wheel torque GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 21 of 392

1421. Remove radiator assembly

22. Remove engine V-belt

23. Remove No. 1 V- belt (A/C compressor to crankshaft pulley)

24. Remove generator assembly

25. Remove A/C compressor

26. Remove compressor installing No. 1 bracket. Remove 4 bolts and compressor installing No.

1 bracket.

27. Remove starter assembly

28. Remove power steering pump V- belt

29. Detach power steering pump assembly

30. Remove power steering pump, adjust the bracket

31. Detach manual transaxle assembly (Separate automatic transaxle assembly)

32. Detach clutch cover panel assembly.

33. Detach clutch pressure plate assembly.

34. Detach flywheel sub-assembly.

35. Remove engine rear end cover.

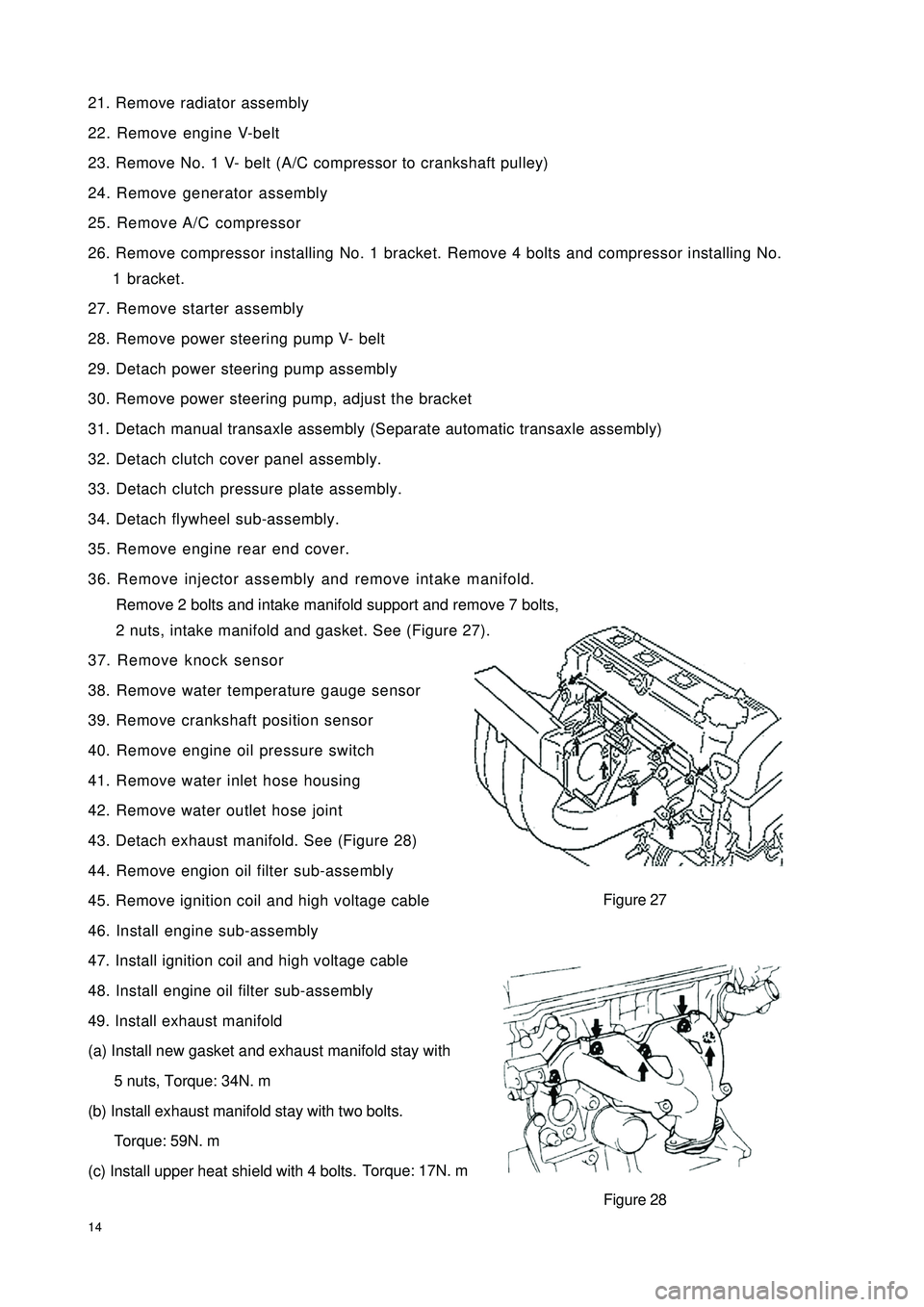

36. Remove injector assembly and remove intake manifold.

Remove 2 bolts and intake manifold support and remove 7 bolts,

2 nuts, intake manifold and gasket. See (Figure 27).

