, bleeder screw fitting

or

transfer

tube.

2.

Remove

the two

bolts that retain

the caliper splash shield,

and

remove

the shield

(Fig. 4).

3.

To

facilitate removal

and

instal-

lation

of the

shoe

and

lining assem-

blies,

the

pistons must

be

pushed into

their bores. Apply

a

steady inward

pressure against each shoe

and

lining

assembly toward

its

respective caliper

housing

on

each side

of the

rotor

(Fig.

6).

Maintain

the

pressure

for at

least

a minute.

If the

pistons will

not go ifi

easily, force them

in

with water pump

pliers.

4.

Grasp

the

metal flange

on the

outer

end of the

shoe with

two

pairs

of pliers

and

pull

the

shoe

out of the

caliper (Fig.

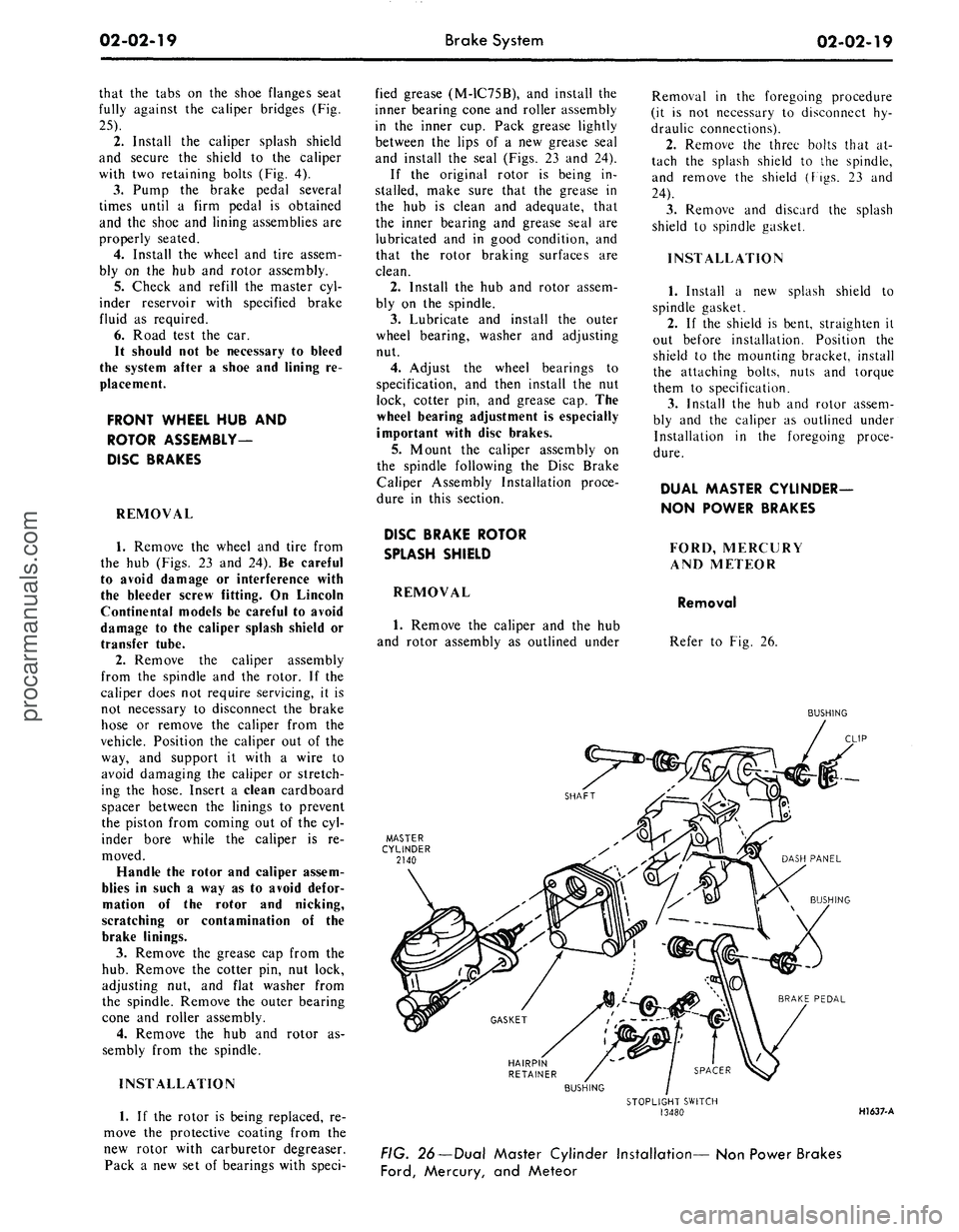

25).

Installation

1.

Position

a new

shoe

and

lining

assembly

on

each side

of the

rotor

so

that

the

lining faces

the

rotor.

Be

sure

AB

AB

USE SECOND

PAIR

OF

PLIERS HERE

H 1651

A

FIG. 25—Removing Disc Brake

Shoe

and

Lining Assembly—

Lincoln Continentalprocarmanuals.com

Page 38 of 413

02-02-19

Brake System

02-02-19

that the tabs on the shoe flanges seat

fully against the caliper bridges (Fig.

25).

2.

Install the caliper splash shield

and secure the shield to the caliper

with two retaining bolts (Fig. 4).

3.

Pump the brake pedal several

times until a firm pedal is obtained

and the shoe and lining assemblies are

properly seated.

4.

Install the wheel and tire assem-

bly on the hub and rotor assembly.

5.

Check and refill the master cyl-

inder reservoir with specified brake

fluid as required.

6. Road test the car.

It should not be necessary to bleed

the system after a shoe and lining re-

placement.

FRONT WHEEL HUB AND

ROTOR ASSEMBLY-

DISC BRAKES

REMOVAL

1.

Remove the wheel and tire from

the hub (Figs. 23 and 24). Be careful

to avoid damage or interference with

the bleeder screw fitting. On Lincoln

Continental models be careful to avoid

damage to the caliper splash shield or

transfer tube.

2.

Remove the caliper assembly

from the spindle and the rotor. If the

caliper does not require servicing, it is

not necessary to disconnect the brake

hose or remove the caliper from the

vehicle. Position the caliper out of the

way, and support it with a wire to

avoid damaging the caliper or stretch-

ing the hose. Insert a clean cardboard

spacer between the linings to prevent

the piston from coming out of the cyl-

inder bore while the caliper is re-

moved.

Handle the rotor and caliper assem-

blies in such a way as to avoid defor-

mation of the rotor and nicking,

scratching or contamination of the

brake linings.

3.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly.

4.

Remove the hub and rotor as-

sembly from the spindle.

INSTALLATION

1.

If the rotor is being replaced, re-

move the protective coating from the

new rotor with carburetor degreaser.

Pack a new set of bearings with speci-

fied grease (M-1C75B), and install the

inner bearing cone and roller assembly

in the inner cup. Pack grease lightly

between the lips of a new grease seal

and install the seal (Figs. 23 and 24).

If the original rotor is being in-

stalled, make sure that the grease in

the hub is clean and adequate, that

the inner bearing and grease seal are

lubricated and in good condition, and

that the rotor braking surfaces are

clean.

2.

Install the hub and rotor assem-

bly on the spindle.

3.

Lubricate and install the outer

wheel bearing, washer and adjusting

nut.

4.

Adjust the wheel bearings to

specification, and then install the nut

lock, cotter pin, and grease cap. The

wheel bearing adjustment is especially

important with disc brakes.

5. Mount the caliper assembly on

the spindle following the Disc Brake

Caliper Assembly Installation proce-

dure in this section.

DISC BRAKE ROTOR

SPLASH SHIELD

REMOVAL

1.

Remove the caliper and the hub

and rotor assembly as outlined under

Removal in the foregoing procedure

(it is not necessary to disconnect hy-

draulic connections).

2.

Remove the three bolts that at-

tach the splash shield to the spindle,

and remove the shield (Figs. 23 and

24).

3.

Remove and discard the splash

shield to spindle gasket.

INSTALLATION

1.

