engine FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 96 of 234

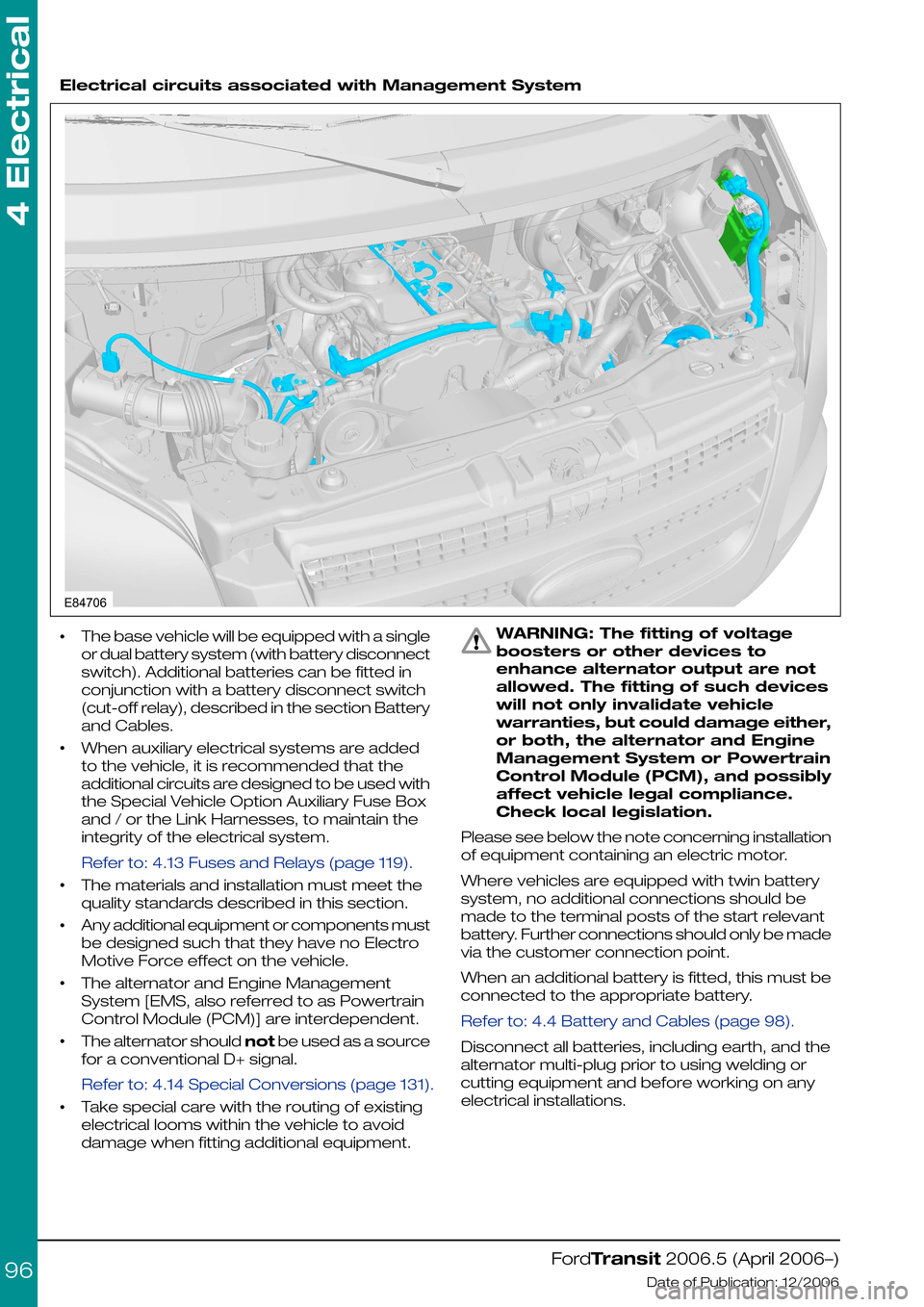

Electrical circuits associated with Management System

•The base vehicle will be equipped with a single

or dual battery system (with battery disconnect

switch). Additional batteries can be fitted in

conjunction with a battery disconnect switch

(cut-off relay), described in the section Battery

and Cables.

•When auxiliary electrical systems are added

to the vehicle, it is recommended that the

additional circuits are designed to be used with

the Special Vehicle Option Auxiliary Fuse Box

and / or the Link Harnesses, to maintain the

integrity of the electrical system.

Refer to: 4.13 Fuses and Relays (page 119).

•The materials and installation must meet the

quality standards described in this section.

•Any additional equipment or components must

be designed such that they have no Electro

Motive Force effect on the vehicle.

•The alternator and Engine Management

System [EMS, also referred to as Powertrain

Control Module (PCM)] are interdependent.

•The alternator should not be used as a source

for a conventional D+ signal.

Refer to: 4.14 Special Conversions (page 131).

•Take special care with the routing of existing

electrical looms within the vehicle to avoid

damage when fitting additional equipment.

WARNING: The fitting of voltage

boosters or other devices to

enhance alternator output are not

allowed. The fitting of such devices

will not only invalidate vehicle

warranties, but could damage either,

or both, the alternator and Engine

Management System or Powertrain

Control Module (PCM), and possibly

affect vehicle legal compliance.

Check local legislation.

Please see below the note concerning installation

of equipment containing an electric motor.

Where vehicles are equipped with twin battery

system, no additional connections should be

made to the terminal posts of the start relevant

battery. Further connections should only be made

via the customer connection point.

When an additional battery is fitted, this must be

connected to the appropriate battery.

Refer to: 4.4 Battery and Cables (page 98).

Disconnect all batteries, including earth, and the

alternator multi-plug prior to using welding or

cutting equipment and before working on any

electrical installations.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

96E84706

Page 97 of 234

•Before disconnecting the battery, check

availability of radio key code.

