steering wheel FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 13 of 413

02-01-02

Brakes

02*01-02

STEERING

WHEEL RIW

TOEBOARD

OR

DASH

METAL

CHECKING

POINTS

STEERING

COLUMN-

STEEL

MEASURING TAPE

VEHICLE

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FAIRLANE,

MONTEGO AND FALCON

FAIRLANE,

MONTEGO AND FALCON

MUSTANG

AND COUGAR

MUSTANG

AND COUGAR

THUNDERBIRD

CONTINENTAL

MARK III

LINCOLN

CONTINENTAL

TYPE

NON-POWER

DRUM

POWER

DRUM & DISC

NON-POWER

DISC

POLICE

POWER DISC

NON-POWER

DRUM

POWER

DISC

NON-POWER

DRUM

POWER

DISC

POWER

DISC

POWER

DISC

POWER

DISC

PEDAL

FREE

HEIGHT-A

8.09-7.17

6.18-5.99

8.65-7.82

7.58-6.72

8.13-6.91

7.25-5.71

7.49-6.43

6.25-5.56

PEDAL

FREE

HEIGHT-B"

5.96-5.04

5.96-5.04

6.50-5.50

PEDAL

TRAVEL-C

3.10

3.27

2.18

3.27

2.90

2.35

2.58

1.75

3.00

3.00

2.25

NOTE:AgB

DIMENSION TO BE MEASURED TO SHEET METAL

C

DIMENSION TO BE MEASURED PARALLEL TO THE VERTICAL CENTERLINE OF THE

STEERING

COLUMN WITH A 50 POUND LOAD APPLIED TO THE CENTERLINE OF THE

BRAKE

PEDAL PAD. (CHECKS ON POWER BRAKE VEHICLES MADE WITH ENGINE RUNNING

H1630-A

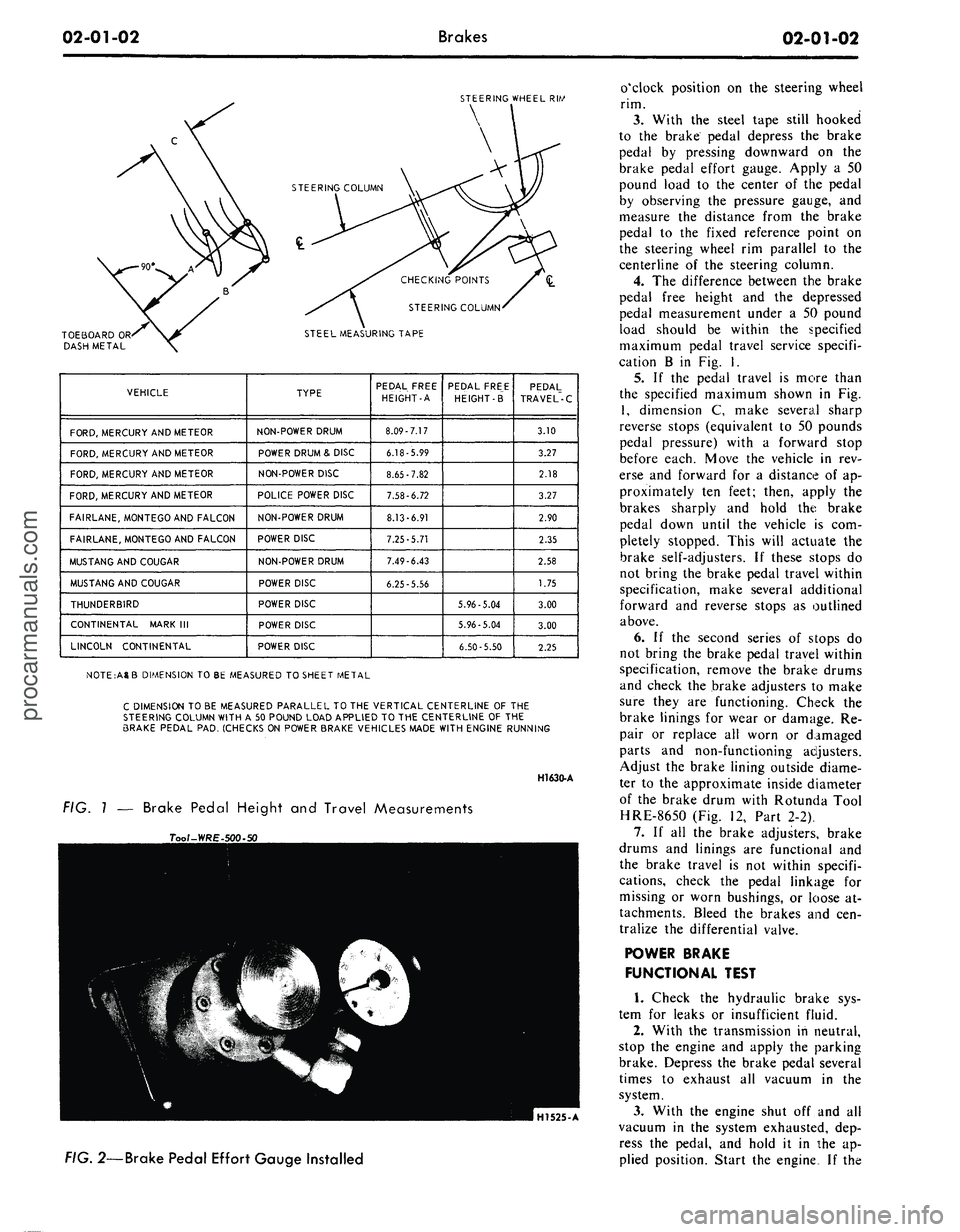

FIG. 1 — Brake Pedal Height and Travel Measurements

Tool-WRE-l

HI525-A

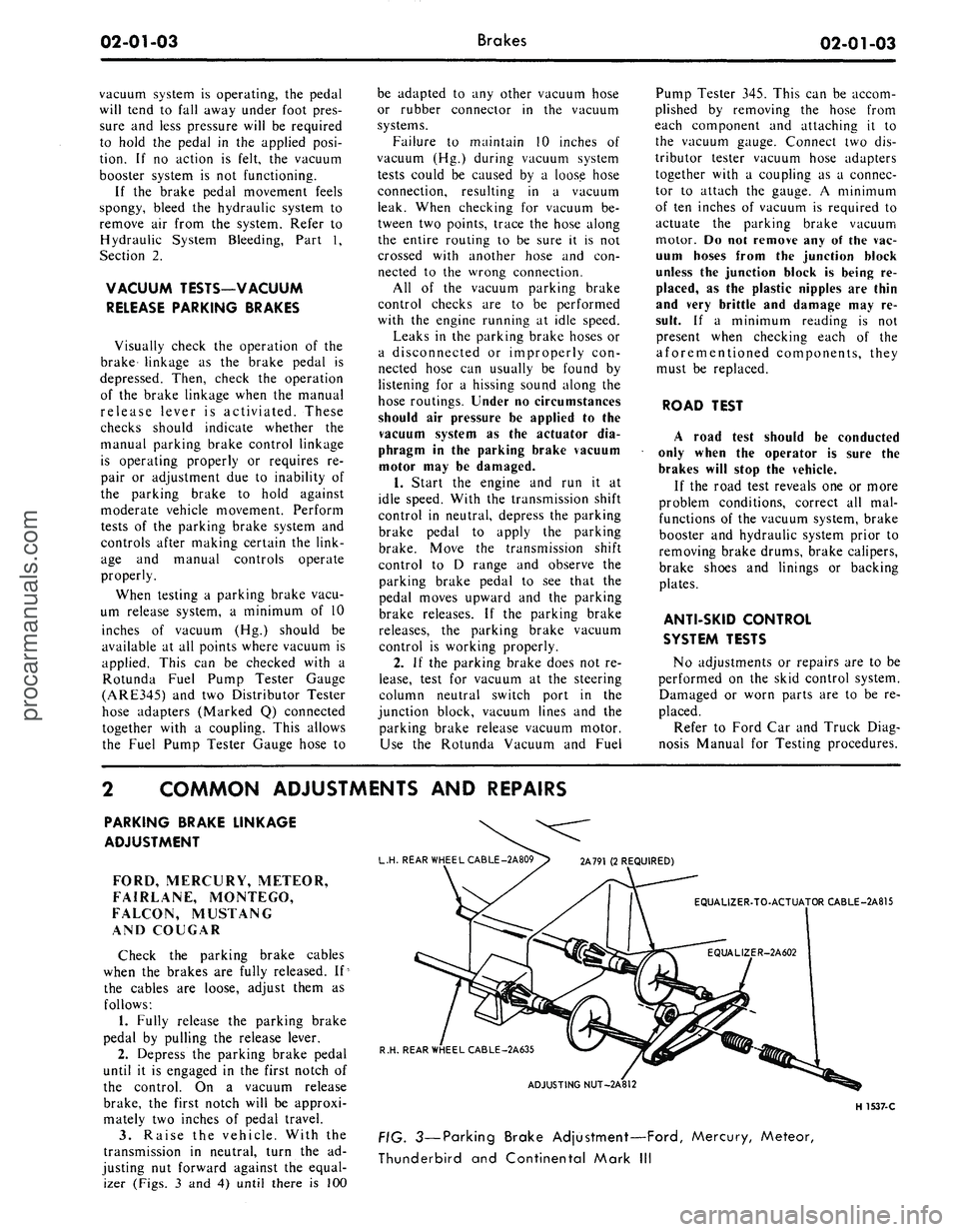

FIG.

2—Brake Pedal Effort Gauge Installed

o'clock position on the steering wheel

rim.

3.

With the steel tape still hooked

to the brake pedal depress the brake

pedal by pressing downward on the

brake pedal effort gauge. Apply a 50

pound load to the center of the pedal

by observing the pressure gauge, and

measure the distance from the brake

pedal to the fixed reference point on

the steering wheel rim parallel to the

centerline of the steering column.

4.

