service GEELY MK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 213 of 416

Chapter 4 Light SystemSection 1 Light System IntroductionI. Composition Light system comprises external illumination and signal system and internal illumination system.

The function of the external illumination and signal system is to illuminate the road ahead and send signals

to other vehicles.

The internal illumination system provides internal illumination for driver and passengers.II. Precaution for service1. Precaution when repairing electrical equipments

Disconnect the battery ground cable.

2. Precaution when replacing a headlamp bulb

(1) Before replacing a halogen bulb, turn the headlamp OFF to make it cool.

(2) When installing a new halogen bulb, do not touch the glass part of the bulb with bare hands.

(3) If there is oil stain on the surface of halogen bulb (headlamp and front fog lamp) when the lamps are

turned ON, its service life will be shortened.

(4) Halogen bulbs (headlamp and front fog lamp) have pressurized gas inside and require special handling.

They can explode if dropped to ground. The glass fragments will splash up.

(5) When replacing, make sure to use the bulbs with the same power, same model.

(6) After the bulb is installed, make the lamp holder tight.III. Bulb specificationsRemark: All bulbs are made by Philips Corp..Light System-

Light System Introduction5-26Name Specifications

Headlamp (High beam and Low beam) H1 12V 55W

Turn signal lamp PY21W 12V 21W

Position lamp W5W 12V 5W

Front fog lamp H3 12V 55W

Rear combination lamp (Turn signal lamp) PY21W 12V 21W

Rear combination lamp (Brake / Position lamp) P21/5W 12V 21/5W

Rear combination lamp (Rear fog lamp) P21W 12V 21W

Rear combination lamp (Back-up lamp) P21W 12V 21W

Interior lamp (dome lamp) R5W 12V 5W

Rear row reading lamp C5W 12V 5W

Side turn signal lamp W5W 12V 5W

High mounted stop lamp (incl. rear trunk lamp) W5W 12V 5W

License plate lamp W5W 12V 5W

Door courtesy lamp W5W 12V 5W

Page 239 of 416

Section 4 Audio System ReplacementI. Notice on operation Please explain to the customer that the AM/FM broadcast channel information will be cleared when removing

the battery negative terminal cable. Record the channel information before removing the negative terminal cable

if necessary. Reset after connecting the negative terminal cable.

All cassette tapes and CDs must be taken out before radio removal and installation.

If the cassette tapes and CDs can not be taken out due to radio fault. Do not take them out by force. Drive the

vehicle to Service Station.

Make sure the grounding bolts are tightened before antenna removal and installation.

There will be noise when receiving electric wave if the grounding bolts are not tightened.

Don't touch the speaker cone.II. Radio assembly1. Remove middle instrument board (see internal decorations)

