warning GEELY CK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 258 of 392

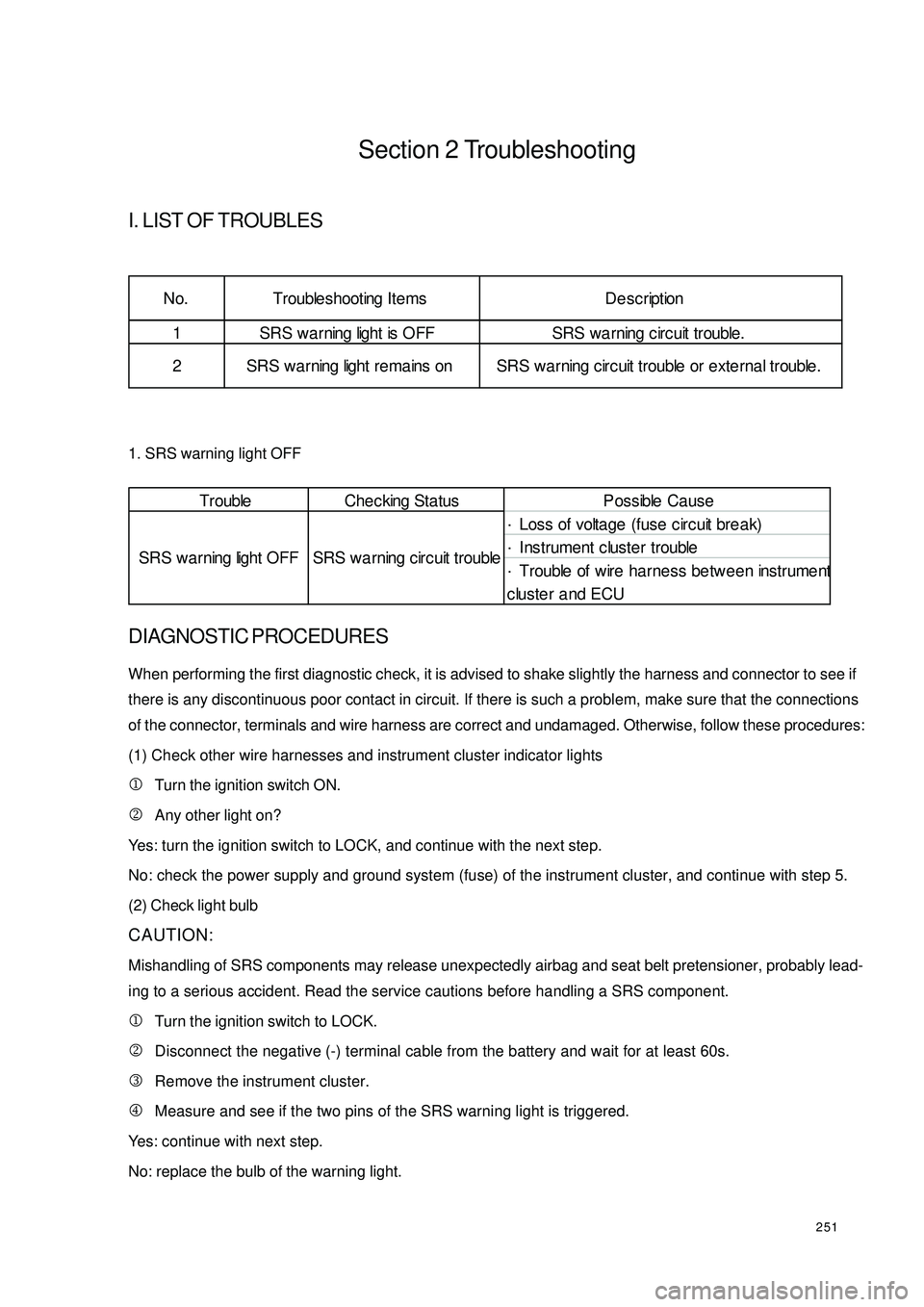

251Section 2 TroubleshootingI. LIST OF TROUBLES1. SRS warning light OFFDIAGNOSTIC PROCEDURESWhen performing the first diagnostic check, it is advised to shake slightly the harness and connector to see if

there is any discontinuous poor contact in circuit. If there is such a problem, make sure that the connections

of the connector, terminals and wire harness are correct and undamaged. Otherwise, follow these procedures:

(1) Check other wire harnesses and instrument cluster indicator lights

1Turn the ignition switch ON.

2Any other light on?

Yes: turn the ignition switch to LOCK, and continue with the next step.

No: check the power supply and ground system (fuse) of the instrument cluster, and continue with step 5.