The difference between the brake

pedal free height and the depressed

pedal measurement under a 50 pound

load should be within the specified

maximum pedal travel service specifi-

cation B in Fig. I.

5.

If the pedal travel is more than

the specified maximum shown in Fig.

1,

dimension C, make several sharp

reverse stops (equivalent to 50 pounds

pedal pressure) with a forward stop

before each. Move the vehicle in rev-

erse and forward for a distance of ap-

proximately ten feet; then, apply the

brakes sharply and hold the brake

pedal down until the vehicle is com-

pletely stopped. This will actuate the

brake self-adjusters. If these stops do

not bring the brake pedal travel within

specification, make several additional

forward and reverse stops as outlined

above.

6. If the second series of stops do

not bring the brake pedal travel within

specification, remove the brake drums

and check the brake adjusters to make

sure they are functioning. Check the

brake linings for wear or damage. Re-

pair or replace all worn or damaged

parts and non-functioning adjusters.

Adjust the brake lining outside diame-

ter to the approximate inside diameter

of the brake drum with Rotunda Tool

HRE-8650 (Fig. 12, Part 2-2).

7.

If all the brake adjusters, brake

drums and linings are functional and

the brake travel is not within specifi-

cations, check the pedal linkage for

missing or worn bushings, or loose at-

tachments. Bleed the brakes and cen-

tralize the differential valve.

POWER BRAKE

FUNCTIONAL TEST

1.

Check the hydraulic brake sys-

tem for leaks or insufficient fluid.

2.

With the transmission in neutral,

stop the engine and apply the parking

brake. Depress the brake pedal several

times to exhaust all vacuum in the

system.

3.

With the engine shut off and all

vacuum in the system exhausted, dep-

ress the pedal, and hold it in the ap-

plied position. Start the engine If theprocarmanuals.com

Page 14 of 413

02-01-03

Brakes

02-01-03

vacuum system is operating, the pedal

will tend to fall away under foot pres-

sure and less pressure will be required

to hold the pedal in the applied posi-

tion. If no action is felt, the vacuum

booster system is not functioning.

If the brake pedal movement feels

spongy, bleed the hydraulic system to

remove air from the system. Refer to

Hydraulic System Bleeding, Part 1,

Section 2.

VACUUM TESTS—VACUUM

RELEASE PARKING BRAKES

Visually check the operation of the

brake linkage as the brake pedal is

depressed. Then, check the operation

of the brake linkage when the manual

release lever is activiated. These

checks should indicate whether the

manual parking brake control linkage

is operating properly or requires re-

pair or adjustment due to inability of

the parking brake to hold against

moderate vehicle movement. Perform

tests of the parking brake system and

controls after making certain the link-

age and manual controls operate

properly.

When testing a parking brake vacu-

um release system, a minimum of 10

inches of vacuum (Hg.) should be

available at all points where vacuum is

applied. This can be checked with a

Rotunda Fuel Pump Tester Gauge

(ARE345) and two Distributor Tester

hose adapters (Marked Q) connected

together with a coupling. This allows

the Fuel Pump Tester Gauge hose to

be adapted to any other vacuum hose

or rubber connector in the vacuum

systems.

Failure to maintain 10 inches of

vacuum (Hg.) during vacuum system

tests could be caused by a loose hose

connection, resulting in a vacuum

leak. When checking for vacuum be-

tween two points, trace the hose along

the entire routing to be sure it is not

crossed with another hose and con-

nected to the wrong connection.

All of the vacuum parking brake

control checks are to be performed

with the engine running at idle speed.

Leaks in the parking brake hoses or

a disconnected or improperly con-

nected hose can usually be found by

listening for a hissing sound along the

hose routings. Under no circumstances

should air pressure be applied to the

vacuum system as the actuator dia-

phragm in the parking brake vacuum

motor may be damaged.

1.

Start the engine and run it at

idle speed. With the transmission shift

control in neutral, depress the parking

brake pedal to apply the parking

brake. Move the transmission shift

control to D range and observe the

parking brake pedal to see that the

pedal moves upward and the parking

brake releases. If the parking brake

releases, the parking brake vacuum

control is working properly.

2.

If the parking brake does not re-

lease, test for vacuum at the steering

column neutral switch port in the

junction block, vacuum lines and the

parking brake release vacuum motor.

Use the Rotunda Vacuum and Fuel

Pump Tester 345. This can be accom-

plished by removing the hose from

each component and attaching it to

the vacuum gauge. Connect two dis-

tributor tester vacuum hose adapters

together with a coupling as a connec-

tor to attach the gauge. A minimum

of ten inches of vacuum is required to

actuate the parking brake vacuum

motor. Do not remove any of the vac-

uum hoses from the junction block

unless the junction block is being re-

placed, as the plastic nipples are thin

and very brittle and damage may re-

sult. If a minimum reading is not

present when checking each of the

aforementioned components, they

must be replaced.

ROAD TEST

A road test should be conducted

only when the operator is sure the

brakes will stop the vehicle.

If the road test reveals one or more

problem conditions, correct all mal-

functions of the vacuum system, brake

booster and hydraulic system prior to

removing brake drums, brake calipers,

brake shoes and linings or backing

plates.

ANTI-SKID CONTROL

SYSTEM TESTS

No adjustments or repairs are to be

performed on the skid control system.

Damaged or worn parts are to be re-

placed.

Refer to Ford Car and Truck Diag-

nosis Manual for Testing procedures.

COMMON ADJUSTMENTS AND REPAIRS

PARKING BRAKE LINKAGE

ADJUSTMENT

FORD, MERCURY, METEOR,

FAIRLANE, MONTEGO,

FALCON, MUSTANG

AND COUGAR

Check the parking brake cables

when the brakes are fully released. If1

the cables are loose, adjust them as

follows:

1.

Fully release the parking brake

pedal by pulling the release lever.

2.

Depress the parking brake pedal

until it is engaged in the first notch of

the control. On a vacuum release

brake, the first notch will be approxi-

mately two inches of pedal travel.

3.

Raise the vehicle. With the

transmission in neutral, turn the ad-

justing nut forward against the equal-

izer (Figs. 3 and 4) until there is 100

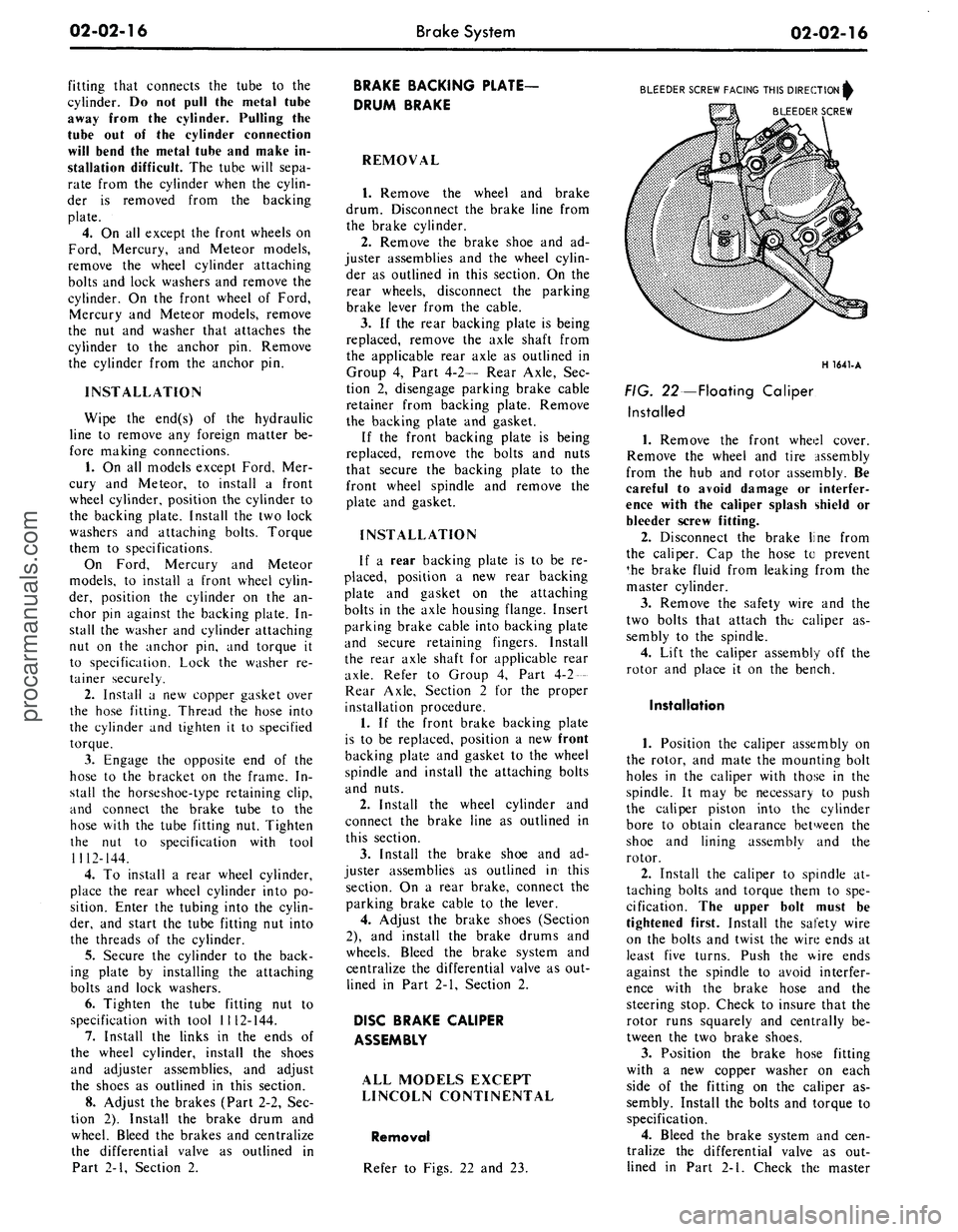

L.H. REAR WHEEL CABLE -2A809> 2A791 (2 REQUIRED)

EQUALIZER-TO-ACTUATOR CABLE-2A815

R.H. REAR WHEEL CABLE-2A635

ADJUSTING NUT-2A812

H 1537-C

FIG. 3—Parking Brake Adjustment—Ford, Mercury, Meteor,

Thunderbird and Continental Mark IIIprocarmanuals.com

Page 35 of 413

02-02-16

Brake System

02-02-16

fitting that connects the tube to the

cylinder. Do not pull the metal tube

away from the cylinder. Pulling the

tube out of the cylinder connection

will bend the metal tube and make in-

stallation difficult. The tube will sepa-

rate from the cylinder when the cylin-

der is removed from the backing

plate.

