gas FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 307 of 413

07-01-16

General Transmission bervice

07-01-16

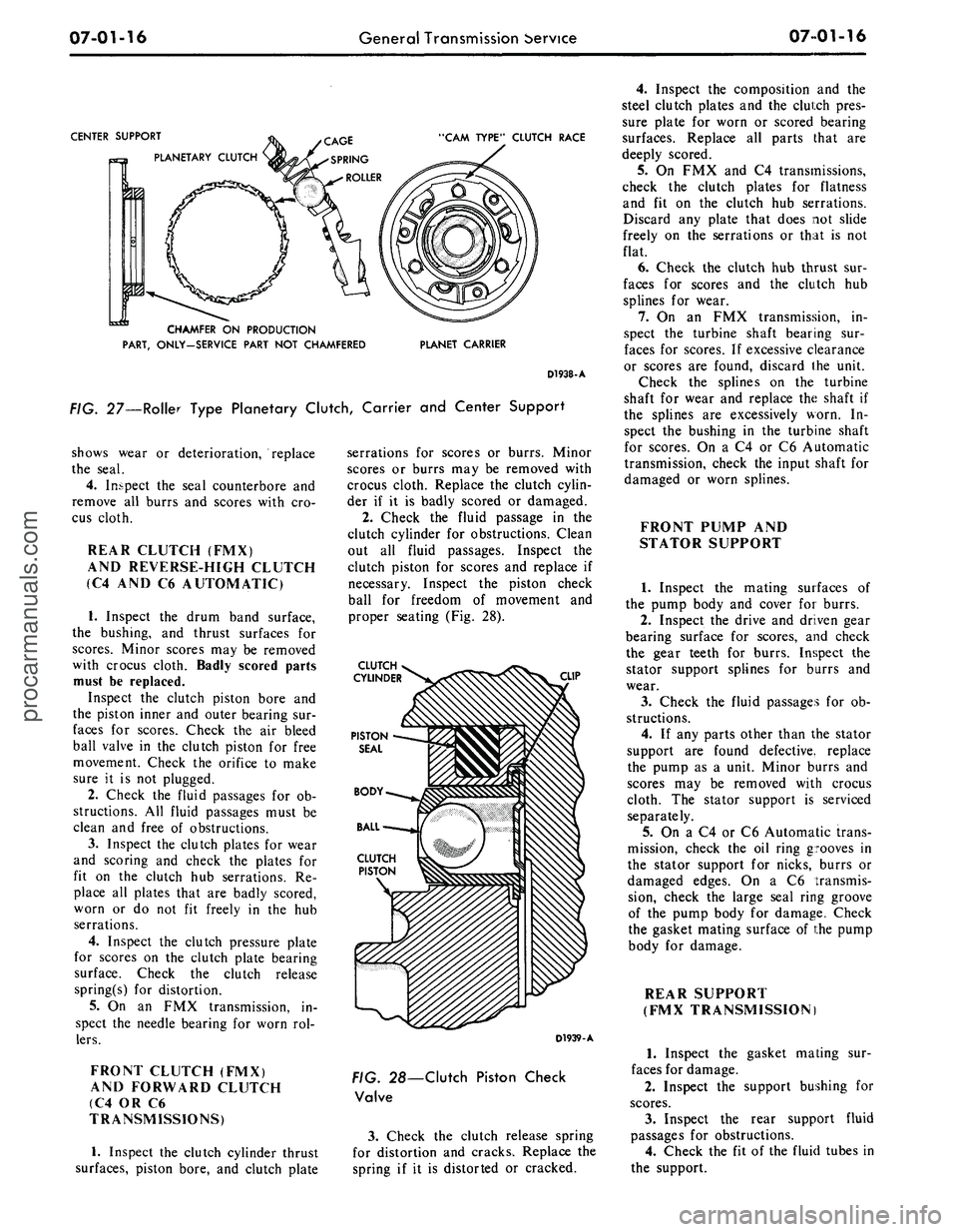

CENTER SUPPORT

PLANETARY CLUTCH

"CAM TYPE" CLUTCH RACE

CHAMFER ON PRODUCTION

PART, ONLY-SERVICE PART NOT CHAMFERED

PLANET CARRIER

D1938-A

FIG. 27—Roller Type Planetary Clutch, Carrier and Center Support

shows wear or deterioration, replace

the seal.

4.

Inspect the seal counterbore and

remove all burrs and scores with cro-

cus cloth.

REAR CLUTCH (FMX)

AND REVERSE-HIGH CLUTCH

(C4 AND C6 AUTOMATIC)

1.

Inspect the drum band surface,

the bushing, and thrust surfaces for

scores. Minor scores may be removed

with crocus cloth. Badly scored parts

must be replaced.

Inspect the clutch piston bore and

the piston inner and outer bearing sur-

faces for scores. Check the air bleed

ball valve in the clutch piston for free

movement. Check the orifice to make

sure it is not plugged.

2.

Check the fluid passages for ob-

structions. All fluid passages must be

clean and free of obstructions.

3.

Inspect the clutch plates for wear

and scoring and check the plates for

fit on the clutch hub serrations. Re-

place all plates that are badly scored,

worn or do not fit freely in the hub

serrations.

4.

Inspect the clutch pressure plate

for scores on the clutch plate bearing

surface. Check the clutch release

spring(s) for distortion.

5.

On an FMX transmission, in-

spect the needle bearing for worn rol-

lers.

FRONT CLUTCH (FMX)

AND FORWARD CLUTCH

(C4 OR C6

TRANSMISSIONS)

1.

Inspect the clutch cylinder thrust

surfaces, piston bore, and clutch plate

serrations for scores or burrs. Minor

scores or burrs may be removed with

crocus cloth. Replace the clutch cylin-

der if it is badly scored or damaged.

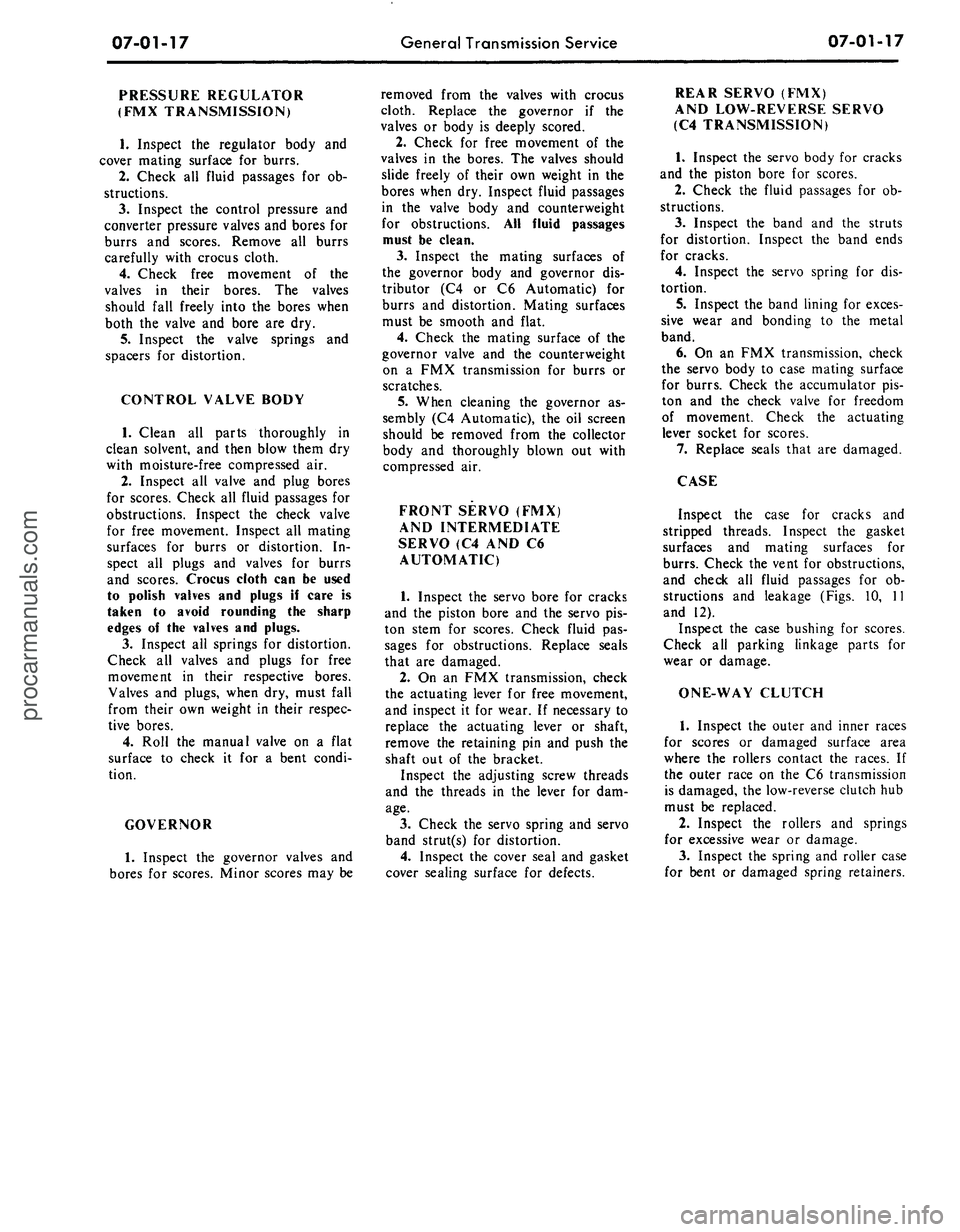

2.

