ignition FORD TRANSIT 2016 5.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: TRANSIT, Model: FORD TRANSIT 2016 5.GPages: 411, PDF Size: 5.65 MB

Page 204 of 411

Circuits switched

Relay

Not used (spare).

R1

Auxiliary power points.

R2

Trailer tow parking lamp.

R3

Not used.

R4

Power windows.

R5

Ignition 1.

R6

Horn.

R7

Trailer tow back-up lamp.

R8

Front blower motor.

R9

Rear blower motor.

R10

Heated rear window.

R11 Heated exterior mirrors.

Not used.

R12

Modified vehicle connections.

R13

201

Transit (TTH) Canada/United States of America, enUSA, First Printing Fuses

Page 208 of 411

Circuits protected

Fuse rating

Fuse

Central locking system 2.

15A

F1

Central locking system 1.

15A

F2

Ignition switch.

15A

F3

Parking assist control module.

5A

F4

Brake transmission shift interlock.

Rain sensor module.

5A

F5

Windshield washer pump.

15A

F6

Not used.

-

F7

Not used.

-

F8

Right-hand high beam.

10A

F9

Left-hand high beam.

10A

F10

Right-hand exterior lamps.

25A

F11

Left-hand position lamps.

Not used.

-

F12

On-board diagnostic.

15A

F13

Battery saver.

Turn signal indicator.

25A

F14 Power windows delayed accessory.

Lane departure sensor heated windshield pad.

Left-hand exterior lamps.

25A

F15 Right-hand position lamps.

High mounted stoplamp.

Audio unit.

20A

F16

Navigation unit.

Instrument panel cluster.

7.5A

F17

Heater control.

Headlamp switch module.

10A

F18 Steering wheel module.

Stoplamp switch supply.

205

Transit (TTH) Canada/United States of America, enUSA, First Printing Fuses

Page 209 of 411

Circuits protected

Fuse rating

Fuse

Front control/display interface module.

5A

F19

Ignition passive anti-theft system.

5A

F20

Accessory relay, customer access feed.

3A

F21

CHANGING A FUSE WARNINGS

Do not modify the electrical system

of your vehicle in any way. Have

repairs to the electrical system and

the replacement of relays and high current

fuses carried out by an authorized dealer. Switch the ignition and all electrical

equipment off before attempting to

change a fuse.

Always replace a fuse with one that

has the specified amperage rating.

Using a fuse with a higher amperage

rating can cause severe wire damage and

could start a fire. If electrical components in your vehicle are

not working, a fuse may have blown. A

break in the fuse wire will indicate a blown

fuse. Check the appropriate fuses before

replacing any electrical components.

206

Transit (TTH) Canada/United States of America, enUSA, First Printing FusesE142430

Page 217 of 411

•

Sustained high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Sustained use of diesel fuel other than

ultra-low sulfur diesel (ULSD).

OIL CHANGE INDICATOR

RESET

Resetting the Oil Life Monitoring

System

Only reset the oil life monitoring system

after changing the engine oil and oil filter.

1. Switch the ignition on. Do not start the

engine. For vehicles with push-button

start, press and hold the start button

for two seconds without pressing the

brake pedal. Do not start the engine.

2. Press the accelerator and brake pedals

at the same time.

3. Keep the accelerator and brake pedals

fully pressed.

4. After three seconds, a message confirming that the reset is in progress

will be displayed.

5. After 25 seconds, a message confirming that the reset is complete

will be displayed.

6. Release the accelerator and brake pedals.

7. The message confirming that the reset

is complete will no longer be displayed.

8. Switch the ignition off. For vehicles with

push-button start, press the start

button to switch the ignition off. ENGINE COOLANT CHECK

Checking the Engine Coolant

When the engine is cold, check the

concentration and level of the engine

coolant at the intervals listed in the

scheduled maintenance information. See

Scheduled Maintenance (page 363).

Note: Make sure that the level is between

the MIN and MAX marks on the coolant

reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.

Note: If the level is at the MIN mark, below

the MIN mark, or empty, add coolant

immediately. See

Adding Engine Coolant

in this chapter.

The coolant concentration should be

maintained within 48% to 50%, which

equates to a freeze point between -30°F

(-34°C) and -34°F (-37°C).

