engine FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 76 of 234

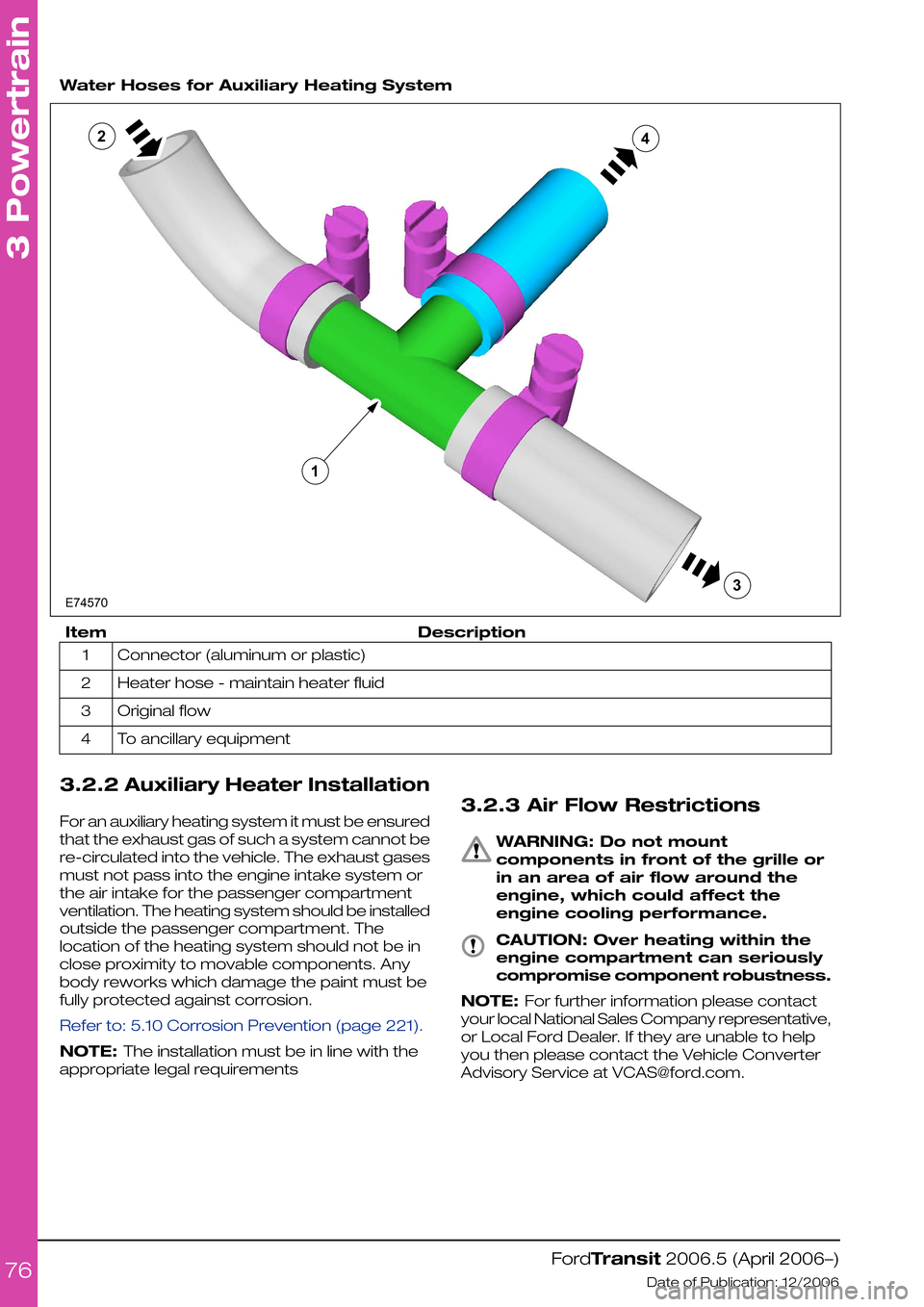

Water Hoses for Auxiliary Heating System

DescriptionItem

Connector (aluminum or plastic)1

Heater hose - maintain heater fluid2

Original flow3

To ancillary equipment4

3.2.2 Auxiliary Heater Installation

For an auxiliary heating system it must be ensured

that the exhaust gas of such a system cannot be

re-circulated into the vehicle. The exhaust gases

must not pass into the engine intake system or

the air intake for the passenger compartment

ventilation. The heating system should be installed

outside the passenger compartment. The

location of the heating system should not be in

close proximity to movable components. Any

body reworks which damage the paint must be

fully protected against corrosion.

