tow FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 330 of 413

07-02-22

C4 Automatic Transmission

07-02-22

Handle

Fress

Ram

ress

Ram

Hand!

Tool

-

T66L-7003-S9

Too/

-

T66L-7003-B5

INSTALL BUSHING WITH GROOVE

JAND SLOT

IN

THIS POSITION

REMOVAL

INSTALLATION

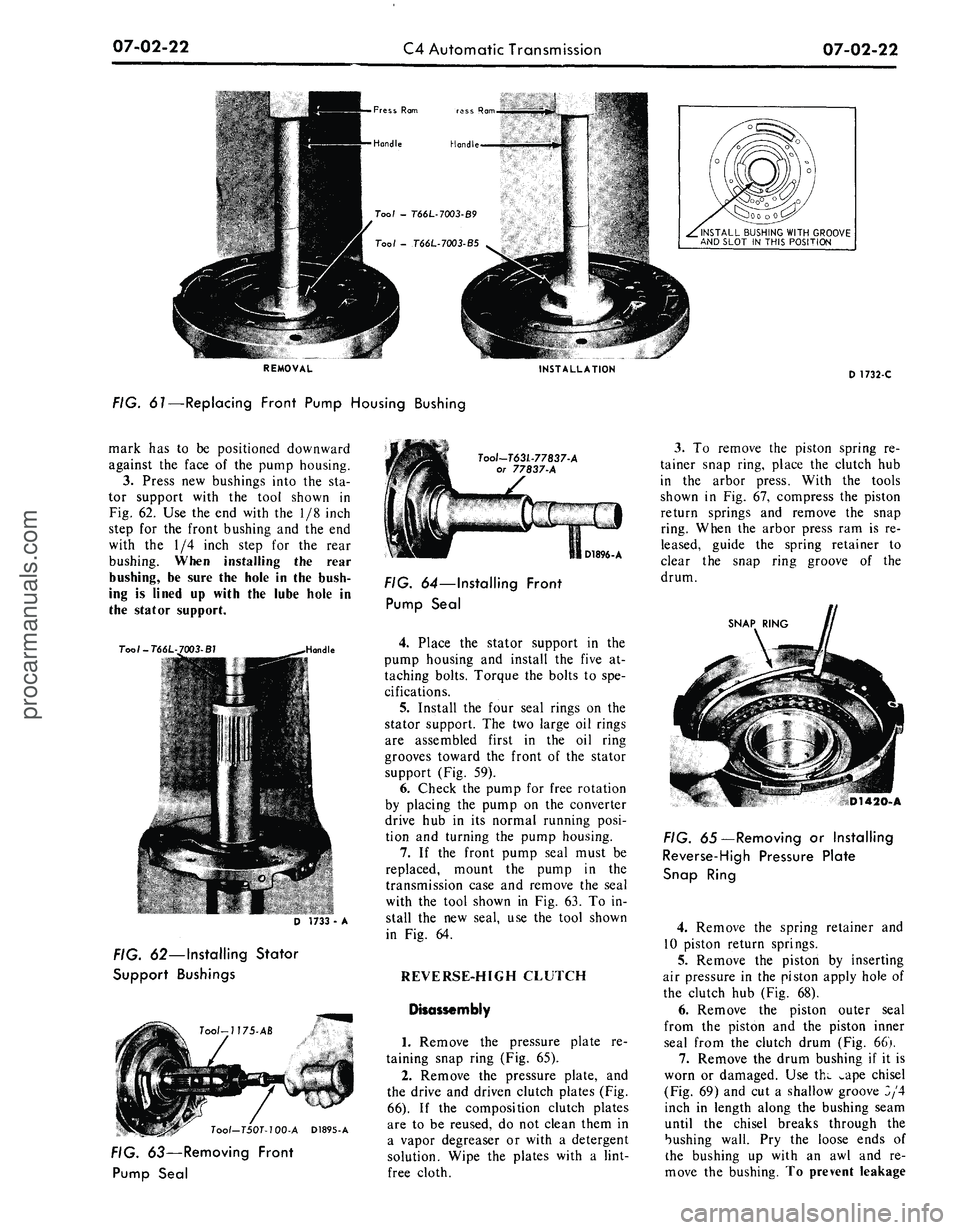

FIG. 61—Replacing Front Pump Housing Bushing

D 1732-C

mark

has to be

positioned downward

against

the

face

of the

pump housing.

3.

Press

new

bushings into

the sta-

tor support with

the

tool shown

in

Fig. 62.

Use the end

with

the 1/8

inch

step

for the

front bushing

and the end

with

the 1/4

inch step

for the

rear

bushing. When installing

the

rear

bushing,

be

sure

the

hole

in the

bush-

ing

is

lined

up

with

the

lube hole

in

the stator support.

T00I-T66L

Toot-T63L-77837-A

or 77837-A

D 1733

-

A

FIG. 62—Installing Stator

Support Bushings

Tool-T50T-100-A D1895-A

FIG. 63—Removing Front

Pump Seal

D1896-A

FIG. 64—Installing Front

Pump Seal

4.

Place

the

stator support

in the

pump housing

and

install

the

five

at-

taching bolts. Torque

the

bolts

to

spe-

cifications.

5.

Install

the

four seal rings

on the

stator support.

The two

large

oil

rings

are assembled first

in the oil

ring

grooves toward

the

front

of the

stator

support (Fig.

59).

6. Check

the

pump

for

free rotation

by placing

the

pump

on the

converter

drive

hub in its

normal running posi-

tion

and

turning

the

pump housing.

7.

If the

front pump seal must

be

replaced, mount

the

pump

in the

transmission case

and

remove

the

seal

with

the

tool shown

in Fig.

63.

To in-

stall

the new

seal,

use the

tool shown

in

Fig. 64.

REVERSE-HIGH CLUTCH

Disassembly

1.

Remove

the

pressure plate

re-

taining snap ring (Fig.

65).

2.

Remove

the

pressure plate,

and

the drive

and

driven clutch plates (Fig.

66).

If the

composition clutch plates

are

to be

reused,

do not

clean them

in

a vapor degreaser

or

with

a

detergent

solution. Wipe

the

plates with

a

lint-

free cloth.

3.

To

remove

the

piston spring

re-

tainer snap ring, place

the

clutch

hub

in

the

arbor press. With

the

tools

shown

in Fig. 67,

compress

the

piston

return springs

and

remove

the

snap

ring. When

the

arbor press

ram is re-

leased, guide

the

spring retainer

to

clear

the

snap ring groove

of the

drum.

SNAP RING

D1420-A

FIG. 65—Removing

or

Installing

Reverse-High Pressure Plate

Snap Ring

4.

Remove

the

spring retainer

and

10 piston return springs.

5.

Remove

the

piston

by

inserting

air pressure

in the

piston apply hole

of

the clutch

hub

(Fig.

68).

6. Remove

the

piston outer seal

from

the

piston

and the

piston inner

seal from

the

clutch drum (Fig.

66).

7.

Remove

the

drum bushing

if it is

worn

or

damaged.

Use

thw ^ape chisel

(Fig. 69)

and cut a

shallow groove

3/4

inch

in

length along

the

bushing seam

until

the

chisel breaks through

the

bushing wall.

Pry the

loose ends

of

the bushing

up

with

an awl and re-

move

the

bushing.

