torque FORD SUPER DUTY 2023 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2023Pages: 738, PDF Size: 18.49 MB

Page 521 of 738

Note:For F-350 Dual Rear Wheel, F-450,F-550 and F-600 Vehicles, insert thenotched end of the jack handle to therelease valve, open the release valve slightlyby turning the handle counterclockwise.Stop turning the release valve when vehiclestart to lower. Make sure to close the valvewhen you completely lower your vehicle.

F-350 Dual Rear Wheel, F-450, F-550and F-600 Vehicles.

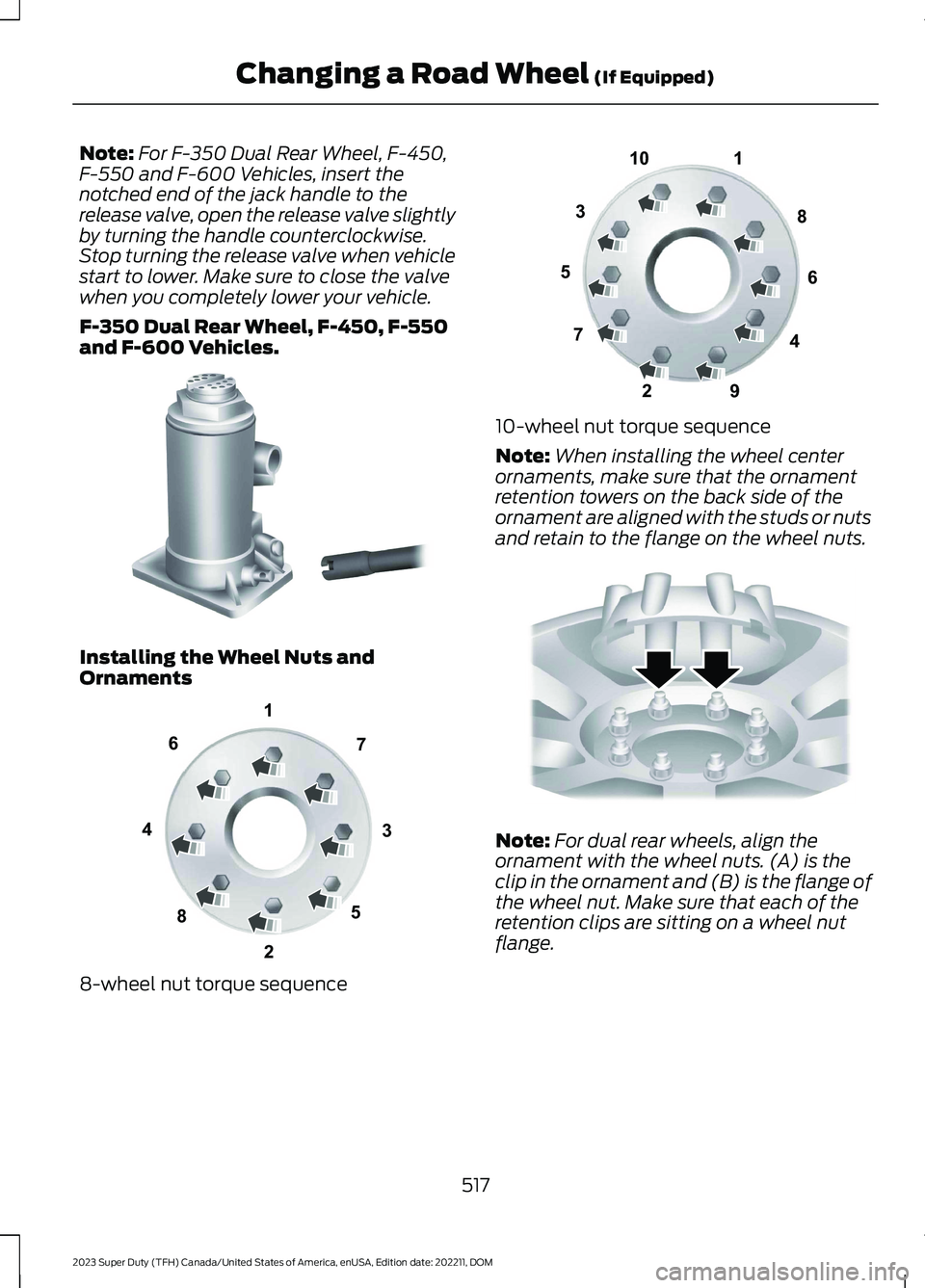

Installing the Wheel Nuts andOrnaments

8-wheel nut torque sequence

10-wheel nut torque sequence

Note:When installing the wheel centerornaments, make sure that the ornamentretention towers on the back side of theornament are aligned with the studs or nutsand retain to the flange on the wheel nuts.

Note:For dual rear wheels, align theornament with the wheel nuts. (A) is theclip in the ornament and (B) is the flange ofthe wheel nut. Make sure that each of theretention clips are sitting on a wheel nutflange.

517

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E162812 13427658E161441 12345678910E169375 E162820

Page 523 of 738

3.Reinsert the lug wrench extension(s)through the rear bumper and guidetube and turn the lug wrench clockwiseuntil the tire is raised to its stowedposition underneath the vehicle. Thewrench will become harder to turn andthe spare tire winch will ratchet or slipwhen the tire is raised to maximumtightness. You will hear a clicking soundfrom the winch indicating that the tireis properly stowed, tighten until aminimum of three clicks are heard.Check that the tire lies flat against theframe and is secure.

4.Carefully place all tools back in the toolkit bag.