(2) Check light bulb

CAUTION:

Mishandling of SRS components may release unexpectedly airbag and seat belt pretensioner, probably lead-

ing to a serious accident. Read the service cautions before handling a SRS component.

1Turn the ignition switch to LOCK.

2Disconnect the negative (-) terminal cable from the battery and wait for at least 60s.

3Remove the instrument cluster.

4Measure and see if the two pins of the SRS warning light is triggered.

Yes: continue with next step.

No: replace the bulb of the warning light.

Trouble Che c king Status P ossible Ca use

·Loss of voltage (fuse c irc uit bre a k)

·Instrument cluster trouble

·Trouble of wire harness between instrument

cluster and ECU SRS warning light OFF SRS wa rning c ircuit trouble1 SRS warning light is OFF SRS wa rning c irc uit trouble. No. Trouble shooting Ite ms De sc ription

2 SRS warning light re mains on SRS wa rning circ uit trouble or exte rna l trouble.

Page 259 of 392

252(3)Check the connection between ECU and instrument cluster

1Turn the ignition switch to LOCK.

2Disconnect the negative (-) terminal cable from the battery.

3Disconnect the connector of instrument cluster.

4Check if the related circuits of the warning light are connected or not.

Yes: continue with next step.

No: replace the wire harness, and then continue with step 5.

2. SRS warning light remains on.DIAGNOSTIC PROCEDURESTo begin the check, first use special diagnostic instruments and ECU to perform communication diagnosis

and find out the causes of the trouble. If the communication fails, continue with the following procedures:

(1) Check battery

1Check battery voltage.

2Is voltage higher than 9V?

Yes: continue with next step.

No: Insufficient battery supply. Check the charging/discharging system, and then continue with step (5).

(2) Check the continuity of the wire harness between ECU and instrument cluster

1Turn the ignition switch to LOCK.

2Disconnect negative (-) terminal cable from the battery.

3Open the guard plate of the central passage.

4Disconnect the connector of the instrument cluster.

5Connect the negative (-) terminal cable of the battery.

6Turn the ignition switch ON.

7Check whether the voltage of the connector terminal of the instrument is 12V (power supply and instrument

connecting wire).Trouble Che cking Sta tus P ossible Cause�z Insufficient battery supply�z ECU internal trouble�z SRS wa rning light trouble of instrument c luste r�z Improper connection of ECU connector�z P oor c ontac t of instrume nt c luste r c onne c tor�z Ope n circ uit or poor c onta c t of ECU power supply fuse�z P oor c onne c tion of ECU connec tor te rmina l�z P oor conta ct of the wire ha rne ss be twe en ECU

connec tor te rmina l a nd ground�z Drive r or pa ssenge r side circ uit trouble of SRS SRS wa rning light

remains onSRS warning light

remains on

Page 260 of 392

253Yes: continue with next step.

No: check the circuit, repair it and continue with step (5).

8Turn the ignition switch to LOCK.

9Check the continuity of the terminal of instrument connector and that of diagnostic interface (check the

two ends of K line).

Yes: continue with next step.

No: repair or replace the wire harness. Continue with step (5).

�VMake sure to disconnect the negative terminal cable from the battery and wait for at least 60s.Disconnect

the ECU connector. 11Disconnect the connectors of the instrument cluster 12 Are the connector terminals 5, 7 and 9 and those of instrument cluster continuity?

Yes: continue with next step.

No: replace the wire harness, and then continue with step (5). 13Remove ECU and see whether the terminals are in good condition and whether the shorting bar is

broken.

Yes: replace the ECU.

No: reconnect the ECU connector, and then continue with next step.

(3) Make sure of the nonrecurrence of the trouble after repair

1Turn the ignition switch to LOCK.

2Disconnect the negative (-) terminal cable from the battery and wait for at least 60s.

3Connect all the ECU connectors.

4Connect the connector of driver airbag assembly.

5Connect the connector of passenger airbag assembly.

6Connect the connectors of driver and passenger seat belt pretensioners (vehicle with pretensioner).

7Connect clock spring connector.

8Connect the negative (-) terminal cable of the battery.

9Turn the ignition switch to ON.

�VIs the SRS warning light working normal?

Yes: the trouble is eliminated. Explain the repair procedures to the Customer.

No: recheck symptoms of the trouble. Repeat these procedures from the first step if the trouble reoccurs.

Page 268 of 392

261IV. WARNING MARKSWhen using or maintaining an airbag, the warnings shall be indicated. When maintaining, proceed in accor-

dance with the description of mark. In addition, if the mark is damaged or stained, it shall be replaced.

