jacking FORD SIERRA 1993 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: SIERRA, Model: FORD SIERRA 1993 2.GPages: 24, PDF Size: 0.93 MB

Page 8 of 24

Mitsubishi type

21Unscrew the pulley nut. To prevent the

shaft rotating, insert an Allen key in the end of

the shaft.

22Remove the spring washer, pulley, fan,

spacer and dust shield.

23Scribe an alignment mark along the length

of the alternator to facilitate reassembly of the

drive end housing, stator and rear housing.

24Unscrew the through-bolts and withdraw

the drive end housing from the rotor shaft.

25Remove the seal and spacer from the

rotor shaft.

26Remove the rotor from the rear housing

and the stator. This may require the

application of local heat to the rear housing

using a large soldering iron. Do not use a heat

gun, as this may result in damage to the

diodes.

27Unscrew the four securing bolts and

withdraw the diode pack stator assembly

from the rear housing.

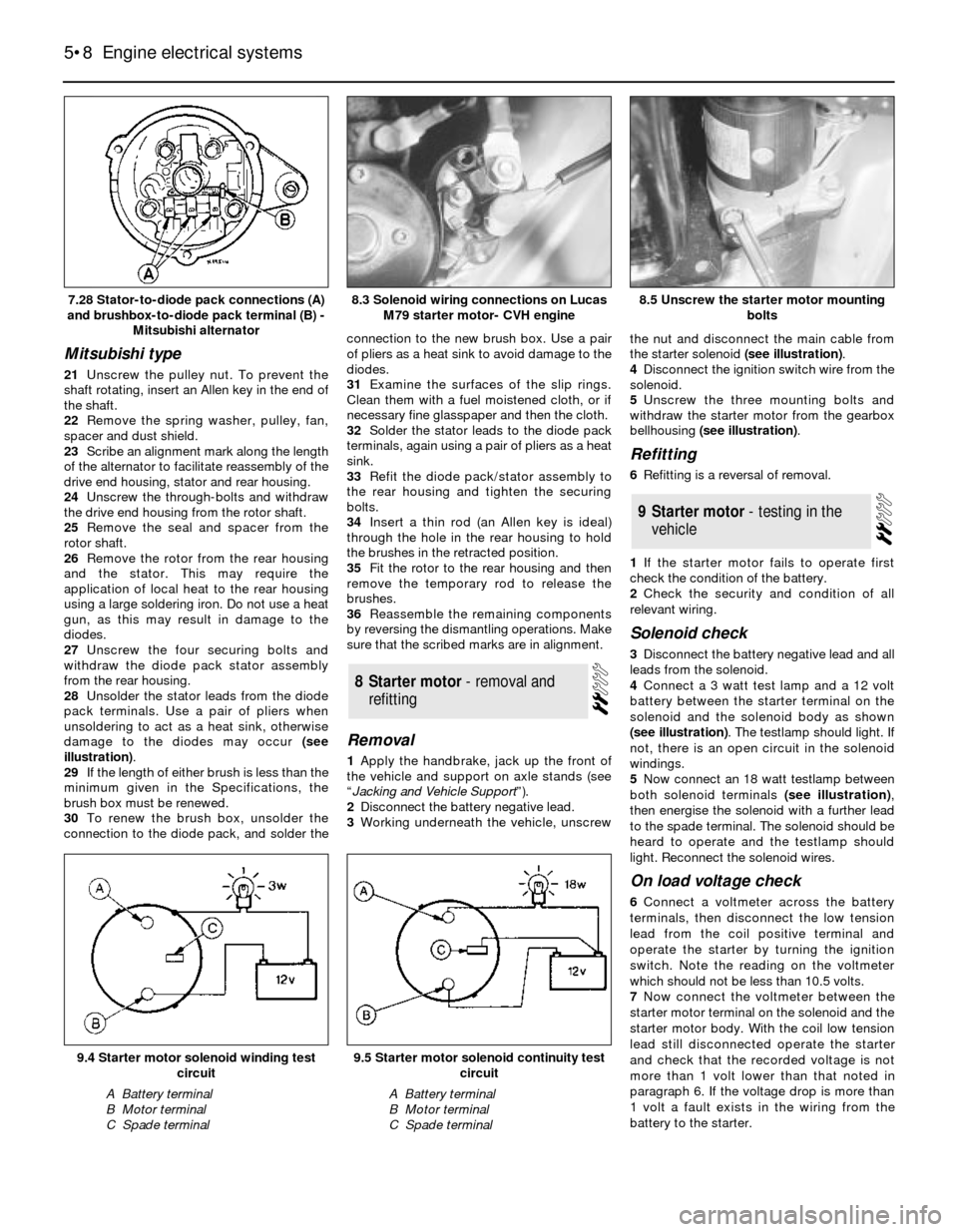

28Unsolder the stator leads from the diode

pack terminals. Use a pair of pliers when

unsoldering to act as a heat sink, otherwise

damage to the diodes may occur (see

illustration).

29If the length of either brush is less than the

minimum given in the Specifications, the

brush box must be renewed.

30To renew the brush box, unsolder the

connection to the diode pack, and solder theconnection to the new brush box. Use a pair

of pliers as a heat sink to avoid damage to the

diodes.

31Examine the surfaces of the slip rings.

Clean them with a fuel moistened cloth, or if

necessary fine glasspaper and then the cloth.

32Solder the stator leads to the diode pack

terminals, again using a pair of pliers as a heat

sink.

33Refit the diode pack/stator assembly to

the rear housing and tighten the securing

bolts.

34Insert a thin rod (an Allen key is ideal)

through the hole in the rear housing to hold

the brushes in the retracted position.

35Fit the rotor to the rear housing and then

remove the temporary rod to release the

brushes.

36Reassemble the remaining components

by reversing the dismantling operations. Make

sure that the scribed marks are in alignment.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

2Disconnect the battery negative lead.

3Working underneath the vehicle, unscrewthe nut and disconnect the main cable from

the starter solenoid (see illustration).