37. Remove knock sensor

38. Remove water temperature gauge sensor

39. Remove crankshaft position sensor

40. Remove engine oil pressure switch

41. Remove water inlet hose housing

42. Remove water outlet hose joint

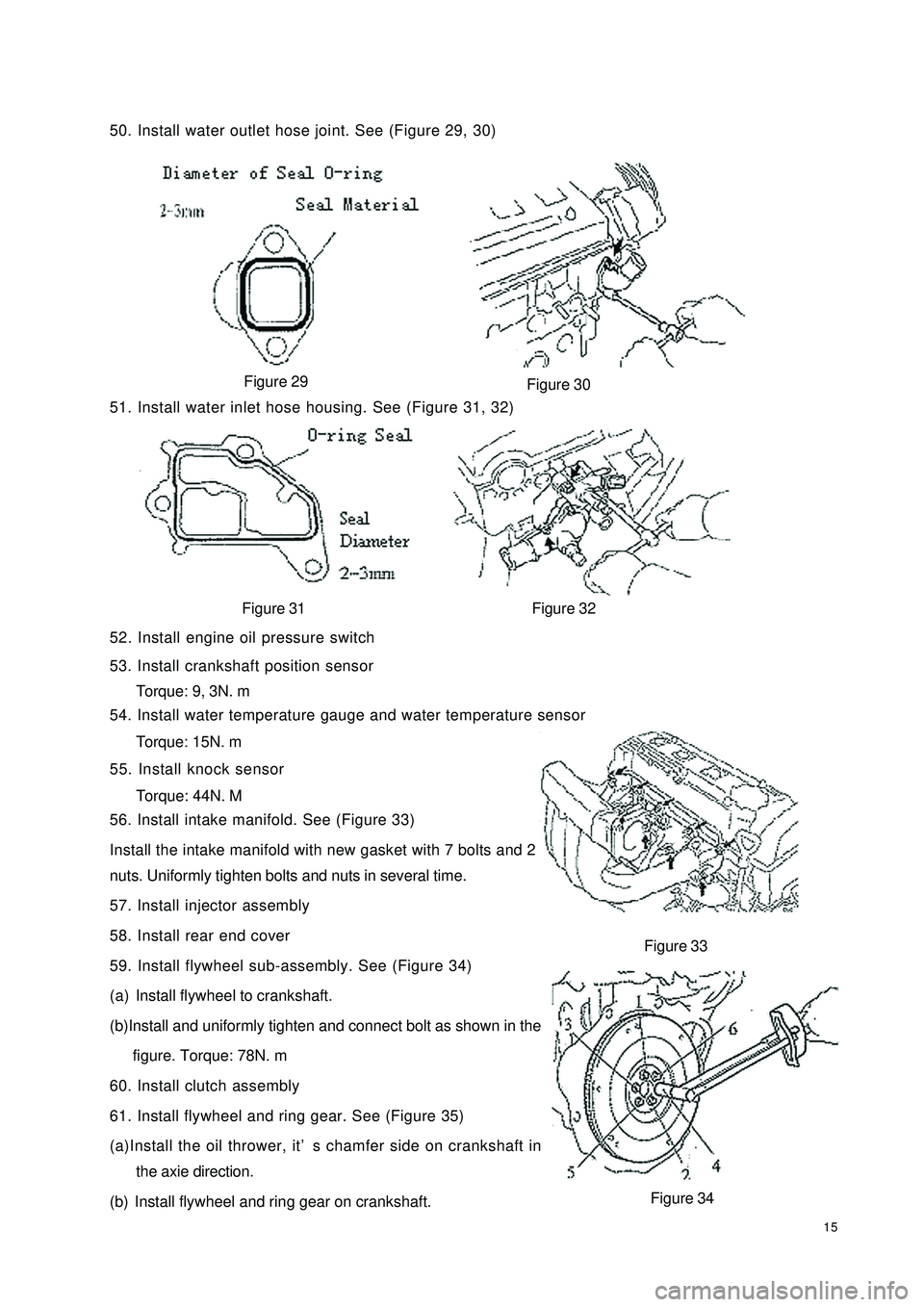

43. Detach exhaust manifold. See (Figure 28)

44. Remove engion oil filter sub-assembly

45. Remove ignition coil and high voltage cable

46. Install engine sub-assembly

47. Install ignition coil and high voltage cable

48. Install engine oil filter sub-assembly

49. Install exhaust manifold

(a) Install new gasket and exhaust manifold stay with

5 nuts, Torque: 34N. m

(b) Install exhaust manifold stay with two bolts.

Torque: 59N. m

(c) Install upper heat shield with 4 bolts.Torque: 17N. mFigure 27

Figure 28

Page 22 of 392

1550. Install water outlet hose joint. See (Figure 29, 30)

Figure 29

51. Install water inlet hose housing. See (Figure 31, 32)

Figure 31 Figure 32

52. Install engine oil pressure switch

53. Install crankshaft position sensor

Torque: 9, 3N. m

54. Install water temperature gauge and water temperature sensor

Torque: 15N. m

55. Install knock sensor

Torque: 44N. M

56. Install intake manifold. See (Figure 33)

Install the intake manifold with new gasket with 7 bolts and 2

nuts. Uniformly tighten bolts and nuts in several time.

57. Install injector assembly

58. Install rear end cover

59. Install flywheel sub-assembly. See (Figure 34)

(a) Install flywheel to crankshaft.

(b)Install and uniformly tighten and connect bolt as shown in the

figure. Torque: 78N. m

60. Install clutch assembly

61. Install flywheel and ring gear. See (Figure 35)

(a)Install the oil thrower, it’s chamfer side on crankshaft in

the axie direction.

(b) Install flywheel and ring gear on crankshaft.Figure 33

Figure 34 Figure 30

Page 23 of 392

16(c) Install and uniformly tighten connecting bolt in the sequence shown inthe figure.

