check engine GEELY CK 2008 Owner's Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 78 of 392

713. Poor acceleration

(1) Symptom

Engine speed can not be increased immediately after depressing the accelerator pedal, there is time lag,and the acceleration reaction is delayed or there is slight fluctuation during the acceleration.(2) Causes and Troubleshooting

a. There is fault in throttle position sensor, repair or replace it;

b. Poor intake system seal, repair it;

c. There is low fuel pressure, troubleshoot it;

d. Poor injector operation, clean or replace it;

e. Intake pressure temperature sensor fault, repair or replace it;

f. Check valve is damaged and shall be replaced;

g. Ignition advance angle is not correct and shall be adjusted;

h. Fuel pressure regulator is damaged and shall be replaced;

i. Air cleaner is clogged and shall be cleaned or replaced;

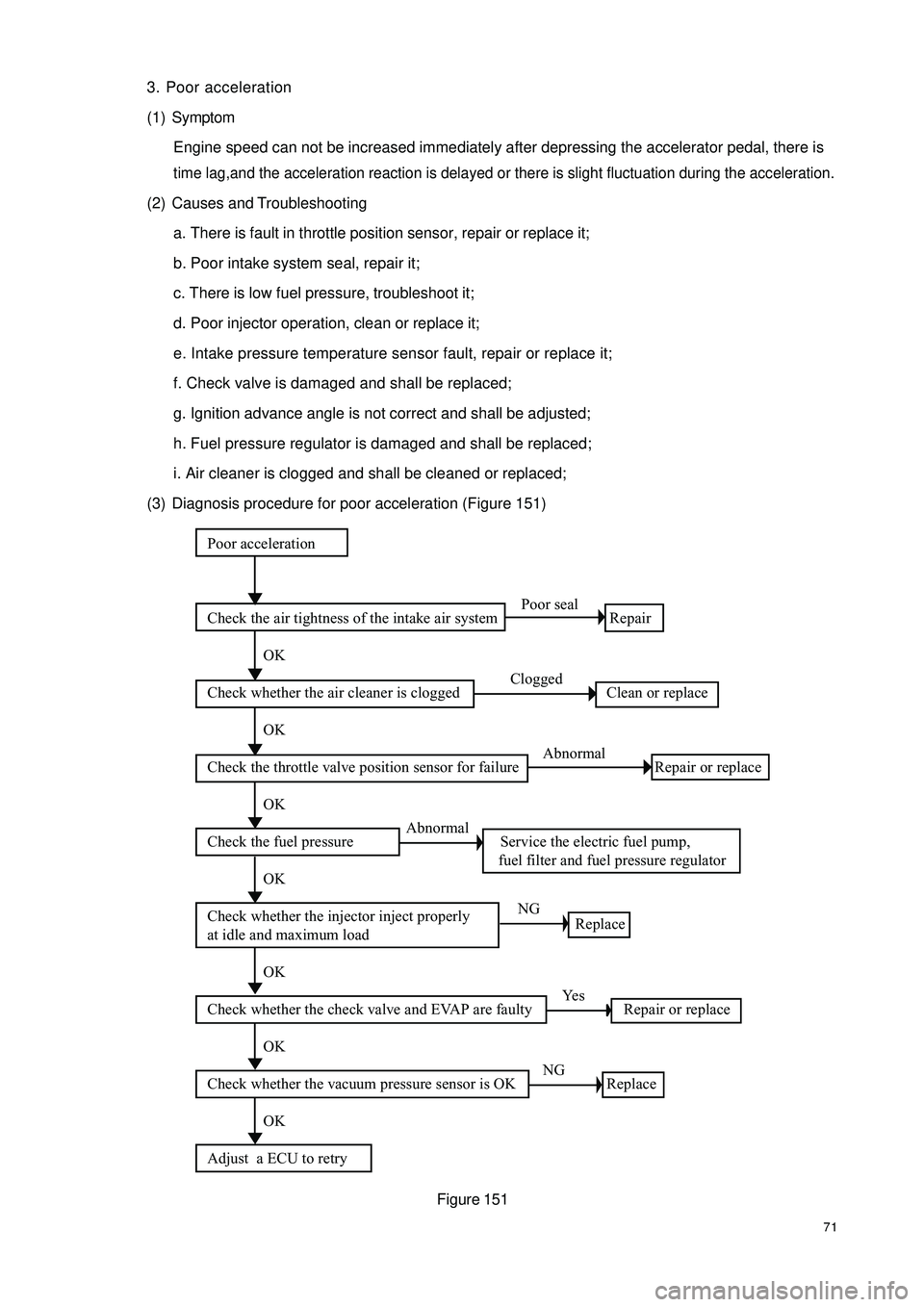

(3) Diagnosis procedure for poor acceleration (Figure 151)

Figure 151Poor acceleration

Check the air tightness of the intake air system Poor seal

Repair

OK

Check whether the air cleaner is clogged Clogged

Clean or replace

OK

Check the throttle valve position sensor for failure Abnormal

Repair or replace

OK

Check the fuel pressure Abnormal

Service the electric fuel pump,

fuel filter and fuel pressure regulator

OK

Check whether the injector inject properly

at idle and maximum load NG

Replace

OK

Check whether the check valve and EVAP are faulty Yes

Repair or replace

OK

Check whether the vacuum pressure sensor is OK NG

Replace

OK

Adjust a ECU to retry

Page 80 of 392

737. Unstable idle or engine shut off at hot status

(1) Symptom

Idle speed is normal during the cold start and becomes unstable at hot status, idle speed is too

low or engine is shut off.

(2) Causes and Troubleshooting

a. Idle is adjusted too low, adjust it to normal condition;

b. Water temperature sensor fault, repair or replace it;

c. Poor injector operation or big injection variation, repair or replace it;

d. Poor water temperature switch and thermostat operation, repair or replace it;

