engine FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 146 of 234

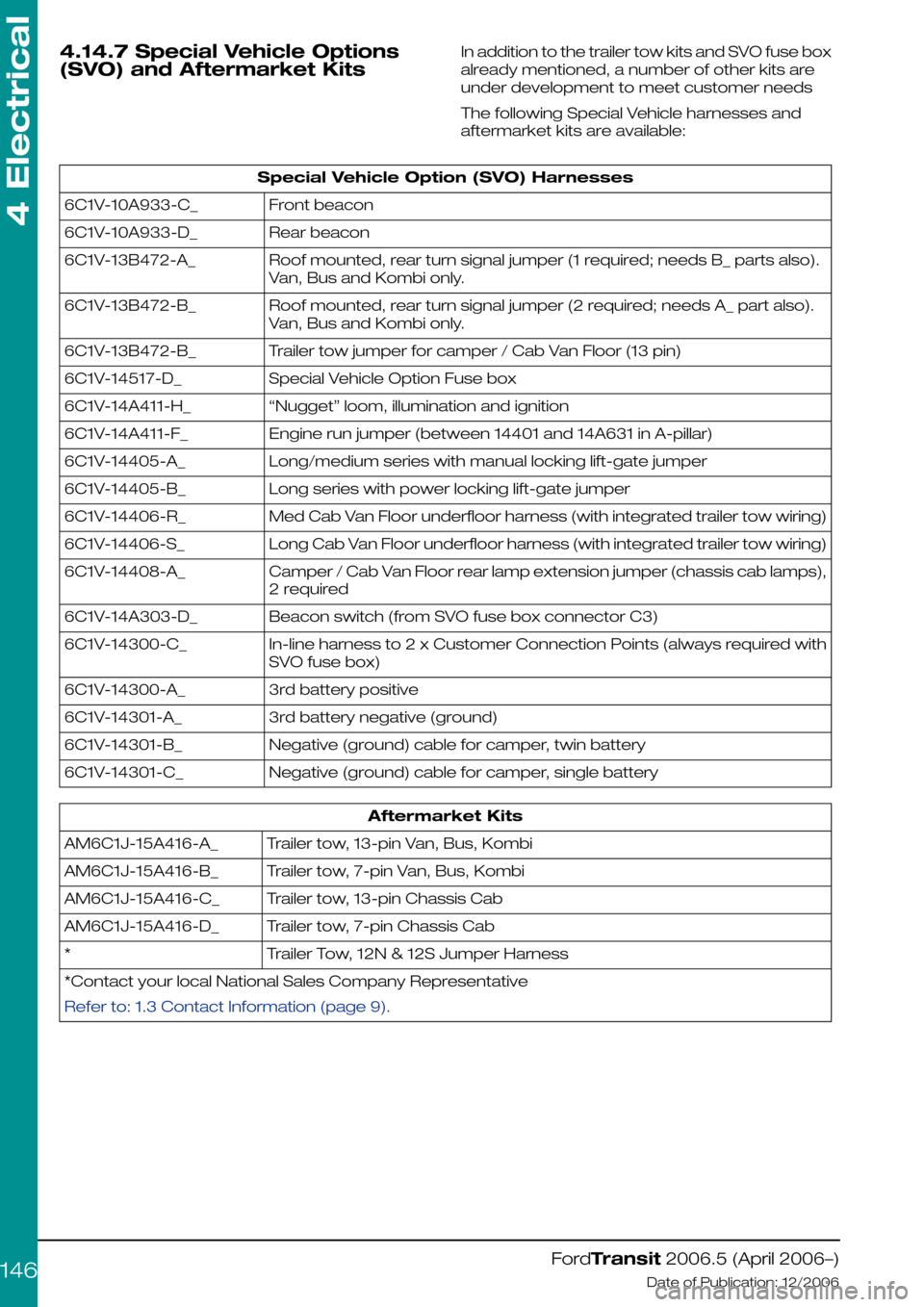

4.14.7 Special Vehicle Options

(SVO) and Aftermarket Kits

In addition to the trailer tow kits and SVO fuse box

already mentioned, a number of other kits are

under development to meet customer needs

The following Special Vehicle harnesses and

aftermarket kits are available:

Special Vehicle Option (SVO) Harnesses

Front beacon6C1V-10A933-C_

Rear beacon6C1V-10A933-D_

Roof mounted, rear turn signal jumper (1 required; needs B_ parts also).

Van, Bus and Kombi only.

6C1V-13B472-A_

Roof mounted, rear turn signal jumper (2 required; needs A_ part also).

Van, Bus and Kombi only.

6C1V-13B472-B_

Trailer tow jumper for camper / Cab Van Floor (13 pin)6C1V-13B472-B_

Special Vehicle Option Fuse box6C1V-14517-D_

“Nugget” loom, illumination and ignition6C1V-14A411-H_

Engine run jumper (between 14401 and 14A631 in A-pillar)6C1V-14A411-F_

Long/medium series with manual locking lift-gate jumper6C1V-14405-A_

Long series with power locking lift-gate jumper6C1V-14405-B_

Med Cab Van Floor underfloor harness (with integrated trailer tow wiring)6C1V-14406-R_

Long Cab Van Floor underfloor harness (with integrated trailer tow wiring)6C1V-14406-S_

Camper / Cab Van Floor rear lamp extension jumper (chassis cab lamps),

2 required

6C1V-14408-A_

Beacon switch (from SVO fuse box connector C3)6C1V-14A303-D_

In-line harness to 2 x Customer Connection Points (always required with

SVO fuse box)

6C1V-14300-C_

3rd battery positive6C1V-14300-A_

3rd battery negative (ground)6C1V-14301-A_

Negative (ground) cable for camper, twin battery6C1V-14301-B_

Negative (ground) cable for camper, single battery6C1V-14301-C_

Aftermarket Kits

Trailer tow, 13-pin Van, Bus, KombiAM6C1J-15A416-A_

Trailer tow, 7-pin Van, Bus, KombiAM6C1J-15A416-B_

Trailer tow, 13-pin Chassis CabAM6C1J-15A416-C_

Trailer tow, 7-pin Chassis CabAM6C1J-15A416-D_

Trailer Tow, 12N & 12S Jumper Harness*

*Contact your local National Sales Company Representative

Refer to: 1.3 Contact Information (page 9).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