•Fuses – when auxiliary electrical systems are

to be added to the vehicle it is mandatory that

the additional circuit design includes the

necessary fuses.

•The Special Vehicle Option auxiliary fuse box

is recommended.

Refer to: 4.13 Fuses and Relays (page 119).

4.3.4 Fitting of Equipment

Containing an Electric Motor

WARNINGS:

When equipment containing an

electrical motor is connected, it

must be connected via a blocking

diode or relay to prevent “back

Electro Motive Force (EMF)” being

applied to the auxiliary terminal.

When electric motors are to be

fitted, account must be taken of the

potentially high currents that a

motor can draw.

CAUTION: The following must be

observed:

•All motors must be driven via relays with

contacts rated at least 3 times the maximum

rated current of the motor.

•All motor supply circuits must be individually

fused with the proper fuse rating for the

motor.

•All power wiring must be rated for at least 3

times the rating of the motor and installed as

far away as possible from any existing vehicle

wiring.

•All motors fitted should be fully suppressed to

ensure electrical interference does not affect

the vehicle systems.

•Add EMC emissions statement to CE

approval.

4.3.5 Vehicle Electrical Capacity

- Alternator

WARNING: Do not cut into the

alternator wires or use the

alternator as a source to obtain a

'D+ Signal'

An engine run signal is available from the Central

Junction Box by installing a T-piece jumper

harness (Ford Part Number 6C1V-14A411-F_).

Refer to: 4.14 Special Conversions (page 131).

4.3.6 Charge Balance Guidelines

The base vehicle is fitted with a 150A alternator.

It is recommended to conduct a charge balance

calculation in case the conversion comprises a

high number of electrical consumers or high

electrical consumption is expected.

4.3.7 Circuit Diagrams

For circuit diagrams for Auxiliary Fuse Box

Connections and Standard Ford relays.

Refer to: 4.13 Fuses and Relays (page 119).

Full vehicle wiring and circuit diagrams are in the

Ford Workshop Manual.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

97

Page 100 of 234

Pull-in us actuvated within 70 ms of switching to

key position II

Pull-out is activated when switching to key

position I, or 0, and in key position II when no

engine run signal is sensed within 120 secs.

It is not possible to change state within 500 ms.

Removal of the Battery Disconnect

Switch (on twin battery models) and

wiring of batteries in parallel for high

current applications.

For vehicles equipped with a twin battery system,

wiring of the two batteries in parallel is not

recommended. If higher current is required,

680Ah batteries can be fitted (or a deep cycle

battery in lieu of the non-start relevant battery

only). Where a single passenger seat is fitted,

further batteries (1 or 2) can be installed in the

pedestal and added in parallel to the

non-start-relevant battery, although due

consideration then needs to be given to

increased current availability in the event of a

short circuit. Additional batteries should not be

installed under a passenger bench seat.

if this requirement is imperative, it would be

possible to disconnect the battery disconnect

switch and put the start-relevant and

non-start-relevant batteries in parallel using a

shorting bar (available from the Ford Delerships,

part number 6C1T-14A439-A*). There is one

important consideration when replacing the

battery disconnect switch with a shorting bar:

•Where the vehicle is configured for

twin-battery operation, the Central Junction

Box will detect if the battery disconnect switch

is missing (or has been removed), or the

mating connector short-circuited, and although

the vehicle will be functional, Diagnostic

Trouble Codes will be generated that will

flag-up during service. Hence if a shorting bar

is fitted, the vehicle needs to be reconfigured

(via the Dealership and Dealership Hotline).

Single to Dual Battery Conversion

For vehicles equipped with a single battery, it is

possible to upgrade to a twin battery system -

the connector for the battery disconnect switch

is present on all vehicles. In addition to

reconfiguring the vehicle for twin battery

operation (at a Dealership), the following battery

cables and components are required:

