engine FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 198 of 234

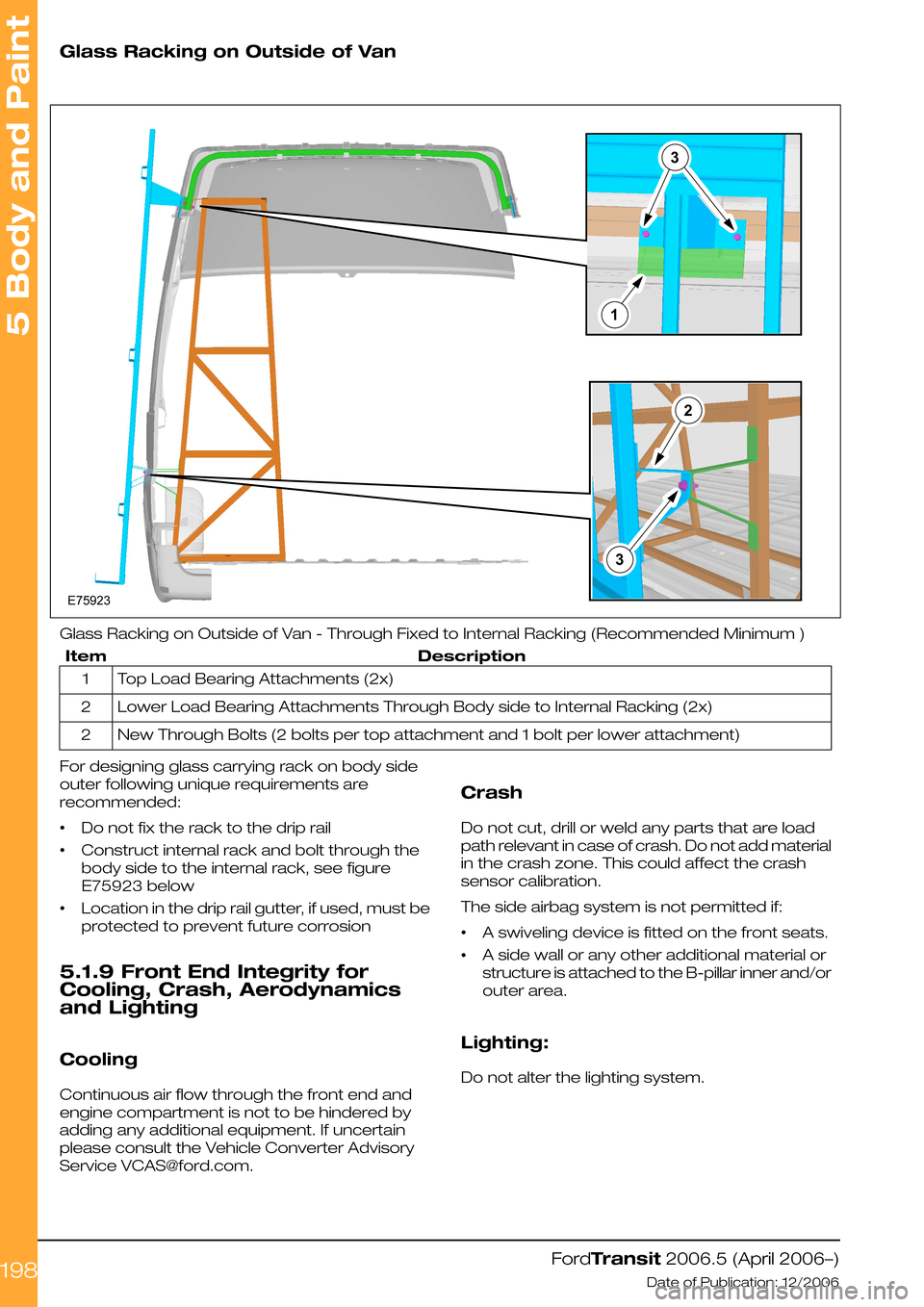

Glass Racking on Outside of Van

Glass Racking on Outside of Van - Through Fixed to Internal Racking (Recommended Minimum )

DescriptionItem

Top Load Bearing Attachments (2x)1

Lower Load Bearing Attachments Through Body side to Internal Racking (2x)2

New Through Bolts (2 bolts per top attachment and 1 bolt per lower attachment)2

For designing glass carrying rack on body side

outer following unique requirements are

recommended:

•Do not fix the rack to the drip rail

•Construct internal rack and bolt through the

body side to the internal rack, see figure

E75923 below

•Location in the drip rail gutter, if used, must be

protected to prevent future corrosion

5.1.9 Front End Integrity for

Cooling, Crash, Aerodynamics

and Lighting

Cooling

Continuous air flow through the front end and

engine compartment is not to be hindered by

adding any additional equipment. If uncertain

please consult the Vehicle Converter Advisory

Service [email protected].

Crash

Do not cut, drill or weld any parts that are load

path relevant in case of crash. Do not add material

in the crash zone. This could affect the crash

sensor calibration.

The side airbag system is not permitted if:

•A swiveling device is fitted on the front seats.

•A side wall or any other additional material or

structure is attached to the B-pillar inner and/or

outer area.

Lighting:

Do not alter the lighting system.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

198E759233123

Page 199 of 234

Static & Dynamic Sealing and

Finishing

Use Ford approved sealing and finishing material,

and underbody corrosion protection.

Refer to: 5.10 Corrosion Prevention (page 221).

Ensure proper sealing against ingress of water,

salt, dust etc. after cutting or drilling the body.