1. Driver airbag assembly, see Fig. 1.

2. Clock spring, see Fig. 2.

3. ECU, see Fig. 3.

4. Sun Visor, see Fig. 4.

5. Steering wheel, Fig. 5.Warning MarkFigure 1Warning

MarkFigure 2Warning Mark

Figure 3Warning Mark Warning MarkFigure 4 Sun VisorFigure 5

Page 269 of 392

262Section 3 Removal & InstallationI. SRS ELECTRONICAL CONTROL UNIT (ECU)1. Operations prior to Removal

(1) Turn the ignition switch OFF.

(2) Remove negative (-) terminal cable of the battery. Put it in a proper position or wrap it up with insulating

tape.

2. Removal procedures:

(1) Remove the central passage side cover plate (or remove auxiliary console).

(2) Remove the connectors to SRS ECU.

(3) Remove ECU.

3. Installation procedures:

(1) Install ECU.

(2) Install the connectors to SRS ECU.

(3) Install the central passage side cover plate (or install auxiliary console).

(4) Connect negative (-) terminal cable of the battery.

4. Key points for Installation:

(1) Install ECU.

(2) Check after installation.

1Turn the ignition switch ON.

2The warning light goes on within 6s, and then goes out.

(3) If the light doesn't go out, check the trouble and eliminate it.NOTICE1. Work must be started 60s after the negative (-) terminal cable is detached from battery. The detachednegative (-) terminal cable shall be protected with insulating tape for insulation.

2. Never attempt to dismantle or repair an ECU. If there is any trouble, replace the ECU with a new one.

3. Prevent the ECU from shock or vibration. If pitting, crack or distortion is found, replace the ECU with

a new one.

4. Every time an airbag is deployed, the ECU shall be replaced with a new one.

5. When disassembling or maintaining the parts around ECU, attention must be given to avoid contacting

the ECU.NOTICE

If the ECU cannot be installed correctly, the airbag will not act normally.

Page 273 of 392

2664. Check after installation

(1) Slightly rotate the steering wheel left and right, make sure that there is no abnormality or noise. (Driver

airbag module, clock spring)

(2) Turn the ignition switch ON.

(3) The warning light goes on within 6s, and then goes out.

(4) The trouble shall be eliminated if the warning light remains on when the ignition switch is turned on or

after it goes out after 6s.IV. CHECKING1. Driver airbag assembly checking

Check the following items and replace the related components of the airbag assembly if any badness is

found. The old components shall be deployed before scrapping.

(1) Check the hood for pitting, crack, distortion, etc.

(2) Check the joint of the wire harness for damage and the terminal for distortion.

(3) Check the case of the gas generator for pitting, crack and distortion.

(4) Check the installation status of the airbag assembly.

2. Check the clock spring

Check the following items, and replace the clock spring if any badness is found.

(1) Check the joint and protecting tube for damage and the terminal for distortion.

(2) Check the case for damage.

(3) Check and see if the joint terminal at the upper end of the clock spring are in conduction with that at the

lower end.

(4) A thin probe shall be inserted from the back of the yellow connector of the clock spring.NOTICE

If there is pitting, crack or distortion, replace the airbag assembly with new one. The old components of the

airbag shall be deployed before scrapping.

The circuit resistance of the airbag assembly (squib) cannot be measured even with a designated tester.Since there is current flowing in the squib, when a tester is involved in measuring the resistance, sometimesthe airbag is unexpectedly deployed in case of static electricity, leading to serious accident.

Page 279 of 392

272Chapter 8 MK-20 ABS SystemSection 1 ABS DiagnosisI. Check the ABS Warning Light1. Check the ABS Warning Light goes on as the following:

1Turn the ignition switch to ON, the ABS Warning Light goes on for about 1.7 seconds and then goes off.

2If the above condition is not satisfied, it indicates that there is a fault, please check the DTC.

3If the warning light does not light up at all, refer to the Non-DTC fault inspection table.II. The Reading of the information statusAfter connecting the scan meter, turn the ignition switch to¡°ON¡±, select the function menu item 01, press

OK to confirm, the screen will display the following information:

1. ECU drawing number and its version:

ABS MK20 IE

2. Code 01901III. Read and Clear the DTC1. After selecting the "02 Read DTC" in the function menu, it displays the total amount of the fault, if there

is no DTC, then it displays no DTC. Then, press OK button to proceed to next page to review the DTC

and its description. Generally, there is a P or O before the DTC, indicating that it is a Persistent fault or

Occasional fault. Persistent fault remains existing all the time, while the Occasional fault can be cleared

and is only able to reoccur during the driving.

