wheel torque GEELY FC 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 142 of 419

Left rear shaft hub boltChange1. Disassemble rear wheels

2. Disassemble left rear brake caliper assembleDisassemble two bolts and take down brake caliper.3. Disassemble left rear brake assembly [64000137]

4. Disassemble left rear shaft hub bolt(a) Screw the shaft to the position in figure, then use special

tool to disassemble shaft hub bolt.

Note: shaft hub bolt should be screwed to the position

in figure, or you could not change shaft hub bolt.

(b) Use special tool and screw driver to disassemble shaft hub

bolt.5. Assemble left rear shaft hub bolt(a) Liking that shown in figure, assemble new gasket and screw

cap on new shaft hub bolt.

(b) Use screw driver to fix and lock screw cap to make the bolt

enter hole.6. Assemble left rear brake assembly [64000137]

7. Assemble left rear brake branch pump assemblyUse two bolts to assemble rear brake branch pump assembly.

Torque: 46 ± 5 N

⋅ ⋅⋅ ⋅

⋅m8. Assemble rear wheelsTorque: 103 ± 10 N

⋅ ⋅⋅ ⋅

⋅mDrive shaft--Left rear shaft hub bolt131

Page 146 of 419

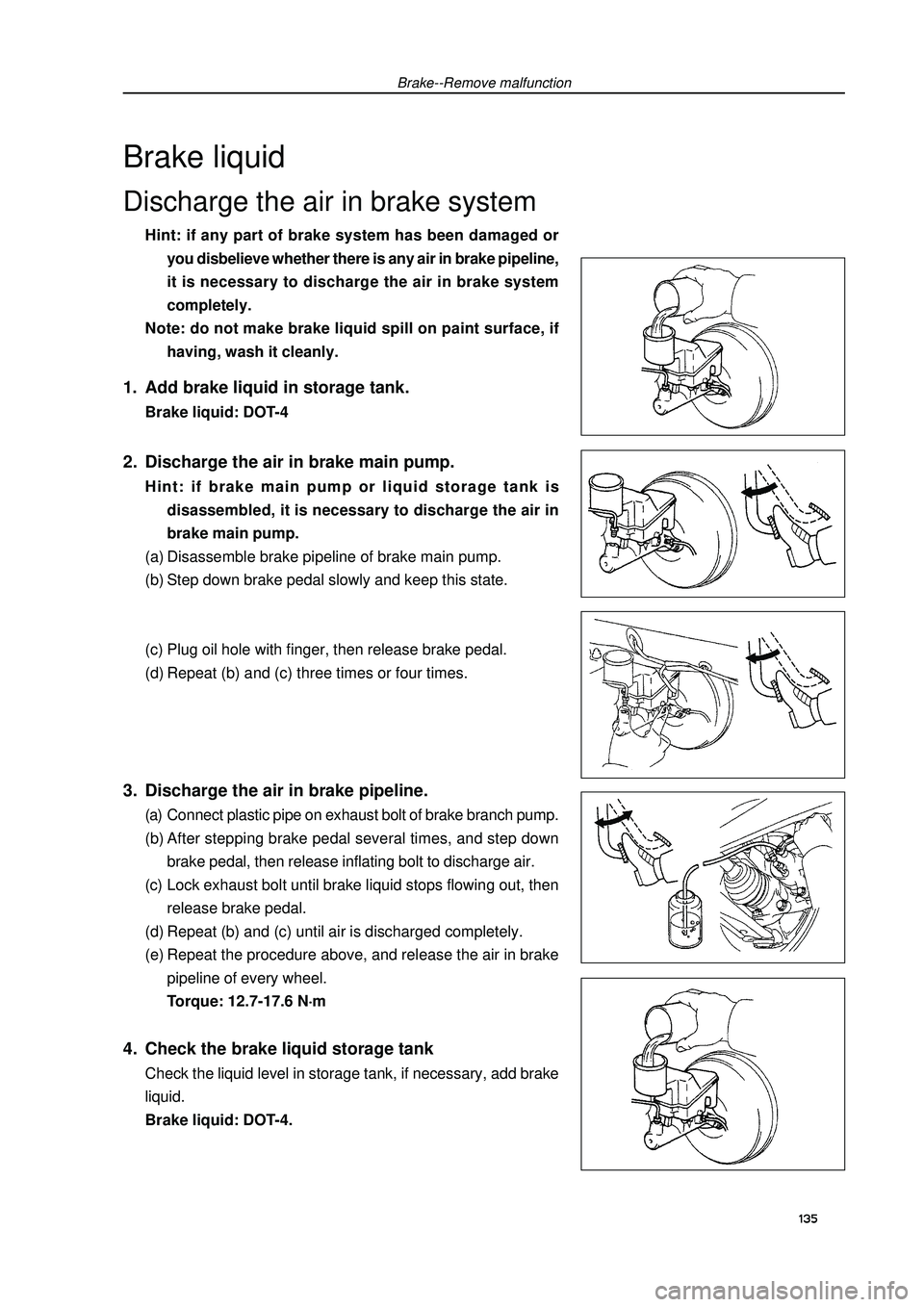

Brake--Remove malfunction1. Add brake liquid in storage tank.Brake liquid: DOT-42. Discharge the air in brake main pump.Hint: if brake main pump or liquid storage tank is

disassembled, it is necessary to discharge the air in

brake main pump.

(a) Disassemble brake pipeline of brake main pump.

(b) Step down brake pedal slowly and keep this state.

(c) Plug oil hole with finger, then release brake pedal.

(d) Repeat (b) and (c) three times or four times.3. Discharge the air in brake pipeline.(a) Connect plastic pipe on exhaust bolt of brake branch pump.

(b) After stepping brake pedal several times, and step down