Refer to: 5.10 Corrosion Prevention (page 221).

NOTE: The installation must be in line with the

appropriate legal requirements

3.2.3 Air Flow Restrictions

WARNING: Do not mount

components in front of the grille or

in an area of air flow around the

engine, which could affect the

engine cooling performance.

CAUTION: Over heating within the

engine compartment can seriously

compromise component robustness.

NOTE: For further information please contact

your local National Sales Company representative,

or Local Ford Dealer. If they are unable to help

you then please contact the Vehicle Converter

Advisory Service at [email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

76E745701234

Page 77 of 234

3.3 Accessory Drive

When the correct belt is used, tensioning is and

remains fully automatic for the life of the belt.

CAUTIONS:

Only use the manufacturers

recommended (or equivalent

specification) components

Make sure that the ancillary pulley

diameter is less than the crankshaft

pulley diameter.

Systems requiring a unique belt

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

The eigenfrequency of any bracket including the

auxiliary added should be above the maximum

excitation frequency of the main excitation order

of the individual engine at engine top speed. On

4-cylinder inline engines, this is the second

engine order.

3.3.1 Front End Accessory Drive

2.4l Diesel and 2.3l Petrol

CAUTION: Do not fit an additional

front end accessory drive to a

vehicle already equipped with and

air-conditioning compressor.

When engineering and installing a new front end

accessory drive, i.e. belt drive of the crankshaft

pulley, the longitudinal alignment must be within

+/- 0.25mm and angular within +/- 0.33°.

For most front end accessory drive applications

the longer Regular Production Option air

-conditioning belt can replace the standard belt

and pulley layout.

The maximum power that is available for front

end accessory drive applications, in lieu of the

air conditioning compressor is 26Nm torque at

any engine speed up to a maximum of 6kW.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

