seats FORD SIERRA 1982 1.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1982, Model line: SIERRA, Model: FORD SIERRA 1982 1.GPages: 26, PDF Size: 0.57 MB

Page 8 of 26

REF•8MOTtest checks

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

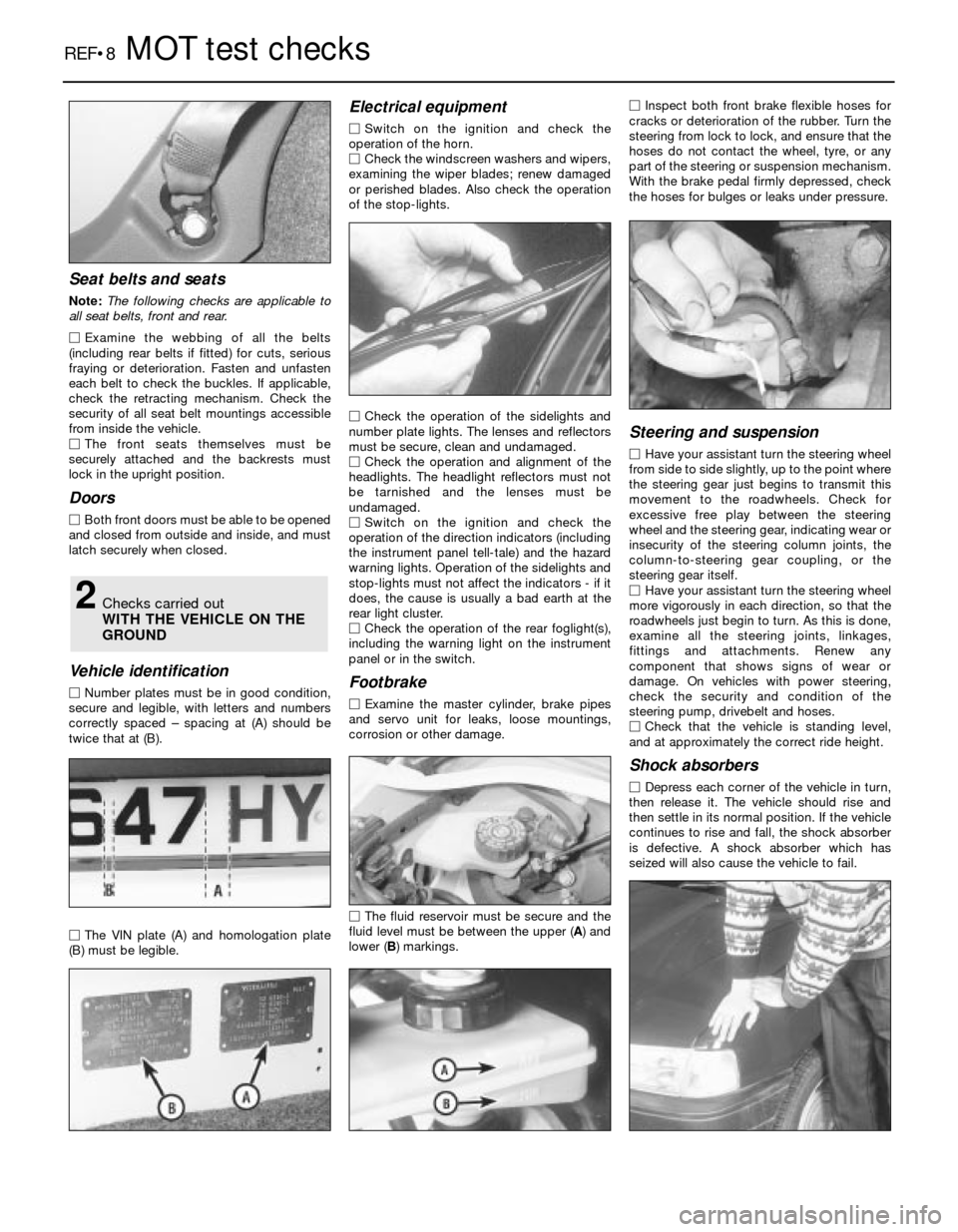

Vehicle identification

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate (A) and homologation plate