4Disconnect the ignition switch wire from the

solenoid.

5Unscrew the three mounting bolts and

withdraw the starter motor from the gearbox

bellhousing (see illustration).

Refitting

6Refitting is a reversal of removal.

1If the starter motor fails to operate first

check the condition of the battery.

2Check the security and condition of all

relevant wiring.

Solenoid check

3Disconnect the battery negative lead and all

leads from the solenoid.

4Connect a 3 watt test lamp and a 12 volt

battery between the starter terminal on the

solenoid and the solenoid body as shown

(see illustration). The testlamp should light. If

not, there is an open circuit in the solenoid

windings.

5Now connect an 18 watt testlamp between

both solenoid terminals (see illustration),

then energise the solenoid with a further lead

to the spade terminal. The solenoid should be

heard to operate and the testlamp should

light. Reconnect the solenoid wires.

On load voltage check

6Connect a voltmeter across the battery

terminals, then disconnect the low tension

lead from the coil positive terminal and

operate the starter by turning the ignition

switch. Note the reading on the voltmeter

which should not be less than 10.5 volts.

7Now connect the voltmeter between the

starter motor terminal on the solenoid and the

starter motor body. With the coil low tension

lead still disconnected operate the starter

and check that the recorded voltage is not

more than 1 volt lower than that noted in

paragraph 6. If the voltage drop is more than

1 volt a fault exists in the wiring from the

battery to the starter.

9Starter motor - testing in the

vehicle

8Starter motor - removal and

refitting

5•8Engine electrical systems

7.28 Stator-to-diode pack connections (A)

and brushbox-to-diode pack terminal (B) -

Mitsubishi alternator8.5 Unscrew the starter motor mounting

bolts

9.5 Starter motor solenoid continuity test

circuit

A Battery terminal

B Motor terminal

C Spade terminal

9.4 Starter motor solenoid winding test

circuit

A Battery terminal

B Motor terminal

C Spade terminal

8.3 Solenoid wiring connections on Lucas

M79 starter motor- CVH engine

Page 21 of 24

3Partially drain the cooling system. There is no

need to remove the cylinder block drain plug.

4Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

5Unscrew the sensor from the inlet manifold

and remove it.

