horn FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 115 of 413

03-05-02

Steering Columns

And

Linkage

03-05-02

which also will shear away during

im-

pact.

TILT STEERING COLUMNS

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed.

The tilt column features nine driv-

ing positions (four

up and

four down

from

a

center position).

The

.column

also features

a

turn signal switch with

a lane-changer position turn indicating

position

and

emergency warning flash-

er control.

TILT-AWAY STEERING COLUMNS

The tilt-away steering column

fea-

tures nine driving positions (four

up

and four down from

a

center position)

and

a

tilt-away position that

is

auto-

matically accomplished

on

Mustang

and Cougar models when

the

ignition

key

is

turned

to the

OFF

position

and

the left door

is

opened.

On

Thunder-

bird models,

the

tilt-away occurs when

the shift lever

is

placed

in

PARK

and

the driverns door

is

opened.

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed along with mounting

brackets which will also shear away

during impact.

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

STEERING WHEEL SPOKE

POSITION ADJUSTMENT

When

the

steering gear

is on the

high point,

the

front wheels should

be

in

the

straight-ahead position

and the

steering wheel spokes should

be in

their normal position with

the

Pitman

arm pointing directly forward.

If the

spokes

are not in

their normal posi-

tion, they

can be

adjusted without

dis-

turbing

the

toe-in adjustment (Part

3-1).

STEERING WHEEL

REPLACEMENT

1.

Disconnect

the

negative cable

from

the

battery.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

crash

pad

attaching screws. Lift

the

crash

pad

from

the

wheel.

(On

Conti-

nental Mark

III

models,

pry out the

crash

pad

insert

and

remove

the two

screws that secure

the

crash

pad. Re-

move

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

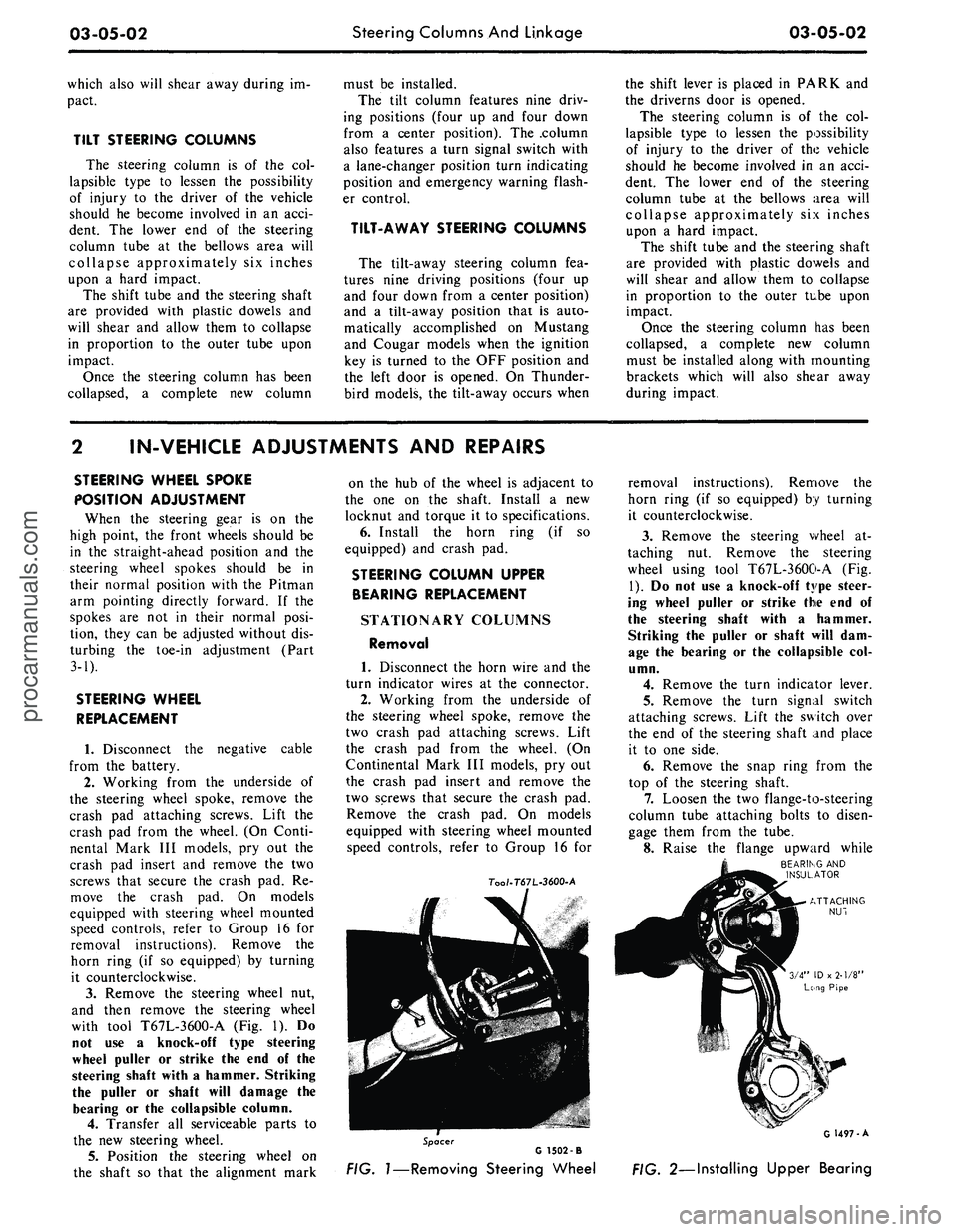

3.