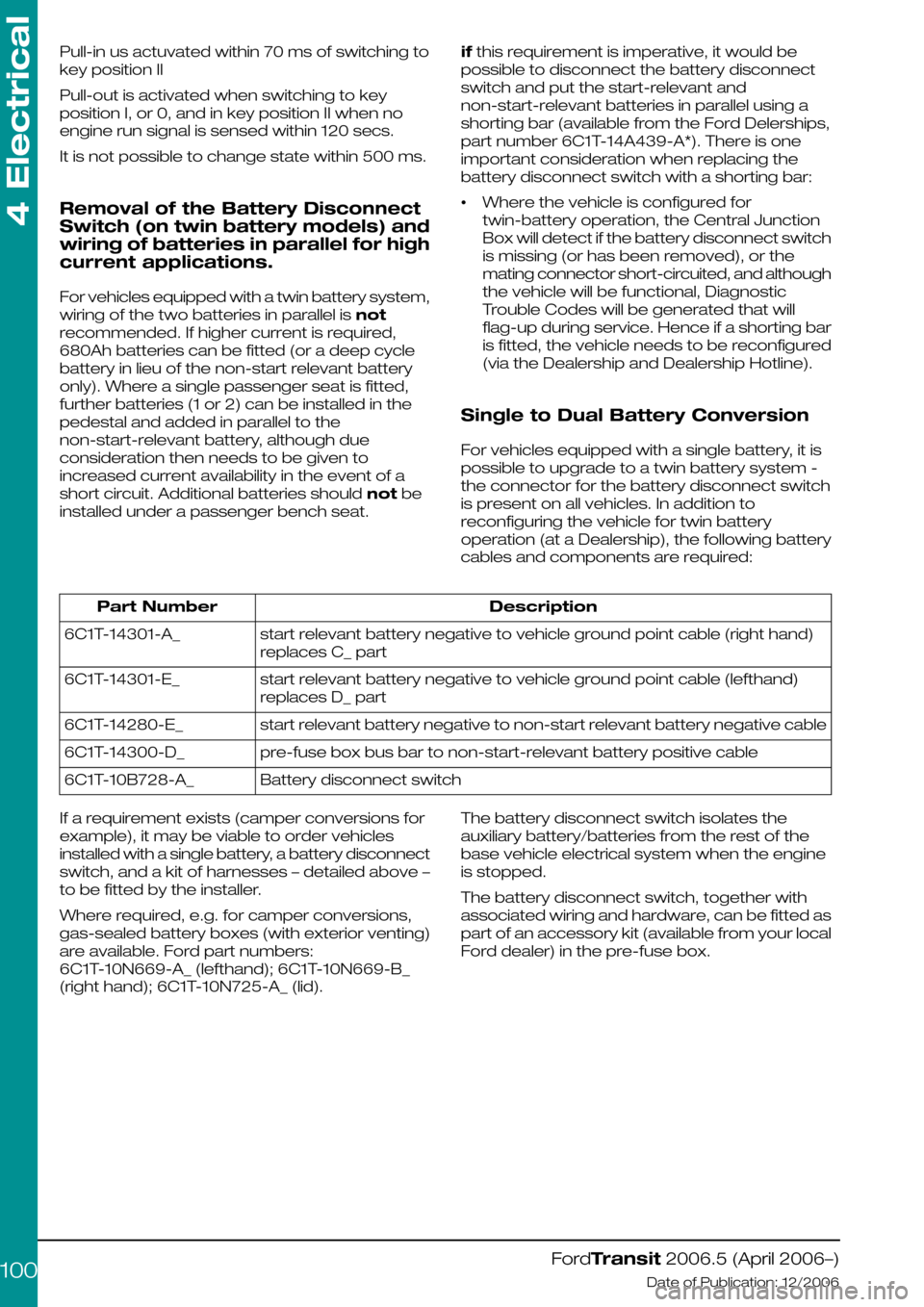

DescriptionPart Number

start relevant battery negative to vehicle ground point cable (right hand)

replaces C_ part

6C1T-14301-A_

start relevant battery negative to vehicle ground point cable (lefthand)

replaces D_ part

6C1T-14301-E_

start relevant battery negative to non-start relevant battery negative cable6C1T-14280-E_

pre-fuse box bus bar to non-start-relevant battery positive cable6C1T-14300-D_

Battery disconnect switch6C1T-10B728-A_

If a requirement exists (camper conversions for

example), it may be viable to order vehicles

installed with a single battery, a battery disconnect

switch, and a kit of harnesses – detailed above –

to be fitted by the installer.

Where required, e.g. for camper conversions,

gas-sealed battery boxes (with exterior venting)

are available. Ford part numbers:

6C1T-10N669-A_ (lefthand); 6C1T-10N669-B_

(right hand); 6C1T-10N725-A_ (lid).

The battery disconnect switch isolates the

auxiliary battery/batteries from the rest of the

base vehicle electrical system when the engine

is stopped.

The battery disconnect switch, together with

associated wiring and hardware, can be fitted as

part of an accessory kit (available from your local

Ford dealer) in the pre-fuse box.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

100

Page 103 of 234

![FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual 4.4.2 Generator and Alternator

Torque Curve of Alternator

Diagram E75871 shows the torque in Nm which

is required to drive the alternator. The vertical

axis (A) shows the torque [Nm] and the horizon FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual 4.4.2 Generator and Alternator

Torque Curve of Alternator

Diagram E75871 shows the torque in Nm which

is required to drive the alternator. The vertical

axis (A) shows the torque [Nm] and the horizon](/img/11/5471/w960_5471-102.png)

4.4.2 Generator and Alternator

Torque Curve of Alternator

Diagram E75871 shows the torque in Nm which

is required to drive the alternator. The vertical

axis (A) shows the torque [Nm] and the horizontal

axis (B) shows the alternators revolutions per

minute [1/min].

NOTE: For equivalent engine revs per minute

(RPM), the alternators revolutions, axis (B) should

be divided by the following factors: 2.66 for diesel

(2.2L and 2.4L), 2.4 for Gasoline (2.3L).

NOTE: These alternator curves do not show

spare output capacity as this would be

dependant on original vehicle features and

options

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

1030246810121402000400060008000100001200014000160001800020000ABE75871

Page 119 of 234

4.13 Fuses and Relays

4.13.1 Wiring Specification

When designing wire installations for additional

equipment use the cable size recommended by

the equipment manufacturer or select a suitable

size from the Current Rating Wire Sizes

specifications chart.

Refer to: 4.2 (page 94).

Wiring consists a soft annealed copper core in

accordance with DIN 57201 (VDDE 0201)

sheathed in Hypalon or irradiated PVC.

For 0,5mm cable an alternative material with

conductor E-CU F20 or F21 in accordance with

DIN 40500 sheathed in cross linked PVC is

available.

4.13.2 Auxiliary Fuses, Fuse Box

and Relays (Fuses - Standard)

WARNING: No increase in existing

vehicle standard fuse capacity is

allowed under any circumstances.

There are no spare fuses in the

Engine Junction Box, Standard Relay

Box or Central Junction Box. The

vehicle converter/modifier must

provide additional fuses as required.

Please refer to below chart.