To

prevent leakageprocarmanuals.com

Page 335 of 413

07-02-27

C4 Automatic Transmission

07-02-27

'OIL RINGS

SNAP RING

SECONDARY

GOVERNOR VALVE

1 v s

GOVERNOR HOUSING

D1907-A

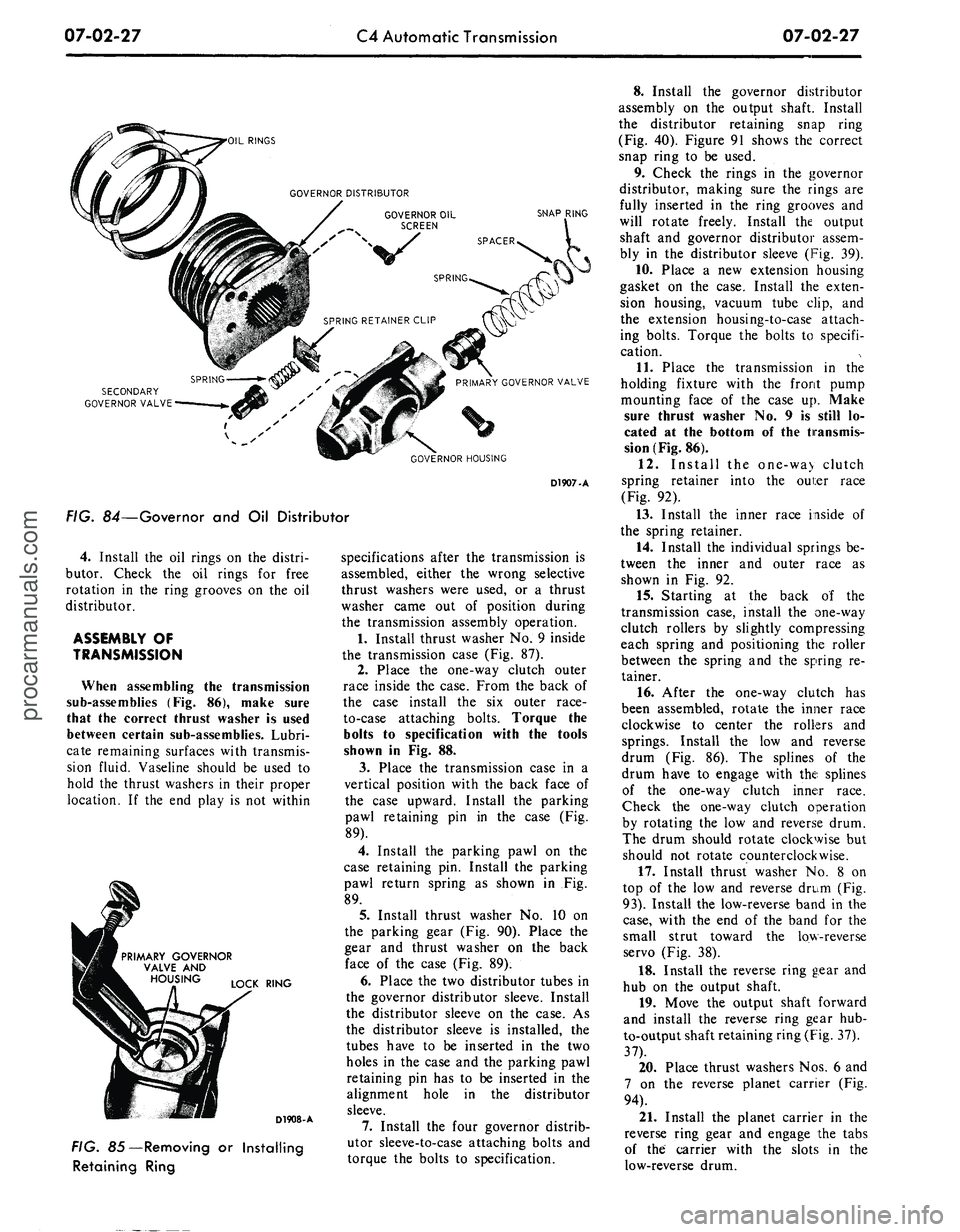

FIG. 84—Governor and Oil Distributor

4.

Install the oil rings on the distri-

butor. Check the oil rings for free

rotation in the ring grooves on the oil

distributor.

ASSEMBLY OF

TRANSMISSION

When assembling the transmission

sub-assemblies (Fig. 86), make sure

that the correct thrust washer is used

between certain sub-assemblies. Lubri-

cate remaining surfaces with transmis-

sion fluid. Vaseline should be used to

hold the thrust washers in their proper

location. If the end play is not within

PRIMARY GOVERNOR

VALVE AND

LOCK RING

D1908-A

FIG. 85—Removing or Installing

Retaining Ring

specifications after the transmission is

assembled, either the wrong selective

thrust washers were used, or a thrust

washer came out of position during

the transmission assembly operation.

1.

Install thrust washer No. 9 inside

the transmission case (Fig. 87).

2.

Place the one-way clutch outer

race inside the case. From the back of

the case install the six outer race-

to-case attaching bolts. Torque the

bolts to specification with the tools

shown in Fig. 88.

3.

Place the transmission case in a

vertical position with the back face of

the case upward. Install the parking

pawl retaining pin in the case (Fig.

89).

4.

Install the parking pawl on the

case retaining pin. Install the parking

pawl return spring as shown in Fig.

89.

5.

Install thrust washer No. 10 on

the parking gear (Fig. 90). Place the

gear and thrust washer on the back

face of the case (Fig. 89).

6. Place the two distributor tubes in

the governor distributor sleeve. Install

the distributor sleeve on the case. As

the distributor sleeve is installed, the

tubes have to be inserted in the two

holes in the case and the parking pawl

retaining pin has to be inserted in the

alignment hole in the distributor

sleeve.

7.

Install the four governor distrib-

utor sleeve-to-case attaching bolts and

torque the bolts to specification.

8. Install the governor distributor

assembly on the output shaft. Install

the distributor retaining snap ring

(Fig. 40). Figure 91 shows the correct

snap ring to be used.

9. Check the rings in the governor

distributor, making sure the rings are

fully inserted in the ring grooves and

will rotate freely. Install the output

shaft and governor distributor assem-

bly in the distributor sleeve (Fig. 39).

10.

Place a new extension housing

gasket on the case. Install the exten-

sion housing, vacuum tube clip, and

the extension housing-to-case attach-

ing bolts. Torque the bolts to specifi-

cation.

11.

Place the transmission in the

holding fixture with the front pump

mounting face of the case up. Make

sure thrust washer No. 9 is still lo-

cated at the bottom of the transmis-

sion (Fig. 86).

12.

Install the one-wa> clutch

spring retainer into the oui:er race

(Fig. 92).

13.

Install the inner race inside of

the spring retainer.

14.

Install the individual springs be-

tween the inner and outer race as

shown in Fig. 92.

15.

Starting at the back of the

transmission case, install the one-way

clutch rollers by slightly compressing

each spring and positioning the roller

between the spring and the spring re-

tainer.

16.

After the one-way clutch has

been assembled, rotate the inner race

clockwise to center the rollers and

springs. Install the low and reverse

drum (Fig. 86). The splines of the

drum have to engage with the splines

of the one-way clutch inner race.

Check the one-way clutch operation

by rotating the low and reverse drum.

The drum should rotate clockwise but

should not rotate counterclockwise.

17.

Install thrust washer No. 8 on

top of the low and reverse drum (Fig.

93).

Install the low-reverse band in the

case,

with the end of the band for the

small strut toward the low-reverse

servo (Fig. 38).

18.

Install the reverse ring gear and

hub on the output shaft.

19.

Move the output shaft forward

and install the reverse ring gear hub-

to-output shaft retaining ring (Fig. 37).

37).

20.

Place thrust washers Nos. 6 and

7 on the reverse planet carrier (Fig.

94).

21.

Install the planet carrier in the

reverse ring gear and engage the tabs

of the carrier with the slots in the

low-reverse drum.procarmanuals.com

Page 349 of 413

07-03-09

FMX Transmission

07-03-09

4.

Remove the pointer back-up

shield attaching screws and the shield.

5.

Disconnect the dial indicator

light.

6. Disconnect the neutral start

switch and dial indicator light wires

from their connectors at the dash

panel.

7.

Remove the selector housing and

lever assembly attaching bolts. Re-

move the selector lever and housing.

8. Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

9. Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

10.

Install the selector lever handle.

11.

Position the selector lever as

shown in Figure 10. With a feeler

gauge check the clearance between the

detent pawl and plate. The clearince

should be 0.005 to 0.010 inch. If nec-

essary, adjust the height of the detent

pawl as shown in Figure 10.

12.

Remo"~ the handle from tte se-

lector lever.

13.

Install the selector housing and

lever assembly as shown in Figure 4.

Torque the attaching bolts 4-6 ft-lbs.

14.

Connect the dial indicator light.

15.

Connect the neutral start switch

and dial indicator light wires to their

respective connectors at the dash

panel.

16.

Install the pointer back-up

shield and tighten the attaching

screws.

17.

Install the selector lever handle

and tighten the attaching screw.

18.

Position the selector lever in the

D position.

19.

Raise the vehicle. Install the

transmission manual lever rod to the

selector lever. Adjust the manual link-

age.

20.

Lower the vehicle and check the

transmission operation in each selec-

tor lever detent position.

BAND ADJUSTMENTS

FRONT BAND

ADJUSTMENT

1.

Drain the fluid from the trans-

mission by loosening the pan attach-

ing bolts starting at the rear of the

pan and working toward the front.

When most of the fluid has drained

from the pan, remove the remainder

of the attaching bolts. Use a clean

drain can equipped with a 100-mesh

screen if the fluid is to be reused.

Too/—

7225-C-13B

/A

-inch

Spacer

FRONT SERVO

ACTUATING LEVER

D 2048-A

FIG.

7

7—Adjusting Front Band—

Typical

2.

Remove the pan, then remove

the fluid filter and clip from the trans-

mission. Clean the inside of the pan.

Remove all gasket material from the

pan and pan mounting face of the

case.

3.

Loosen the front servo adjusting

screw lock nut.

4.

Pull back on the actuating rod,

and insert the 1/4 inch spacer between

the adjusting screw and servo piston

stem (Fig. 11). Tighten the adjusting

screw to 10 in-lbs. torque. Remove the

spacer and tighten the adjusting screw

an additional 3/4 turn. Hold the ad-

justing screw stationary and tighten

the lock nut securely.

5.

Install the transmission fluid

screen and clip. Install the pan using a

new gasket.

6. Refill the transmission to the

FULL mark on the dipstick.

7.

Start the engine and engage the

transmission in each drive range to fill

all fluid passages, then place the selec-

tor lever in the P position. Check the

fluid level and add enough fluid to

bring the level above the ADD mark

on the dipstick.

ALTERNATE FRONT

BAND ADJUSTMENT

1.

Drain the fluid from the trans-

mission. If the same fluid is to be

used again in the transmission after

Che band adjustment, filter the fluid

through a 100-mesh screen as it drains

from the transmission. Re-use the

fluid only if it is in good condition.

2.

Remove and thoroughly clean

the pan and screen. Discard the pan

gasket.

3.

Loosen the front servo adjusting

screw locknut two full turns with a

inch Driv

Detail #2

D.tai\

#3

T-Hond/e

Extension

Tool-758L-7195-A

f/2 inch Driv

Detail

#7

Qj-«—

TM-470 TM-82

D1950-A

FIG. 12—Front and Rear Band

Adjusting Tools

9/16-inch wrench. Check the. adjusting

screw for free rotation in the actuating

lever after the lock nut is loosened,

and free the screw if necessary.

4.

Pull the adjusting screw end of

the actuating lever away from the

servo body, and insert the 1/4 inch

spacer (Fig. 12) between the servo pis-

ton stem and the adjusting screw.

5.

Install the socket handle on the

9/16-inch socket.