77

Page 78 of 234

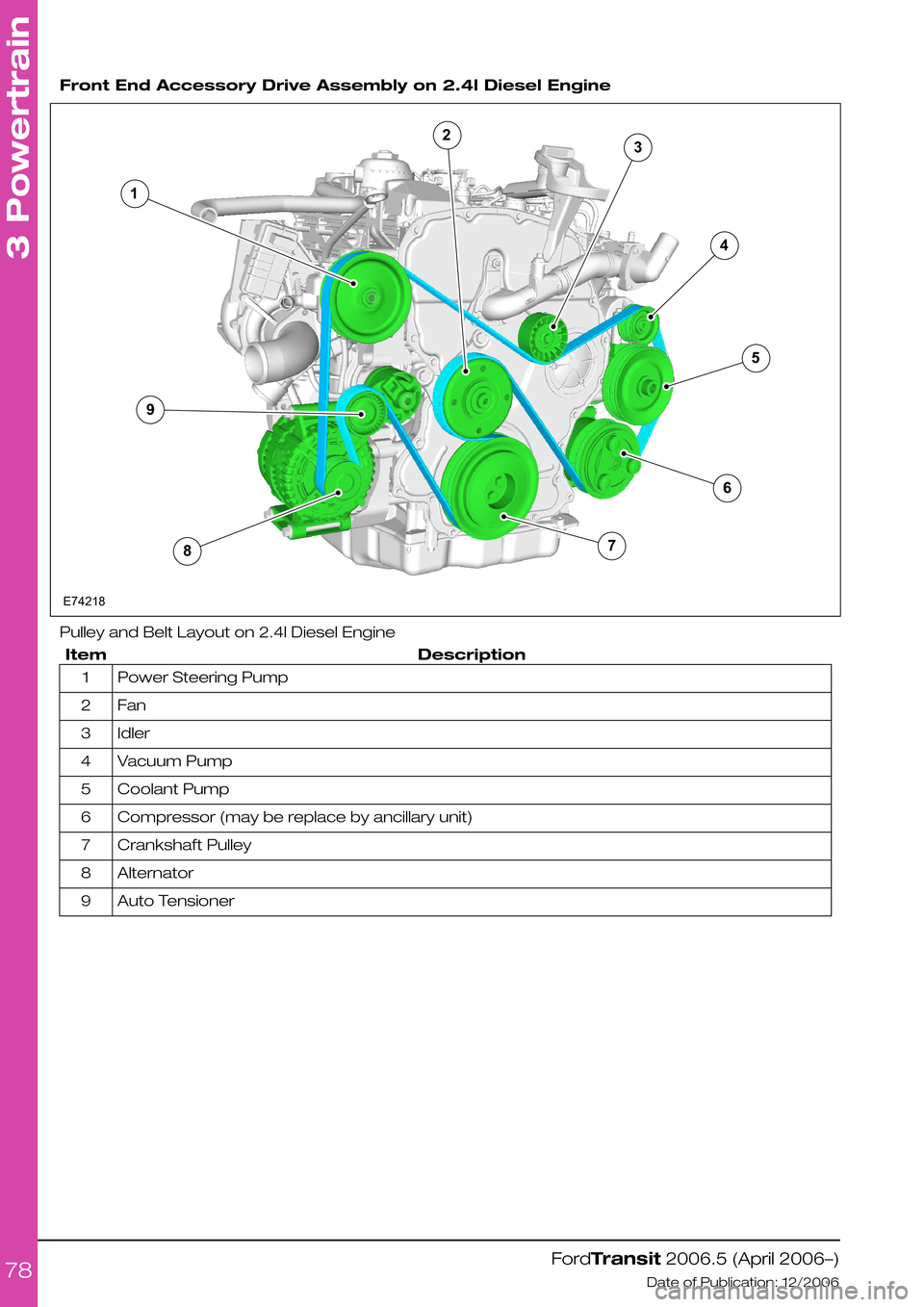

Front End Accessory Drive Assembly on 2.4l Diesel Engine

Pulley and Belt Layout on 2.4l Diesel Engine

DescriptionItem

Power Steering Pump1

Fan2

Idler3

Vacuum Pump4

Coolant Pump5

Compressor (may be replace by ancillary unit)6

Crankshaft Pulley7

Alternator8

Auto Tensioner9

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

78123456789E74218

Page 79 of 234

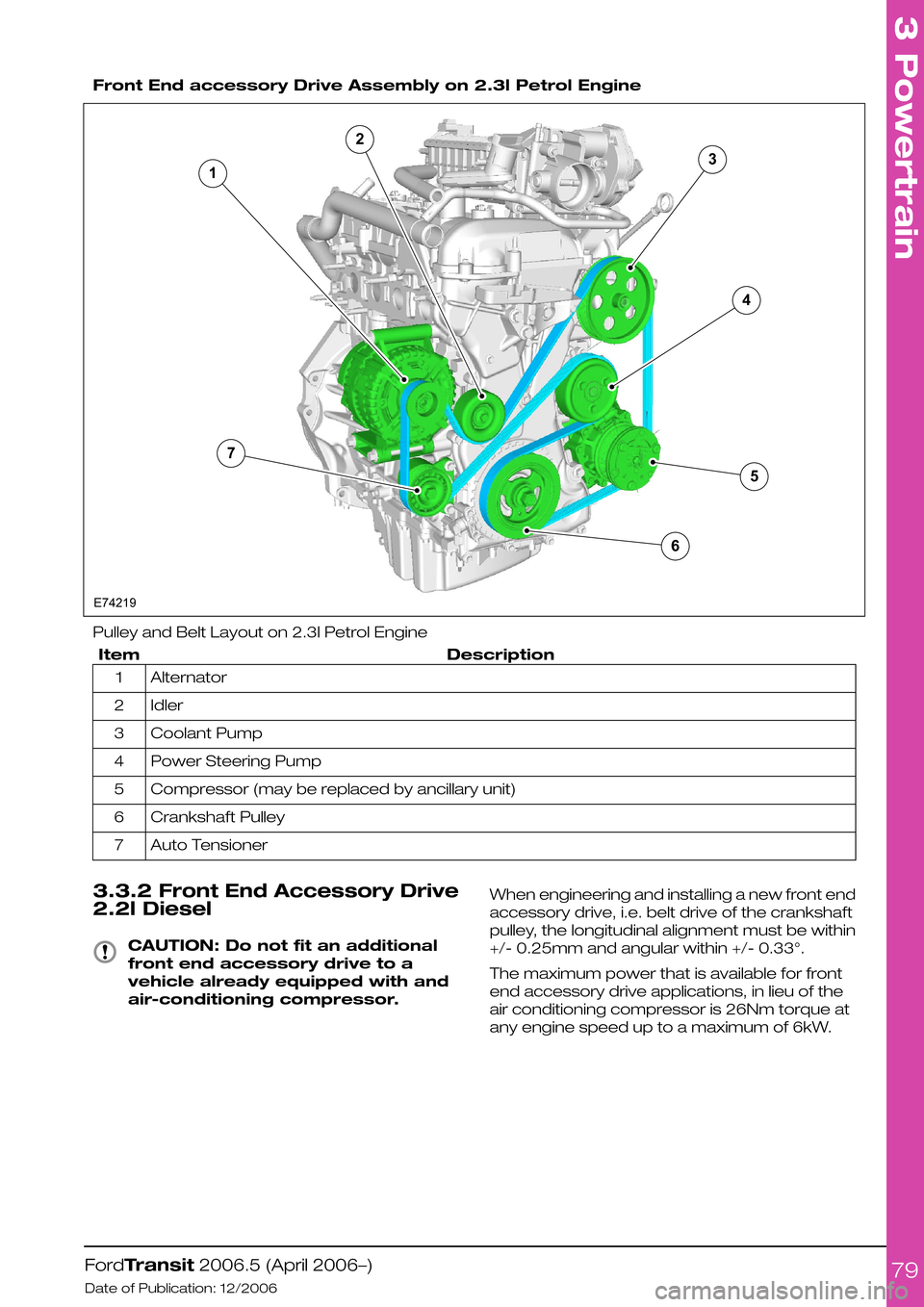

Front End accessory Drive Assembly on 2.3l Petrol Engine

Pulley and Belt Layout on 2.3l Petrol Engine

DescriptionItem

Alternator1

Idler2

Coolant Pump3

Power Steering Pump4

Compressor (may be replaced by ancillary unit)5

Crankshaft Pulley6

Auto Tensioner7

3.3.2 Front End Accessory Drive

2.2l Diesel

CAUTION: Do not fit an additional

front end accessory drive to a

vehicle already equipped with and

air-conditioning compressor.

When engineering and installing a new front end

accessory drive, i.e. belt drive of the crankshaft

pulley, the longitudinal alignment must be within

+/- 0.25mm and angular within +/- 0.33°.

The maximum power that is available for front

end accessory drive applications, in lieu of the

air conditioning compressor is 26Nm torque at

any engine speed up to a maximum of 6kW.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

