auxiliary battery location FORD SIERRA 1983 1.G Body Electrical System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 25, PDF Size: 1.7 MB

Page 3 of 25

5To find the source of an intermittent wiring

fault (usually due to a poor or dirty

connection, or damaged wiring insulation), an

integrity test can be performed on the wiring,

which involves moving the wiring by hand, to

see if the fault occurs as the wiring is moved.

It should be possible to narrow down the

source of the fault to a particular section of

wiring. This method of testing can be used in

conjunction with any of the tests described in

the following sub-Sections.

6Apart from problems due to poor

connections, two basic types of fault can

occur in an electrical circuit - open-circuit, or

short-circuit.

7Open-circuit faults are caused by a break

somewhere in the circuit, which prevents

current from flowing. An open-circuit fault will

prevent a component from working, but will

not cause the relevant circuit fuse to blow.

8Short-circuit faults are caused by a “short”

somewhere in the circuit, which allows the

current flowing in the circuit to “escape” along

an alternative route, usually to earth. Short-

circuit faults are normally caused by a

breakdown in wiring insulation, which allows a

feed wire to touch either another wire, or an

earthed component such as the bodyshell. A

short-circuit fault will normally cause the

relevant circuit fuse to blow.

Note: A short-circuit that occurs in the wiring

between a circuit’s battery supply and its fuse

will not cause the fuse in that particular circuit

to blow. This part of the circuit is unprotected

- bear this in mind when fault-finding on the

vehicle’s electrical system.

Finding an open-circuit

9To check for an open-circuit, connect one

lead of a circuit tester or voltmeter to either

the negative battery terminal or a known good

earth.

10Connect the other lead to a connector in

the circuit being tested, preferably nearest to

the battery or fuse.

11Switch on the circuit, bearing in mind that

some circuits are live only when the ignition

switch is moved to a particular position.

12If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading,

as applicable), this means that the section of

the circuit between the relevant connector

and the battery is problem-free.

13Continue to check the remainder of the

circuit in the same fashion.

14When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

15To check for a short-circuit, first

disconnect the load(s) from the circuit (loads

are the components which draw current from

a circuit, such as bulbs, motors, heating

elements, etc).

16Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.17Switch on the circuit, bearing in mind that

some circuits are live only when the ignition

switch is moved to a particular position.

18If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading,

as applicable), this means that there is a

short-circuit.

19If no voltage is present, but the fuse still

blows with the load(s) connected, this

indicates an internal fault in the load(s).

Finding an earth fault

20The battery negative terminal is connected

to “earth” - the metal of the

engine/transmission and the car body - and

most systems are wired so that they only

receive a positive feed, the current returning via

the metal of the car body. This means that the

component mounting and the body form part

of that circuit. Loose or corroded mountings

can therefore cause a range of electrical faults,

ranging from total failure of a circuit, to a

puzzling partial fault. In particular, lights may

shine dimly (especially when another circuit

sharing the same earth point is in operation),

motors (eg wiper motors or the radiator cooling

fan motor) may run slowly, and the operation of

one circuit may have an apparently-unrelated

effect on another. Note that on many vehicles,

earth straps are used between certain

components, such as the engine/transmission

and the body, usually where there is no metal-

to-metal contact between components, due to

flexible rubber mountings, etc.

21To check whether a component is

properly earthed, disconnect the battery, and

connect one lead of an ohmmeter to a known

good earth point. Connect the other lead to

the wire or earth connection being tested. The

resistance reading should be zero; if not,

check the connection as follows.

22If an earth connection is thought to be

faulty, dismantle the connection, and clean

back to bare metal both the bodyshell and the

wire terminal, or the component’s earth

connection mating surface. Be careful to

remove all traces of dirt and corrosion, then

use a knife to trim away any paint, so that a

clean metal-to-metal joint is made. On

reassembly, tighten the joint fasteners

securely; if a wire terminal is being refitted,

use serrated washers between the terminaland the bodyshell, to ensure a clean and

secure connection. When the connection is

remade, prevent the onset of corrosion in the

future by applying a coat of petroleum jelly or

silicone-based grease, or by spraying on (at

regular intervals) a proprietary ignition sealer.Location

1The main fuses and relays are located in a

box in the engine compartment on the right-

hand side of the bulkhead. The circuits

protected are identified by symbols on the

underside of the fusebox cover. On certain

models, additional relays and fuses are located

in various positions beneath the facia panels. If

uncertain of the location of an auxiliary relay or

fuse, it is suggested that a Ford dealer is

consulted, as the relay and fuse locations vary

substantially depending on model.