6Refitting is a reversal of removal. Fill the

cooling system.

2.0 litre DOHC models

7The sensor is located in the side of the inlet

manifold. The removal and refitting

procedures are as described for the 1.6 and

1.8 litre CVH (R6A type) engines in the

relevent Section of this Chapter.

Inlet manifold heater

Note: When refitting the heater, a new gasket

and O-ring must be used.

8Do not attempt to remove the heater while it

is hot.

9For improved access, remove the air

cleaner.

10Disconnect the wiring from the heater.

11Unscrew the three securing bolts and

remove the heater. Recover the gasket and

O-ring (see illustration).

12Refitting is a reversal of removal, using a

new gasket and O-ring, but be careful to

tighten the securing bolts evenly, otherwise

the heater may tilt and jam in its recess.

Carburettor stepper motor (2.0

litre models)

Note: Irregular idle is not necessarily caused by

a faulty or badly adjusted stepper motor. Good

electrical contact between the stepper motor

plunger and the adjusting screw (which from the

throttle position switch) is essential. Before

attempting adjustment or renewal of the motor,

try the effect of cleaning the plunger and

adjusting screw contact faces with abrasive

paper followed by switch cleaning fluid. Switch

cleaning fluid is available from electronic

component shops. Refer to the precautions in

Chapter 3 before proceeding.

13Remove the air cleaner.

14Depress the locking tab and disconnect

the stepper motor wiring plug. Pull on the

plug, not the wiring.

15Remove the four securing screws and

withdraw the stepper motor and bracket from

the carburettor.

16If desired, the stepper motor can be

separated from the bracket by removing thefour securing screws (see illustration).

17Commence refitting by securing the

stepper motor to the bracket, where

applicable.

18Refit the stepper motor and bracket to the

carburettor and secure with the four screws.

19Reconnect the wiring plug.

20Reconnect the air cleaner vacuum hose to

the inlet manifold, and position the air cleaner

to one side to allow access to the carburettor

and stepper motor.

21Reconnect the battery negative lead.

22Connect a tachometer to the engine in

accordance with the manufacturer’s

instructions.

23Start the engine, then check and if

necessary adjust the idle mixture.