Torque: 64N. m

62. Install manual transaxle assembly

63. Install starter assembly

64. Install power steering pump bracket

65. Install power steering pump adjusting bracket with 2 bolts.

66. Connect power steering pump assembly

67. Install engine assembly and transaxle

68. Connect left, right, front and rear lower suspension arm sub-assembly

69. Connect left and right tie rod ball stud pin assembly

70. Connect left, right and front vehicle speed sensor (with ABS)

71. Install left & right nuts on the front shaft hub

72. Install front exhaust pipe assembly

73. Connect steering shaft assembly and steering column hole cover. See (Figure 36)

74. Connect wire harness

75. Install belt adjusting bracket of A/C compressor

76. Connect A/C compressor

77. Install generator assembly

78. Install A/C compressor to crankshaft pulleyV-belt

79. Install generator belt

80. Install engine assembly with transaxle

81. Install radiator assembly

82. Install throttle body assembly

83. Install fuel delivery pipe sub-assembly

84. Install battery

85. Install air filter assembly with hose

86. Install front wheel

87. Fill engine oil

88. Fill coolant

89. Check engine oil for leakage

90. Check engine coolant for leakage

91. Check fuel for leakage

92. Check idle and ignition timing

93. Check CO/HC

94. Check and adjust front wheel alignment

95. Check ABS vehicle speed sensor signalFigure 35

Figure 36

Page 26 of 392

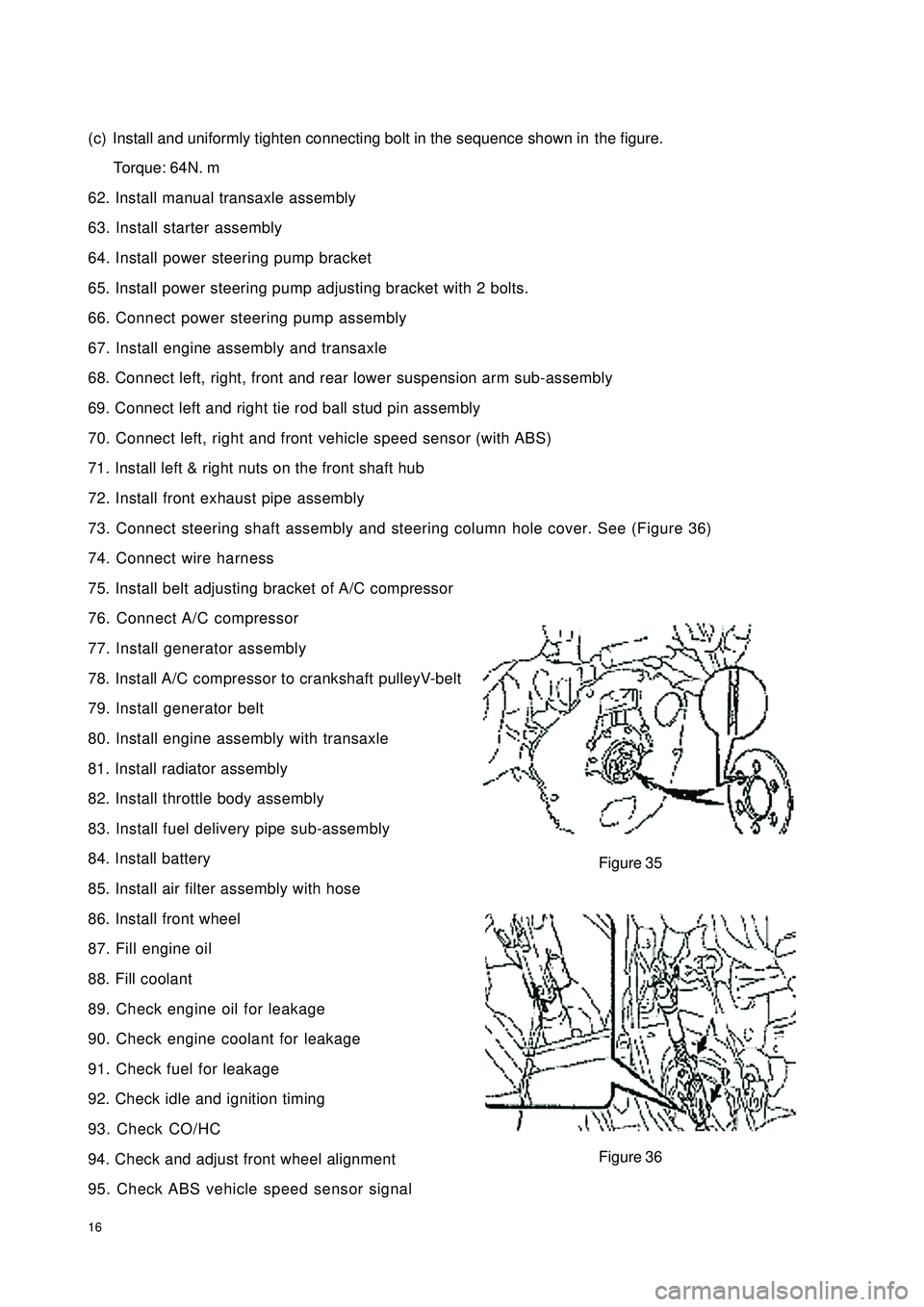

1920. Remove timing belt guide wheel

Hint:

(a) Mark on pulley and belt (in engine turning direction) if re-using timing belt (See Figure 42).

(b) Install bolt to the idler pulley. Move pulley to its far left and tighten it temperarily (See Figure 43).