Renewal

2Always renew a fuse with one of identical

rating and never renew it more than once

without finding the source of the trouble

(usually a short circuit). Always switch off the

ignition before renewing a fuse or relay, and

when renewing the wiper motor fuse keep the

hands clear of the wiper linkage as it may

return to the parked position. Note that the

fuses are colour-coded as follows:

10ARed

15ABlue

20AYellow

25ANatural

10AGreen

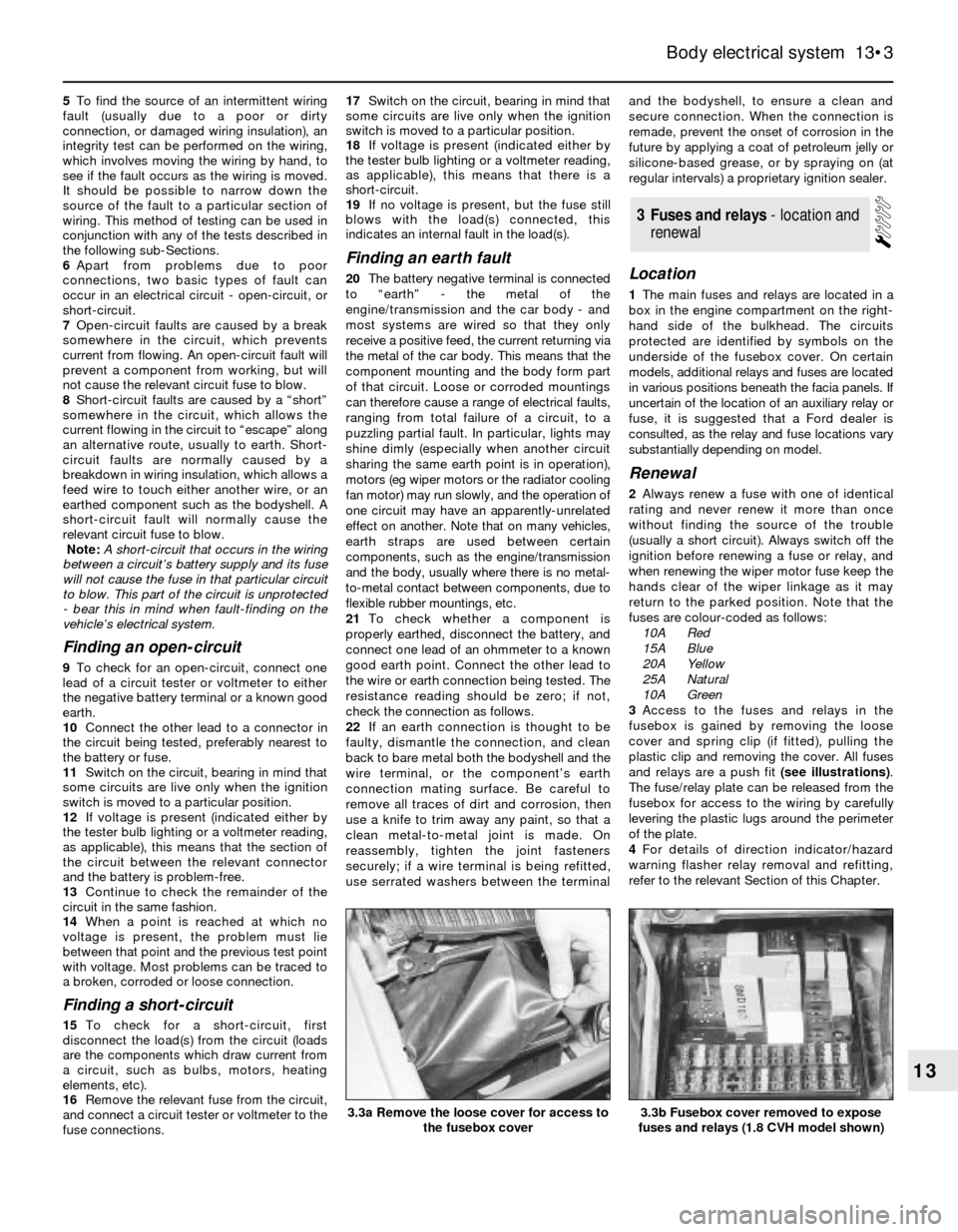

3Access to the fuses and relays in the

fusebox is gained by removing the loose

cover and spring clip (if fitted), pulling the

plastic clip and removing the cover. All fuses

and relays are a push fit (see illustrations).

The fuse/relay plate can be released from the

fusebox for access to the wiring by carefully

levering the plastic lugs around the perimeter

of the plate.

4For details of direction indicator/hazard

warning flasher relay removal and refitting,

refer to the relevant Section of this Chapter.

3Fuses and relays - location and

renewal

Body electrical system 13•3

13

3.3b Fusebox cover removed to expose

fuses and relays (1.8 CVH model shown)3.3a Remove the loose cover for access to

the fusebox cover

Page 9 of 25

Location

1The AWS control unit, and (when fitted) the

bulb failure monitor, are located behind the

glovebox on models up to 1987.

2On models from 1987, the control and bulb

failure modules are located behind the driver’s

side footwell trim panel.

Testing

3Thorough testing and fault finding should

be left to a Ford dealer or other electrical

specialist, having test equipment. Unskilled or

uninformed testing may cause damage.

4Investigation of malfunctions should begin

by checking that all wiring is intact and

securely connected. If checking wires or

sensors for continuity, always disconnect the

control unit and/or bulb failure monitor before

so doing, otherwise damage may be caused.

5Note that false oil level readings can result if

the car is parked on a slope. False bulb failure

warnings may occur if incorrect wattage bulbs

are fitted.

Removal and refitting

6Disconnect the battery negative lead.