Check the fluid passage in the

clutch cylinder for obstructions. Clean

out all fluid passages. Inspect the

clutch piston for scores and replace if

necessary. Inspect the piston check

ball for freedom of movement and

proper seating (Fig. 28).

CLUTCH

CYLINDER

PISTON

SEAL

CLIP

D1939-A

. 28—Clutch Piston Check

Valve

3.

Check the clutch release spring

for distortion and cracks. Replace the

spring if it is distorted or cracked.

4.

Inspect the composition and the

steel clutch plates and the clutch pres-

sure plate for worn or scored bearing

surfaces. Replace all parts that are

deeply scored.

5.

On FMX and C4 transmissions,

check the clutch plates for flatness

and fit on the clutch hub serrations.

Discard any plate that does not slide

freely on the serrations or that is not

flat.

6. Check the clutch hub thrust sur-

faces for scores and the clutch hub

splines for wear.

7.

On an FMX transmission, in-

spect the turbine shaft bearing sur-

faces for scores. If excessive clearance

or scores are found, discard the unit.

Check the splines on the turbine

shaft for wear and replace the shaft if

the splines are excessively worn. In-

spect the bushing in the turbine shaft

for scores. On a C4 or C6 Automatic

transmission, check the input shaft for

damaged or worn splines.

FRONT PUMP AND

STATOR SUPPORT

1.

Inspect the mating surfaces of

the pump body and cover for burrs.

2.

Inspect the drive and driven gear

bearing surface for scores, and check

the gear teeth for burrs. Inspect the

stator support splines for burrs and

wear.

3.

Check the fluid passages for ob-

structions.

4.

If any parts other than the stator

support are found defective, replace

the pump as a unit. Minor burrs and

scores may be removed with crocus

cloth. The stator support is serviced

separately.

5.

On a C4 or C6 Automatic trans-

mission, check the oil ring grooves in

the stator support for nicks, burrs or

damaged edges. On a C6 transmis-

sion, check the large seal ring groove

of the pump body for damage. Check

the gasket mating surface of the pump

body for damage.

REAR SUPPORT

(FMX TRANSMISSION)

1.

Inspect the gasket mating sur-

faces for damage.

2.

Inspect the support bushing for

scores.

3.

Inspect the rear support fluid

passages for obstructions.

4.

Check the fit of the fluid tubes in

the support.procarmanuals.com

Page 308 of 413

07-01-17

General Transmission Service

07-01-17

PRESSURE REGULATOR

(FMX TRANSMISSION)

1.

Inspect the regulator body and

cover mating surface for burrs.

2.

Check all fluid passages for ob-

structions.

3.

Inspect the control pressure and

converter pressure valves and bores for

burrs and scores. Remove all burrs

carefully with crocus cloth.

4.

Check free movement of the

valves in their bores. The valves

should fall freely into the bores when

both the valve and bore are dry.

5.

Inspect the valve springs and

spacers for distortion.

CONTROL VALVE BODY

1.

Clean all parts thoroughly in

clean solvent, and then blow them dry

with moisture-free compressed air.

2.

Inspect all valve and plug bores

for scores. Check all fluid passages for

obstructions. Inspect the check valve

for free movement. Inspect all mating

surfaces for burrs or distortion. In-

spect all plugs and valves for burrs

and scores. Crocus cloth can be used

to polish valves and plugs if care is

taken to avoid rounding the sharp

edges of the valves and plugs.

3.

Inspect all springs for distortion.

Check all valves and plugs for free

movement in their respective bores.

Valves and plugs, when dry, must fall

from their own weight in their respec-

tive bores.

4.

Roll the manual valve on a flat

surface to check it for a bent condi-

tion.

GOVERNOR

1.

Inspect the governor valves and

bores for scores. Minor scores may be

removed from the valves with crocus

cloth. Replace the governor if the

valves or body is deeply scored.

2.

Check for free movement of the

valves in the bores. The valves should

slide freely of their own weight in the

bores when dry. Inspect fluid passages

in the valve body and counterweight

for obstructions. All fluid passages

must be clean.

3.

Inspect the mating surfaces of

the governor body and governor dis-

tributor (C4 or C6 Automatic) for

burrs and distortion. Mating surfaces

must be smooth and flat.

4.

Check the mating surface of the

governor valve and the counterweight

on a FMX transmission for burrs or

scratches.

5.

When cleaning the governor as-

sembly (C4 Automatic), the oil screen

should be removed from the collector

body and thoroughly blown out with

compressed air.

FRONT SERVO (FMX)

AND INTERMEDIATE

SERVO (C4 AND C6

AUTOMATIC)

1.

Inspect the servo bore for cracks

and the piston bore and the servo pis-

ton stem for scores. Check fluid pas-

sages for obstructions. Replace seals

that are damaged.

2.

On an FMX transmission, check

the actuating lever for free movement,

and inspect it for wear. If necessary to

replace the actuating lever or shaft,

remove the retaining pin and push the

shaft out of the bracket.

Inspect the adjusting screw threads

and the threads in the lever for dam-

age.

3.

Check the servo spring and servo

band strut(s) for distortion.

4.

Inspect the cover seal and gasket

cover sealing surface for defects.

REAR SERVO (FMX)

AND LOW-REVERSE SERVO

(C4 TRANSMISSION)

1.

Inspect the servo body for cracks

and the piston bore for scores.

2.

Check the fluid passages for ob-

structions.

3.

Inspect the band and the struts

for distortion. Inspect the band ends

for cracks.

4.

Inspect the servo spring for dis-

tortion.

5.

Inspect the band lining for exces-

sive wear and bonding to the metal

band.

6. On an FMX transmission, check

the servo body to case mating surface

for burrs. Check the accumulator pis-

ton and the check valve for freedom

of movement. Check the actuating

lever socket for scores.

7.

Replace seals that are damaged.

CASE

Inspect the case for cracks and

stripped threads. Inspect the gasket

surfaces and mating surfaces for

burrs.

Check the vent for obstructions,

and check all fluid passages for ob-

structions and leakage (Figs. 10, 11

and 12).

Inspect the case bushing for scores.

Check all parking linkage parts for

wear or damage.

ONE-WAY CLUTCH

1.

Inspect the outer and inner races

for scores or damaged surface area

where the rollers contact the races. If

the outer race on the C6 transmission

is damaged, the low-reverse clutch hub

must be replaced.

2.

Inspect the rollers and springs

for excessive wear or damage.

3.

Inspect the spring and roller case

for bent or damaged spring retainers.procarmanuals.com

Page 317 of 413

07-02-09

C4 Automatic Transmission

07-02-09

11.

Remove the handle from the se-

lector lever.

12.

Install the selector housing and

lever assembly as shown in Figure 8.

Torque the attaching bolts 4-6 ft-lbs.

13.

Connect the dial indicator light.

14.

Install the pointer back-up

shield on the housing and lever assem-

bly.

15.

Install the dial housing and

tighten the attaching screws.

16.

Install the selector lever handle

and tighten the attaching screw.

17.

Position the selector lever in the

D position.

18.

Raise the vehicle. Install the

transmission manual lever rod to the

selector lever. Adjust the manual link-

age.

19.

Lower the vehicle and check the

transmission operation in each selo:c-

tor lever detent position.