Install a new splash shield to

spindle gasket.

2.

If the shield is bent, straighten it

out before installation. Position the

shield to the mounting bracket, install

the attaching bolts, nuts and torque

them to specification.

3.

Install the hub and rotor assem-

bly and the caliper as outlined under

Installation in the foregoing proce-

dure.

DUAL MASTER CYLINDER—

NON POWER BRAKES

FORD, MERCURY

AND METEOR

Removal

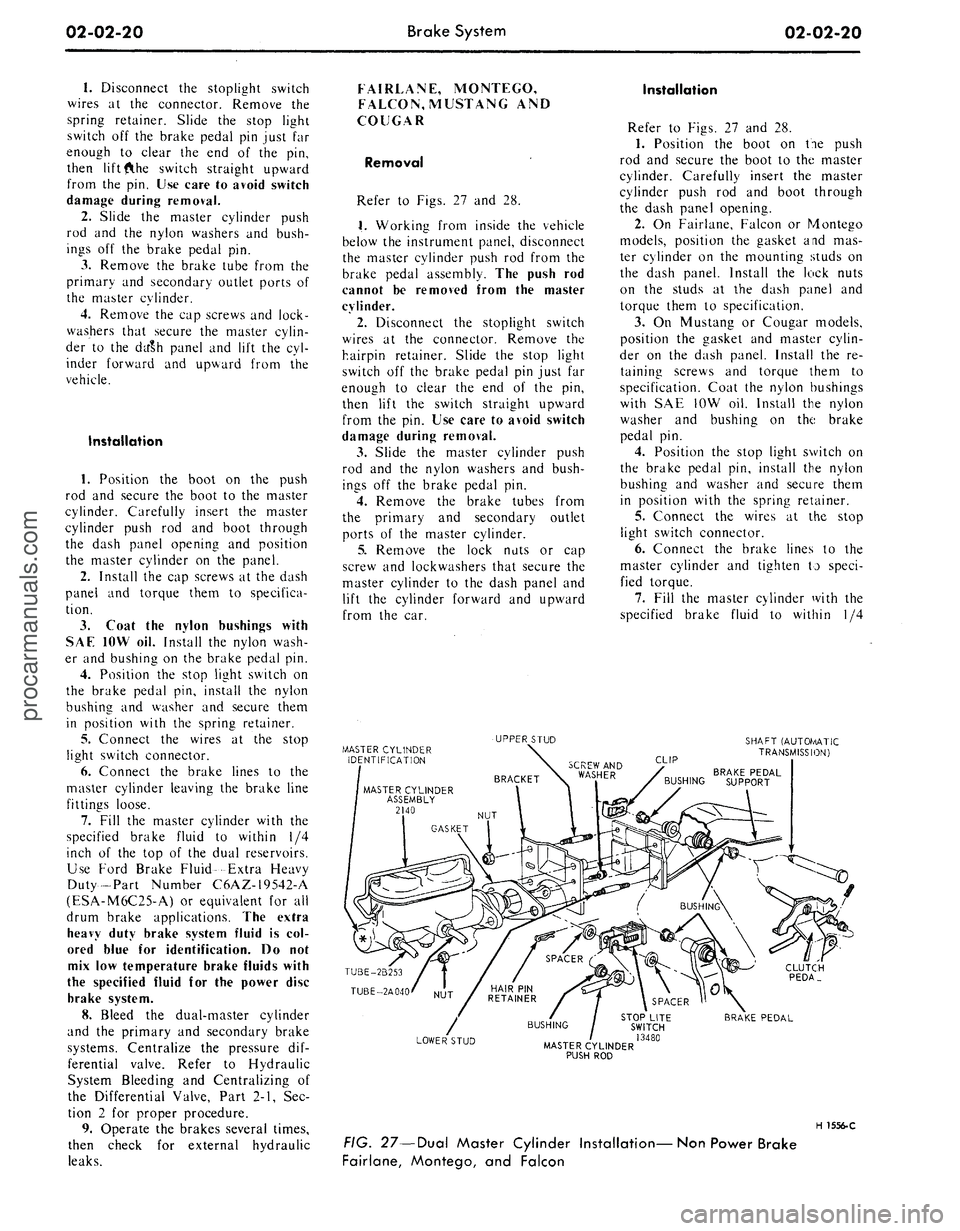

Refer to Fig. 26.

BUSHING

HAIRPIN

RETAINER

BUSHING

STOPLIGHT SWITCH

13480

HI 637-A

FIG. 26—Dual Master Cylinder Installation— Non Power Brakes

Ford,

Mercury, and Meteorprocarmanuals.com

Page 39 of 413

02-02-20

Brake System

02-02-20

1.

Disconnect the stoplight switch

wires at the connector. Remove the

spring retainer. Slide the stop light

switch off the brake pedal pin just far

enough to clear the end of the pin,

then liftfthe switch straight upward

from the pin. Use care to avoid switch

damage during removal.

2.

Slide the master cylinder push

rod and the nylon washers and bush-

ings off the brake pedal pin.

3.

Remove the brake tube from the

primary and secondary outlet ports of

the master cylinder.

4.

Remove the cap screws and lock-

washers that secure the master cylin-

der to the dirSh panel and lift the cyl-

inder forward and upward from the

vehicle.

Installation

1.

Position the boot on the push

rod and secure the boot to the master

cylinder. Carefully insert the master

cylinder push rod and boot through

the dash panel opening and position

the master cylinder on the panel.

2.

Install the cap screws at the dash

panel and torque them to specifica-

tion.

3.

Coat the nylon bushings with

SAE 10W oil. Install the nylon wash-

er and bushing on the brake pedal pin.

4.

Position the stop light switch on

the brake pedal pin, install the nylon

bushing and washer and secure them

in position with the spring retainer.

5.

Connect the wires at the stop

light switch connector.

6. Connect the brake lines to the

master cylinder leaving the brake line

fittings loose.

7.

Fill the master cylinder with the

specified brake fluid to within 1/4

inch of the top of the dual reservoirs.

Use Ford Brake Fluid— Extra Heavy

Duty-Part Number C6AZ-19542-A

(ESA-M6C25-A) or equivalent for all

drum brake applications. The extra

heavy duty brake system fluid is col-

ored blue for identification. Do not

mix low temperature brake fluids with

the specified fluid for the power disc

brake system.

8. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to Hydraulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for proper procedure.

9. Operate the brakes several times,

then check for external hydraulic

leaks.