146

Page 157 of 234

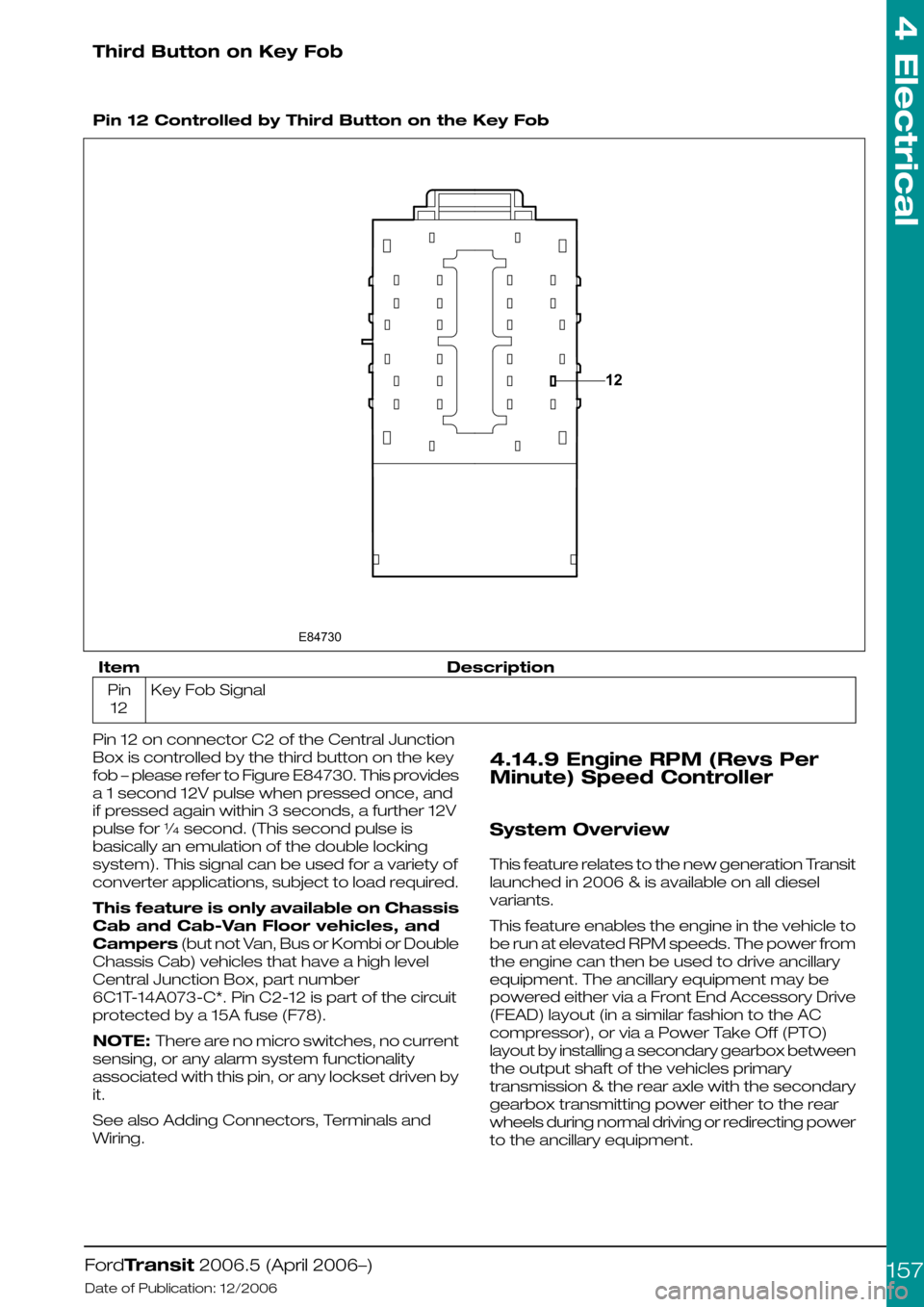

Third Button on Key Fob

Pin 12 Controlled by Third Button on the Key Fob

DescriptionItem

Key Fob SignalPin

12

Pin 12 on connector C2 of the Central Junction

Box is controlled by the third button on the key

fob – please refer to Figure E84730. This provides

a 1 second 12V pulse when pressed once, and

if pressed again within 3 seconds, a further 12V

pulse for ¼ second. (This second pulse is

basically an emulation of the double locking

system). This signal can be used for a variety of

converter applications, subject to load required.

This feature is only available on Chassis

Cab and Cab-Van Floor vehicles, and

Campers (but not Van, Bus or Kombi or Double

Chassis Cab) vehicles that have a high level

Central Junction Box, part number

6C1T-14A073-C*. Pin C2-12 is part of the circuit

protected by a 15A fuse (F78).

NOTE: There are no micro switches, no current

sensing, or any alarm system functionality

associated with this pin, or any lockset driven by

it.

See also Adding Connectors, Terminals and

Wiring.

4.14.9 Engine RPM (Revs Per

Minute) Speed Controller

System Overview

This feature relates to the new generation Transit

launched in 2006 & is available on all diesel

variants.

This feature enables the engine in the vehicle to

be run at elevated RPM speeds. The power from

the engine can then be used to drive ancillary

equipment. The ancillary equipment may be

powered either via a Front End Accessory Drive

(FEAD) layout (in a similar fashion to the AC

compressor), or via a Power Take Off (PTO)

layout by installing a secondary gearbox between

the output shaft of the vehicles primary

transmission & the rear axle with the secondary

gearbox transmitting power either to the rear

wheels during normal driving or redirecting power

to the ancillary equipment.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

15712E84730

Page 158 of 234

NOTE: A power take off layout can only be

implemented on vehicles fitted with an ABS

braking system. Manual braking systems employ

a transmission speed sensor to determine vehicle

speed & the RPM speed control software

contains vehicle speed restrictions which prohibit

RPM speed control operation if vehicle speed is

detected above very low levels (approx 2.5 mph).

A vehicle fitted with an ABS braking system

derives vehicle speed via the vehicles wheel

speed sensors, so the transmission can operate

normally without effecting RPM speed control

operation.

3 Modes of Operation

There are 3 principle modes in which this feature

can operate, they are:

1.3 speed mode – this provides the end user a

choice of up to 3 preset RPM values to select

from. The end user cannot easily override

these values so there is minimal risk of damage

to ancillary equipment due to it being run at

speeds it was not designed for. Very limited

vehicle speed is allowable while in this mode

(up to 2.5mph approx)

2.Variable speed mode – this provides the end

user with RPM speed ramp up & down

buttons. The end user is free to select RPM

values between 1300-3000rpm in 25rpm

steps. A single press results in a 25 rpm jump.

If a ramp button is held depressed by the end

user then the rate of change is 250rpm/sec.

Very limited vehicle speed is allowable while in

this mode (up to 2.5mph approx)

3.Idle up speed – this mode allows the engines

normal idle to be increased to any value (in 25

rpm steps) in the range 900-1200rpm. There

is not a vehicle speed restriction in this mode

as the intended use is to raise the engine idle

to reduce the likelihood of engine stall when

ancillary equipment is being run from the

engine during normal drive operations. Eg

refrigerator units used to keep the cargo bay

cool.