BAND ADJUSTMENT

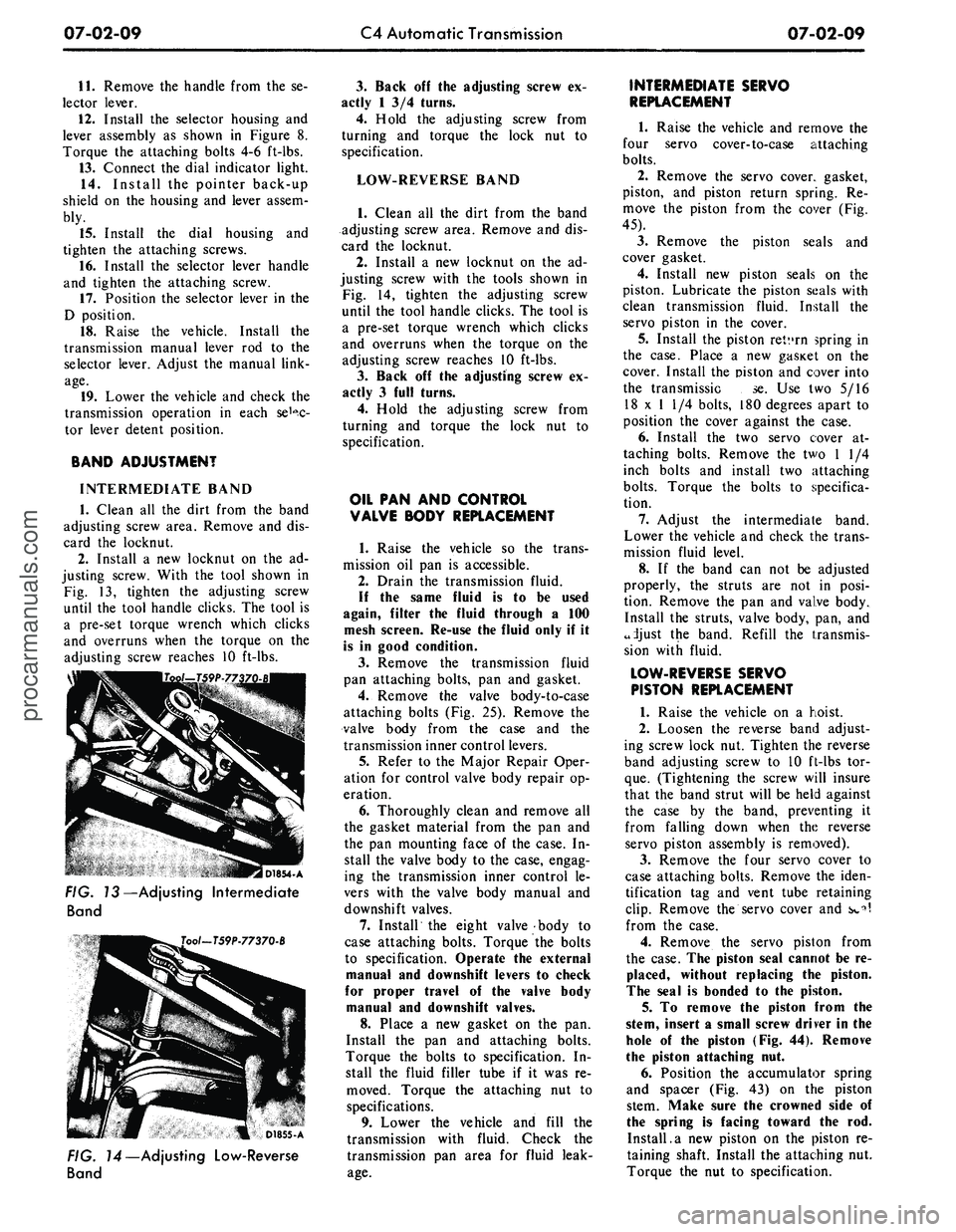

INTERMEDIATE BAND

1.

Clean all the dirt from the band

adjusting screw area. Remove and dis-

card the locknut.

2.

Install a new locknut on the ad-

justing screw. With the tool shown in

Fig. 13, tighten the adjusting screw

until the tool handle clicks. The tool is

a pre-set torque wrench which clicks

and overruns when the torque on the

adjusting screw reaches 10 ft-lbs.

I D1854-A

FIG. 13—Adjusting Intermediate

Band

Tool-T59P-77370-B

D1855-A

FIG. 14—Adjusting Low-Reverse

Band

3.

Back off the adjusting screw ex-

actly 1 3/4 turns.

4.

Hold the adjusting screw from

turning and torque the lock nut to

specification.

LOW-REVERSE BAND

1.

Clean all the dirt from the band

adjusting screw area. Remove and dis-

card the locknut.

2.

Install a new locknut on the ad-

justing screw with the tools shown in

Fig. 14, tighten the adjusting screw

until the tool handle clicks. The tool is

a pre-set torque wrench which clicks

and overruns when the torque on the

adjusting screw reaches 10 ft-lbs.

3.

Back off the adjusting screw ex-

actly 3 full turns.

4.

Hold the adjusting screw from

turning and torque the lock nut to

specification.

OIL PAN AND CONTROL

VALVE BODY REPLACEMENT

1.

Raise the vehicle so the trans-

mission oil pan is accessible.

2.

Drain the transmission fluid.

If the same fluid is to be used

again, filter the fluid through a 100

mesh screen. Re-use the fluid only if it

is in good condition.

3.

Remove the transmission fluid

pan attaching bolts, pan and gasket.

4.

Remove the valve body-to-case

attaching bolts (Fig. 25). Remove the

valve body from the case and the

transmission inner control levers.

5.

Refer to the Major Repair Oper-

ation for control valve body repair op-

eration.

6. Thoroughly clean and remove all

the gasket material from the pan and

the pan mounting face of the case. In-

stall the valve body to the case, engag-

ing the transmission inner control le-

vers with the valve body manual and

downshift valves.

7.

Install the eight valve body to

case attaching bolts. Torque the bolts

to specification. Operate the external

manual and downshift levers to check

for proper travel of the valve body

manual and downshift valves.

8. Place a new gasket on the pan.

Install the pan and attaching bolts.

Torque the bolts to specification. In-

stall the fluid filler tube if it was re-

moved. Torque the attaching nut to

specifications.

9. Lower the vehicle and fill the

transmission with fluid. Check the

transmission pan area for fluid leak-

age.

INTERMEDIATE SERVO

REPLACEMENT

1.

Raise the vehicle and remove the

four servo cover-to-case attaching

bolts.

2.

Remove the servo cover, gasket,

piston, and piston return spring. Re-

move the piston from the cover (Fig.

45).

3.

Remove the piston seals and

cover gasket.

4.

Install new piston seals on the

piston. Lubricate the piston seals with

clean transmission fluid. Install the

servo piston in the cover.

5.

Install the piston retvrn spring in

the case. Place a new gasicet on the

cover. Install the piston and cover into

the transmissic se. Use two 5/16

18 x 1 1/4 bolts, 180 degrees apart to

position the cover against the case.

6. Install the two servo cover at-

taching bolts. Remove the two 1 1/4

inch bolts and install two attaching

bolts.

Torque the bolts to specifica-

tion.

7.

Adjust the intermediate band.

Lower the vehicle and check the trans-

mission fluid level.

8. If the band can not be adjusted

properly, the struts are not in posi-

tion. Remove the pan and valve body.

Install the struts, valve body, pan, and

adjust the band. Refill the transmis-

sion with fluid.

LOW-REVERSE SERVO

PISTON REPLACEMENT

1.

Raise the vehicle on a hoist.

2.

Loosen the reverse band adjust-

ing screw lock nut. Tighten the reverse

band adjusting screw to 10 ft-lbs tor-

que.

(Tightening the screw will insure

that the band strut will be held against

the case by the band, preventing it

from falling down when the reverse

servo piston assembly is removed).

3.

Remove the four servo cover to

case attaching bolts. Remove the iden-

tification tag and vent tube retaining

clip.

Remove the servo cover and s»»^

from the case.

4.

Remove the servo piston from

the case. The piston seal cannot be re-

placed, without replacing the piston.

The seal is bonded to the piston.

5. To remove the piston from the

stem, insert a small screw driver in the

hole of the piston (Fig. 44). Remove

the piston attaching nut.

6. Position the accumulator spring

and spacer (Fig. 43) on the piston

stem. Make sure the crowned side of

the spring is facing toward the rod.

Install.a new piston on the piston re-

taining shaft. Install the attaching nut.

Torque the nut to specification.procarmanuals.com

Page 318 of 413

07-02-10

C4 Automatic Transmission

07-02-10

7.

Install

the

piston into

the

case.

Install

a new

seal

on the

cover. Install

the cover

by

using

two

5/16—18 bolts,

1

1/4

inch long,

at

180

degrees apart

to position

the

servo cover

on the

case.

Install

the

vent tube retaining

clip

and

identification

tag.

Install

two

cover attaching bolts. Remove

the two

installing bolts

and

install

the

last

two

attaching bolts. Torque

the

cover-

to-case attaching bolts

to

specifica-

tion.

8. Adjust

the

low-reverse band.

Lower

the

vehicle

and

check

the

trans-

mission fluid level.

9.

If the

band

can not be

adjusted

properly,

the

struts

are not in

posi-

tion. Remove

the

fluid

pan and

valve

body. Install

the

struts, valve body,

pan

and

adjust

the

band. Refill

the

transmission with fluid.