21. Remove spark plug and gasket

Figure 42

22. Install spark plug and gasket

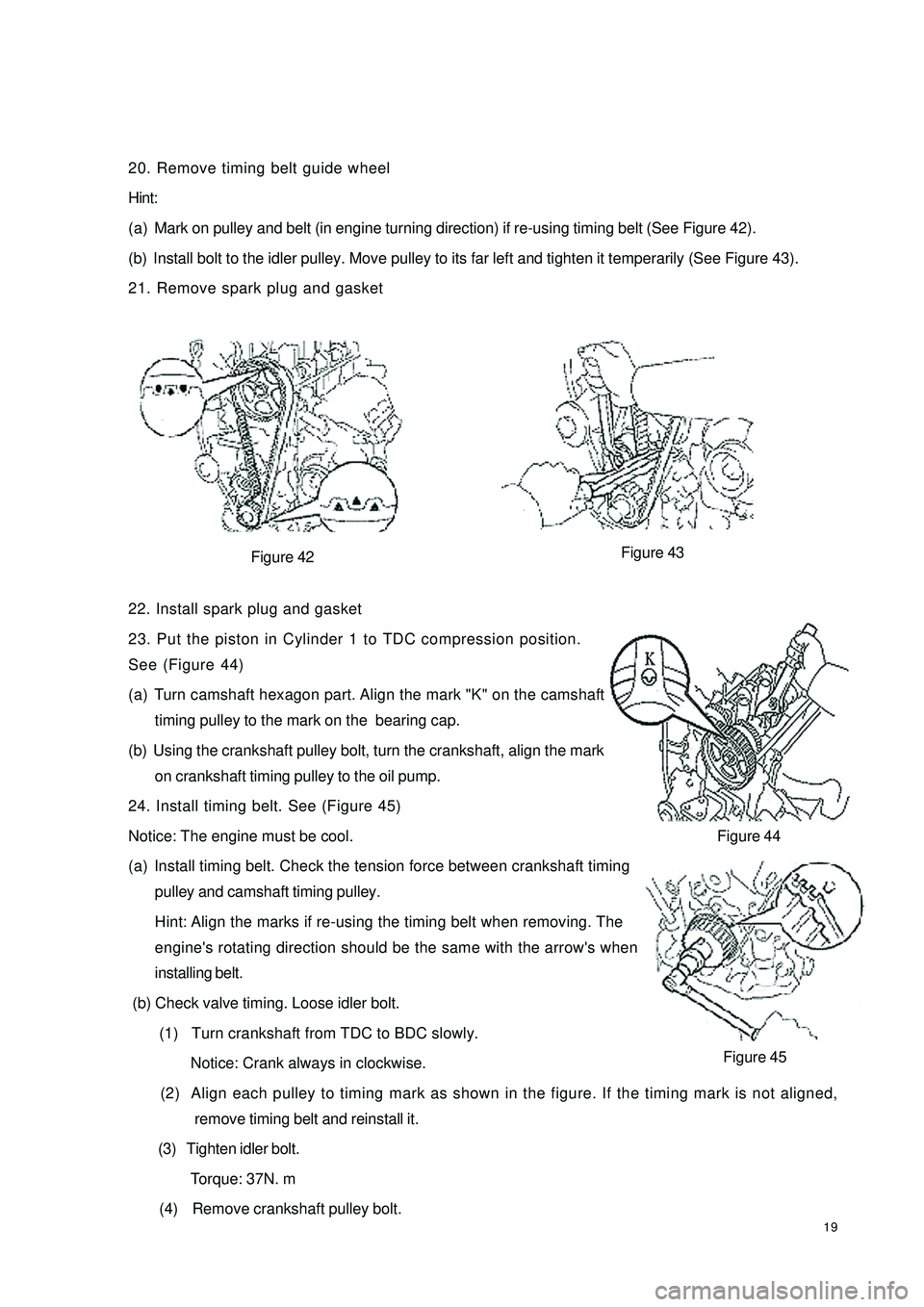

23. Put the piston in Cylinder 1 to TDC compression position.

See (Figure 44)

(a) Turn camshaft hexagon part. Align the mark "K" on the camshaft

timing pulley to the mark on the bearing cap.

(b) Using the crankshaft pulley bolt, turn the crankshaft, align the mark

on crankshaft timing pulley to the oil pump.

24. Install timing belt. See (Figure 45)

Notice: The engine must be cool.

(a) Install timing belt. Check the tension force between crankshaft timing

pulley and camshaft timing pulley.

Hint: Align the marks if re-using the timing belt when removing. The

engine's rotating direction should be the same with the arrow's when

installing belt.

(b) Check valve timing. Loose idler bolt.

(1) Turn crankshaft from TDC to BDC slowly.

Notice: Crank always in clockwise.

(2) Align each pulley to timing mark as shown in the figure. If the timing mark is not aligned,

remove timing belt and reinstall it.

(3) Tighten idler bolt.

Torque: 37N. m

(4) Remove crankshaft pulley bolt.Figure 44

Figure 45 Figure 43

Page 27 of 392

20(c) Check timing belt for deflection

Check the belt distorn as shown in the figure.

Belt deflection:

20N: 5~6mm

Re-adjust the idler if the deflection does not comply with the regulation.