Remove

the

steering wheel

nut,

and then remove

the

steering wheel

with tool T67L-3600-A

(Fig. 1). Do

not

use a

knock-off type steering

wheel puller

or

strike

the end of the

steering shaft with

a

hammer. Striking

the puller

or

shaft will damage

the

bearing

or the

collapsible column.

4.

Transfer

all

serviceable parts

to

the

new

steering wheel.

5.

Position

the

steering wheel

on

the shaft

so

that

the

alignment mark

on

the hub of the

wheel

is

adjacent

to

the

one on the

shaft. Install

a new

locknut

and

torque

it to

specifications.

6. Install

the

horn ring

(if so

equipped)

and

crash

pad.

STEERING COLUMN UPPER

BEARING REPLACEMENT

STATIONARY COLUMNS

Removal

1. Disconnect

the

horn wire

and the

turn indicator wires

at the

connector.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

two crash

pad

attaching screws. Lift

the crash

pad

from

the

wheel.

(On

Continental Mark

III

models,

pry out

the crash

pad

insert

and

remove

the

two screws that secure

the

crash

pad.

Remove

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

7oo/-T67L-3600-A

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

at-

taching

nut.

Remove

the

steering

wheel using tool T67L-3600-A

(Fig.

1).

Do not use a

knock-off type steer-

ing wheel puller

or

strike

the end of

the steering shaft with

a

hammer.

Striking

the

puller

or

shaft will

dam-

age

the

bearing

or the

collapsible

col-

umn.

4.

Remove

the

turn indicator lever.

5.

Remove

the

turn signal switch

attaching screws. Lift

the

switch over

the

end of the

steering shaft

and

place

it

to one

side.

6. Remove

the

snap ring from

the

top

of the

steering shaft.

7.

Loosen

the two

flange-to-steering

column tube attaching bolts

to

disen-

gage them from

the

tube.

8. Raise

the

flange upward while

BEARING

AND

INSULATOR

Spacer

G 1502 -B

FIG.

1—Removing

Steering Wheel

G 1497-A

FIG. 2—Installing Upper Bearingprocarmanuals.com

Page 116 of 413

03-05-03

Steering Columns And Linkage

03-05-03

tapping the steering shaft lightly with

a plastic hammer to free the bearing

and flange from the shaft.

9. Remove the bearing and insula-

tor from the flange.

Installation

1.

Install flange bolts (square head)

in flange if they were removed. Turn

the nuts onto the bolts one complete

turn only.

2.

Position the flange onto the

steering column tube.

3.

Engage the two flange bolt heads

with the square holes in the column

tube,

then tighten the two attaching

nuts to specification.

4.

Position the bearing and insula-

tor on the shaft. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of the shaft and install

the steering wheel attaching nut (Fig.

2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws.

7.

Make certain that the wheels are

in the straight ahead position. Place

the steering wheel on the steering

shaft with the spokes in the horizontal

position. Install and torque the attach-

ing nut to specification.

8. Secure the crash pad to the

steering wheel with the two attaching

screws.

9. Connect the horn and turn signal

wires.

10.

Install the turn signal lever.