e. Check valve is damaged and needs to be replaced.

Figure 152Rough ildling, easy for engine shut off

Check whethe the air tightness of the intake system is good Poor

Troubleshooting

OK

Check idle control valve for operation Inoperative

Disassemble or replace

Operative

Reset the initial idle speed

Check the spark plug Poor

Adjust the clearance or replace

OK

Check the fuel pressure NG

Check the electric pump, fuel

pressure regulator and fuel filter

OK

Check the injector NG

Replace

OK

Check the pressure sensor NG

Replace

OK

Check the cylinder compression pressure NG

Disassemble the engine

OK

Check and adjust the valve clearance

Page 81 of 392

748. Idle speed too high at hot status

(1) Symptom

The engine runs at fast idle during cold start and remains fast idle at hot status, leading to excessively fast

idle.

(2) Causes and Troubleshooting

a. The initial idle value is not properly adjusted,

b. High system fuel pipeline pressure, need to be adjusted;

c. Water temperature sensor fault, repair or replace it;

d. Water temperature switch and thermostat fault, repair or replace it;

e. Idle control valve fault, repair or replace it;

f. Throttle is binding and not tightly closed, repair or replace it;

g. Fuel evaporation control valve is always open, repair or replace it;

h. Speed sensor fault, repair or replace it.

9. Idle fluctuation

(1) Symptom

when idling, the engine speed fluctuates.

(2) Causes and Troubleshooting

a. Intake pressure temperature sensor fault, repair or replace it;

b. Check valve is damaged and needs to be replaced;

c. Water temperature sensor , water temperature switch and thermostat is poorly coordinated, repair,

adjust and troubleshoot them;

d. Oxygen sensor fault, need to be replaced;

e. Spark plug poor connection, repair or replace it;

f. Idle control valve and its control circuit fault, repair or replace it;

g. Idle switch is not closed, need to be repaired.

Page 84 of 392

77IV. Exhaust Pipe Discharges Gas with Abnormal Color (or odor)When there is failure in engine combustion system, the exhaust pipe discharges gas with abnormal color.