6. Insert the T-handle extension

through the socket handle and socket,

and install the screwdriver socket on

the T-handle extension.

7.

Place the tool on the adjusting

screw so that the screwdriver socket

engages the screw and the 9/16-inch

socket engages the lock nut.

8. With a torque wrench on the T-

handle extension, tighten the adjusting

screw to 10 in-lbs torque.

9. Remove the spacer and tighten

the adjusting screw an additional 3/4

turn. Hold the adjusting screw station-

ary, and torque the lock nut to speci-

fication.

10.

Place a new gasket on the pan,

and install the screen and pan on the

transmission.

11.

Fill the transmission with fluid.

REAR BAND ADJUSTMENT—

FORD-METEOR

1.

Fold back the floor mat to ex-

pose the right side of the floor pan.

2.

Remove the access hole cover

from the floor pan. Remove all dirt

from the adjusting screw threads, then

oil the threads.

3.

Loosen the rear band adjusting

screw lock nut with the tool shown in

Fig. 13. Using the T-handle portion of

the tool, tighten the adjusting screw

until the wrench overruns.procarmanuals.com

Page 351 of 413

07-03-11

FMX Transmission

07

03-11

GOVERNOR

COMPENSATOR

PRESSURE TUBE

MAIN CONTROL

VALVE TUBE

COUNTERWEIGHT

D 1815-A

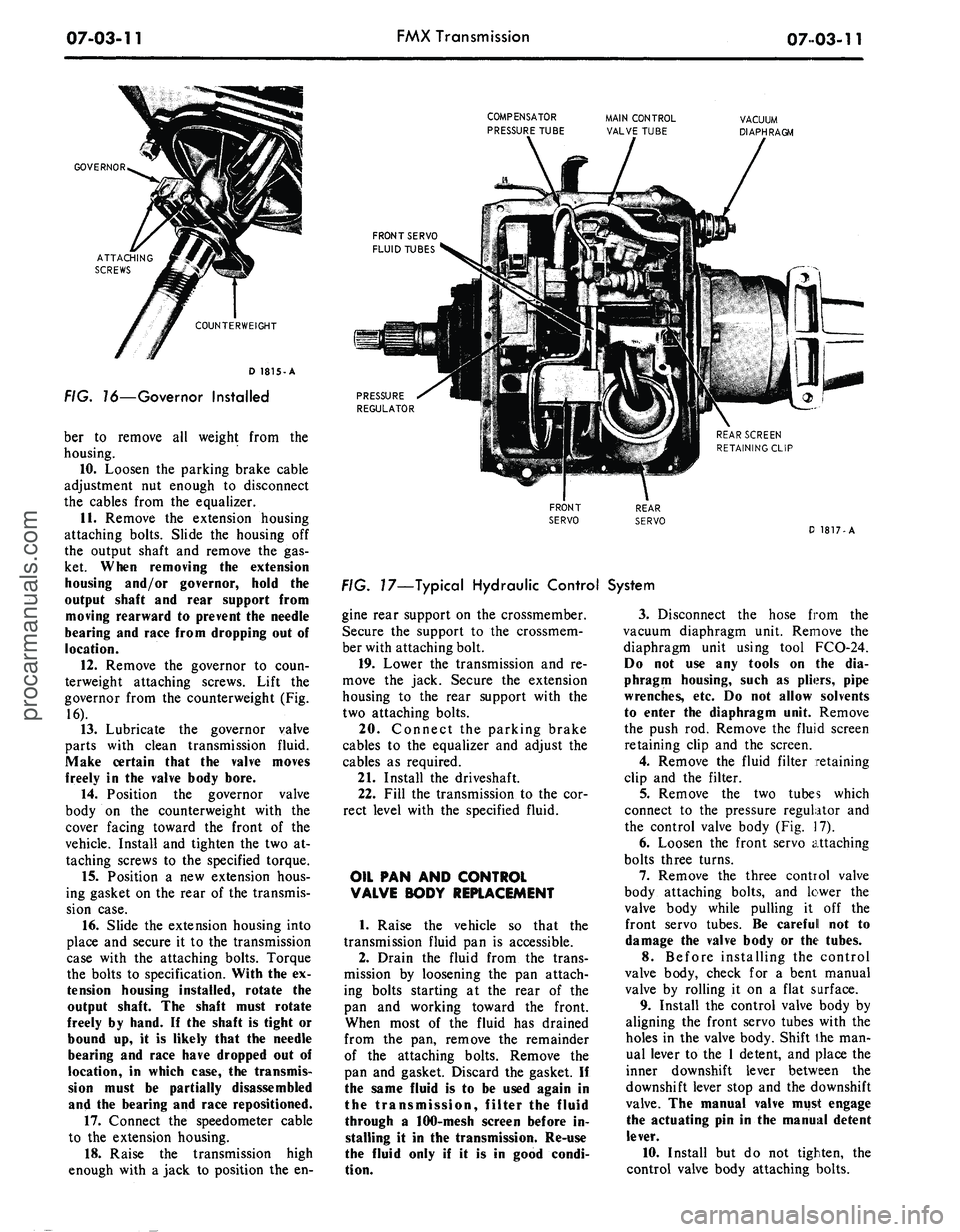

FIG. 16—Governor Installed

ber to remove all weight from the

housing.

10.

Loosen the parking brake cable

adjustment nut enough to disconnect

the cables from the equalizer.

11.

Remove the extension housing

attaching bolts. Slide the housing off

the output shaft and remove the gas-

ket. When removing

the

extension

housing and/or governor, hold

the

output shaft

and

rear support from

moving rearward

to

prevent

the

needle

bearing

and

race from dropping

out of

location.

12.

Remove the governor to coun-

terweight attaching screws. Lift the

governor from the counterweight (Fig.

16).

13.

Lubricate the governor valve

parts with clean transmission fluid.

Make certain that

the

valve moves

freely

in the

valve body bore.

14.

Position the governor valve

body on the counterweight with the

cover facing toward the front of the

vehicle. Install and tighten the two at-

taching screws to the specified torque.

15.

Position a new extension hous-

ing gasket on the rear of the transmis-

sion case.

16.

Slide the extension housing into

place and secure it to the transmission

case with the attaching bolts. Torque

the bolts to specification. With the ex-

tension housing installed, rotate

the

output shaft.

The

shaft must rotate

freely

by

hand.

If the

shaft

is

tight

or

bound

up, it is

likely that

the

needle

bearing

and

race have dropped

out of

location,

in

which case,

the

transmis-

sion must

be

partially disassembled

and

the

bearing

and

race repositioned.

17.

Connect the speedometer cable

to the extension housing.

18.

Raise the transmission high

enough with a jack to position the en-

FRONT SERVO

FLUID TUBES

PRESSURE

REGULATOR

D 1817-A

FIG. 17—Typical Hydraulic Control System

gine rear support on the crossmember.

Secure the support to the crossmem-

ber with attaching bolt.

19.

Lower the transmission and re-

move the jack. Secure the extension

housing to the rear support with the

two attaching bolts.

20.

Connect the parking brake

cables to the equalizer and adjust the

cables as required.

21.

Install the driveshaft.

22.

Fill the transmission to the cor-

rect level with the specified fluid.

OIL

PAN AND

CONTROL

VALVE BODY REPLACEMENT

1. Raise the vehicle so that the

transmission fluid pan is accessible.

2.

Drain the fluid from the trans-

mission by loosening the pan attach-

ing bolts starting at the rear of the

pan and working toward the front.

When most of the fluid has drained

from the pan, remove the remainder

of the attaching bolts. Remove the

pan and gasket. Discard the gasket. If

the same fluid is to be used again in

the transmission, filter the fluid

through a 100-mesh screen before in-

stalling it in the transmission. Re-use

the fluid only if it is in good condi-

tion.

3.

Disconnect the hose from the

vacuum diaphragm unit. Remove the

diaphragm unit using tool FCO-24.

Do

not use any

tools

on the dia-

phragm housing, such

as

pliers, pipe

wrenches,

etc. Do not

allow solvents

to enter

the

diaphragm unit. Remove

the push rod. Remove the fluid screen

retaining clip and the screen.

4.

Remove the fluid filter retaining

clip and the filter.

5.

Remove the two tubes which

connect to the pressure regulator and

the control valve body (Fig. 17).

6. Loosen the front servo attaching

bolts three turns.

7.

Remove the three control valve

body attaching bolts, and lower the

valve body while pulling it off the

front servo tubes. Be carefull not to

damage

the

valve body

or the

tubes.

8.

Before installing the control

valve body, check for a bent manual

valve by rolling it on a flat surface.

9. Install the control valve body by

aligning the front servo tubes with the

holes in the valve body. Shift the man-

ual lever to the 1 detent, and place the

inner downshift lever between the

downshift lever stop and the downshift

valve.

The

manual valve must engage

the actuating

pin in the

manual detent

lever.

10.

Install but do not tighten, the

control valve body attaching bolts.procarmanuals.com

Page 352 of 413

07-03-12

FMX Transmission

07-03-12

11.

Move the control valve body

toward the center of the case until the

clearance is less than 0.050 inch, be-

tween the manual valve and the act-

uating pin on the manual detent lever.

12.

Torque the attaching bolts to

specification. Be sure that the rear

fluid filter retaining clip is installed

under the valve body bolt as shown in

Figure 17.

13.

Install the tubes to the pressure

regulator and the control valve body.

14.

Turn the manual valve one full

turn in each manual lever detent posi-

tion. If the manual valve binds against

the actuating pin in any detent posi-

tion, loosen the valve body attaching

bolts and move the body away from

the center of the case. Move the valve

body only enough to relieve the bind-

ing. Torque the attaching bolts and

recheck the manual valve for binding.