(B) must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

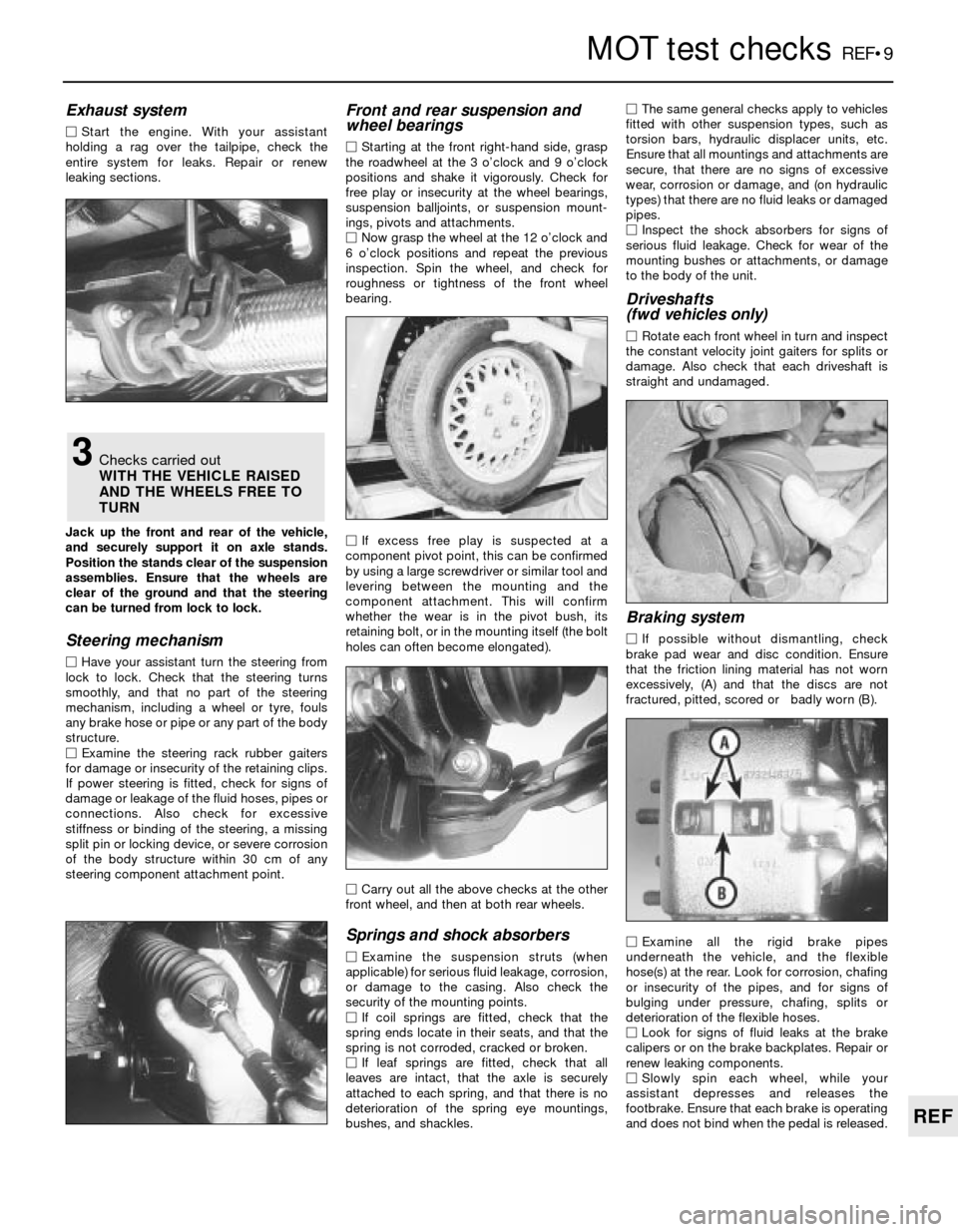

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

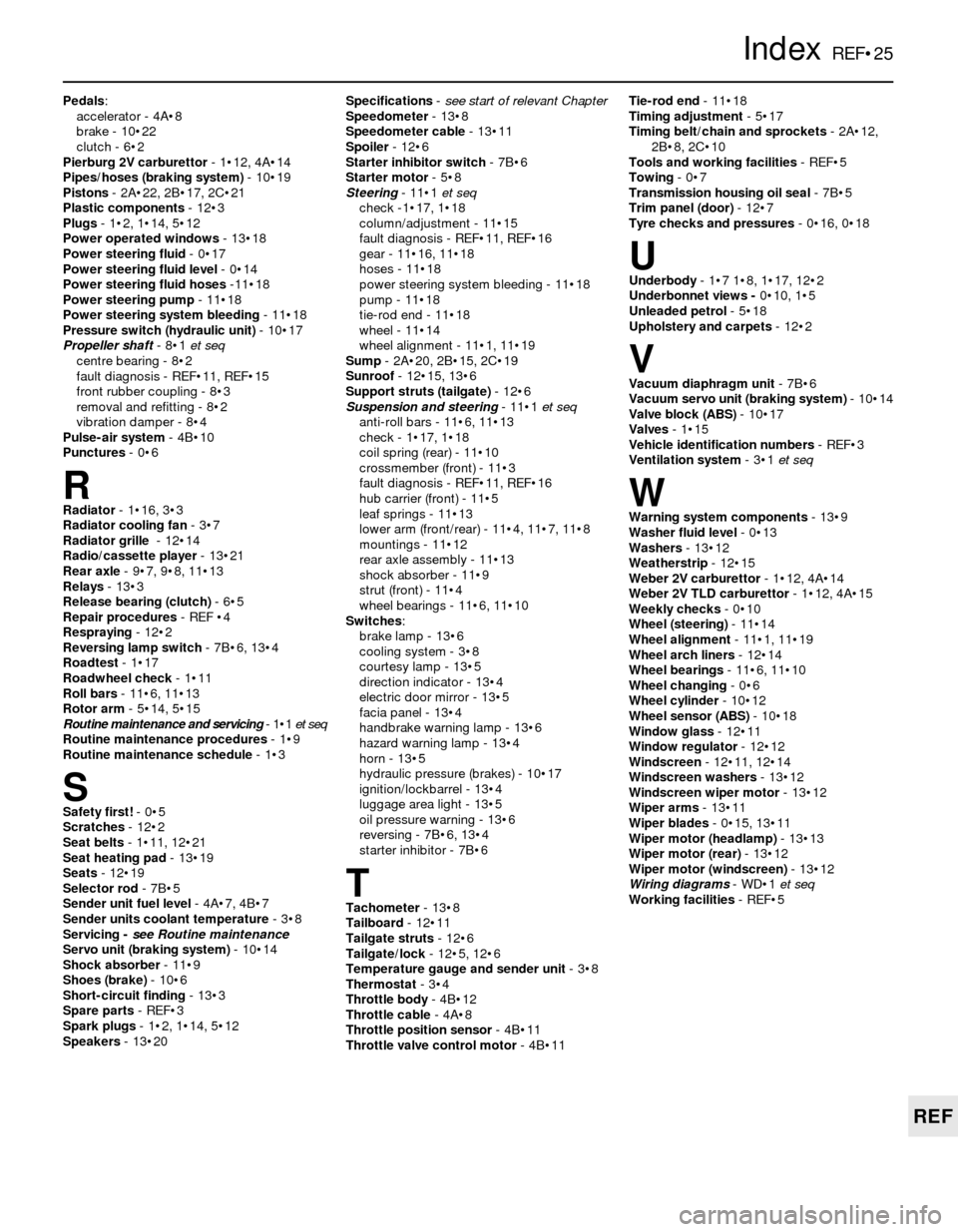

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

Page 9 of 26

MOTtest checksREF•9

REF

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entire system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from

lock to lock. Check that the steering turns

smoothly, and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

MExamine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stiffness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

MStarting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

free play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

MNow grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

roughness or tightness of the front wheel

bearing.

MIf excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

retaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

MCarry out all the above checks at the other

front wheel, and then at both rear wheels.

Springs and shock absorbers

MExamine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

MIf coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles.MThe same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensure that all mountings and attachments are

secure, that there are no signs of excessive

wear, corrosion or damage, and (on hydraulic

types) that there are no fluid leaks or damaged

pipes.

MInspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

MRotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

Braking system

MIf possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively, (A) and that the discs are not

fractured, pitted, scored or badly worn (B).

MExamine all the rigid brake pipes

underneath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

renew leaking components.

MSlowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

Page 25 of 26

Pedals:

accelerator - 4A•8

brake - 10•22

clutch - 6•2

Pierburg 2V carburettor- 1•12, 4A•14

Pipes/hoses (braking system)- 10•19

Pistons- 2A•22, 2B•17, 2C•21

Plastic components- 12•3

Plugs- 1•2, 1•14, 5•12

Power operated windows- 13•18

Power steering fluid- 0•17

Power steering fluid level- 0•14

Power steering fluid hoses-11•18

Power steering pump- 11•18

Power steering system bleeding- 11•18

Pressure switch (hydraulic unit)- 10•17

Propeller shaft- 8•1 et seq

centre bearing - 8•2

fault diagnosis - REF•11, REF•15

front rubber coupling - 8•3

removal and refitting - 8•2

vibration damper - 8•4

Pulse-air system- 4B•10

Punctures- 0•6

RRadiator- 1•16, 3•3

Radiator cooling fan- 3•7

Radiator grille- 12•14

Radio/cassette player- 13•21

Rear axle- 9•7, 9•8, 11•13

Relays- 13•3

Release bearing (clutch)- 6•5

Repair procedures- REF •4

Respraying- 12•2

Reversing lamp switch- 7B•6, 13•4

Roadtest- 1•17

Roadwheel check- 1•11

Roll bars- 11•6, 11•13

Rotor arm- 5•14, 5•15

Routine maintenance and servicing- 1•1 et seq

Routine maintenance procedures- 1•9

Routine maintenance schedule- 1•3

SSafety first!- 0•5

Scratches- 12•2

Seat belts- 1•11, 12•21

Seat heating pad- 13•19

Seats- 12•19

Selector rod- 7B•5

Sender unit fuel level- 4A•7, 4B•7

Sender units coolant temperature- 3•8

Servicing -see Routine maintenance

Servo unit (braking system)- 10•14

Shock absorber- 11•9

Shoes (brake)- 10•6

Short-circuit finding- 13•3

Spare parts- REF•3

Spark plugs- 1•2, 1•14, 5•12

Speakers- 13•20Specifications- see start of relevant Chapter

Speedometer- 13•8

Speedometer cable- 13•11

Spoiler- 12•6

Starter inhibitor switch- 7B•6

Starter motor- 5•8

Steering- 11•1 et seq

check -1•17, 1•18

column/adjustment - 11•15

fault diagnosis - REF•11, REF•16

gear - 11•16, 11•18

hoses - 11•18

power steering system bleeding - 11•18

pump - 11•18

tie-rod end - 11•18

wheel - 11•14

wheel alignment - 11•1, 11•19

Sump- 2A•20, 2B•15, 2C•19

Sunroof- 12•15, 13•6

Support struts (tailgate)- 12•6

Suspension and steering- 11•1 et seq

anti-roll bars - 11•6, 11•13

check - 1•17, 1•18

coil spring (rear) - 11•10

crossmember (front) - 11•3

fault diagnosis - REF•11, REF•16

hub carrier (front) - 11•5

leaf springs - 11•13

lower arm (front/rear) - 11•4, 11•7, 11•8

mountings - 11•12

rear axle assembly - 11•13

shock absorber - 11•9

strut (front) - 11•4

wheel bearings - 11•6, 11•10

Switches:

brake lamp - 13•6

cooling system - 3•8

courtesy lamp - 13•5

direction indicator - 13•4

electric door mirror - 13•5

facia panel - 13•4

handbrake warning lamp - 13•6

hazard warning lamp - 13•4

horn - 13•5

hydraulic pressure (brakes) - 10•17

ignition/lockbarrel - 13•4

luggage area light - 13•5

oil pressure warning - 13•6

reversing - 7B•6, 13•4

starter inhibitor - 7B•6

TTachometer- 13•8

Tailboard- 12•11

Tailgate struts- 12•6

Tailgate/lock- 12•5, 12•6

Temperature gauge and sender unit- 3•8

Thermostat- 3•4

Throttle body- 4B•12

Throttle cable- 4A•8

Throttle position sensor- 4B•11

Throttle valve control motor- 4B•11Tie-rod end- 11•18

Timing adjustment- 5•17

Timing belt/chain and sprockets- 2A•12,

2B•8, 2C•10

Tools and working facilities- REF•5

Towing- 0•7

Transmission housing oil seal- 7B•5

Trim panel (door)- 12•7

Tyre checks and pressures- 0•16, 0•18

UUnderbody- 1•7 1•8, 1•17, 12•2

Underbonnet views -0•10, 1•5

Unleaded petrol- 5•18

Upholstery and carpets- 12•2

VVacuum diaphragm unit- 7B•6

Vacuum servo unit (braking system)- 10•14

Valve block (ABS)- 10•17

Valves- 1•15

Vehicle identification numbers- REF•3

Ventilation system- 3•1 et seq

WWarning system components- 13•9

Washer fluid level- 0•13

Washers- 13•12

Weatherstrip- 12•15

Weber 2V carburettor- 1•12, 4A•14

Weber 2V TLD carburettor- 1•12, 4A•15

Weekly checks- 0•10

Wheel (steering) - 11•14

Wheel alignment- 11•1, 11•19

Wheel arch liners- 12•14

Wheel bearings- 11•6, 11•10

Wheel changing- 0•6

Wheel cylinder- 10•12

Wheel sensor(ABS)- 10•18

Window glass- 12•11

Window regulator- 12•12

Windscreen- 12•11, 12•14

Windscreen washers- 13•12

Windscreen wiper motor- 13•12

Wiper arms- 13•11

Wiper blades- 0•15, 13•11

Wiper motor (headlamp)- 13•13

Wiper motor (rear)- 13•12

Wiper motor (windscreen)- 13•12

Wiring diagrams- WD•1 et seq

Working facilities- REF•5

IndexREF•25

REF