FORD SIERRA 1993 2.G Bodywork And Fittings Workshop Manual

Manufacturer: FORD, Model Year: 1993, Model line: SIERRA, Model: FORD SIERRA 1993 2.GPages: 22, PDF Size: 1.2 MB

Page 1 of 22

Torque wrench settingsNm lbf ft

Front seat belt stalk-to-seat bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 to 28 18 to 22

Seat belt anchor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat belt inertia reel securing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Cab safety grille securing bolts (P100 models) . . . . . . . . . . . . . . . . . . . 20 to 27 15 to 20

Rear bump stop securing nuts (P100 models) . . . . . . . . . . . . . . . . . . . . 8 to 11 6 to 8

Cargo area-to-chassis bolts (P100 models) . . . . . . . . . . . . . . . . . . . . . . 40 to 50 29 to 37

Tailboard hinge securing screws (P100 models) . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Chapter 12

Bodywork and fittings

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Bonnet lock release cable - removal and refitting . . . . . . . . . . . . . . . .7

Boot lid (Saloon models) - removal and refitting . . . . . . . . . . . . . . . . .9

Boot lid lock (Saloon models) - removal and refitting . . . . . . . . . . . . .10

Bumper - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Bumper trim moulding - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Cab air vent panel (P100 models) - removal and refitting . . . . . . . . .35

Cab interior trim panels (P100 models) - removal and refitting . . . . .42

Cargo area (P100 models) - removal and refitting . . . . . . . . . . . . . . .23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .44

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Door check arm - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .22

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .19

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . .17

Door interior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Door lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .20

Door mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Door window - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .27

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . .28

Exterior rear pillar trim panel (Saloon models) - removal and refitting .34

Facia panels - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .43

Front seat air cushion assembly - removal and refitting . . . . . . . . . .49

Fuel filler flap - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .37

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Inner gutter weatherstrip (Saloon, Hatchback and Estate models)-

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Interior pillar trim panels - removal and refitting . . . . . . . . . . . . . . . . .41

Interior trim panels - general information . . . . . . . . . . . . . . . . . . . . . .40

Maintenance - bodywork, underside and fittings . . . . . . . . . . . . . . . . .2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . . .3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . .45

Opening rear quarter window - removal and refitting . . . . . . . . . . . . .26

Radiator grille panel - removal and refitting . . . . . . . . . . . . . . . . . . . .32

Rear seat catch - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .48

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Sunroof - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .39

Tailboard (P100 models) - removal and refitting . . . . . . . . . . . . . . . .24

Tailgate/boot lid/fuel filler flap release cable - removal and refitting .14

Tailgate/boot lid spoiler - removal and refitting . . . . . . . . . . . . . . . . .15

Tailgate (Hatchback and Estate models) - removal and refitting . . . .11

Tailgate lock (Hatchback and Estate models) - removal and refitting . .12

Tailgate strut (Hatchback and Estate models) - removal and refitting .13

Wheel arch liners - removal and refitting . . . . . . . . . . . . . . . . . . . . . .36

Windscreen cowl panel - removal and refitting . . . . . . . . . . . . . . . . .33

Windscreen, rear window and fixed rear quarter windows - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

12•1

Specifications Contents

12

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 2 of 22

The model range includes 4-door Saloon, 3

and 5-door Hatchback, 5-door Estate, and 2-

door Pick-up body styles.

Each body is of all-steel welded energy-

absorbing monocoque construction, with a

separate load-bearing rear chassis frame on

P100 Pick-up models. Corrosion protection is

applied to all new vehicles, and includes zinc

phosphate dipping of the body panels, and

wax injection of box sections and doors.

All models have flush direct-glazed fixed glass

panels, and integrated polycarbonate bumpers.

All body panels are welded, including the

front wings, so it is recommended that major

body damage repairs are entrusted to a dealer.

A wide range of interior equipment and trim

options are available depending on model.

The procedures given in this Chapter apply to

original equipment fitments, and do not cover

after-market products.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts of

the vehicle not immediately visible, for instance

the underside, inside all the wheel arches and

the lower part of the engine compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way to remove any

accumulated mud which will retain moisture

and tend to encourage rust. Oddly enough,

the best time to clean the underframe and

wheel arches is in wet weather when the mud

is thoroughly wet and soft. In very wet

weather the underframe is usually cleaned of

large accumulations automatically and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the underframe

of the vehicle steam cleaned, engine

compartment included, so that a thorough

inspection can be carried out to see what

minor repairs and renovations are necessary.

Steam cleaning is available at many garages

and is necessary for removal of the

accumulation of oily grime which sometimes is

allowed to become thick in certain areas. If

steam cleaning facilities are not available,

there are one or two excellent grease solvents

available, which can be brush applied. The dirt

can then be simply hosed off. Note that thesemethods should not be used on vehicles with

wax-based underbody protective coating or

the coating will be removed. Such vehicles

should be inspected annually, preferably just

prior to winter, when the underbody should be

washed down and any damage to the wax

coating repaired using a proprietry brand

undershield. Ideally, a completely fresh coat

should be applied. It would also be worth

considering the use of such wax-based

protection for injection into door panels, sills,

box sections, etc, as an additional safeguard

against rust damage where such protection is

not provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish, will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to be

taken with metallic paintwork, as special non-

abrasive cleaner/polisher is required to avoid

damage to the finish. Always check that the

door and ventilator opening drain holes and

pipes are completely clear so that water can be

drained out. Bright work should be treated in

the same way as paint work. Windscreens and

windows can be kept clear of the smeary film

which often appears by the use of a proprietary

glass cleaner. Never use any form of wax or

other body or chromium polish on glass.

At the specified intervals, check the

operation of the door locks and check straps

and lubricate the hinges with a little oil. Also

lubricate the hinges of the bonnet and boot lid

or tailgate, as applicable, and the bonnet

release mechanism.

Mats and carpets should be brushed or

vacuum cleaned regularly to keep them free of

grit. If they are badly stained remove them

from the vehicle for scrubbing or sponging and

make quite sure they are dry before refitting.

Seats and interior trim panels can be kept

clean by wiping with a damp cloth and a

proprietry wax polish. If they do become

stained (which can be more apparent on light

coloured upholstery) use a little liquid

detergent and a soft nail brush to scour the

grime out of the grain of the material. Do not

forget to keep the headlining clean in the same

way as the upholstery. When using liquid

cleaners inside the vehicle do not over-wet the

surfaces being cleaned. Excessive damp

could get into the seams and padded interior

causing stains, offensive odours or even rot. If

the inside of the vehicle gets wet accidentally it

is worthwhile taking some trouble to dry it out

properly, particularly where carpets are

involved. Do not leave oil or electric heaters

inside the vehicle for this purpose.Repair of minor scratches in

bodywork

If the scratch is very superficial, and does not

penetrate to the metal of the bodywork, repair is

very simple. Lightly rub the area of the scratch

with a paintwork renovator, or a very fine cutting

paste, to remove loose paint from the scratch

and to clear the surrounding bodywork of wax

polish. Rinse the area with clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden: then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply a good wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique is

required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust inhibiting paint, to prevent the

formation of rust in the future. Using a rubber or

nylon applicator fill the scratch with bodystopper

paste. If required, this paste can be mixed with

cellulose thinners to provide a very thin paste

which is ideal for filling narrow scratches. Before

the stopper-paste in the scratch hardens, wrap

a piece of smooth cotton rag around the top of a

finger. Dip the finger in cellulose thinners; and

then quickly sweep it across the surface of the

stopper-paste in the scratch; this will ensure that

the surface of the stopper-paste is slightly

hollowed. The scratch can now be painted over

as described earlier in this Section.

Repair of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact and cannot be

reshaped fully to its original contour. It is better

to bring the level of the dent up to a point which

is about 1/8 in (3 mm) below the level of the

surrounding bodywork. In cases where the dent

is very shallow anyway, it is not worth trying to

pull it out at all. If the underside of the dent is

accessible, it can be hammered out gently from

behind, using a mallet with a wooden or plastic

head. Whilst doing this, hold a suitable block of

wood firmly against the outside of the panel to

absorb the impact from the hammer blows and

thus prevent a large area of the bodywork from

being “belled-out”.

Should the dent be in a section of the

bodywork which has a double skin or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area particularly in the deeper section.

4Minor body damage - repair

3Maintenance - upholstery and

carpets

2Maintenance - bodywork,

underside and fittings

1General information

12•2Bodywork and fittings

Page 3 of 22

Then screw long self-tapping screws into the

holes just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal of

the paint from the damaged area, and from an

inch or so of the surrounding “sound”

bodywork. This is accomplished most easily by

using a wire brush or abrasive pad on a power

drill, although it can be done just as effectively

by hand using sheets of abrasive paper. To

complete the preparation for filling, score the

surface of the bare metal with a screwdriver or

the tang of a file, or alternatively, drill small

holes in the affected area. This will provide a

really good “key” for the filler paste.

To complete the repair see the Section on

filling and re-spraying.

Repair of rust holes or gashes in

bodywork

Remove all paint from the affected area and

from an inch or so of the surrounding “sound”

bodywork, using an abrasive pad or a wire brush

on a power drill. If these are not available a few

sheets of abrasive paper will do the job just as

effectively. With the paint removed you will be

able to gauge the severity of the corrosion and

therefore decide whether to renew the whole

panel (if this is possible) or to repair the affected

area. New body panels are not as expensive as

most people think and it is often quicker and

more satisfactory to fit a new panel than to

attempt to repair large areas of corrosion.

Remove all fittings from the affected area

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlamp shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards in order

to create a slight depression for the filler paste.