NOTE: Items 1) & 2) will be available from Nov

2006, while item 3) should be available from Jan

2007. Any latest generation diesel Transit can be

updated to include item 3) Idle up speed with a

simple calibration update once it becomes

available.

System Availability

This feature is built into the latest Powertrain

Control Module (PCM) software on all diesel

engine variants.

By default the feature is not enabled unless the

vehicle is specifically ordered with the feature

from the factory.

Vehicles which have not been ordered with this

feature may have the feature enabled at a dealer

via the IDS diagnostics system. The dealer should

charge for this service.

How to control this feature

A loop of wire (green/white) is provided in the

main electrical loom to permit control of the RPM

Speed Control software. Cutting this loop will

provide two wires to connect a control box to the

PCM.

The control box needs to switch resistors into the

circuit across the two green/white wires which

formally formed the loop prior to being cut. This

sort of circuit is known as a resistance ladder. The

PCM software monitors the green/white wire

circuit & when certain resistances are detected

they are interpreted as various inputs which

control the feature. The switch box can be

located where it’s ideally required for the vehicle

conversion in question, rather than having to be

mounted on the Instrument Panel (IP). If the

converter chooses to locate the switch box in a

location which is subject to an adverse

environment then the converter should design

the switch box to withstand with these conditions.

How to locate the green/white loop

The main electrical loom enters the vehicle cab

from the engine bay on the left hand side of the

vehicle via a large diameter hole in the engine bay

/ cabin bulkhead. This hole is just above the left

hand front suspension turret. See following Figure

E88307

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

158

Page 160 of 234

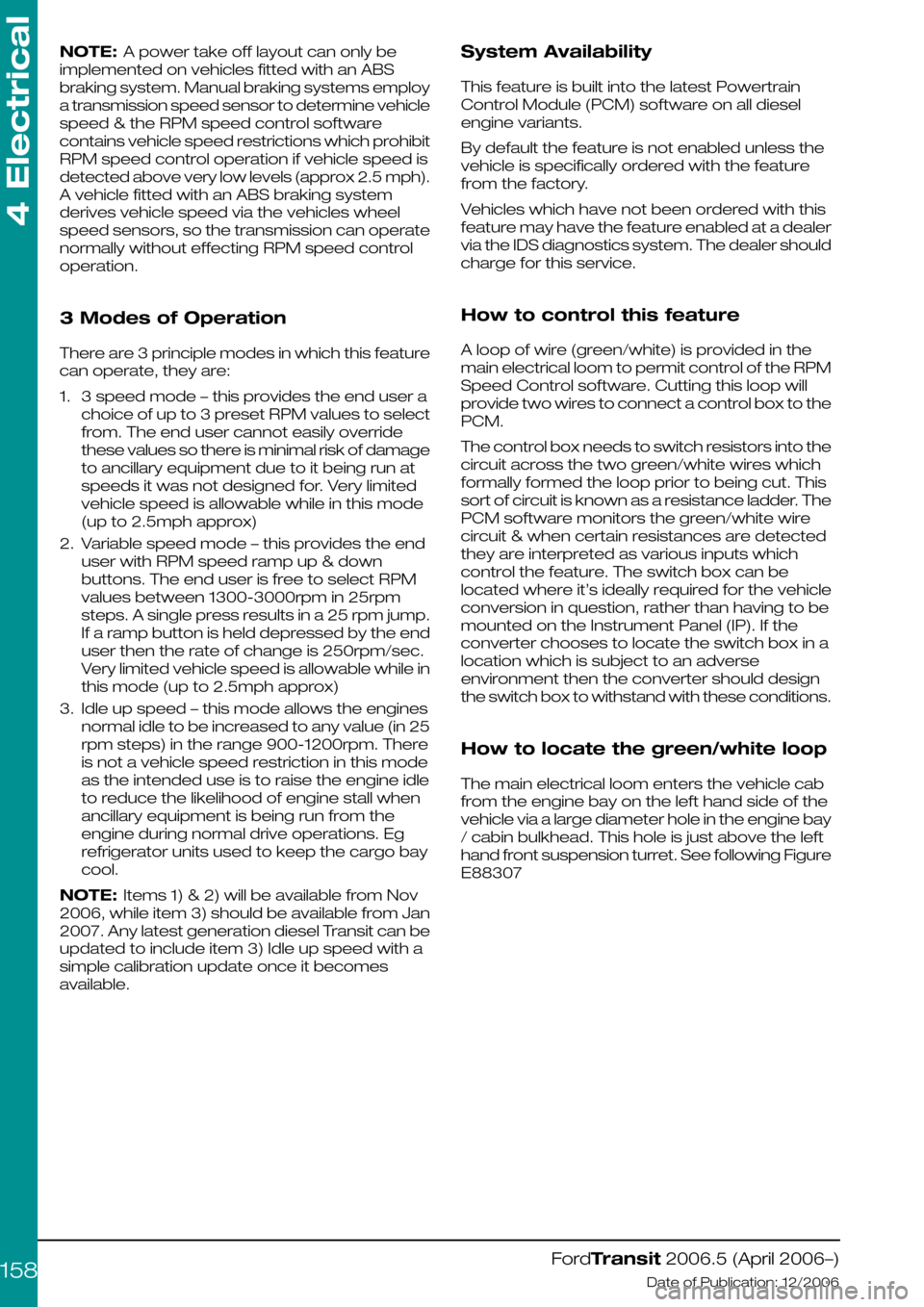

Resistance Ladder

Resistance Ladder Circuit

DescriptionItem

To Green / White Wire1

Stop Engine2

RPM 1 on / off or Variable Control 'Idle'3

RPM 2 on / off or Variable Control 'Negative (-)'4

RPM 3 on / off or Variable Control 'Positive (+)'5

RPM control Armed or Increased Idle on / off6

The resistance ladder circuit acts as a potential

divider. The PCM has an internal reference

voltage of 5 volts. Current passes through an

internal 320 ohm resistor (not shown above) prior

to passing through the resistance ladder. There

is also a (second) 220 nF capacitor internally

within the PCM between the 320 ohm resistor &

ground (not shown above) & this is to reduce

EMC effects.

With all the switches open there a total resistance

in the green/white loop of approx 4330 ohms &

this corresponds to normal driving operation (as

does short circuit – the condition prior to the loop

being cut).