15.

Position the push rod in the

bore of the vacuum diaphragm unit.

Using the diaphragm unit as a guide,

insert the push rod into the threaded

opening of the case. Torque the dia-

phragm unit to specification. Connect

the vacuum hose.

16.

Torque the front servo attach-

ing bolts to specification.

17.

Adjust the front band. If the

unit is a model PHB-C, D, E, F, G or

H, adjust the rear band at this time.

18.

Install the fluid filter and the

filter retaining clip.

19.

Position a new fluid pan gasket

on the bottom of the transmission

case,

and install the pan. Torque the

pan screws to specification.

20.

Adjust the rear band on

PHB-A and PHD models.

21.

Fill the transmission with fluid.

If

the

fluid that

was

drained from

the

transmission

is to be

used

again,

filter

the fluid through

a

100-mesh screen

as

it

is

poured back into

the

transmis-

sion.

Re-use

the

fluid only

if it is in

good

condition.

22.

If the control valve body was

replaced, adjust the transmission con-

trol linkage.

PRESSURE REGULATOR

REPLACEMENT

1. Drain the fluid from the trans-

mission, and remove the pan and fluid

filter.

2.

Remove the small compensator

pressure tube and the large control

pressure tube from the control valve

body and the pressure regulator.

3.

Remove the pressure regulator

spring retainer, springs, and spacer.

Maintain pressure

on the

retainer

to

prevent

the

springs from flying

out.

4.

Remove the pressure regulator

attaching bolts and washers, and re-

move the regulator.

5.

Position the replacement regula-

tor body on the transmission case and

install the two attaching bolts. Torque

the bolts to specification.

6. Check the converter pressure and

control pressure valves to be sure the

valves operate freely in the bores.

7.

Install the valve springs, spacer,

and retainer.

8. Install the large control pressure

tube,

and the small compensator pres-

sure tube.

9. Install the fluid filter and the

pan, and fill the transmission to the

correct level with the specified fluid.

FRONT SERVO REPLACEMENT

1. Drain the fluid from the trans-

mission, and remove the pan and fluid

filter.

2.

Remove the vacuum diaphragm

unit.

3.

Loosen the three control valve

body attaching bolts.

4.

Remove the attaching bolts from

the front servo (Fig. 17), hold the

strut with the fingers, and remove the

servo.

5.

To install the front servo, posi-

tion the front band forward in the

case with the end of the band facing

downward. Make sure the front servo

anchor pin is in position in the case

web.

Align the large end of the servo

strut with the servo actuating lever,

and align the small end with the band

end.

6. Rotate the band, strut, and servo

to align the anchor end of the band

with the anchor in the case.

Push the servo body onto the con-

trol valve body tubes.

7.

Install the attaching bolts and

torque to specification.

8. Torque the control valve body

attaching bolts to specification.

Check the clearance between the

manual valve and manual lever actuat-

ing pin as given in Oil Pan and Con-

trol Valve Body Replacement.

9. Adjust the front band.

10.

Install the vacuum diaphragm

unit and rod.

11.

Install the fluid filter and pan,

and fill the transmission with fluid.

12.

Adjust the downshift and manu-

al linkage.

REAR SERVO REPLACEMENT

1. Drain the fluid from the trans-

mission, and remove the pan and fluid

filter.

2.

Remove the vacuum diaphragm

unit.

3.

Remove the control valve body

and the two front servo tubes.

4.

Remove the attaching bolts from

the rear servo, hold the actuating and

anchor struts with the fingers, and re-

move the servo. Remove the servo

dowel on PHB models.

5.

To install the rear servo, position

the servo anchor strut on the servo

band, and rotate the band to engage

the strut.

6. Hold the servo anchor strut in

position with the fingers, position the

actuating lever strut, and install the

servo. Insert the servo dowel on PHB

models.

7.

Install the servo attaching bolts,

and torque them to specification. The

longer bolt must

be

installed

in the

inner bolt

hole.

8.

Install the two front servo tubes

and the control valve body.

Check the clearance between the

manual valve and the manual lever

actuating pin as given above in Oil

Pan and Control Valve Body Replace-

ment.

9. Adjust the rear band.

10.

Install the fluid filter and pan,

and fill the transmission with fluid.

Too/~7?75-AB

7oo/-T50T-JOO-A

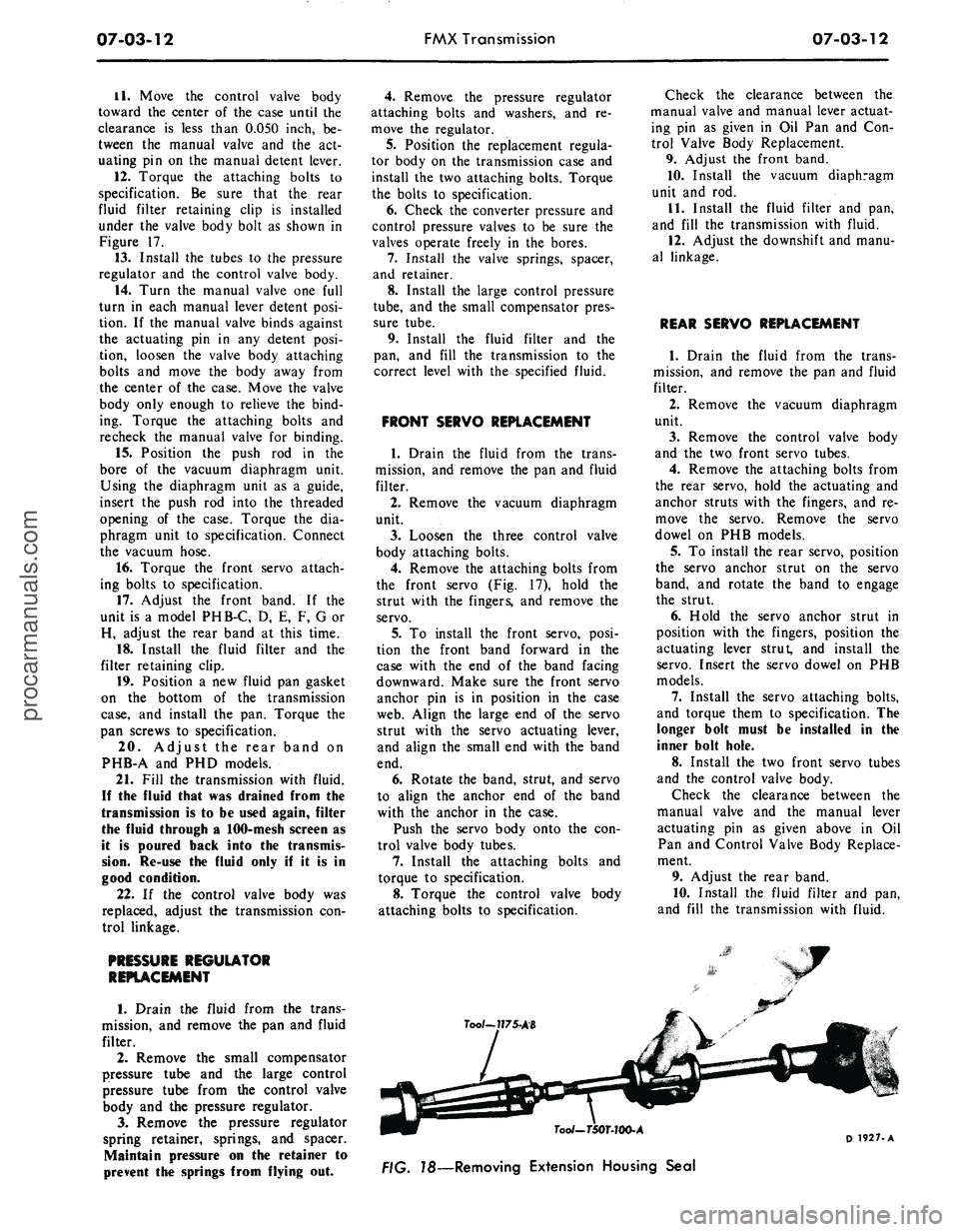

78—Removing Extension Housing Seal

D 1927-Aprocarmanuals.com

Page 353 of 413

07-03-13

FMX Transmission

07-03-13

EXTENSION HOUSING

BUSHING AND REAR SEAL

REPLACEMENT

1.

Disconnect the drive shaft from

the transmission.

2.

Carefully remove the seal with

the tools shown in Fig. 18.