FAIRLANE, MONTEGO,

FALCON, MUSTANG AND

COUGAR

Removal

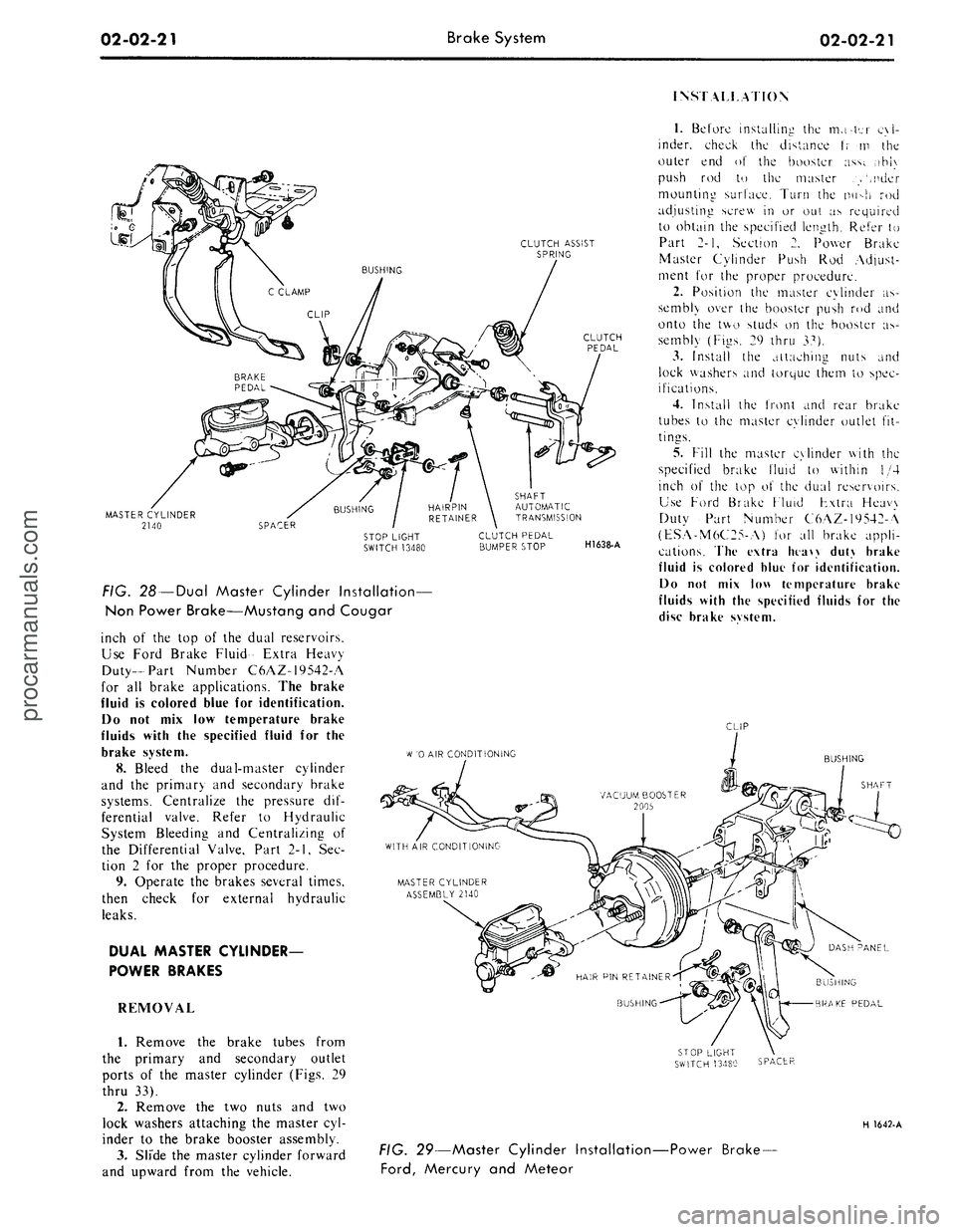

Refer to Figs. 27 and 28.

1.

Working from inside the vehicle

below the instrument panel, disconnect

the master cylinder push rod from the

brake pedal assembly. The push rod

cannot be removed from the master

cylinder.

2.

Disconnect the stoplight switch

wires at the connector. Remove the

hairpin retainer. Slide the stop light

switch off the brake pedal pin just far

enough to clear the end of the pin,

then lift the switch straight upward

from the pin. Use care to avoid switch

damage during removal.

3.

Slide the master cylinder push

rod and the nylon washers and bush-

ings off the brake pedal pin.

4.

Remove the brake tubes from

the primary and secondary outlet

ports of the master cylinder.

5.

Remove the lock nuts or cap

screw and lockwashers that secure the

master cylinder to the dash panel and

lift the cylinder forward and upward

from the car.

Installation

Refer to Figs. 27 and 28.

1.

Position the boot on tie push

rod and secure the boot to the master

cylinder. Carefully insert the master

cylinder push rod and boot through

the dash panel opening.

2.

On Fairlane, Falcon or Montego

models, position the gasket and mas-

ter cylinder on the mounting studs on

the dash panel. Install the lock nuts

on the studs at the dash panel and

torque them to specification.

3.

On Mustang or Cougar models,

position the gasket and master cylin-

der on the dash panel. Install the re-

taining screws and torque them to

specification. Coat the nylon bushings

with SAE 10W oil. Install the nylon

washer and bushing on the brake

pedal pin.

4.

Position the stop light switch on

the brake pedal pin, install the nylon

bushing and washer and secure them

in position with the spring retainer.

5.

Connect the wires at the stop

light switch connector.

6. Connect the brake lines to the

master cylinder and tighten to speci-

fied torque.

7.

Fill the master cylinder with the

specified brake fluid to within 1/4

MASTER CYLINDER

IDENTIFICATION

UPPER STUD

SHAFT (AUTOf/lATIC

TRANSMISSION)

CLIP

BRAKE PEDAL

BUSHING SUPPORT

TUBE-2B253

TUBE-2A040

CLUTCH

PEDA_

LOWER STUD

STOP LITE

SWITCH

/ 13480

MASTER CYLINDER

PUSH ROD

BRAKE PEDAL

H 1556-C

FIG. 27—Dual Master Cylinder Installation—Non Power Brake

Fairlane, Montego, and Falconprocarmanuals.com

Page 40 of 413

02-02-21

Brake System

02-02-21

INSTALLATION

CLUTCH ASSIST

SPRING

MASTER CYLINDER

2140

FIG. 28 —Dual Master Cylinder Installation—

Non Power Brake—Mustang and Cougar

inch of the top of the dual reservoirs.

Use Ford Brake Fluid- Extra Heavy

Duty-Part Number C6AZ-19542-A

for all brake applications. The brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluid for the

brake system.

8. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to Hydraulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for the proper procedure.

9. Operate the brakes several times,

then check for external hydraulic

leaks.

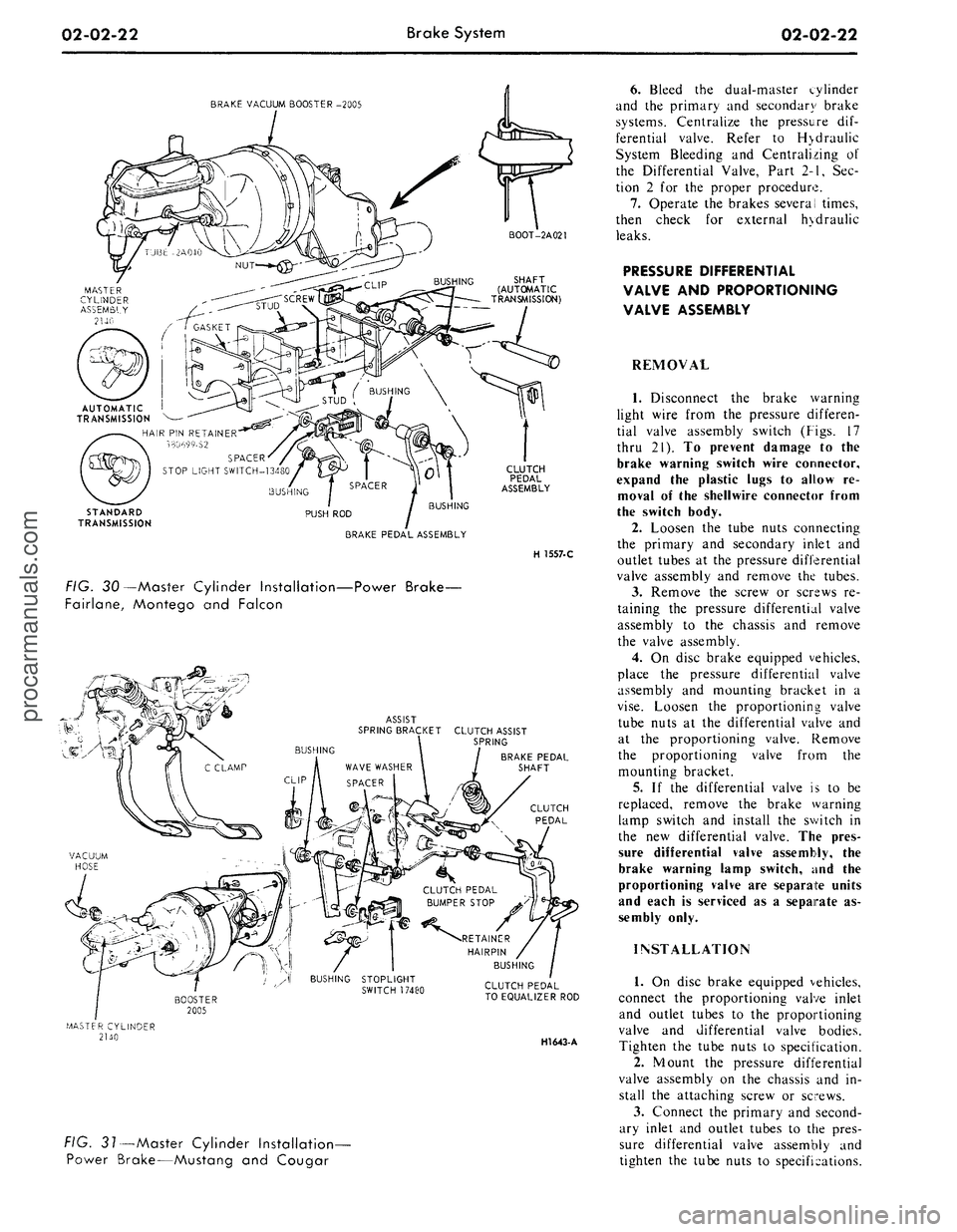

DUAL MASTER CYLINDER-

POWER BRAKES

REMOVAL

1.