brake pedal, then release inflating bolt to discharge air.

(c) Lock exhaust bolt until brake liquid stops flowing out, then

release brake pedal.

(d) Repeat (b) and (c) until air is discharged completely.

(e) Repeat the procedure above, and release the air in brake

pipeline of every wheel.

Torque: 12.7-17.6 N

⋅ ⋅⋅ ⋅

⋅m4. Check the brake liquid storage tankCheck the liquid level in storage tank, if necessary, add brake

liquid.

Brake liquid: DOT-4.Brake liquidDischarge the air in brake systemHint: if any part of brake system has been damaged or

you disbelieve whether there is any air in brake pipeline,

it is necessary to discharge the air in brake system

completely.

Note: do not make brake liquid spill on paint surface, if

having, wash it cleanly.135

Page 150 of 419

5. Disconnect the U-shaped joint of brake main pump

lever(a) Release fixing screw cap of lever U-shaped joint.

(b) Disassemble locking pin of U-shaped joint and lever pin of

brake main pump.6. Disassemble left front wheel

7. Disassemble vacuum booster(a) Use special tool and wrench to disassemble brake hose of

left front wheel.

(b) Disassemble the bolts, two screw caps and activated car-

bon canister bracket.

(c) Disassemble vacuum hose on vacuum booster.

(d) Disassemble four screw caps and U-shaped joint.

(e) Take out vacuum booster and gasket.8. Assemble vacuum booster with brake pump assem-

bly [64000164](a) Assemble U-shaped joint on booster lever.

(b) Assemble new gasket and vacuum booster with four nuts.

Torque: 13 N

⋅ ⋅⋅ ⋅

⋅m

(c) Connect vacuum hose to vacuum booster.

(d) Use the bolts and nuts to assemble carbon canister bracket.

Torque: 5.4 N

⋅ ⋅⋅ ⋅

⋅m

(e) Use special tool and wrench to connect brake hose of left

front wheel.