2. Remove radio with bracket assembly

a. Remove four screws

b. Disconnect connector

3. Remove left bracket

a. Remove four screws

4. Remove right bracket

a. Remove four screws

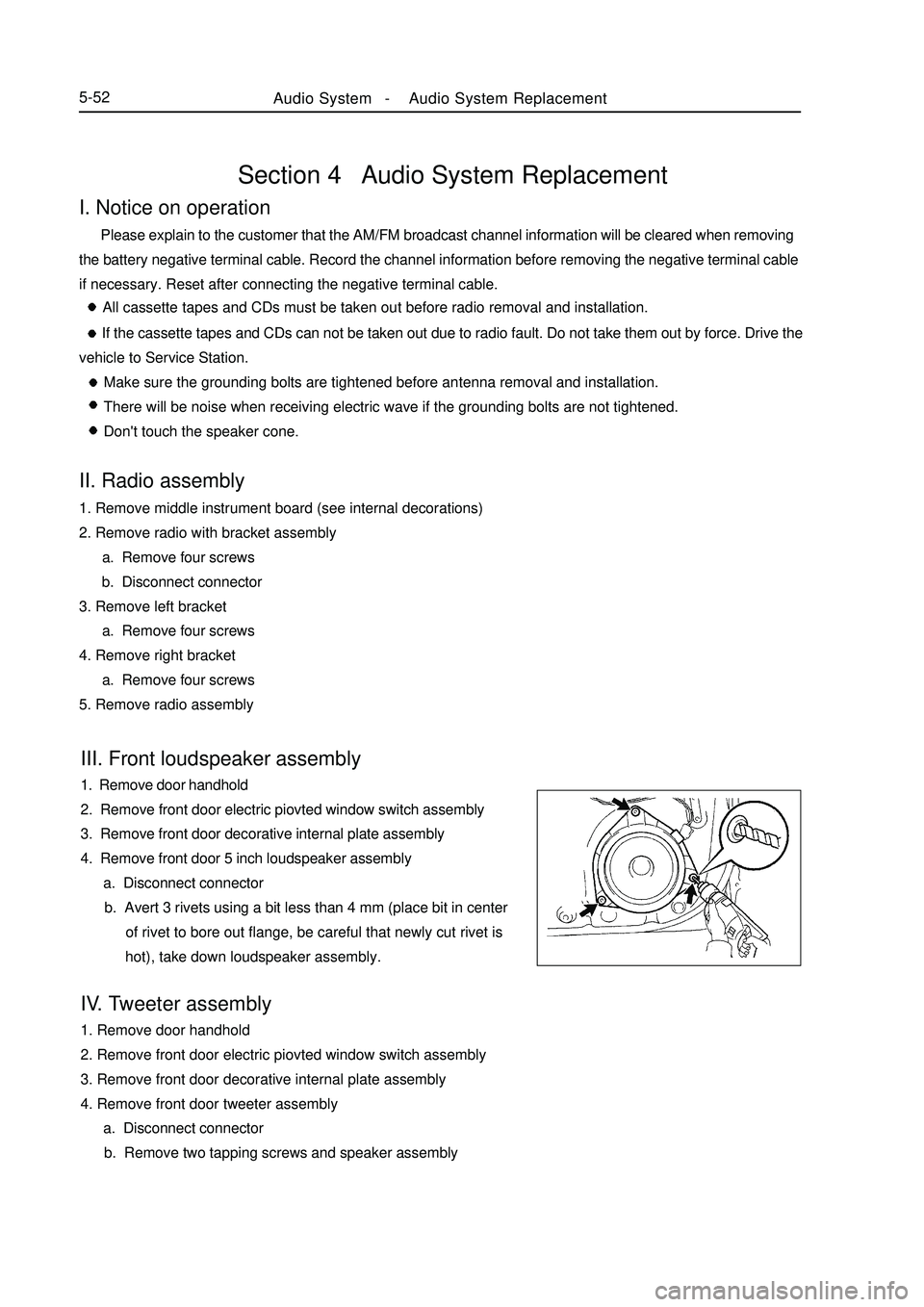

5. Remove radio assemblyAudio System -Audio System Replacement5-52III. Front loudspeaker assembly

1. Remove door handhold

2. Remove front door electric piovted window switch assembly

3. Remove front door decorative internal plate assembly

4. Remove front door 5 inch loudspeaker assembly

a. Disconnect connector

b. Avert 3 rivets using a bit less than 4 mm (place bit in center

of rivet to bore out flange, be careful that newly cut rivet is

hot), take down loudspeaker assembly.

IV. Tweeter assembly

1. Remove door handhold

2. Remove front door electric piovted window switch assembly

3. Remove front door decorative internal plate assembly

4. Remove front door tweeter assembly

a. Disconnect connector

b. Remove two tapping screws and speaker assembly

Page 241 of 416

Chapter 6 SRS (Supplemental Restraint System)Section 1 SRS-General InformationI. Precaution for service For safe reasons, read the following precaution before starting any operation.