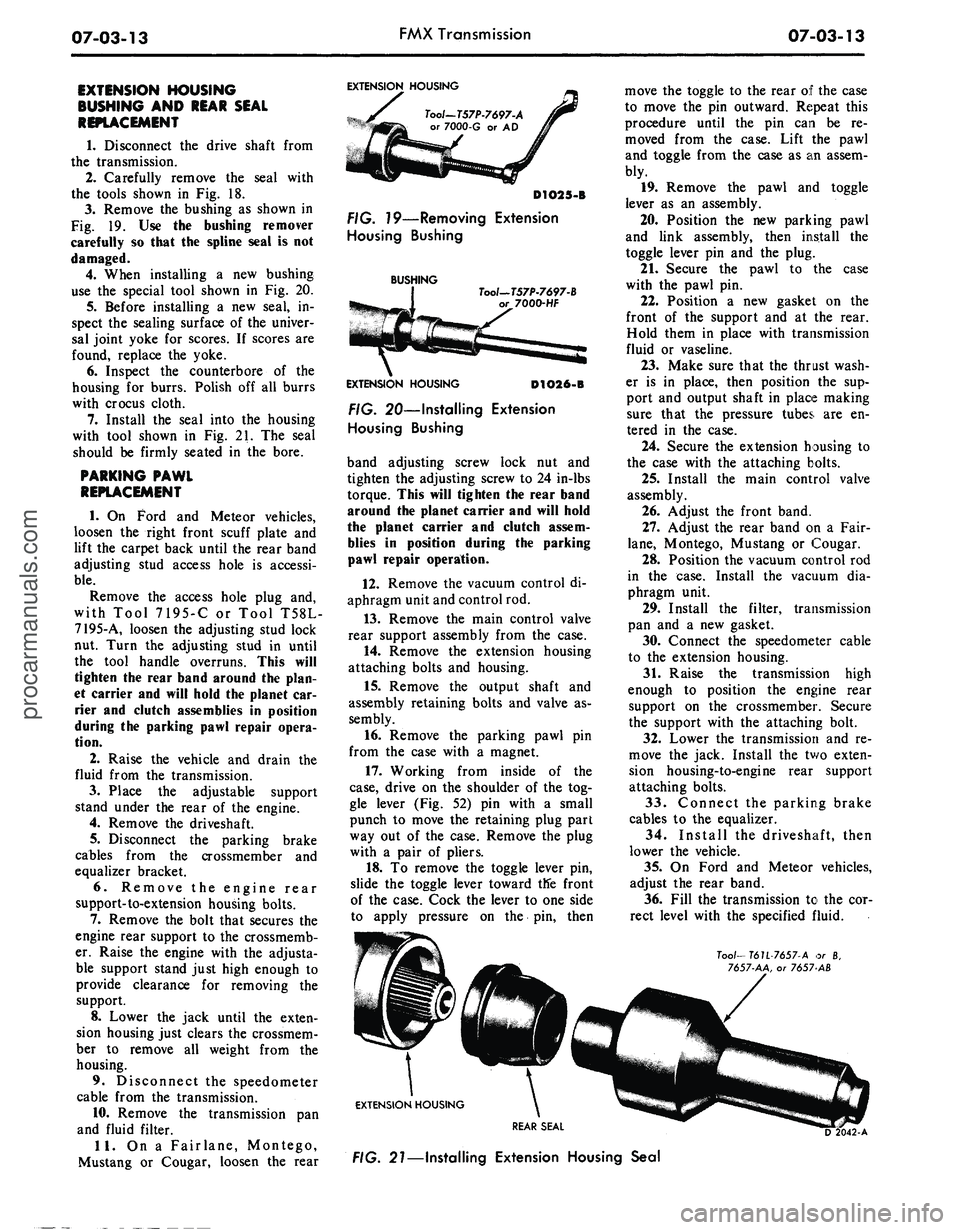

3.

Remove the bushing as shown in

Fig. 19. Use the bushing remover

carefully so that the spline seal is not

damaged.

4.

When installing a new bushing

use the special tool shown in Fig. 20.

5.

Before installing a new seal, in-

spect the sealing surface of the univer-

sal joint yoke for scores. If scores are

found, replace the yoke.

6. Inspect the counterbore of the

housing for burrs. Polish off all burrs

with crocus cloth.

7.

Install the seal into the housing

with tool shown in Fig. 21. The seal

should be firmly seated in the bore.

PARKING PAWL

REPLACEMENT

1.

On Ford and Meteor vehicles,

loosen the right front scuff plate and

lift the carpet back until the rear band

adjusting stud access hole is accessi-

ble.

Remove the access hole plug and,

with Tool 7195-C or Tool T58L-

7195-A, loosen the adjusting stud lock

nut. Turn the adjusting stud in until

the tool handle overruns. This will

tighten the rear band around the plan-

et carrier and will hold the planet car-

rier and clutch assemblies in position

during the parking pawl repair opera-

tion.

2.

Raise the vehicle and drain the

fluid from the transmission.

3.

Place the adjustable support

stand under the rear of the engine.

4.

Remove the driveshaft.

5.

Disconnect the parking brake

cables from the crossmember and

equalizer bracket.

6. Remove the engine rear

support-to-extension housing bolts.

7.

Remove the bolt that secures the

engine rear support to the crossmemb-

er. Raise the engine with the adjusta-

ble support stand just high enough to

provide clearance for removing the

support.

8. Lower the jack until the exten-

sion housing just clears the crossmem-

ber to remove all weight from the

housing.

9. Disconnect the speedometer

cable from the transmission.

10.

Remove the transmission pan

and fluid filter.

11.

On a Fairlane, Montego,

Mustang or Cougar, loosen the rear

EXTENSION HOUSING

Tool-T57P-7697-A

or 7000-G or AD

D1O25-B

FIG. 79—Removing Extension

Housing Bushing

BUSHING

Tool—T57P-7697-B

7000-HF

EXTENSION HOUSING

D1O26-B

FIG. 20—Installing Extension

Housing Bushing

band adjusting screw lock nut and

tighten the adjusting screw to 24 in-lbs

torque. This will tighten the rear band

around the planet carrier and will hold

the planet carrier and clutch assem-

blies in position during the parking

pawl repair operation.

12.

Remove the vacuum control di-

aphragm unit and control rod.

13.

Remove the main control valve

rear support assembly from the case.

14.

Remove the extension housing

attaching bolts and housing.

15.

Remove the output shaft and

assembly retaining bolts and valve as-

sembly.

16.

Remove the parking pawl pin

from the case with a magnet.

17.

Working from inside of the

case,

drive on the shoulder of the tog-

gle lever (Fig. 52) pin with a small

punch to move the retaining plug part

way out of the case. Remove the plug

with a pair of pliers.

18.

To remove the toggle lever pin,

slide the toggle lever toward tlfe front

of the case. Cock the lever to one side

to apply pressure on the pin, then

move the toggle to the rear of the case

to move the pin outward. Repeat this

procedure until the pin can be re-

moved from the case. Lift the pawl

and toggle from the case as an assem-

bly.

19.

Remove the pawl and toggle

lever as an assembly.

20.

Position the new parking pawl

and link assembly, then install the

toggle lever pin and the plug.

21.

Secure the pawl to the case

with the pawl pin.

22.

Position a new gasket on the

front of the support and at the rear.

Hold them in place with transmission

fluid or vaseline.

23.

Make sure that the thrust wash-

er is in place, then position the sup-

port and output shaft in place making

sure that the pressure tubes are en-

tered in the case.

24.

Secure the extension housing to

the case with the attaching bolts.

25.

Install the main control valve

assembly.

26.

Adjust the front band.

27.

Adjust the rear band on a Fair-

lane,

Montego, Mustang or Cougar.

28.

Position the vacuum control rod

in the case. Install the vacuum dia-

phragm unit.

29.

Install the filter, transmission

pan and a new gasket.

30.

Connect the speedometer cable

to the extension housing.

31.

Raise the transmission high

enough to position the engine rear

support on the crossmember. Secure

the support with the attaching bolt.

32.

Lower the transmission and re-

move the jack. Install the two exten-

sion housing-to-engine rear support

attaching bolts.

33.

Connect the parking brake

cables to the equalizer.

34.

Install the driveshaft, then

lower the vehicle.

35.

On Ford and Meteor vehicles,

adjust the rear band.

36.

Fill the transmission to the cor-

rect level with the specified fluid.