Remove the brake tubes from

the primary and secondary outlet

ports of the master cylinder (Figs. 29

thru 33).

2.

Remove the two nuts and two

lock washers attaching the master cyl-

inder to the brake booster assembly.

3.

Slide the master cylinder forward

and upward from the vehicle.

SHAFT

AUTOMATIC

TRANSMISSION

CLUTCH PEDAL

BUMPER STOP

H1638-A

1.

Before installing the mater cyl-

inder, check the distance t; m the

outer end of the booster ass;. ,ihi\

push rod to the master .>',nder

mounting surface. Turn the nu->h rod

adjusting screw in or out as required

to obtain the specified length. Refer to

Part 2-1, Section 2. Power Brake

Master Cylinder Push Rod Adjust-

ment for the proper procedure.

2.

Position the master cylinder as-

sembly over the booster push rod and

onto the two studs on the booster as-

sembly (Figs. 29 thru 37).

3.

Install the attaching nuts and

lock washers and torque them to spec-

ifications.

4.

Install the front and rear brake

tubes to the master cylinder outlet fit-

tings.

5.

Fill the master cylinder with the

specified brake fluid to within 1/4

inch of the top o\ the dual reservoirs.

Use Ford Brake Fluid Fxtra Heavy

Duty Part Number C6AZ-19542-A

(ESA-M6C25-A) for all brake appli-

cations. The extra htaw duty brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluids for the

disc brake svstem.

CLIP

W

'0 AIR CONDITIONING

BUSHING

SHAFT

BUSHING

BRAKE PEDAL

SPACER

H 1642-A

FIG. 29—Master Cylinder Installation-

Ford,

Mercury and Meteor

-Power Brake-procarmanuals.com

Page 41 of 413

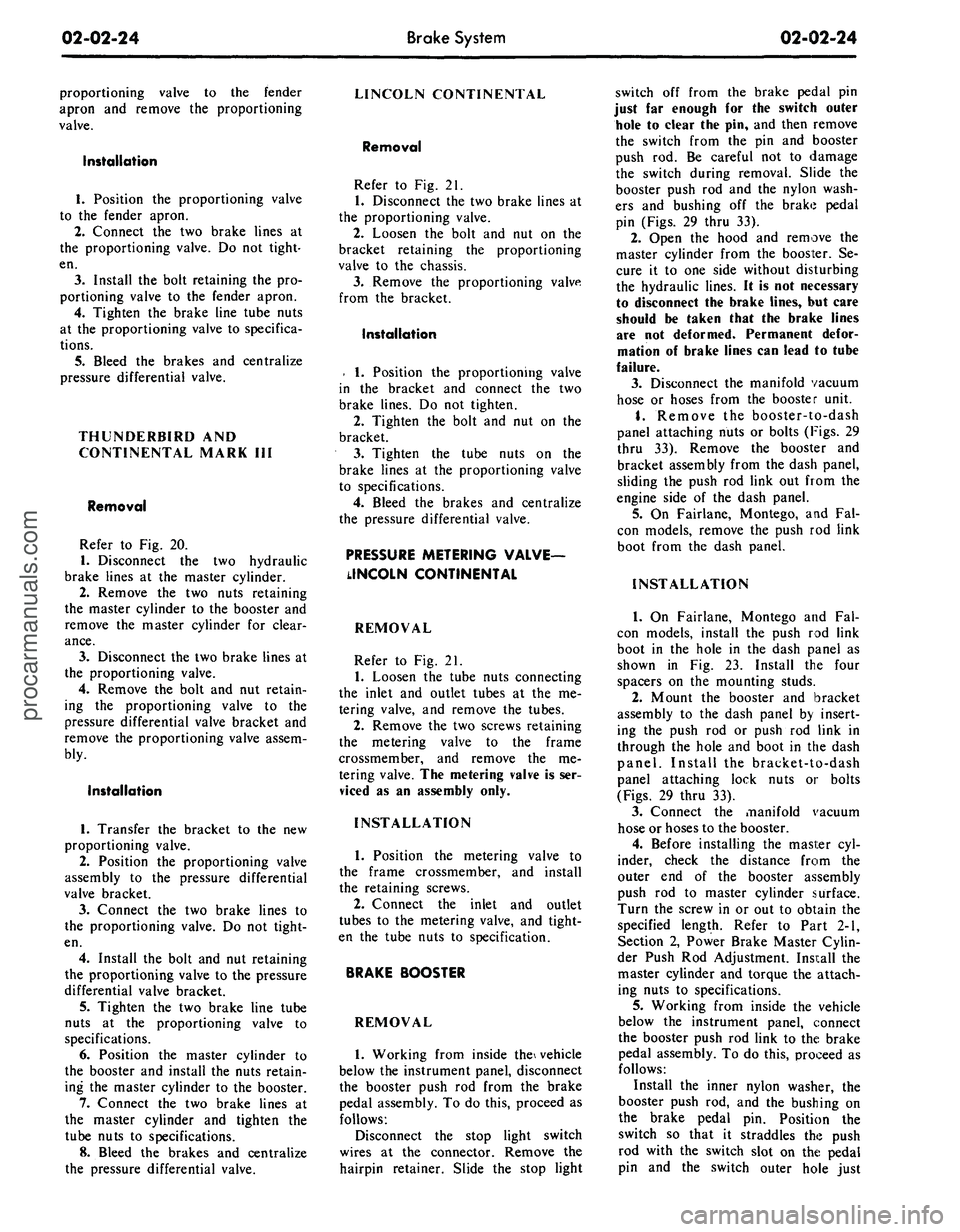

02-02-22

Brake System

02-02-22

BRAKE VACUUM BOOSTER -2005

AUTOMATIC I

TRANSMISSION

HAIR PIN RETAINER

330699-S2

SPACER

STOP LIGHT SWITCH-13480

STANDARD

TRANSMISSION

BUSHING

BUSHING

PUSH ROD

BRAKE PEDAL ASSEMBLY

CLUTCH

PEDAL

ASSEMBLY

H 1557-C

FIG. 30—Master Cylinder Installation—Power Brake-

Fairlane, Montego and Falcon

ASSIST

SPRING BRACKET CLUTCH ASSIST

\ SPRING

BRAKE PEDAL

SHAFT

CLUTCH

PEDAL

CLUTCH PEDAL

TO EQUALIZER ROD

HI643-

A

FIG. 31—Master Cylinder Installation-

Power Brake—Mustang and Cougar

6. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to H>draulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for the proper procedure.

7.

Operate the brakes several times,

then check for external hydraulic

leaks.

PRESSURE DIFFERENTIAL

VALVE AND PROPORTIONING

VALVE ASSEMBLY

REMOVAL

1.

Disconnect the brake warning

light wire from the pressure differen-

tial valve assembly switch (Figs. 17

thru 21). To prevent damage to the

brake warning switch wire connector,

expand the plastic lugs to allow re-

moval of the shellwire connector from

the switch body.

2.