4.

On all except the front wheels on

Ford, Mercury, and Meteor models,

remove the wheel cylinder attaching

bolts and lock washers and remove the

cylinder. On the front wheel of Ford,

Mercury and Meteor models, remove

the nut and washer that attaches the

cylinder to the anchor pin. Remove

the cylinder from the anchor pin.

INSTALLATION

Wipe the end(s) of the hydraulic

line to remove any foreign matter be-

fore making connections.

1.

On all models except Ford, Mer-

cury and Meteor, to install a front

wheel cylinder, position the cylinder to

the backing plate. Install the two lock

washers and attaching bolts. Torque

them to specifications.

On Ford, Mercury and Meteor

models, to install a front wheel cylin-

der, position the cylinder on the an-

chor pin against the backing plate. In-

stall the washer and cylinder attaching

nut on the anchor pin, and torque it

to specification. Lock the washer re-

tainer securely.

2.

Install a new copper gasket over

the hose fitting. Thread the hose into

the cylinder and tighten it to specified

torque.

3.

Engage the opposite end of the

hose to the bracket on the frame. In-

stall the horseshoe-type retaining clip,

and connect the brake tube to the

hose with the tube fitting nut. Tighten

the nut to specification with tool

1112-144.

4.

To install a rear wheel cylinder,

place the rear wheel cylinder into po-

sition. Enter the tubing into the cylin-

der, and start the tube fitting nut into

the threads of the cylinder.

5.

Secure the cylinder to the back-

ing plate by installing the attaching

bolts and lock washers.

6. Tighten the tube fitting nut to

specification with tool 1112-144.

7.

Install the links in the ends of

the wheel cylinder, install the shoes

and adjuster assemblies, and adjust

the shoes as outlined in this section.

8. Adjust the brakes (Part 2-2, Sec-

tion 2). Install the brake drum and

wheel. Bleed the brakes and centralize

the differential valve as outlined in

Part 2-1, Section 2.

BRAKE BACKING PLATE

DRUM BRAKE

REMOVAL

1.

Remove the wheel and brake

drum. Disconnect the brake line from

the brake cylinder.

2.

Remove the brake shoe and ad-

juster assemblies and the wheel cylin-

der as outlined in this section. On the

rear wheels, disconnect the parking

brake lever from the cable.

3.

If the rear backing plate is being

replaced, remove the axle shaft from

the applicable rear axle as outlined in

Group 4, Part 4-2— Rear Axle, Sec-

tion 2, disengage parking brake cable

retainer from backing plate. Remove

the backing plate and gasket.

If the front backing plate is being

replaced, remove the bolts and nuts

that secure the backing plate to the

front wheel spindle and remove the

plate and gasket.

INSTALLATION

If a rear backing plate is to be re-

placed, position a new rear backing

plate and gasket on the attaching

bolts in the axle housing flange. Insert

parking brake cable into backing plate

and secure retaining fingers. Install

the rear axle shaft for applicable rear

axle.

Refer to Group 4, Part 4-2 —

Rear Axle, Section 2 for the proper

installation procedure.

1.

If the front brake backing plate

is to be replaced, position a new front

backing plate and gasket to the wheel

spindle and install the attaching bolts

and nuts.

2.

Install the wheel cylinder and

connect the brake line as outlined in

this section.

3.

Install the brake shoe and ad-

juster assemblies as outlined in this

section. On a rear brake, connect the

parking brake cable to the lever.

4.

Adjust the brake shoes (Section

2),

and install the brake drums and

wheels. Bleed the brake system and

centralize the differential valve as out-

lined in Part 2-1, Section 2.

DISC BRAKE CALIPER

ASSEMBLY

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

Removal

Refer to Figs. 22 and 23.

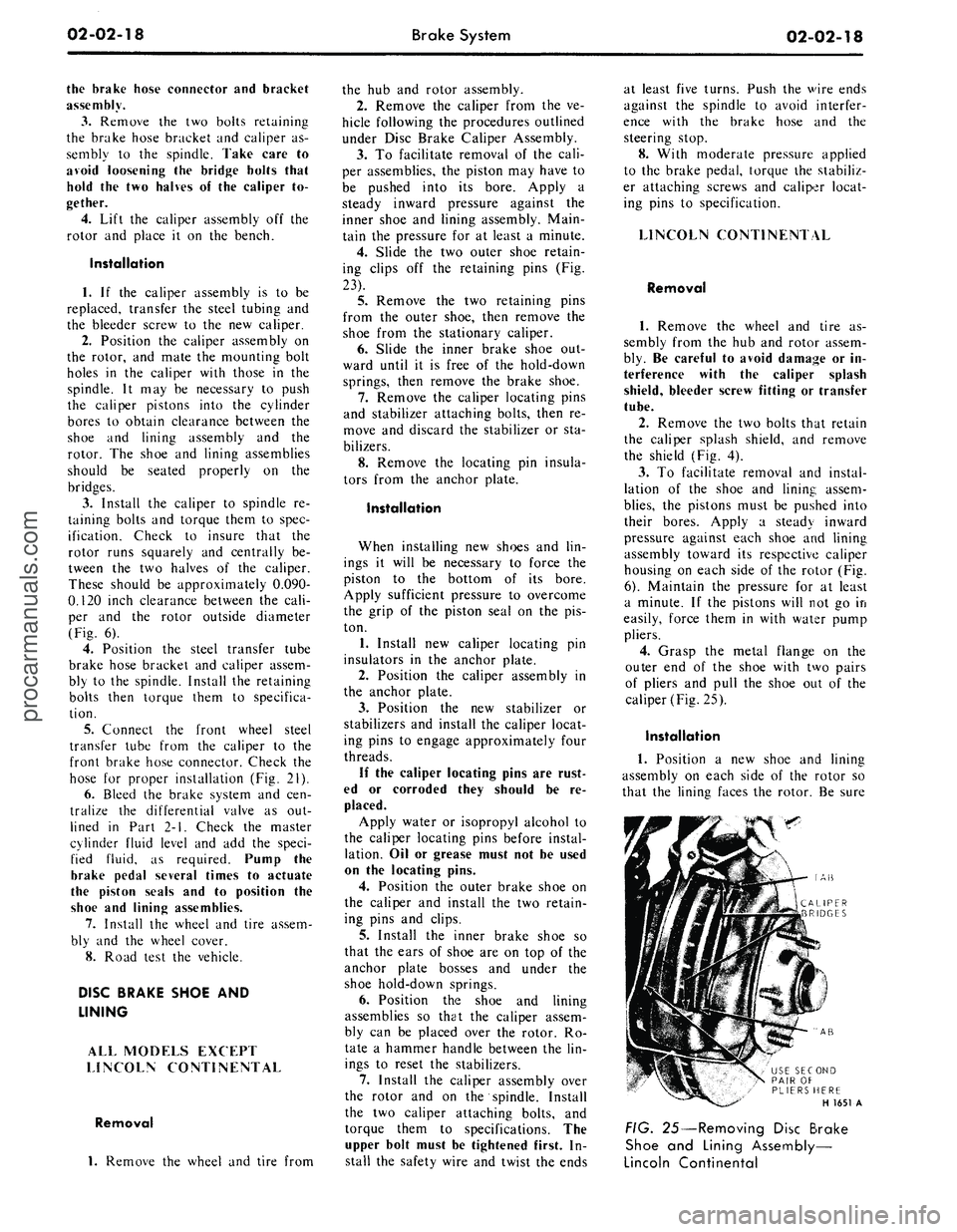

BLEEDER SCREW FACING THIS DIRECTION^

BLEEDER SCREW

H 1641-A

FIG. 22—Floating Caliper

Installed

1.

Remove the front wheel cover.

Remove the wheel and tire assembly

from the hub and rotor assembly. Be

careful to avoid damage or interfer-

ence with the caliper splash shield or

bleeder screw fitting.

2.

Disconnect the brake line from

the caliper. Cap the hose to prevent

*he brake fluid from leaking from the

master cylinder.

3.

Remove the safety wire and the

two bolts that attach the caliper as-

sembly to the spindle.

4.

Lift the caliper assembly off the

rotor and place it on the bench.

Installation

1.

Position the caliper assembly on

the rotor, and mate the mounting bolt

holes in the caliper with those in the

spindle. It may be necessary to push

the caliper piston into the cylinder

bore to obtain clearance between the

shoe and lining assembly and the

rotor.

2.

Install the caliper to spindle at-

taching bolts and torque them to spe-

cification. The upper bolt must be

tightened first. Install the safety wire

on the bolts and twist the wire ends at

least five turns. Push the wire ends

against the spindle to avoid interfer-

ence with the brake hose and the

steering stop. Check to insure that the

rotor runs squarely and centrally be-

tween the two brake shoes.

3.

Position the brake hose fitting

with a new copper washer on each

side of the fitting on the caliper as-

sembly. Install the bolts and torque to

specification.

4.

Bleed the brake system and cen-

tralize the differential valve as out-

lined in Part 2-1. Check the masterprocarmanuals.com

Page 37 of 413

02-02-18

Brake System

02-02-18

the brake hose connector

and

bracket

assembly.

3.

Remove

the two

bolts retaining

the brake hose bracket

and

caliper

as-

sembly

to the

spindle. Take care

to

avoid loosening

the

bridge bolts that

hold

the two

halves

of the

caliper

to-

gether.

4.

Lift

the

caliper assembly

off the

rotor

and

place

it on the

bench.