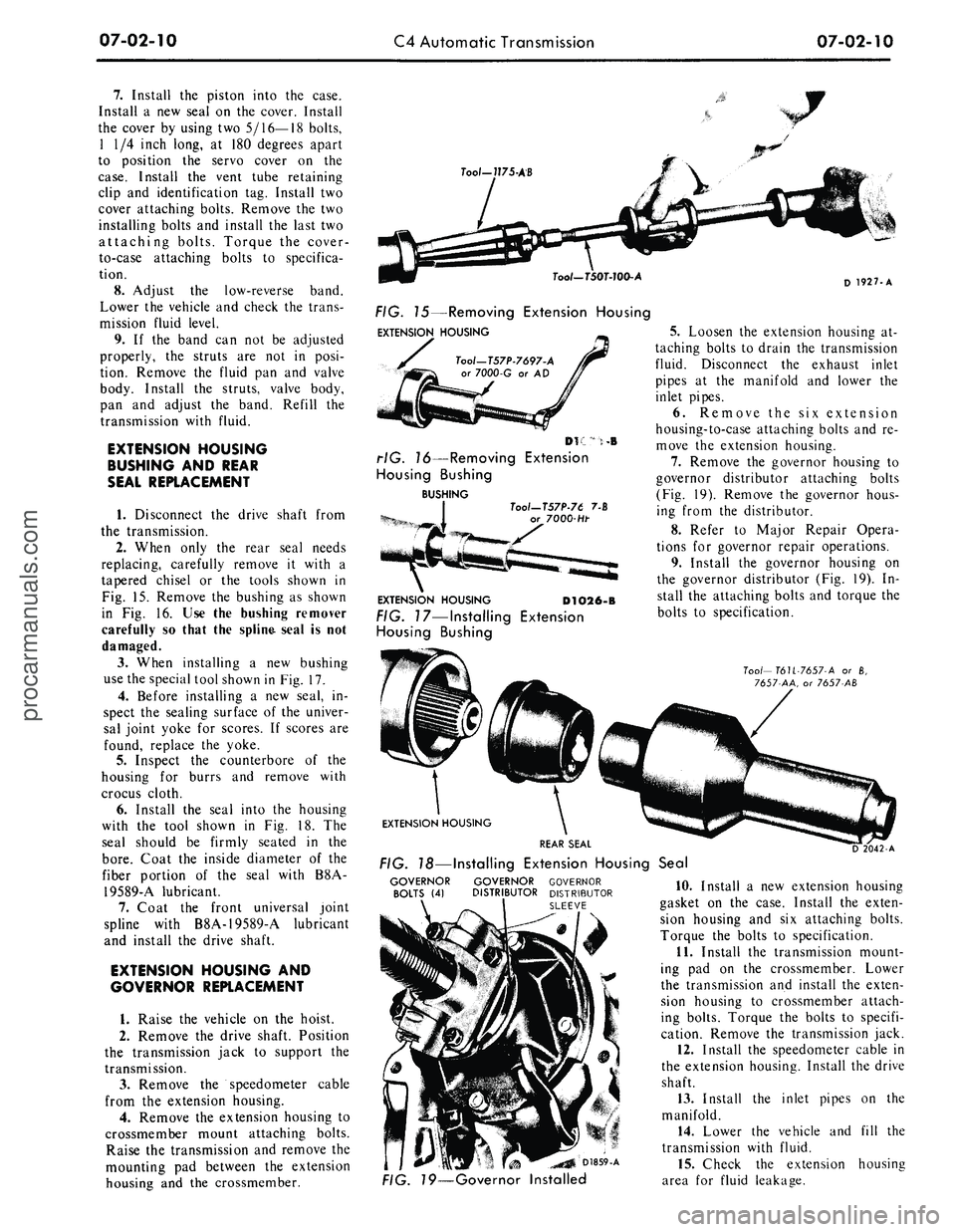

EXTENSION HOUSING

BUSHING

AND

REAR

SEAL REPLACEMENT

1.

Disconnect

the

drive shaft from

the transmission.

2.

When only

the

rear seal needs

replacing, carefully remove

it

with

a

tapered chisel

or the

tools shown

in

Fig.

15.

Remove

the

bushing

as

shown

in

Fig. 16. Use the

bushing remover

carefully

so

that

the

spline- seal

is not

damaged.

3.

When installing

a new

bushing

use

the

special tool shown

in

Fig.

17.

4.

Before installing

a new

seal,

in-

spect

the

sealing surface

of the

univer-

sal joint yoke

for

scores.

If

scores

are

found, replace

the

yoke.

5.

Inspect

the

counterbore

of the

housing

for

burrs

and

remove with

crocus cloth.

6. Install

the

seal into

the

housing

with

the

tool shown

in Fig. 18. The

seal should

be

firmly seated

in the

bore.

Coat

the

inside diameter

of the

fiber portion

of the

seal with

B8A-

19589-A lubricant.

7.

Coat

the

front universal joint

spline with B8A-19589-A lubricant

and install

the

drive shaft.

EXTENSION HOUSING

AND

GOVERNOR REPLACEMENT

1.

Raise

the

vehicle

on the

hoist.

2.

Remove

the

drive shaft. Position

the transmission jack

to

support

the

transmission.

3.

Remove

the

speedometer cable

from

the

extension housing.

4.

Remove

the

extension housing

to

crossmember mount attaching bolts.

Raise

the

transmission

and

remove

the

mounting

pad

between

the

extension

housing

and the

crossmember.

Tool—

I775-AB

Tool—

T50T-100-A

FIG. 15—Removing Extension Housing

EXTENSION HOUSING

rIG. 16—Removing Extension

Housing Bushing

BUSHING

I Tool—T57P-76 7-B

^mmmfm^

0^7000-Ht

EXTENSION HOUSING

D1O26-B

FIG. 17—Installing Extension

Housing Bushing

D 1927-A

5.

Loosen

the

extension housing

at-

taching bolts

to

drain

the

transmission

fluid. Disconnect

the

exhaust inlet

pipes

at the

manifold

and

lower

the

inlet pipes.

6. Remove

the six

extension

housing-to-case attaching bolts

and re-

move

the

extension housing.

7.

Remove

the

governor housing

to

governor distributor attaching bolts

(Fig.

19).

Remove

the

governor hous-

ing from

the

distributor.

8. Refer

to

Major Repair Opera-

tions

for

governor repair operations.

9. Install

the

governor housing

on

the governor distributor

(Fig.

19). In-

stall

the

attaching bolts

and

torque

the

bolts

to

specification.

Tool—

T6

U-7657-A

or B,

7657AA,

or

7657-AB

EXTENSION HOUSING

REAR SEAL

FIG. 18—Installing Extension Housing Seal

D 2042-A

GOVERNOR GOVERNOR GOVERNOR

BOLTS

(4)

DISTRIBUTOR DISTRIBUTOR

SLEEVE

I

D1859-A

FIG. 79—Governor Installed

10.

Install

a new

extension housing

gasket

on the

case. Install

the

exten-

sion housing

and six

attaching bolts.

Torque

the

bolts

to

specification.

11.

Install

the

transmission mount-

ing

pad on the

crossmember. Lower

the transmission

and

install

the

exten-

sion housing

to

crossmember attach-

ing bolts. Torque

the

bolts

to

specifi-

cation. Remove

the

transmission jack.

12.

Install

the

speedometer cable

in

the extension housing. Install

the

drive

shaft.

13.

Install

the

inlet pipes

on the

manifold.

14.

Lower

the

vehicle

and

fill

the

transmission with fluid.

15.

Check

the

extension housing

area

for

fluid leakage.procarmanuals.com

Page 320 of 413

07-02-12

C4 Automatic Transmission

07-02-12

MAJOR REPAIR OPERATIONS

Before removing

any of the sub-

assemblies, thoroughly clean

the out-

side

of the

transmission

to

prevent dirt

from entering

the

mechanical parts.

During

the

repair operations, refer

to

Part 7-1

for

common adjustments

and

repairs

or

cleaning

and

inspection

pro-

cedures.

During

the

transmission disassem-

bly

or

assembly operations,

ten

thrust

washers located between

the sub-

assemblies must

be

removed

and in-

stalled.

It is

important that each

thrust washer

be in the

correct posi-

tion during

the

assembly operation.

To properly locate

and

identify

the

thrust washers,

the

various positions

of

the

thrust washers

are

shown

in the

illustrations

and are

numbered

1

through

10. No. 1 is at the

first thrust

washer located

at the

front pump.

The

last thrust washer,

No. 10, is

located

at

the

parking pawl ring gear.

DISASSEMBLY

OF

TRANSMISSION

1.

Remove

the

converter from

the

transmission front pump

and

convert-

er housing.

2.

Remove

the

transmission vacuum

unit with

the

tool shown

in Fig. 22.

Remove

the

vacuum unit gasket and

the control

rod.

GRIND OFF

SHADED AREA

TO DIMENSION SHOWN L .

SNAP-ON

Tool-FCO-24

(Reworked)

D1380-A

FIG. 22—Removing Vacuum Unit

3.

Remove

the

primary throttle

valve (Fig.

23)

from

the

opening

at the

rear

of the

case.

4.

Remove

the two

extension

housing-to-case bolts shown

in Fig. 24

and mount

the

transmission

in the

holding fixture.

5.

Remove

the

transmission

pan at-

taching bolts,

pan and

gasket.

6. Remove

the

control valve body

attaching bolts (Fig.

25).

Remove

the

control valve body from

the

case.

7.

Loosen

the

intermediate band

adjusting screw

(Fig. 26) and

remove

the intermediate band struts from

the

case.

Loosen

the

low-reverse band

ad-

justing screw

and

remove

the low-

reverse band struts.

TRANSMISSION END

PLAY CHECK

1.

To

keep

the

output shaft

in

alignment during

the end

play check,

install

the

extension housing

oil

seal

replacer tool

or a

front universal

D1861-A

FIG. 23—Removing

or

Installing

Primary Throttle Valve

Tool-T57L-500-A

or 6005-M or 6005-MS

D1862-A

joint yoke in the extension housing.

2.

Remove

one of the

converter

housing-to-case attaching bolts

and

mount

the

dial indicator

as

shown

in

Fig. 27.

3.

The

input shaft

is a

loose part

and

has to be

properly engaged with

the spline

of the

forward clutch

hub

during

the end

play checking proce-

dure.

Move

the

input shaft

and

gear

train toward

the

rear

of the

transmis-

sion case.

V*

- 20 x

V/7 INCH

V*

- 20 x 1

INCH

V*

- 20 x 1

INCH

D1863-A

FIG. 25—Control Valve Body

Attaching Bolts

INTERMEDIATE

BAND STRUTS

INTERMEDIATE BAND

ADJUSTING SCREW

I

LOW-REVERSE BAND

ADJUSTING SCREW

LOW-REVERSE

BAND STRUTS

D

1384-B

FIG.

24—Transmission

Mounted

in Holding Fixture

FIG. 26—Band Adjusting Screws

and Struts—Typicalprocarmanuals.com

Page 322 of 413

07-02-14

C4 Automatic Transmission

07-02-14

FORWARD CLUTCH

FORWARD CLUTCH FRONT PLANET CARRIER INPU^ SHELL

HUB AND

RING GEAR

SUN GEAR

REVERSE-HIGH CLUTCH

THRUST WASHER

NO.