Loosen the tube nuts connecting

the primary and secondary inlet and

outlet tubes at the pressure differential

valve assembly and remove the tubes.

3.

Remove the screw or screws re-

taining the pressure differential valve

assembly to the chassis and remove

the valve assembly.

4.

On disc brake equipped vehicles,

place the pressure differential valve

assembly and mounting bracket in a

vise.

Loosen the proportioning valve

tube nuts at the differential valve and

at the proportioning valve. Remove

the proportioning valve from the

mounting bracket.

5.

If the differential valve is to be

replaced, remove the brake warning

lamp switch and install the switch in

the new differential valve. The pres-

sure differential valve assembly, the

brake warning lamp switch, and the

proportioning valve are separate units

and each is serviced as a separate as-

sembly only.

INSTALLATION

1.

On disc brake equipped vehicles,

connect the proportioning valve inlet

and outlet tubes to the proportioning

valve and differential valve bodies.

Tighten the tube nuts to specification.

2.

Mount the pressure differential

valve assembly on the chassis and in-

stall the attaching screw or screws.

3.

Connect the primary and second-

ary inlet and outlet tubes to the pres-

sure differential valve assembly and

tighten the tube nuts to specifications.procarmanuals.com

Page 43 of 413

02-02-24

Brake

System

02-02-24

proportioning valve to the fender

apron and remove the proportioning

valve.

Installation

1.

Position the proportioning valve

to the fender apron.

2.

Connect the two brake lines at

the proportioning valve. Do not tight-

en.

3.

Install the bolt retaining the pro-

portioning valve to the fender apron.

4.

Tighten the brake line tube nuts

at the proportioning valve to specifica-

tions.

5.

Bleed the brakes and centralize

pressure differential valve.

THUNDERBIRD AND

CONTINENTAL MARK III

Removal

Refer to Fig. 20.

1.

Disconnect the two hydraulic

brake lines at the master cylinder.

2.

Remove the two nuts retaining

the master cylinder to the booster and

remove the master cylinder for clear-

ance.

3.

Disconnect the two brake lines at

the proportioning valve.

4.

Remove the bolt and nut retain-

ing the proportioning valve to the

pressure differential valve bracket and

remove the proportioning valve assem-

bly.

Installation

1.

Transfer the bracket to the new

proportioning valve.

2.

Position the proportioning valve

assembly to the pressure differential

valve bracket.

3.

Connect the two brake lines to

the proportioning valve. Do not tight-

en.

4.

Install the bolt and nut retaining

the proportioning valve to the pressure

differential valve bracket.

5.

Tighten the two brake line tube

nuts at the proportioning valve to

specifications.

6. Position the master cylinder to

the booster and install the nuts retain-

ing the master cylinder to the booster.

7.

Connect the two brake lines at

the master cylinder and tighten the

tube nuts to specifications.

8. Bleed the brakes and centralize

the pressure differential valve.

LINCOLN CONTINENTAL

Removal

Refer to Fig. 21.

1.

Disconnect the two brake lines at

the proportioning valve.

2.

Loosen the bolt and nut on the

bracket retaining the proportioning

valve to the chassis.

3.

Remove the proportioning valve

from the bracket.

Installation

- 1. Position the proportioning valve

in the bracket and connect the two

brake lines. Do not tighten.

2.

Tighten the bolt and nut on the

bracket.

3.

Tighten the tube nuts on the

brake lines at the proportioning valve

to specifications.

4.

Bleed the brakes and centralize

the pressure differential valve.

PRESSURE METERING VALVE—

LINCOLN CONTINENTAL

REMOVAL

Refer to Fig. 21.

1.

Loosen the tube nuts connecting

the inlet and outlet tubes at the me-

tering valve, and remove the tubes.

2.

Remove the two screws retaining

the metering valve to the frame

crossmember, and remove the me-

tering valve. The metering valve is ser-

viced as an assembly only.

INSTALLATION

1.

Position the metering valve to

the frame crossmember, and install

the retaining screws.

2.

Connect the inlet and outlet

tubes to the metering valve, and tight-

en the tube nuts to specification.

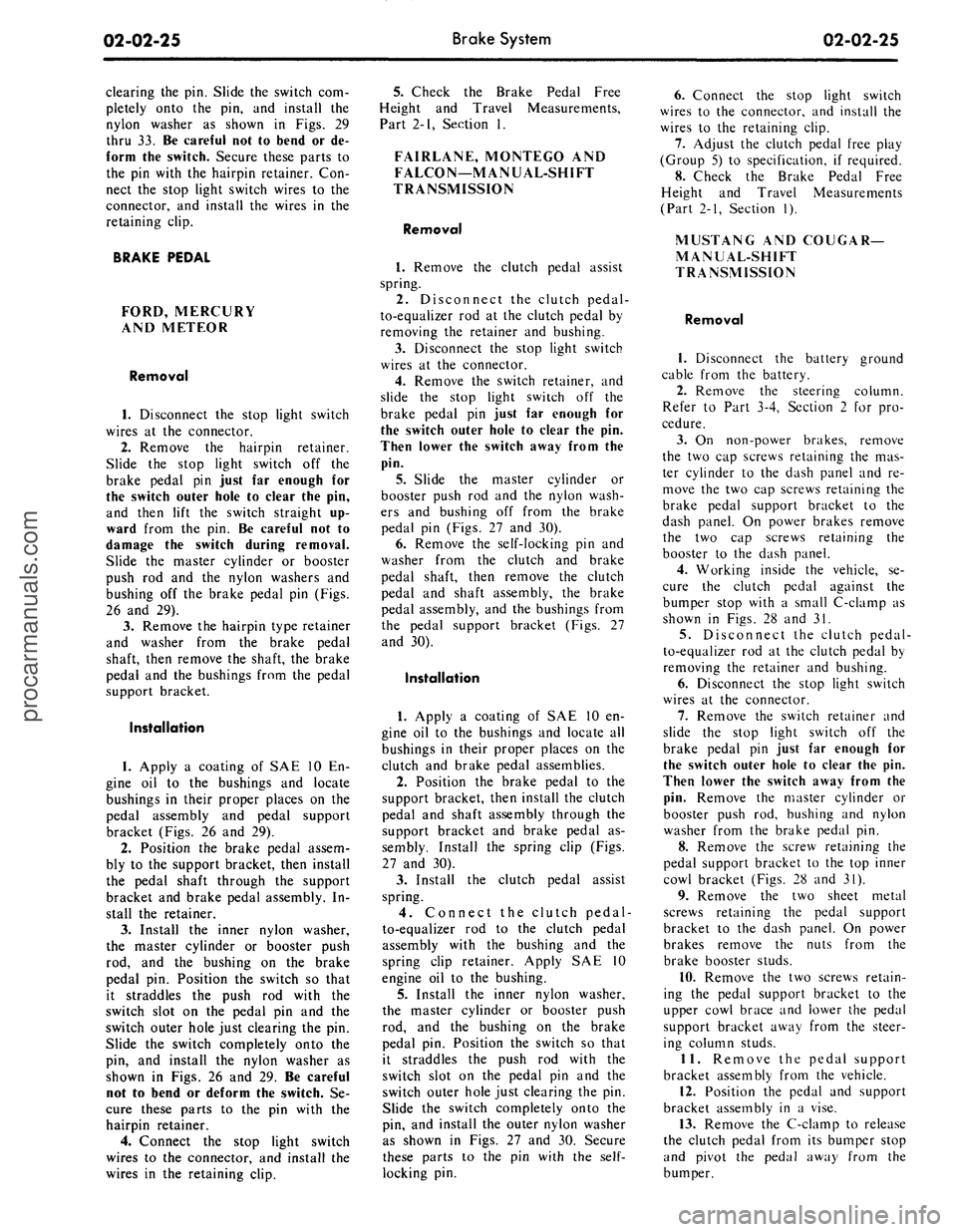

BRAKE BOOSTER

REMOVAL

1.