Note: For best results, coolant

concentration should be tested with a

refractometer, for example Robinair®

Coolant and Battery Refractometer 75240.

We do not recommend the use of

hydrometers or coolant test strips for

measuring coolant concentrations.

Note: Automotive fluids are not

interchangeable. Do not use engine coolant,

antifreeze or windshield washer fluid outside

of its specified function and vehicle location.

Adding Engine Coolant WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, spilling

coolant on hot engine parts can burn you.

214

Transit (TTH) Canada/United States of America, enUSA, First Printing Maintenance

Page 220 of 411

The engine is capable of completely

shutting down automatically to prevent

engine damage, if this situation occurs:

1. Stop your vehicle as soon as it is safe

to do so and switch the ignition off.

2. Have your vehicle towed to an authorized dealer.

3. If this is not possible, wait a short period for the engine to cool.

4. Check the coolant level and replenish if low.

5. Re-start the engine and take your vehicle to an authorized dealer.

Note: Driving the vehicle without repairing

the engine problem increases the chance of

engine damage. Take your vehicle to an

authorized dealer as soon as possible.

Engine Fluid Temperature

Management (If Equipped) WARNING

To reduce the risk of a crash and

injury, be prepared that the vehicle

speed may reduce and the vehicle

may not be able to accelerate with full

power until the fluid temperature reduces. When towing a trailer the vehicle

’s engine

may temporarily reach a higher

temperature during severe operating

conditions, for example ascending a long

or steep grade in hot ambient

temperatures.

You may notice a reduction in vehicle

speed caused by reduced engine power.

The design of your vehicle allows it to enter

this mode if certain high-temperature and

high-load conditions take place in order to

manage the engine fluid temperatures. The amount of speed reduction will depend on

the vehicle loading, towing, grade, ambient

temperature and other factors. If this

occurs, there is no need to pull off the road.

You can continue to drive your vehicle

while this message is active.

The air conditioning may also cycle on and

off during severe operating conditions to

protect overheating of the engine. When

the engine coolant temperature decreases

normal operating temperature, the air

conditioning will turn on. If you notice any

of the following:

•

The engine coolant temperature gauge

moves fully into the red area.

• The coolant temperature warning light

illuminates.

• The service engine soon indicator

illuminates.

1. Stop your vehicle as soon as it is safe to do so and place the vehicle in park

(P).

2. Leave the engine running until the coolant temperature gauge needle

moves away from the red area. After

several minutes, if this does not

happen, follow the remaining steps.

3. Switch the engine off and wait for it to

cool before checking the coolant level.

4. If the coolant level is normal, you may restart the engine and continue on.

5. If the coolant is low, add coolant, restart the engine and take your vehicle

to an authorized dealer.

AUTOMATIC TRANSMISSION

FLUID CHECK

The automatic transmission does not have

a transmission fluid dipstick.