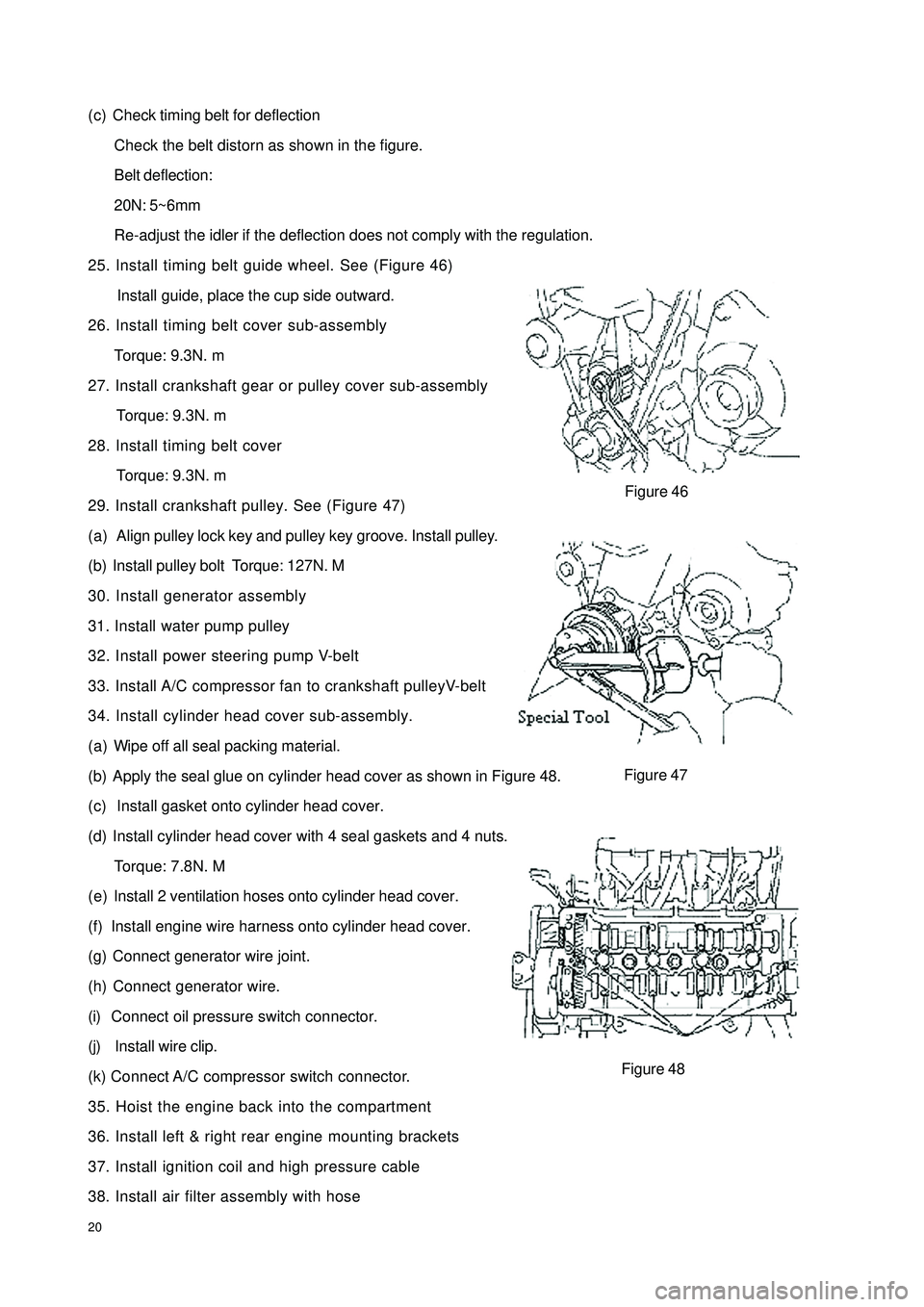

25. Install timing belt guide wheel. See (Figure 46)

Install guide, place the cup side outward.

26. Install timing belt cover sub-assembly

Torque: 9.3N. m

27. Install crankshaft gear or pulley cover sub-assembly

Torque: 9.3N. m

28. Install timing belt cover

Torque: 9.3N. m

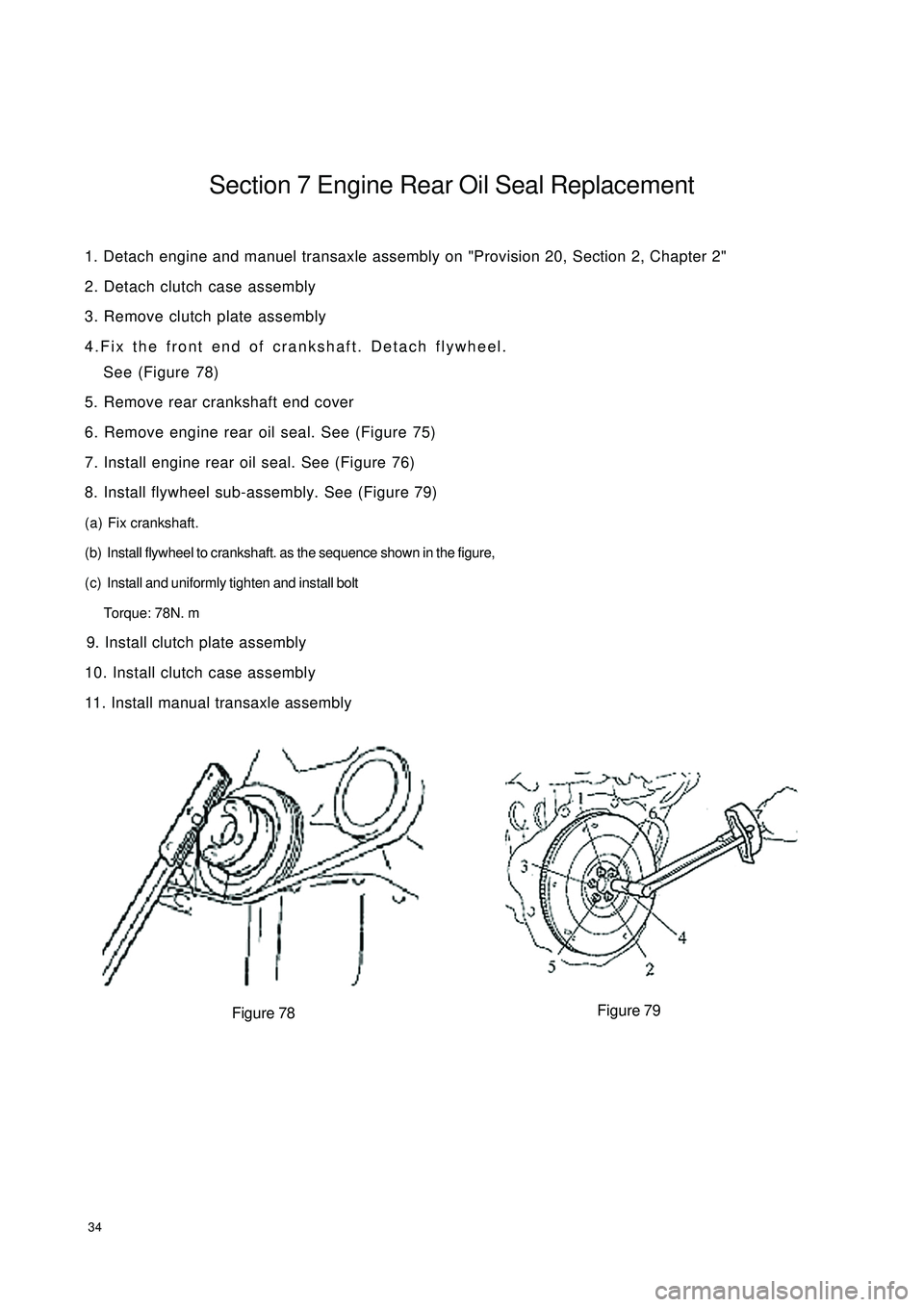

29. Install crankshaft pulley. See (Figure 47)

(a) Align pulley lock key and pulley key groove. Install pulley.