Starting from the right of the diagram, when the

key switch is closed only 2110 ohms is in the

circuit & the PCM software recognizes this as the

RPM mode being armed & ready for operation

(Key switch closed = on, open = off). A key switch

is recommended in this position for a couple of

reasons:

•If the control box is located externally on the

vehicle, the requirement for a key avoids any

passers by being able to put the vehicle into

RPM Speed Control mode by simply pressing

a button.

•Using a key switch where the key can be

removed in either the ‘on’ or ‘off’ condition

could be used as an aid to anti theft. If the

operator uses a key to put the vehicle into

RPM Speed control mode & then removes the

key, then the vehicle cannot quickly & easily

be taken out of RPM speed control mode. If

a foot pedal is pressed while in either the 3

speed or variable speed modes, the vehicles

engine will stall & therefore the vehicle can not

easily be driven away & stolen.

When in 3 speed mode pressing any of the

middle 3 switches (with the feature armed) results

in the engine RPM jumping to the corresponding

RPM value held in memory (defaults of 1100, 1600

or 2030rpm) for the 3 switch positions. A second

consecutive press of the same button returns to

normal idle.

When in variable speed mode the same 3 buttons

act as ramp up, ramp down & return to idle

selections respectively.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

16065432E88295711

Page 161 of 234

The software in the PCM responds to the change

of state, so it is recommended that these 3

middle switches be non-latching push button

micro switches. When going from idle to an

elevated RPM the execution of the command

will occur as the button is released. When going

to idle the execution of the command occurs as

the button is pressed.

The final button (the one on the left in Fig. 4) acts

as an ‘emergency’ vehicle engine stop. It is

recommended that this be a red & oversize

non-latching micro switch button. The execution

of this command will occur as the button is

pressed.

All wiring connecting the PCM to the resistance

ladder control box should be shielded & twisted

(33 twists / m) to reduce EMC effects

All resistors should have a tolerance of +/- 5% or

better

Switch contact, connectors & loom (loom

between the green/white wires & the control

box) total resistance must be no greater than 5

ohm max.

The PCM to resister ladder control switch box

loom should not come within 100mm of any other

harness, especially any carrying heavy loads.

Designs which do not require all the button

switches must still have the complete resistor

network with the switches positioned correctly

within the network.

The resistance ladder is acting as a potential

divider

The 220 nF capacitor is used in the circuit to

reduce EMC effects on the system

A suitable two way quality connector should be

used to connect the control box to the two

green/white wires

How to change the default settings

By default, when the feature is first enabled

(either via factory order or via dealer IDS tools),

it will be set to the 3 speed mode of operation

with preset RPM values of 1100, 1600 & 2030rpm

for the 3 speeds.

There are two methods by which these defaults

can be modified:

1.via the IDS diagnostics system at a Ford dealer

(there may be a charge for this)

2.via an inbuilt vehicle ‘learn mode’

Via the IDS system the mode of operation can

freely be changed between any of the 3 modes

of operation, the feature can even be turn off

(disabled). The 3 default RPM speeds can also

be modified.

Via the vehicle ‘learn mode’ the 3 speed mode

& the variable speed mode can be freely

interchanged, however it is not possible to select

the idle up speed mode via the vehicle learn

mode. The 3 default RPM speeds can also be

modified via ‘learn mode’

It is not possible via either method above, to

change the step value of 25rpm per press or the

250 rpm per sec for a held down button, in the

variable rpm speed mode.

Via IDS The RPM Speed Controller menu is under

the tool box tab, then Powertrain, then service

functions, then PCM. The IDS on screen menus

will guide the dealer through the options & setup.

How to enter vehicle ‘Learn mode’

1.Make sure that the RPM Speed controller

switch box is connected but turned off (not

‘armed’)

2.Start the engine (vehicle out of gear & no foot

pedals being pressed, handbrake on)

3.Wait a couple of seconds for the instrument

panel start up diagnostic lights to extinguish

4.Press & release the clutch pedal

5.Press & release the brake pedal

6.Repeat steps 4) & 5) a further four times

(clutch & brake pressed a total of five times

sequentially each)

NOTE: Steps 4) to 6) have to be started within

10 seconds of the engine start

The vehicle should now be in ‘learn mode’

How to Select between modes

1.Enter ‘learn mode’ (see directions above)

2.Arm the RPM speed controller (turn the key

switch to ‘on’)

If the vehicle is already in 3 speed mode (the

initial default):

3.Press & release the brake pedal five times

The vehicle should now be in variable speed

mode. The new settings can be saved & learn

mode exited (see below)

Alternatively

4.Press & release the brake pedal once

The vehicle should now be in 3 speed mode.

The new settings can be saved & learn mode

exited (see below)

Using this method it is easy to change between

these two modes of operation for the RPM

speed controller

NOTE: If the engine stalls out at the initial brake

pedal input then the vehicle was not in, or has

dropped out of ‘learn mode’ & you will have to

restart the procedure.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

161

Page 162 of 234

How to change the 3 pre-set default

RPM values in the 3 speed mode

1.Enter ‘learn mode’ (see directions above)

2.Arm the RPM speed controller (turn the key

switch to ‘on’)

3.Press & release the brake pedal once

4.Press & release the RPM button that requires

re-programming

5.Use the accelerator pedal to rev the engine to

the new desired RPM speed & hold at this

speed (only speeds between 1200 to 3000

rpm can be selected in 3 speed mode)

6.Press & release the same RPM button to reset

the stored RPM speed to the current engines

RPM

7.Release the accelerator pedal

8.Repeat steps 4) to 7) for the remaining RPM

buttons

The 3 RPM speeds should now be

re-programmed to the new RPM speeds. The

new settings can be saved & learn mode exited

(see below)

NOTE: If the engine RPM responds to the initial

RPM button press, then the vehicle has not

entered ‘learn mode’ correctly & you will have to

restart the procedure. If the engine stalls out at

the brake or accelerator pedal inputs then the

vehicle was not in, or has dropped out of ‘learn

mode’ & you will have to restart the procedure.

How to save new settings & exit

from ‘Learn mode’

1.From within the ‘learn mode’ & with the RPM

Speed Control switch box ‘armed’, press the

clutch pedal repeatedly until the engine stalls.

2.Restart the engine & test the new settings,

repeat above procedures if necessary

NOTE: The engine stalling indicates that the

settings should have been saved & the vehicle

has exited from ‘learn mode’. Learn mode

however is very specific that the exact steps are

taken in the correct order & within certain time

limits otherwise the learn procedure fails & it may

take several attempts to get this order & timing

correct & a successful modification from the

default settings.

Some Reasons why RPM speed

Control operation may stop or fail

The RPM Speed control software monitors

vehicle information during operation in RPM

speed control mode & will drop out of RPM speed

control and / or stall the engine should any

adverse signals be detected. For example:

•If the engine temperature becomes too hot

then RPM speed control will stop in order to

protect the engine.