217

Transit (TTH) Canada/United States of America, enUSA, First Printing Maintenance

Page 223 of 411

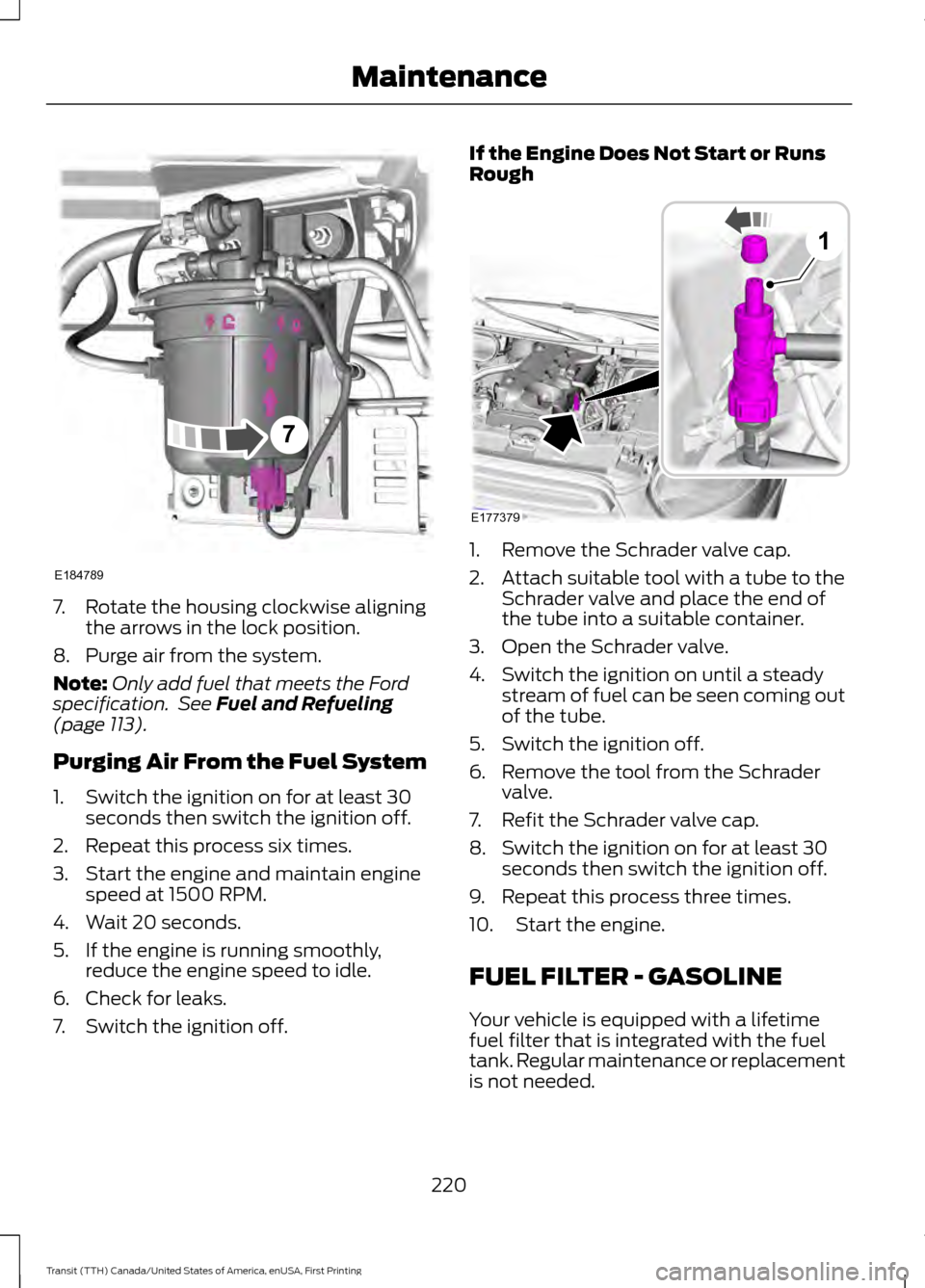

7. Rotate the housing clockwise aligning

the arrows in the lock position.

8. Purge air from the system.

Note: Only add fuel that meets the Ford

specification. See Fuel and Refueling

(page 113).

Purging Air From the Fuel System

1. Switch the ignition on for at least 30 seconds then switch the ignition off.

2. Repeat this process six times.

3. Start the engine and maintain engine speed at 1500 RPM.

4. Wait 20 seconds.

5. If the engine is running smoothly, reduce the engine speed to idle.

6. Check for leaks.

7. Switch the ignition off. If the Engine Does Not Start or Runs

Rough

1. Remove the Schrader valve cap.

2. Attach suitable tool with a tube to the

Schrader valve and place the end of

the tube into a suitable container.

3. Open the Schrader valve.

4. Switch the ignition on until a steady stream of fuel can be seen coming out

of the tube.

5. Switch the ignition off.

6. Remove the tool from the Schrader valve.

7. Refit the Schrader valve cap.

8. Switch the ignition on for at least 30 seconds then switch the ignition off.

9. Repeat this process three times.

10. Start the engine.

FUEL FILTER - GASOLINE

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

220

Transit (TTH) Canada/United States of America, enUSA, First Printing MaintenanceE184789