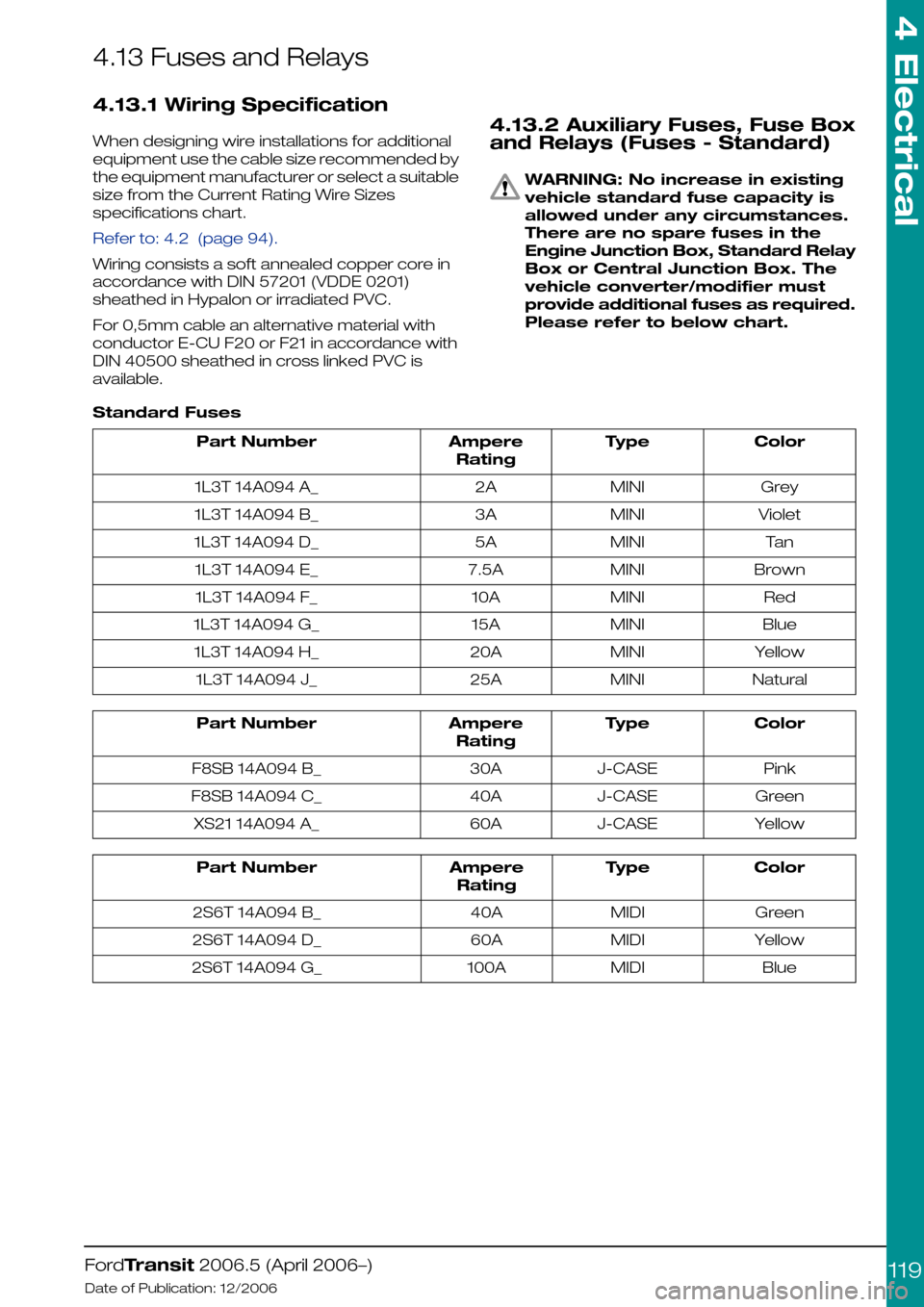

Standard Fuses

ColorTypeAmpere

Rating

Part Number

GreyMINI2A1L3T 14A094 A_

VioletMINI3A1L3T 14A094 B_

TanMINI5A1L3T 14A094 D_

BrownMINI7.5A1L3T 14A094 E_

RedMINI10A1L3T 14A094 F_

BlueMINI15A1L3T 14A094 G_

YellowMINI20A1L3T 14A094 H_

NaturalMINI25A1L3T 14A094 J_

ColorTypeAmpere

Rating

Part Number

PinkJ-CASE30AF8SB 14A094 B_

GreenJ-CASE40AF8SB 14A094 C_

YellowJ-CASE60AXS21 14A094 A_

ColorTypeAmpere

Rating

Part Number

GreenMIDI40A2S6T 14A094 B_

YellowMIDI60A2S6T 14A094 D_

BlueMIDI100A2S6T 14A094 G_

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

119