Wire brush the affected area to remove the

powdery rust from the surface of the

remaining metal. Paint the affected area with

rust inhibiting paint; if the back of the rusted

area is accessible treat this also.

Before filling can take place it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh or glass fibre

matting is probably the best material to use for

a large hole. Cut a piece to the approximate

size and shape of the hole to be filled, then

position it in the hole so that its edges are

below the level of the surrounding bodywork. It

can be retained in position by several blobs of

filler paste around its periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll and

trim it to the approximate size and shape

required, then pull off the backing paper (if

used) and stick the tape over the hole; it can

be overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and re-

spraying

Before using this Section, see the Sections on

dent, deep scratch, rust holes and gash repairs.

Many types of bodyfiller are available, but

generally speaking those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair. A

wide, flexible plastic or nylon applicator will be

found invaluable for imparting a smooth and

well contoured finish to the surface of the filler.

Mix up a little filler on a clean piece of card or

board measure the hardener carefully (follow

the maker’s instructions on the pack) otherwise

the filler will set too rapidly or too slowly.

Alternatively, a no-mix filler can be used straight

from the tube without mixing, but daylight is

required to cure it. Using the applicator apply

the filler paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the filler

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too long

the paste will become sticky and begin to “pick

up” on the applicator. Continue to add thin

layers of filler paste at twenty-minute intervals

until the level of the filler is just proud of the

surrounding bodywork.

Once the filler has hardened, excess can be

removed using a metal plane or file. From then

on, progressively finer grades of abrasive

paper should be used, starting with a 40

grade production paper and finishing with 400

grade wet-and-dry paper. Always wrap the

abrasive paper around a flat rubber, cork, or

wooden block - otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface the wet-and-dry

paper should be periodically rinsed in water.

This will ensure that a very smooth finish is

imparted to the filler at the final stage.

At this stage the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

of the dust produced by the rubbing-down

operation has gone.

Spray the whole repair area with a light coat

of primer, this will show up any imperfections

in the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. If bodystopper is

used, it can be mixed with cellulose thinners

to form a really thin paste which is ideal for

filling small holes.

Repeat this spray and repair procedure until

you are satisfied that the surface of the filler,

and the feathered edge of the paintwork are

perfect. Clean the repair area with clean water

and allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day verycarefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this willhelp to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape and several thicknesses of

newspaper for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick coat

of primer; the thickness should be built up using

several thin layers of paint rather than one thick

one. Using 400 grade wet-and-dry paper, rub

down the surface of the primer until it is really

smooth. While doing this, the work area should

be thoroughly doused with water, and the wet-

and-dry paper periodically rinsed in water. Allow

to dry before spraying on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying in the centre of the repair area

and then work outwards, with a side-to-side

motion, until the whole repair area and about 2

inches of the surrounding original paintwork is

covered. Remove all masking material 10 to 15

minutes after spraying on the final coat of paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers, spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter of

either entrusting repair work to a specialist in this

field, or renewing complete components. Repair

of such damage by the DIY owner is not really

feasible owing to the cost of the equipment and

materials required for effecting such repairs. The

basic technique involves making a groove along

the line of the crack in the plastic using a rotary

burr in a power drill. The damaged part is then

welded back together by using a hot air gun to

heat up and fuse a plastic filler rod into the

groove. Any excess plastic is then removed and

the area rubbed down to a smooth finish. It is

important that a filler rod of the correct plastic is

used, as body components can be made of a

variety of different types (eg polycarbonate,

ABS, polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions,

this is used in similar fashion to the bodywork

filler used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it with

epoxy filler, he will be left with the problem of

finding a suitable paint for finishing which is

Bodywork and fittings 12•3

12

Page 4 of 22

compatible with the type of plastic used. At one

time the use of a universal paint was not

possible owing to the complex range of plastics

encountered in body component applications.

Standard paints, generally speaking, will not

bond to plastic or rubber satisfactorily.

However, it is now possible to obtain a plastic

body parts finishing kit which consists of a pre-

primer treatment, a primer and coloured top

coat. Full instructions are normally supplied with

a kit, but basically the method of use is to first

apply the pre-primer to the component

concerned and allow it to dry for up to 30

minutes. Then the primer is applied and left to

dry for about an hour before finally applying the

special coloured top coat. The result is a

correctly coloured component where the paint

will flex with the plastic or rubber, a property

that standard paint does not normally possess.

Where serious damage has occurred or large

areas need renewal due to neglect, it means

certainly that completely new sections or panels

will need welding in and this is best left to

professionals. If the damage is due to impact, it

will also be necessary to completely check the

alignment of the bodyshell structure. Due to the

principle of construction, the strength and shape

of the whole car can be affected by damage to

one part. In such instances the services of a

Ford agent with specialist checking jigs are

essential. If a body is left misaligned, it is first of

all dangerous as the car will not handle properly,

and secondly uneven stresses will be imposed

on the steering, engine and transmission,

causing abnormal wear or complete failure. Tyre

wear may also be excessive.

Removal

1Support the bonnet in its open position,

and place protective covers (old rags or

cardboard) beneath the corners of the bonnet,

and over the front wings to prevent damage to

the paintwork.

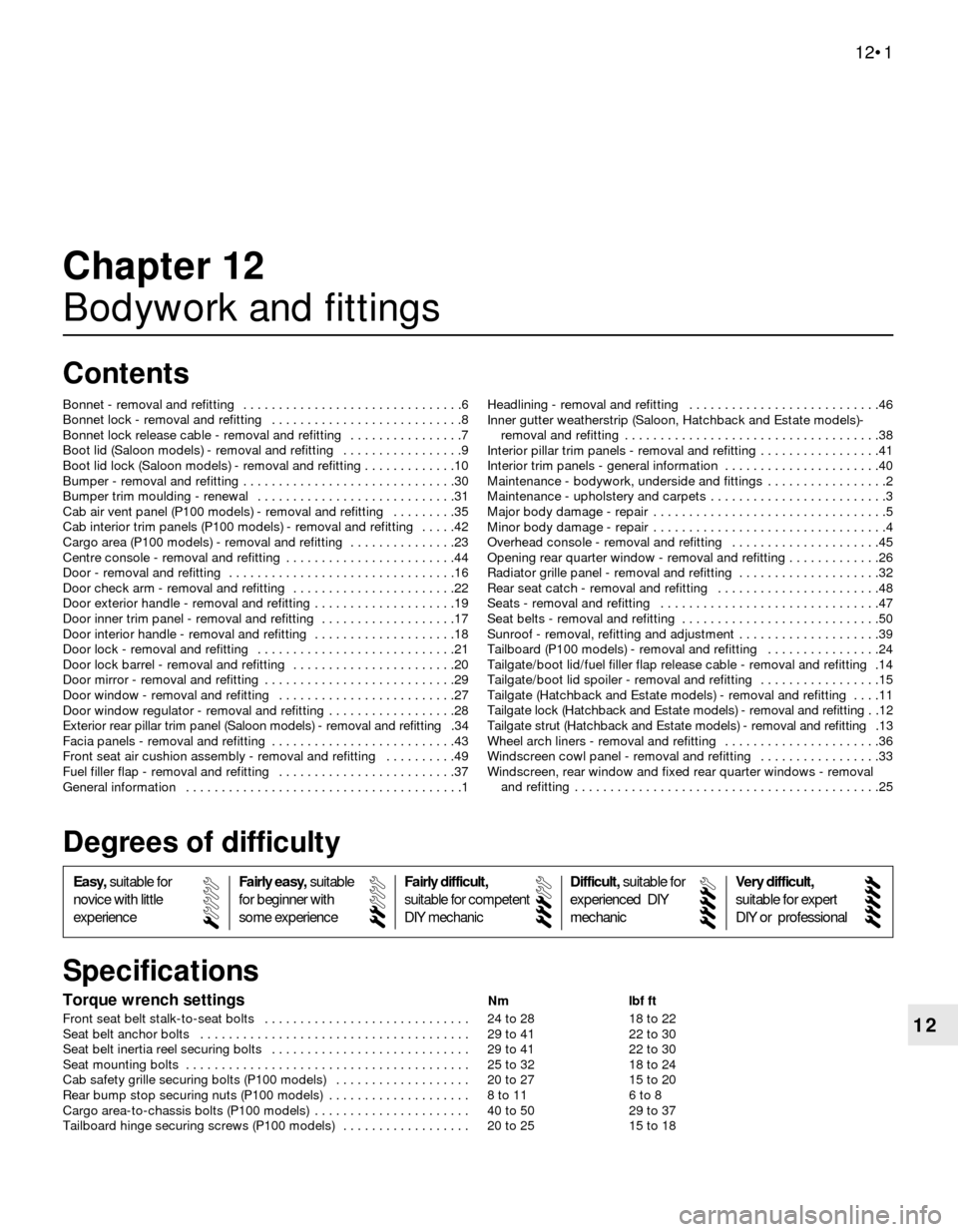

2Remove the screw and disconnect the earth

strap from the rear left-hand edge of the bonnet

(see illustration). Where applicable, disconnect

the wiring from the underbonnet lamp.

3Mark the location of the hinges on the sides

of the bonnet with a soft pencil or masking

tape, then loosen the four hinge bolts.