Too/—

T6U-7657-A or 8,

7657-AA, or 7657 AB

EXTENSION HOUSING

REAR SEAL

FIG. 21—Installing Extension Housing Sealprocarmanuals.com

Page 358 of 413

07-03-18

FMX Transmission

07-03-18

Press

Rom

Handle

Tool - T64L-7003-A4

Tool - T64L.7003.B4

REMOVAL INSTALLATION

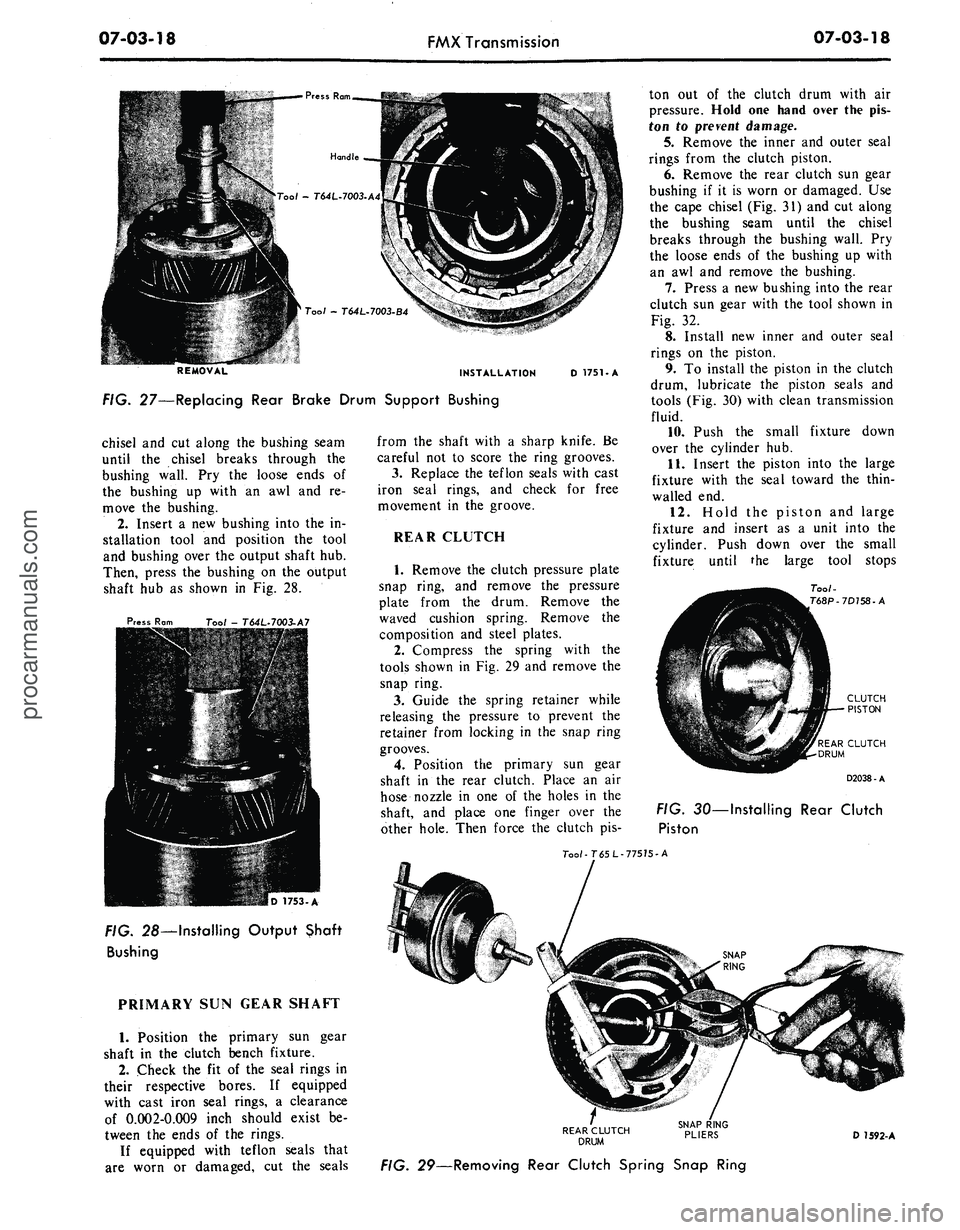

FIG. 27—Replacing Rear Brake Drum Support Bushing

D 1751-A

chisel

and cut

along

the

bushing seam

until

the

chisel breaks through

the

bushing wall.

Pry the

loose ends

of

the bushing

up

with

an awl and re-

move

the

bushing.

2.

Insert

a new

bushing into

the in-

stallation tool

and

position

the

tool

and bushing over

the

output shaft

hub.

Then, press

the

bushing

on the

output

shaft

hub as

shown

in Fig. 28.

Press

Ram

Tool - T64L-7003.A7

FIG. 28—Installing Output Shaft

Bushing

PRIMARY

SUN

GEAR SHAFT

1.

Position

the

primary

sun

gear

shaft

in the

clutch bench fixture.

2.

Check

the fit of the

seal rings

in

their respective bores.

If

equipped

with cast iron seal rings,

a

clearance

of 0.002-0.009 inch should exist

be-

tween

the

ends

of the

rings.

If equipped with teflon seals that

are worn

or

damaged,

cut the

seals

from

the

shaft with

a

sharp knife.

Be

careful

not to

score

the

ring grooves.

3.

Replace

the

teflon seals with cast

iron seal rings,

and

check

for

free

movement

in the

groove.

REAR CLUTCH

1.

Remove

the

clutch pressure plate

snap ring,

and

remove

the

pressure

plate from

the

drum. Remove

the

waved cushion spring. Remove

the

composition

and

steel plates.

2.

Compress

the

spring with

the

tools shown

in Fig. 29 and

remove

the

snap ring.

3.

Guide

the

spring retainer while

releasing

the

pressure

to

prevent

the

retainer from locking

in the

snap ring

grooves.

4.

Position

the

primary

sun

gear

shaft

in the

rear clutch. Place

an air

hose nozzle

in one of the

holes

in the

shaft,

and

place

one

finger over

the

other hole. Then force

the

clutch

pis-

ton

out of the

clutch drum with

air

pressure. Hold

one

hand over

the pis-

ton

to

prevent damage.

5.

Remove

the

inner

and

outer seal

rings from

the

clutch piston.

6. Remove

the

rear clutch

sun

gear

bushing

if it is

worn

or

damaged.

Use

the cape chisel

(Fig. 31) and cut

along

the bushing seam until

the

chisel

breaks through

the

bushing wall.

Pry

the loose ends

of the

bushing

up

with

an

awl and

remove

the

bushing.

7.

Press

a new

bushing into

the

rear

clutch

sun

gear with

the

tool shown

in

Fig.

32.

8. Install

new

inner

and

outer seal

rings

on the

piston.

9.

To

install

the

piston

in the

clutch

drum, lubricate

the

piston seals

and

tools

(Fig. 30)

with clean transmission

fluid.

10.

Push

the

small fixture down

over

the

cylinder

hub.

11.

Insert

the

piston into

the

large

fixture with

the

seal toward

the

thin-

walled

end.

12.

Hold

the

piston

and

large

fixture

and

insert

as a

unit into

the

cylinder. Push down over

the

small

fixture until

the

large tool stops

Too/-

T68P-7D758-A

REAR CLUTCH

DRUM

D2038-A

FIG.

30—

Installing

Rear Clutch

Piston

Too/-T65L-77575-A

REAR CLUTCH

DRUM

D 1592-A

FIG. 29—Removing Rear Clutch Spring Snap Ringprocarmanuals.com

Page 361 of 413

07-03-21

FMX Transmission

07-03-21

Tool—1175-AB

Tool— T50T-100-A

D1962-A

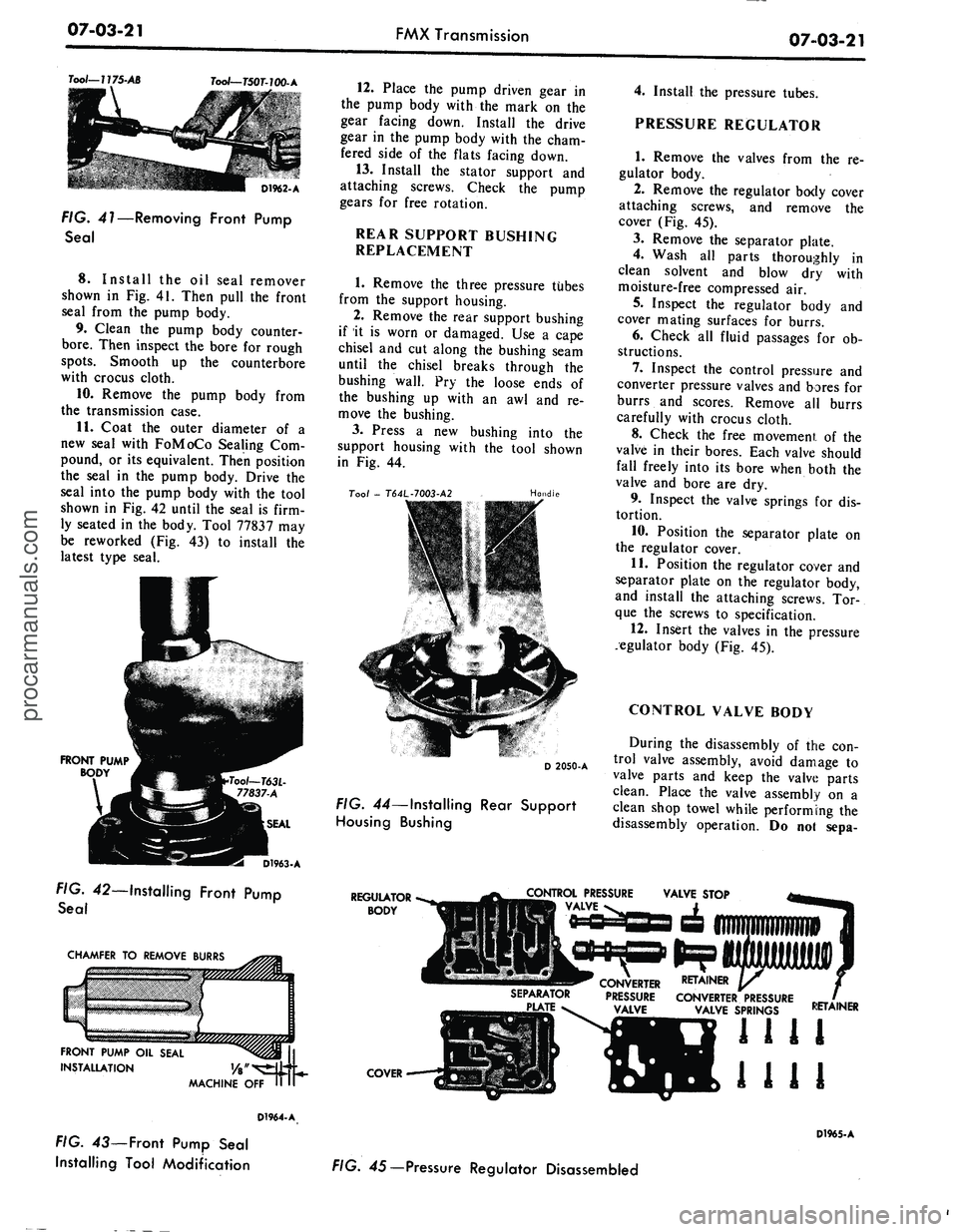

FIG. 41—Removing Front Pump

Seal

8. Install

the oil

seal remover

shown

in Fig. 41.

Then pull

the

front

seal from

the

pump body.

9. Clean

the

pump body counter-

bore.

Then inspect

the

bore

for

rough

spots.

Smooth

up the

counterbore

with crocus cloth.

10.

Remove

the

pump body from

the transmission case.

11.