5

FIG. 35—Forward Part of Gear Train Disassembled

D1872-A

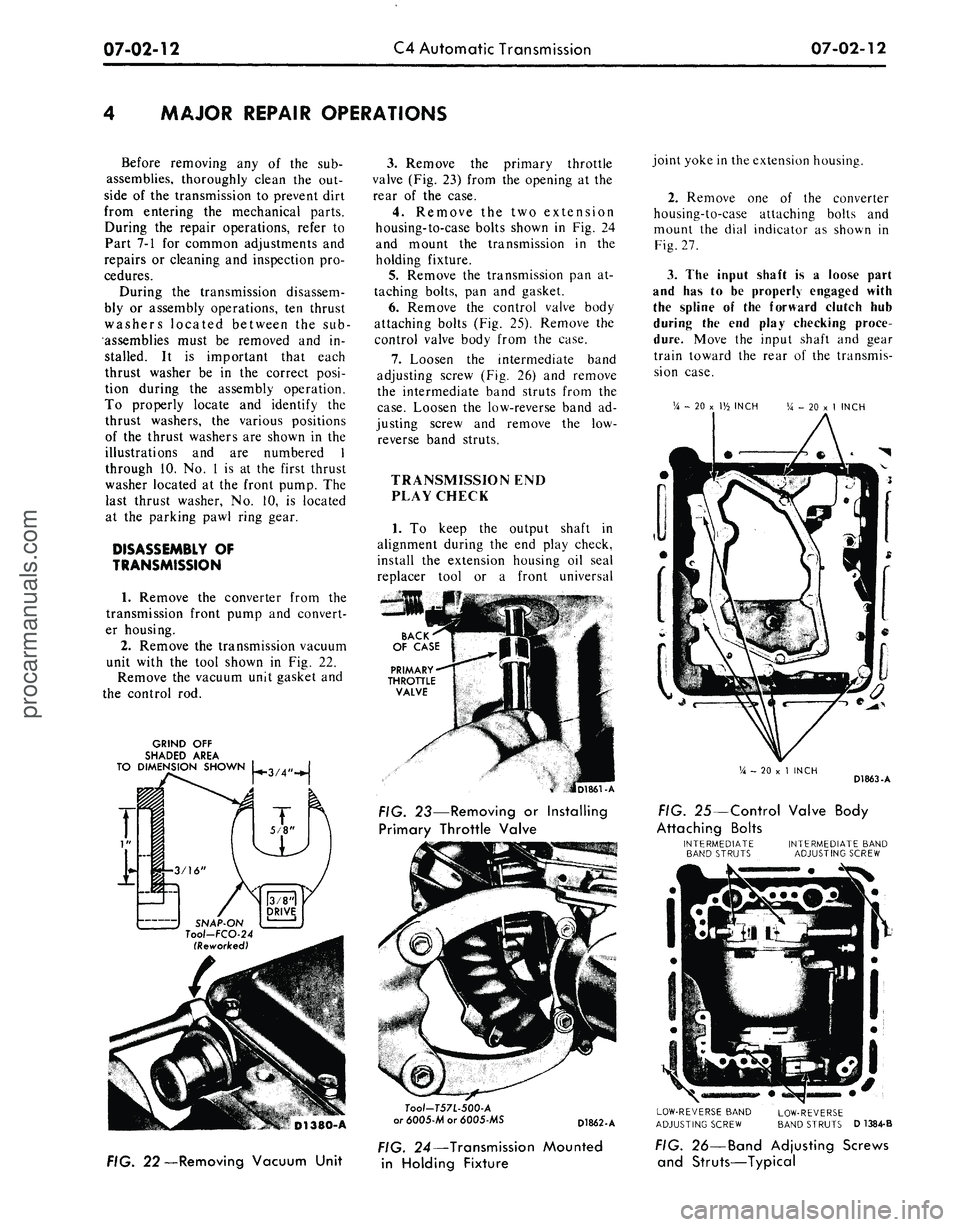

taching bolts. Remove the front pump

by inserting a screwdriver behind the

input shell (Fig. 30). Move the input

shell forward until the front pump seal

is above the edge of the case.

Remove the front pump and gasket

from the case. If the selective thrust

washer No. 1 did not come out with

the front pump, remove it from the

top of the reverse-high clutch.

4.

Remove the intermediate and

low-reverse band adjusting screws

from the case. Rotate the intermediate

band to align the band ends with the

clearance hole in the case (Fig. 31).

Remove the intermediate band from

the case.

5.

Using a screwdriver between the

input shell and rear planet carrier

(Fig. 32), lift the input shell upward

and remove the forward part of the

gear train as an assembly (Fig. 33).

6. Place the forward part of the

gear train in the holding fixture shown

in Fig. 34.

7.

From the gear train in the hold-

ing fixture, remove the reverse-high

clutch and drum from the forward

clutch (Fig. 35).

8. If thrust washer No. 2 (Fig. 28)

did not come out with the front pump,

remove the thrust washer from the

forward clutch cylinder. Remove the

forward clutch from the forward

clutch hub and ring gear (Fig. 35).

9. If thrust washer No. 3 (Fig. 35)

did not come out with the forward

clutch, remove the thrust washer from

the forward clutch hub.

10.

Remove the forward clutch hub

and ring gear from the front planet

carrier (Fig. 35).

11.

Remove thrust washer No. 4

and the front planet carrier from the

input shell.

12.

Remove the input shell, sun

gear and thrust washer No. 5 from the

holding fixture.

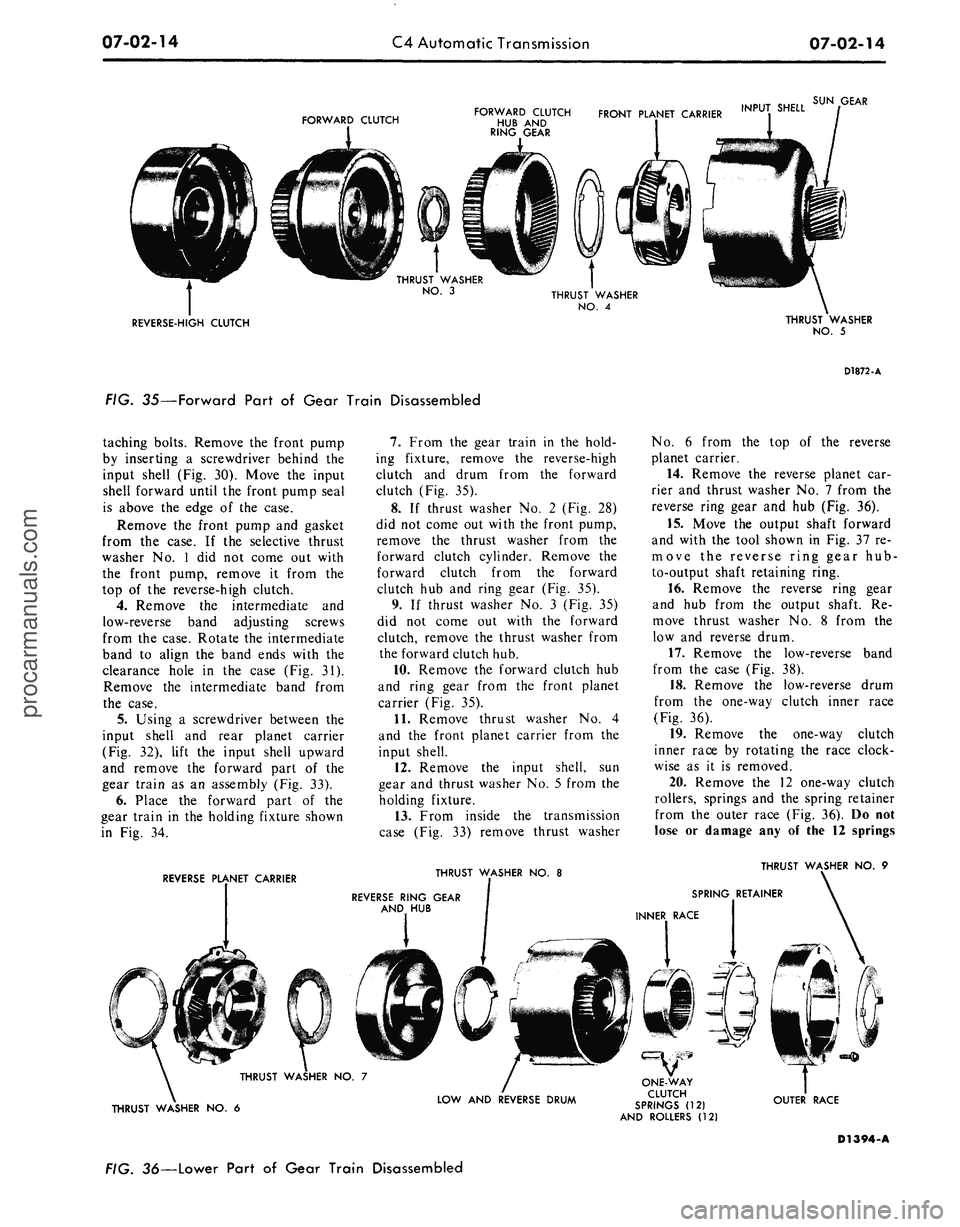

13.

From inside the transmission

case (Fig. 33) remove thrust washer

No.

6 from the top of the reverse

planet carrier.

14.

Remove the reverse planet car-

rier and thrust washer No. 7 from the

reverse ring gear and hub (Fig. 36).

15.

Move the output shaft forward

and with the tool shown in Fig. 37 re-

move the reverse ring gear hub-

to-output shaft retaining ring.

16.

Remove the reverse ring gear

and hub from the output shaft. Re-

move thrust washer No. 8 from the

low and reverse drum.

17.

Remove the low-reverse band

from the case (Fig. 38).

18.

Remove the low-reverse drum

from the one-way clutch inner race

(Fig. 36).