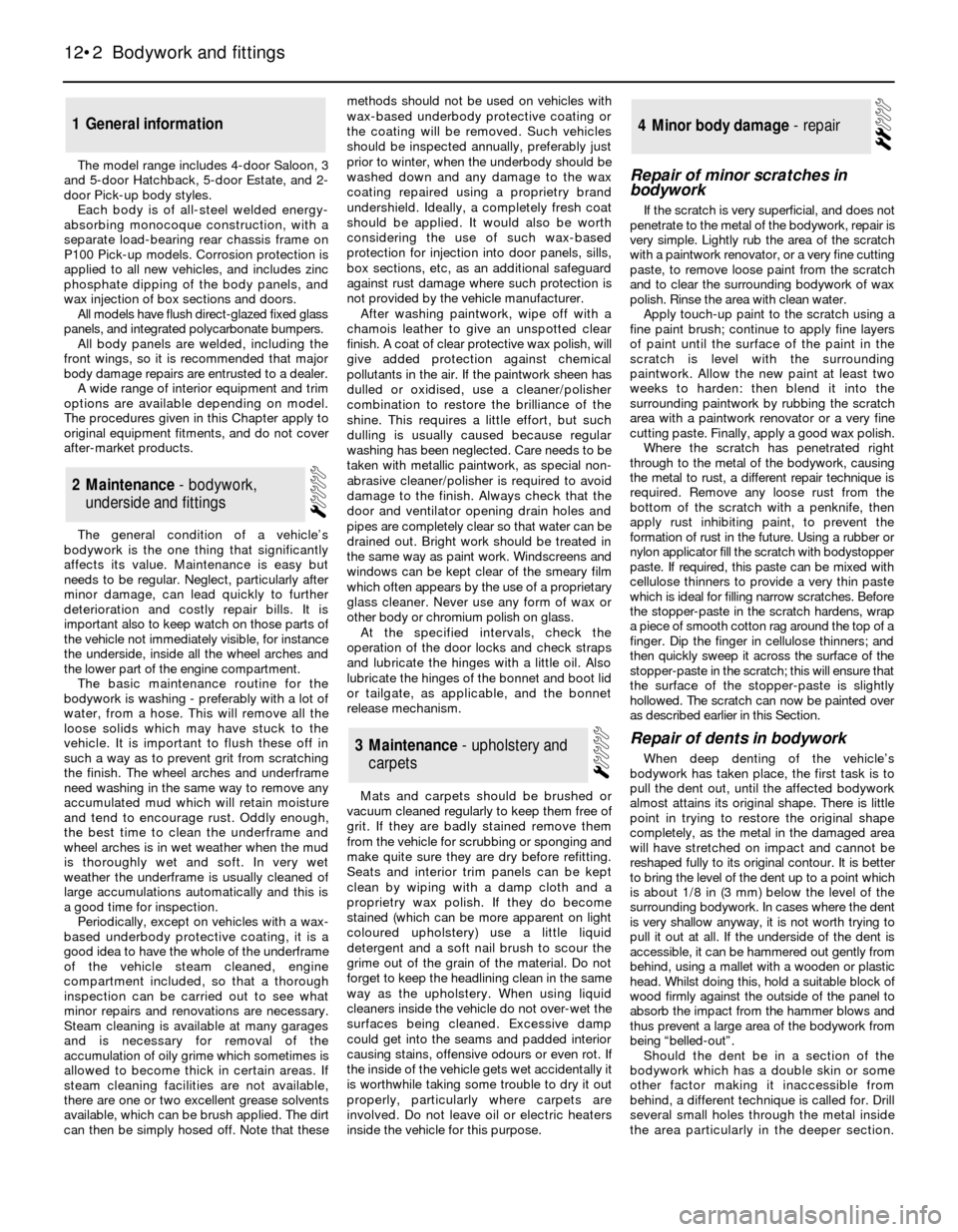

4With the help of an assistant, remove the

bolts and lift the bonnet from the vehicle (see

illustration).

5If required, the underbonnet insulation can

be removed by prising out the two-piece

plastic securing clips.

Refitting

6Refitting is a reversal of removal, bearing in

mind the following points.7Adjust the hinges to their original marked

positions before tightening the bolts.

8On completion, check that the bonnet is

central within its aperture and aligned with the

surrounding bodywork. Re-adjust the hinges

to give satisfactory alignment if necessary.

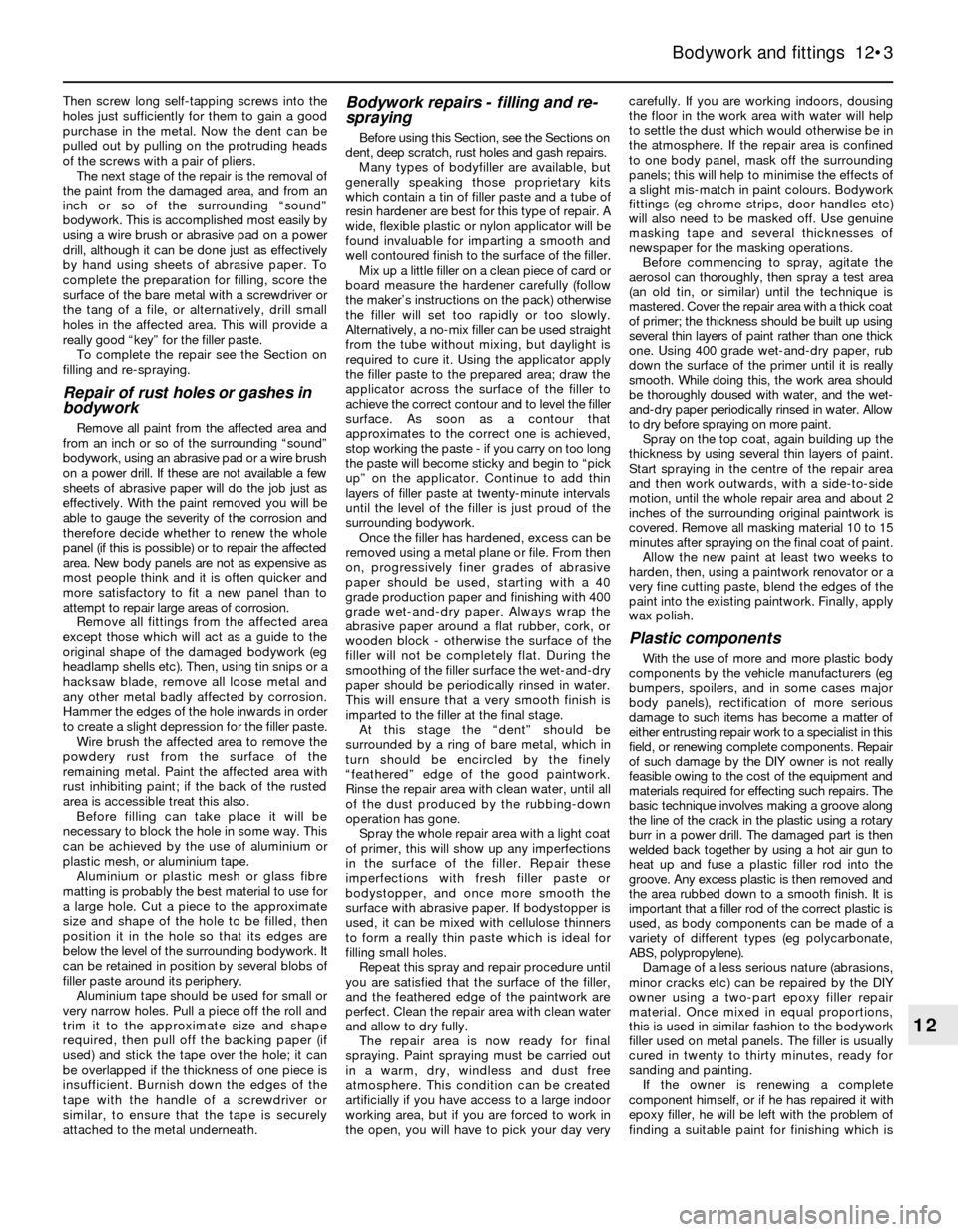

9Check that the bonnet lock striker engages

fully in the lock, and if necessary adjust the

position of the lock striker and/or the height of

the bonnet rubber bump stops (see

illustration).

Removal

1Working inside the vehicle, remove the

three retaining screws, and withdraw the

lower steering column shroud.

2Remove the retaining screw, and withdraw

the release cable bracket from the steering

column.