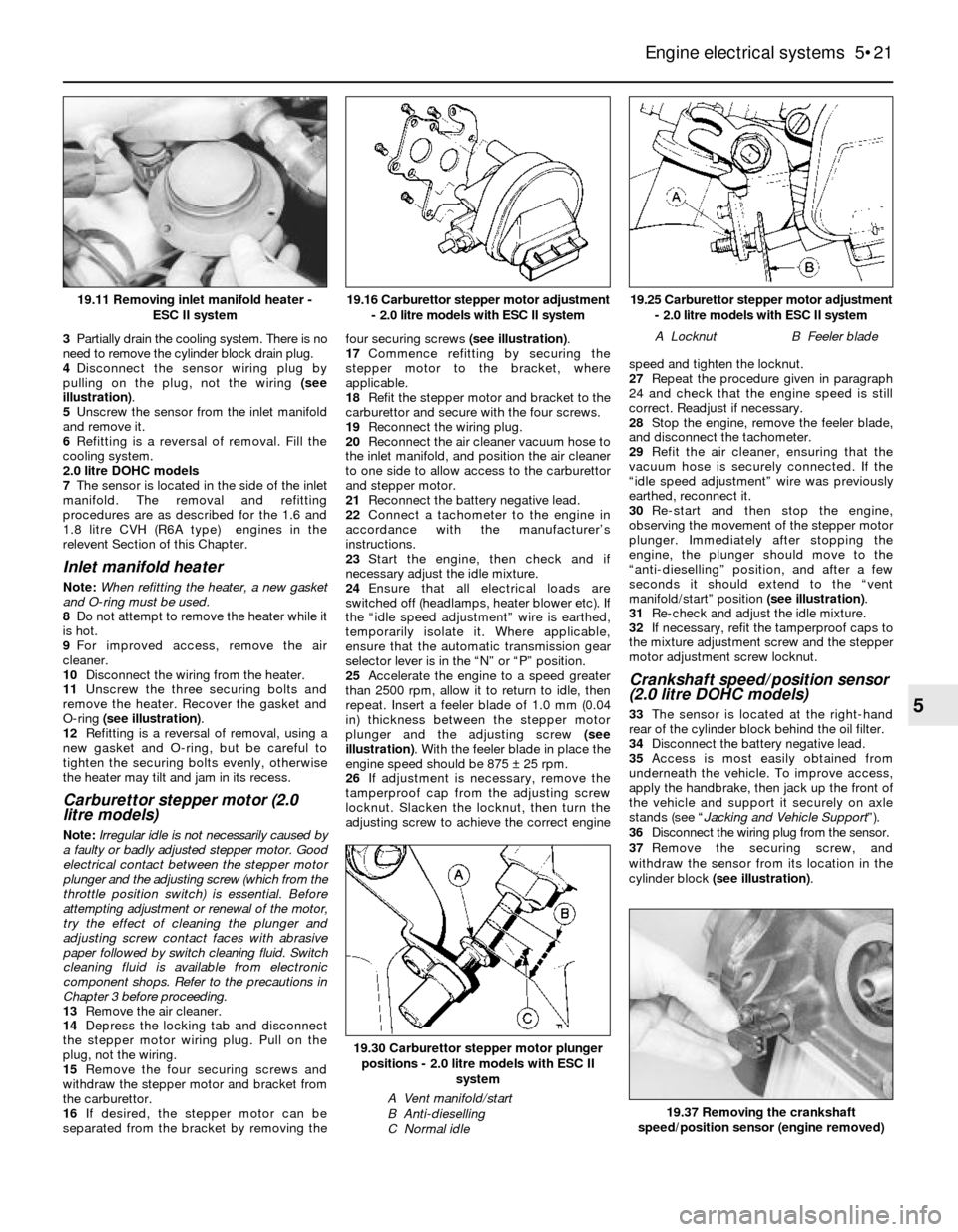

24Ensure that all electrical loads are

switched off (headlamps, heater blower etc). If

the “idle speed adjustment” wire is earthed,

temporarily isolate it. Where applicable,

ensure that the automatic transmission gear

selector lever is in the “N” or “P” position.

25Accelerate the engine to a speed greater

than 2500 rpm, allow it to return to idle, then

repeat. Insert a feeler blade of 1.0 mm (0.04

in) thickness between the stepper motor

plunger and the adjusting screw (see

illustration). With the feeler blade in place the

engine speed should be 875 ±25 rpm.

26If adjustment is necessary, remove the

tamperproof cap from the adjusting screw

locknut. Slacken the locknut, then turn the

adjusting screw to achieve the correct enginespeed and tighten the locknut.

27Repeat the procedure given in paragraph

24 and check that the engine speed is still

correct. Readjust if necessary.

28Stop the engine, remove the feeler blade,

and disconnect the tachometer.

29Refit the air cleaner, ensuring that the

vacuum hose is securely connected. If the

“idle speed adjustment” wire was previously

earthed, reconnect it.

30Re-start and then stop the engine,

observing the movement of the stepper motor

plunger. Immediately after stopping the

engine, the plunger should move to the

“anti-dieselling” position, and after a few

seconds it should extend to the “vent

manifold/start” position (see illustration).

31Re-check and adjust the idle mixture.

32If necessary, refit the tamperproof caps to

the mixture adjustment screw and the stepper

motor adjustment screw locknut.

Crankshaft speed/position sensor

(2.0 litre DOHC models)

33The sensor is located at the right-hand

rear of the cylinder block behind the oil filter.

34Disconnect the battery negative lead.

35Access is most easily obtained from

underneath the vehicle. To improve access,

apply the handbrake, then jack up the front of

the vehicle and support it securely on axle

stands (see “Jacking and Vehicle Support”).

36Disconnect the wiring plug from the sensor.

37Remove the securing screw, and

withdraw the sensor from its location in the

cylinder block (see illustration).