1. When servicing the SRS, correct sequence and items are described in the following chapter.

2. Instruments and special tools recommended in this chapter shall be used for operation.

3. When servicing the following components, replace them with the new ones if there is a failure.

(1) SRS ECU

(2) Clock Spring Module

(3) Driver Airbag Module

(4) Passenger Airbag Assembly

(5) Front Seat Belt Pretensioner

4. If there is any abnormality in the wire harness of the SRS, replace it with a new one. Correct or replace the

abnormal wire harness in accordance with Table 1.pin1 pin15

pin29

pin16SRS (Supplemental Restraint System)-SRS-General Information5-54No Designation

1 Belt-pretensioner, Driver, Low

2 Belt-pretensioner, Driver, High

3 Belt-pretensioner, Passenger, High

4 Belt-pretensioner, Passenger, Low

5 IGN

6 GND

7WL

9K

10 DAB Hi

11 DAB Lo

13 (Optional) PAB Hi

14 (Optional) PAB Lo

27 Crash Output ECU Terminal Description5. Servicing operation shall be carried out 60s after the negative(-) terminal cable is disconnected from the battery.

In addition, the disconnected negative (-) terminal cable shall be protected with insulating tape for insulation. In

Page 242 of 416

Instrument Designation Usage

Diagnostic detector (Hi-DS T Scan meter)

Special diagnostic meterCheck system troubles of the SRS,

and clear the DTC of ECUIII. Troubleshooting1. Basic process of trouble diagnosis

DTC of the present fault may coexist with that of the history fault.

Notice:

After the new SRS ECU is installed, the warning light of the SRS, with the ignition switch ON, will be on

for 4s and then go out permanently, indicating SRS works normal. In this case, no service is needed. Otherwise,

system diagnosis and service shall be carried out.

If with the ignition switch ON, the warning light of the SRS is not on, the relevant circuits of the warning

light shall be serviced. Then go on with the operation and enable it to work.SRS (Supplemental Restraint System)-

SRS-General Information5-55order to deploy an airbag within a certain time period after the battery

is disconnected, condenser in the ECU shall retain some electrical

energy. Otherwise, it could lead to a serious accident because of the

unexpected deployment of airbag.

6. During spray paint work, ECU, airbag assembly, clock

springassembly, etc shall be removed and kept in place to avoid the

effects of overheat. (Over 93)

7. When the SRS is serviced, a diagnostic scan meter is used to clear

the DTC to enable the normal work ofthe warning light.II. Test instrumentWarning light con-

stantly goes onuse scanner find out the troubletroubleshootingtrouble eliminated Check SRS warning light (see the right figure)

(1) Turn the ignition switch ON and find out whether the warning

light is on.

(2) 4 seconds after the process of ON-OFF, confirm that the

warning light goes out permanently.

(3) Otherwise, diagnosis and checking have to be involved in.

2. System Diagnosis

The SRS ECU will perform a series of circular diagnostic tests to check the readiness of the SRS functions.

This test can avoid unexpected explosion of the restrain system and in the same time ensure the necessary explosion

in a crash. If a trouble is detected, the SRS ECU will store a proper DTC and turn on the warning light indicating

a trouble for service.SRS Air Bag

Warning LightBattery

Cable Insulation BandSRS Air Bag

Warning Light

Page 249 of 416

5-62 (22) There are problems in the configuration of the airbag ECU (DTC 93D6)

When using the scan tool to test the airbag ECU, the DTC is 93D6, indicating that there are problems in the

configuration of the airbag ECU.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93D6? Go to step 2 other

2Go to step 3

3 Go to step 4 Go to step 1

4 The fault has been removed, use the scan tool to eliminate the DTC.Check whether the configuration of the airbag ECU is consistent with the

actual on-board configuration?

After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check). (23) The impact signal output interface of the airbag ECU is short to ground or the impact output circuit is

disconnected. (DTC 93D7)

When using the scan tool to test the airbag ECU, the DTC is 93D7, indicating that the impact signal output

interface of the airbag ECU is short to ground or the impact output circuit is disconnected.IV. Diagnosis of collided vehicle No matter airbag is unfolded or folded, inspection and maintenance of collided vehicle should be performed

according to the following sequence.