Installation

1.

If the

caliper assembly

is to be

replaced, transfer

the

steel tubing

and

the bleeder screw

to the new

caliper.

2.

Position

the

caliper assembly

on

the rotor,

and

mate

the

mounting bolt

holes

in the

caliper with those

in the

spindle.

It may be

necessary

to

push

the caliper pistons into

the

cylinder

bores

to

obtain clearance between

the

shoe

and

lining assembly

and the

rotor.

The

shoe

and

lining assemblies

should

be

seated properly

on the

bridges.

3.

Install

the

caliper

to

spindle

re-

taining bolts

and

torque them

to

spec-

ification. Check

to

insure that

the

rotor runs squarely

and

centrally

be-

tween

the two

halves

of the

caliper.

These should

be

approximately 0.090-

0.120 inch clearance between

the

cali-

per

and the

rotor outside diameter

(Fig.

6).

4.

Position

the

steel transfer tube

brake hose bracket

and

caliper assem-

bly

to the

spindle. Install

the

retaining

bolts then torque them

to

specifica-

tion.

5.

Connect

the

front wheel steel

transfer tube from

the

caliper

to the

front brake hose connector. Check

the

hose

for

proper installation

(Fig. 21).

6. Bleed

the

brake system

and cen-

tralize

the

differential valve

as out-

lined

in

Part

2-1.

Check

the

master

cylinder fluid level

and add the

speci-

fied fluid,

as

required. Pump

the

brake pedal several times

to

actuate

the piston seals

and to

position

the

shoe

and

lining assemblies.

7.

Install

the

wheel

and

tire assem-

bly

and the

wheel cover.

8. Road test

the

vehicle.

DISC BRAKE SHOE

AND

LINING

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire from

the

hub and

rotor assembly.

2.

Remove

the

caliper from

the ve-

hicle following

the

procedures outlined

under Disc Brake Caliper Assembly.

3.

To

facilitate removal

of the

cali-

per assemblies,

the

piston

may

have

to

be pushed into

its

bore. Apply

a

steady inward pressure against

the

inner shoe

and

lining assembly. Main-

tain

the

pressure

for at

least

a

minute.

4.

Slide

the two

outer shoe retain-

ing clips

off the

retaining pins

(Fig.

23).

5.

Remove

the two

retaining pins

from

the

outer shoe, then remove

the

shoe from

the

stationary caliper.

6. Slide

the

inner brake shoe

out-

ward until

it is

free

of the

hold-down

springs, then remove

the

brake shoe.

7.

Remove

the

caliper locating pins

and stabilizer attaching bolts, then

re-

move

and

discard

the

stabilizer

or sta-

bilizers.

8. Remove

the

locating

pin

insula-

tors from

the

anchor plate.

Installation

When installing

new

shoes

and lin-

ings

it

will

be

necessary

to

force

the

piston

to the

bottom

of its

bore.

Apply sufficient pressure

to

overcome

the grip

of the

piston seal

on the pis-

ton.

1.

Install

new

caliper locating

pin

insulators

in the

anchor plate.

2.

Position

the

caliper assembly

in

the anchor plate.

3.

Position

the new

stabilizer

or

stabilizers

and

install

the

caliper locat-

ing pins

to

engage approximately four

threads.

If

the

caliper locating pins

are

rust-

ed

or

corroded they should

be re-

placed.

Apply water

or

isopropyl alcohol

to

the caliper locating pins before instal-

lation.

Oil or

grease must

not be

used

on

the

locating pins.

4.

Position

the

outer brake shoe

on

the caliper

and

install

the two

retain-

ing pins

and

clips.

5.

Install

the

inner brake shoe

so

that

the

ears

of

shoe

are on top of the

anchor plate bosses

and

under

the

shoe hold-down springs.

6. Position

the

shoe

and

lining

assemblies

so

that

the

caliper assem-

bly

can be

placed over

the

rotor.

Ro-

tate

a

hammer handle between

the lin-

ings

to

reset

the

stabilizers.

7.

Install

the

caliper assembly over

the rotor

and on the

spindle. Install

the

two

caliper attaching bolts,

and

torque them

to

specifications.

The

upper bolt must

be

tightened first.

In-

stall

the

safety wire

and

twist

the

ends

at least five turns. Push

the

wire ends

against

the

spindle

to

avoid interfer-

ence with

the

brake hose

and the

steering stop.

8. With moderate pressure applied

to

the

brake pedal, torque

the

stabiliz-

er attaching screws

and

caliper locat-

ing pins

to

specification.

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire

as-

sembly from

the hub and

rotor assem-

bly.

Be

careful

to

avoid damage

or in-

terference with

the

caliper splash

shield, bleeder screw fitting

or

transfer

tube.

2.

Remove

the two

bolts that retain

the caliper splash shield,

and

remove

the shield

(Fig. 4).

3.

To

facilitate removal

and

instal-

lation

of the

shoe

and

lining assem-

blies,

the

pistons must

be

pushed into

their bores. Apply

a

steady inward

pressure against each shoe

and

lining

assembly toward

its

respective caliper

housing

on

each side

of the

rotor

(Fig.

6).

Maintain

the

pressure

for at

least

a minute.

If the

pistons will

not go ifi

easily, force them

in

with water pump

pliers.

4.

Grasp

the

metal flange

on the

outer

end of the

shoe with

two

pairs

of pliers

and

pull

the

shoe

out of the

caliper (Fig.

25).

Installation

1.

Position

a new

shoe

and

lining

assembly

on

each side

of the

rotor

so

that

the

lining faces

the

rotor.