Torque: 15

± ±± ±

± 2 N

⋅ ⋅⋅ ⋅

⋅m9. Assemble left front wheelTorque: 103

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅mBrake--Vacuum booster assembly139

Page 154 of 419

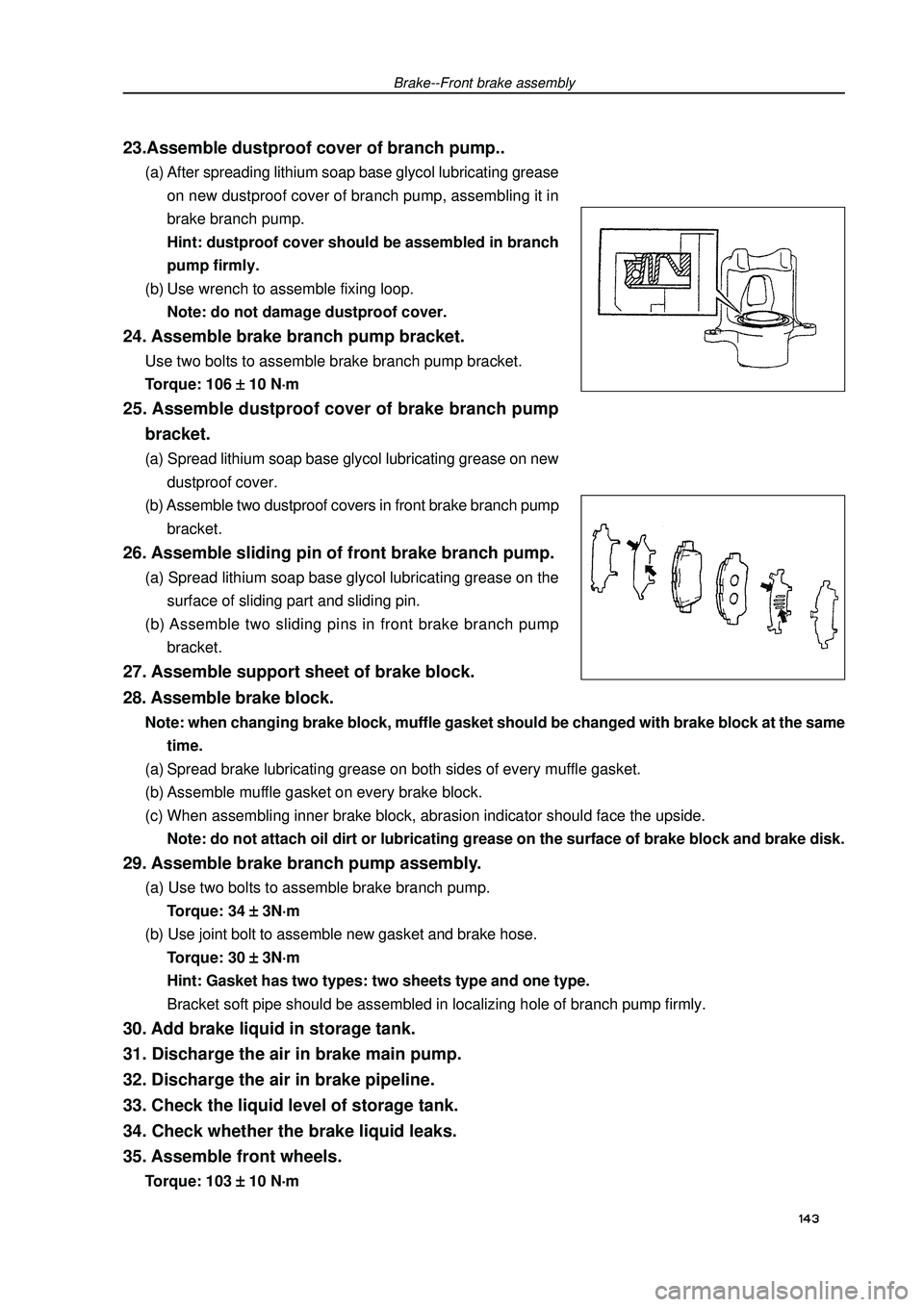

Brake--Front brake assembly23.Assemble dustproof cover of branch pump..(a) After spreading lithium soap base glycol lubricating grease

on new dustproof cover of branch pump, assembling it in

brake branch pump.

Hint: dustproof cover should be assembled in branch

pump firmly.

(b) Use wrench to assemble fixing loop.