Page 121 of 234

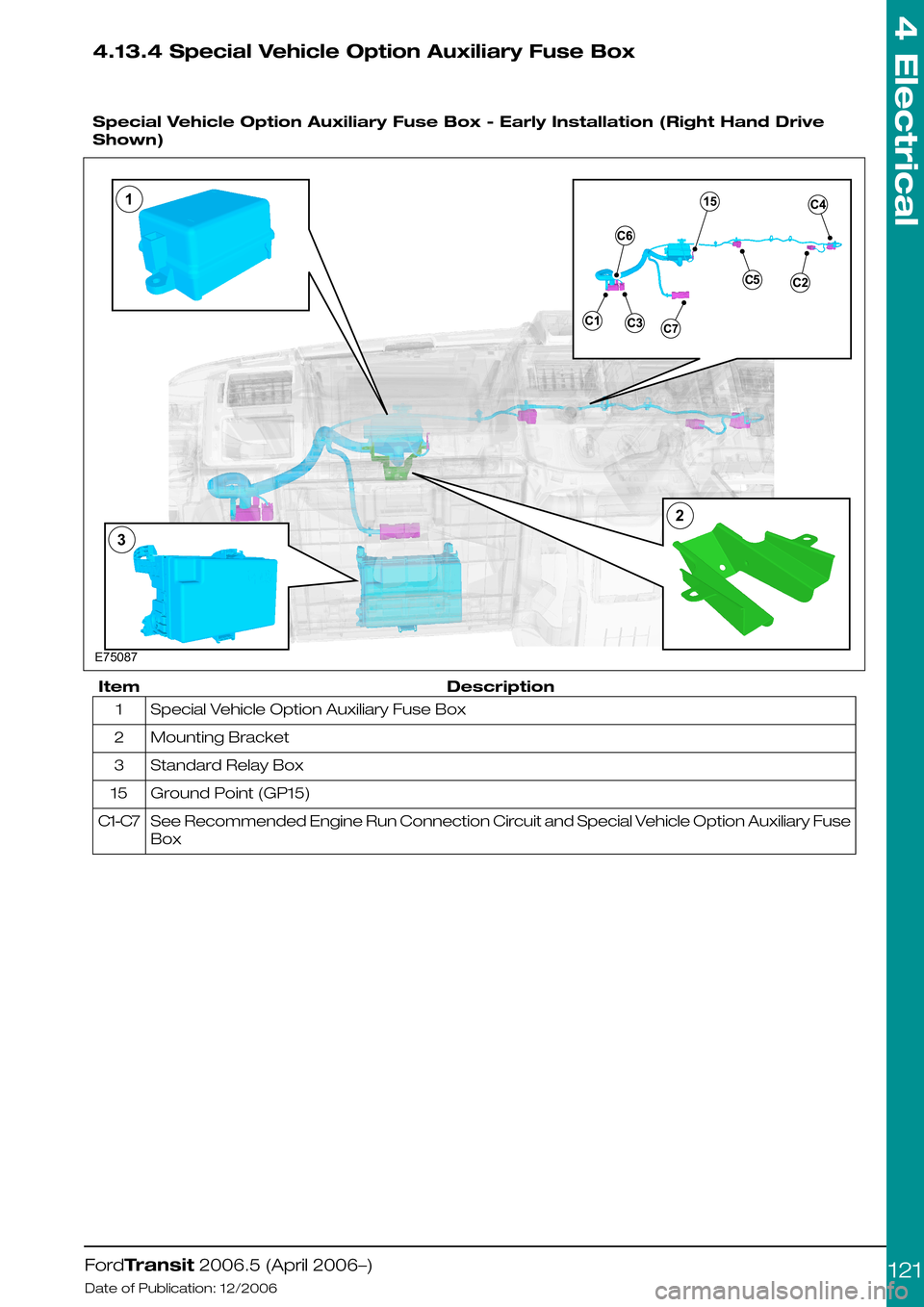

4.13.4 Special Vehicle Option Auxiliary Fuse Box

Special Vehicle Option Auxiliary Fuse Box - Early Installation (Right Hand Drive

Shown)

DescriptionItem

Special Vehicle Option Auxiliary Fuse Box1

Mounting Bracket2

Standard Relay Box3

Ground Point (GP15)15

See Recommended Engine Run Connection Circuit and Special Vehicle Option Auxiliary Fuse

Box

C1-C7

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

121E75087132

Page 122 of 234

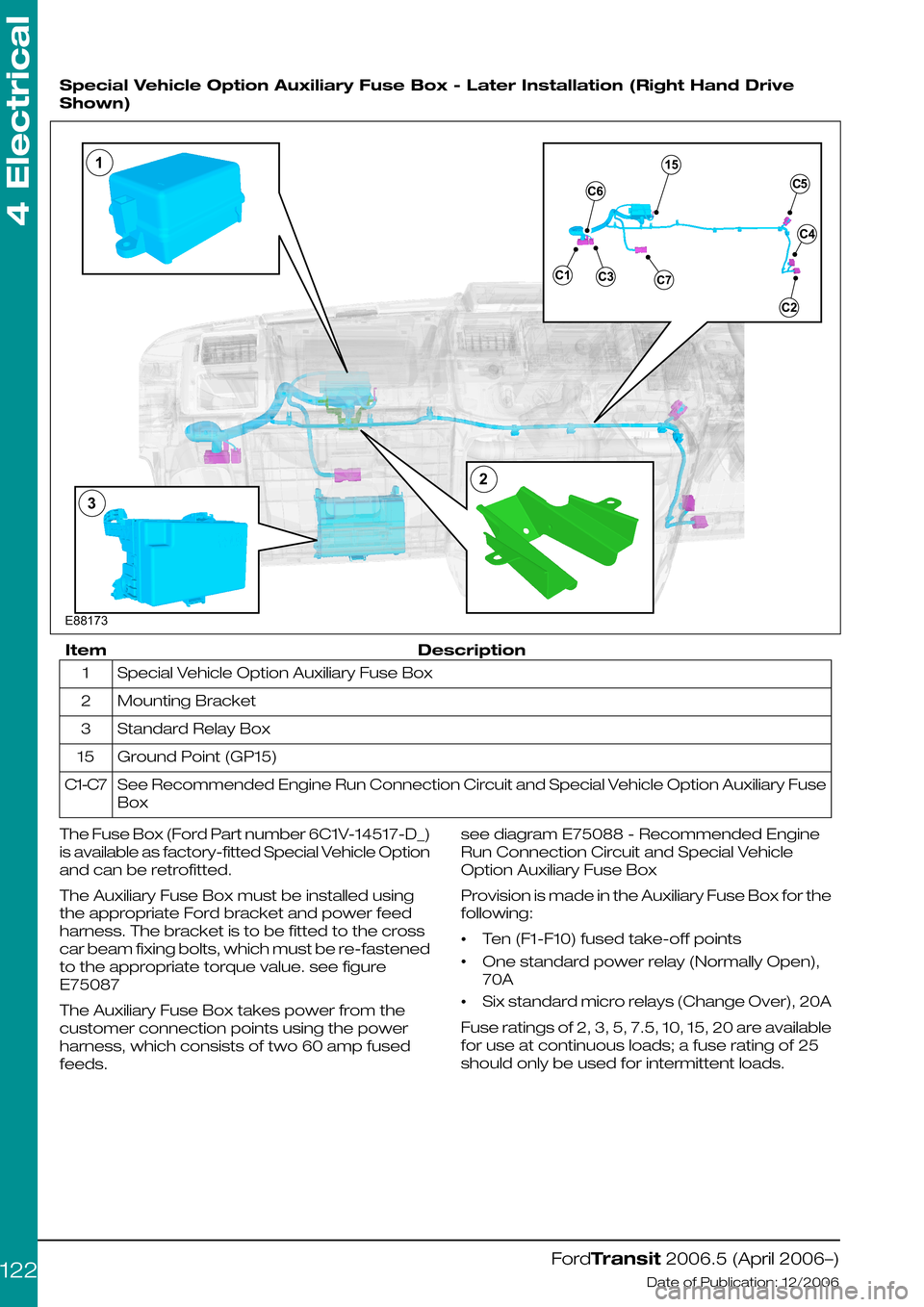

Special Vehicle Option Auxiliary Fuse Box - Later Installation (Right Hand Drive

Shown)