79E742191234567

Page 80 of 234

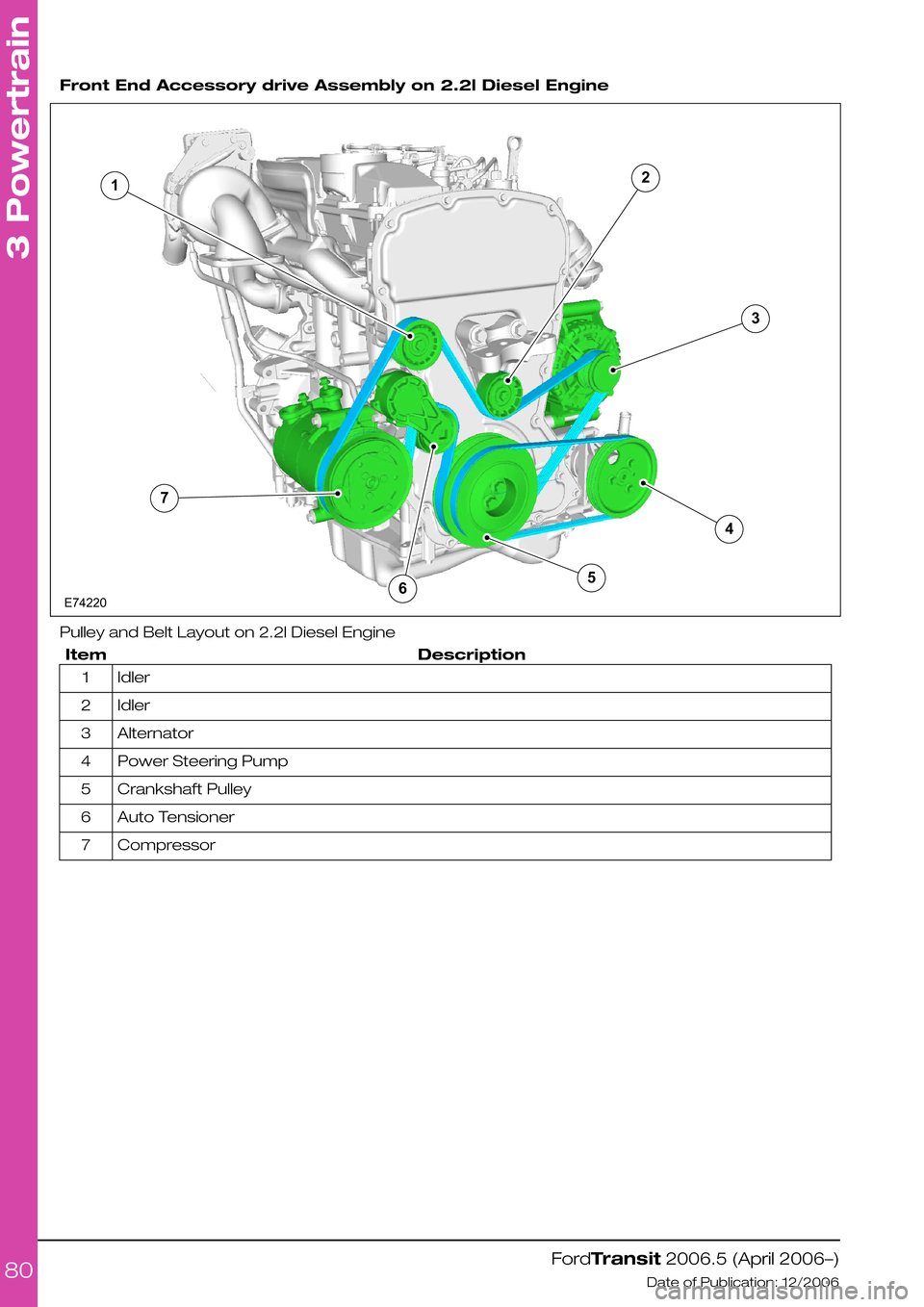

Front End Accessory drive Assembly on 2.2l Diesel Engine

Pulley and Belt Layout on 2.2l Diesel Engine

DescriptionItem

Idler1

Idler2

Alternator3

Power Steering Pump4

Crankshaft Pulley5

Auto Tensioner6

Compressor7

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

807123456E74220

Page 81 of 234

3.4 Electronic Engine Controls

CAUTION: Do not make any

additional connections to the

electrical circuits associated with

the engine management system

NOTE: It is not necessary to disconnect or

remove engine management modules.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

81

Page 82 of 234

3.5 Clutch

The manufacturer does not offer the option of a

reinforced clutch system. The axle ratio available

is dependent on the weight of the specified donor

vehicle.

It is necessary to select the appropriate drive,

engine, gear ratio, gross vehicle mass, gross train

mass, axle plates and payloads of the base

vehicle to match the customers order.