19.

Remove the one-way clutch

inner race by rotating the race clock-

wise as it is removed.

20.

Remove the 12 one-way clutch

rollers, springs and the spring retainer

from the outer race (Fig. 36). Do not

lose or damage any of the 12 springs

REVERSE PLANET CARRIER

THRUST WASHER NO. 8

THRUST WASHER NO. 9

SPRING RETAINER

INNER RACE

THRUST WASHER NO. 6

LOW AND REVERSE DRUM

ONE-WAY

CLUTCH

SPRINGS (12)

AND ROLLERS (12)

OUTER RACE

D1394-A

FIG. 36—Lower Part of Gear Train Disassembledprocarmanuals.com

Page 323 of 413

07-02-15

C4 Automatic Transmission

07-02-15

GOVERNOR DISTRIBUTOR

REVERSE RING GEAR

HUB RETAINING RING

D 2044-A

FIG.

37—Removing

or

Installing

Reverse

Ring Gear

Hub

Retaining

Ring

I®

LOW-RE'VERSE BAND

D1873-A

FIG.

38—Removing

or

Installing

Low-Reverse

Band

OUTPUT SHAFT

GOVERNOR

DISTRIBUTOR

SLEEVE

D1875-A

FIG.

39—Removing

or

Installing

Output

Shaft

and

Governor

Distributor

LOCK RING

D1876-A

FIG.

40—Removing

or

Installing

Governor

Distributor Snap Ring

or rollers.

The

outer race

of the one-

way clutch cannot

be

removed worn

the case until

the

extension housing,

output shaft

and

governor distributor

sleeve

are

removed.

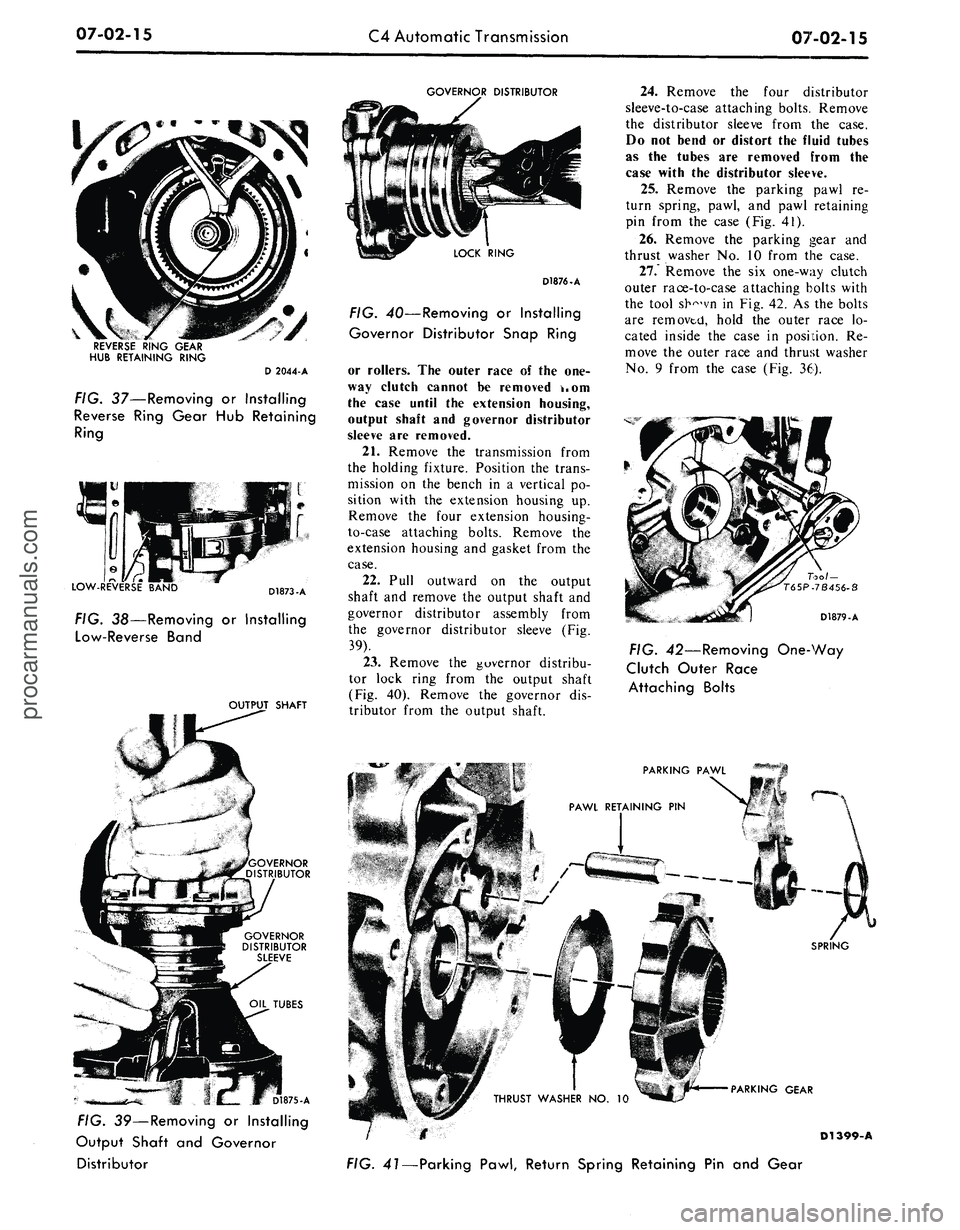

21.

Remove

the

transmission from

the holding fixture. Position

the

trans-

mission

on the

bench

in a

vertical

po-

sition with

the

extension housing

up.

Remove

the

four extension housing-

to-case attaching bolts. Remove

the

extension housing

and

gasket from

the

case.

22.

Pull outward

on the

output

shaft

and

remove

the

output shaft

and

governor distributor assembly from

the governor distributor sleeve

(Fig.

39).

23.

Remove

the

governor distribu-

tor lock ring from

the

output shaft

(Fig.

40).

Remove

the

governor

dis-

tributor from

the

output shaft.

24.

Remove

the

four distributor

sleeve-to-case attaching bolts. Remove

the distributor sleeve from

the

case.

Do

not

bend

or

distort

the

fluid tubes

as

the

tubes

are

removed from

the

case with

the

distributor sleeve.

25.

Remove

the

parking pawl

re-

turn spring, pawl,

and

pawl retaining

pin from

the

case (Fig.

41).

26.

Remove

the

parking gear

and

thrust washer

No. 10

from

the

case.

27.

Remove

the six

one-way clutch

outer race-to-case attaching bolts with

the tool sh^'vn

in

Fig. 42.

As the

bolts

are removed, hold

the

outer race

lo-

cated inside

the

case

in

position.

Re-

move

the

outer race

and

thrust washer

No.

9

from

the

case (Fig.

36).

Too/-

T65P.7B456-8

D1879-A

FIG.

42—Removing One-Way

Clutch

Outer Race

Attaching

Bolts

PARKING GEAR

i^ffif

THRUST WASHER NO. 10 ^*t^

$

D1399-A

FIG.