•If the engine oil light illuminates then RPM

speed control will stop in order to protect the

engine

•If the low fuel level light illuminates then RPM

speed control will stop so that the vehicle can

be driven to a refueling point.

•If the vehicle speed exceeds approx 2.5 mph

wile in 3 speed or variable speed modes, then

RPM speed control may stop. RPM speed

control should normally be operated with the

hand brake on, but some uses may require a

low level of vehicle ‘creep’ during RPM speed

control operation. Note that there is no sensing

of the park brake on this version of RPM speed

controller to facilitate this type of operation.

•The software monitors for ‘stuck on’ buttons

on the control switch box, this may result in

RPM speed control being halted. A button that

is held down for too long may be registered

by the software as a ‘stuck’ button.

•The software monitors the foot pedals, if

depressed these may stall the engine if in 3

speed mode or variable speed mode (does

not apply to idle up speed)

•If the control switch box circuitry significantly

exceeds 2110 ohms or there is a short circuit

then RPM speed control will not be possible.

•If a PTO conversion has been attempted on a

vehicle with a non ABS braking system then

RPM speed control will fail due to vehicle

speed being registered via a transmission

speed sensor and / or the need to press the

clutch in order to put the vehicle in gear while

in RPM speed control mode.

4.14.10 Adding Connectors,

Terminals and Wiring

Additional Rear Speakers

NOTE: The connectors on the Instrument Panel

harness (14K024) and the main harness (14401)

are reversed between Left Hand Drive (LHD) and

Right Hand Drive (RHD) vehicles, hence different

sets of terminals/wires are required to cover all

the markets.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

162

Page 172 of 234

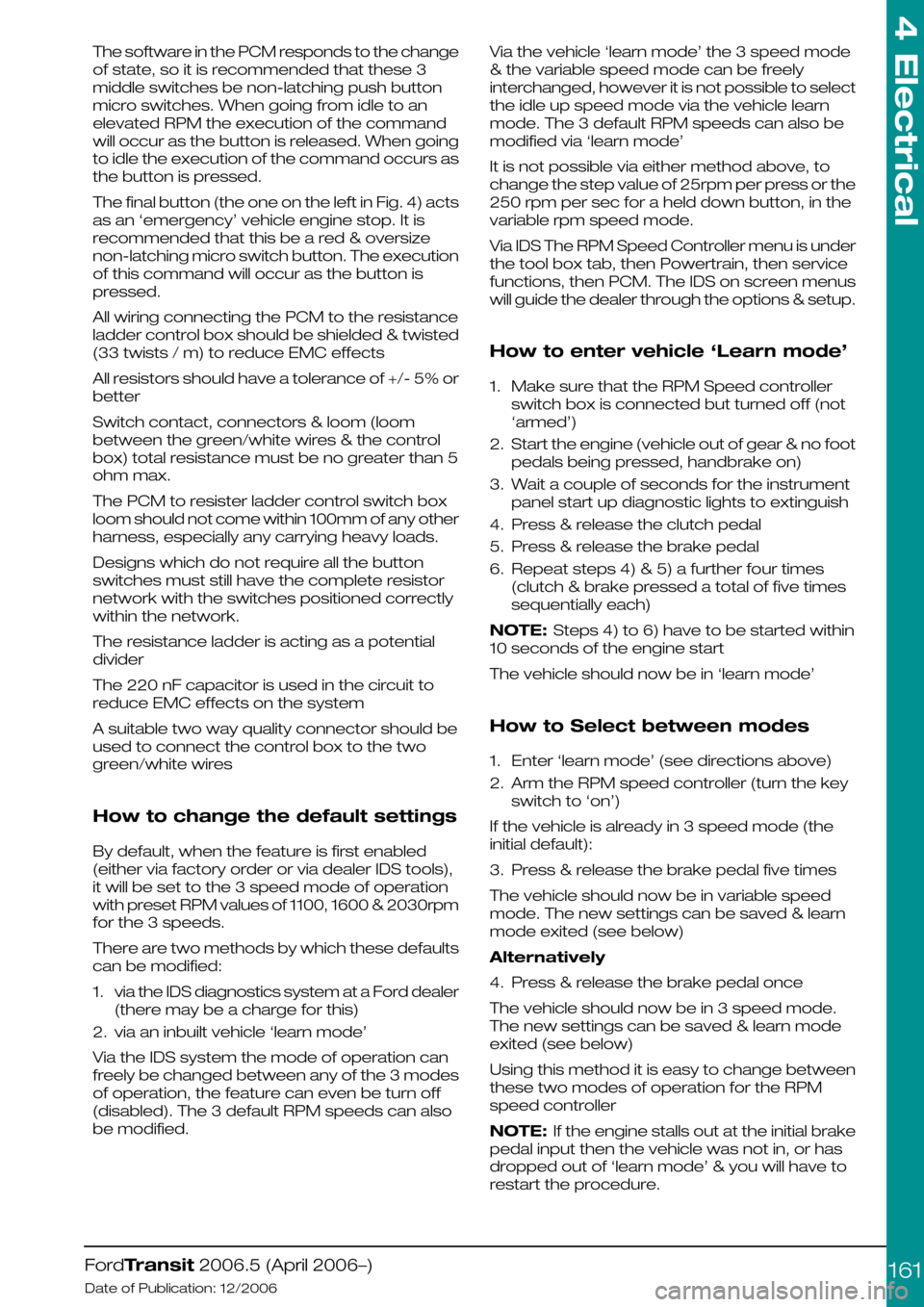

Pin 27 on connector C2 for 75W ‘Theater Lighting’

DescriptionItem

Rear Theater LightingPin

27

4. Push home the cream secondary lock

Third button on key fob

For Information only

As per Additional ‘Theater’ Lighting, but the pre-crimped wire is inserted in cavity C2-12.