7 E177379

1

Page 228 of 411

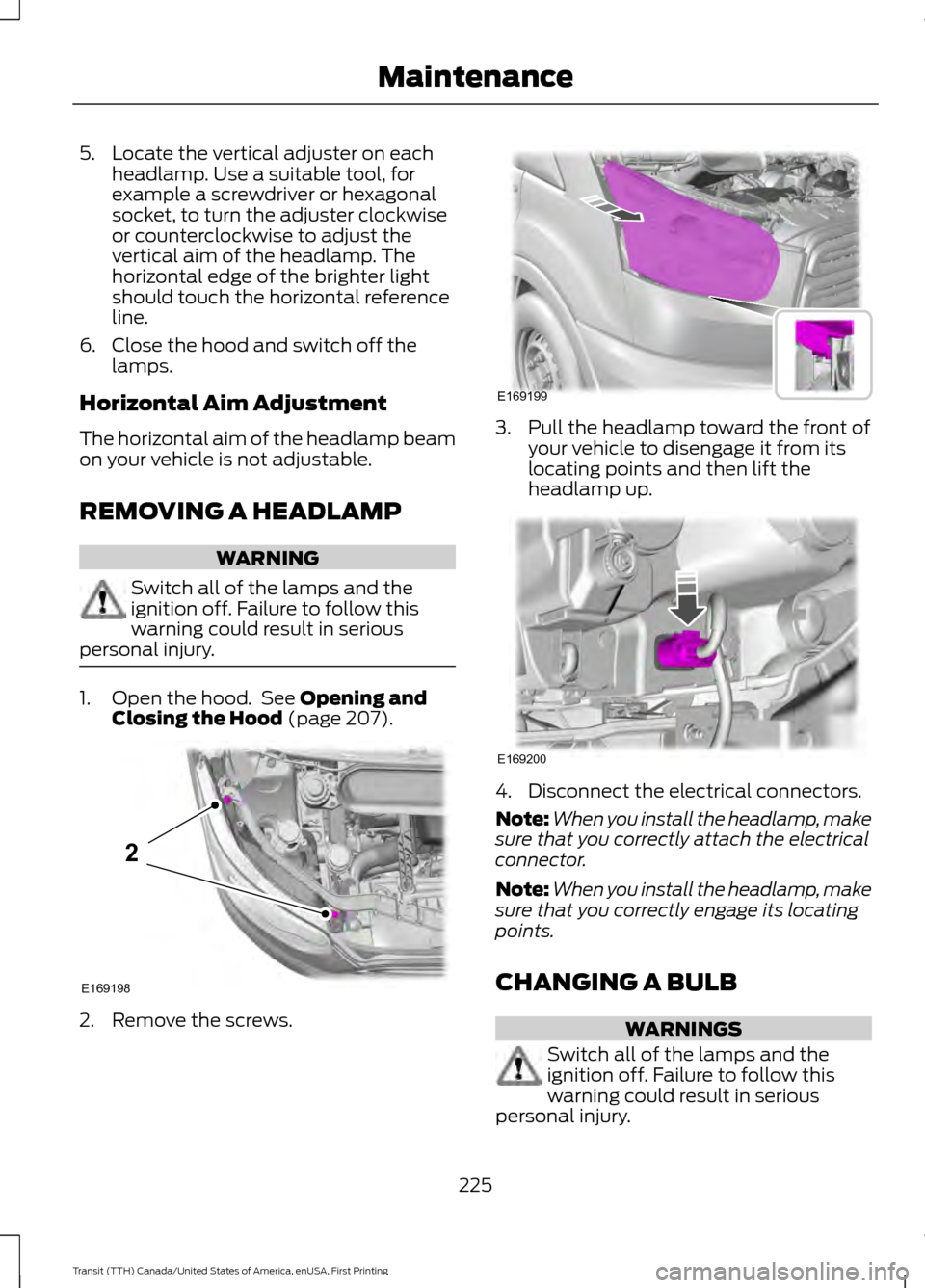

5. Locate the vertical adjuster on each

headlamp. Use a suitable tool, for

example a screwdriver or hexagonal

socket, to turn the adjuster clockwise

or counterclockwise to adjust the

vertical aim of the headlamp. The

horizontal edge of the brighter light

should touch the horizontal reference

line.

6. Close the hood and switch off the lamps.

Horizontal Aim Adjustment

The horizontal aim of the headlamp beam

on your vehicle is not adjustable.

REMOVING A HEADLAMP WARNING

Switch all of the lamps and the

ignition off. Failure to follow this

warning could result in serious

personal injury. 1. Open the hood. See Opening and

Closing the Hood (page 207). 2. Remove the screws. 3. Pull the headlamp toward the front of

your vehicle to disengage it from its

locating points and then lift the

headlamp up. 4. Disconnect the electrical connectors.