1. The discharged gas is thickly black

This is caused by incomplete combustion. Since the mixed air is too thick, the combustion is not complete and

part of the fuel is discharged without combustion, leading to decrease of engine power. At this moment, you

should check fuel pressure regulator, throttle position sensor, injector and ECU system and correct the

problems in time.

2. Exhaust is blue and stinks

This is caused by large amount of oil vapor mixed in the exhaust gas that enters in the cylinder and partici-

pates in combustion. One of the primary reasons is that the piston oil ring is dirty and damaged, and shall be

replaced; another reason may be the failure of valve oil seal or excessive clearance between the valve stem

and guide bush hole resulting in oil entering the combustion chamber for combustion, oil seal or valve guide

bush shall be replaced to resume normal condition.

3. Exhaust is white

This is caused by water or fuel vapor mixed in the exhaust. The primary reason is that cylinder head gasket

is damaged, resulting in slow infiltration of coolant into cylinder and the water vapor entry into the exhaust

pipe after combustion, cylinder head gasket shall be replaced to resume the normal condition.Section 3 Engine Noise Diagnosis and TroubleshootingAbnormal sounds generated during engine operation (e.g. knocking sound, chuckle, hiss, rattle) are called

noise.

Engine noise is primarily generated in valve train, connecting rod piston crankshaft components and other

accessory system. The following description discusses the diagnosis and troubleshooting of the noise gener-

ated in valve train and crankshaft connecting rod mechanism.I. Diagnosis and troubleshooting of the noise in valve trainvalve train consists of intake & exhaust camshaft , valve, valve bushing, tappetand counter gear.

1. camshaft noise

(1) camshaft end play is excessively big (normal intake camshaft : 0.030~0.085mm, exhaust camshaft : 0.

035~0.090mm) , when it exceeds 0.11mm and noise is generated, replace it;

(2) Camshaft bend is another cause for noise; it shall be aligned or scraped. ;

(3) Camshaft journal is excessively worn, resulting in big radial clearance between camshaft and bearing and

noise, replace it;

2. Valve group knock noise

(1) Valve noise is caused by excessive valve clearance, the valve spring seat flange is damaged and shall be

replaced;

(2) Valve spring knock noise is caused by broken valve spring. It shall be replaced;

Page 92 of 392

85Part II ChassisChapter 1 Transmission Control DeviceSection 1 Transmission Control DeviceDescription on Transmission Control DeviceThis model is equipped with lever and cable transmission control devices, respectively used for 1.3L and 1.5L

engine, both of their gears are: 5 forward gears + 1 reverse gear.PROBLEM SYMPTOMS TABLEUse the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace these parts.Section 2 Lever Type Transmission Control DeviceComponentsSymptom

1. Tra nsmission c ontrol de vic e se le ctor (position

changing) cable (improperly assembled)

2. Ca ble or rela te d pa rts worn

3. Ca ble a sse mbly (incorrec t)

4. T r a ns mis s ion ( f a ult y)

1. Transmission control device selector (position

changing ) cable (improperly assembled)

2. Ca ble or rela te d pa rts worn

3. Ca ble a sse mbly (incorrec t)

4. Transmission (faulty) Transmission out of gea r

Transmission shift difficultControl lever Assembly

Dust Proof Cover

Botton Panel

Assembly of body

Dust Proof Cover Retainer

Control Pull Rod AssemblySuspected Area

Page 97 of 392

90Chapter 2 Accelerator PedalSection 1 Accelerator PedalComponents

Replacement1. Remove the accelerator cable

Loosen the set nut attaching the accelerator cable to the accelerator

cable bracket on the engine, remove the accelerator cable from

the throttle valve rocker arm

2. Remove accelerator pedal

(1) Remove two set nut between the accelerator pedal

and vehicle body

(2) Separate the accelerator cable

3. Detach the accelerator cable

4.Install the accelerator cable and accelerator pedal assembly in the reverse order of the

Notice:

(1) Accelerator pedal assembly fixing bolt torque: 20~25N.m

(2) Properly adjust the position of the accelerator cable set screw to ensure the adequate

tension of the accelerator cable

(3) Check whether the accelerator control is flexible and reliableCowl BaffleHole Plug

Accelerator

Pedal Assembly Accelerator CableAdjusting NutConnect

The Engineabove procedure.