Be

sure

AB

AB

USE SECOND

PAIR

OF

PLIERS HERE

H 1651

A

FIG. 25—Removing Disc Brake

Shoe

and

Lining Assembly—

Lincoln Continentalprocarmanuals.com

Page 66 of 413

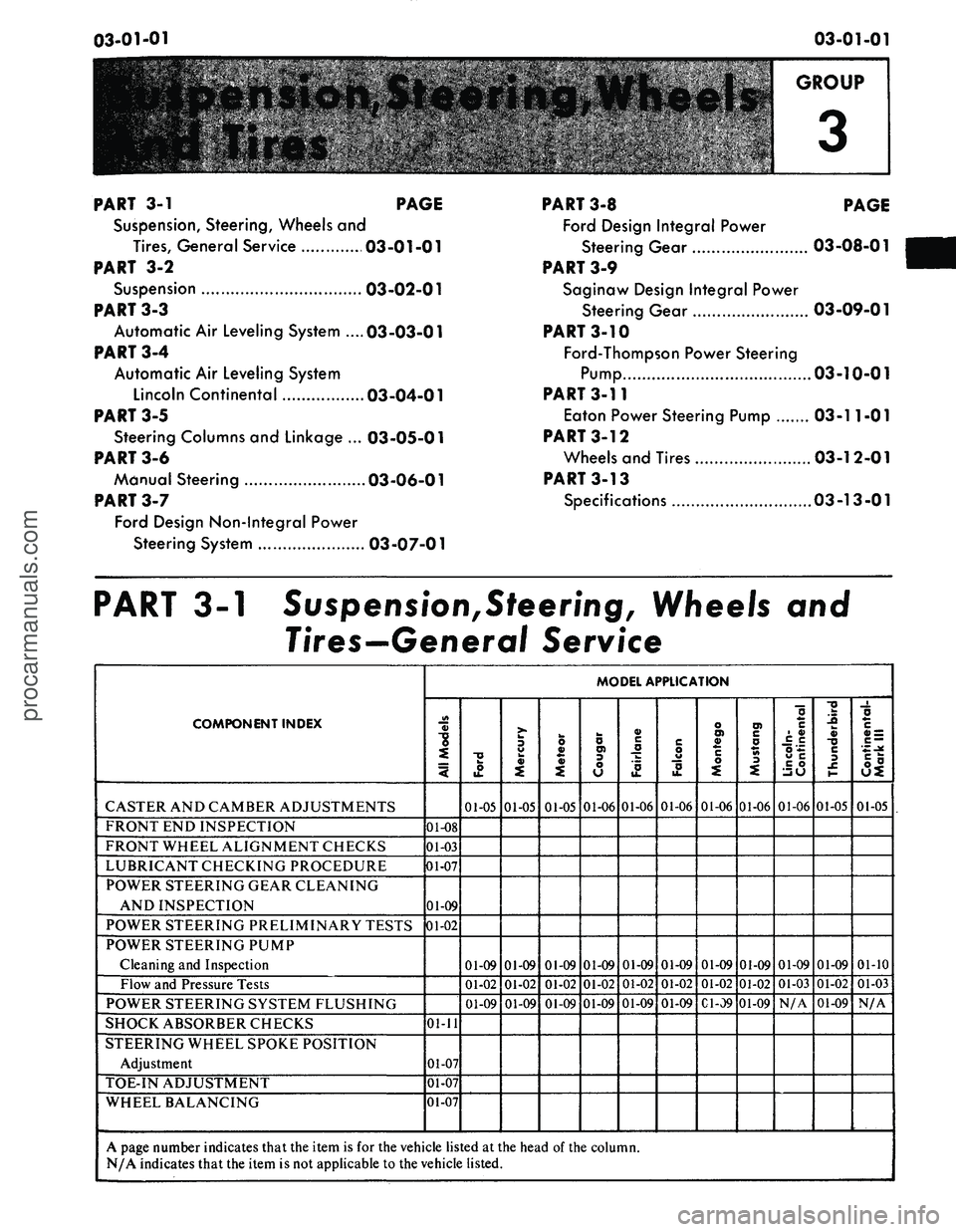

03-01-01

PART

3-1

PAGE

Suspension,

Steering, Wheels and

Tires,

General Service 03-01-01

PART

3-2

Suspension 03-02-01

PART

3-3

Automatic

Air

Leveling System ....03-03-01

PART

3-4

Automatic

Air

Leveling System

Lincoln Continental 03-04-01

PART

3-5

Steering Columns and Linkage ... 03-05-01

PART

3-6

Manual Steering 03-06-01

PART

3-7

Ford Design Non-Integral Power

Steering System

03-07-01

PART

3-8

PAGE

Ford Design Integral Power

Steering Gear 03-08-01

PART

3-9

Saginaw Design Integral Power

Steering Gear 03-09-01

PART

3-10

Ford-Thompson Power Steering

Pump 03-10-01

PART

3-11

Eaton Power Steering Pump 03-1

1-01

PART 3-12

Wheels and Tires 03-1 2-01

PART

3-13

Specifications

03-13-01

PART

3-1

Suspension,Steering, Wheels

and

Tires—General Service

COMPONENT INDEX

CASTER AND CAMBER ADJUSTMENTS

FRONT

END

INSPECTION

FRONT WHEEL ALIGNMENT CHECKS

LUBRICANT CHECKING PROCEDURE

POWER STEERING GEAR CLEANING

AND INSPECTION

POWER STEERING PRELIMINARY TESTS

POWER STEERING PUMP

Cleaning

and

Inspection

Flow

and

Pressure Tests

POWER STEERING SYSTEM FLUSHING

SHOCK ABSORBER CHECKS

STEERING WHEEL SPOKE POSITION

Adjustment

TOE-IN ADJUSTMENT

WHEEL BALANCING

MODEL APPLICATION

All

Models

01-08

01-03

01-07

01-09

01-02

01-11

01-07

01-07

01-07

Ford

01-05

01-09

01-02

01-09

Mercury

01-05

01-09

01-02

01-09

Meteor

01-05

01-09

01-02

01-09

Cougar

01-06

01-09

01-02

01-09

Fairlane

01-06

01-09

01-02

01-09

Falcon

01-06

01-09

01-02

01-09

Montego

01-06

01-09

01-02

Gl-09

Mustang

01-06

01-09

01-02

01-09

Lincoln-

Continental

01-06

01-09

01-03

N/A

Thunderbird

01-05

01-09

01-02

01-09

Continental-

Mark

III

01-05

01-10

01-03

N/A

A page number indicates that

the

item

is for the

vehicle listed

at the

head

of the

column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

procarmanuals.com

Page 67 of 413

03-01-02

Suspension — Steering, Wheels And Tires — General Service

03-01-02

1 TESTING

POWER STEERING-

PRELIMINARY TESTS

The following preliminary checks

should always be made before per-

forming any operations.

AIR BLEEDING

Air in the power steering system

(shown by bubbles in the fluid) should

be bled. After making sure that the

reservoir is filled to specification (the

fluid must be at normal operating

temperature when the check is made),

turn the steering wheel through its full

travel three or four times. Do not hold

the wheels against their stops. Re-

check the fluid level.

CHECK FLUID LEVEL

Run the engine until the fluid is at

normal operating temperature. Then

turn the steering wheel all the way to

the left and right several times, and

shut off the engine.

Check the fluid level in the power

steering reservoir. The level must show

on the cross hatching between the bot-

tom of the dipstick and the full mark

(Fig. 1). If the level is low, add

enough automatic transmission fluid

C1AZ-19582-A to raise the level to

the F mark on the dipstick. Do not

overfill the reservoir.

CHECK PUMP BELT

If the pump belt is broken, glazed,

or worn, replace it with a new belt.

Use only the specified type of belt.

Refer to Part 3-13 for belt adjustment

procedure.

CHECK FOR FLUID

LEAKS

With the engine idling, turn the

steering wheel from stop to stop sever-

al times. Check all possible leakage

points. Tighten all loose fittings, and

replace any damaged lines or defective

seats.

CHECK TURNING EFFORT

With the front wheels properly al-

igned and tire pressures correct, check

the effort required to turn the steering

wheel.

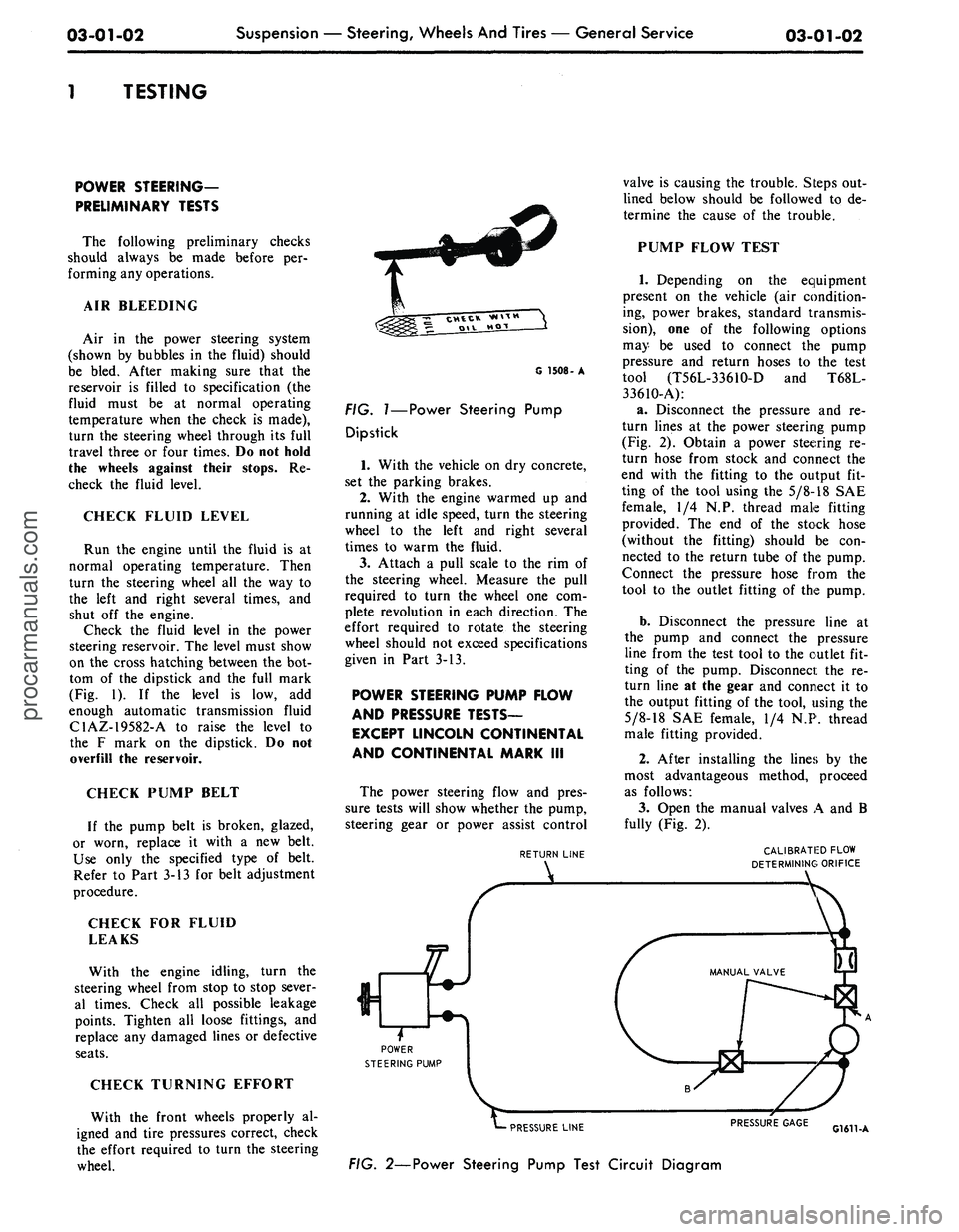

G 1508- A

FIG.

1—Power

Steering Pump

Dipstick

1.

With the vehicle on dry concrete,

set the parking brakes.

2.

With the engine warmed up and

running at idle speed, turn the steering

wheel to the left and right several

times to warm the fluid.

3.

Attach a pull scale to the rim of

the steering wheel. Measure the pull

required to turn the wheel one com-

plete revolution in each direction. The

effort required to rotate the steering

wheel should not exceed specifications

given in Part 3-13.

POWER STEERING PUMP FLOW

AND PRESSURE TESTS—

EXCEPT LINCOLN CONTINENTAL

AND CONTINENTAL MARK III

The power steering flow and pres-

sure tests will show whether the pump,

steering gear or power assist control

RETURN LINE

POWER

STEERING PUMP

Sr

valve is causing the trouble. Steps out-

lined below should be followed to de-

termine the cause of the trouble.

PUMP FLOW TEST

1.

Depending on the equipment

present on the vehicle (air condition-

ing, power brakes, standard transmis-

sion),

one of the following options

may be used to connect the pump

pressure and return hoses to the test

tool (T56L-3361O-D and T68L-

33610-A):

a. Disconnect the pressure and re-

turn lines at the power steering pump

(Fig. 2). Obtain a power steering re-

turn hose from stock and connect the

end with the fitting to the output fit-

ting of the tool using the

5/8-18

SAE

female, 1/4 N.P. thread male fitting

provided. The end of the stock hose

(without the fitting) should be con-

nected to the return tube of the pump.

Connect the pressure hose from the

tool to the outlet fitting of the pump.

b.

Disconnect the pressure line at

the pump and connect the pressure

line from the test tool to the outlet fit-

ting of the pump. Disconnect the re-

turn line at the gear and connect it to

the output fitting of the tool, using the

5/8-18

SAE female, 1/4 N.P. thread

male fitting provided.

2.

After installing the lines by the

most advantageous method, proceed

as follows:

3.

Open the manual valves A and B

fully (Fig. 2).

CALIBRATED FLOW

DETERMINING ORIFICE

PRESSURE LINE

FIG. 2—Power Steering Pump Test Circuit Diagram

PRESSURE GAGE

G1611-Aprocarmanuals.com

Page 68 of 413

03-01-03

Suspension — Steering, Wheels And Tires — General Service

03-01-03

4.

Connect a tachometer, start the

engine and operate it at idle speed

until the reservoir fluid temperature

reaches 165 to 175. This temperature

must be maintained throughout the

test. Valve B may be partially closed

to create a back pressure up to 350

psi to hasten the temperature rise. The

reservoir fluid must be at the proper

level.