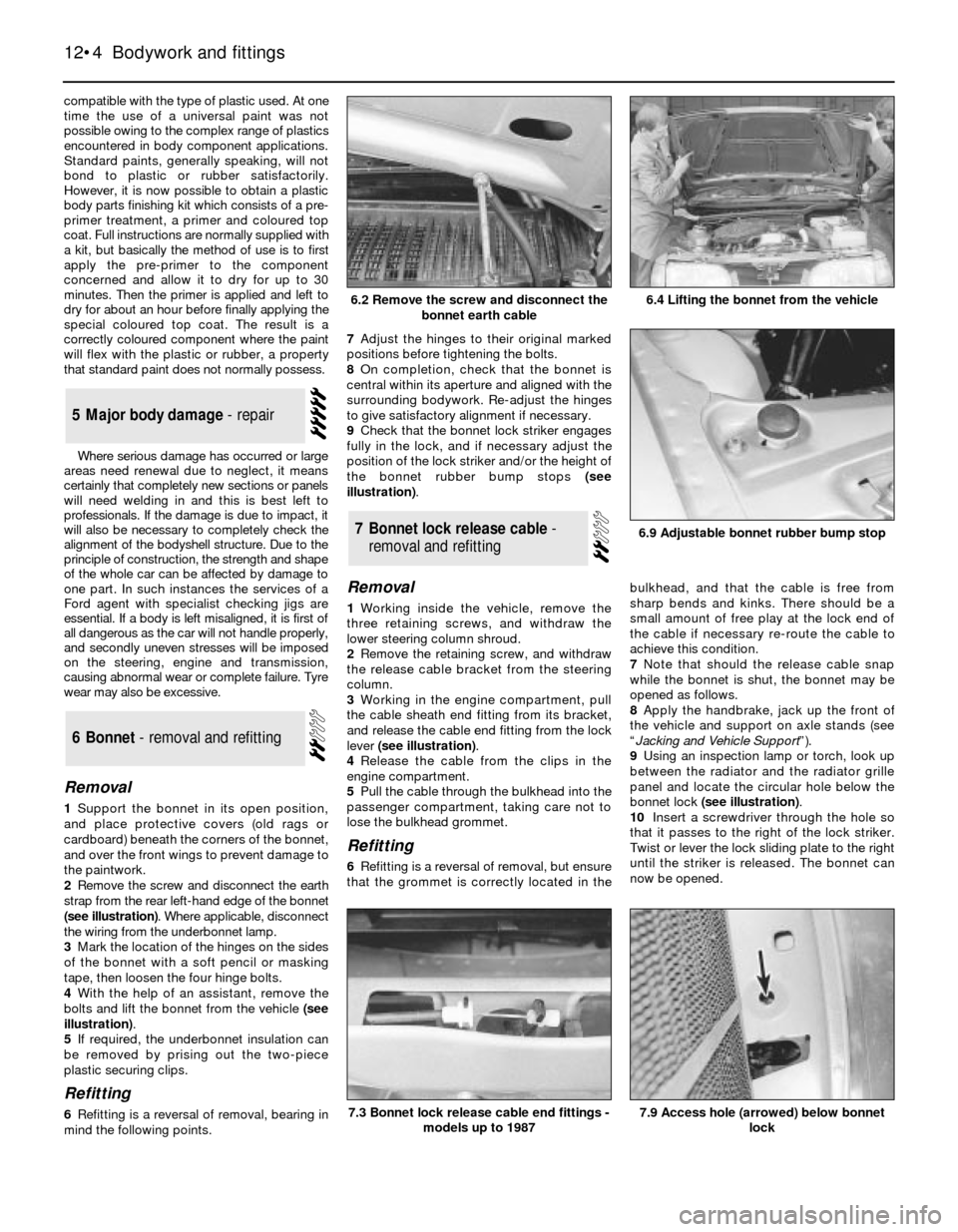

3Working in the engine compartment, pull

the cable sheath end fitting from its bracket,

and release the cable end fitting from the lock

lever (see illustration).

4Release the cable from the clips in the

engine compartment.

5Pull the cable through the bulkhead into the

passenger compartment, taking care not to

lose the bulkhead grommet.

Refitting

6Refitting is a reversal of removal, but ensure

that the grommet is correctly located in thebulkhead, and that the cable is free from

sharp bends and kinks. There should be a

small amount of free play at the lock end of

the cable if necessary re-route the cable to

achieve this condition.

7Note that should the release cable snap

while the bonnet is shut, the bonnet may be

opened as follows.

8Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“

Jacking and Vehicle Support”).

9Using an inspection lamp or torch, look up

between the radiator and the radiator grille

panel and locate the circular hole below the

bonnet lock (see illustration).

10Insert a screwdriver through the hole so

that it passes to the right of the lock striker.

Twist or lever the lock sliding plate to the right

until the striker is released. The bonnet can

now be opened.

7Bonnet lock release cable -

removal and refitting

6Bonnet - removal and refitting

5Major body damage - repair

12•4Bodywork and fittings

6.2 Remove the screw and disconnect the

bonnet earth cable

6.9 Adjustable bonnet rubber bump stop

7.9 Access hole (arrowed) below bonnet

lock7.3 Bonnet lock release cable end fittings -

models up to 1987

6.4 Lifting the bonnet from the vehicle

Page 5 of 22

Models up to 1987

1Working in the engine compartment,

disconnect the cable from the bonnet lock by

pulling the cable sheath end fitting from its

bracket, then releasing the end fitting from the

lock lever.

2Remove the three securing screws and

withdraw the lock from the front panel.

3Refitting is a reversal of removal.

Models from 1987

4Remove the radiator grille panel.

5Disconnect the cable from the bonnet lock

by pulling the cable sheath end fitting from its

bracket, then releasing the end fitting from the

lock lever.

6Detach the bracing strut from the lock by

removing the screw, then remove the two

securing screws and withdraw the lock from

the front panel.

7Refitting is a reversal of removal.

Removal

1Open the boot lid, and place protective

covers (old rags or cardboard) beneath the

corners of the lid, and over the rear wings to

prevent damage to the paintwork.

2Where applicable, disconnect the wiring

from the lock solenoid and “boot lid ajar”

sensor, after disconnecting the battery

negative lead.

3Release the wiring loom grommets, taking

care not to lose them, then tie string to the

wiring loom(s), and pull the loom(s) through

the boot lid. Leave the string(s) in position in

the boot lid to aid refitting of the loom(s).

4Mark the location of the hinges on the

underside of the lid using a soft pencil or

masking type, then loosen the four hinge bolts.5With the help of an assistant, remove the

bolts and lift the boot lid from the vehicle.

Refitting

6Refitting is a reversal of removal, bearing in

mind the following points.

7Adjust the hinges to their original marked

positions before tightening the bolts.

8On completion, check that the boot lid is

central within its aperture and aligned with the

surrounding bodywork. Re-adjust the hinges

to give satisfactory alignment if necessary.

9Check that the lock striker engages fully in

the lock, and if necessary adjust the position

of the lock striker.

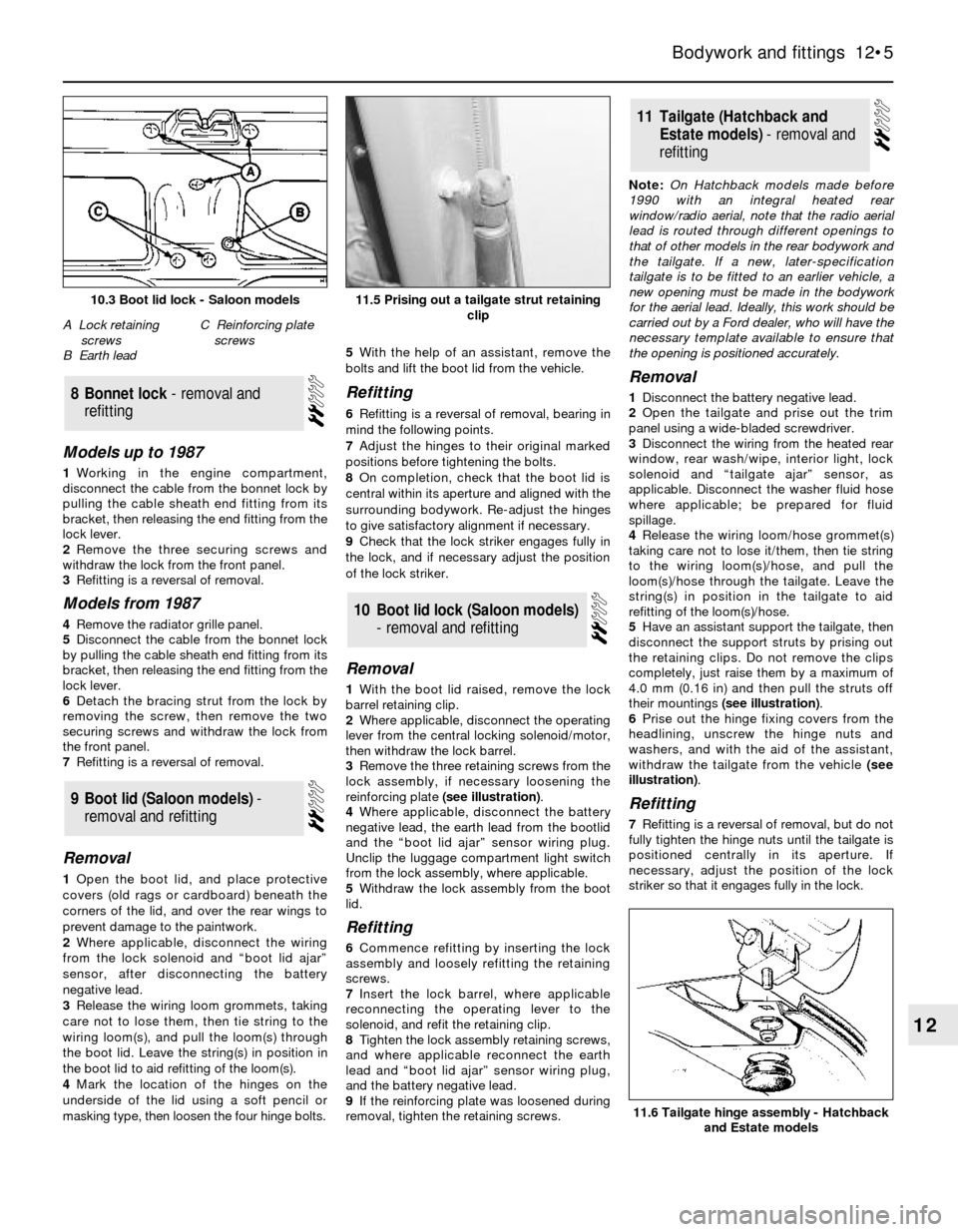

Removal

1With the boot lid raised, remove the lock

barrel retaining clip.

2Where applicable, disconnect the operating

lever from the central locking solenoid/motor,

then withdraw the lock barrel.

3Remove the three retaining screws from the

lock assembly, if necessary loosening the

reinforcing plate (see illustration).