41—Parking

Pawl,

Return Spring Retaining

Pin and

Gearprocarmanuals.com

Page 324 of 413

07-02-16

C4 Automatic Transmission

07-02-16

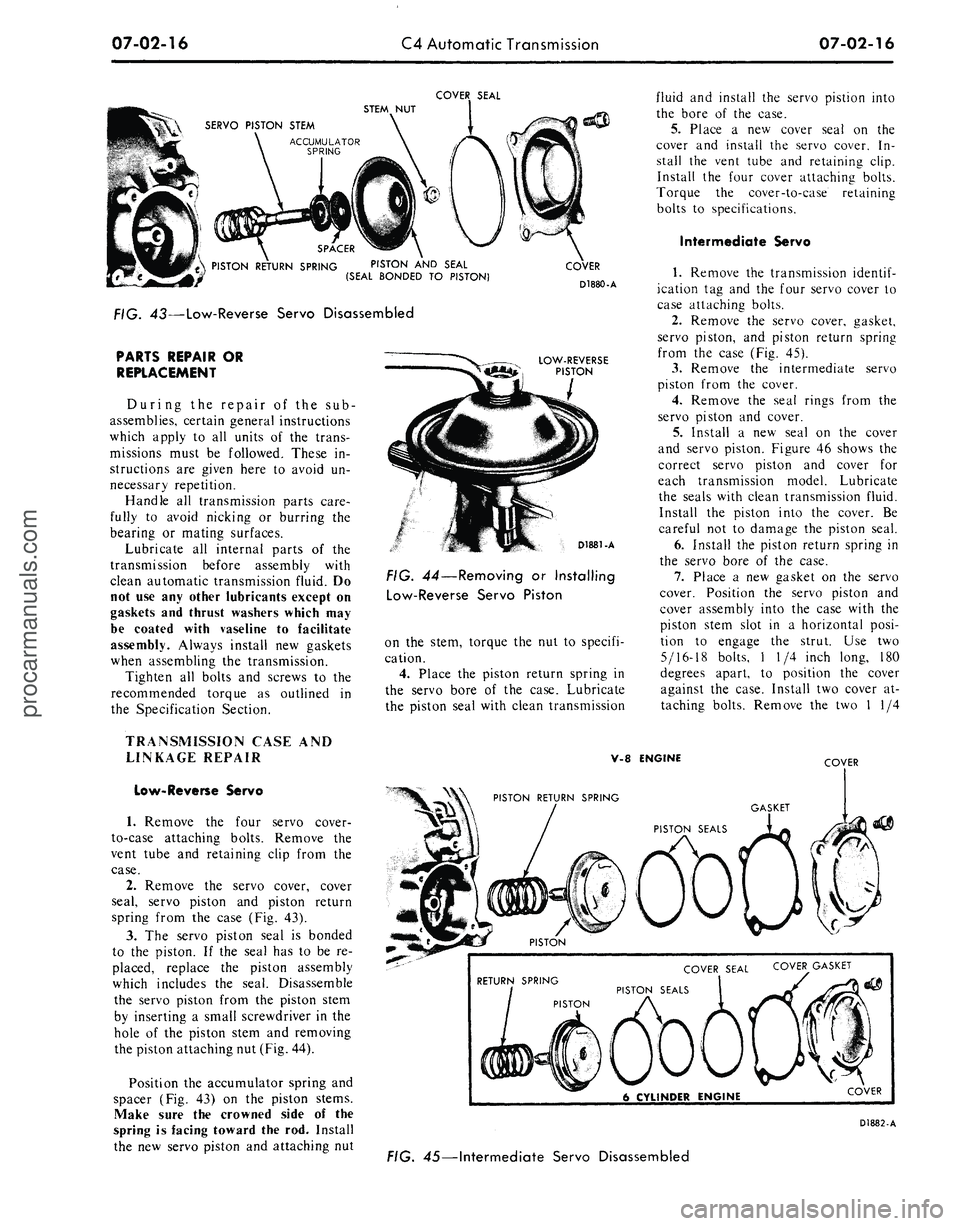

COVER SEAL

STEM NUT

SERVO PISTON STEM

PISTON RETURN SPRING PISTON AND SEAL

(SEAL BONDED TO PISTON)

FIG. 43—Low-Reverse Servo Disassembled

PARTS REPAIR OR

REPLACEMENT

During the repair of the sub-

assemblies, certain general instructions

which apply to all units of the trans-

missions must be followed. These in-

structions are given here to avoid un-

necessary repetition.

Handle all transmission parts care-

fully to avoid nicking or burring the

bearing or mating surfaces.

Lubricate all internal parts of the

transmission before assembly with

clean automatic transmission fluid. Do

not use any other lubricants except on

gaskets and thrust washers which may

be coated with vaseline to facilitate

assembly. Always install new gaskets

when assembling the transmission.

Tighten all bolts and screws to the

recommended torque as outlined in

the Specification Section.

TRANSMISSION CASE AND

LINKAGE REPAIR

Low-Reverse Servo

1.

Remove the four servo cover-

to-case attaching bolts. Remove the

vent tube and retaining clip from the

case.

2.

Remove the servo cover, cover

seal, servo piston and piston return

spring from the case (Fig. 43).

3.

The servo piston seal is bonded

to the piston. If the seal has to be re-

placed, replace the piston assembly

which includes the seal. Disassemble

the servo piston from the piston stem

by inserting a small screwdriver in the

hole of the piston stem and removing

the piston attaching nut (Fig. 44).

Position the accumulator spring and

spacer (Fig. 43) on the piston stems.

Make sure the crowned side of the

spring is facing toward the rod. Install

the new servo piston and attaching nut

COVER

D1880-A

LOW-REVERSE

PISTON

D1881-A

FIG. 44—Removing or Installing

Low-Reverse Servo Piston

on the stem, torque the nut to specifi-

cation.

4.

Place the piston return spring in

the servo bore of the case. Lubricate

the piston seal with clean transmission

fluid and install the servo pistion into

the bore of the case.

5.

Place a new cover seal on the

cover and install the servo cover. In-

stall the vent tube and retaining clip.

Install the four cover attaching bolts.

Torque the cover-to-case retaining

bolts to specifications.

Intermediate Servo

1.

Remove the transmission

identif-

ication tag and the four servo cover to

case attaching bolts.

2.

Remove the servo cover, gasket,

servo piston, and piston return spring

from the case (Fig. 45).

3.

Remove the intermediate servo

piston from the cover.

4.

Remove the seal rings from the

servo piston and cover.

5.

Install a new seal on the cover

and servo piston. Figure 46 shows the

correct servo piston and cover for

each transmission model. Lubricate

the seals with clean transmission fluid.

Install the piston into the cover. Be

careful not to damage the piston seal.

6. Install the piston return spring in

the servo bore of the case.

7.

Place a new gasket on the servo

cover. Position the servo piston and

cover assembly into the case with the

piston stem slot in a horizontal posi-

tion to engage the strut. Use two

5/16-18 bolts, 1 1/4 inch long, 180

degrees apart, to position the cover

against the case. Install two cover at-

taching bolts. Remove the two 1 1/4

V-8 ENGINE

COVER

RETURN SPRING

PISTON

COVER SEAL COVER^ GASKET

PISTON SEALS

6 CYLINDER ENGINE

COVER

D1882-A

FIG. 45—Intermediate Servo Disassembledprocarmanuals.com

Page 327 of 413

07-02-19

C4 Automatic Transmission

07-02-19

Tool-T64P-7A128-A

OIL

SCREEN

LOWER

VALVE BODY

-,

-^L*«^M*if

GASKET

UPPER

VALVE BODY

D1891-A

FIG. 54—Upper and Lower Valve Bodies Disassembled

MANUAL VALVE

D1892-A

FIG. 56—Removing Manual Valve

Exert downward pressure on the tool

and turn it counterclockwise until the

insert is removed.

CONTROL VALVE BODY

Disassembly

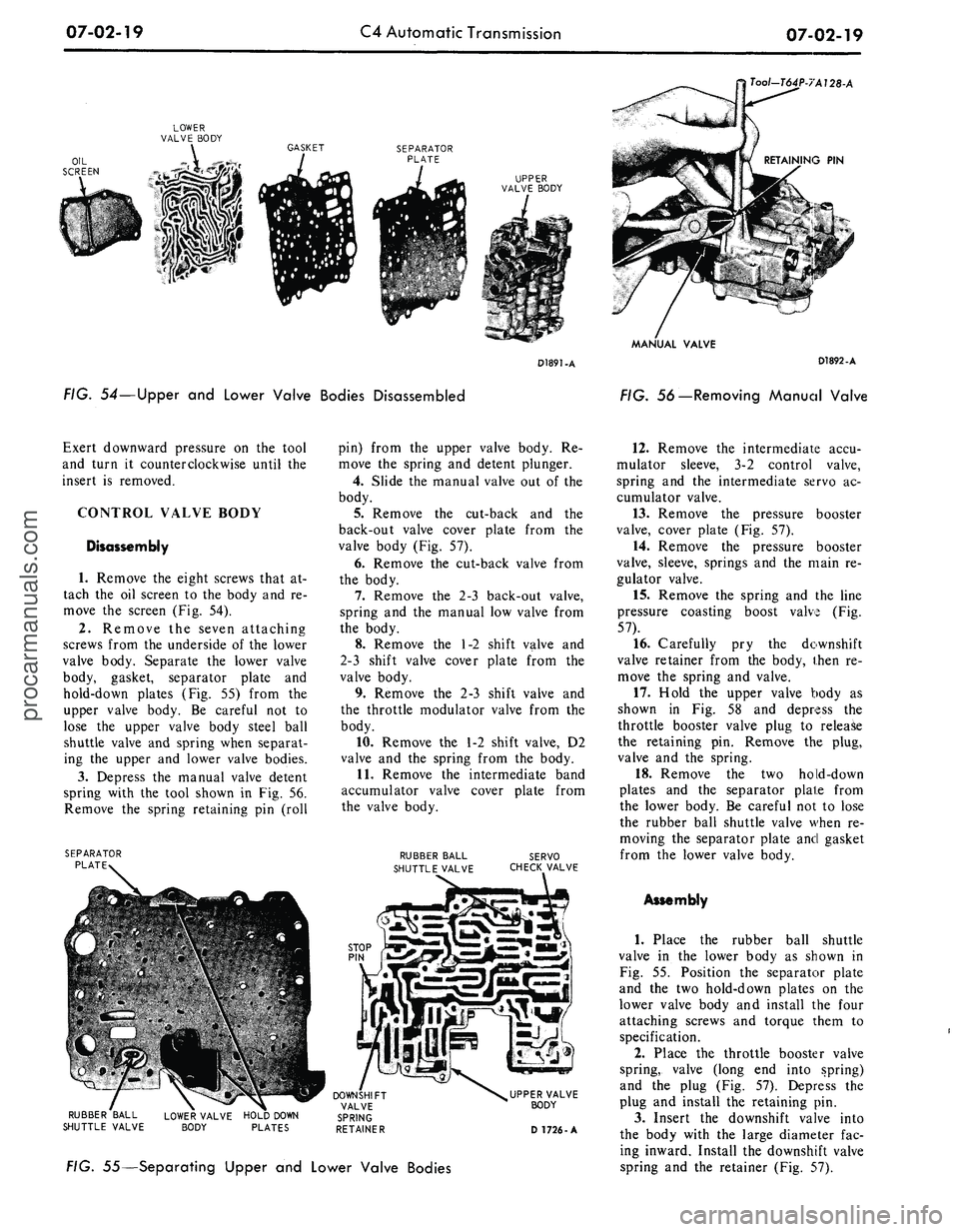

1.

Remove the eight screws that at-

tach the oil screen to the body and re-

move the screen (Fig. 54).

2.