5.1.10 Tipper Bodies

For tipper conversions single an double Chassis

Cab versions except extended rear chassis

frame can be used. All variants allow single and

three way tipping.

It is recommended to have the tipping system

operative only when the engine is running. It is

also recommended to have the master control

switch in the security of the cab. According

routing of wires and hydraulic lines please refer

to section hydraulic lift.

Ensure that axle plated weights including the

front axle minimum are not exceeded.

For tipper sub-frames please refer to the

following guidelines:

•Design for full length continuous frame with

mountings for motor, pump unit, reservoir,

pivot points and ram

•Use all mounting points on chassis frame to

mount sub-frame

•The rear two sets of chassis frame mounting

brackets should have a full torque with 100%

grip. The attachment to the remaining forward

chassis frame brackets must be precisely

located and retained, but allow some relative

flexing between the sub-frame and chassis

frame. That is clamp control devices such as

conical washer stacks or machine springs with

self locking fastenings.

•Very stiff sub-frames may damage the chassis

frame by preventing its natural flexing,

therefore compliant mounts should be captive

fail safe with up to plus and minus 12mm

compliance, vehicle laden or un-laden

whichever is worst case, rated 2mm

deflection minimum per 200kg mass at each

chassis frame forward mount, please see also

Figures E74696 Sub-frame attachment to

Chassis frame and Figure E75880 Rigid or

Torsion Stiff sub-frame for Chassis Cab.

•Use two M10 grade 8.8 minimum bolts,

washers and self locking nuts at each solid

and compliant chassis frame location.

•Sub-frame must extend to the back of the

cab and attach to all mounting locations, with

the forward end designed to minimize local

frame stress, please refer to Figure E74575

Sub-frame for low floor or other equipment.

However it is preferable to mount the

sub-frame onto the mounting brackets with

a clearance to the chassis frame top surface.

•Side tipping loads/forces must be resolved

by the sub-frame. It is not recommended to

strain the chassis frame.

5.1.11 Tank and Dry Bulk Carriers

Due to the high rigidity of tanks it is necessary to

isolate the tank and its sub-frame from the

chassis frame allowing the chassis frame to

naturally flex. Please refer to the following

guidelines:

•Mount tank to full length of sub-frame.

•Mount sub-frame to all chassis frame

mounting points.

•The rear two sets of chassis frame mounting

brackets should have solid full bolts torque

with 100% grip.

•The remaining forward location mounts must

be compliant to allow relative chassis frame

to sub-frame deflections.

•Sub-frame must extend to the back of the

cab and not contact chassis frame at forward

end under worst case deflection.

•Compliant mounts should have captive fail

safe through bolts, please refer to Figures

E74696 Sub-frame attachment to Chassis

frame and Figure E75880 Rigid or Torsion Stiff

sub-frame for Chassis Cab, with up to

plus/minus 12mm compliance, vehicle laden

or un-laden whatever is worst case, rated at

2.0mm minimum deflection per 200kg mass

each.