Note: do not damage dustproof cover.24. Assemble brake branch pump bracket.Use two bolts to assemble brake branch pump bracket.

Torque: 106

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅m25. Assemble dustproof cover of brake branch pump

bracket.(a) Spread lithium soap base glycol lubricating grease on new

dustproof cover.

(b) Assemble two dustproof covers in front brake branch pump

bracket.26. Assemble sliding pin of front brake branch pump.(a) Spread lithium soap base glycol lubricating grease on the

surface of sliding part and sliding pin.

(b) Assemble two sliding pins in front brake branch pump

bracket.27. Assemble support sheet of brake block.143 28. Assemble brake block.Note: when changing brake block, muffle gasket should be changed with brake block at the same

time.

(a) Spread brake lubricating grease on both sides of every muffle gasket.

(b) Assemble muffle gasket on every brake block.

(c) When assembling inner brake block, abrasion indicator should face the upside.

Note: do not attach oil dirt or lubricating grease on the surface of brake block and brake disk.29. Assemble brake branch pump assembly.(a) Use two bolts to assemble brake branch pump.

Torque: 34

± ±± ±

± 3N

⋅ ⋅⋅ ⋅

⋅m

(b) Use joint bolt to assemble new gasket and brake hose.

Torque: 30

± ±± ±

± 3N

⋅ ⋅⋅ ⋅

⋅m

Hint: Gasket has two types: two sheets type and one type.

Bracket soft pipe should be assembled in localizing hole of branch pump firmly.30. Add brake liquid in storage tank.