4Where applicable, disconnect the battery

negative lead, the earth lead from the bootlid

and the “boot lid ajar” sensor wiring plug.

Unclip the luggage compartment light switch

from the lock assembly, where applicable.

5Withdraw the lock assembly from the boot

lid.

Refitting

6Commence refitting by inserting the lock

assembly and loosely refitting the retaining

screws.

7Insert the lock barrel, where applicable

reconnecting the operating lever to the

solenoid, and refit the retaining clip.

8Tighten the lock assembly retaining screws,

and where applicable reconnect the earth

lead and “boot lid ajar” sensor wiring plug,

and the battery negative lead.

9If the reinforcing plate was loosened during

removal, tighten the retaining screws.Note: On Hatchback models made before

1990 with an integral heated rear

window/radio aerial, note that the radio aerial

lead is routed through different openings to

that of other models in the rear bodywork and

the tailgate. If a new, later-specification

tailgate is to be fitted to an earlier vehicle, a

new opening must be made in the bodywork

for the aerial lead. Ideally, this work should be

carried out by a Ford dealer, who will have the

necessary template available to ensure that

the opening is positioned accurately.

Removal

1Disconnect the battery negative lead.

2Open the tailgate and prise out the trim

panel using a wide-bladed screwdriver.

3Disconnect the wiring from the heated rear

window, rear wash/wipe, interior light, lock

solenoid and “tailgate ajar” sensor, as

applicable. Disconnect the washer fluid hose

where applicable; be prepared for fluid

spillage.

4Release the wiring loom/hose grommet(s)

taking care not to lose it/them, then tie string

to the wiring loom(s)/hose, and pull the

loom(s)/hose through the tailgate. Leave the

string(s) in position in the tailgate to aid

refitting of the loom(s)/hose.

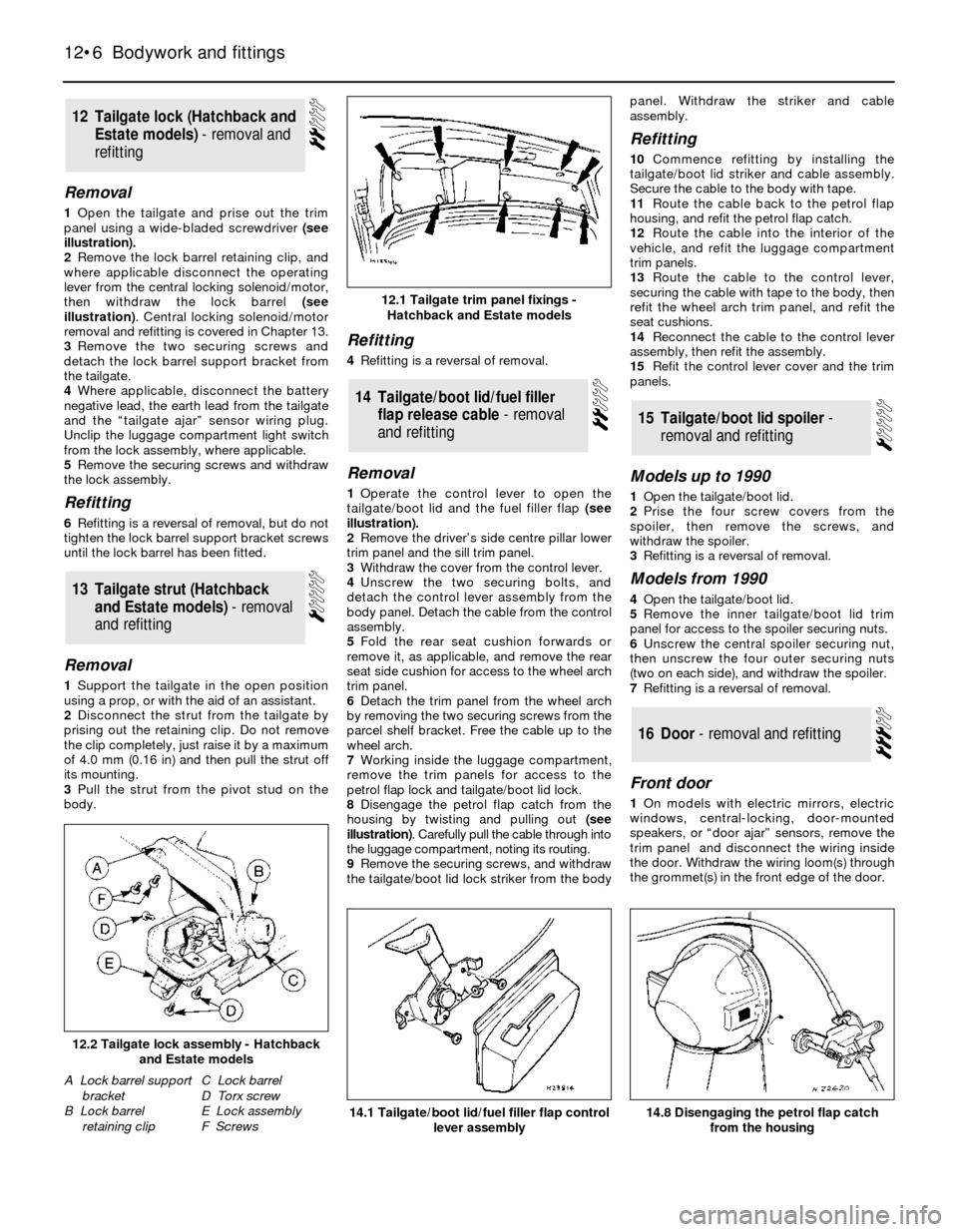

5Have an assistant support the tailgate, then

disconnect the support struts by prising out

the retaining clips. Do not remove the clips

completely, just raise them by a maximum of

4.0 mm (0.16 in) and then pull the struts off

their mountings (see illustration).

6Prise out the hinge fixing covers from the

headlining, unscrew the hinge nuts and

washers, and with the aid of the assistant,

withdraw the tailgate from the vehicle (see

illustration).

Refitting

7Refitting is a reversal of removal, but do not

fully tighten the hinge nuts until the tailgate is

positioned centrally in its aperture. If

necessary, adjust the position of the lock

striker so that it engages fully in the lock.

11Tailgate (Hatchback and

Estate models) - removal and

refitting

10Boot lid lock (Saloon models)

- removal and refitting

9Boot lid (Saloon models) -

removal and refitting

8Bonnet lock - removal and

refitting

Bodywork and fittings 12•5

12

11.6 Tailgate hinge assembly - Hatchback

and Estate models

11.5 Prising out a tailgate strut retaining

clip10.3 Boot lid lock - Saloon models

A Lock retaining

screws

B Earth leadC Reinforcing plate

screws

Page 6 of 22

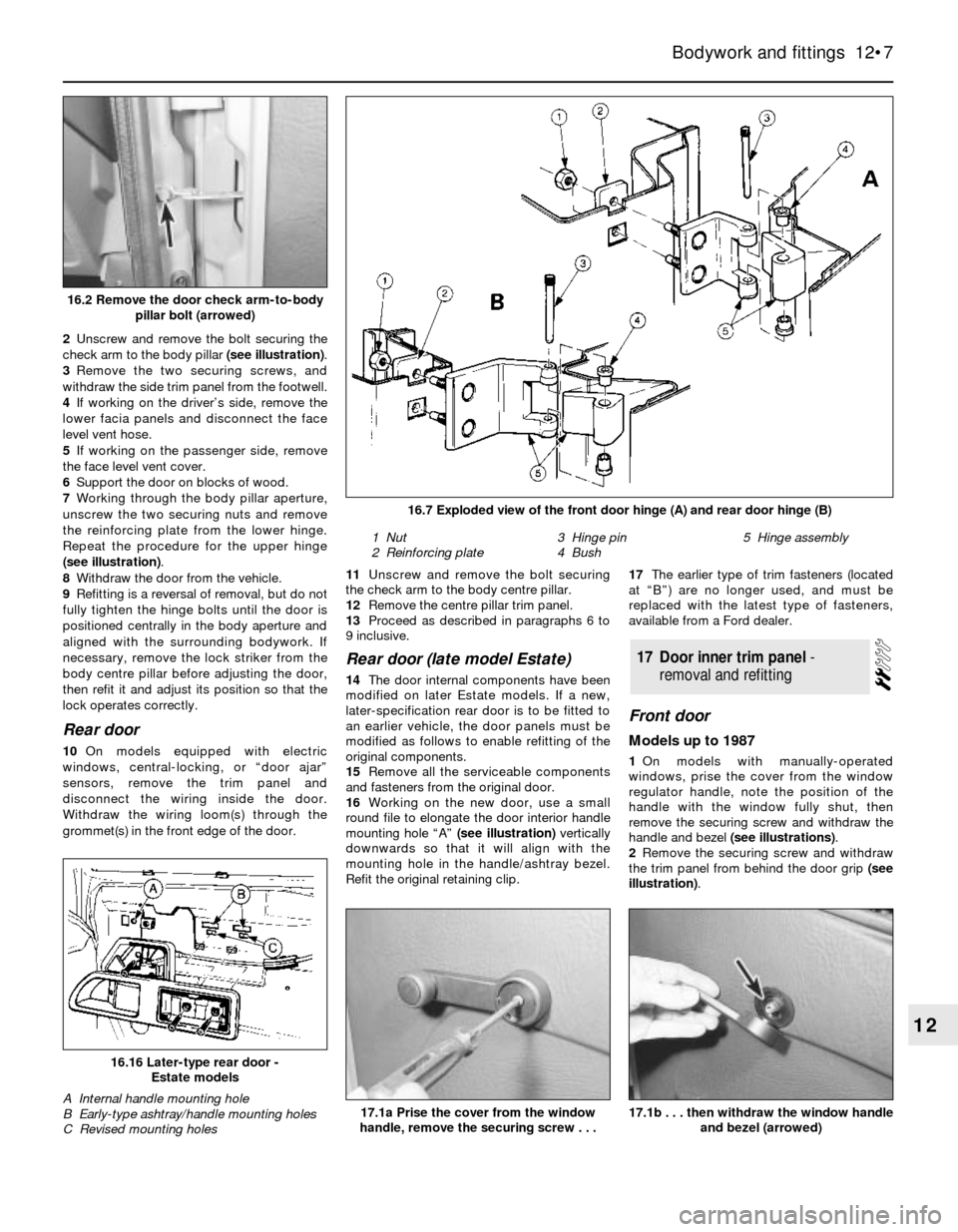

Removal

1Open the tailgate and prise out the trim

panel using a wide-bladed screwdriver(see

illustration).