5.

With the engine operating at rec-

ommended idle rpm and fluid temper-

ature noted in Step 4, close the manu-

al valve B. The minimum acceptable

pressure reading is 620 psi.

6. If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

7.

If the reading is at or above the

minimum specification, the pump flow

is normal. Open manual valve B and

proceed to the Pump Fluid Pressure

Test.

PUMP FLUID

PRESSURE TEST

1.

Keep the lines and tools con-

nected as in the Pump Flow Test.

2.

With manual valves A and B

opened fully, operate the engine at

recommended idle speed (Fig. 2).

Close manual valve A, then manual

valve B. Do not keep both valves

closed for more than 5 seconds as this

would abnormally increase the fluid

temperature and cause undue pump

and/or gear wear.

3.

With the valves fully closed, the

pressure gauge should read 1000 psi

minimum for Ford, Mercury, Meteor

or Thunderbird and 750 psi minimum

for Cougar, Fairlane, Falcon, Monte-

go or Mustang.

4.

If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

5.

If the pressure gauge reading is

at or above the minimum specifica-

tions,

the pump is normal and the

power steering gear or power assist

control valve is at fault.

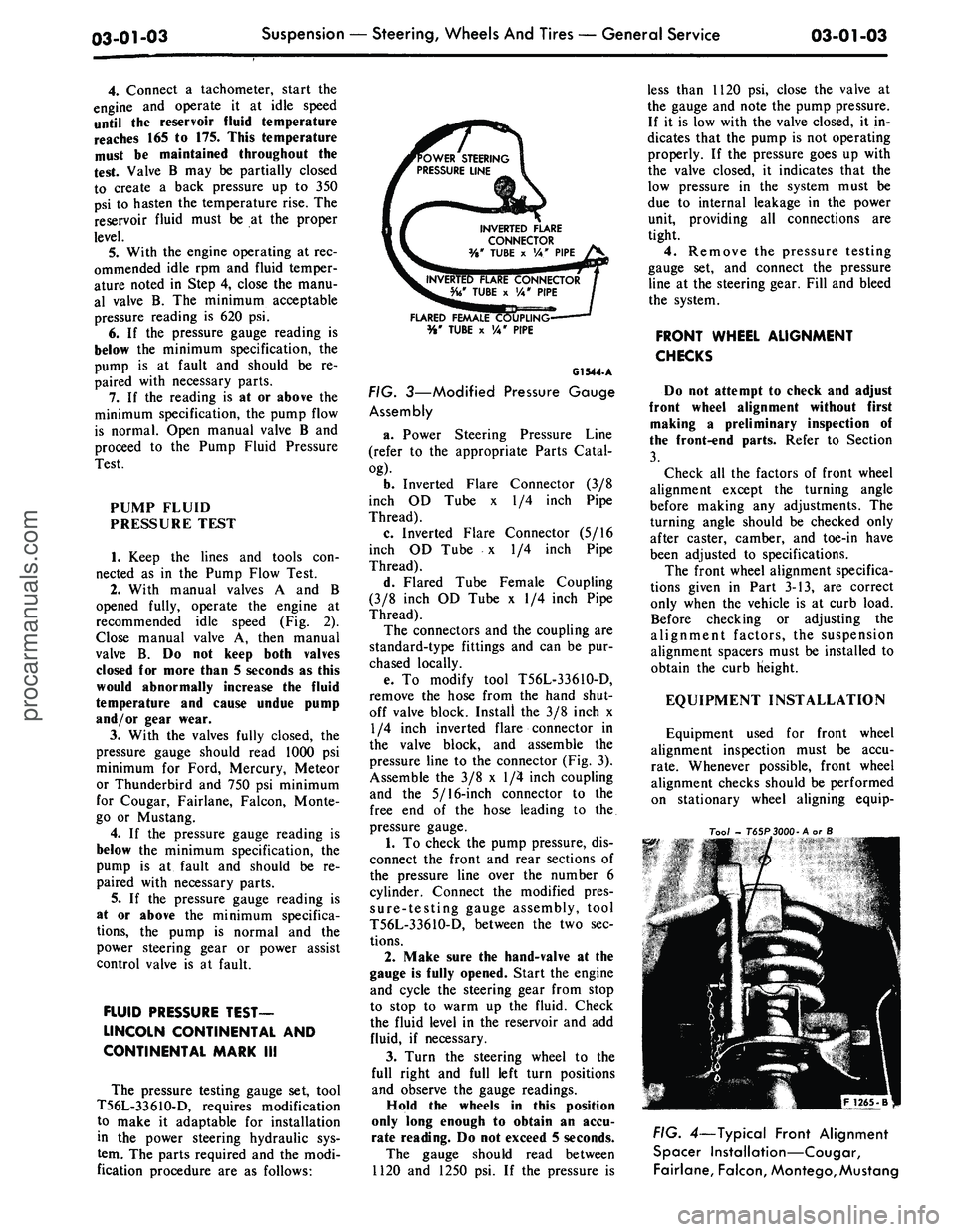

FLUID PRESSURE TEST-

LINCOLN CONTINENTAL AND

CONTINENTAL MARK III

The pressure testing gauge set, tool

T56L-33610-D, requires modification

to make it adaptable for installation

in the power steering hydraulic sys-

tem. The parts required and the modi-

fication procedure are as follows:

OWER STEERING

PRESSURE LINE

INVERTED FLARE

CONNECTOR

%* TUBE x VA" PIPE

FLARED FEMALE COUPW

%' TUBE x VA" PIPE

G1544.A

FIG. 3—Modified Pressure Gauge

Assembly

a. Power Steering Pressure Line

(refer to the appropriate Parts Catal-

og).

b.

Inverted Flare Connector (3/8

inch OD Tube x 1/4 inch Pipe

Thread).

c. Inverted Flare Connector (5/16

inch OD Tube x 1/4 inch Pipe

Thread).

d. Flared Tube Female Coupling

(3/8 inch OD Tube x 1/4 inch Pipe

Thread).

The connectors and the coupling are

standard-type fittings and can be pur-

chased locally.

e. To modify tool T56L-33610-D,

remove the hose from the hand shut-

off valve block. Install the 3/8 inch x

1/4 inch inverted flare connector in

the valve block, and assemble the

pressure line to the connector (Fig. 3).

Assemble the 3/8 x 1/4 inch coupling

and the 5/16-inch connector to the

free end of the hose leading to the.

pressure gauge.

1.

To check the pump pressure, dis-

connect the front and rear sections of

the pressure line over the number 6

cylinder. Connect the modified pres-

sure-testing gauge assembly, tool

T56L-3361O-D, between the two sec-

tions.

2.

Make sure the hand-valve at the

gauge is fully opened. Start the engine

and cycle the steering gear from stop

to stop to warm up the fluid. Check

the fluid level in the reservoir and add

fluid, if necessary.

3.

Turn the steering wheel to the

full right and full left turn positions

and observe the gauge readings.

Hold the wheels in this position

only long enough to obtain an accu-

rate reading. Do not exceed 5 seconds.

The gauge should read between

1120 and 1250 psi. If the pressure is

less than 1120 psi, close the valve at

the gauge and note the pump pressure.

If it is low with the valve closed, it in-

dicates that the pump is not operating

properly. If the pressure goes up with

the valve closed, it indicates that the

low pressure in the system must be

due to internal leakage in the power

unit, providing all connections are

tight.

4.

Remove the pressure testing

gauge set, and connect the pressure

line at the steering gear. Fill and bleed

the system.

FRONT WHEEL ALIGNMENT

CHECKS

Do not attempt to check and adjust

front wheel alignment without first

making a preliminary inspection of

the front-end parts. Refer to Section

3.

Check all the factors of front wheel

alignment except the turning angle

before making any adjustments. The

turning angle should be checked only

after caster, camber, and toe-in have

been adjusted to specifications.

The front wheel alignment specifica-

tions given in Part 3-13, are correct

only when the vehicle is at curb load.

Before checking or adjusting the

alignment factors, the suspension

alignment spacers must be installed to

obtain the curb Height.