Page 98 of 392

91Chapter 3 Clutch Control SystemSection 1 Clutch Control SystemClutch operating system descriptionThis model is equipped with hydraulic and cable clutch control system, respectively used for 1.3L engine

1.5L engine.PROBLEM SYMPTOMS TABLEUse the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace these parts.Section 2 Clutch Cable Control MechanismComponentsSympto m Sus pe cte d Are a

1. Clutc h pe da l position (Too low)

2. Control mec ha nism (Stagna tion)

3. Clutc h pe da l fre e stroke (too la rge)

C lut c h doe s not r e le a s e 1. H ydr a ulic pipe line ( A ir in line )

1. Control system (Incorrect assembly & adjustment)

2. Clutc h asse mbly (Fa ulty) Clutch noisyC lut c h s lipsConnect The

Clutch Fork Clutch Cable

Assmbly

Adjusting NutCowl Baffle

Clutch and Brake

Pedal Assembly

Page 109 of 392

102(7) Install front wheel, wheel nut torque: 95~115N.m

(8) Make sure that the propeller shafts for 1.3L engine and 1.5L engine are not interchanged

at the time of replacement

(9) Check the ABS sensor signal, check and adjust the front wheel alignment if necessary.

Page 141 of 392

134On-vehicle inspection1. check the drive belt

Observe the drive belt for excessive wear and cordline wear. Replace the drive belt if necessary.

Hint: Cracks on the rib side of a belt are considered acceptable. If missing chunks from the

ribs are found on the drive belt, it should be replaced.

2. Bleed the power steering system

(1) Check the fluid level

(2) Jack up the front of the vehicle and make sure it is safe

(3) Rotate the steering wheel

a. With the engine off, turn the steering wheel from LH limit position to RH limit position several

times

(4) Release the jack and lower the vehicle

(5) Start the engine, run the engine at idle for a few minutes

(6) Turn the steering wheel to left or right limit position and keep it there for 2 - 3 seconds, then turn the

steering wheel to the opposite limit position and keep it there for 2 - 3 seconds. Repeat it several

times.

(7) Shut off the engine, check for foaming or emulsification in the reservoir. If there is foaming or

emulsification, bleed power steering system repeatedly

(8) Check the fluid level and for leakage

2. Check the fluid level

(1) Park the vehicle on a level surface

(2) With the engine stopped, check the fluid level in the reservoir. Add power steering fluid AT F

DEXRON if necessary.

Hint: the fluid level should be within the range of lowest level and highest level

(3) Check for foaming or emulsification, if there is, drain the power steering systemNormalAbnormal