Warning lamp bulbs

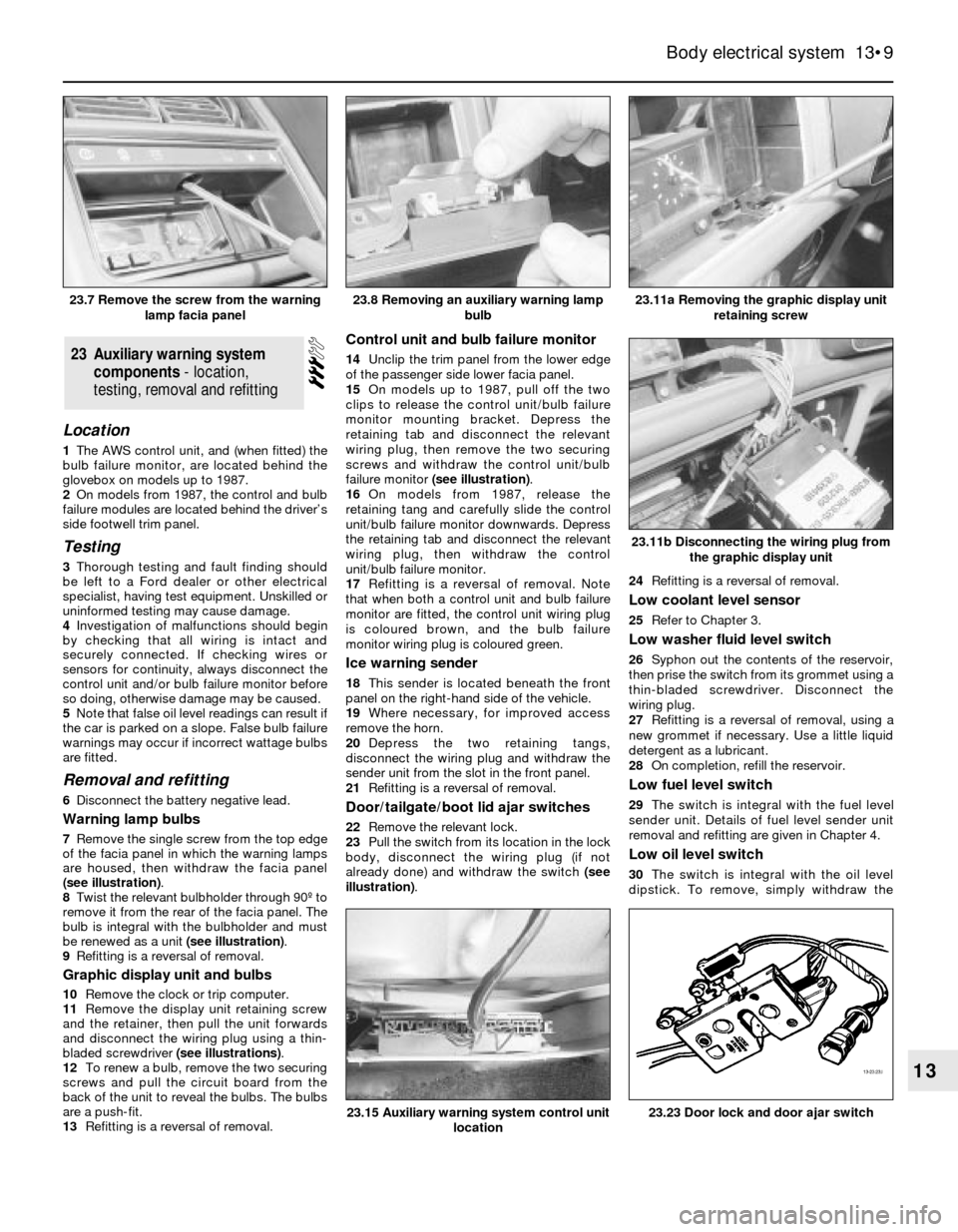

7Remove the single screw from the top edge

of the facia panel in which the warning lamps

are housed, then withdraw the facia panel

(see illustration).

8Twist the relevant bulbholder through 90º to

remove it from the rear of the facia panel. The

bulb is integral with the bulbholder and must

be renewed as a unit (see illustration).

9Refitting is a reversal of removal.

Graphic display unit and bulbs

10Remove the clock or trip computer.

11Remove the display unit retaining screw

and the retainer, then pull the unit forwards

and disconnect the wiring plug using a thin-

bladed screwdriver (see illustrations).

12To renew a bulb, remove the two securing

screws and pull the circuit board from the

back of the unit to reveal the bulbs. The bulbs

are a push-fit.

13Refitting is a reversal of removal.

Control unit and bulb failure monitor

14Unclip the trim panel from the lower edge

of the passenger side lower facia panel.

15On models up to 1987, pull off the two

clips to release the control unit/bulb failure

monitor mounting bracket. Depress the

retaining tab and disconnect the relevant

wiring plug, then remove the two securing

screws and withdraw the control unit/bulb

failure monitor (see illustration).

16On models from 1987, release the

retaining tang and carefully slide the control

unit/bulb failure monitor downwards. Depress

the retaining tab and disconnect the relevant

wiring plug, then withdraw the control

unit/bulb failure monitor.

17Refitting is a reversal of removal. Note

that when both a control unit and bulb failure

monitor are fitted, the control unit wiring plug

is coloured brown, and the bulb failure

monitor wiring plug is coloured green.

Ice warning sender

18This sender is located beneath the front

panel on the right-hand side of the vehicle.

19Where necessary, for improved access

remove the horn.

20Depress the two retaining tangs,

disconnect the wiring plug and withdraw the

sender unit from the slot in the front panel.

21Refitting is a reversal of removal.

Door/tailgate/boot lid ajar switches

22Remove the relevant lock.

23Pull the switch from its location in the lock

body, disconnect the wiring plug (if not

already done) and withdraw the switch (see

illustration).24Refitting is a reversal of removal.

Low coolant level sensor

25Refer to Chapter 3.

Low washer fluid level switch

26Syphon out the contents of the reservoir,

then prise the switch from its grommet using a

thin-bladed screwdriver. Disconnect the

wiring plug.