Note:

When you install the headlamp, make

sure that you correctly attach the electrical

connector.

Note: When you install the headlamp, make

sure that you correctly engage its locating

points.

CHANGING A BULB WARNINGS

Switch all of the lamps and the

ignition off. Failure to follow this

warning could result in serious

personal injury.

225

Transit (TTH) Canada/United States of America, enUSA, First Printing MaintenanceE169198

2 E169199 E169200

Page 239 of 411

•

Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

• Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

Note: Do not use razor blades or other

sharp objects to clean or remove decals

from the inside of the heated rear window.

The vehicle warranty does not cover

damage caused to the heated rear window

grid lines. CLEANING THE INTERIOR

Note:

Do not allow air fresheners and hand

sanitizers to spill on interior surfaces. If a

spill occurs, wipe off immediately. Damage

may not be covered by your warranty.

Seatbelts

Note: Do not use abrasives, or chemical

solvents to clean them.

Note: Do not allow moisture to penetrate

the seatbelt retractor mechanism.

Note: Cleaning may safely be carried out

using mild soap and water. Let them dry

naturally, away from artificial heat.

Instrument Cluster Screens, LCD

Screens and Radio Screens

Note: Do not use abrasives, alcoholic

solvents or chemical solvents to clean the

instrument cluster screens, LCD screens or

radio screens. These cleaning products can

damage the screens.

Clean the instrument panel and cluster

lens with a clean, damp and soft cloth,

then use a clean, dry and soft cloth to dry

these areas.

Rear Windows

Note: Do not use any abrasive materials to

clean the interior of the rear windows.

Note: Do not install stickers or labels to the

interior of the rear windows.

236

Transit (TTH) Canada/United States of America, enUSA, First Printing Vehicle Care

Page 267 of 411

Carrying Out the System Reset

Procedure

Read the entire procedure before carrying

out a system reset.

1. Drive your vehicle above 20 mph (32

km/h) for at least two minutes and

then park in a safe location where you

can easily get to all four tires and have

access to a tire inflation pump.

2. Switch the ignition off.

3. Switch the ignition on with the engine off.

4. Turn the hazard flashers on then off three times, this must be completed

within 10 seconds. If the reset mode

has been entered successfully, the horn

will chirp once and the system indicator

will flash. If this does not occur, repeat

the procedure from step 2. If after

repeated attempts to enter the reset

mode, the horn does not chirp and the

system indicator does not flash, have

your vehicle checked by an authorized

dealer as soon as possible.

5. Train the system sensors in the tires using the following reset sequence

starting with the left front tire and

following a clockwise order: Left front,

right front, right rear, left rear.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn chirps.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by your vehicle for this position. If a

double horn chirp is heard, the reset

procedure was unsuccessful and must be

repeated.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn chirps.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn chirps. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn chirps.

Training is complete when the horn

chirps after the last system sensor (left

rear) has been trained and the system

indicator stops flashing.

10. Switch the ignition off. If two short horn chirps are heard, the reset

procedure was unsuccessful and

must be repeated.

Note: If after repeating the procedure two

short horn chirps are heard again, have your

vehicle checked by an authorized dealer as

soon as possible.

11. Set all four tires to the correct pressure See Maintenance (page

207). or the tire inflation pressure label

(located on the edge of driver door or

the B-Pillar).

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be

used. The tire pressure monitoring system

sensor and valve stem on the wheel must

be replaced by an authorized dealer after

use of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See

Tire Pressure

Monitoring System (page 260). Note:

The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on this vehicle.