Where possible make sure that the base vehicle

is ordered with plant fit options

NOTE: For further information please contact

your local National Sales Company representative,

or Local Ford Dealer. If they are unable to help

you then please contact the Vehicle Converter

Advisory Service at [email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

82

Page 83 of 234

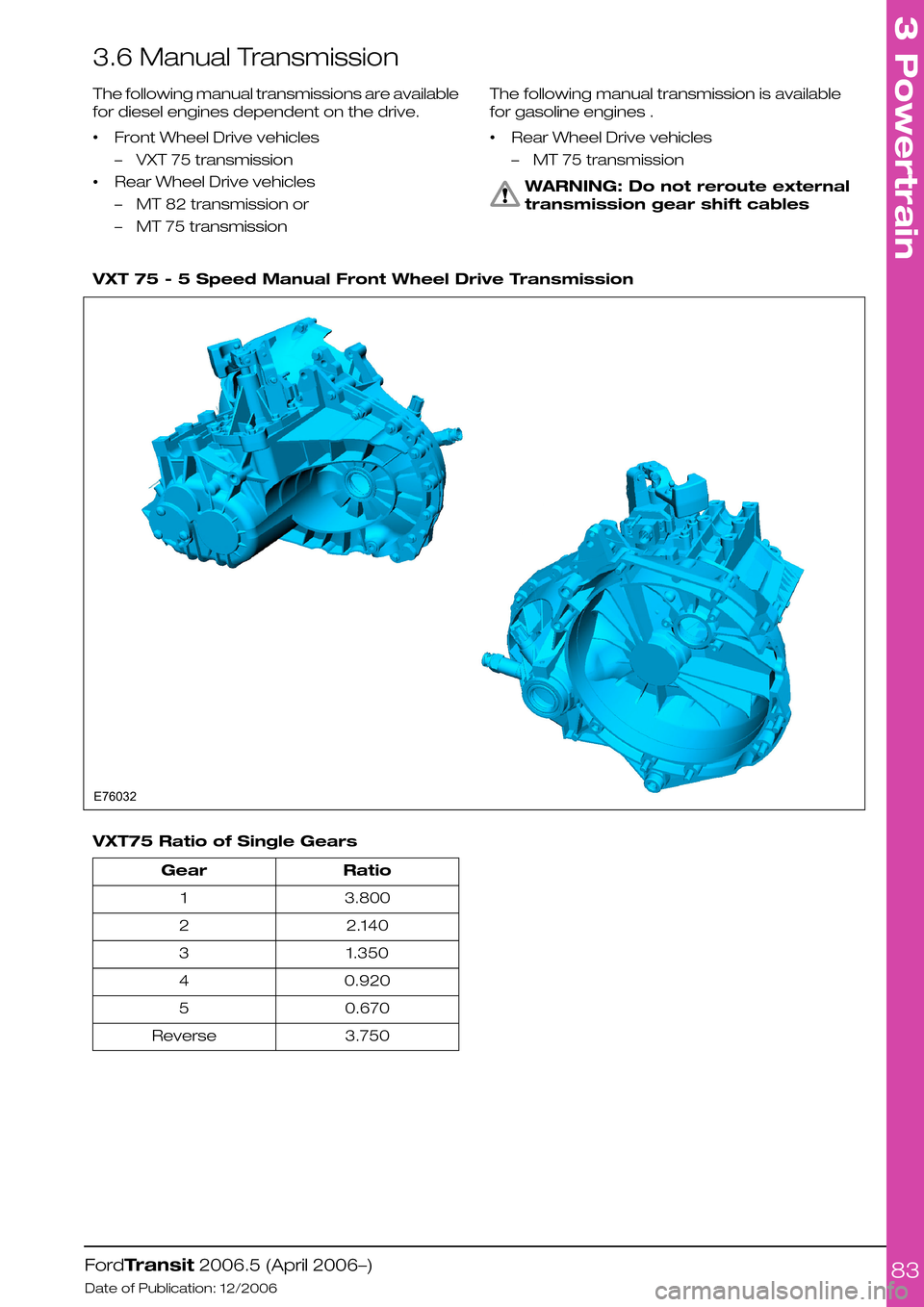

3.6 Manual Transmission

The following manual transmissions are available

for diesel engines dependent on the drive.