DescriptionItem

Special Vehicle Option Auxiliary Fuse Box1

Mounting Bracket2

Standard Relay Box3

Ground Point (GP15)15

See Recommended Engine Run Connection Circuit and Special Vehicle Option Auxiliary Fuse

Box

C1-C7

The Fuse Box (Ford Part number 6C1V-14517-D_)

is available as factory-fitted Special Vehicle Option

and can be retrofitted.

The Auxiliary Fuse Box must be installed using

the appropriate Ford bracket and power feed

harness. The bracket is to be fitted to the cross

car beam fixing bolts, which must be re-fastened

to the appropriate torque value. see figure

E75087

The Auxiliary Fuse Box takes power from the

customer connection points using the power

harness, which consists of two 60 amp fused

feeds.

see diagram E75088 - Recommended Engine

Run Connection Circuit and Special Vehicle

Option Auxiliary Fuse Box

Provision is made in the Auxiliary Fuse Box for the

following:

•Ten (F1-F10) fused take-off points

•One standard power relay (Normally Open),

70A

•Six standard micro relays (Change Over), 20A

Fuse ratings of 2, 3, 5, 7.5, 10, 15, 20 are available

for use at continuous loads; a fuse rating of 25

should only be used for intermittent loads.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

122E88173132

Page 123 of 234

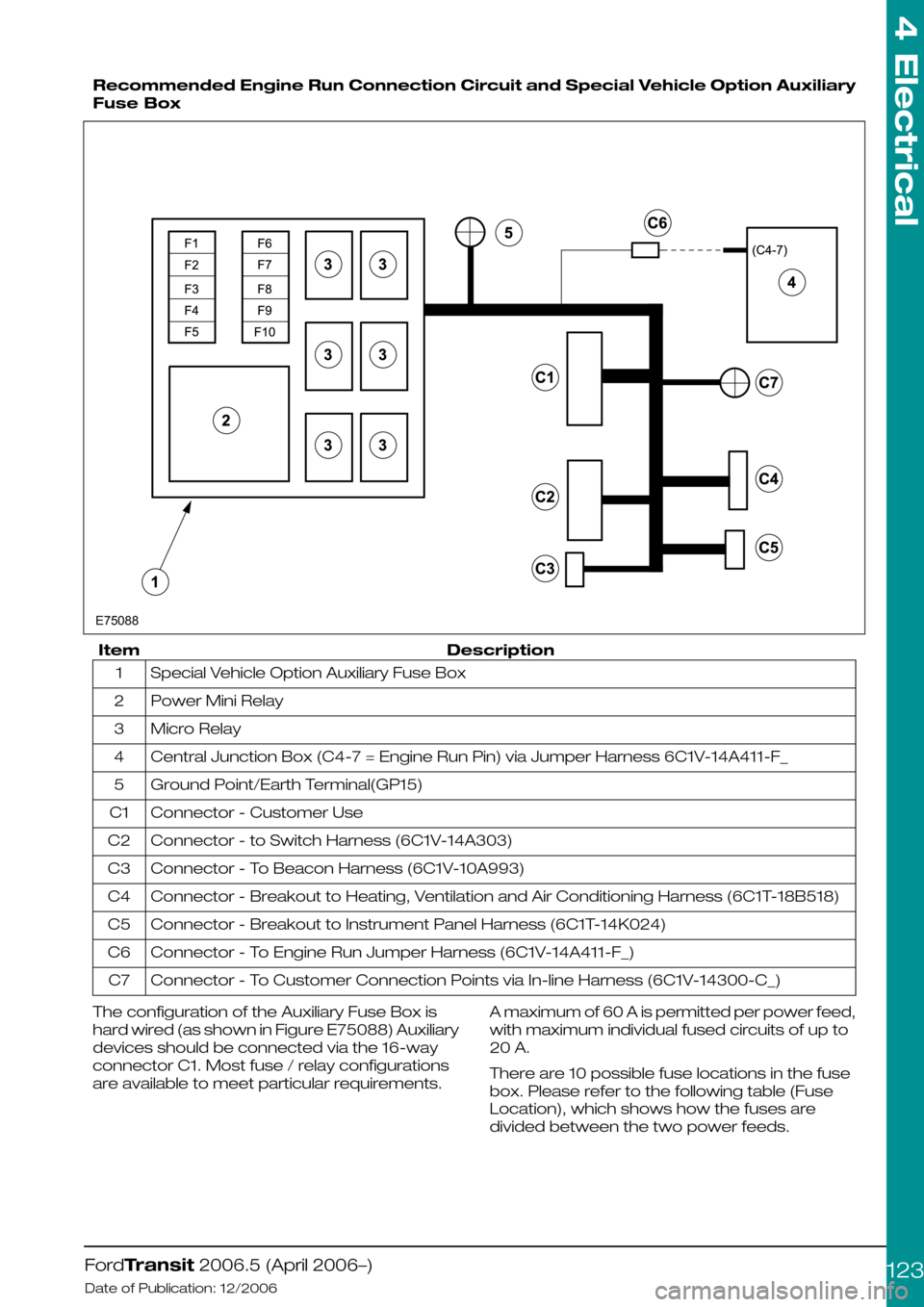

Recommended Engine Run Connection Circuit and Special Vehicle Option Auxiliary

Fuse Box

DescriptionItem

Special Vehicle Option Auxiliary Fuse Box1

Power Mini Relay2

Micro Relay3

Central Junction Box (C4-7 = Engine Run Pin) via Jumper Harness 6C1V-14A411-F_4

Ground Point/Earth Terminal(GP15)5

Connector - Customer UseC1

Connector - to Switch Harness (6C1V-14A303)C2

Connector - To Beacon Harness (6C1V-10A993)C3

Connector - Breakout to Heating, Ventilation and Air Conditioning Harness (6C1T-18B518)C4