Note:

The reading of the DTC can not be quitted middle way, you can return to the function menu only

after reading all the DTC.

Clear DTC

2. Select function menu item 05, press OK button to clear the DTC, if the DTC can not be cleared, it

indicates that the DTC represent exist all the time, if the saved DTC can be cleared, it indicates that it is

occasional fault can only be detected during the driving.

Page 280 of 392

273IV. DTC Display Method

V. HCU DiagnosisUse the scan meter to diagnose the Hydraulic Control Unit (HCU), select the "3 HCU diagnosis" in the

options and perform the following procedures.

* Perform the above step 2 - 8 test for each wheel in the following order LF RF LR RR.

* If the result of some one of the above steps is different from the normal result, it indicates that the

corresponding element fails the normal operation, please check the corresponding element.

* You can use “ESC” button to end the test to return the function menu in any place in the screen where

there is “return” displayed to return to the function menu.Code Displa ye d

Ne ve r ha ppe ne d be fore No DTC

Happened before Occasional DTC

Ne ve r ha ppe ne d be fore Non-occ a sional DTC

Happened beforeOccasional DTC and Non-

occasional DTC System P roblem

The re is no proble m current ABS

Warning Light does not light up)

The problem still e xists(

ABS

Wa rning Light goe s on)Step Action Screen Display Normal Result

1 HCU dia gnosis – hydra ulic pump te st P ump motor operate s

2 LF Wheel——Depress the brake pedal

3LF Whe e l—— norma lly ope n va lve

ope n, norma lly c losed va lve c lose d,

wheel locked?Wheel locked

4LF Whe e l—— norma lly ope n va lve

closed, normally closed valve closed,

wheel locked?Wheel locked

5LF Wheel — — normally open valve

close d, norma lly close d va lve open,

wheel can rotate freelyWheel can rotate freely, the

pe da l re bound, the c ylinde r

motor ope ra ting noise is a udible

6LF Whe e l—— norma lly ope n va lve

closed, normally closed valve closed,

wheel can rotate freelyWheel can rotate freely

7LF Wheel — — normally open valve

ope n, normally c lose d va lve close d,

wheel locked?Wheel locked, the pedal sag

slightly

8Release the brake

pe dal De pre ss and hold

the brake pedal→→→

Page 282 of 392

275VIII. ABS ECU Connector Pin LayoutABS ECU Connector (End Views)

Electrical Wiring DiagramCombination MeterABS Warning Light

Drive ModuleABS ECU

ABS RR Wheel Sensor

ABS LR Wheel Sensor ABS RF Wheel Sensor

ABS LF Wheel Sensor

Brake Lamp Switch

Page 290 of 392

![GEELY CK 2008 Owners Manual 283II. Non-DTC Problem Inspection Table1 With ignition s witch ON (Engine Off),

the AB S warning lig ht do e s no t g o o nLike ly Caus e s[De s cription] ABS Wa rning Light doe s not go

on, th GEELY CK 2008 Owners Manual 283II. Non-DTC Problem Inspection Table1 With ignition s witch ON (Engine Off),

the AB S warning lig ht do e s no t g o o nLike ly Caus e s[De s cription] ABS Wa rning Light doe s not go

on, th](/img/58/57159/w960_57159-289.png)

283II. Non-DTC Problem Inspection Table1 With ignition s witch ON (Engine Off),

the AB S warning lig ht do e s no t g o o nLike ly Caus e s[De s cription] ABS Wa rning Light doe s not go

on, the like ly c a use ma y be the ope n in the

warning light powe r supply c irc uit, burne d bulb

or dama ged wa rning light drive module .�z Burned fuse

�z A B S W a r ning L ight B ulb bur ne d

�z Power supply circuit open

�z ABS Wa rning Light Drive Module da mage dCheck the ABS warning light

fuse in the fuse blockRemove the ECU connector,

does the warning light goes on

with the ignition switch ON? Check whether the ABS

warning light is burnedCheck whether the warn-

ing light power supply cir-

cuit and ground circuit in the

wire harness is openCheck the connector of the

warning light power supply

circuit and ground circuit in

the wire harness Does the fault reoccur?Abn.

Replace

Repair the wire harnessNo

Ye s

Abn.

Abn. Ok

Ye s No

Ok

OkReplace

Repair the wire

harness

Repair the connectorCheck whether the wire in the

ABS wire harness connecting

the ABS warning light drive

module and the ECU is short

to ground Ye s Replace the warning light

drive module Ye sNoRefer to "Occa-

sional Problem

Service Key Points"