•Use two M10 grade 8.8 minimum bolts,

washers and self lock nuts per chassis frame

mount bracket at each solid and compliant

location.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

199

Page 212 of 234

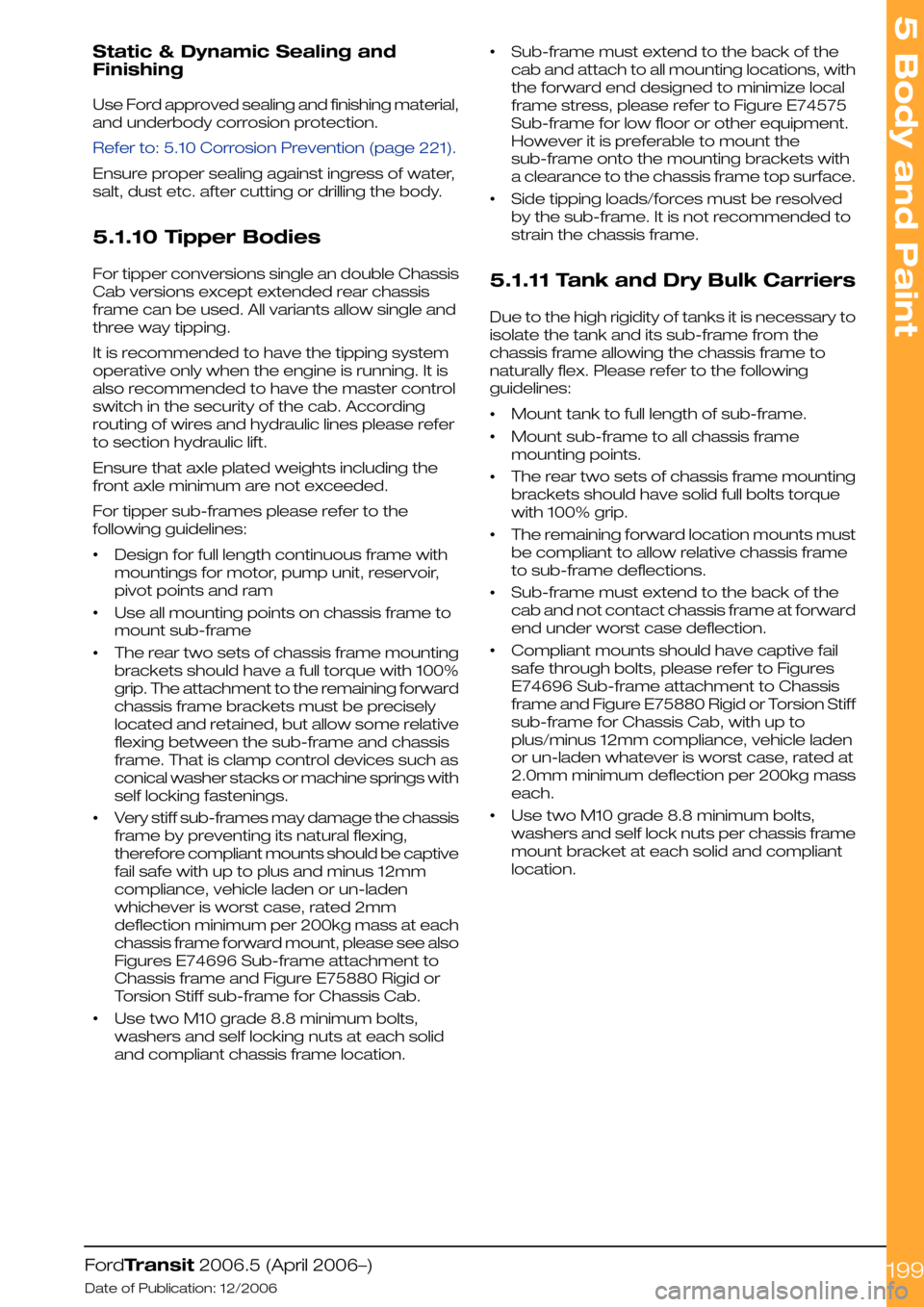

Section through typical Van Body Side for Window Engineering

DescriptionItem

Horizontal Section Through 'C'-PillarA

Horizontal Section Through Rear Vent Window Hinge PillarB

Vertical Section Through Side Window (Non Side Load Door)C

Section through typical Van Body Side for Window Engineering

Window trim strip4Glass1

Use standard vent hinge assembly5Adhesive2

Cut within 0 and 1.5mm of inner body panel flange edge all around3

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

2121413ABC21251424444211E74533

Page 214 of 234

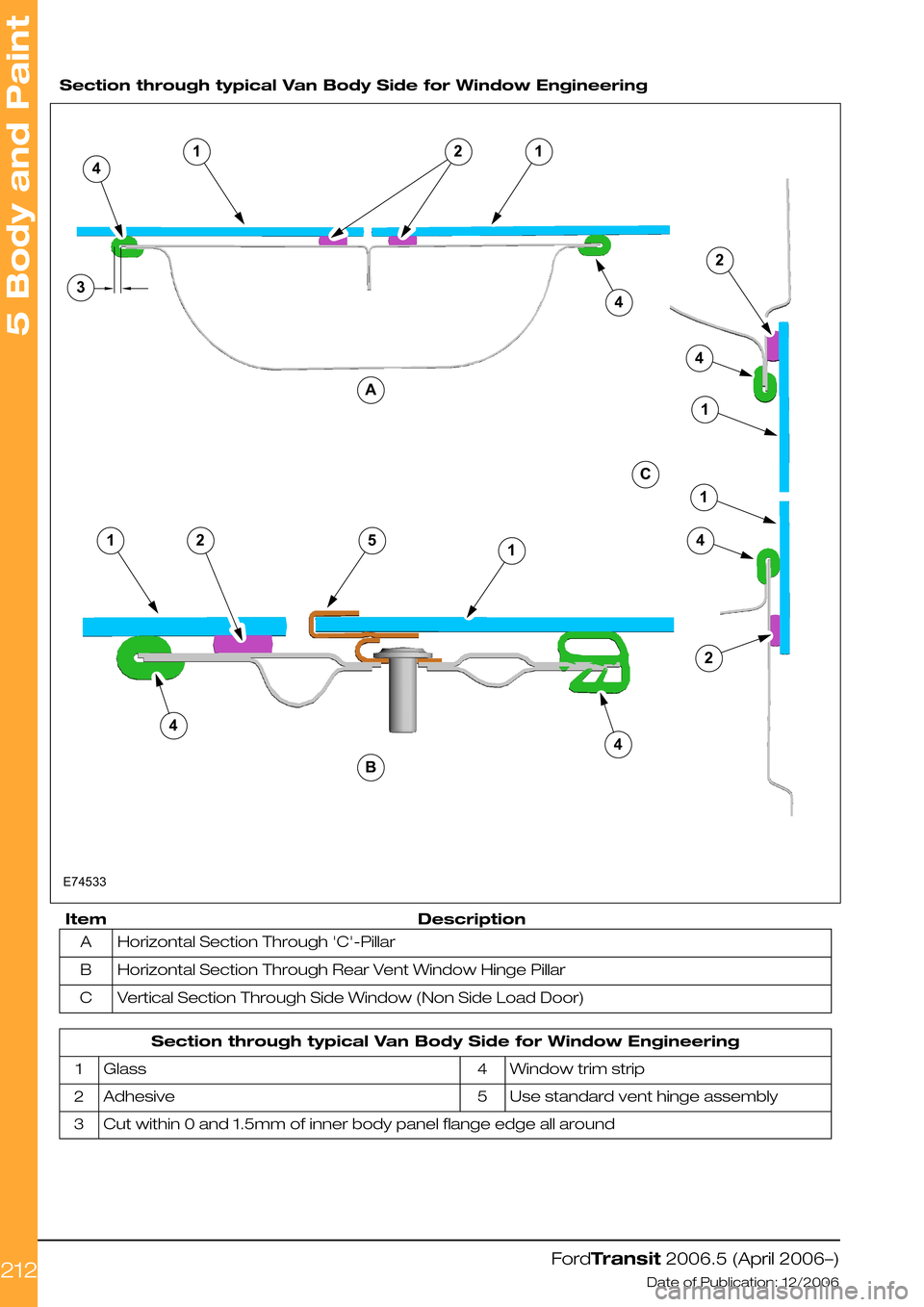

5.7 Roof Opening Panel

5.7.1 Driver's Standing Head

Room

When planning cab walk-through capability on a

Van, Bus or Kombi, select the Special Vehicle

option, which replaces the front headlining and

parcel shelf in Vans and provides the maximum

height headlining for increased standing head

room height.