Connector - Breakout to Instrument Panel Harness (6C1T-14K024)C5

Connector - To Engine Run Jumper Harness (6C1V-14A411-F_)C6

Connector - To Customer Connection Points via In-line Harness (6C1V-14300-C_)C7

The configuration of the Auxiliary Fuse Box is

hard wired (as shown in Figure E75088) Auxiliary

devices should be connected via the 16-way

connector C1. Most fuse / relay configurations

are available to meet particular requirements.

A maximum of 60 A is permitted per power feed,

with maximum individual fused circuits of up to

20 A.

There are 10 possible fuse locations in the fuse

box. Please refer to the following table (Fuse

Location), which shows how the fuses are

divided between the two power feeds.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

123E75088

Page 124 of 234

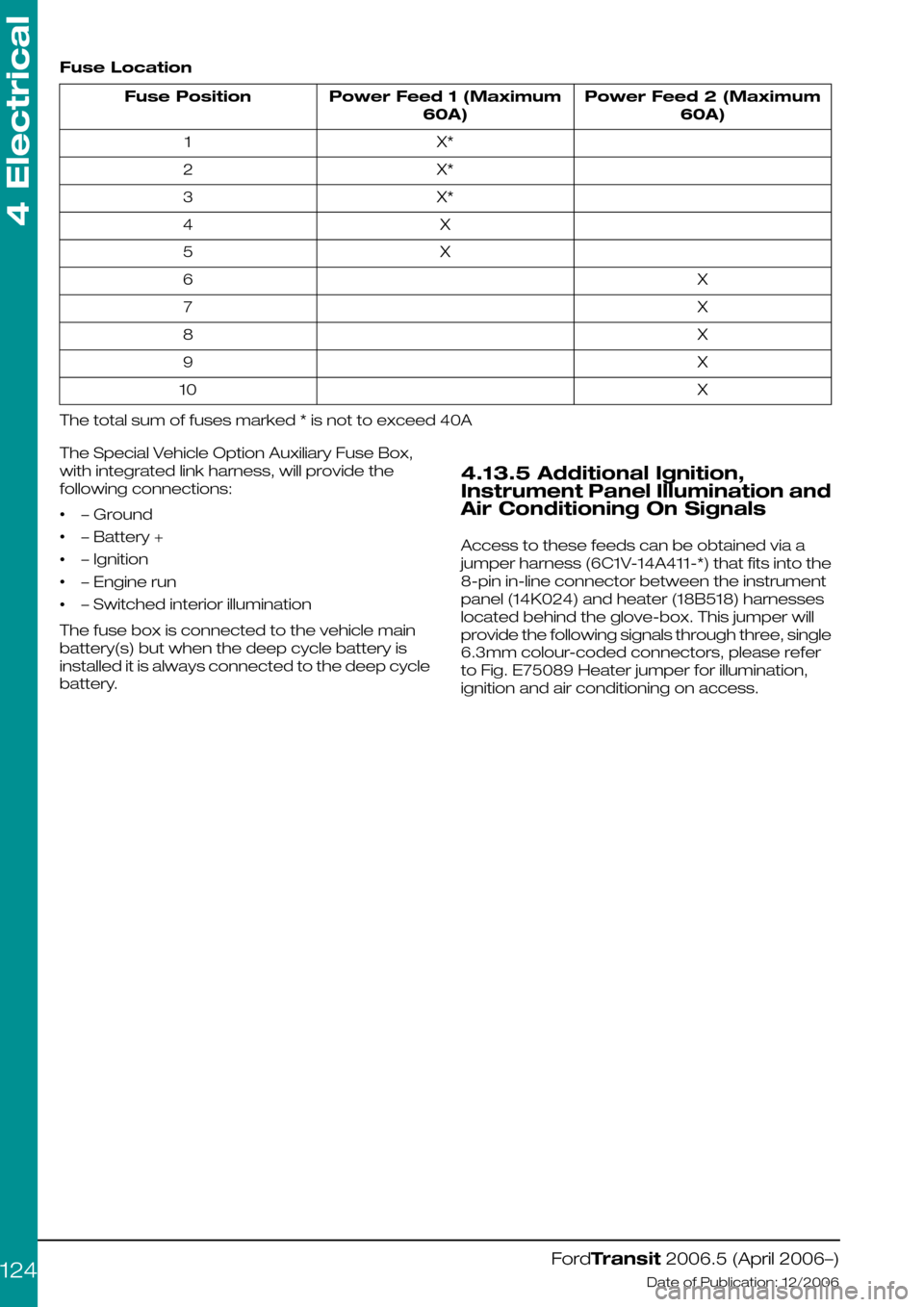

Fuse Location

Power Feed 2 (Maximum

60A)

Power Feed 1 (Maximum

60A)

Fuse Position

X*1

X*2

X*3

X4

X5

X6

X7

X8

X9

X10

The total sum of fuses marked * is not to exceed 40A

The Special Vehicle Option Auxiliary Fuse Box,

with integrated link harness, will provide the

following connections:

•– Ground

•– Battery +

•– Ignition

•– Engine run

•– Switched interior illumination

The fuse box is connected to the vehicle main

battery(s) but when the deep cycle battery is

installed it is always connected to the deep cycle

battery.