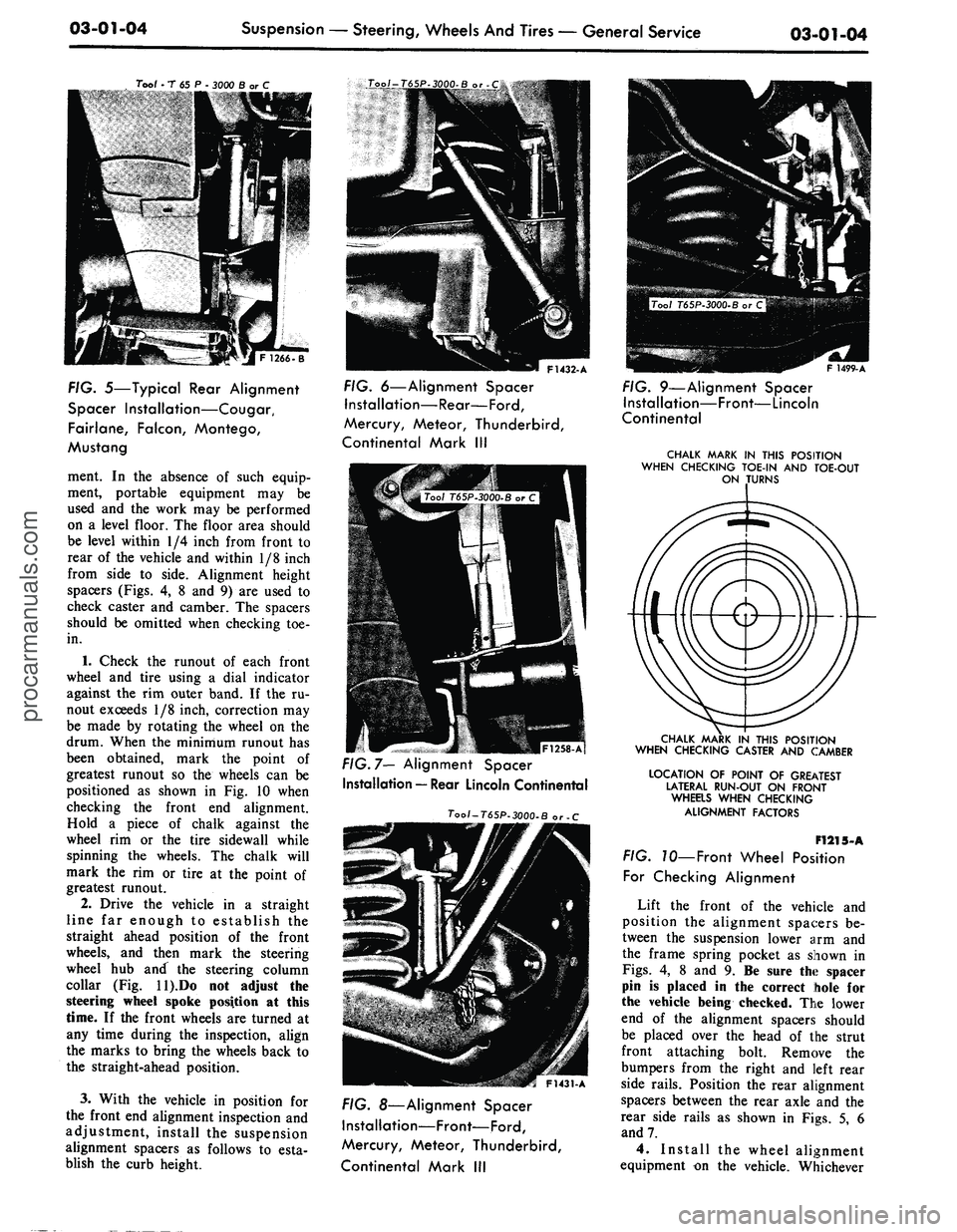

EQUIPMENT INSTALLATION

Equipment used for front wheel

alignment inspection must be accu-

rate.

Whenever possible, front wheel

alignment checks should be performed

on stationary wheel aligning equip-

Too/

- T65P3000-A or S

FIG. 4—Typical Front Alignment

Spacer Installation—Cougar,

Fairlane, Falcon,

Montego,

Mustangprocarmanuals.com

Page 69 of 413

03-01-04

Suspension — Steering, Wheels And Tires — General Service

03-01-04

Tool

- T 65 P -

3000

B or C

1266-B

FIG. 5—Typical Rear Alignment

Spacer Installation—Cougar,

Fairlane, Falcon, Montego,

Mustang

ment. In the absence of such equip-

ment, portable equipment may be

used and the work may be performed

on a level floor. The floor area should

be level within 1/4 inch from front to

rear of the vehicle and within 1/8 inch

from side to side. Alignment height

spacers (Figs. 4, 8 and 9) are used to

check caster and camber. The spacers

should be omitted when checking toe-

in.

1.

Check the runout of each front

wheel and tire using a dial indicator

against the rim outer band. If the ru-

nout exceeds 1/8 inch, correction may

be made by rotating the wheel on the

drum. When the minimum runout has

been obtained, mark the point of

greatest runout so the wheels can be

positioned as shown in Fig. 10 when

checking the front end alignment.

Hold a piece of chalk against the

wheel rim or the tire sidewall while

spinning the wheels. The chalk will

mark the rim or tire at the point of

greatest runout.

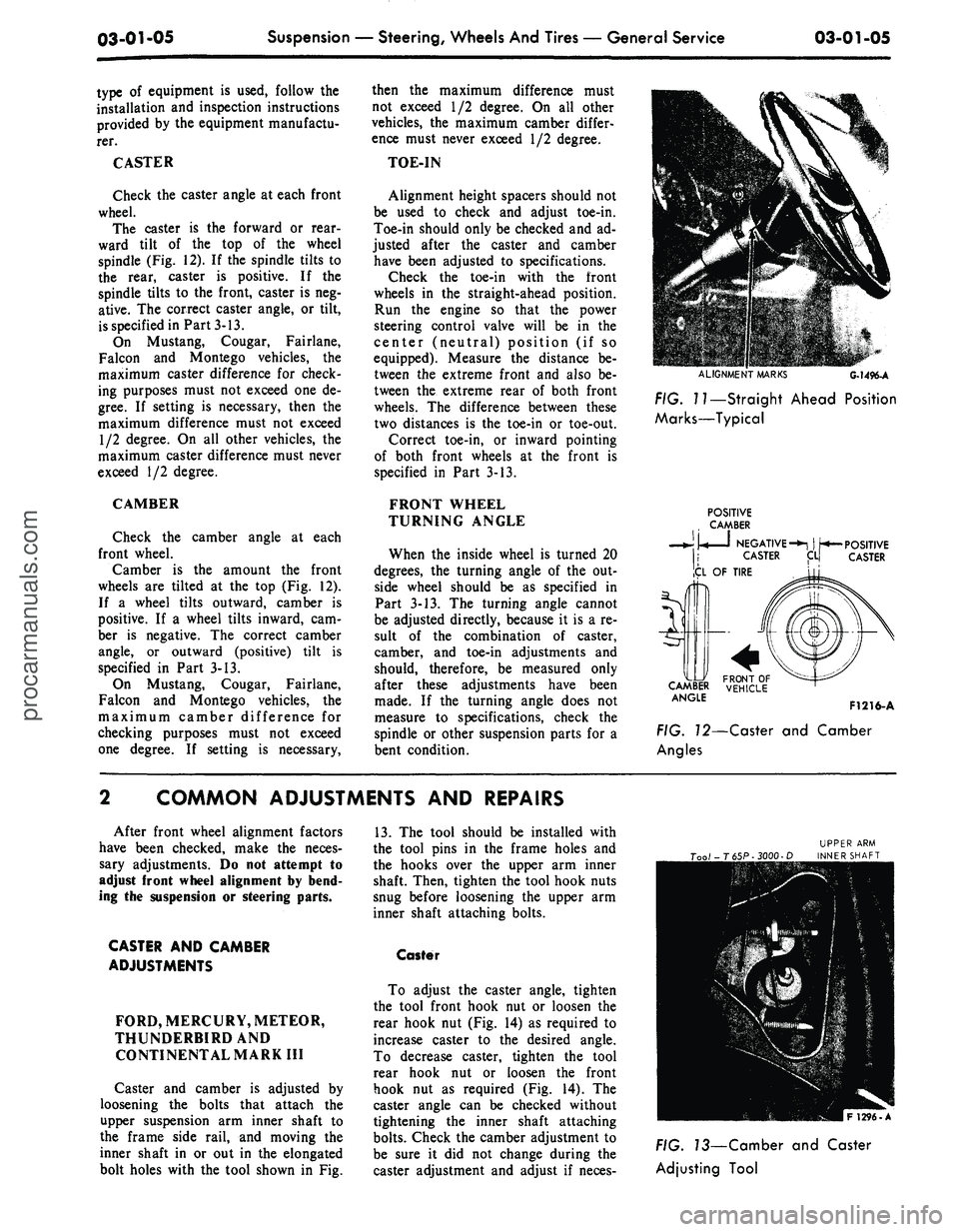

2.

Drive the vehicle in a straight

line far enough to establish the

straight ahead position of the front

wheels, and then mark the steering

wheel hub and the steering column

collar (Fig. ll).Do not adjust the

steering wheel spoke position at this

time. If the front wheels are turned at

any time during the inspection, align

the marks to bring the wheels back to

the straight-ahead position.

3.

With the vehicle in position for

the front end alignment inspection and

adjustment, install the suspension

alignment spacers as follows to esta-

blish the curb height.

F1432-A

FIG. 6—Alignment Spacer

Installation—Rear—Ford,

Mercury, Meteor, Thunderbird,

Continental Mark III

|F1258-Af

FIG. 7— Alignment Spacer

Installation — Rear Lincoln Continental

Tool-T65P-3000-B or -C

F1431-A

FIG. 8—Alignment Spacer

Installation—Front—Ford,

Mercury, Meteor, Thunderbird,

Continental Mark III

F 1499-A

FIG. 9—Alignment Spacer

Installation—Front—Lincoln

Continental

CHALK MARK IN THIS POSITION

WHEN CHECKING TOE-IN AND TOE-OUT

ON TURNS

CHALK MARK IN THIS POSITION

WHEN CHECKING CASTER AND CAMBER

LOCATION OF POINT OF GREATEST

LATERAL RUN-OUT ON FRONT

WHEaS WHEN CHECKING

ALIGNMENT FACTORS

F1215-A

FIG. 70—Front Wheel Position

For Checking Alignment

Lift the front of the vehicle and

position the alignment spacers be-

tween the suspension lower arm and

the frame spring pocket as shown in

Figs.

4, 8 and 9. Be sure the spacer

pin is placed in the correct hole for

the vehicle being checked. The lower

end of the alignment spacers should

be placed over the head of the strut

front attaching bolt. Remove the

bumpers from the right and left rear

side rails. Position the rear alignment

spacers between the rear axle and the

rear side rails as shown in Figs. 5, 6

and 7.

4.

Install the wheel alignment

equipment on the vehicle. Whicheverprocarmanuals.com

Page 70 of 413

03-01-05

Suspension — Steering, Wheels And Tires — General Service

03-01-05

type of equipment is used, follow the

installation and inspection instructions

provided by the equipment manufactu-

rer.

CASTER

Check the caster angle at each front

wheel.

The caster is the forward or rear-

ward tilt of the top of the wheel

spindle (Fig. 12). If the spindle tilts to

the rear, caster is positive. If the

spindle tilts to the front, caster is neg-

ative. The correct caster angle, or tilt,

is specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum caster difference for check-

ing purposes must not exceed one de-

gree.

If setting is necessary, then the

maximum difference must not exceed

1/2 degree. On all other vehicles, the

maximum caster difference must never

exceed 1/2 degree.