2Remove the lock barrel retaining clip, and

where applicable disconnect the operating

lever from the central locking solenoid/motor,

then withdraw the lock barrel (see

illustration). Central locking solenoid/motor

removal and refitting is covered in Chapter 13.

3Remove the two securing screws and

detach the lock barrel support bracket from

the tailgate.

4Where applicable, disconnect the battery

negative lead, the earth lead from the tailgate

and the “tailgate ajar” sensor wiring plug.

Unclip the luggage compartment light switch

from the lock assembly, where applicable.

5Remove the securing screws and withdraw

the lock assembly.

Refitting

6Refitting is a reversal of removal, but do not

tighten the lock barrel support bracket screws

until the lock barrel has been fitted.

Removal

1Support the tailgate in the open position

using a prop, or with the aid of an assistant.

2Disconnect the strut from the tailgate by

prising out the retaining clip. Do not remove

the clip completely, just raise it by a maximum

of 4.0 mm (0.16 in) and then pull the strut off

its mounting.

3Pull the strut from the pivot stud on the

body.

Refitting

4Refitting is a reversal of removal.

Removal

1Operate the control lever to open the

tailgate/boot lid and the fuel filler flap (see

illustration).

2Remove the driver’s side centre pillar lower

trim panel and the sill trim panel.

3Withdraw the cover from the control lever.

4Unscrew the two securing bolts, and

detach the control lever assembly from the

body panel. Detach the cable from the control

assembly.

5Fold the rear seat cushion forwards or

remove it, as applicable, and remove the rear

seat side cushion for access to the wheel arch

trim panel.

6Detach the trim panel from the wheel arch

by removing the two securing screws from the

parcel shelf bracket. Free the cable up to the

wheel arch.

7Working inside the luggage compartment,

remove the trim panels for access to the

petrol flap lock and tailgate/boot lid lock.

8Disengage the petrol flap catch from the

housing by twisting and pulling out (see

illustration). Carefully pull the cable through into

the luggage compartment, noting its routing.

9Remove the securing screws, and withdraw

the tailgate/boot lid lock striker from the bodypanel. Withdraw the striker and cable

assembly.

Refitting

10Commence refitting by installing the

tailgate/boot lid striker and cable assembly.

Secure the cable to the body with tape.

11Route the cable back to the petrol flap

housing, and refit the petrol flap catch.

12Route the cable into the interior of the

vehicle, and refit the luggage compartment

trim panels.

13Route the cable to the control lever,

securing the cable with tape to the body, then

refit the wheel arch trim panel, and refit the

seat cushions.

14Reconnect the cable to the control lever

assembly, then refit the assembly.

15Refit the control lever cover and the trim

panels.

Models up to 1990

1Open the tailgate/boot lid.

2Prise the four screw covers from the

spoiler, then remove the screws, and

withdraw the spoiler.

3Refitting is a reversal of removal.

Models from 1990

4Open the tailgate/boot lid.

5Remove the inner tailgate/boot lid trim

panel for access to the spoiler securing nuts.

6Unscrew the central spoiler securing nut,

then unscrew the four outer securing nuts

(two on each side), and withdraw the spoiler.

7Refitting is a reversal of removal.

Front door

1On models with electric mirrors, electric

windows, central-locking, door-mounted

speakers, or “door ajar” sensors, remove the

trim panel and disconnect the wiring inside

the door. Withdraw the wiring loom(s) through

the grommet(s) in the front edge of the door.

16Door - removal and refitting

15Tailgate/boot lid spoiler -

removal and refitting

14Tailgate/boot lid/fuel filler

flap release cable - removal

and refitting

13Tailgate strut (Hatchback

and Estate models) - removal

and refitting

12Tailgate lock (Hatchback and

Estate models) - removal and

refitting

12•6Bodywork and fittings

14.1 Tailgate/boot lid/fuel filler flap control

lever assembly14.8 Disengaging the petrol flap catch

from the housing

12.2 Tailgate lock assembly - Hatchback

and Estate models

A Lock barrel support

bracket

B Lock barrel

retaining clipC Lock barrel

D Torx screw

E Lock assembly

F Screws

12.1 Tailgate trim panel fixings -

Hatchback and Estate models

Page 7 of 22

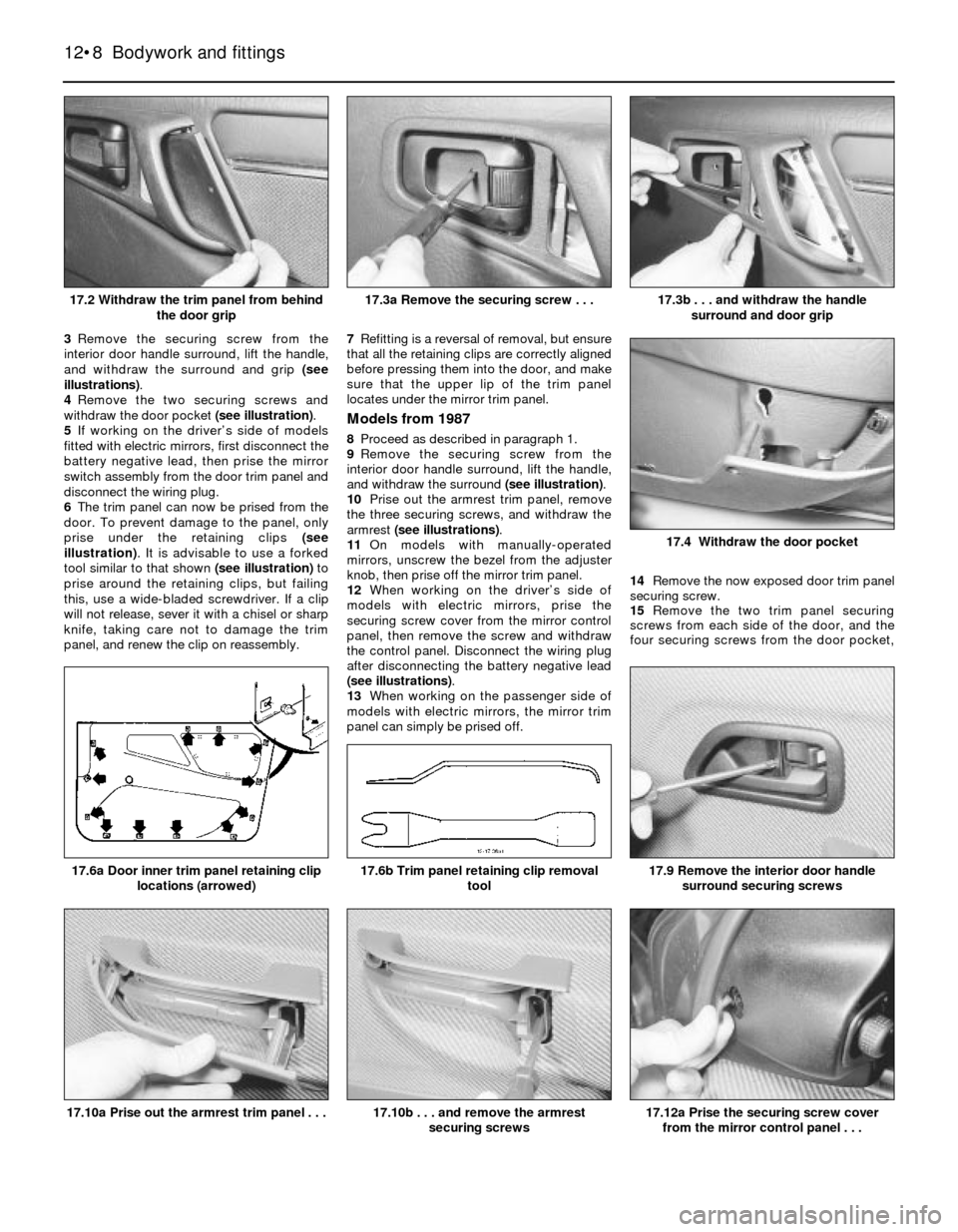

2Unscrew and remove the bolt securing the

check arm to the body pillar (see illustration).

3Remove the two securing screws, and

withdraw the side trim panel from the footwell.

4If working on the driver’s side, remove the

lower facia panels and disconnect the face

level vent hose.

5If working on the passenger side, remove

the face level vent cover.

6Support the door on blocks of wood.

7Working through the body pillar aperture,

unscrew the two securing nuts and remove

the reinforcing plate from the lower hinge.

Repeat the procedure for the upper hinge

(see illustration).

8Withdraw the door from the vehicle.