For Chassis Cab and Cab Van Floor vehicles, the

Special Vehicle Option “Roof Cutout Preparation”

can be ordered as shown in below Figure

E74678. Please consult your local National Sales

Company representative for availability.

Chassis Cab with Roof Cut Out Preparation

5.7.2 Back Panel Removal

When planning, select the Special Vehicle Option,

which has a detachable cab back panel (Chassis

Cab). Please consult your local National Sales

Company representative for availability.

5.7.3 Cab Roof Removal

For enhanced head room in the cabin of a Single

Chassis Cab, it is recommended to specify the

base vehicle with the Special Vehicle Option Roof

Cutout Preparation Pack, which provides a

perforated roof cut-out (only on Chassis Cabs)

and deletes “B”-pillar roof bow. Alternative

structure is added to comply with seat belt pull

requirements.

A unique Body Builder application where the

original Ford roof and back panel structure are

cut away must have a bolt-on reinforcing 'goal

post' structure or equivalent to resist seat belt

pull loads.

Body Preparation

When it is not possible to specify the Special

Vehicle Option it is advisable to observe the

engineering intent of the Special Vehicle

Engineering design.

Where new add-on bodies are attached to the

cab for an enclosed walk-through, the body

structure must be self-supporting and fixed such

that no local stress is created in the parent cab

structure.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

214E74678

Page 215 of 234

Use metal fasteners through double thickness

flanges for example with nuts, bolts and spreader

plates where possible.

“Pop” type rivet structural value is only as good

as the material or thickness of the body panels,

therefore ensure the application is suitably

engineered.

Protect all metal edges to comply with interior

projection legislation.

Corrosion protect all cut or drilled metal edges

and repair any paint damage.

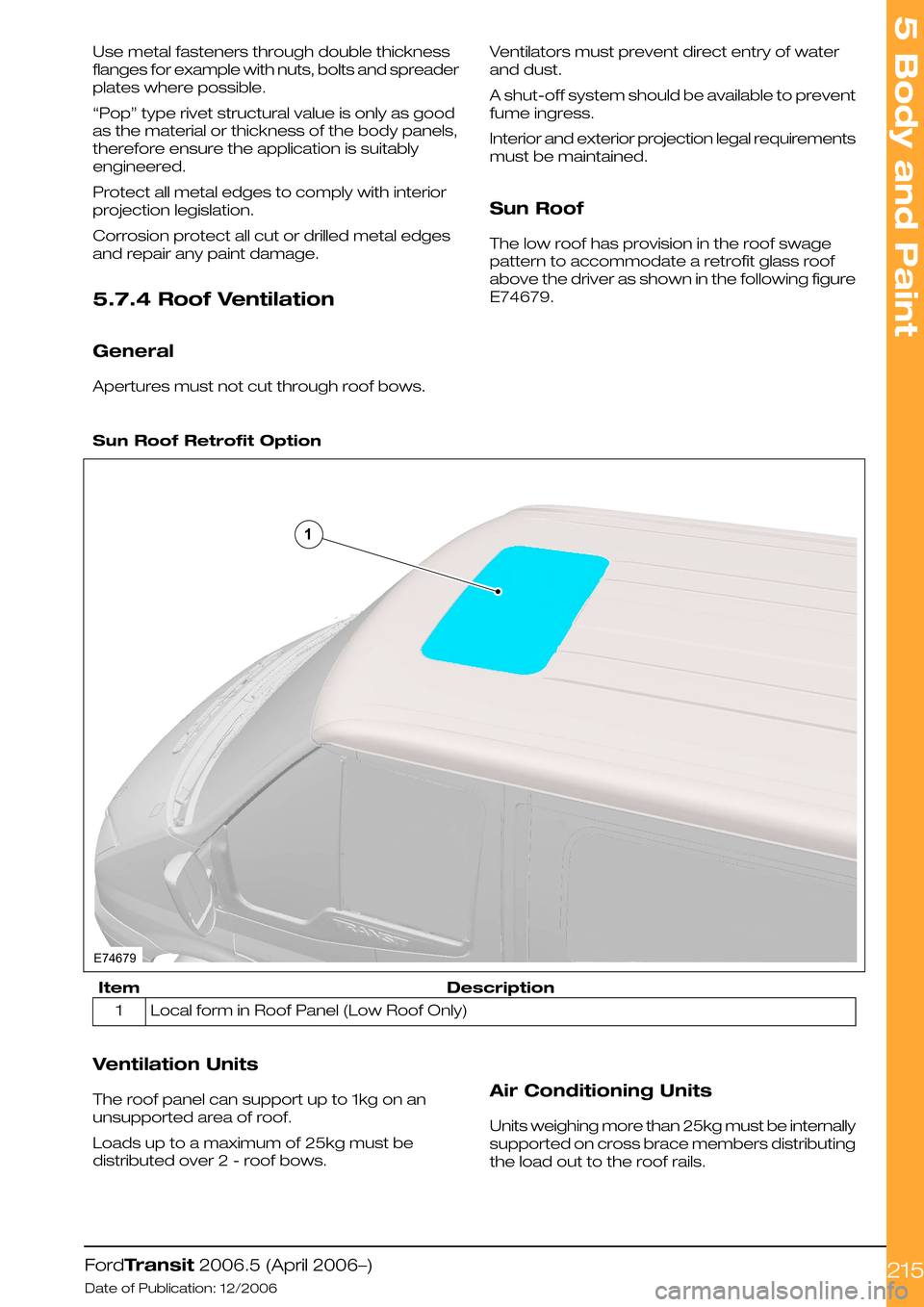

5.7.4 Roof Ventilation

General

Apertures must not cut through roof bows.