(b) Install pulley bolt Torque: 127N. M

30. Install generator assembly

31. Install water pump pulley

32. Install power steering pump V-belt

33. Install A/C compressor fan to crankshaft pulleyV-belt

34. Install cylinder head cover sub-assembly.

(a) Wipe off all seal packing material.

(b) Apply the seal glue on cylinder head cover as shown in Figure 48.

(c) Install gasket onto cylinder head cover.

(d) Install cylinder head cover with 4 seal gaskets and 4 nuts.

Torque: 7.8N. M

(e) Install 2 ventilation hoses onto cylinder head cover.

(f) Install engine wire harness onto cylinder head cover.

(g) Connect generator wire joint.

(h) Connect generator wire.

(i) Connect oil pressure switch connector.

(j) Install wire clip.

(k) Connect A/C compressor switch connector.

35. Hoist the engine back into the compartment

36. Install left & right rear engine mounting brackets

37. Install ignition coil and high pressure cable

38. Install air filter assembly with hoseFigure 48Figure 46

Figure 47

Page 41 of 392

34Section 7 Engine Rear Oil Seal Replacement1. Detach engine and manuel transaxle assembly on "Provision 20, Section 2, Chapter 2"

2. Detach clutch case assembly

3. Remove clutch plate assembly

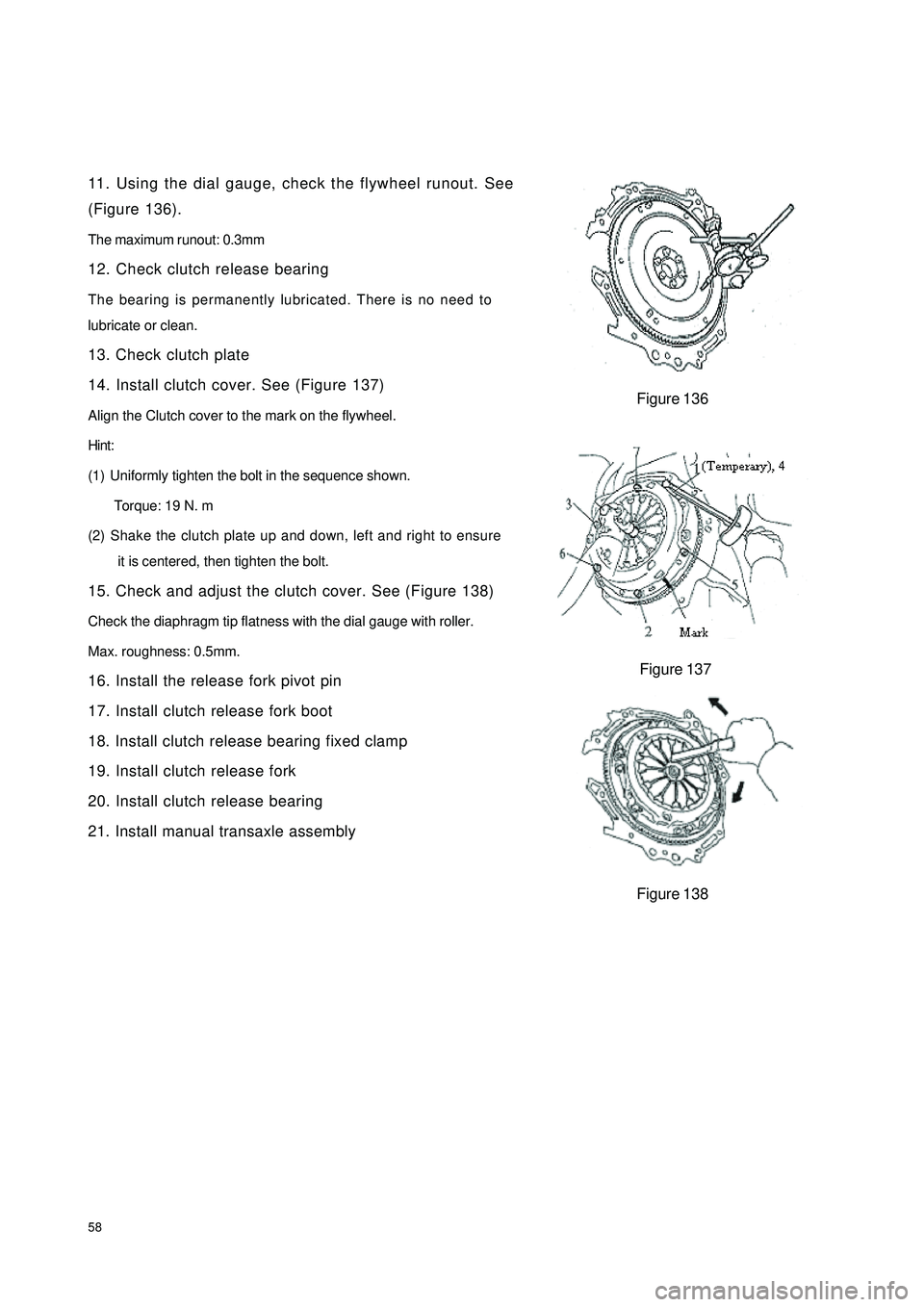

4.Fix the front end of crankshaft. Detach flywheel.