9Refitting is a reversal of removal, but do not

fully tighten the hinge bolts until the door is

positioned centrally in the body aperture and

aligned with the surrounding bodywork. If

necessary, remove the lock striker from the

body centre pillar before adjusting the door,

then refit it and adjust its position so that the

lock operates correctly.

Rear door

10On models equipped with electric

windows, central-locking, or “door ajar”

sensors, remove the trim panel and

disconnect the wiring inside the door.

Withdraw the wiring loom(s) through the

grommet(s) in the front edge of the door.11Unscrew and remove the bolt securing

the check arm to the body centre pillar.

12Remove the centre pillar trim panel.

13Proceed as described in paragraphs 6 to

9 inclusive.

Rear door (late model Estate)

14The door internal components have been

modified on later Estate models. If a new,

later-specification rear door is to be fitted to

an earlier vehicle, the door panels must be

modified as follows to enable refitting of the

original components.

15Remove all the serviceable components

and fasteners from the original door.

16Working on the new door, use a small

round file to elongate the door interior handle

mounting hole “A” (see illustration)vertically

downwards so that it will align with the

mounting hole in the handle/ashtray bezel.

Refit the original retaining clip.17The earlier type of trim fasteners (located

at “B”) are no longer used, and must be

replaced with the latest type of fasteners,

available from a Ford dealer.

Front door

Models up to 1987

1On models with manually-operated

windows, prise the cover from the window

regulator handle, note the position of the

handle with the window fully shut, then

remove the securing screw and withdraw the

handle and bezel (see illustrations).

2Remove the securing screw and withdraw

the trim panel from behind the door grip (see

illustration).

17Door inner trim panel -

removal and refitting

Bodywork and fittings 12•7

12

16.16 Later-type rear door -

Estate models

A Internal handle mounting hole

B Early-type ashtray/handle mounting holes

C Revised mounting holes17.1a Prise the cover from the window

handle, remove the securing screw . . .17.1b . . . then withdraw the window handle

and bezel (arrowed)

16.2 Remove the door check arm-to-body

pillar bolt (arrowed)

1 Nut

2 Reinforcing plate3 Hinge pin

4 Bush5 Hinge assembly

16.7 Exploded view of the front door hinge (A) and rear door hinge (B)

Page 8 of 22

3Remove the securing screw from the

interior door handle surround, lift the handle,

and withdraw the surround and grip (see

illustrations).

4Remove the two securing screws and

withdraw the door pocket (see illustration).

5If working on the driver’s side of models

fitted with electric mirrors, first disconnect the

battery negative lead, then prise the mirror

switch assembly from the door trim panel and

disconnect the wiring plug.

6The trim panel can now be prised from the

door. To prevent damage to the panel, only

prise under the retaining clips (see

illustration). It is advisable to use a forked

tool similar to that shown (see illustration)to

prise around the retaining clips, but failing

this, use a wide-bladed screwdriver. If a clip

will not release, sever it with a chisel or sharp

knife, taking care not to damage the trim

panel, and renew the clip on reassembly.7Refitting is a reversal of removal, but ensure

that all the retaining clips are correctly aligned

before pressing them into the door, and make

sure that the upper lip of the trim panel

locates under the mirror trim panel.

Models from 1987

8Proceed as described in paragraph 1.

9Remove the securing screw from the

interior door handle surround, lift the handle,

and withdraw the surround (see illustration).

10Prise out the armrest trim panel, remove

the three securing screws, and withdraw the

armrest (see illustrations).

11On models with manually-operated

mirrors, unscrew the bezel from the adjuster

knob, then prise off the mirror trim panel.

12When working on the driver’s side of

models with electric mirrors, prise the

securing screw cover from the mirror control

panel, then remove the screw and withdraw

the control panel. Disconnect the wiring plug

after disconnecting the battery negative lead

(see illustrations).

13When working on the passenger side of

models with electric mirrors, the mirror trim

panel can simply be prised off.14Remove the now exposed door trim panel

securing screw.

15Remove the two trim panel securing

screws from each side of the door, and the

four securing screws from the door pocket,

12•8Bodywork and fittings

17.4 Withdraw the door pocket

17.6b Trim panel retaining clip removal

tool

17.12a Prise the securing screw cover

from the mirror control panel . . .17.10b . . . and remove the armrest

securing screws17.10a Prise out the armrest trim panel . . .

17.9 Remove the interior door handle

surround securing screws17.6a Door inner trim panel retaining clip

locations (arrowed)

17.3a Remove the securing screw . . .17.3b . . . and withdraw the handle

surround and door grip17.2 Withdraw the trim panel from behind

the door grip

Page 9 of 22

then lift the trim panel to disengage it from the

top retaining clips, and withdraw the panel

from the door (see illustrations).

16Refitting is a reversal of removal.

Rear door

Models up to 1987

17Proceed as shown in paragraphs 1 to 3.

18On models fitted with electric windows,

disconnect the battery negative lead, then

prise the switch from the armrest and

disconnect the wiring plug.

19Proceed as described in paragraph 6.

20Refitting is a reversal of removal, but

ensure that all the retaining clips are correctly

aligned before pressing them into the door.

Models from 1987

21Proceed as described in paragraph 1.

22Remove the securing screw from the

interior door handle, then pull out the ashtray,

and remove the two now exposed screws.23Lift the interior door handle, and withdraw

the handle/ashtray surround.

24Prise out the armrest trim panel, remove

the three securing screws and withdraw the

armrest.

25Remove the two trim panel securing

screws from each side of the door, then lift the

trim panel to disengage it from the top

retaining clips, and withdraw the panel from

the door.

26Refitting is a reversal of removal.

Removal

1Remove the door inner trim panel.

2Where necessary for improved access, peel

back the waterproof plastic sheet from the

door.

3Remove the two securing screws in the

case of models up to 1987, or the single

securing screw on models from 1987, and

slide the handle assembly from the door

aperture, if necessary unclipping the remote

control rods from their guides (see

illustrations).

4Disconnect the remote control rods from

the handle assembly, and withdraw the

handle assembly.

Refitting

5Refitting is a reversal of removal, but check

that the remote control rods are correctly

located in their guides (see illustration).

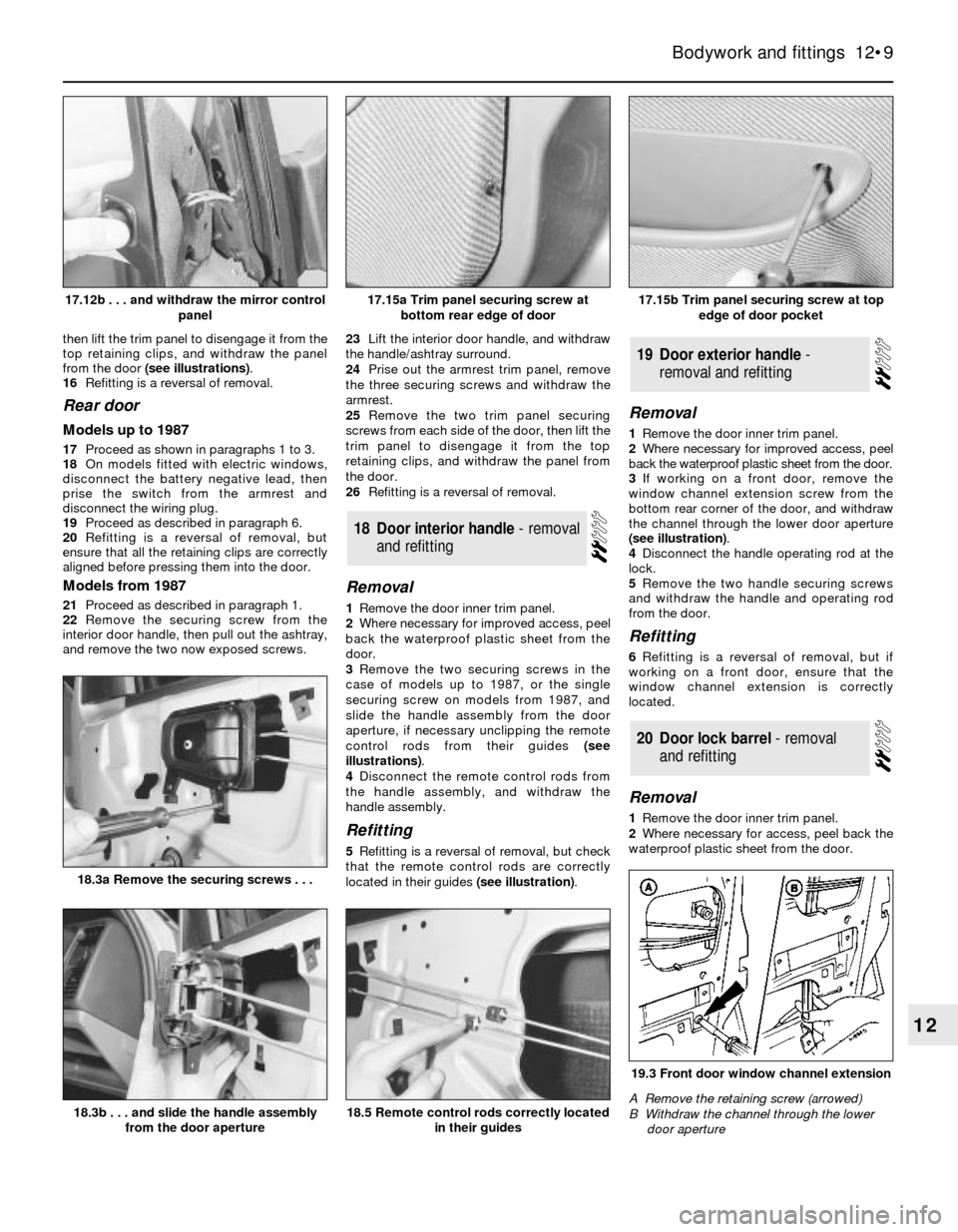

Removal

1Remove the door inner trim panel.