Ventilators must prevent direct entry of water

and dust.

A shut-off system should be available to prevent

fume ingress.

Interior and exterior projection legal requirements

must be maintained.

Sun Roof

The low roof has provision in the roof swage

pattern to accommodate a retrofit glass roof

above the driver as shown in the following figure

E74679.

Sun Roof Retrofit Option

DescriptionItem

Local form in Roof Panel (Low Roof Only)1

Ventilation Units

The roof panel can support up to 1kg on an

unsupported area of roof.

Loads up to a maximum of 25kg must be

distributed over 2 - roof bows.

Air Conditioning Units

Units weighing more than 25kg must be internally

supported on cross brace members distributing

the load out to the roof rails.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

215E746791

Page 224 of 234

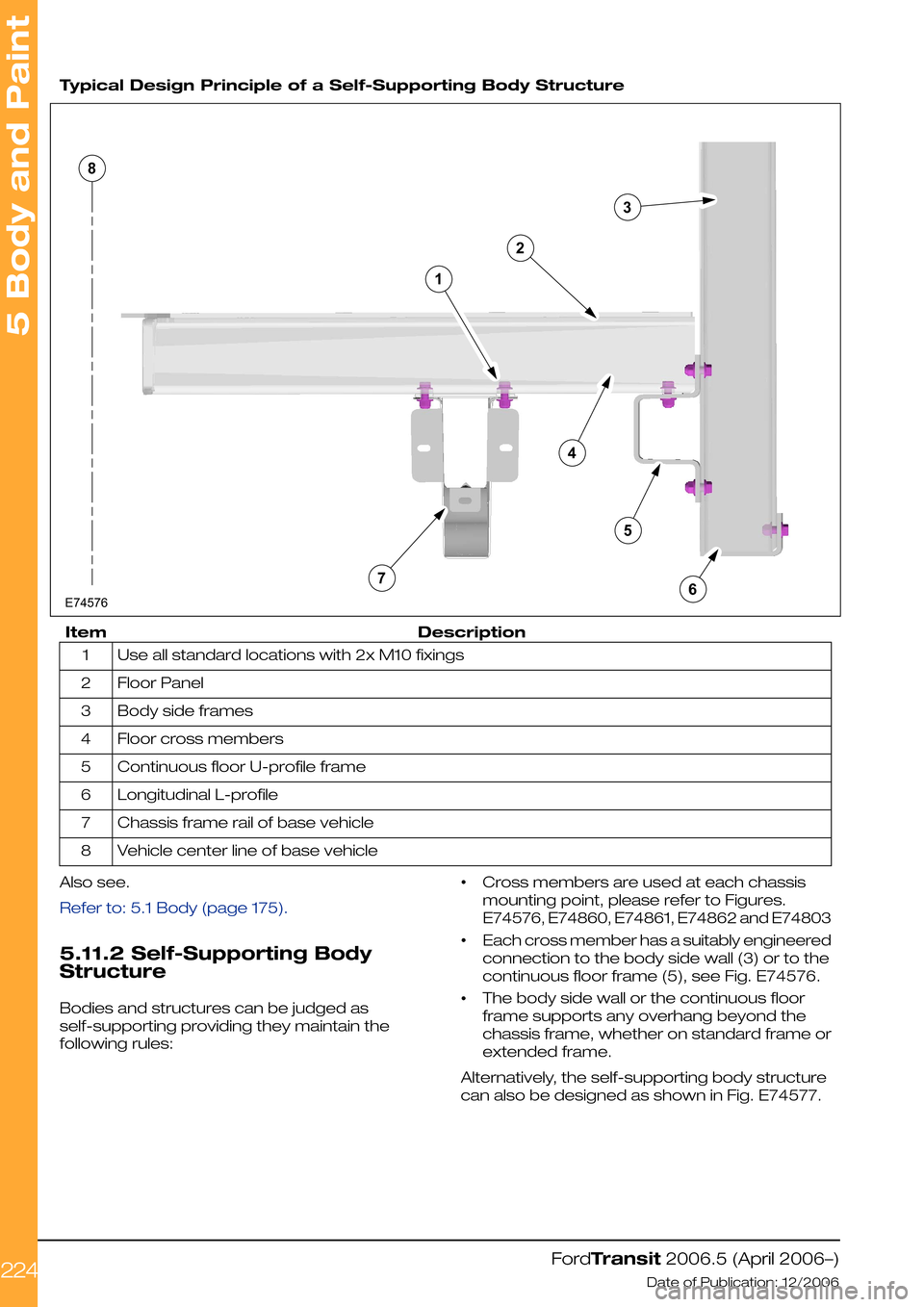

Typical Design Principle of a Self-Supporting Body Structure

DescriptionItem

Use all standard locations with 2x M10 fixings1

Floor Panel2

Body side frames3

Floor cross members4

Continuous floor U-profile frame5

Longitudinal L-profile6

Chassis frame rail of base vehicle7

Vehicle center line of base vehicle8

Also see.