•Front Wheel Drive vehicles

–VXT 75 transmission

•Rear Wheel Drive vehicles

–MT 82 transmission or

–MT 75 transmission

The following manual transmission is available

for gasoline engines .

•Rear Wheel Drive vehicles

–MT 75 transmission

WARNING: Do not reroute external

transmission gear shift cables

VXT 75 - 5 Speed Manual Front Wheel Drive Transmission

VXT75 Ratio of Single Gears

RatioGear

3.8001

2.1402

1.3503

0.9204

0.6705

3.750Reverse

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

83E76032

Page 86 of 234

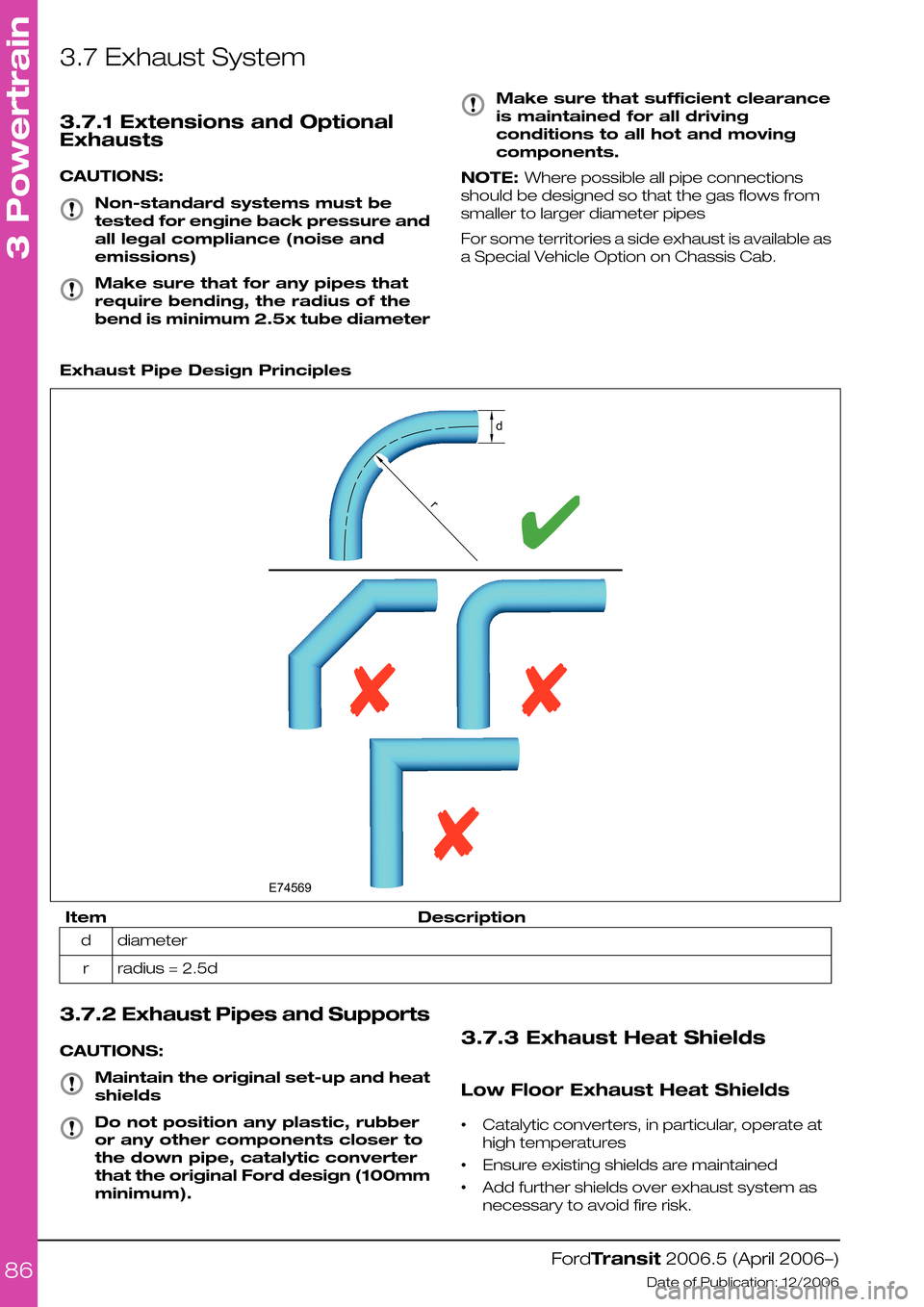

3.7 Exhaust System

3.7.1 Extensions and Optional

Exhausts

CAUTIONS:

Non-standard systems must be

tested for engine back pressure and

all legal compliance (noise and

emissions)

Make sure that for any pipes that

require bending, the radius of the

bend is minimum 2.5x tube diameter

Make sure that sufficient clearance

is maintained for all driving

conditions to all hot and moving

components.

NOTE: Where possible all pipe connections

should be designed so that the gas flows from

smaller to larger diameter pipes

For some territories a side exhaust is available as

a Special Vehicle Option on Chassis Cab.

Exhaust Pipe Design Principles

DescriptionItem

diameterd

radius = 2.5dr

3.7.2 Exhaust Pipes and Supports

CAUTIONS:

Maintain the original set-up and heat

shields

Do not position any plastic, rubber

or any other components closer to

the down pipe, catalytic converter

that the original Ford design (100mm

minimum).

3.7.3 Exhaust Heat Shields

Low Floor Exhaust Heat Shields

•Catalytic converters, in particular, operate at

high temperatures

•Ensure existing shields are maintained

•Add further shields over exhaust system as

necessary to avoid fire risk.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

86E74569rd

Page 95 of 234

4.3 Charging System

4.3.1 General Information and

Specific Warnings

The Transit electrical system is a 12-Volt supply

with a negative earth return. The alternator and

battery equipment used as standard are

designed for normal operations with the type of

engine fitted. Higher capacity batteries are

available as standard production options and

special vehicle options. Before installing additional

electrical equipment check that the battery

capacity, harness load capability, and alternator

output are suitable for the extra load.

The battery capacity and charge available from

the alternator must be adequate to ensure

engine cranking in unfavorable climatic conditions

but excessive battery capacity could damage

the starter motor.

The Transit utilizes multiplexed vehicle electronics

- it is recommended that the appropriate Ford

proprietary accessory systems are used.

Inappropriate or incorrect connection of

additional equipment could cause mis-operation,

or damage to the vehicle, and so invalidate any

warranty.

Additional connection points are provided

specifically for customer use (except M1 and M2

Bus), and are located on the outside of the

driver's seat base.

Do not jump-start the vehicle directly from the

battery. Use designated jump-start points. Refer

to the owners literature.

4.3.2 Power Management

Settings

There are four Power Management Settings

available:

•Factory

•Transport

•Normal

•Crash

Factory and Transport modes are only active

with ignition off; with ignition on, the vehicle

operates with full functionality. When in Transport

mode, the interior lights, clocks, and power

locking and alarms (where fitted) do not work.

It is possible to switch from Transport Mode to

Normal Mode without the use of any ancillary

equipment, but not vice versa. To change mode,

the brake pedal must be depressed five times,

and the hazard warning switch operated twice

(in any combination) within 10 seconds.

WARNING: It is not possible to return

the transport setting without using

the vehicle's diagnostics.

At the end of production, the vehicle is

configured to the transport setting to minimize

power consumption. As part of the Pre Delivery

Inspection process at the Ford dealership, the

vehicle is reconfigured to normal operation.

4.3.3 Electrical Conversions

Operator requirements for additional and

specialised electrical equipment varies. The

vehicle converter/modifier must, therefore,

consider the following points when designing the

installation:

•Legality and regulatory conformity of the base

vehicle.

•Drive-ability and serviceability of the base

vehicle.

•The effect of regulations governing the

proposed conversion including National

Legislation in the country of sale.

•The method of integrating the circuit into the

base vehicle.

•No additional circuits are to be run alongside

the electrical circuits (shown in blue in the

figure below) associated with the

Management System (shown in green in the

figure below), due to the possible Electro

Motive Force (EMF) effect on the circuits.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

95