4.13.5 Additional Ignition,

Instrument Panel Illumination and

Air Conditioning On Signals

Access to these feeds can be obtained via a

jumper harness (6C1V-14A411-*) that fits into the

8-pin in-line connector between the instrument

panel (14K024) and heater (18B518) harnesses

located behind the glove-box. This jumper will

provide the following signals through three, single

6.3mm colour-coded connectors, please refer

to Fig. E75089 Heater jumper for illumination,

ignition and air conditioning on access.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

124

Page 125 of 234

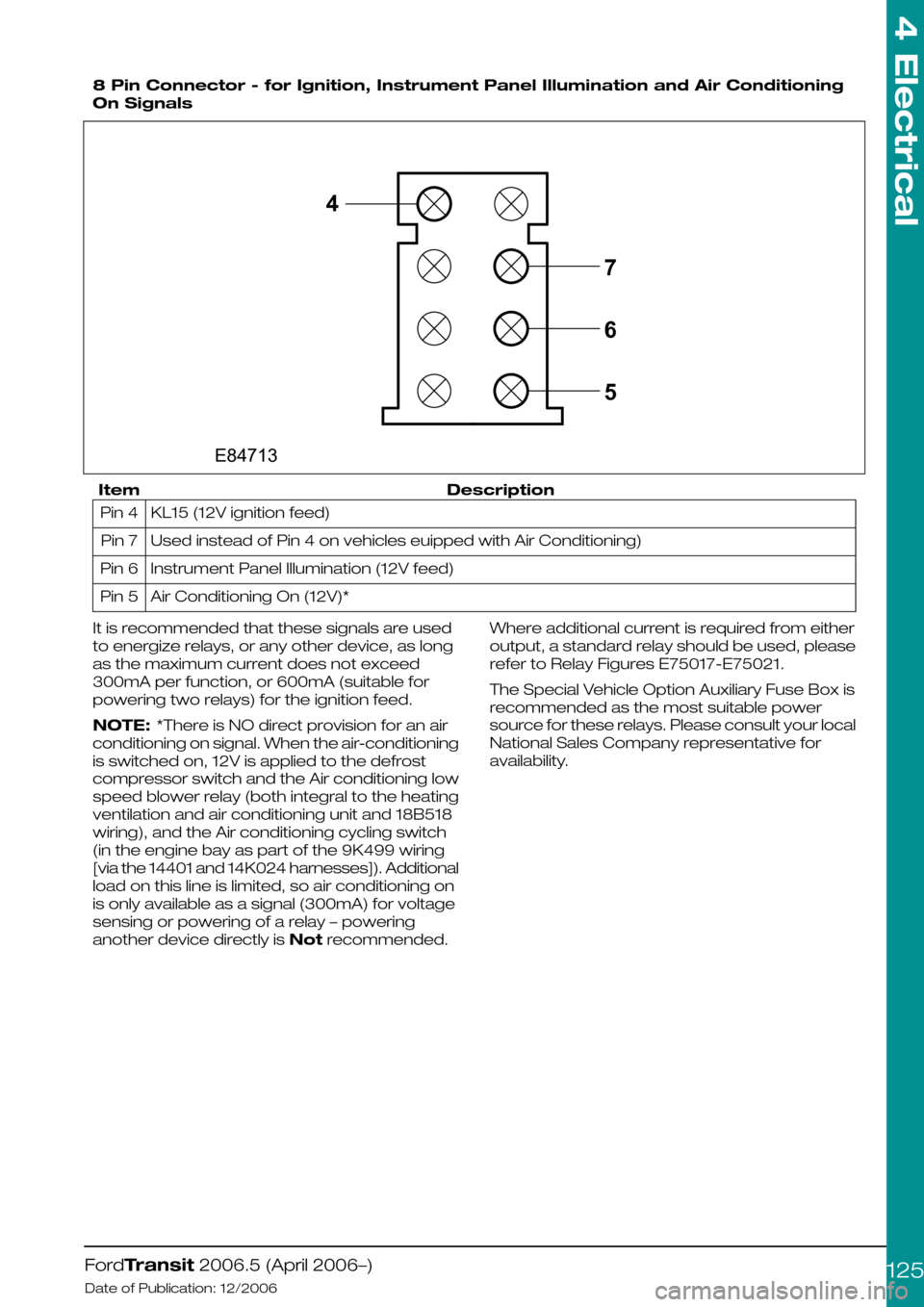

8 Pin Connector - for Ignition, Instrument Panel Illumination and Air Conditioning

On Signals

DescriptionItem

KL15 (12V ignition feed)Pin 4

Used instead of Pin 4 on vehicles euipped with Air Conditioning)Pin 7

Instrument Panel Illumination (12V feed)Pin 6

Air Conditioning On (12V)*Pin 5

It is recommended that these signals are used

to energize relays, or any other device, as long

as the maximum current does not exceed

300mA per function, or 600mA (suitable for

powering two relays) for the ignition feed.

NOTE: *There is NO direct provision for an air

conditioning on signal. When the air-conditioning

is switched on, 12V is applied to the defrost

compressor switch and the Air conditioning low

speed blower relay (both integral to the heating

ventilation and air conditioning unit and 18B518

wiring), and the Air conditioning cycling switch

(in the engine bay as part of the 9K499 wiring

[via the 14401 and 14K024 harnesses]). Additional

load on this line is limited, so air conditioning on

is only available as a signal (300mA) for voltage

sensing or powering of a relay – powering

another device directly is Not recommended.

Where additional current is required from either

output, a standard relay should be used, please

refer to Relay Figures E75017-E75021.

The Special Vehicle Option Auxiliary Fuse Box is

recommended as the most suitable power

source for these relays. Please consult your local

National Sales Company representative for

availability.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

1254E84713765