Terminal part number: 97BG-14474-ACB

Wire size and Color: 1.5 CSA, yellow-violet

Engine Run Signal (D+ Alternative)

To install the T-piece jumper loom the outer mirror

needs to be removed (remove the cover and 3

x M6 screws – Note, for RHD vehicles these are

shear bolts that need to be replaced, part number

W712939-S422). Push out the visible plastic insert

from inside and disconnect connector. Put in the

T-piece jumper loom and reassemble all parts,

replacing the M6 screws as required.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

172E8471227

Page 173 of 234

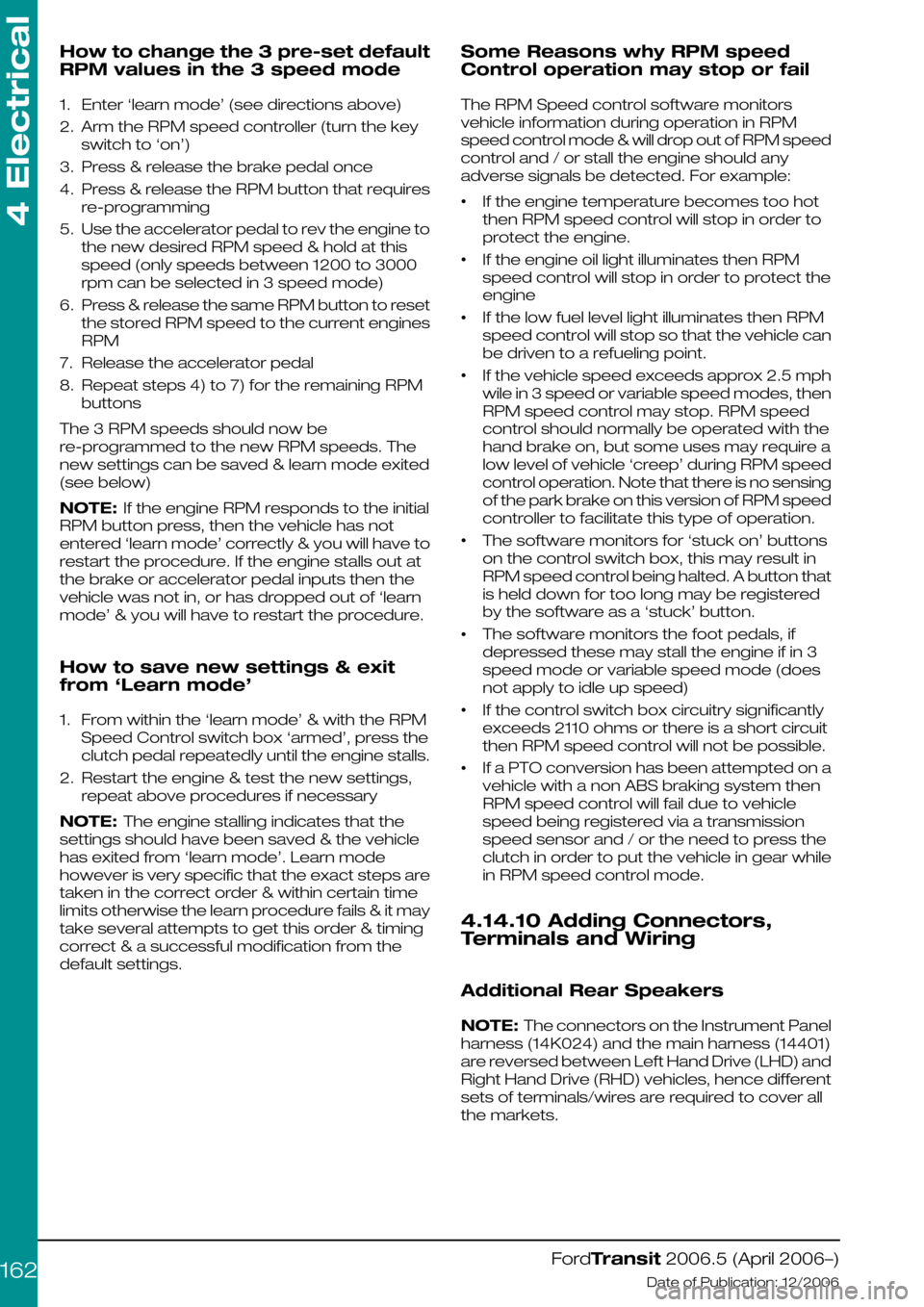

Male and Female connectors with pin

for engine run signal shown

DescriptionItem

Male connector Pin16 - Engine Run

Signal

A

Female connector Pin16 - Engine Run

Signal

B

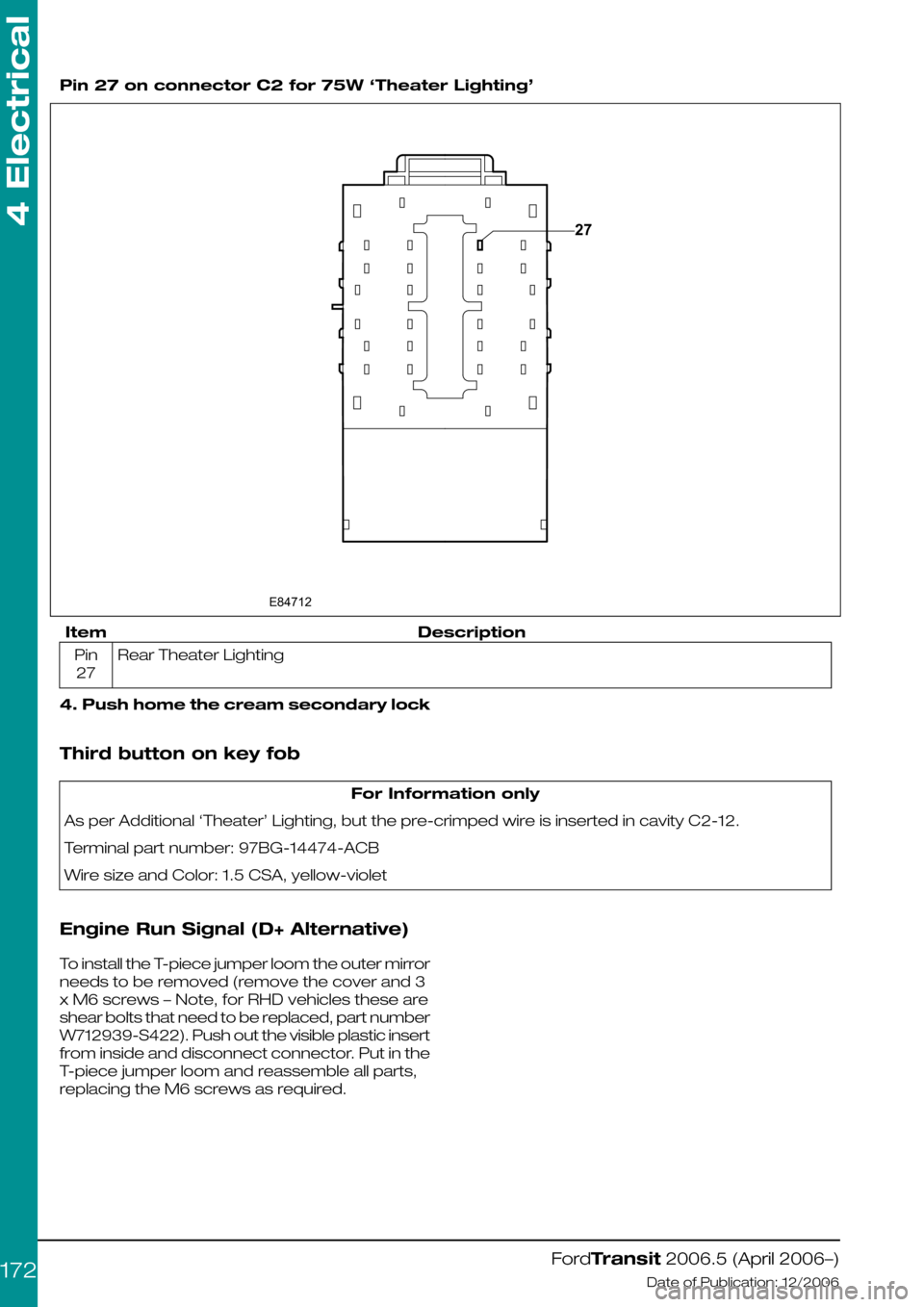

Additional Position Lights at the rear

For Information only

Mating connector part number: 89FG-14A624-AB* Seal: 89FG-10C930-AA (Note: this is a waterproof

connector)

Terminal part number: 93FG-14421-BBA (0.5–1.0 CSA)

Wire size and Color: 0.75 CSA, violet-white (feed); black-yellow (ground)

If larger cross section wire is to be used (1.5–2.5 CSA), the following parts should be used: Terminal

part number: 93FG-14421-BCA Seal: 89FG-10C930-BA

Connector for licence plate lighting

DescriptionItem

Feed1