1. Check ECU diagnosis signal.

(1) Connect scanner diagnosis joint

(2) Use scanner to read out diagnosis result.

2. Repair sequence

(1) when airbag is unfolded.

The following components should be replaced with new parts

a. Airbag assembly on passenger side

b. ECU

c. Airbag assembly on driver side

d. Seat belt with pretensionerNote:

due to impact, when battery power is insufficient, scanner can not communicate with ECU, now check and

service instrument board wire harness or use external power supply.SRS (Supplemental Restraint System)-SRS-General Information (2 ) Check the following components, if there is any abnormity, replace with new parts

a. Clock spring.

b. Steering wheel, steering column, lower steering shaft assembly

(3 ) The installation status of driver airbag assembly in relation to steering wheel

a. Check and see if there is abnormal noise in the steering wheel, the action of the same is good, or the

clearance is normal.

b. Check the connecter of the wire harness for damage and the terminal for distortion.

Page 256 of 416

5-69Notice

Work must be started 60s after the positive (+) and negative (-) terminal cables are detached from battery.

3) The airbag assembly shall be deployed according to the following procedures.

(1) Driver airbag assembly

a. Remove the knee bolster.

b. Remove the connector (yellow) that connecting the lower end of the clock spring with the wire harness

of the instrument panel (see the figure below).Notice

Remove the connector of the clock spring from the wire harness of the instrument, the connector will be

short circuited automatically, which can avoid the possible serious accident resulted from the deployment of

the diver airbag assembly due to static electricity.

c. Tie two 6m plus wire harnesses for deployment to the

adaptor wire harness of the airbag, and wrap the connecting points

with insulating tape for insulation.The other ends of the wire harness

for deployment are connected to each other (short circuited). Unex-

pected deployment resulted from static electricity shall be prevented.

d. From the yellow connector of the clock spring, lead the

airbag adapter wire harnesses out of the vehicle by means of the wire

harnesses for deployment (see the figure below).

e. To restrain the noise, close all the windows and doors and

put on the vehicle cover.Notice

The glass will likely break up if there is crack. Vehicle covers shall be put on.

f. Try to disconnect at a location far away from the vehicle the connector of the wire harness for deployment

of the driver airbag assembly, connect them with the two terminals of the battery removed from the

vehicle and deploy the airbag (see the figure below).Notice

Make sure there is no man inside or near the vehicle and then

carry out the operations.

After the driver airbag is deployed, the gas generator is of high

temperature. Keep it for 30 minutes until it gets cool for use.

If the driver airbag assembly cannot be deployed, discuss the

problem with the local Geely service station.Deployed

HarnessCovering the car g. The deployed driver airbag assembly shall be scrapped according to the scrapping procedures.

Deploy outside the vehicleNotice

Keep the airbag over 6m away from a obstacle or person and deploy the airbag in an open flat area.

Deployed the airbag outside the vehicle, avoid to do this job in the strong wind. In case of breeze, fire should

be against the wind.SRS (Supplemental Restraint System)-

SRS-General InformationDAB

Connector Horn

Connector

Page 258 of 416

Used Tire Without

hub

Deployed HarnessDeployed Harness h. Try to disconnect at a location far away from the vehicle the

connector of the wire harness for deployment of the driver

airbag assembly, connect with the two terminals of the

battery removed from the vehicle and deploy the airbag

(see the figure on the right). g. Put three used tires without hubs onto the tire used to fix the

driver airbag assembly (see the figure on the right).

i. The deployed driver airbag assembly shall be scrapped according to the scrapping procedures.Notice

Make sure to deploy the driver airbag assembly when there is no person close by.

After the driver airbag is deployed, the gas generator is of high temperature. Keep it for over 30 minutes

until it gets cool for use.