Working from inside the\ vehicle

below the instrument panel, disconnect

the booster push rod from the brake

pedal assembly. To do this, proceed as

follows:

Disconnect the stop light switch

wires at the connector. Remove the

hairpin retainer. Slide the stop light

switch off from the brake pedal pin

just far enough for the switch outer

hole to clear the pin, and then remove

the switch from the pin and booster

push rod. Be careful not to damage

the switch during removal. Slide the

booster push rod and the nylon wash-

ers and bushing off the brake pedal

pin (Figs. 29 thru 33).

2.

Open the hood and remove the

master cylinder from the booster. Se-

cure it to one side without disturbing

the hydraulic lines. It is not necessary

to disconnect the brake lines, but care

should be taken that the brake lines

are not deformed. Permanent defor-

mation of brake lines can lead to tube

failure.

3.

Disconnect the manifold vacuum

hose or hoses from the booster unit.

4.

Remove the booster-to-dash

panel attaching nuts or bolts (Figs. 29

thru 33). Remove the booster and

bracket assembly from the dash panel,

sliding the push rod link out from the

engine side of the dash panel.

5.

On Fairlane, Montego, and Fal-

con models, remove the push rod link

boot from the dash panel.

INSTALLATION

1.

On Fairlane, Montego and Fal-

con models, install the push rod link

boot in the hole in the dash panel as

shown in Fig. 23. Install the four

spacers on the mounting studs.

2.

Mount the booster and bracket

assembly to the dash panel by insert-

ing the push rod or push rod link in

through the hole and boot in the dash

panel. Install the bracket-to-dash

panel attaching lock nuts or bolts

(Figs.

29 thru 33).

3.

Connect the manifold vacuum

hose or hoses to the booster.

4.

Before installing the master cyl-

inder, check the distance from the

outer end of the booster assembly

push rod to master cylinder surface.

Turn the screw in or out to obtain the

specified length. Refer to Part 2-1,

Section 2, Power Brake Master Cylin-

der Push Rod Adjustment. Install the

master cylinder and torque the attach-

ing nuts to specifications.

5.

Working from inside the vehicle

below the instrument panel, connect

the booster push rod link to the brake

pedal assembly. To do this, proceed as

follows:

Install the inner nylon washer, the

booster push rod, and the bushing on

the brake pedal pin. Position the

switch so that it straddles the push

rod with the switch slot on the pedal

pin and the switch outer hole justprocarmanuals.com

Page 44 of 413

02-02-25

Brake System

02-02-25

clearing the pin. Slide the switch com-

pletely onto the pin, and install the

nylon washer as shown in Figs. 29

thru 33. Be careful not to bend or de-

form the switch. Secure these parts to

the pin with the hairpin retainer. Con-

nect the stop light switch wires to the

connector, and install the wires in the

retaining clip.

BRAKE PEDAL

FORD, MERCURY

AND METEOR

Removal

1.

Disconnect the stop light switch

wires at the connector.

2.

Remove the hairpin retainer.

Slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin,

and then lift the switch straight up-

ward from the pin. Be careful not to

damage the switch during removal.

Slide the master cylinder or booster

push rod and the nylon washers and

bushing off the brake pedal pin (Figs.

26 and 29).

3.

Remove the hairpin type retainer

and washer from the brake pedal

shaft, then remove the shaft, the brake

pedal and the bushings from the pedal

support bracket.

Installation

1.

Apply a coating of SAE 10 En-

gine oil to the bushings and locate

bushings in their proper places on the

pedal assembly and pedal support

bracket (Figs. 26 and 29).

2.

Position the brake pedal assem-

bly to the support bracket, then install

the pedal shaft through the support

bracket and brake pedal assembly. In-

stall the retainer.

3.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the nylon washer as

shown in Figs. 26 and 29. Be careful

not to bend or deform the switch. Se-

cure these parts to the pin with the

hairpin retainer.

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

5.

Check the Brake Pedal Free

Height and Travel Measurements,

Part 2-1, Section 1.

FAIRLANE, MONTEGO AND

FALCON—MANUAL-SHIFT

TRANSMISSION

Removal

1.

Remove the clutch pedal assist

spring.

2.

Disconnect the clutch pedal-

to-equalizer rod at the clutch pedal by

removing the retainer and bushing.

3.

Disconnect the stop light switch

wires at the connector.

4.

Remove the switch retainer, and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

5. Slide the master cylinder or

booster push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Figs. 27 and 30).

6. Remove the self-locking pin and

washer from the clutch and brake

pedal shaft, then remove the clutch

pedal and shaft assembly, the brake

pedal assembly, and the bushings from

the pedal support bracket (Figs. 27

and 30).

Installation

1.

Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

clutch and brake pedal assemblies.

2.

Position the brake pedal to the

support bracket, then install the clutch

pedal and shaft assembly through the

support bracket and brake pedal as-

sembly. Install the spring clip (Figs.

27 and 30).

3.

Install the clutch pedal assist

spring.

4.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and the

spring clip retainer. Apply SAE 10

engine oil to the bushing.

5.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the outer nylon washer

as shown in Figs. 27 and 30. Secure

these parts to the pin with the

self-

locking pin.

6. Connect the stop light switch

wires to the connector, and install the

wires to the retaining clip.

7.

Adjust the clutch pedal free play

(Group 5) to specification, if required.

8. Check the Brake Pedal Free

Height and Travel Measurements

(Part 2-1, Section 1).

MUSTANG AND COUGAR—

MANUAL-SHIFT

TRANSMISSION

Removal

1.

Disconnect the battery ground

cable from the battery.

2.

Remove the steering column.

Refer to Part 3-4, Section 2 for pro-

cedure.

3.

On non-power brakes, remove

the two cap screws retaining the mas-

ter cylinder to the dash panel and re-

move the two cap screws retaining the

brake pedal support bracket to the

dash panel. On power brakes remove

the two cap screws retaining the

booster to the dash panel.

4.

Working inside the vehicle, se-

cure the clutch pedal against the

bumper stop with a small C-clamp as

shown in Figs. 28 and 31.

5.

Disconnect the clutch pedal-

to-equalizer rod at the clutch pedal by

removing the retainer and bushing.

6. Disconnect the stop light switch

wires at the connector.

7.

Remove the switch retainer and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

Remove the master cylinder or

booster push rod, bushing and nylon

washer from the brake pedal pin.

8. Remove the screw retaining the

pedal support bracket to the top inner

cowl bracket (Figs. 28 and 31).

9. Remove the two sheet metal

screws retaining the pedal support

bracket to the dash panel. On power

brakes remove the nuts from the

brake booster studs.

10.

Remove the two screws retain-

ing the pedal support bracket to the

upper cowl brace and lower the pedal

support bracket away from the steer-

ing column studs.

11.

Remove the pedal support

bracket assembly from the vehicle.

12.

Position the pedal and support

bracket assembly in a vise.

13.

Remove the C-clamp to release

the clutch pedal from its bumper stop

and pivot the pedal away from the

bumper.procarmanuals.com

Page 45 of 413

02-02-26

Brake System

02-02-26

14.

Remove the clutch pedal assist

spring.

15.

On non-power brakes, remove

the retainer clip from the clutch and

brake pedal shaft, then remove the

clutch pedal and shaft assembly, the

brake pedal assembly, and the bush-

ings from the pedal support bracket.

On power brakes, remove the retainer

nut from the brake pedal shaft then

remove the pedal shaft, the brake

pedal assembly and the bushings from

the pedal support bracket.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

clutch and brake pedal assemblies.

2.

On non-power brakes, position

the brake pedal to the pedal support

bracket, then install the clutch pedal

and shaft assembly through the sup-

port bracket and brake pedal assem-

bly. On power brakes position the

brake pedal to the pedal support

bracket, then install the pedal shaft

and nut.

3.

Install the clutch pedal assist

spring and pivot the clutch pedal

against its bumper stop. Secure the

pedal to the stop with a small C-

clamp as shown in Figs. 28 and 31.

4.

Position the pedal support

bracket assembly to the dash panel,

and to the steering column retainer

studs.

5.

Align the pedal support bracket

holes with the holes in the dash panel

and install the two attaching sheet

metal screws. On power brakes install

the nuts on the brake booster studs.