See (Figure 78)

5. Remove rear crankshaft end cover

6. Remove engine rear oil seal. See (Figure 75)

7. Install engine rear oil seal. See (Figure 76)

8. Install flywheel sub-assembly. See (Figure 79)

(a) Fix crankshaft.

(b) Install flywheel to crankshaft. as the sequence shown in the figure,

(c) Install and uniformly tighten and install bolt

Torque: 78N. m

9. Install clutch plate assembly

10. Install clutch case assembly

11. Install manual transaxle assembly

Figure 78Figure 79

Page 65 of 392

5811. Using the dial gauge, check the flywheel runout. See

(Figure 136).

The maximum runout: 0.3mm

12. Check clutch release bearing

The bearing is permanently lubricated. There is no need to

lubricate or clean.

13. Check clutch plate

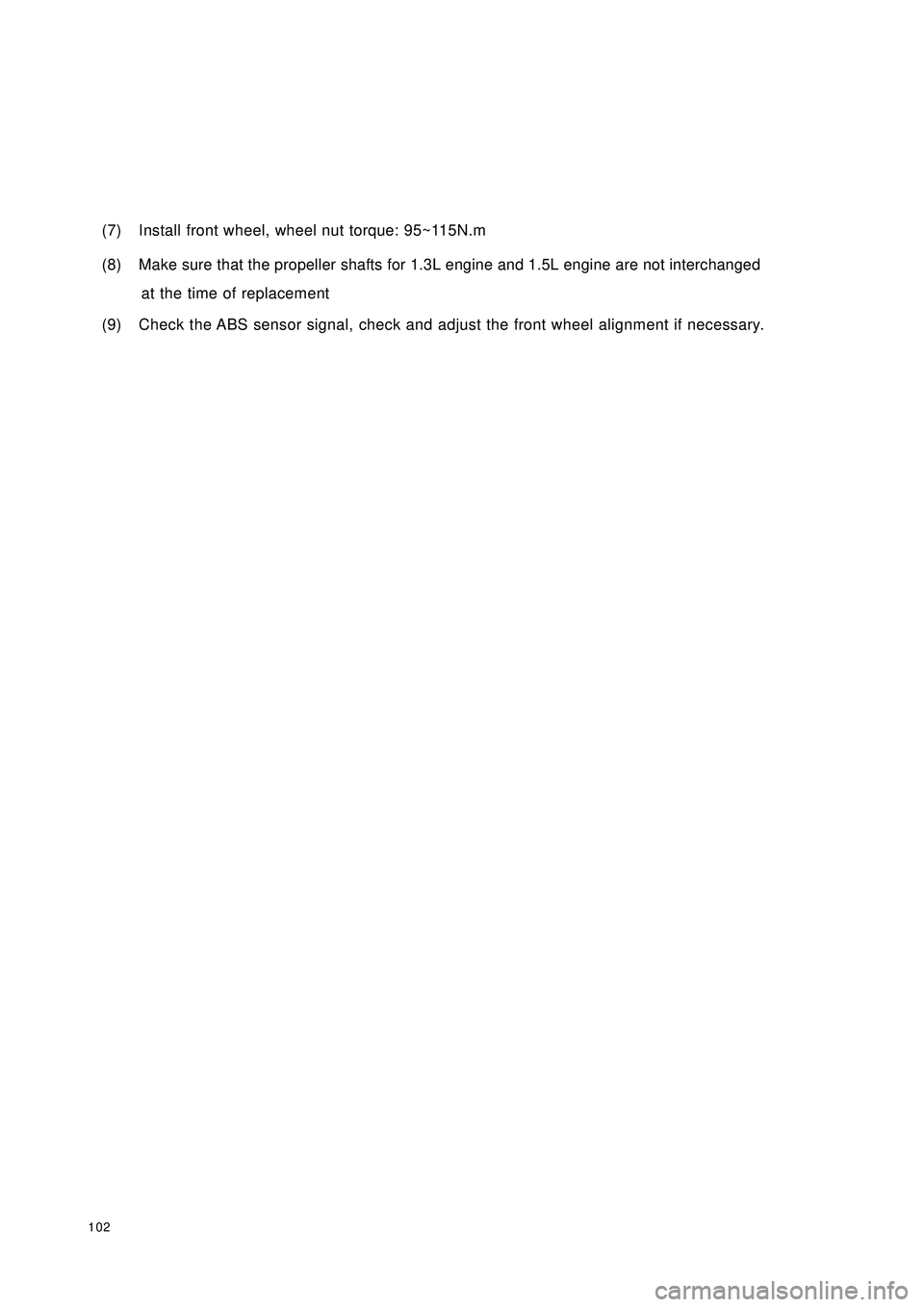

14. Install clutch cover. See (Figure 137)

Align the Clutch cover to the mark on the flywheel.

Hint:

(1) Uniformly tighten the bolt in the sequence shown.

Torque: 19 N. m

(2) Shake the clutch plate up and down, left and right to ensure

it is centered, then tighten the bolt.

15. Check and adjust the clutch cover. See (Figure 138)

Check the diaphragm tip flatness with the dial gauge with roller.

Max. roughness: 0.5mm.

16. Install the release fork pivot pin

17. Install clutch release fork boot

18. Install clutch release bearing fixed clamp

19. Install clutch release fork

20. Install clutch release bearing

21. Install manual transaxle assemblyFigure 136

Figure 137

Figure 138

Page 109 of 392

102(7) Install front wheel, wheel nut torque: 95~115N.m

(8) Make sure that the propeller shafts for 1.3L engine and 1.5L engine are not interchanged

at the time of replacement

(9) Check the ABS sensor signal, check and adjust the front wheel alignment if necessary.