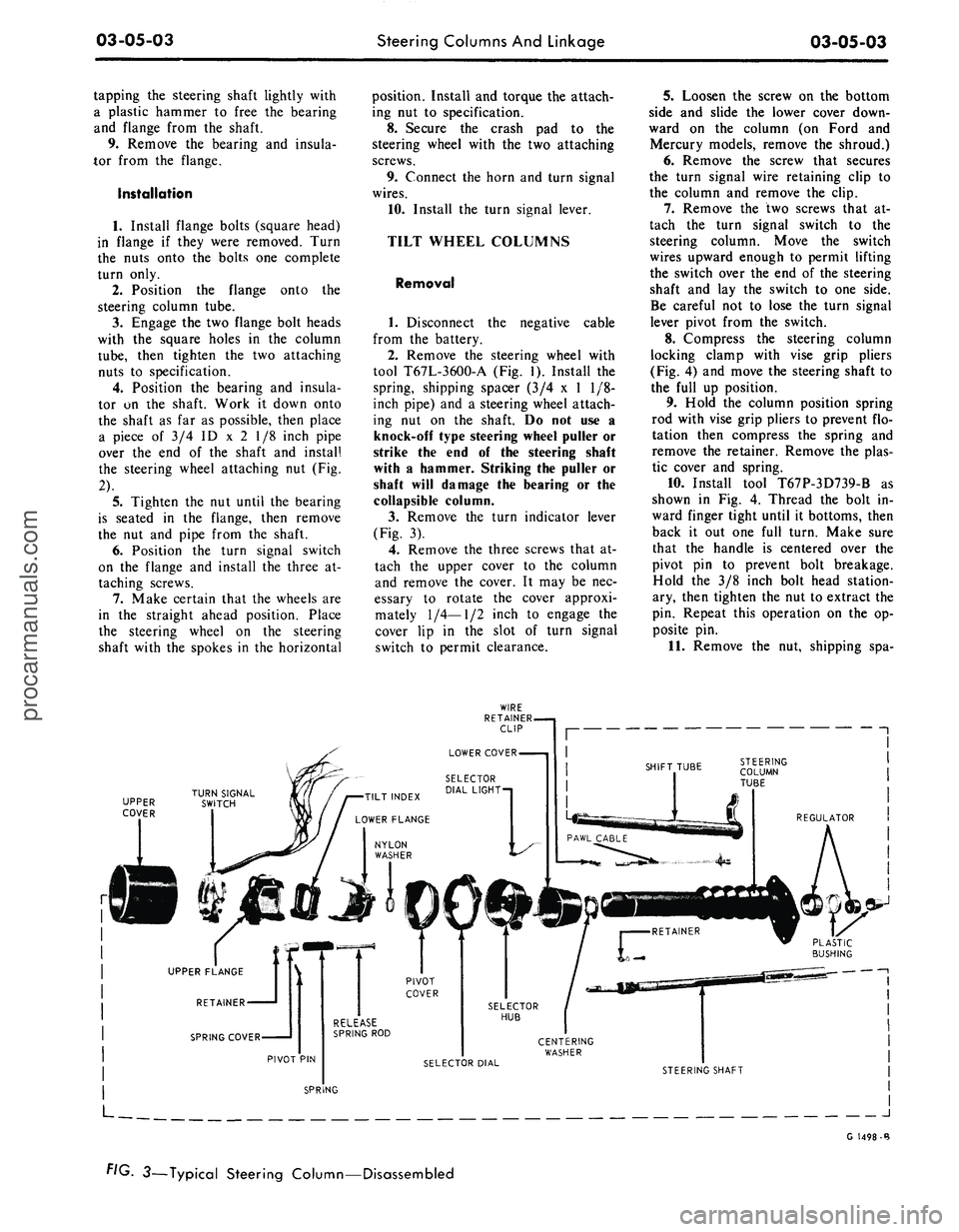

TILT WHEEL COLUMNS

Removal

1.

Disconnect the negative cable

from the battery.

2.

Remove the steering wheel with

tool T67L-3600-A (Fig. 1). Install the

spring, shipping spacer (3/4 x 1 1/8-

inch pipe) and a steering wheel attach-

ing nut on the shaft. Do not use a

knock-off type steering wheel puller or

strike the end of the steering shaft

with a hammer. Striking the puller or

shaft will damage the bearing or the

collapsible column.

3.

Remove the turn indicator lever

(Fig. 3).

4.

Remove the three screws that at-

tach the upper cover to the column

and remove the cover. It may be nec-

essary to rotate the cover approxi-

mately

1/4—1/2

inch to engage the

cover lip in the slot of turn signal

switch to permit clearance.

5.

Loosen the screw on the bottom

side and slide the lower cover down-

ward on the column (on Ford and

Mercury models, remove the shroud.)

6. Remove the screw that secures

the turn signal wire retaining clip to

the column and remove the clip.

7.

Remove the two screws that at-

tach the turn signal switch to the

steering column. Move the switch

wires upward enough to permit lifting

the switch over the end of the steering

shaft and lay the switch to one side.

Be careful not to lose the turn signal

lever pivot from the switch.

8. Compress the steering column

locking clamp with vise grip pliers

(Fig. 4) and move the steering shaft to

the full up position.

9. Hold the column position spring

rod with vise grip pliers to prevent flo-

tation then compress the spring and

remove the retainer. Remove the plas-

tic cover and spring.

10.

Install tool T67P-3D739-B as

shown in Fig. 4. Thread the bolt in-

ward finger tight until it bottoms, then

back it out one full turn. Make sure

that the handle is centered over the

pivot pin to prevent bolt breakage.

Hold the 3/8 inch bolt head station-

ary, then tighten the nut to extract the

pin. Repeat this operation on the op-

posite pin.

11.

Remove the nut, shipping spa-

UPPER

COVER

J

G 1498-B

FIG. 3—Typical Steering Column—Disassembledprocarmanuals.com