31. Discharge the air in brake main pump.

32. Discharge the air in brake pipeline.

33. Check the liquid level of storage tank.

34. Check whether the brake liquid leaks.

35. Assemble front wheels.Torque: 103

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅m

Page 158 of 419

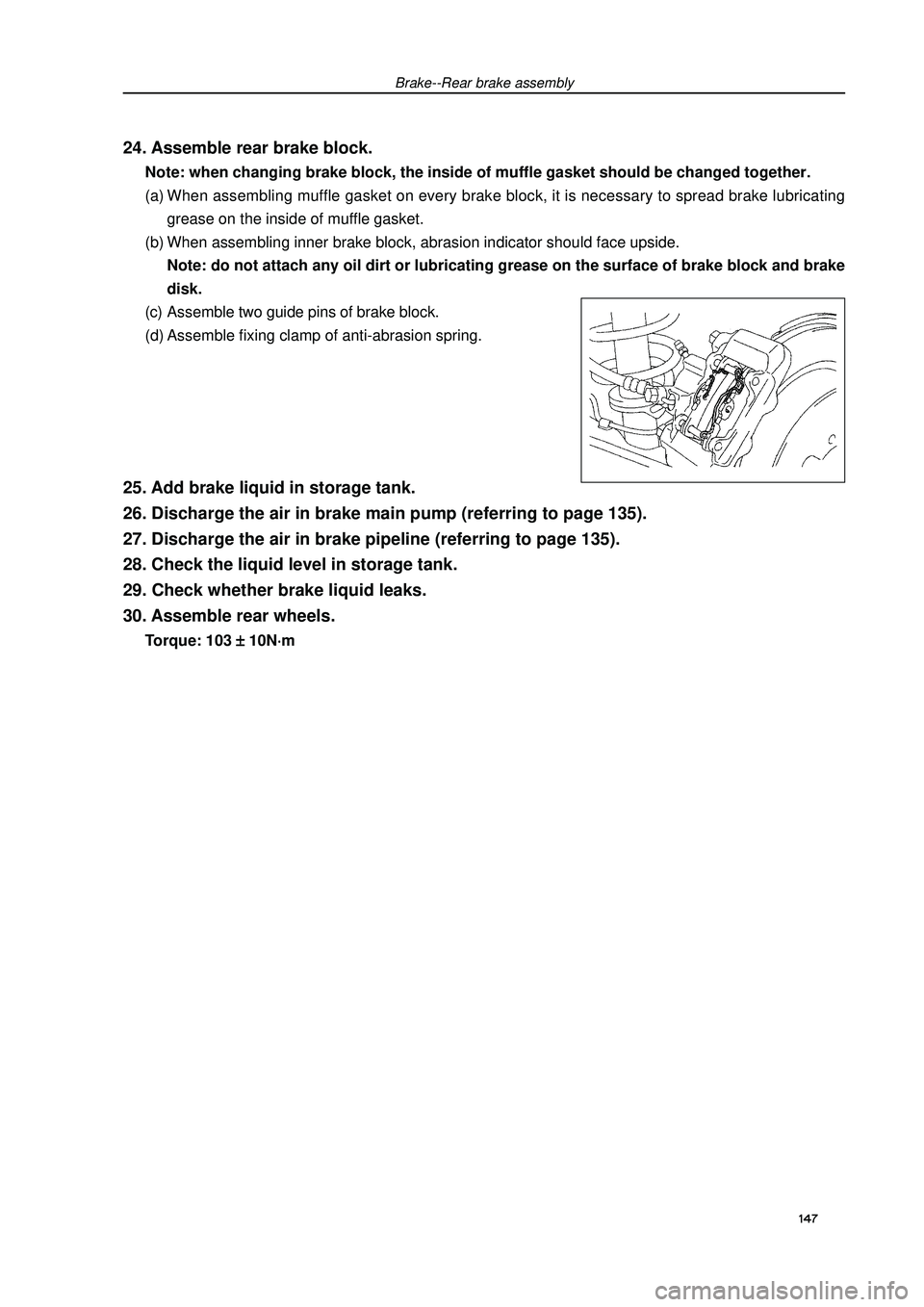

Brake--Rear brake assembly24. Assemble rear brake block.Note: when changing brake block, the inside of muffle gasket should be changed together.

(a) When assembling muffle gasket on every brake block, it is necessary to spread brake lubricating

grease on the inside of muffle gasket.

(b) When assembling inner brake block, abrasion indicator should face upside.

Note: do not attach any oil dirt or lubricating grease on the surface of brake block and brake

disk.

(c) Assemble two guide pins of brake block.

(d) Assemble fixing clamp of anti-abrasion spring.25. Add brake liquid in storage tank.

26. Discharge the air in brake main pump (referring to page 135).

27. Discharge the air in brake pipeline (referring to page 135).

28. Check the liquid level in storage tank.

29. Check whether brake liquid leaks.

30. Assemble rear wheels.Torque: 103

± ±± ±

± 10N

⋅ ⋅⋅ ⋅

⋅m147

Page 160 of 419

Brake--Hydraulic pressure control unit3. Disassemble gasket of right wheel wing.

4. Disassemble hydraulic control unit and bracket.(a) Disassemble the joint and bolt.

(b) Turn the locking bolt of joint of hydraulic control unit, and

disassemble the joint.

(c) Use special tool to disassemble the brake oil pipe on hy-

draulic control unit.

(d) Use label to mark the name of every oil pipe, and tie it on

oil pipe.

(e) Disassemble screw caps, two bolts and hydraulic control

unit and bracket.5. Disassemble hydraulic control unit assembly.Disassemble three bolts and hydraulic control unit from the bracket.6. Assemble hydraulic control unit assembly.Assemble three bolts and hydraulic control unit on the bracket with three bolts.