Ground2

Side (and End Outline) Marker Lights

For Information only

Mating connector part number: F75B-14A624-F* Seal: integrated in connector

Terminal part number: E7EB-14461-BA

Wire size and Color: 0.75 CSA, violet-white (feed); black-yellow (ground)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

173E8472116AB 1E847272

Page 190 of 234

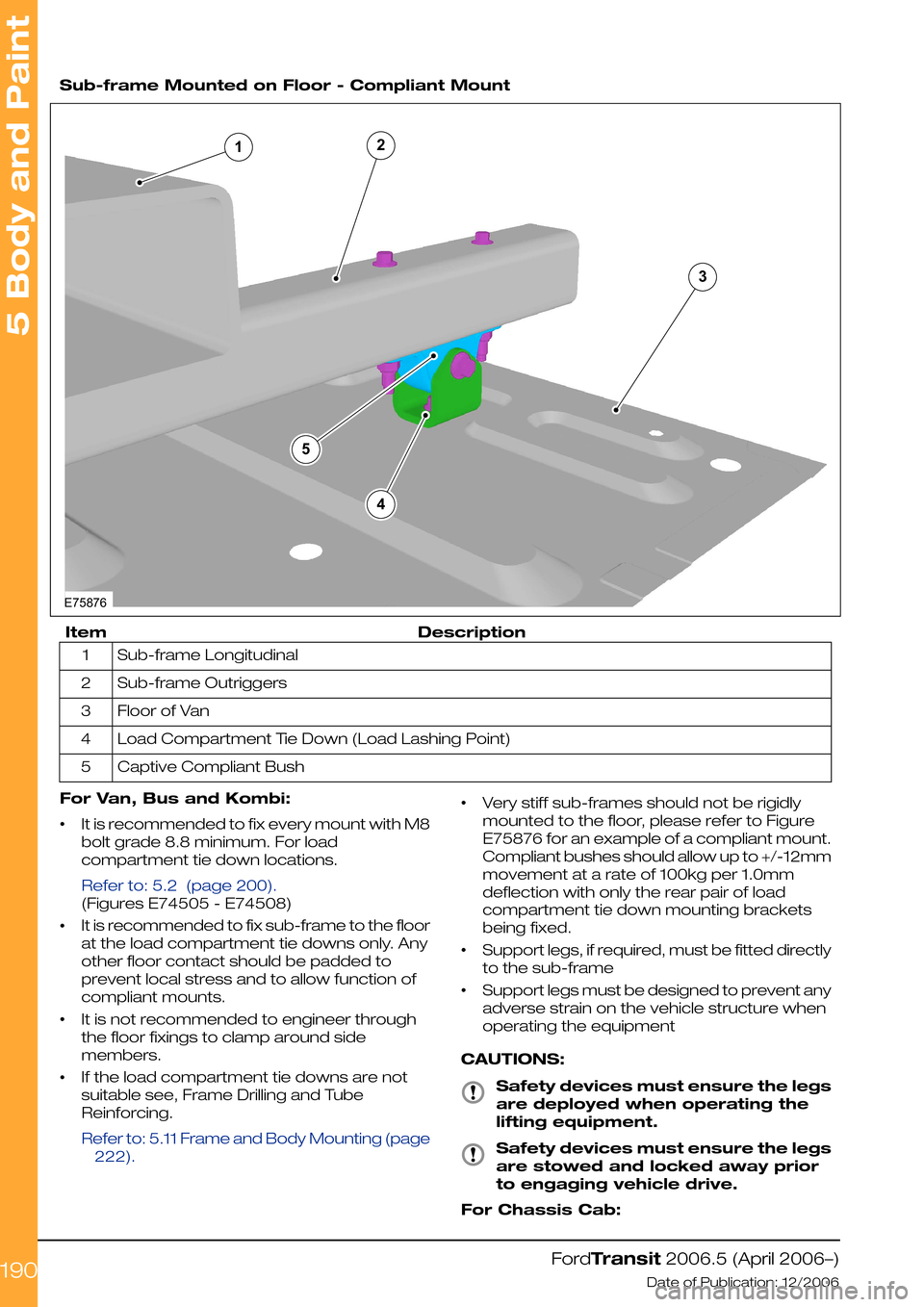

Sub-frame Mounted on Floor - Compliant Mount

DescriptionItem

Sub-frame Longitudinal1

Sub-frame Outriggers2

Floor of Van3

Load Compartment Tie Down (Load Lashing Point)4

Captive Compliant Bush5

For Van, Bus and Kombi:

•It is recommended to fix every mount with M8

bolt grade 8.8 minimum. For load

compartment tie down locations.

Refer to: 5.2 (page 200).

(Figures E74505 - E74508)

•It is recommended to fix sub-frame to the floor

at the load compartment tie downs only. Any

other floor contact should be padded to

prevent local stress and to allow function of

compliant mounts.

•It is not recommended to engineer through

the floor fixings to clamp around side

members.

•If the load compartment tie downs are not

suitable see, Frame Drilling and Tube

Reinforcing.

Refer to: 5.11 Frame and Body Mounting (page

222).

•Very stiff sub-frames should not be rigidly

mounted to the floor, please refer to Figure

E75876 for an example of a compliant mount.