Remove the seven attaching

screws from the underside of the lower

valve body. Separate the lower valve

body, gasket, separator plate and

hold-down plates (Fig. 55) from the

upper valve body. Be careful not to

lose the upper valve body steel ball

shuttle valve and spring when separat-

ing the upper and lower valve bodies.

3.

Depress the manual valve detent

spring with the tool shown in Fig. 56.

Remove the spring retaining pin (roll

SEPARATOR

PLATE

pin) from the upper valve body. Re-

move the spring and detent plunger.

4.

Slide the manual valve out of the

body.

5.

Remove the cut-back and the

back-out valve cover plate from the

valve body (Fig. 57).

6. Remove the cut-back valve from

the body.

7.

Remove the 2-3 back-out valve,

spring and the manual low valve from

the body.

8. Remove the 1-2 shift valve and

2-3 shift valve cover plate from the

valve body.

9. Remove the 2-3 shift valve and

the throttle modulator valve from the

body.

10.

Remove the 1-2 shift valve, D2

valve and the spring from the body.

11.

Remove the intermediate band

accumulator valve cover plate from

the valve body.

RUBBER BALL

SHUTTLE VALVE

SERVO

CHECK VALVE

RUBBER BALL

SHUTTLE VALVE

UPPER VALVE

BODY

D 1726-A

FIG. 55—Separating Upper and Lower Valve Bodies

12.

Remove the intermediate accu-

mulator sleeve, 3-2 control valve,

spring and the intermediate servo ac-

cumulator valve.

13.

Remove the pressure booster

valve, cover plate (Fig. 57).

14.

Remove the pressure booster

valve, sleeve, springs and the main re-

gulator valve.

15.

Remove the spring and the line

pressure coasting boost valve (Fig.

57).

16.

Carefully pry the downshift

valve retainer from the body, then re-

move the spring and valve.

17.

Hold the upper valve body as

shown in Fig. 58 and depress the

throttle booster valve plug to release

the retaining pin. Remove the plug,

valve and the spring.

18.

Remove the two hold-down

plates and the separator plate from

the lower body. Be careful not to lose

the rubber ball shuttle valve when re-

moving the separator plate and gasket

from the lower valve body.

Assembly

1.

Place the rubber ball shuttle

valve in the lower body as shown in

Fig. 55. Position the separator plate

and the two hold-down plates on the

lower valve body and install the four

attaching screws and torque them to

specification.

2.

Place the throttle booster valve

spring, valve (long end into spring)

and the plug (Fig. 57). Depress the

plug and install the retaining pin.

3.

Insert the downshift valve into

the body with the large diameter fac-

ing inward. Install the downshift valve

spring and the retainer (Fig. 57).procarmanuals.com

Page 329 of 413

07-02-21

C4 Automatic Transmission

07-02-21

D1893-A

FIG. 58—Removing or Installing

Throttle Booster Valve

4.

Insert the line pressure coasting

boost valve and spring in the body

(Fig. 57).

5.

Place the main regulator valve in

the body (Fig. 57) with the large di-

ameter facing inward. Install the two

springs and the pressure booster valve

and sleeve.

6. Hold the pressure booster valve

cover plate in place and install the

three attaching screws and torque

them to specification.

7.

Place the intermediate servo ac-

cummulator valve and spring in the

body. Install the interim iiate accum-

mulator sleeve and 3-2 control valve.

Secure the cover to the body with the

attaching screw. Torque the screw to

specifications.

8. Position the spring, D2 valve and

the I-2 shift valve in the body.

9. Place the throttle modulator

valve, spring, and 2-3 shift valve in the

body.

10.

Secure the 1-2 shift valve and

the 2-3 valve cover plate to the body

and torque the screws to specifica-

tions.

11.

Place the manual low valve,

spring, and the 2-3 back-out valve in

the body.

12.

Place the cut-back valve in the

body.

13.

Secure the cut-back and the

back-out cover plate to the body with

two screws. Torque the screws to

specifications.

14.

Slide the manual valve into the

body making sure that the notch for

the manual lever is toward the inside

and that the detent notches are facing

upward.

15.

Place the detent plunger and

spring in the body. Depress the spring

and install a new roll pin.

16.

Position a new rubber check

valve in the upper valve body (Fig.

55).

17.

Position the check valve and

spring in the upper valve body (Fig.

55).

Place a new gasket, the separator

plate and the lower valve body in

place on the upper valve body and se-

cure it with the seven attaching

screws. Torque the screws to specifica-

tions.

18.

Secure the oil screen to the

body with the eight attaching screws.

Torque the screws to specifications.

FRONT PUMP

Disassembly

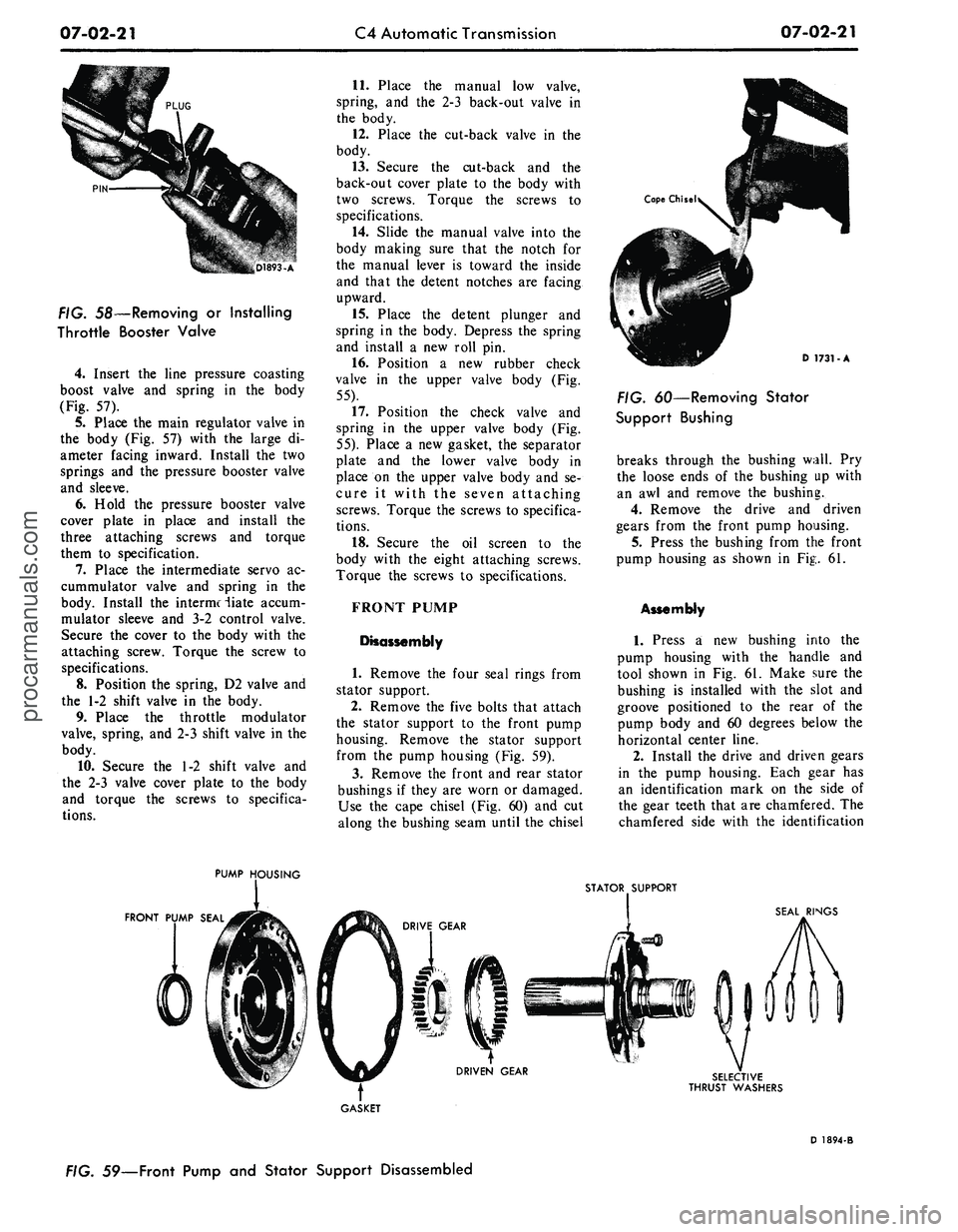

1.

Remove the four seal rings from

stator support.

2.

Remove the five bolts that attach

the stator support to the front pump

housing. Remove the stator support

from the pump housing (Fig. 59).

3.

Remove the front and rear stator

bushings if they are worn or damaged.

Use the cape chisel (Fig. 60) and cut

along the bushing seam until the chisel

D 1731-A

FIG. 60—Removing Stator

Support Bushing

breaks through the bushing wall. Pry

the loose ends of the bushing up with

an awl and remove the bushing.

4.

Remove the drive and driven

gears from the front pump housing.

5.

Press the bushing from the front

pump housing as shown in Fig. 61.

Assembly

1.

Press a new bushing into the

pump housing with the handle and

tool shown in Fig. 61. Make sure the

bushing is installed with the slot and

groove positioned to the rear of the

pump body and 60 degrees below the

horizontal center line.

2.

Install the drive and driven gears

in the pump housing. Each gear has

an identification mark on the side of

the gear teeth that are chamfered. The

chamfered side with the identification

PUMP HOUSING

STATOR SUPPORT

FRONT PUMP SEAL

SEAL RINGS

SELECTIVE

THRUST WASHERS

GASKET

D 1894-B

59—Front Pump and Stator Support Disassembledprocarmanuals.com