rims FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 73 of 413

03-01-08

Suspension

—

Steering,

Wheels

And

Tires

—

General Service

03-01-08

3.

Remove the lower (upper on

Mustang and Cougar) cover- to-

housing attaching bolt.

4.

With a clean punch or like in-

strument, clean out or push inward

the loose lubricant in the filler plug

hole and cover to housing attaching

bolt hole.

5.

Slowly turn the steering wheel to

the left stop, lubricant should rise

within the lower cover bolt hole; then

slowly turn the steering wheel to the

right stop, lubricant should rise within

the filler plug hole. If lubricant does

not rise in both the cover bolt hole

and the filler plug hole, add lubricant

until it comes out both holes during

this check.

6. Install the lower (upper on

Mustang and Cougar) cover- to-

housing attaching bolt and the filler

plug.

CLEANING

AND

INSPECTION

FRONT

END

GENERAL

INSPECTION

Do not check and adjust front

wheel alignment without first making

the following inspection for front-end

damage, or wear.

1.

Check for specified air pressures

in all four tires.

2.

Raise the front of the vehicle off

the floor. Shake each front wheel

grasping the upper and lower surfaces

of the tire. Check the front suspension

ball joints and mountings for loose-

ness,

wear, and damage. Check the

brake backing plate mountings. Tor-

que all loose nuts and bolts to specifi-

cation. Replace all worn parts as out-

lined in Part 3-2.

3.

Check the steering gear mount-

ings and all steering linkage connec-

tions for looseness. Torque all mount-

ings to specifications. If any of the

linkage is worn or bent, replace the

parts as outlined in Part 3-5.

4.

Check the front wheel bearings.

If any in-and-out free play is noticed,

adjust the bearings to specifications.

Replace worn or damaged bearings as

outlined in Part 3-12.

5.

Spin each front wheel with a

wheel spinner, and check and balance

each wheel as required.

6. Check the action of the shock

absorbers. If the shock absorbers are

not in good condition, the vehicle may

not settle in a normal, level position,

and front wheel alignment may be af-

fected.

WHEEL INSPECTION

Wheel hub nuts should be inspected

and tightened to specification at pre-

delivery. Loose wheel hub nuts may

cause shimmy and vibration. Elongat-

ed stud holes in the wheels may also

result from loose hub nuts.

Keep the wheels and hubs clean.

Stones wedged between the wheel and

drum and lumps of mud or grease can

unbalance a wheel and tire.

Check for damage that would affect

the runout of the wheels. Wobble or

shimmy caused by a damaged wheel

will eventually damage the wheel bear-

ings.

Inspect the wheel rims for dents

that could permit air to leak from the

tires.

UPPER BALL JOINT

INSPECTION

Ford,

Mercury,

Meteor,

Thunderbird,

Lincoln Continental

and

Continental Mark

III

1.

Raise the vehicle and place floor

jacks beneath the lower arms.

2.

Ask an assistant to grasp the

lower edge of the tire and move the

wheel in and out.

3.

As the wheel is being moved in

and out, observe the upper end of the

spindle and the upper arm.

4.

Any movement between the

upper end of the spindle and the upper

arm indicates ball joint wear and loss

of preload. If any such movement is

observed, replace the upper ball joint.

During

the

foregoing

check,

the

lower ball joint will

be

unloaded

and

may

move.

Disregard

all

such

move-

ment

of the

lower ball

joint.

Also,

do

not mistake loose wheel bearings

for a

worn ball

joint.