6. Install the two cap screws at-

taching the pedal support bracket to

the upper cowl bracket.

7. Install the cap screw attaching

the pedal support bracket to the top

inner cowl bracket (Figs. 28 and 31).

8. Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the stop light switch so that it

straddles the push rod with the switch

slot on the pedal pin and the switch

outer hole just clearing the pin. Slide

the switch completely onto the pin,

and install the outer nylon washer as

shown in Figs. 28 and 31. Secure

these parts to the pin with the

self-

locking retainer.

9. Connect the stop light switch

wires to the connector.

10.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and the

spring clip retainer. Apply SAE 10

engine oil to the bushing. Remove the

C-clamp from the clutch pedal.

11.

Working from the engine side

of the dash panel, on non-power

brakes, install the two cap screws at-

taching the pedal support bracket to

the dash panel. Then install the two

screws attaching the master cylinder

to the dash panel. On power brakes

install the cap screws retaining the

brake booster to the dash panel.

12.

Install the steering column.

Refer to Part 3-4, Section 2 for pro-

cedure.

13.

Adjust the clutch pedal free

play (Group 5) to specification, if re-

quired.

14.

Check the Brake Pedal Free

Height and Travel Measurements

(Part 2-1, Section 1).

15.

Connect the ground cable to the

battery.

FAIRLANE, MONTEGO,

FALCON, MUSTANG

AND COUGAR-

AUTOMATIC TRANSMISSION

Removal

1. Disconnect the stop light switch

wires at the connector.

2.

Remove the self-locking pin and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin. Slide the master cylinder or

booster push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Figs. 27, 28, 30 and 31).

3.

On all vehicles except Mustang

and Cougar with power brakes, re-

move the self-locking pin and washer

from the brake pedal shaft, then re-

move the shaft, the brake pedal as-

sembly and the bushings from the

pedal support bracket. On Mustang

and Cougar vehicles with power

brakes, remove the locknut and bolt

from the pedal. Remove the pedal as-

sembly from the support bracket (Fig.

3).

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly and pedal support

bracket (Figs. 27, 28, 30 and 31).

2.

Position the brake pedal assem-

bly to the support bracket, then install

the pedal shaft or bolt through the

support bracket and brake pedal as-

sembly. Install the retainer or locknut.

3.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin, and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the outer nylon washer

as shown in Figs. 27, 28, 30 and 31.

Secure these parts to the pin with the

self-locking pin.

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

Check the Brake Pedal Free Height

and Travel Measurements, Part 2,

Section 1.

THUNDERBIRD

AND

CONTINENTAL MARK

III

Removal

1.

Loosen the booster mounting

nuts.

2.

Disconnect the stop light switch

wires at the connector.

3.

Remove the hairpin retainer.

Slide the stop light switch off from

the brake pedal pin just far enough

for

the

switch outer hole

to

clear

the

pin,

and then lift the switch straight

upward from the pin. Slide the master

cylinder push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Fig. 32).

4.

Remove the pivot bolt and nut

that holds the pedal to the pedal sup-

port bracket. Remove the brake pedal

assembly from the pedal support

bracket, and remove the bushings.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly (Fig. 32).

2.

Install the brake pedal assembly

and bushings to the support bracket,

and then install the pivot bolt through

the support bracket and brake pedal

assembly. Install the pivot bolt nut

and torque to specifications.

3.

Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the switch so that it straddles the

push rod with the switch slot on the

pedal pin and the switch outer hole

just clearing the pin. Slide the switch

completely onto the pin, install the

outer nylon washer as shown in Fig.

32.

Secure these parts to the pin with

the hairpin retainer.procarmanuals.com

Page 60 of 413

02-02-41

Brake System

02-02-41

bolt and G-ring in the bottom of the

master cylinder.

8. Install the bleed screw (if so

equipped). Install the gasket (dia-

phragm) in the master cylinder filler

cover. Position the gasket as shown in

Figs.

40 and 41. Make sure the gasket

is securely seated.

9. Install the cover and gasket on

the master cylinder and secure the

cover into position with the retainer.

DISC BRAKE CALIPER

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

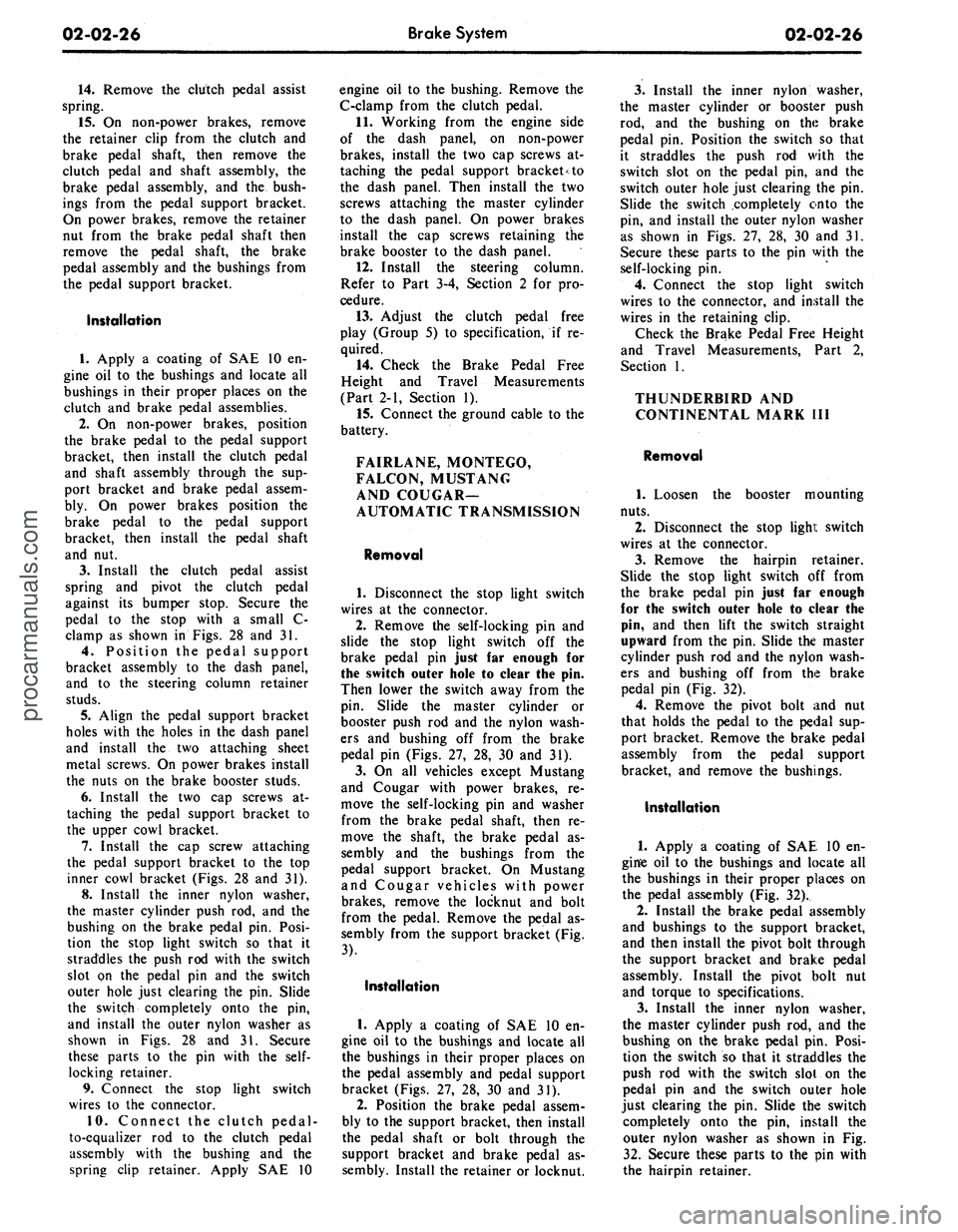

Disassembly

1.

Remove the caliper assembly

from the vehicle as outlined in Section

2.

2.