Refer to: 5.1 Body (page 175).

5.11.2 Self-Supporting Body

Structure

Bodies and structures can be judged as

self-supporting providing they maintain the

following rules:

•Cross members are used at each chassis

mounting point, please refer to Figures.

E74576, E74860, E74861, E74862 and E74803

•Each cross member has a suitably engineered

connection to the body side wall (3) or to the

continuous floor frame (5), see Fig. E74576.

•The body side wall or the continuous floor

frame supports any overhang beyond the

chassis frame, whether on standard frame or

extended frame.

Alternatively, the self-supporting body structure

can also be designed as shown in Fig. E74577.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

224E7457612345678

Page 225 of 234

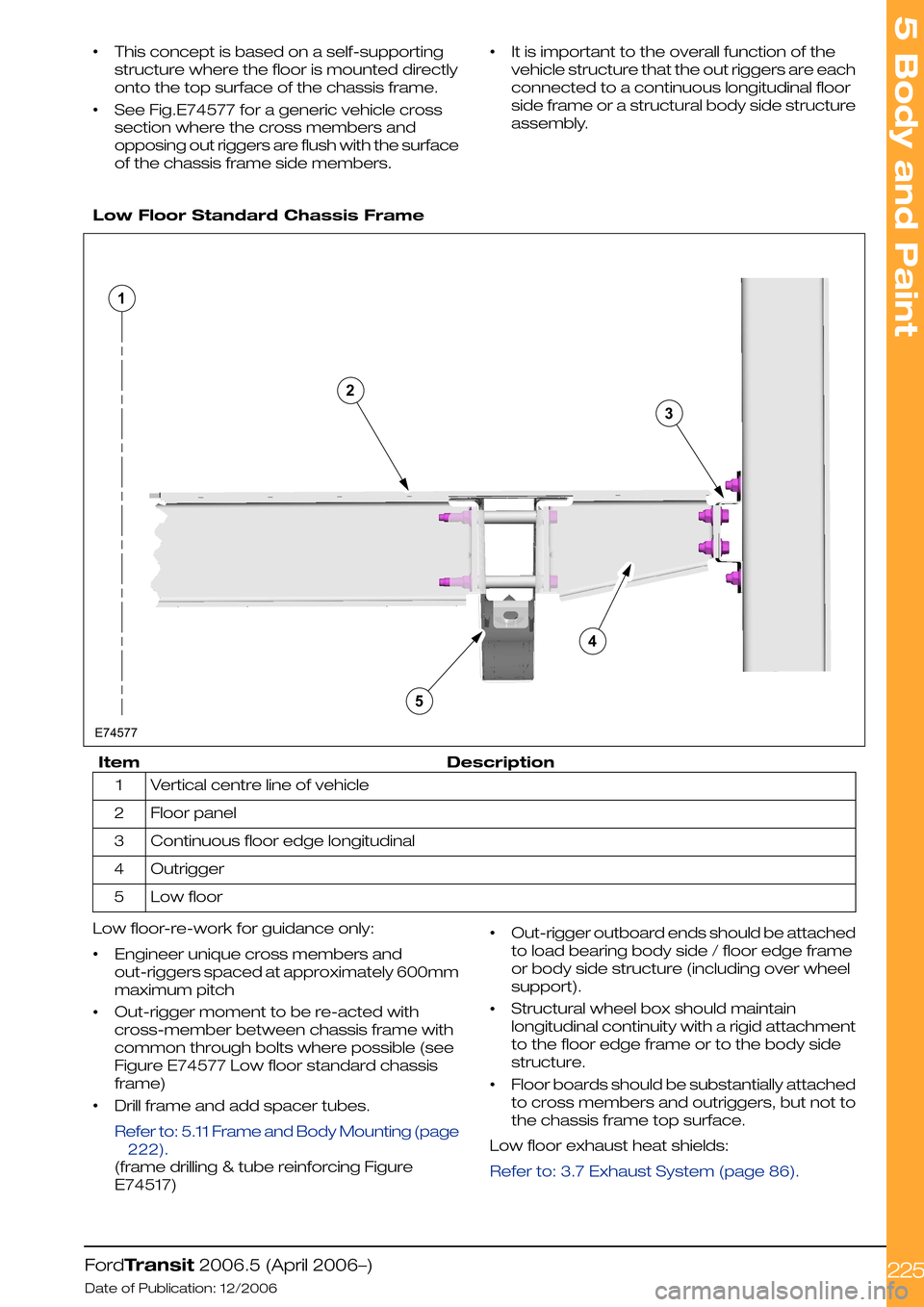

•This concept is based on a self-supporting

structure where the floor is mounted directly

onto the top surface of the chassis frame.

•See Fig.E74577 for a generic vehicle cross

section where the cross members and

opposing out riggers are flush with the surface

of the chassis frame side members.

•It is important to the overall function of the

vehicle structure that the out riggers are each

connected to a continuous longitudinal floor

side frame or a structural body side structure

assembly.

Low Floor Standard Chassis Frame

DescriptionItem

Vertical centre line of vehicle1

Floor panel2

Continuous floor edge longitudinal3

Outrigger4

Low floor5

Low floor-re-work for guidance only:

•Engineer unique cross members and

out-riggers spaced at approximately 600mm

maximum pitch

•Out-rigger moment to be re-acted with

cross-member between chassis frame with

common through bolts where possible (see

Figure E74577 Low floor standard chassis

frame)

•Drill frame and add spacer tubes.

Refer to: 5.11 Frame and Body Mounting (page

222).