Torque: 4.7 N

⋅ ⋅⋅ ⋅

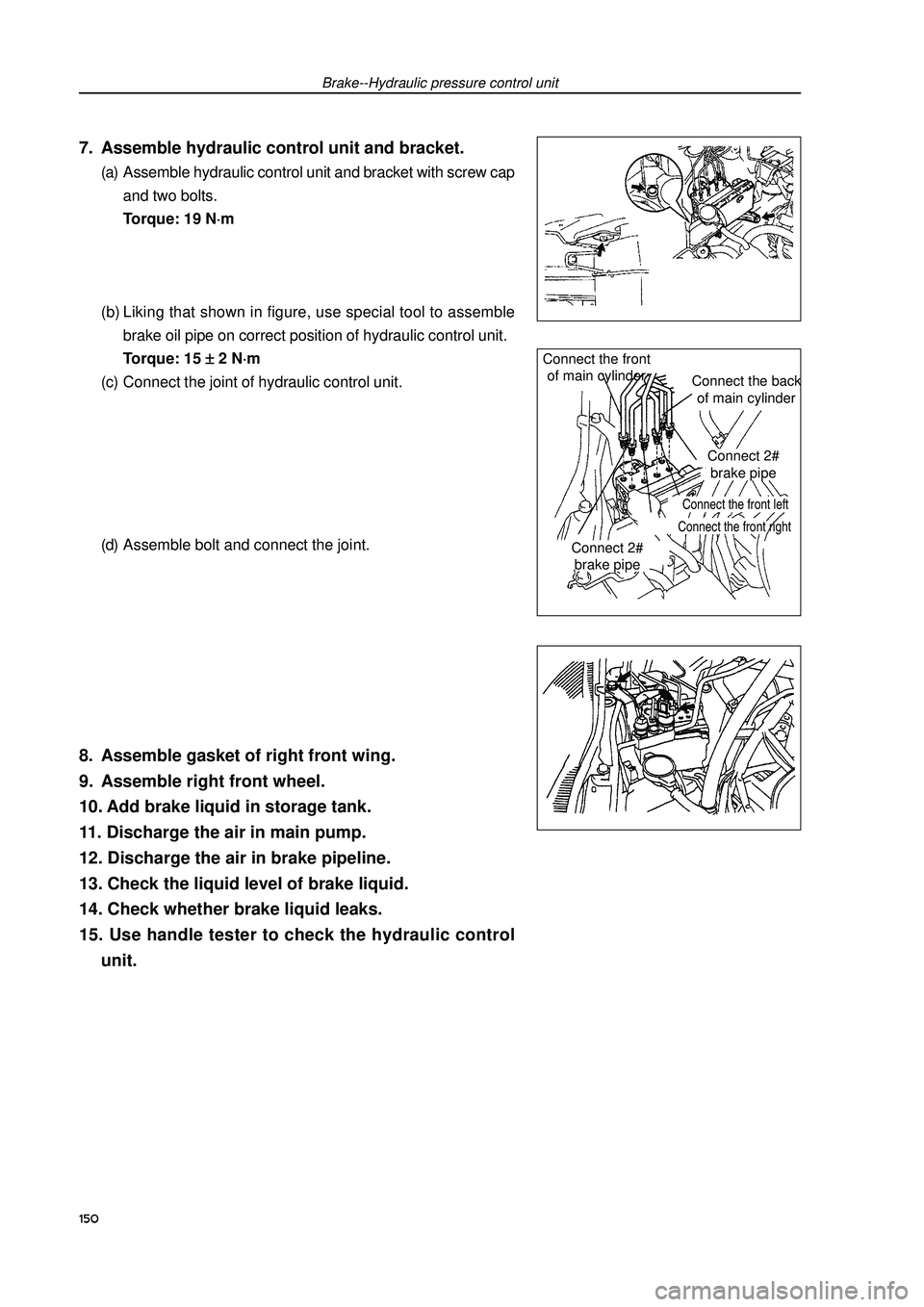

⋅m149Connect the front

of main cylinder

Connect the back

of main cylinder

Connect 2#

brake pipe

Connect the front left

Connect 2#

brake pipeConnect the front right

Page 161 of 419

Brake--Hydraulic pressure control unit7. Assemble hydraulic control unit and bracket.(a) Assemble hydraulic control unit and bracket with screw cap

and two bolts.

Torque: 19 N

⋅ ⋅⋅ ⋅

⋅m

(b) Liking that shown in figure, use special tool to assemble

brake oil pipe on correct position of hydraulic control unit.

Torque: 15

± ±± ±

± 2 N

⋅ ⋅⋅ ⋅

⋅m

(c) Connect the joint of hydraulic control unit.

(d) Assemble bolt and connect the joint.8. Assemble gasket of right front wing.