Cougar,

Fairlane,

Falcon,

Montego

and

Mustang

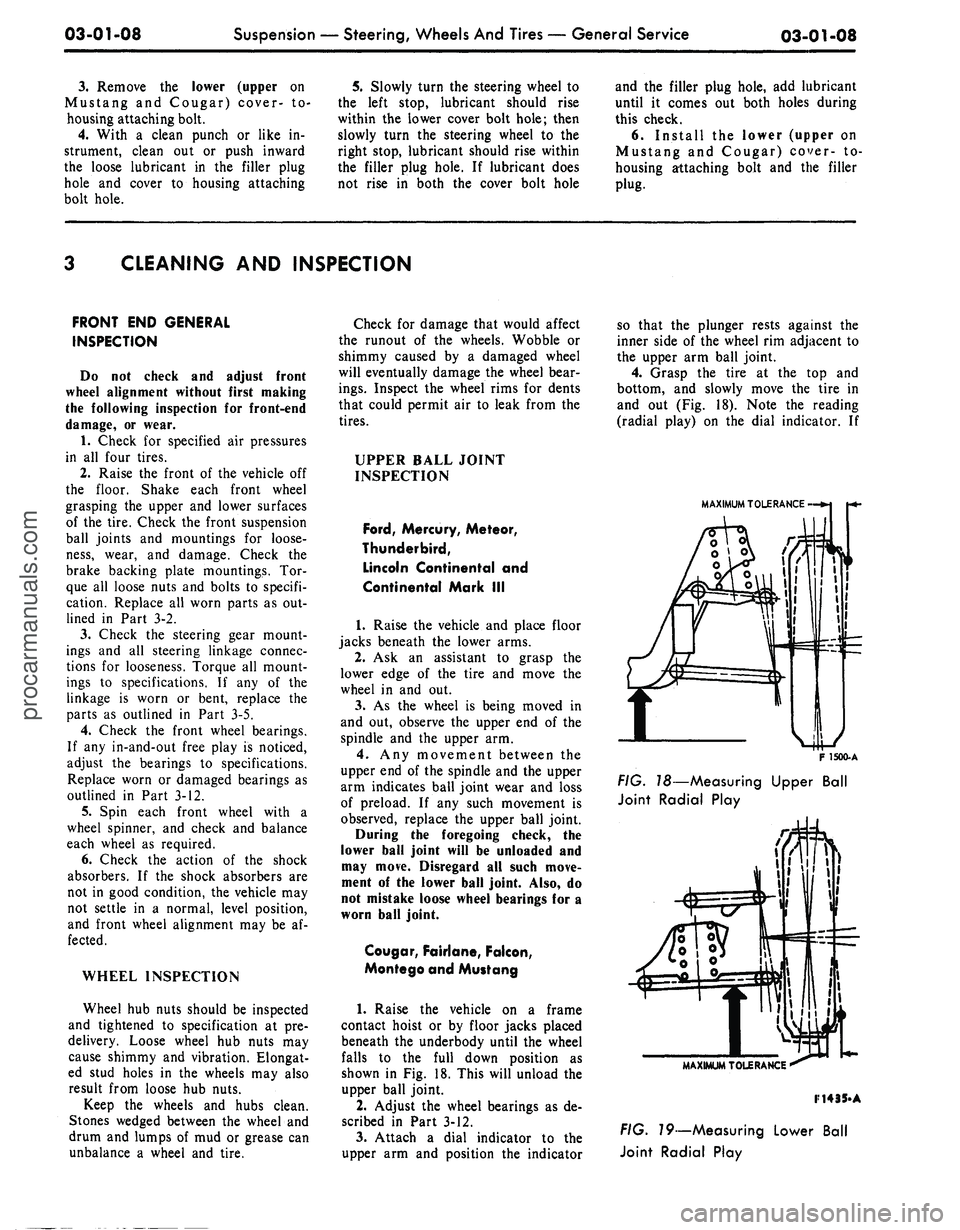

1.

Raise the vehicle on a frame

contact hoist or by floor jacks placed

beneath the underbody until the wheel

falls to the full down position as

shown in Fig. 18. This will unload the

upper ball joint.

2.

Adjust the wheel bearings as de-

scribed in Part 3-12.

3.

Attach a dial indicator to the

upper arm and position the indicator

so that the plunger rests against the

inner side of the wheel rim adjacent to

the upper arm ball joint.

4.

Grasp the tire at the top and

bottom, and slowly move the tire in

and out (Fig. 18). Note the reading

(radial play) on the dial indicator. If

MAXIMUM TOLERANCE

F

1500-A

FIG.

T8—Measuring Upper Ball

Joint Radial Play

MAXIMUM TOLERANCE

F14

35-A

FIG.