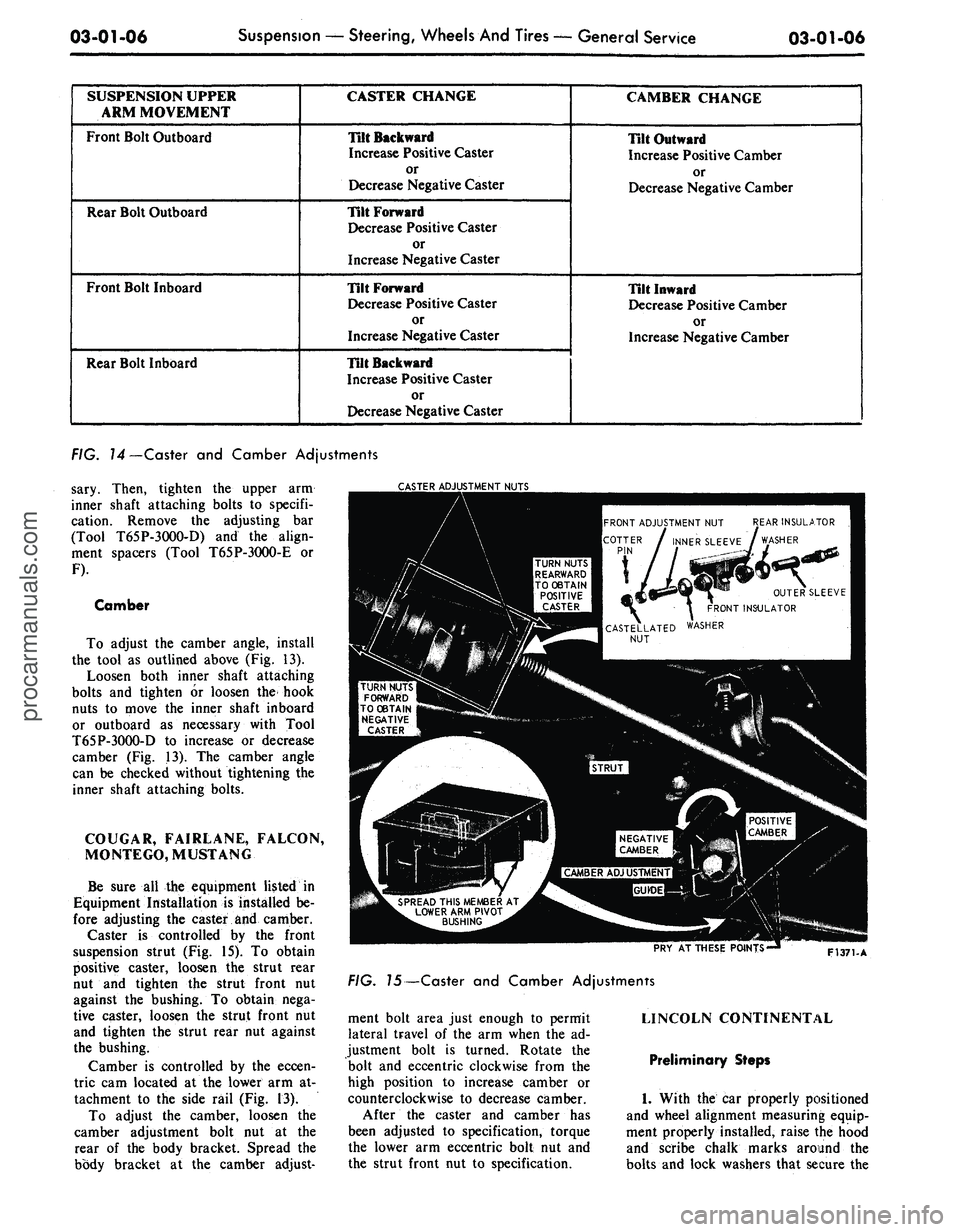

CAMBER

Check the camber angle at each

front wheel.

Camber is the amount the front

wheels are tilted at the top (Fig. 12).

If a wheel tilts outward, camber is

positive. If a wheel tilts inward, cam-

ber is negative. The correct camber

angle, or outward (positive) tilt is

specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum camber difference for

checking purposes must not exceed

one degree. If setting is necessary,

then the maximum difference must

not exceed 1/2 degree. On all other

vehicles, the maximum camber differ-

ence must never exceed 1/2 degree.

TOE-IN

Alignment height spacers should not

be used to check and adjust toe-in.

Toe-in should only be checked and ad-

justed after the caster and camber

have been adjusted to specifications.

Check the toe-in with the front

wheels in the straight-ahead position.

Run the engine so that the power

steering control valve will be in the

center (neutral) position (if so

equipped). Measure the distance be-

tween the extreme front and also be-

tween the extreme rear of both front

wheels. The difference between these

two distances is the toe-in or toe-out.

Correct toe-in, or inward pointing

of both front wheels at the front is

specified in Part 3-13.

FRONT WHEEL

TURNING ANGLE

When the inside wheel is turned 20

degrees, the turning angle of the out-

side wheel should be as specified in

Part 3-13. The turning angle cannot

be adjusted directly, because it is a re-

sult of the combination of caster,

camber, and toe-in adjustments and

should, therefore, be measured only

after these adjustments have been

made. If the turning angle does not

measure to specifications, check the

spindle or other suspension parts for a

bent condition.

ALIGNMENT

MARKS

G-1496-A

FIG. I?—Straight Ahead Position

Marks—Typical

POSITIVE

CAMBER

• •

NEGATIVE-*!

| ^*—

CASTER

ICL

OF TIRE

POSITIVE

CASTER

5r\

CA&U

ANGlE

F1216-A

FIG. 72—Caster and Camber

Angles

COMMON ADJUSTMENTS AND REPAIRS

After front wheel alignment factors

have been checked, make the neces-

sary adjustments. Do not attempt to

adjust front wheel alignment by bend-

ing the suspension or steering parts.

CASTER AND CAMBER

ADJUSTMENTS

FORD, MERCURY, METEOR,

THUNDERBIRDAND

CONTINENTAL MARK III

Caster and camber is adjusted by

loosening the bolts that attach the

upper suspension arm inner shaft to

the frame side rail, and moving the

inner shaft in or out in the elongated

bolt holes with the tool shown in Fig.

13.

The tool should be installed with

the tool pins in the frame holes and

the hooks over the upper arm inner

shaft. Then, tighten the tool hook nuts

snug before loosening the upper arm

inner shaft attaching bolts.

Caster

To adjust the caster angle, tighten

the tool front hook nut or loosen the

rear hook nut (Fig. 14) as required to

increase caster to the desired angle.

To decrease caster, tighten the tool

rear hook nut or loosen the front

hook nut as required (Fig. 14). The

caster angle can be checked without

tightening the inner shaft attaching

bolts.

Check the camber adjustment to

be sure it did not change during the

caster adjustment and adjust if neces-

FIG. 73—Camber and Caster

Adjusting Toolprocarmanuals.com

Page 71 of 413

03-01-06

Suspension — Steering, Wheels And Tires — General Service

03-01-06

SUSPENSION UPPER

ARM MOVEMENT

Front Bolt Outboard

Rear Bolt Outboard

Front Bolt Inboard

Rear Bolt Inboard

CASTER CHANGE

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

CAMBER CHANGE

Tilt Outward

Increase Positive Camber

or

Decrease Negative Camber

Tilt Inward

Decrease Positive Camber

or

Increase Negative Camber

FIG. 14—Caster and Camber Adjustments

sary. Then, tighten the upper arm

inner shaft attaching bolts to specifi-

cation. Remove the adjusting bar

(Tool T65P-3OOO-D) and the align-

ment spacers (Tool T65P-3O00-E or

F).

Camber

To adjust the camber angle, install

the tool as outlined above (Fig. 13).

Loosen both inner shaft attaching

bolts and tighten or loosen the hook

nuts to move the inner shaft inboard

or outboard as necessary with Tool

T65P-3OOO-D to increase or decrease

camber (Fig. 13). The camber angle

can be checked without tightening the

inner shaft attaching bolts.

COUGAR, FAIRLANE, FALCON,

MONTEGO, MUSTANG

Be sure all the equipment listed in

Equipment Installation is installed be-

fore adjusting the caster and camber.

Caster is controlled by the front

suspension strut (Fig. 15). To obtain

positive caster, loosen the strut rear

nut and tighten the strut front nut

against the bushing. To obtain nega-

tive caster, loosen the strut front nut

and tighten the strut rear nut against

the bushing.

Camber is controlled by the eccen-

tric cam located at the lower arm at-

tachment to the side rail (Fig. 13).

To adjust the camber, loosen the

camber adjustment bolt nut at the

rear of the body bracket. Spread the

body bracket at the camber adjust-

TER ADJUSTMENT NUTS

EAR INSULATOR

WASHER

FRONT ADJUSTMENT NUT

INNER SLEEVE

TURN NUTS

REARWARD

TO OBTAIN

POSITIVE

CASTER

OUTER SLEEVE

RONT INSULATOR

WASHER

CASTELLATED

NUT

TURN NUTS

FORWARD

TO OBTAIN

NEGATIVE

CASTER

NEGATIVE

CAMBER

SPREAD THIS MEMBER AT

LOWER ARM PIVOT

BUSHING

PRY AT THESE POINTS'

F1371-A

FIG. J5—Caster and Camber Adjustments

ment bolt area just enough to permit

lateral travel of the arm when the ad-

justment bolt is turned. Rotate the

bolt and eccentric clockwise from the

high position to increase camber or

counterclockwise to decrease camber.

After the caster and camber has

been adjusted to specification, torque

the lower arm eccentric bolt nut and

the strut front nut to specification.

LINCOLN CONTINENTAL

Preliminary Steps

1.

With the car properly positioned

and wheel alignment measuring equip-

ment properly installed, raise the hood

and scribe chalk marks around the

bolts and lock washers that secure theprocarmanuals.com