9. Assemble right front wheel.

10. Add brake liquid in storage tank.

11. Discharge the air in main pump.

12. Discharge the air in brake pipeline.

13. Check the liquid level of brake liquid.

14. Check whether brake liquid leaks.

15. Use handle tester to check the hydraulic control

unit.150Connect the front

of main cylinder

Connect the back

of main cylinder

Connect 2#

brake pipe

Connect the front left

Connect 2#

brake pipeConnect the front right

Page 162 of 419

Brake--Speed sensor of front wheelSpeed sensor of front wheelChangeHint: the process for changing right side is same as the

left side.1. Disassemble front wheels.

2. Disassemble gasket of left front wing.

3. Disassemble speed sensor of left front wheel.(a) Disassemble resinous clamp and speed sensor wiring har-

ness from fixing clamp of automobile body.

(b) Disassemble the sensor joint.

(c) Disassemble two bolts of fixing clamp of sensor wiring har-

ness from automobile body and absorber.

(d) Disassemble bolt and left front sensor.

Note: do not attach any sundries on top of sensor.4. Assemble speed sensor of left front wheel.(a) Use bolt to assemble left front sensor.

Torque: 8.0 N

⋅ ⋅⋅ ⋅

⋅m

Note: do not attach any sundries on top of sensor.

(b) Use two bolts to assemble fixing clamp of sensor wiring

harness on automobile body and absorber.

Bolt A: 9.0 N

⋅ ⋅⋅ ⋅

⋅m

Bolt B: 29 N

⋅ ⋅⋅ ⋅

⋅m

(c) Connect the joint of speed sensor.

(d) Connect resinous clamp and speed sensor wiring harness

on automobile body and fixing clamp.5. Assemble gasket of left front wheel wing.

6. Assemble front wheels.Torque: 103

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅m7. Check the signal of ABS speed sensor.151

Page 164 of 419

Brake--Speed sensor of rear wheels153(c) Use special tool and press to assemble speed sensor of

rear wheels to rear shaft hub.

Note:�zDo not use hammer knock directly in speed sensor

of rear wheels.�zInsure no sundries are attached on the supervising

part of speed sensor of rear wheels�zPress speed sensor of rear wheels straightly and

slowly.8. Assemble left rear shaft hub and bearing assembly

(referring to page 129).

9. Assemble brake disk.

10. Assemble left rear brake branch pump.

11. Assemble wiring harness of speed sensor of rear

wheels.

12. Assemble rear wheels.Torque: 103

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅m13. Check and adjust wheel alignment.

14. Check the signal of ABS speed sensor.Special

tool

Page 165 of 419

Parking brakeParking brake systemMalfunction phenomenon tableUse following table to find the reason of malfunction, the number in table indicates the preferred se-

quence of possible reason. Please check each part by sequence, if necessary, change this part.Parking brake--Parking brake systemAdjustment1. Disassemble rear wheels

2. Adjust the clearance of parking brake shoe

3. Assemble rear wheelsTorque: 103

± ±± ±

± 10 N

⋅ ⋅⋅ ⋅

⋅m4. Check the travel of parking brake handle.Pull up the parking brake handle and calculate the sound num-

ber of handle.

When parking brake handle locates 196N: 6-9 sounds.5. Adjust the travel of parking brake handle(a) Disassemble upper trim board of central box.

(b) Disassemble central box.

(c) Release locking screw cap, then rotate adjusting screw cap

until handle travel accords with the specification.

(d) Tighten locking screw cap.

Torque: 5.0 N

⋅ ⋅⋅ ⋅

⋅m

(e) Assemble central box.

(f) Assemble trim board on central box.Malfunction phenomenon Possible malfunction part Reference page

1. Travel of parking brake handle (adjusted badly). 154

2. Pull cable of parking brake (attached).156, 158

Brake lag 3. Clearance of parking brake shoe (adjusted badly). 161

4. Friction plate of parking brake shoe (damaged or distorted). 161

5. Tension or return spring (damaged). 161Lock the screw cap

Adjust the

screw cap154