Coat

the

outer diameter

of a

new seal with FoMoCo Sealing

Com-

pound,

or its

equivalent. Then position

the seal

in the

pump body. Drive

the

seal into

the

pump body with

the

tool

shown

in Fig. 42

until

the

seal

is

firm-

ly seated

in the

body. Tool 77837

may

be reworked

(Fig. 43) to

install

the

latest type seal.

FRONT PUMP

BODY

D1963-A

FIG. 42—Installing Front Pump

Seal

CHAMFER

TO

REMOVE BURRS

FRONT PUMP

OIL

SEAL

INSTALLATION

MACHINE

OFF

D1964-A

FIG.

43—

Front Pump Seal

Installing Tool Modification

12.

Place

the

pump driven gear

in

the pump body with

the

mark

on the

gear facing down. Install

the

drive

gear

in the

pump body with

the

cham-

fered side

of the

flats facing down.

13.

Install

the

stator support

and

attaching screws. Check

the

pump

gears

for

free rotation.

REAR SUPPORT BUSHING

REPLACEMENT

1.

Remove

the

three pressure tubes

from

the

support housing.

2.

Remove

the

rear support bushing

if

it is

worn

or

damaged.

Use a

cape

chisel

and cut

along

the

bushing seam

until

the

chisel breaks through

the

bushing wall.

Pry the

loose ends

of

the bushing

up

with

an awl and re-

move

the

bushing.

3.

Press

a new

bushing into

the

support housing with

the

tool shown

in

Fig. 44.

Too/

-

T64L-7003-A2

Handle

D 2050-A

FIG. 44—Installing Rear Support

Housing Bushing

4.

Install

the

pressure tubes.

PRESSURE REGULATOR

1.

Remove

the

valves from

the re-

gulator body.

2.

Remove

the

regulator body cover

attaching screws,

and

remove

the

cover

(Fig. 45).

3.

Remove

the

separator plate.

4.

Wash

all

parts thoroughly

in

clean solvent

and

blow

dry

with

moisture-free compressed

air.

5.

Inspect

the

regulator body

and

cover mating surfaces

for

burrs.

6. Check

all

fluid passages

for ob-

structions.

7.

Inspect

the

control pressure

and

converter pressure valves

and

bores

for

burrs

and

scores. Remove

all

burrs

carefully with crocus cloth.

8. Check

the

free movement

of the

valve

in

their bores. Each valve should

fall freely into

its

bore when both

the

valve

and

bore

are dry.

9. Inspect

the

valve springs

for dis-

tortion.

10.

Position

the

separator plate

on

the regulator cover.

11.

Position

the

regulator cover

and

separator plate

on the

regulator body,

and install

the

attaching screws.

Tor-

que

the

screws

to

specification.

12.

Insert

the

valves

in the

pressure

regulator body

(Fig. 45).

CONTROL VALVE BODY

During

the

disassembly

of the con-

trol valve assembly, avoid damage

to

valve parts

and

keep

the

valve parts

clean. Place

the

valve assembly

on a

clean shop towel while performing

the

disassembly operation.

Do not

sepa-

REGULATOR

BODY

CONTROL PRESSURE

VALVE

SEPARATOR

CONVERTER RETAINER

PRESSURE CONVERTER PRESSURE

VALVE SPRINGS

COVER

RETAINER

1111

1111

D1965-A

FIG. 45— Pressure Regulator Disassembledprocarmanuals.com

Page 366 of 413

07-03-26

FMX Transmission

07-03-26

MANUAL SHAFT

AND LEVER

DETENT SPRING—«^ DETENT PLUNGER

DETENT

/ LEVER

MANUAL SHAFT

NUT

INNER DOWNSHIFT LEVER

/ DOWNSHIFT

/ SHAFT

NUT

TOGGLE LIFT

ijG

LEVER SPRING

TOGGLE LEVER-

PAWL RETURN SPRING-

TOGGLE LEVER

PIN-

PLUG'

D1967-A

FIG. 52—Transmission Case Control Linkage

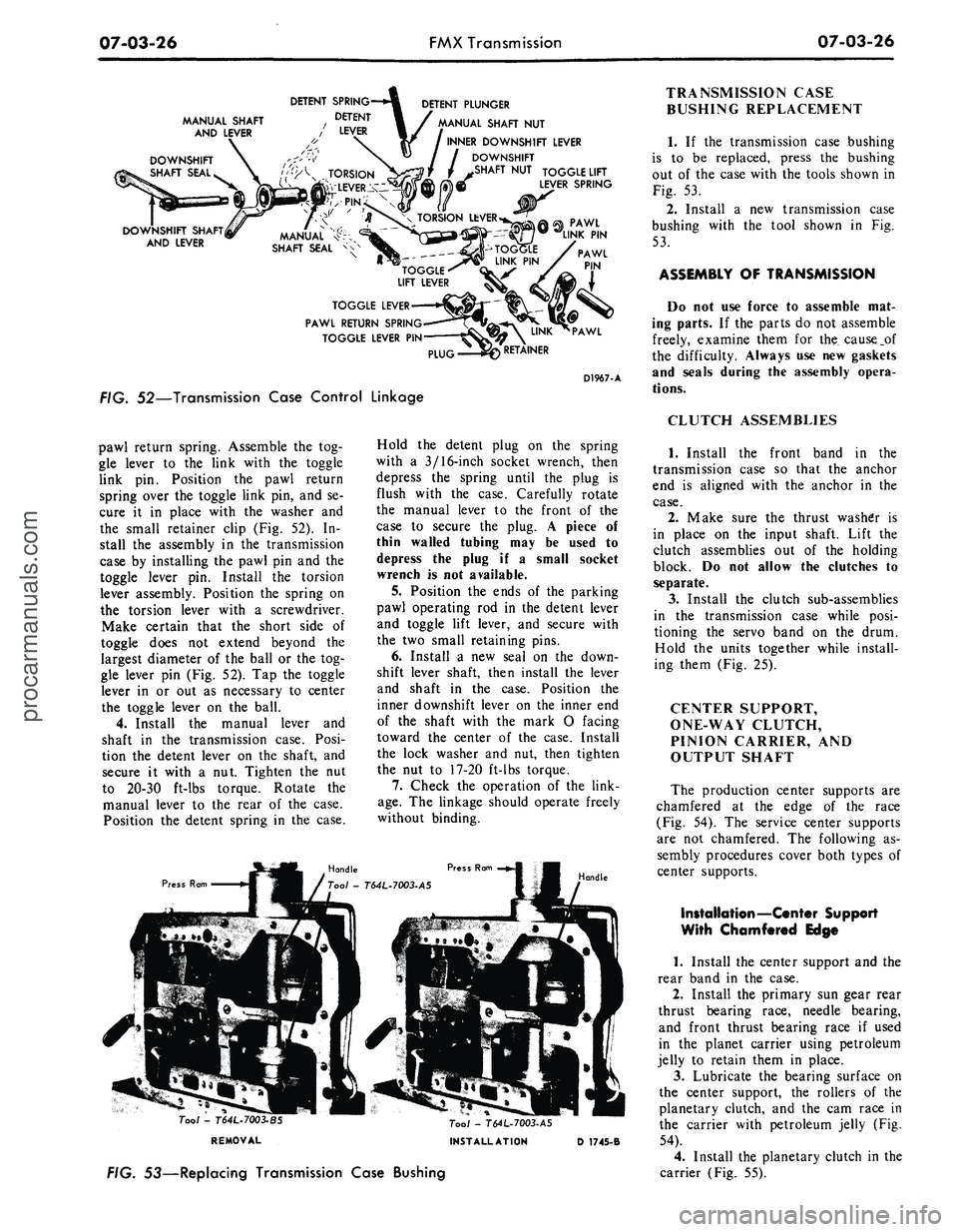

pawl return spring. Assemble

the tog-

gle lever

to the

link with

the

toggle

link

pin.

Position

the

pawl return

spring over

the

toggle link pin,

and se-

cure

it in

place with

the

washer

and

the small retainer clip

(Fig. 52). In-

stall

the

assembly

in the

transmission

case

by

installing

the

pawl

pin and the

toggle lever

pin.

Install

the

torsion

lever assembly. Position

the

spring

on

the torsion lever with

a

screwdriver.

Make certain that

the

short side

of

toggle does

not

extend beyond

the

largest diameter

of the

ball

or the

tog-

gle lever

pin

(Fig. 52).

Tap the

toggle

lever

in or out as

necessary

to

center

the toggle lever

on the

ball.

4.

Install

the

manual lever

and

shaft

in the

transmission case. Posi-

tion

the

detent lever

on the

shaft,

and

secure

it

with

a nut.

Tighten

the nut

to 20-30 ft-lbs torque. Rotate

the

manual lever

to the

rear

of the

case.

Position

the

detent spring

in the

case.

Press Ram

Hold

the

detent plug

on the

spring

with

a

3/16-inch socket wrench, then

depress

the

spring until

the

plug

is

flush with

the

case. Carefully rotate

the manual lever

to the

front

of the

case

to

secure

the

plug.

A

piece

of

thin walled tubing

may be

used

to

depress

the

plug

if a

small socket

wrench

is not

available.

5.

Position

the

ends

of the

parking

pawl operating

rod in the

detent lever

and toggle lift lever,

and

secure with

the

two

small retaining pins.

6. Install

a new

seal

on the

down-

shift lever shaft, then install

the

lever

and shaft

in the

case. Position

the

inner downshift lever

on the

inner

end

of

the

shaft with

the

mark

O

facing

toward

the

center

of the

case. Install

the lock washer

and nut,

then tighten

the

nut to

17-20 ft-lbs torque.

7.

Check

the

operation

of the

link-

age.

The

linkage should operate freely

without binding.