Engine electrical systems 5•21

5

19.25 Carburettor stepper motor adjustment

- 2.0 litre models with ESC II system

A LocknutB Feeler blade

19.37 Removing the crankshaft

speed/position sensor (engine removed)

19.30 Carburettor stepper motor plunger

positions - 2.0 litre models with ESC II

system

A Vent manifold/start

B Anti-dieselling

C Normal idle

19.16 Carburettor stepper motor adjustment

- 2.0 litre models with ESC II system19.11 Removing inlet manifold heater -

ESC II system

Page 24 of 24

Vehicle speed sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

27The sensor is located in the left-hand side

of the gearbox/transmission.

28Disconnect the battery negative lead.

29Jack up the vehicle and support it

securely on axle stands (see “Jacking and

Vehicle Support”).

30Detach the sensor wiring connector from

its bracket, and separate the two halves of the

connector.

31Unscrew the securing bolt, and withdraw

the wiring connector bracket, noting its

orientation.

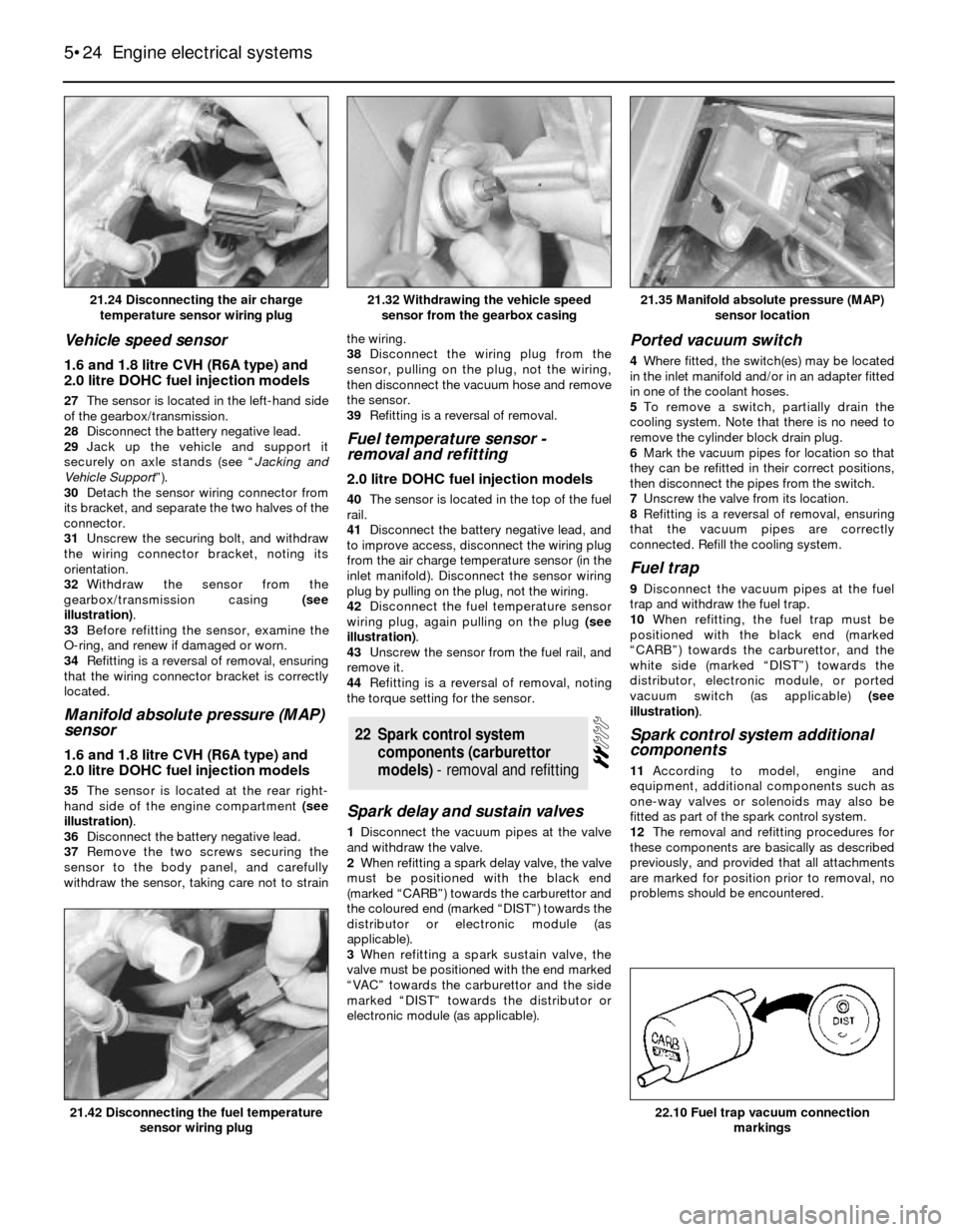

32Withdraw the sensor from the

gearbox/transmission casing (see

illustration).

33Before refitting the sensor, examine the

O-ring, and renew if damaged or worn.

34Refitting is a reversal of removal, ensuring

that the wiring connector bracket is correctly

located.

Manifold absolute pressure (MAP)

sensor

1.6 and 1.8 litre CVH (R6A type) and

2.0 litre DOHC fuel injection models

35The sensor is located at the rear right-

hand side of the engine compartment (see

illustration).

36Disconnect the battery negative lead.

37Remove the two screws securing the

sensor to the body panel, and carefully

withdraw the sensor, taking care not to strainthe wiring.

38Disconnect the wiring plug from the

sensor, pulling on the plug, not the wiring,

then disconnect the vacuum hose and remove

the sensor.

39Refitting is a reversal of removal.

Fuel temperature sensor -

removal and refitting

2.0 litre DOHC fuel injection models

40The sensor is located in the top of the fuel

rail.

41Disconnect the battery negative lead, and

to improve access, disconnect the wiring plug

from the air charge temperature sensor (in the

inlet manifold). Disconnect the sensor wiring

plug by pulling on the plug, not the wiring.

42Disconnect the fuel temperature sensor

wiring plug, again pulling on the plug (see

illustration).

43Unscrew the sensor from the fuel rail, and