27Refitting is a reversal of removal, using a

new grommet if necessary. Use a little liquid

detergent as a lubricant.

28On completion, refill the reservoir.

Low fuel level switch

29The switch is integral with the fuel level

sender unit. Details of fuel level sender unit

removal and refitting are given in Chapter 4.

Low oil level switch

30The switch is integral with the oil level

dipstick. To remove, simply withdraw the

23Auxiliary warning system

components - location,

testing, removal and refitting

Body electrical system 13•9

13

23.11a Removing the graphic display unit

retaining screw

23.23 Door lock and door ajar switch23.15 Auxiliary warning system control unit

location

23.11b Disconnecting the wiring plug from

the graphic display unit

23.8 Removing an auxiliary warning lamp

bulb23.7 Remove the screw from the warning

lamp facia panel

Page 16 of 25

Models from 1987

5Remove the two securing screws, then

withdraw the lamp forwards and disconnect

the two wiring plugs.

6Refitting is a reversal of removal, but where

necessary use a new gasket between the

lamp and bumper.

7On completion, the vertical alignment of the

foglamp must be adjusted. For the foglamps,

dimension “X” (see illustration, 42.4) should

be taken as 220.0 mm (8.7 in). The adjuster

screw is located on the inside edge of the

lamp above the securing screw (see

illustration).

1Disconnect the battery negative lead.

Saloon, Hatchback and Estate

models

2To remove a lamp, simply prise it from the

bumper using a thin-bladed screwdriver, and

disconnect the wiring plug (see illustration).

3Refitting is a reversal of removal.

P100 models

4Working behind the rear crossmember, pull

the wiring plug from its clip and disconnect it.

5Pull the lamp cover from the rubber

housing, then pull the rubber housing and the

wiring from the crossmember.

6Refitting is a reversal of removal.

Note: The glass envelopes of the headlamp,

auxiliary driving lamp and front foglamp bulbs

must not be touched with the fingers. If the

glass is accidentally touched, it should be

washed with methylated spirits and dried with

a soft cloth. Failure to observe this procedure

may result in premature bulb failure.

1Disconnect the battery negative lead.

Headlamps

2Working in the engine compartment,

remove the headlamp rear cover by turning it

anti-clockwise (see illustration).3Pull the wiring plug from the base of the

bulb, then release the spring clip, grasp the

bulb by its contacts and carefully withdraw it

(see illustrations). Do not touch the bulb

glass.

4Refitting is a reversal of removal, but on

models up to 1987, refit the headlamp rear

cover by aligning the arrow on the cover with

the depression on the top of the headlamp

unit and turning the cover clockwise until the

arrow aligns with the lower depression. On

models from 1987, the word “OBEN “ or

“TOP” on the rear cover should be exactly at

the top after refitting.

Sidelamps

5Working in the engine compartment,

remove the headlamp rear cover by turning it

anti-clockwise.

6Pull the sidelamp bulbholder from its

location in the headlamp reflector (seeillustration). On “high specification” models

up to 1987 a retaining tab must be depressed

before withdrawing the bulbholder. Note that

the rubber sleeve should be left in position in

the reflector.

7Refitting is as described in paragraph 4.

Auxiliary driving lamps

Models up to 1987

8Twist the cover on the top of the headlamp

unit anti-clockwise and remove it to expose

the bulb (see illustration).

9Release the bulb from the two clips, then

disconnect the wiring and remove the bulb.

Do not touch the bulb glass (see illustration).

10Refitting is a reversal of removal.

Models from 1987

11Release the spring clip securing the cover

to the rear of the headlamp unit, then remove

the cover (see illustration).

48Exterior lamp bulbs - renewal

47Rear number plate lamp -

removal and refitting

13•16Body electrical system

46.7 Front foglamp adjuster screw (A) and

securing screws (B) - models from 1987

48.2 Remove the headlamp rear cover

48.8 Auxiliary drive lamp bulb cover

(arrowed) - models up to 198748.6 Removing a sidelamp bulbholder48.3b Release the spring clip and withdraw

the headlamp bulb

48.3a Pull off the wiring plug . . .

47.2 Removing a rear number plate lamp -

Saloon, Hatchback and Estate models