Handle

Tool -

T64L.7003-BS

REMOVAL

Tool - T64L-7003-A5

INSTALLATION

D 1745-B

FIG. 53—Replacing Transmission Case Bushing

TRANSMISSION CASE

BUSHING REPLACEMENT

1.

If the

transmission case bushing

is

to be

replaced, press

the

bushing

out

of the

case with

the

tools shown

in

Fig.

53.

2.

Install

a new

transmission case

bushing with

the

tool shown

in Fig.

53.

ASSEMBLY

OF

TRANSMISSION

Do

not use

force

to

assemble

mat-

ing parts.

If the

parts

do not

assemble

freely, examine them

for the

cause_pf

the difficulty. Always

use new

gaskets

and seals during

the

assembly opera-

tions.

CLUTCH ASSEMBLIES

1.

Install

the

front band

in the

transmission case

so

that

the

anchor

end

is

aligned with

the

anchor

in the

case.

2.

Make sure

the

thrust washer

is

in place

on the

input shaft. Lift

the

clutch assemblies

out of the

holding

block.

Do not

allow

the

clutches

to

separate.

3.

Install

the

clutch sub-assemblies

in

the

transmission case while posi-

tioning

the

servo band

on the

drum.

Hold

the

units together while install-

ing them (Fig.

25).

CENTER SUPPORT,

ONE-WAY CLUTCH,

PINION CARRIER,

AND

OUTPUT SHAFT

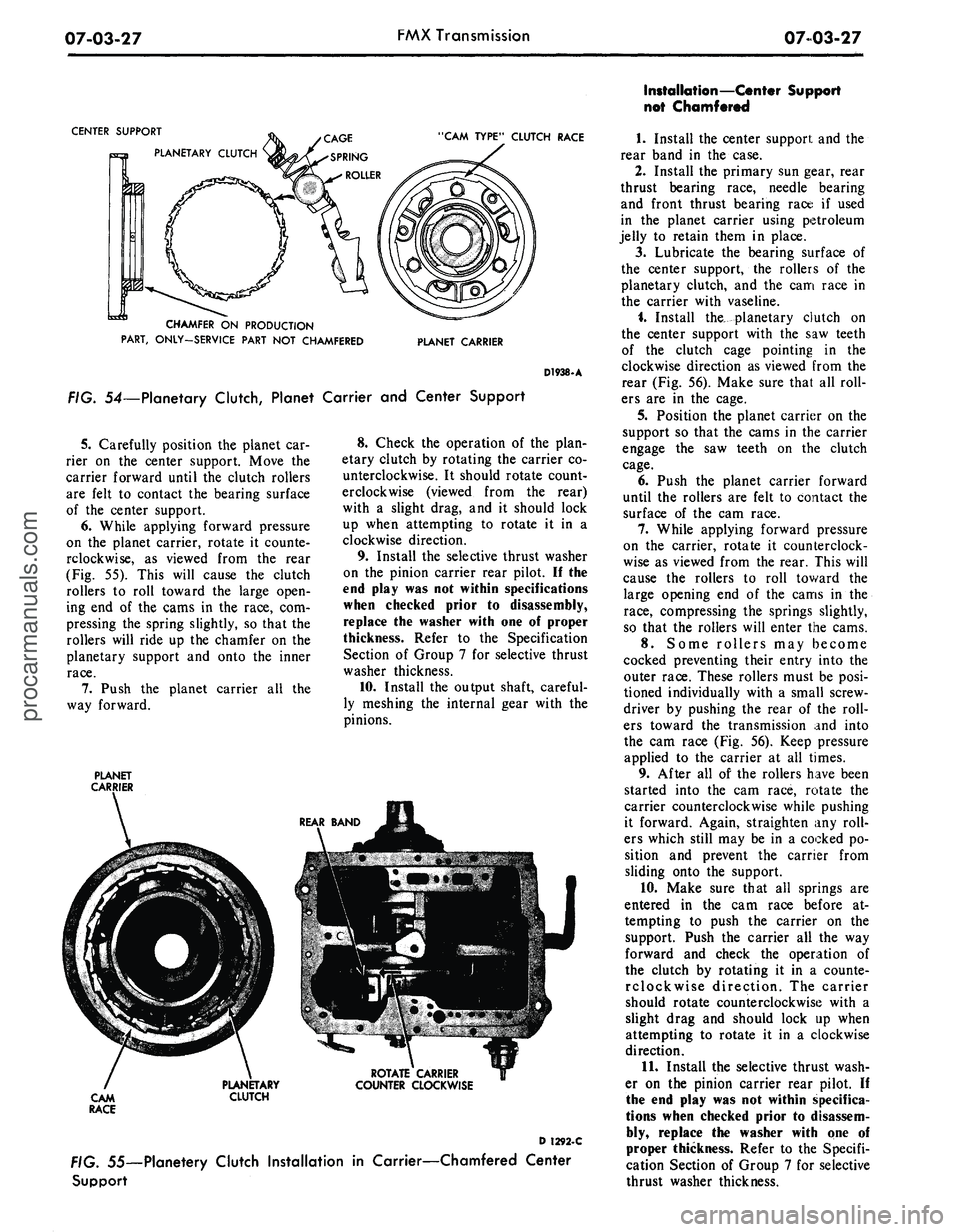

The production center supports

are

chamfered

at the

edge

of the

race

(Fig.

54). The

service center supports

are

not

chamfered.

The

following

as-

sembly procedures cover both types

of

center supports.

Installation—Center Support

With Chamfered Edge

1.

Install

the

center support

and the

rear band

in the

case.

2.

Install

the

primary

sun

gear rear

thrust bearing race, needle bearing,

and front thrust bearing race

if

used

in

the

planet carrier using petroleum

jelly

to

retain them

in

place.

3.

Lubricate

the

bearing surface

on

the center support,

the

rollers

of the

planetary clutch,

and the cam

race

in

the carrier with petroleum jelly

(Fig.

54).

4.

Install

the

planetary clutch

in the

carrier (Fig.

55).procarmanuals.com

Page 367 of 413

07-03-27

FMX Transmission

0703-27

CENTER SUPPORT

PLANETARY CLUTCH

"CAM TYPE" CLUTCH RACE

CHAMFER ON PRODUCTION

PART, ONLY-SERVICE PART NOT CHAMFERED

PLANET CARRIER

D1938-A

FIG. 54—Planetary Clutch, Planet Carrier and Center Support

5.

Carefully position the planet car-

rier on the center support. Move the

carrier forward until the clutch rollers

are felt to contact the bearing surface

of the center support.

6. While applying forward pressure

on the planet carrier, rotate it counte-

rclockwise, as viewed from the rear

(Fig. 55). This will cause the clutch

rollers to roll toward the large open-

ing end of the cams in the race, com-

pressing the spring slightly, so that the

rollers will ride up the chamfer on the

planetary support and onto the inner

race.

7.

Push the planet carrier all the

way forward.

PLANET

CARRIER

8. Check the operation of the plan-

etary clutch by rotating the carrier co-

unterclockwise. It should rotate count-

erclockwise (viewed from the rear)

with a slight drag, and it should lock

up when attempting to rotate it in a

clockwise direction.

9. Install the selective thrust washer

on the pinion carrier rear pilot. II the

end play was not within specifications

when checked prior to disassembly,

replace the washer with one of proper

thickness. Refer to the Specification

Section of Group 7 for selective thrust

washer thickness.

10.

Install the output shaft, careful-

ly meshing the internal gear with the

pinions.

ROTATE CARRIER

COUNTER CLOCKWISE

D 1292-C

. 55—Planetery Clutch Installation in Carrier—Chamfered Center

Support

Installation—Center Support

not Chamfered

1.

Install the center support and the

rear band in the case.

2.

Install the primary sun gear, rear

thrust bearing race, needle bearing

and front thrust bearing race if used

in the planet carrier using petroleum

jelly to retain them in place.

3.

Lubricate the bearing surface of

the center support, the rollers of the

planetary clutch, and the cam race in

the carrier with vaseline.

i. Install the^ planetary clutch on

the center support with the saw teeth

of the clutch cage pointing in the

clockwise direction as viewed from the

rear (Fig. 56). Make sure that all roll-

ers are in the cage.

5.

Position the planet carrier on the

support so that the cams in the carrier

engage the saw teeth on the clutch

cage.

6. Push the planet carrier forward

until the rollers are felt to contact the

surface of the cam race.

7.

While applying forward pressure

on the carrier, rotate it counterclock-

wise as viewed from the rear. This will

cause the rollers to roll toward the

large opening end of the cams in the

race,

compressing the springs slightly,

so that the rollers will enter the cams.

8. Some rollers may become

cocked preventing their entry into the

outer race. These rollers must be posi-

tioned individually with a small screw-

driver by pushing the rear of the roll-

ers toward the transmission and into

the cam race (Fig. 56). Keep pressure

applied to the carrier at all times.

9. After all of the rollers have been

started into the cam race, rotate the

carrier counterclockwise while pushing

it forward. Again, straighten any roll-

ers which still may be in a cocked po-

sition and prevent the carrier from

sliding onto the support.

10.

Make sure that all springs are

entered in the cam race before at-

tempting to push the carrier on the

support. Push the carrier all the way

forward and check the operation of

the clutch by rotating it in a counte-

rclockwise direction. The carrier

should rotate counterclockwise with a

slight drag and should lock up when

attempting to rotate it in a clockwise

direction.

11.

Install the selective thrust wash-

er on the pinion carrier rear pilot. If

the end play was not within specifica-

tions when checked prior to disassem-

bly, replace the washer with one of

proper thickness. Refer to the Specifi-

cation Section of Group 7 for selective

thrust washer thickness.procarmanuals.com