Page 113 of 392

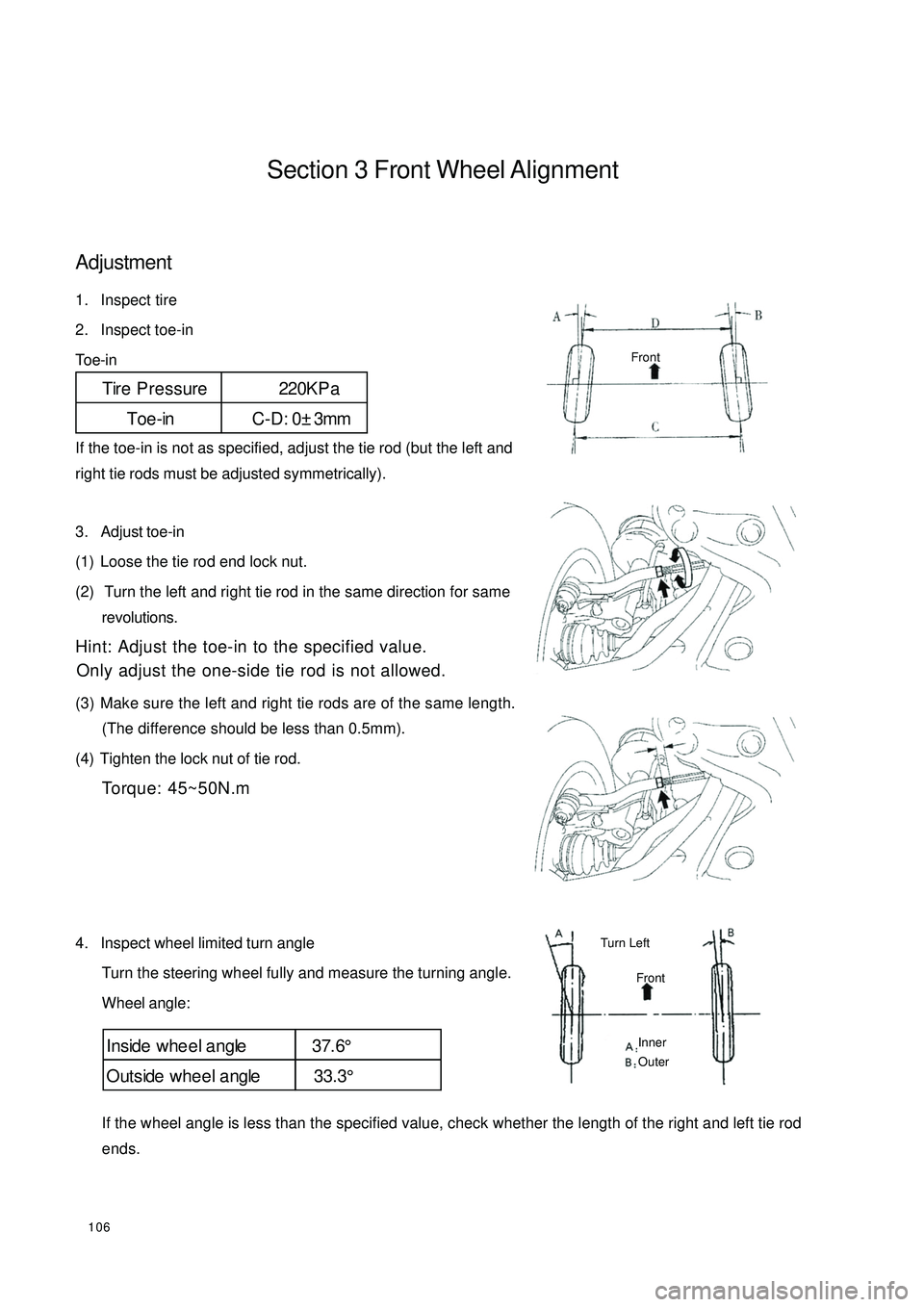

106Section 3 Front Wheel AlignmentAdjustment1. Inspect tire

2. Inspect toe-in

Toe-in

If the toe-in is not as specified, adjust the tie rod (but the left and

right tie rods must be adjusted symmetrically).

3. Adjust toe-in

(1) Loose the tie rod end lock nut.

(2) Turn the left and right tie rod in the same direction for same

revolutions.

Hint: Adjust the toe-in to the specified value.

Only adjust the one-side tie rod is not allowed.

(3) Make sure the left and right tie rods are of the same length.

(The difference should be less than 0.5mm).

(4) Tighten the lock nut of tie rod.

Torque: 45~50N.m

4. Inspect wheel limited turn angle

Turn the steering wheel fully and measure the turning angle.

Wheel angle:

If the wheel angle is less than the specified value, check whether the length of the right and left tie rod

ends.Tire Pressure 220KP a

Toe-in C-D: 0±3mmInside whe e l a ngle 37.6°

Outside whee l a ngle 33.3°FrontFrontTurn Left Inner

Outer

Page 119 of 392

1123. Remove lower swing arm front support frame

Remove the 4 bolts connecting the lower swing arm front support frame and vehicle body.

4. Disassemble lower swing arm assembly

Disassembly of lower swing arm assembly is in the reverse order of the assembly.

Notice: Do not tighten type 1 hexagon nut

5. Install lower swing arm front support frame

Attach the lower swing arm front support frame to the vehicle body with bolts .

Torque: 80~90N.m

6. Install lower swing arm assembly

(1) Install the bolts and nuts connecting the lower swing arm assembly and lower swing arm front support

frame.

Notice: Do not tighten the bolts

(2) Attach the left lower swing arm assembly ball stud pin to the steering knuckle with bolts and nuts.

Torque: 80~90N.m

(3) Install the attaching bolt between the lower swing arm rear spring joint cover and the body.

Torque: 80~90N.m

7. Set nut

(1) Lower the vehicle and center the front wheel.

Be careful of the security

(2) Tighten the bolts connecting lower swing arm assembly and lower swing arm front support frame

Torque: 90~100N.m

(3) Tighten the set nuts on the lower swing arm assembly rear spring joint

Torque: 90~100N.m