Compliant bushes should allow up to +/-12mm

movement at a rate of 100kg per 1.0mm

deflection with only the rear pair of load

compartment tie down mounting brackets

being fixed.

•Support legs, if required, must be fitted directly

to the sub-frame

•Support legs must be designed to prevent any

adverse strain on the vehicle structure when

operating the equipment

CAUTIONS:

Safety devices must ensure the legs

are deployed when operating the

lifting equipment.

Safety devices must ensure the legs

are stowed and locked away prior

to engaging vehicle drive.

For Chassis Cab:

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

190E7587642351

Page 192 of 234

For Chassis Cab with tail lift design as described

above it is recommended to use unique body

sub-frame for fixing to Chassis Cab structure. For

connection between sub-frame Chassis Cab

body structure please refer to Figure E74696.

For Chassis Cab with under-slung tail lift load

capacity is up to 1000kg at 1000mm from rear

end of chassis frame to center of load if mounted

and functioning on centre line of vehicle. If

mounted and functioning off center line or at the

side of the vehicle load capacity is reduced to

500kg at 1000mm from side/rear end to center

of load.

Greater off-sets and/or loads require additional

stabilizing equipment such as outriggers or

ground jacks. It is recommended not to increase

vehicle body stress over limit as given by load

factors above. If uncertain please consult your

local national sales representative or the Vehicle

Converter Advisory Service [email protected].

It is the Vehicle converters responsibility to fit a

decal to the converted vehicle stating that the

equipment must not be used without

outriggers/ground jacks in operating position. It

is also the vehicle converters responsibility to

guarantee safe functioning of the equipment.

For hydraulic tail lifts as used for general loading

or more specialized for wheel-chair lifts please

refer to Figure E75874.

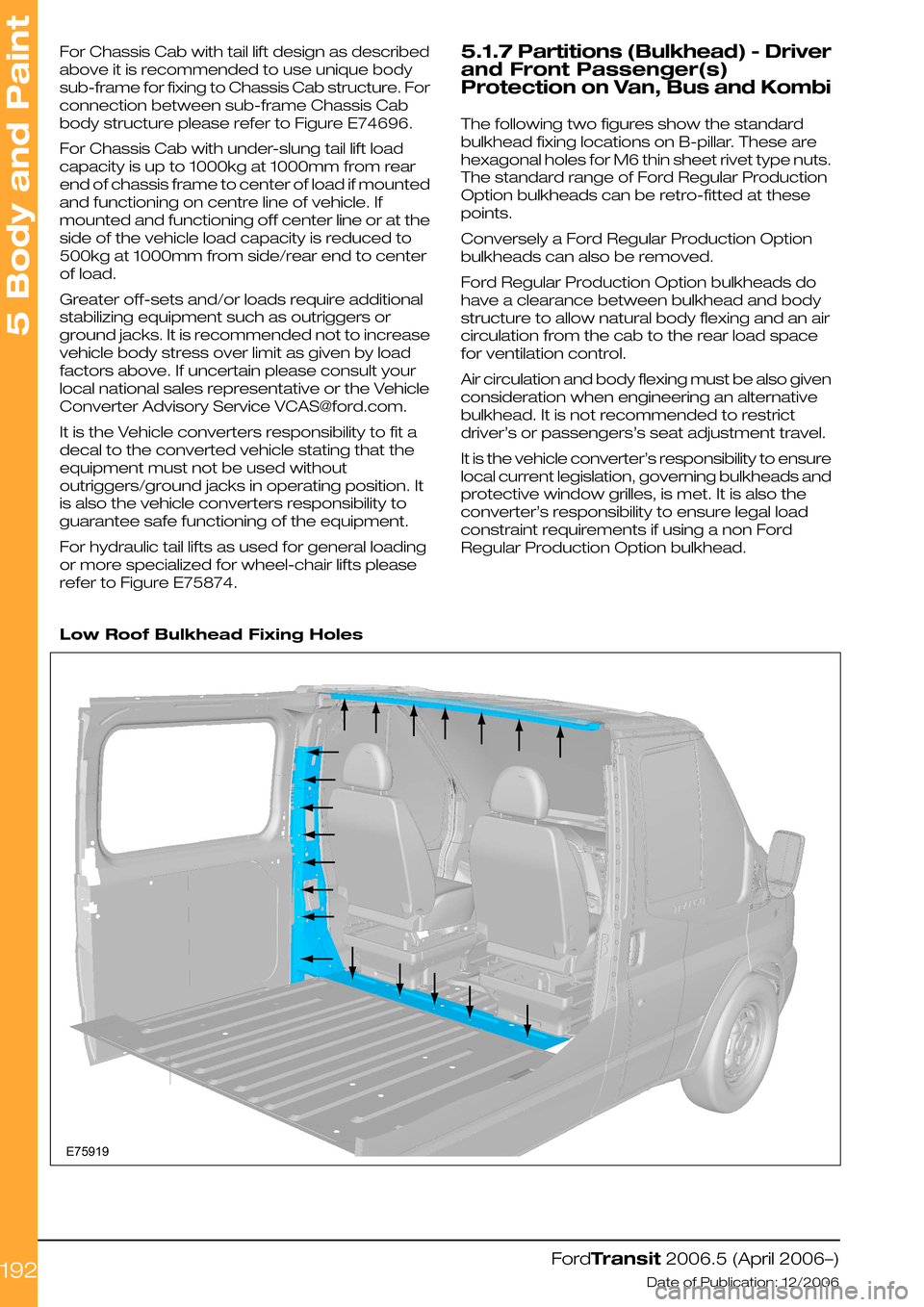

5.1.7 Partitions (Bulkhead) - Driver

and Front Passenger(s)

Protection on Van, Bus and Kombi

The following two figures show the standard

bulkhead fixing locations on B-pillar. These are

hexagonal holes for M6 thin sheet rivet type nuts.

The standard range of Ford Regular Production

Option bulkheads can be retro-fitted at these

points.

Conversely a Ford Regular Production Option

bulkheads can also be removed.

Ford Regular Production Option bulkheads do

have a clearance between bulkhead and body

structure to allow natural body flexing and an air

circulation from the cab to the rear load space

for ventilation control.

Air circulation and body flexing must be also given

consideration when engineering an alternative

bulkhead. It is not recommended to restrict

driver’s or passengers’s seat adjustment travel.

It is the vehicle converter’s responsibility to ensure

local current legislation, governing bulkheads and

protective window grilles, is met. It is also the

converter’s responsibility to ensure legal load

constraint requirements if using a non Ford

Regular Production Option bulkhead.

Low Roof Bulkhead Fixing Holes

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

192E75919