Page 142 of 392

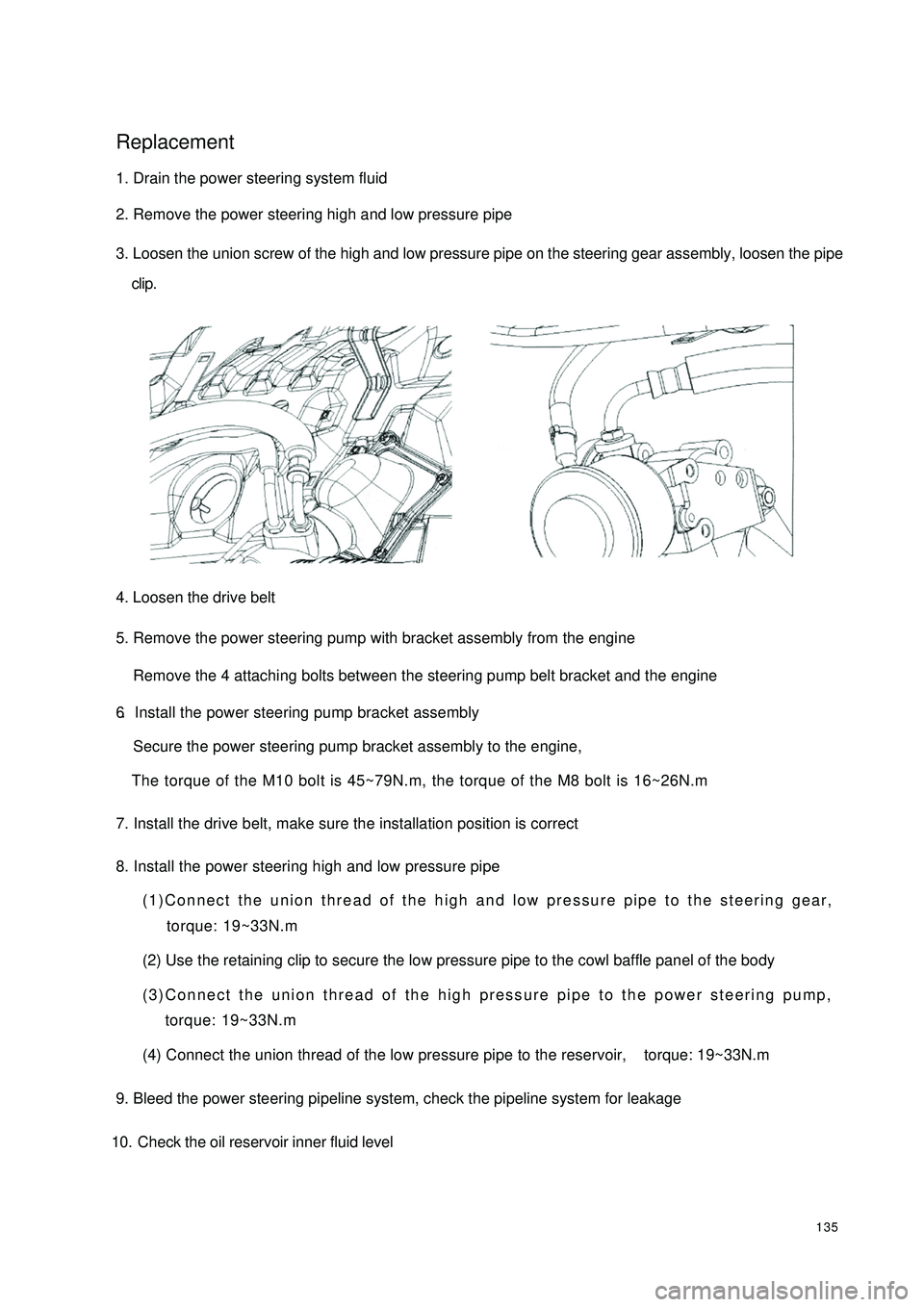

135Replacement1. Drain the power steering system fluid

2. Remove the power steering high and low pressure pipe

3. Loosen the union screw of the high and low pressure pipe on the steering gear assembly, loosen the pipe

clip.

4. Loosen the drive belt

5. Remove the power steering pump with bracket assembly from the engine

Remove the 4 attaching bolts between the steering pump belt bracket and the engine6.Install the power steering pump bracket assemblySecure the power steering pump bracket assembly to the engine,

The torque of the M10 bolt is 45~79N.m, the torque of the M8 bolt is 16~26N.m7. Install the drive belt, make sure the installation position is correct

8. Install the power steering high and low pressure pipe(1)Connect the union thread of the high and low pressure pipe to the steering gear,

torque: 19~33N.m

(2) Use the retaining clip to secure the low pressure pipe to the cowl baffle panel of the body

(3)Connect the union thread of the high pressure pipe to the power steering pump,

torque: 19~33N.m

(4) Connect the union thread of the low pressure pipe to the reservoir, torque: 19~33N.m

9. Bleed the power steering pipeline system, check the pipeline system for leakage

10. Check the oil reservoir inner fluid level