5.Reinstall the tool kit bag and tightenthe wing nut.

6.Properly reinstall the jack into thebracket and tighten the wing nut.

WHEEL NUTS

WARNING: When you install awheel, always remove any corrosion, dirtor foreign materials present on themounting surfaces of the wheel or thesurface of the wheel hub, brake drum orbrake disc that contacts the wheel. Makesure to secure any fasteners that attachthe rotor to the hub so they do notinterfere with the mounting surfaces ofthe wheel. Installing wheels withoutcorrect metal-to-metal contact at thewheel mounting surfaces can cause thewheel nuts to loosen and the wheel tocome off while your vehicle is in motion,resulting in loss of vehicle control,personal injury or death.

lb.ft (Nm)1Bolt Size

150 lb.ft (204 Nm)M14 x 1.5

1 Torque specifications are for nut and boltthreads free of dirt and rust. Use only ourrecommended replacement wheel nutsand or wheel bolts.

Retighten the wheel nuts to the specifiedtorque within 100 mi (160 km) after anywheel disturbance, such as tire rotation,changing a flat tire or wheel removal.

On vehicles equipped with dual rearwheels, retighten the wheel lug nuts to thespecified torque at 100 mi (160 km), andagain at 500 mi (800 km) of new vehicleoperation and after any wheel disturbance,such as tire rotation, changing a flat tire,or wheel removal.

It is important to follow the proper wheelmounting and lug nut torque procedures.

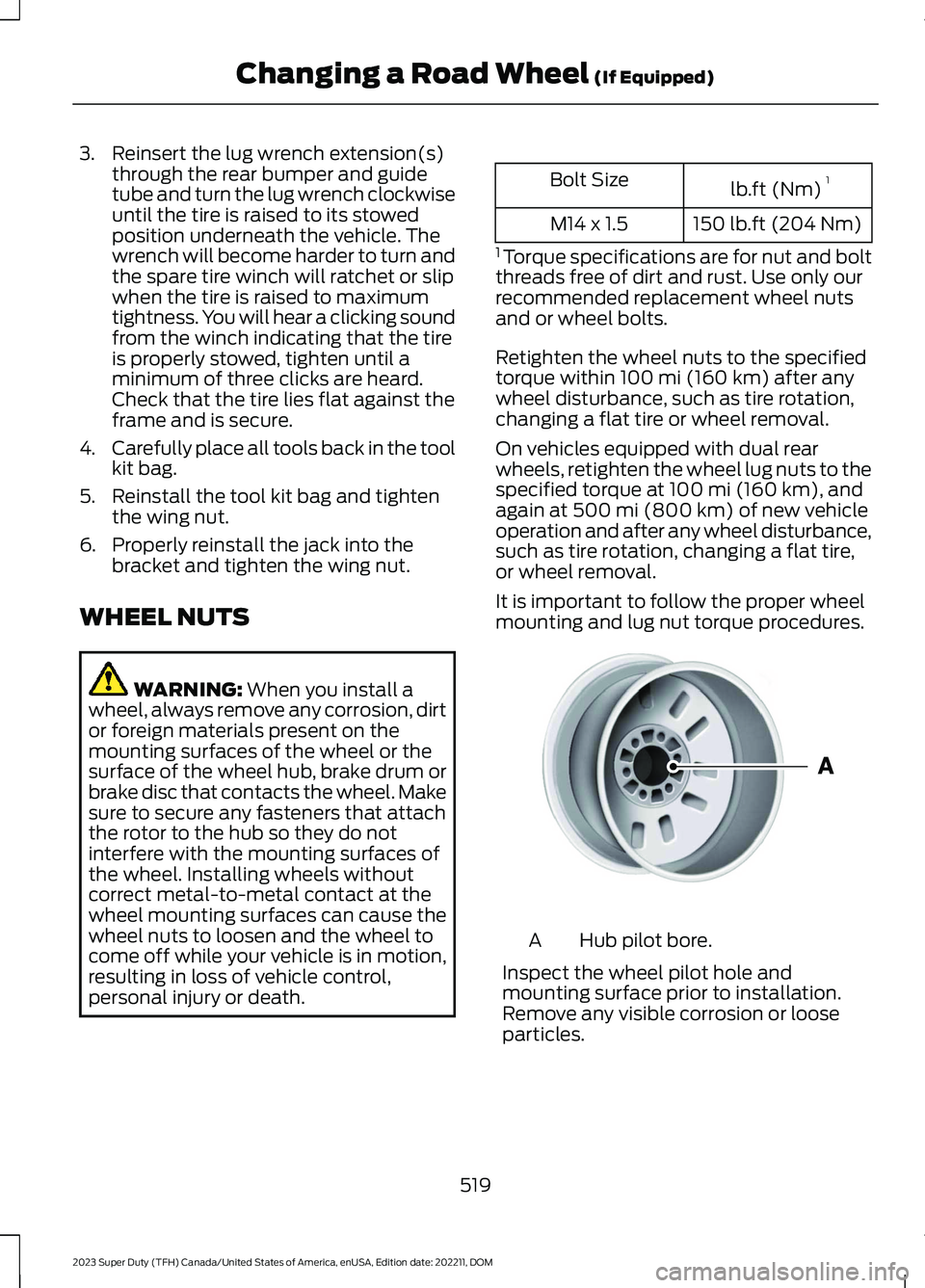

Hub pilot bore.A

Inspect the wheel pilot hole andmounting surface prior to installation.Remove any visible corrosion or looseparticles.

519

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E145950