Remove the caliper locating pins

from the caliper assembly and lift the

anchor plate from the caliper.

3.

Slide the two outer shoe retain-

ing clips off the retaining pins (Fig.

43).

4.

Remove the two retaining pins,

then remove the outer brake shoe

from the caliper.

5.

Slide the inner brake shoe out-

ward until it is free of the hold-down

springs, then remove the brake shoe.

6. Apply air pressure to the fluid

port in the caliper with a rubber

tipped nozzle (Tool 7000-DD) as

shown in Fig. 44 to remove the piston.

Place a cloth over the piston before

applying air pressure to prevent dam-

age to the piston. If the piston is

seized and cannot be forced from the

FIBER

BLOCK

CALIPER

PISTON

H 1574-B

FIG. 44 —Removing Piston From

Caliper —

All

Models Except

Lincoln Continental

caliper, tap lightly around the piston

while applying air pressure. Care

should be taken because the piston

can develop considerable force due to

pressure build-up.

7.

Remove the dust boot from the

caliper assembly.

8. Remove the rubber piston seal

from the cylinder and discard it.

Cleaning and Inspection

Clean all metal parts with isopropyl

alcohol or a suitable solvent. Use

clean, dry, compressed air to clean out

and dry the grooves and passage ways.

Be sure that the caliper bore and com-

ponent parts are completely free of

any foreign material.

Check the cylinder bore and piston

for damage or excessive wear. Replace

the piston if it is pitted, scored, or the

chrome plating is worn off.

Assembly

1.

Apply a film of clean brake fluid

to the new caliper piston seal and in-

stall it in the cylinder bore. Be sure

the seal does not become twisted and

that it is seated fully in the groove.

2.

Install a new dust boot by setting

the flange squarely in the outer groove

of the caliper bore.

3.

Coat the piston with the speci-

fied fluid and install the piston in the

cylinder bore. Spread the dust boot

over the piston as it is installed. Seat

the dust boot in the piston groove.

4.

Position the inner brake shoe so

that the ears of the shoe rests on the

top of the anchor plate bosses and be-

neath the hold-down springs.

5.

Install new caliper locating pin

insulators in the anchor plate.

6. Position the caliper on the an-

chor plate.

7.

Apply water or isopropyl alcohol

to the caliper locating pins and install

them loosely in the anchor plate. Be

sure the guide pins are free of oil,

grease or dirt.

8. Install the caliper on the spindle

as outlined under Disc Brake Caliper

Assembly.

LINCOLN CONTINENTAL

Disassembly

Do not remove the bridge bolts that

hold the two halves of the caliper to-

gether. The two caliper housings are

shown separated in Fig. 46 for illus-

tration purposes only.

1.

Remove the caliper assembly

from the car as outlined in Section 2.

2.

Remove the two attaching bolts

and the caliper splash shield (Fig. 46).

3.

Remove the two shoe and lining

assemblies.

4.

Remove the flexible brake hose

from the caliper.

5.

Remove the external transfer

tube.

6. Remove the four dust boots from

the caliper housings and piston

grooves.

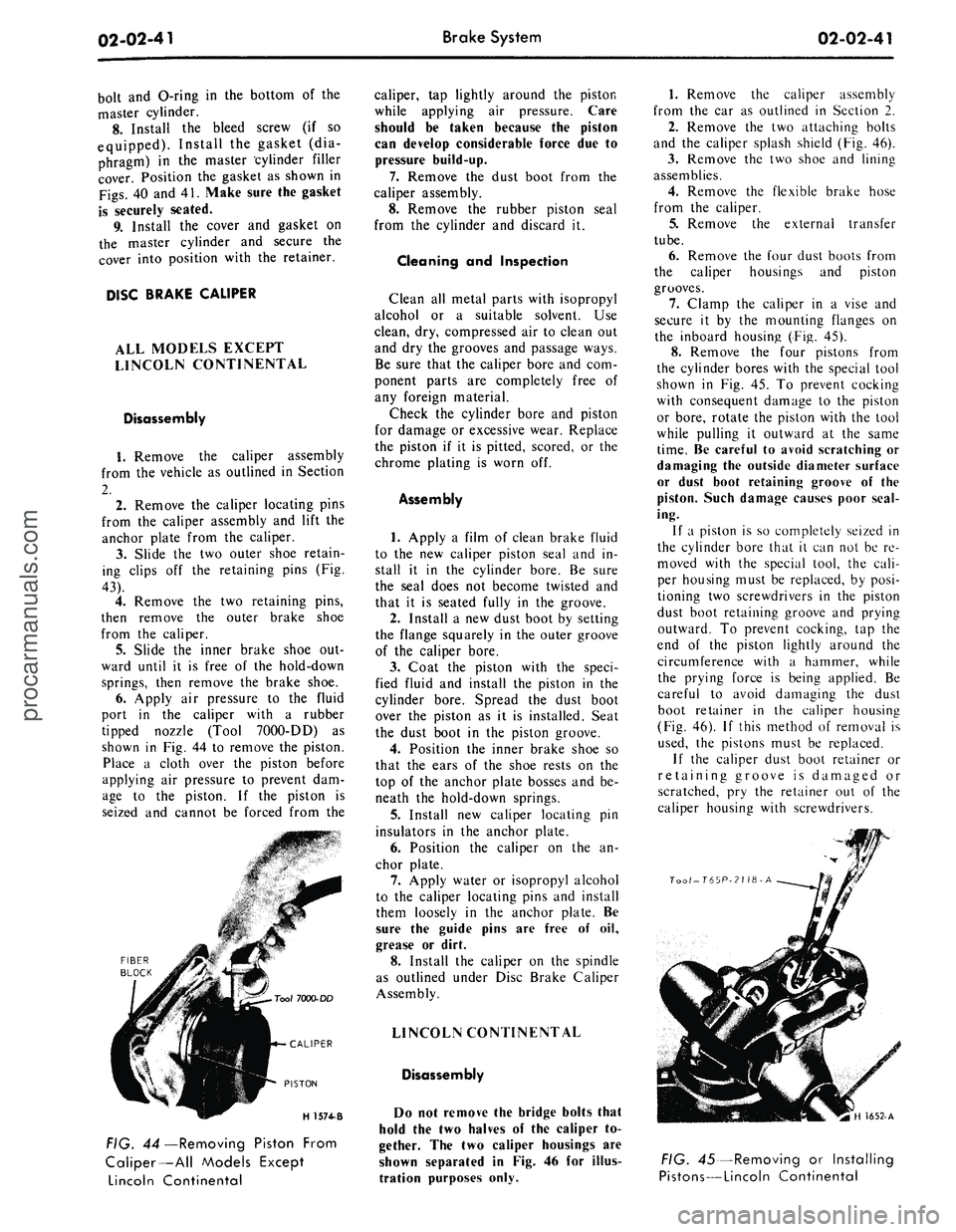

7.

Clamp the caliper in a vise and

secure it by the mounting flanges on

the inboard housing (Fig. 45).

8. Remove the four pistons from

the cylinder bores with the special tool

shown in Fig. 45. To prevent cocking

with consequent damage to the piston

or bore, rotate the piston with the tool

while pulling it outward at the same

time.

Be careful to avoid scratching or

damaging the outside diameter surface

or dust boot retaining groove of the

piston. Such damage causes poor seal-

ing.

If a piston is so completely seized in

the cylinder bore that it can not be re-

moved with the special tool, the cali-

per housing must be replaced, by posi-

tioning two screwdrivers in the piston

dust boot retaining groove and prying

outward. To prevent cocking, tap the

end of the piston lightly around the

circumference with a hammer, while

the prying force is being applied. Be

careful to avoid damaging the dust

boot retainer in the caliper housing

(Fig. 46). If this method of removal is

used, the pistons must be replaced.

If the caliper dust boot retainer or

retaining groove is damaged or

scratched, pry the retainer out of the

caliper housing with screwdrivers.

Too/-T65P-2

J

18- A

H 1652-A

FIG. 45—Removing or Installing

Pistons —

Lincoln

Continentalprocarmanuals.com