2Where necessary for improved access, peel

back the waterproof plastic sheet from the door.

3If working on a front door, remove the

window channel extension screw from the

bottom rear corner of the door, and withdraw

the channel through the lower door aperture

(see illustration).

4Disconnect the handle operating rod at the

lock.

5Remove the two handle securing screws

and withdraw the handle and operating rod

from the door.

Refitting

6Refitting is a reversal of removal, but if

working on a front door, ensure that the

window channel extension is correctly

located.

Removal

1Remove the door inner trim panel.

2Where necessary for access, peel back the

waterproof plastic sheet from the door.

20Door lock barrel - removal

and refitting

19Door exterior handle -

removal and refitting

18Door interior handle - removal

and refitting

Bodywork and fittings 12•9

12

18.5 Remote control rods correctly located

in their guides

19.3 Front door window channel extension

A Remove the retaining screw (arrowed)

B Withdraw the channel through the lower

door aperture18.3b . . . and slide the handle assembly

from the door aperture

18.3a Remove the securing screws . . .

17.15b Trim panel securing screw at top

edge of door pocket17.15a Trim panel securing screw at

bottom rear edge of door17.12b . . . and withdraw the mirror control

panel

Page 10 of 22

3Remove the window channel extension

screw from the bottom rear corner of the

door, and withdraw the channel through the

lower door aperture.

4Working inside the door aperture, pull out

the lock barrel retaining clip using pliers, then

unhook the lock operating rod from the barrel,

and withdraw the barrel from outside the door

(see illustration).

Refitting

5Refitting is a reversal of removal.

Models up to 1990

1Remove the door inner trim panel.

2Where necessary for improved access, peel

back the waterproof plastic sheet from the

door.

3Withdraw the window channel extension

through the lower rear door aperture after

removing the single securing screw if working

on a front door or the two securing screws if

working on a rear door.

4Remove the three securing screws from the

rear edge of the door, then reach inside the

door and turn the lock to disconnect it from

the control rods.

5Where applicable, disconnect the “door

ajar” sensor wiring plug and the central

locking component wiring plug(s). Central

locking component removal and refitting is

covered in Chapter 13.

6Withdraw the lock from inside the door.

7Refitting is a reversal of removal, but ensure

that the window channel extension is correctly

located.

Models from 1990

8From 1990, cable-operated door locks have

been fitted to all Sierra models. To remove the

later type of lock, proceed as follows. Do not

bend or stretch the cable during removal and

refitting, as the operation of the lock will be

impaired.

9Remove the door inner trim panel.

10Where necessary for improved access,

peel back the waterproof plastic sheet from

the door.11Remove the securing screw, and

withdraw the window channel extension

through the door’s lower aperture.

12Disconnect the door outer handle and the

lock barrel (front doors) operating rods at the

lock assembly.

13Disconnect the battery negative lead, and

disconnect the door lock motor and the alarm

system wiring plugs (where applicable).

14Remove the screw securing the door

interior handle to the door panel.

15Remove the three lock securing screws

from the rear edge of the door, then withdraw

the lock assembly complete with the

operating cable and the door interior handle.

16To disconnect the cable from the lock,

proceed as follows.

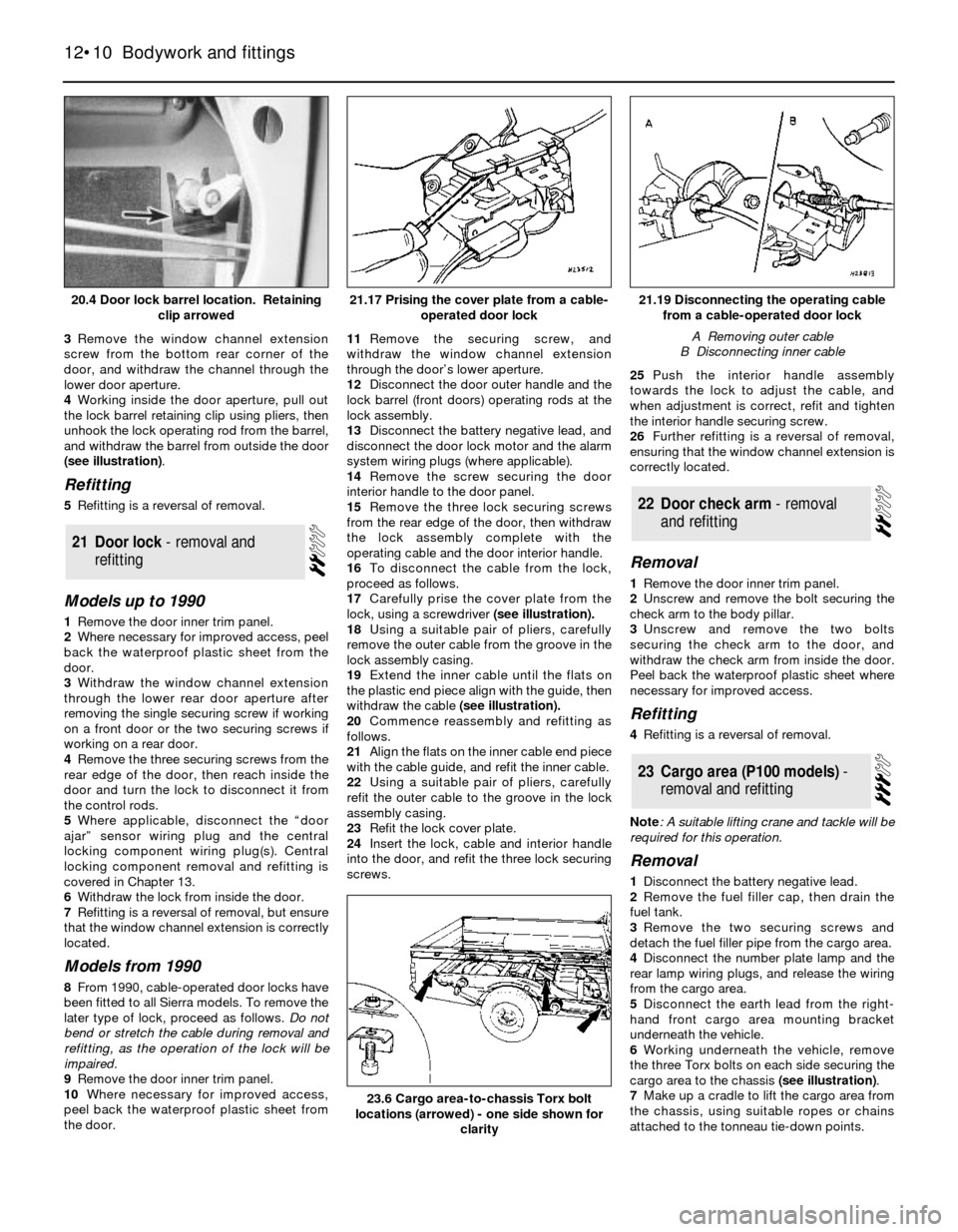

17Carefully prise the cover plate from the

lock, using a screwdriver(see illustration).

18Using a suitable pair of pliers, carefully

remove the outer cable from the groove in the

lock assembly casing.

19Extend the inner cable until the flats on

the plastic end piece align with the guide, then

withdraw the cable (see illustration).

20Commence reassembly and refitting as

follows.

21Align the flats on the inner cable end piece

with the cable guide, and refit the inner cable.

22Using a suitable pair of pliers, carefully

refit the outer cable to the groove in the lock

assembly casing.

23Refit the lock cover plate.

24Insert the lock, cable and interior handle

into the door, and refit the three lock securing

screws. 25Push the interior handle assembly

towards the lock to adjust the cable, and

when adjustment is correct, refit and tighten

the interior handle securing screw.

26Further refitting is a reversal of removal,

ensuring that the window channel extension is

correctly located.

Removal

1Remove the door inner trim panel.

2Unscrew and remove the bolt securing the

check arm to the body pillar.

3Unscrew and remove the two bolts

securing the check arm to the door, and

withdraw the check arm from inside the door.

Peel back the waterproof plastic sheet where

necessary for improved access.

Refitting

4Refitting is a reversal of removal.

Note: A suitable lifting crane and tackle will be

required for this operation.

Removal

1Disconnect the battery negative lead.

2Remove the fuel filler cap, then drain the

fuel tank.

3Remove the two securing screws and

detach the fuel filler pipe from the cargo area.

4Disconnect the number plate lamp and the

rear lamp wiring plugs, and release the wiring

from the cargo area.

5Disconnect the earth lead from the right-

hand front cargo area mounting bracket

underneath the vehicle.

6Working underneath the vehicle, remove

the three Torx bolts on each side securing the

cargo area to the chassis (see illustration).

7Make up a cradle to lift the cargo area from

the chassis, using suitable ropes or chains

attached to the tonneau tie-down points.

23Cargo area (P100 models) -

removal and refitting

22Door check arm - removal

and refitting

21Door lock - removal and

refitting

12•10Bodywork and fittings

21.17 Prising the cover plate from a cable-

operated door lock

23.6 Cargo area-to-chassis Torx bolt

locations (arrowed) - one side shown for

clarity

21.19 Disconnecting the operating cable

from a cable-operated door lock

A Removing outer cable

B Disconnecting inner cable

20.4 Door lock barrel location. Retaining

clip arrowed