If the driver airbag can't be deployed, please contact the Geely service station for help.5-71SRS (Supplemental Restraint System)-

SRS-General Information

Page 348 of 416

Interior & Exterior Trim and Accessory -Windshield6-19 (4) Use a brush to apply primer M onto the glass edge and contacting parts.

(5) Add the polyurethane adhesive sealants

a. Prepare a sealing gun with sleeve;

b. As per the drawing, use the gun to apply the polyurethane adhesive sealants around the glass.

(6) Install glass

a. Use cupule to place glass and align with the reference marks and press it gently along the edge.

b. Press the front surface of glass gently so that it comes to tight contact with the frame.

c. Use a scraper to clean the remaining polyurethane adhesive sealants.

(7) Inspect leakage and service

a. Leakage test will be carried out after the polyurethane adhesive sealants are fully solidified.

b. Use the polyurethane adhesive sealants to seal up all the leaking areas.

Page 358 of 416

Interior & Exterior Trim and Accessory -Front Door Interior Trim6-295. Remove the left front door inside handle

Loosen 2 hooks, unfasten the left front door inside handle and

then disconnect 2 wires from the handle.

6. Peel off the rainproof film

7. Remove the speaker assembly

8. Remove the left front door glass and the left front door glass guide

Tips:

Protect the glass from scratch by inserting a cloth in the LF door

inner panel.

a. Unfix 2 bolts retaining the glass in place;

b. Remove the left front door glass;

c. Take out the glass guide.

9. Remove the left front door muffler

Unfix 2 bolts, 2 liners and the left front door muffler.

10. Remove the left front door glass regulator assembly

a. Disconnect the connector;

b. Unfix 6 bolts and left front door glass regulator assembly.

Caution

Be careful to prevent the glass regulator assembly from damage

when it is not supported by the bolts.

Notes:

Remove the left front door glass regulator assembly through the

service hatch.Hook

Hook

Page 387 of 416

5. Base Anti-rust Processing

Impact-proof Coat

In order to avoid corrosion and protect the body from being damaged by bouncing stone on the road, a layer

of impact-proof coat is applied on the door threshold plate, arc area and balancing plate etc.

Tips: There are two types of painting: impact-resistant coat on the electrophoresis primer or on the surface paint

according to different types and painting positions. (See Fig.5-22)7-15IV. Repair Requirement 1. As the body is an integral structure and the steel plates used are not thick, special attention shall be paid to

reinforce the parts acted in the reshaping process in the plate work processing. For the parts that burden the stress

intensively, measures shall be taken to lower the local stress.

2. After the plate work processing, note to apply the antirust primer on the inside and outside surfaces to avoid

corrosion.

3. In the body repair process, repair the old parts; or remove the parts with serious defects and order new parts

from the manufacturer.

4. When making body reshaping or parts welding, make sure that all main control points of the body are within

the specified scope in the design.

5. The strength and serviceability of the repaired body shall not be lower than those of the new vehicle.

6. The outside decoration of the repaired body shall meet the requirements by the new vehicle body and the

drivers in various aspects, such as modern aesthetics and ergonomics etc. (b) Apply primer

In order to prevent rust and protect the body steel plate from

being damaged by the bouncing stone, sufficient primer is

applied onto the body base and inner wheel cup.

(c) Apply antirust (wax)

In order to prevent the painting part from rusting, sufficient

antirust is applied on the engine cover, door inner corner, hinge

ambiance, or in the inside welding part of the box section

structures such as side beam, body post.Fig. 5-22 Apply the impact-proof coat on the surface paint

Impact-proof coat

Surface paint

Intermediate primer

Electrophoresis primer

Steel sheet Apply the impact-proof coat on the electrophoresis primer

Surface paint

Intermediate primer

Impact-proof coat

Electrophoresis primer

Steel sheetBody Repair -Body Damage Forms and requirements For Repair