(frame drilling & tube reinforcing Figure

E74517)

•Out-rigger outboard ends should be attached

to load bearing body side / floor edge frame

or body side structure (including over wheel

support).

•Structural wheel box should maintain

longitudinal continuity with a rigid attachment

to the floor edge frame or to the body side

structure.

•Floor boards should be substantially attached

to cross members and outriggers, but not to

the chassis frame top surface.

Low floor exhaust heat shields:

Refer to: 3.7 Exhaust System (page 86).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

225E7457723451

Page 226 of 234

5.11.3 Extended Chassis Frame

General:

•Rear overhang extensions are available as

Regular Production Option.

•Bodies or equipment exceeding the standard

extension length must be supported, please

refer to Figure E74575 low body longitudinal

members or Figure E74576 self-supporting

body structures.

•It is the Body Builder's responsibility to mark-up

the owners’ handbook advising the available

payload. Axle plated weights and maximum

allowable axle mass as shown in this manual

must not be exceeded.

•The vehicle should be planned for uniformly

distributed loads.

5.11.4 Non Standard Rear Chassis

Frame Extension

Extensions longer than the standard Regular

Production Option must comply with the following

guidelines:

•The original rear cross member and or

under-run bar or equivalent must be

repositioned at the end of any altered

extension to meet legislation, please refer to

Figure E74578 Non Regular Production Option

rear chassis frame extensions. Also see.

Refer to: 1.17 Towing (page 54).

(Figure E74854)

•The standard fit under-run bar is bolted on as

shown in Figure E74578 and Figure E74854

as mentioned in previous paragraph.

•The altered extension assembly must include

a cross member adjacent to the end of the

original chassis frame to replace the relocated

under-run bar, see Figure E74577.

•Flat-beds and low bodies built onto Non

Regular Production Option extensions must

have continuous longitudinal members

engineered by the Body Builder or equipment

supplier (please refer to Figure. E74577) to

resolve the worst case moments at rear bump

stop.

•Extensions should be secured to the chassis

frame sandwiched under the rear spring

shackle bracket utilizing the four (4) bolts and

four (4) holes in the rear of the chassis frame,

totaling eight (8) per vehicle side (please refer

to Figure E74578).

•The four (4) rear most existing holes in the

chassis frame must be sleeved with tubes to

prevent chassis frame collapse, refer to Figure

E74578.

•The spacer tubes should, ideally, be part of a

welded bracket and tube assembly to hold the

tubes accurately in place, avoiding the need

to weld the tubes in place, see Figure E74578.

•Care must be taken when tightening the spring

shackle bracket bolts and nuts to the correct

torque. See

Refer to: 1.15 (page 43).

(tightening torques).

•Extensions sleeved over the outside of the

chassis frame will necessitate the removal of

the under-run bar attachment flanges turned

out at the chassis frame ends. The cut edges

must be protected against corrosion.

Refer to: 5.10 Corrosion Prevention (page 221).

•Drilling of the top flanges turned out is only

permissible rearward of the spring hanger

brackets, for continuity of the altered extension

closing plate, if required. The diameter of the

holes should be 6.0mm maximum.

•If the chassis frame includes the inverted top

hat closure of the 4.25 tonne chassis double

cab variant, a similar closure must be included

in the extension and sleeved over the chassis

frame. It will be necessary to add two (2) holes

and reinforcing tubes in the inverted top hat

chassis frame vertically in line with the group

of four (4) holes see Figure E74578.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