remove it.

44Refitting is a reversal of removal, noting

the torque setting for the sensor.

Spark delay and sustain valves

1Disconnect the vacuum pipes at the valve

and withdraw the valve.

2When refitting a spark delay valve, the valve

must be positioned with the black end

(marked “CARB”) towards the carburettor and

the coloured end (marked “DIST”) towards the

distributor or electronic module (as

applicable).

3When refitting a spark sustain valve, the

valve must be positioned with the end marked

“VAC” towards the carburettor and the side

marked “DIST” towards the distributor or

electronic module (as applicable).

Ported vacuum switch

4Where fitted, the switch(es) may be located

in the inlet manifold and/or in an adapter fitted

in one of the coolant hoses.

5To remove a switch, partially drain the

cooling system. Note that there is no need to

remove the cylinder block drain plug.

6Mark the vacuum pipes for location so that

they can be refitted in their correct positions,

then disconnect the pipes from the switch.

7Unscrew the valve from its location.

8Refitting is a reversal of removal, ensuring

that the vacuum pipes are correctly

connected. Refill the cooling system.

Fuel trap

9Disconnect the vacuum pipes at the fuel

trap and withdraw the fuel trap.

10When refitting, the fuel trap must be

positioned with the black end (marked

“CARB”) towards the carburettor, and the

white side (marked “DIST”) towards the

distributor, electronic module, or ported

vacuum switch (as applicable) (see

illustration).

Spark control system additional

components

11According to model, engine and

equipment, additional components such as

one-way valves or solenoids may also be

fitted as part of the spark control system.

12The removal and refitting procedures for

these components are basically as described

previously, and provided that all attachments

are marked for position prior to removal, no

problems should be encountered.

22Spark control system

components (carburettor

models) - removal and refitting

5•24Engine electrical systems

21.24 Disconnecting the air charge

temperature sensor wiring plug21.35 Manifold absolute pressure (MAP)

sensor location

22.10 Fuel trap vacuum connection

markings21.42 Disconnecting the fuel temperature

sensor wiring plug

21.32 Withdrawing the vehicle speed

sensor from the gearbox casing