79—Measuring Lower Ball

Joint Radial Playprocarmanuals.com

Page 122 of 413

03-05-09

Steering Columns And Linkage

03-05-09

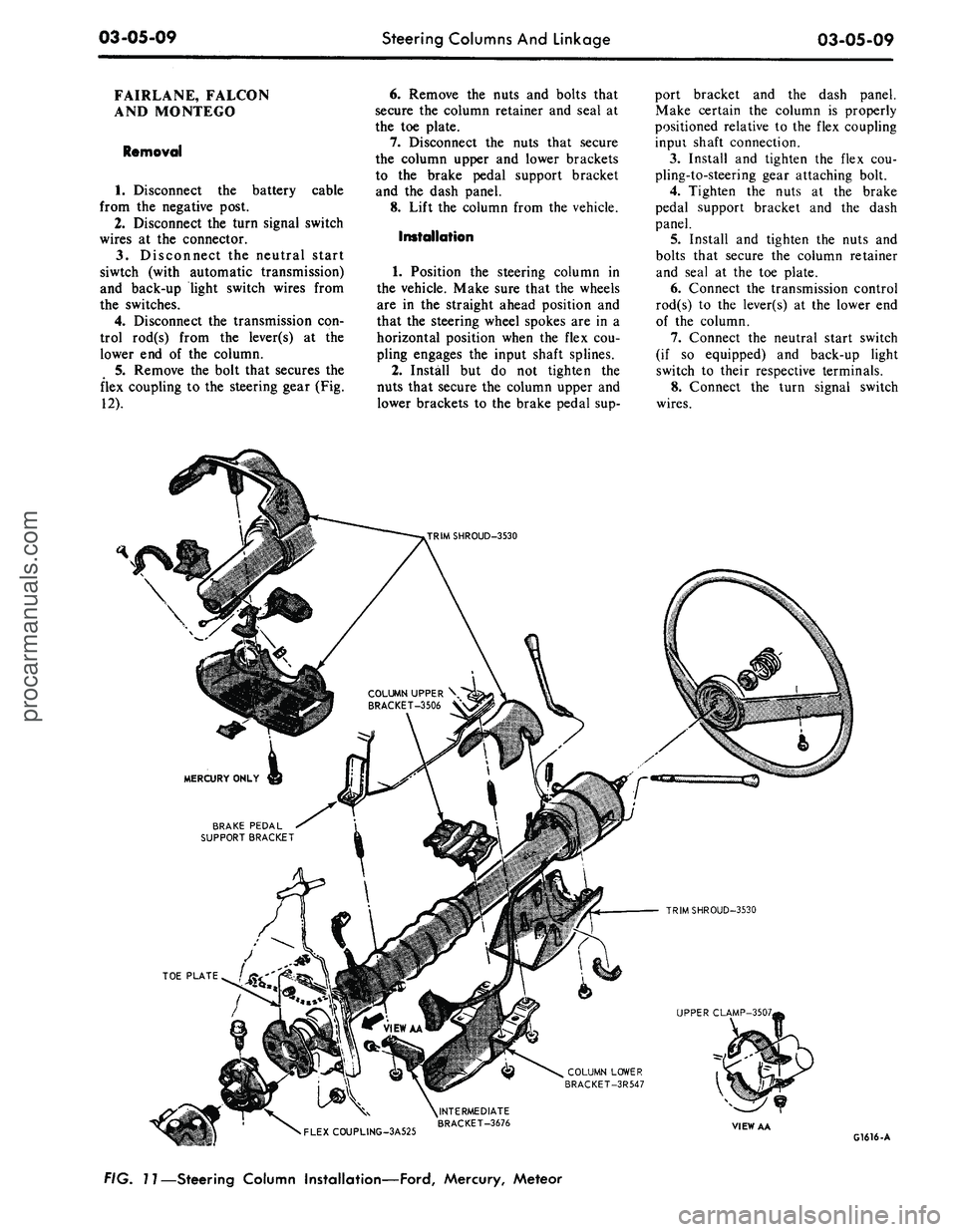

FAIRLANE, FALCON

AND MONTEGO

Removal

1.

Disconnect the battery cable

from the negative post.

2.

Disconnect the turn signal switch

wires at the connector.

3.

Disconnect the neutral start

siwtch (with automatic transmission)

and back-up light switch wires from

the switches.

4.

Disconnect the transmission con-

trol rod(s) from the lever(s) at the

lower end of the column.

5.

Remove the bolt that secures the

flex coupling to the steering gear (Fig.

12).

6. Remove the nuts and bolts that

secure the column retainer and seal at

the toe plate.

7.

Disconnect the nuts that secure

the column upper and lower brackets

to the brake pedal support bracket

and the dash panel.

8. Lift the column from the vehicle.

Installation

1.

Position the steering column in

the vehicle. Make sure that the wheels

are in the straight ahead position and

that the steering wheel spokes are in a

horizontal position when the flex cou-

pling engages the input shaft splines.

2.

Install but do not tighten the

nuts that secure the column upper and

lower brackets to the brake pedal sup-

port bracket and the dash panel.

Make certain the column is properly

positioned relative to the flex coupling

inpui shaft connection.

3.

Install and tighten the flex cou-

pling-to-steering gear attaching bolt.

4.

Tighten the nuts at the brake

pedal support bracket and the dash

panel.

5.

Install and tighten the nuts and

bolts that secure the column retainer

and seal at the toe plate.

6. Connect the transmission control

rod(s) to the lever(s) at the lower end

of the column.

7.

Connect the neutral start switch

(if so equipped) and back-up light

switch to their respective terminals.

8. Connect the turn signal switch

wires.

COLUMN UPPER \

BRACKET-3506 V

BRAKE PEDAL

SUPPORT BRACKET

TRIMSHROUD-3530

UPPER CLAMP-3507,

COLUMN LOWER

BRACKET-3R547

•

FLEXCOUPLING-3A525

^INTERMEDIATE

BRACKET-3676

VIEW AA

G1616-A

FIG. 11—Steering Column Installation—Ford, Mercury, Meteorprocarmanuals.com