226

Page 230 of 234

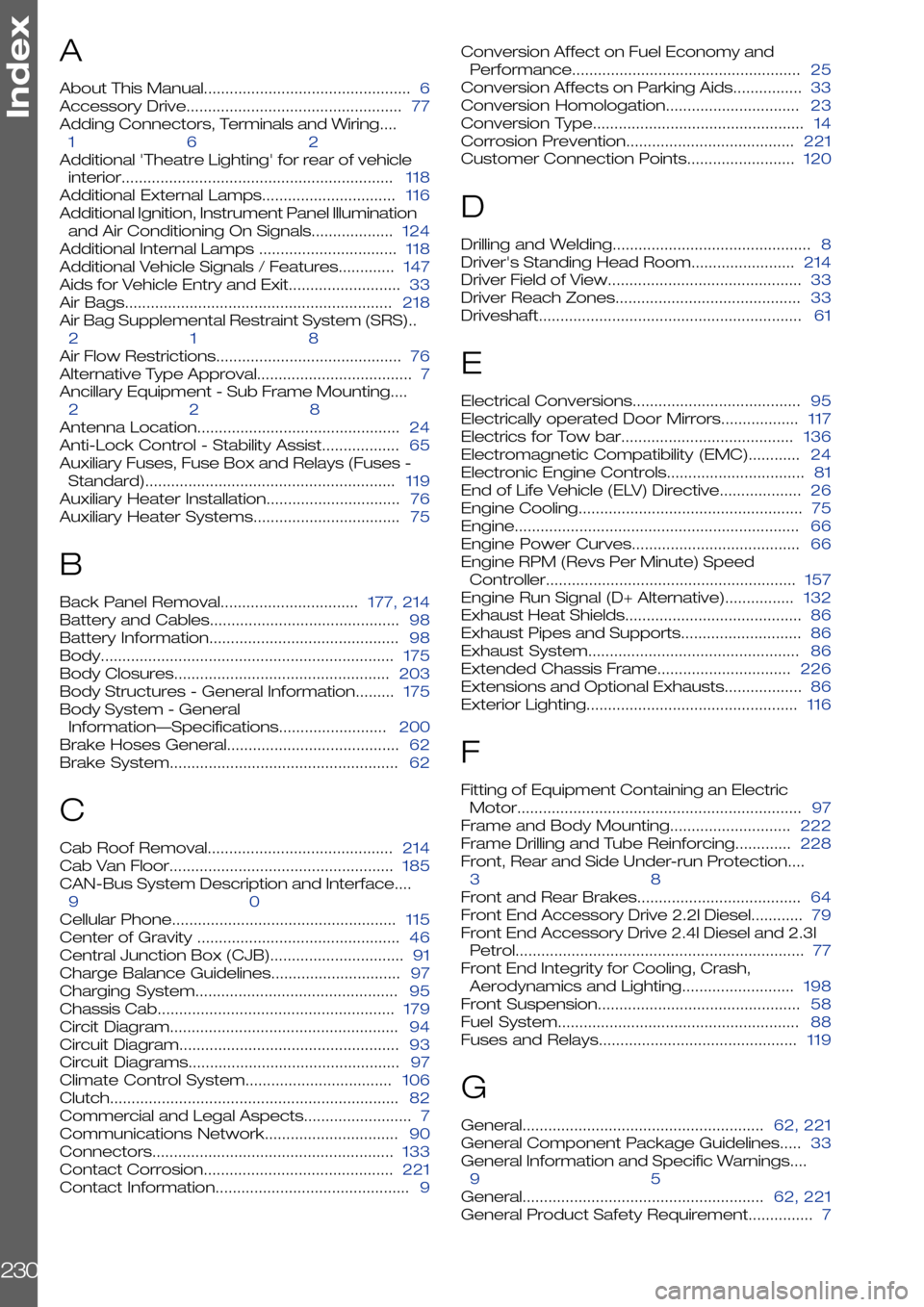

A

About This Manual................................................6

Accessory Drive..................................................77

Adding Connectors, Terminals and Wiring....

162

Additional 'Theatre Lighting' for rear of vehicle

interior...............................................................118

Additional External Lamps...............................116

Additional Ignition, Instrument Panel Illumination

and Air Conditioning On Signals...................124

Additional Internal Lamps ................................118

Additional Vehicle Signals / Features.............147

Aids for Vehicle Entry and Exit..........................33

Air Bags..............................................................218

Air Bag Supplemental Restraint System (SRS)..

218

Air Flow Restrictions...........................................76

Alternative Type Approval....................................7

Ancillary Equipment - Sub Frame Mounting....

228

Antenna Location...............................................24

Anti-Lock Control - Stability Assist..................65

Auxiliary Fuses, Fuse Box and Relays (Fuses -

Standard)..........................................................119

Auxiliary Heater Installation...............................76

Auxiliary Heater Systems..................................75

B

Back Panel Removal................................177, 214

Battery and Cables............................................98

Battery Information............................................98

Body....................................................................175

Body Closures..................................................203

Body Structures - General Information.........175

Body System - General

Information—Specifications.........................200

Brake Hoses General........................................62

Brake System.....................................................62

C

Cab Roof Removal...........................................214

Cab Van Floor....................................................185

CAN-Bus System Description and Interface....

90

Cellular Phone....................................................115

Center of Gravity ...............................................46

Central Junction Box (CJB)...............................91

Charge Balance Guidelines..............................97

Charging System...............................................95

Chassis Cab.......................................................179

Circit Diagram.....................................................94

Circuit Diagram...................................................93

Circuit Diagrams.................................................97

Climate Control System..................................106

Clutch...................................................................82

Commercial and Legal Aspects.........................7

Communications Network...............................90

Connectors........................................................133

Contact Corrosion............................................221

Contact Information.............................................9

Conversion Affect on Fuel Economy and

Performance.....................................................25

Conversion Affects on Parking Aids................33

Conversion Homologation...............................23

Conversion Type.................................................14

Corrosion Prevention.......................................221

Customer Connection Points.........................120

D

Drilling and Welding..............................................8

Driver's Standing Head Room........................214

Driver Field of View.............................................33

Driver Reach Zones...........................................33

Driveshaft.............................................................61

E

Electrical Conversions.......................................95

Electrically operated Door Mirrors..................117

Electrics for Tow bar........................................136

Electromagnetic Compatibility (EMC)............24

Electronic Engine Controls................................81

End of Life Vehicle (ELV) Directive...................26

Engine Cooling....................................................75

Engine..................................................................66

Engine Power Curves.......................................66

Engine RPM (Revs Per Minute) Speed

Controller..........................................................157

Engine Run Signal (D+ Alternative)................132

Exhaust Heat Shields.........................................86

Exhaust Pipes and Supports............................86

Exhaust System.................................................86

Extended Chassis Frame...............................226

Extensions and Optional Exhausts..................86

Exterior Lighting.................................................116

F

Fitting of Equipment Containing an Electric

Motor..................................................................97

Frame and Body Mounting............................222

Frame Drilling and Tube Reinforcing.............228

Front, Rear and Side Under-run Protection....

38

Front and Rear Brakes......................................64

Front End Accessory Drive 2.2l Diesel............79

Front End Accessory Drive 2.4l Diesel and 2.3l

Petrol...................................................................77

Front End Integrity for Cooling, Crash,

Aerodynamics and Lighting..........................198

Front Suspension...............................................58

Fuel System........................................................88

Fuses and Relays..............................................119

G

General........................................................62, 221

General Component Package Guidelines.....33

General Information and Specific Warnings....

95

General........................................................62, 221

General Product Safety Requirement...............7

Index

230