264

Transit (TTH) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 273 of 411

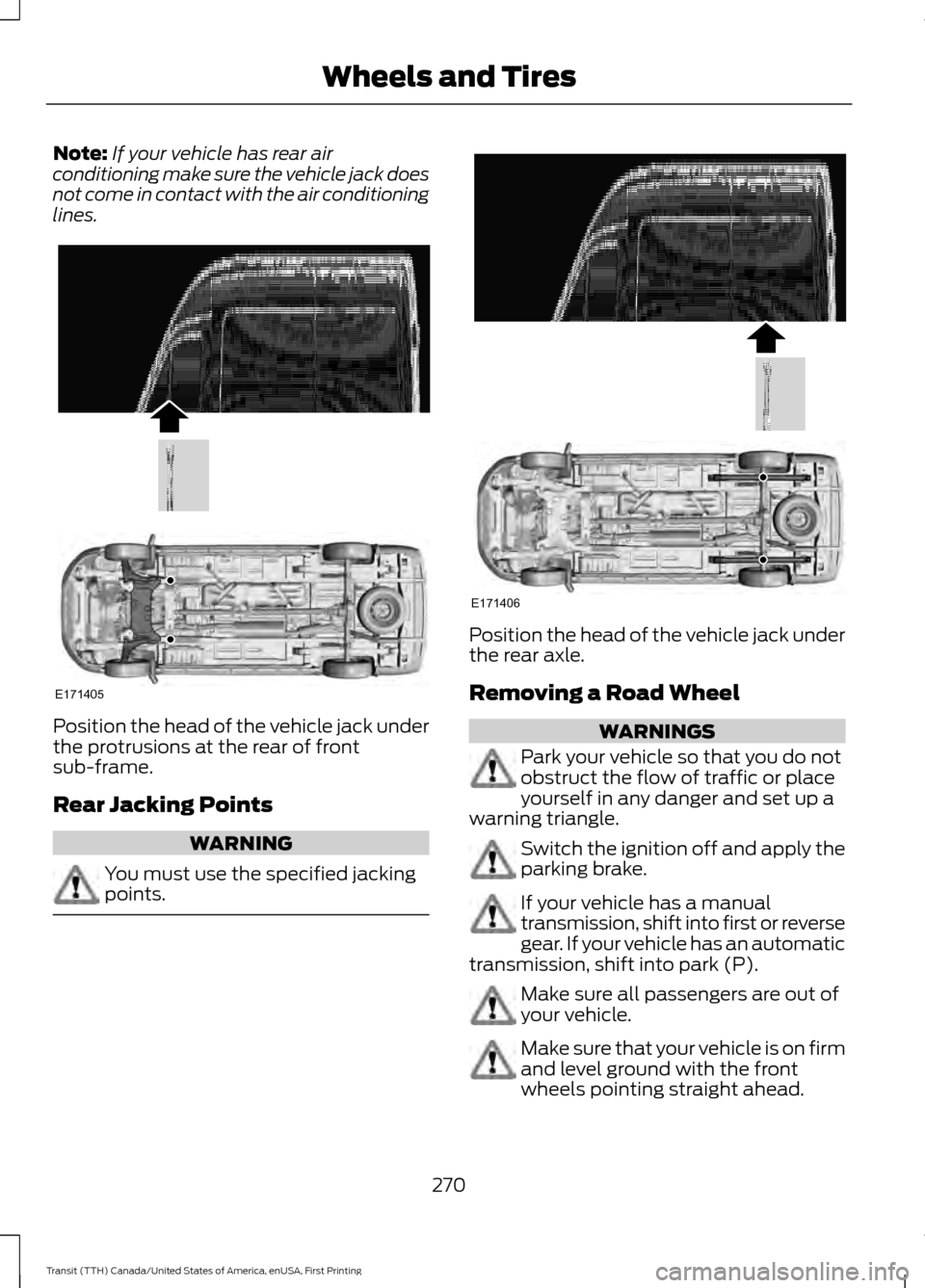

Note:

If your vehicle has rear air

conditioning make sure the vehicle jack does

not come in contact with the air conditioning

lines. Position the head of the vehicle jack under

the protrusions at the rear of front

sub-frame.

Rear Jacking Points

WARNING

You must use the specified jacking

points. Position the head of the vehicle jack under

the rear axle.

Removing a Road Wheel

WARNINGS

Park your vehicle so that you do not

obstruct the flow of traffic or place

yourself in any danger and set up a

warning triangle. Switch the ignition off and apply the

parking brake.

If your vehicle has a manual

transmission, shift into first or reverse

gear. If your vehicle has an automatic

transmission, shift into park (P). Make sure all passengers are out of

your vehicle.

Make sure that your vehicle is on firm

and level ground with the front

wheels pointing straight ahead.

270

Transit (TTH) Canada/United States of America, enUSA, First Printing Wheels and TiresE171405 E171406