roof GEELY MK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 376 of 416

(3) Side Wall Assembly The left/right side wall assembly is a frame structure, which is a side component that connects the front and

rear parts of the body. As shown in Fig.5-4, it includes left/right side wall outside plate assembly, left/right wheel

assembly, left/right A post inside plate assembly, and left/right intermediate post interior plate assembly etc.Survey -Body Structure7-4Fig. 5-4 Side Wall Assembly

1. LH/RH upper front body inner pillar 2.LH/RH lower front body inner pillar 3.LH/RH no.1 crossemember joint panel

4.LH/RH roof inner rail 5.LH/RH center body inner pillar 6.LH/RH rear crossmember tee joint panel

7.LH/RH lower rear pillar remforcement panel 8.LH/RH roof rear inner panel 9.LH/RH side rear pillar inner panel

10.LH/RH luggage compartment support panel 11.LH/RH luggage compartment hinge fixing panel

12.LH/RH wheel house outer panel 13.LH/RH wheel house inner panel 14.LH/RH side panel

15.LH/RH rear combination lamp fixing panel 16.Fuel refilling cap assembly 17.LH/RH side doorsill outer reinforcement panel

18.LH/RH side doorsill inner reinforcement panel 19.LH/RH center pillar upper reinforcement panel

20.LH/RH front seat belt upper reinforcement panel 21.LH/RH roof rail upper master reinforcement panel

22.LH/RH center pillar middle reinforcement panel 23.LH/RH center pillar lower reinforcement panel

24.LH/RH roof rail assistant reinforcement panel 25.LH/RH front body pillar upper reinforcement panel

26.LH/RH front body pillar outer reinforcement panel

Page 377 of 416

(4) Rear Wall Parts As shown in Fig.5-5, the rear wall assembly includes rear wall plate, rear wall reinforced plate, luggage

compartment door lock mounting plate and luggage compartment door cross beam etc.Fig. 5-5 Rear Wall Assembly

1. Rear wall upper cross beam

2. Luggage compartment lock

mounting plate big assembly

3. Rear wall left double-hole plate

4. Rear wall outer plate

Fig. 5-6 Roof Assembly

1. Roof outer panel 2. Roof No.1 cross beam 3. Roof No.2 cross beam 4.Roof rear cross beam 5.Roof No.3 cross beam

6. Moon roof reinforcement panel It is mainly used as a cross beam to improve the strength of the rear part of the vehicle and form a luggage

compartment door.5) Roof Assembly The roof assembly includes roof outer panel, roof No.1 and No.2 cross beam, and roof rear cross beam etc.

Inside the roof, there is top interior decoration. There is a heat pad in the center and there is bond between the cross

beam and the roof. The rain from the roof is discharged out of the rear part through the channels at both sides. These

cross beams are used to reinforce the roof's transverse stiffness. For disassembled parts, see Fig. 5-6.(6) Luggage Compartment Main Cover Assembly The luggage compartment main cover assembly includes luggage compartment main cover sub-assembly, rear

seat hook mounting plate assembly, left/right side angle plate, drip channel and reinforced upper cross beam etc.

When the luggage compartment main cover assembly is welded to the left/right side wall, it forms a luggageSurvey -Body Structure7-51 14432526143 2

Page 382 of 416

3. External Force Having an Angle with Vehicle Centerline (Fig. 5-15)Body Repair -Body Damage Forms and requirements For Repair7-10Fig. 5-15 External Force Having an Angle with Vehicle Centerline As shown in Fig. 5-15, when the vehicle is acted by an external force having an angle with its centerline, the

force will affect the hood root and the front window side post if it is strong enough.

4. Body Side Center Acted by External Force in Upright Direction (Fig. 5-16)Fig. 5-16 Body Side Center Acted by External Force in Upright Direction As shown in Fig. 5-16, when the body side center is acted by an external force in the upright direction, check

the following positions:

a. Front window side post upper/lower installation position;

b. Side window intermediate post upper/lower installation position;

c. Side window rear post deformation;

d. Roof and frame deformation.

When the body is acted by an external force on the rear part, its damage is the same as that caused by an external

force on the front part. Check the parts in full consideration of the rear structure and feature.External ForceExternal Force

Page 383 of 416

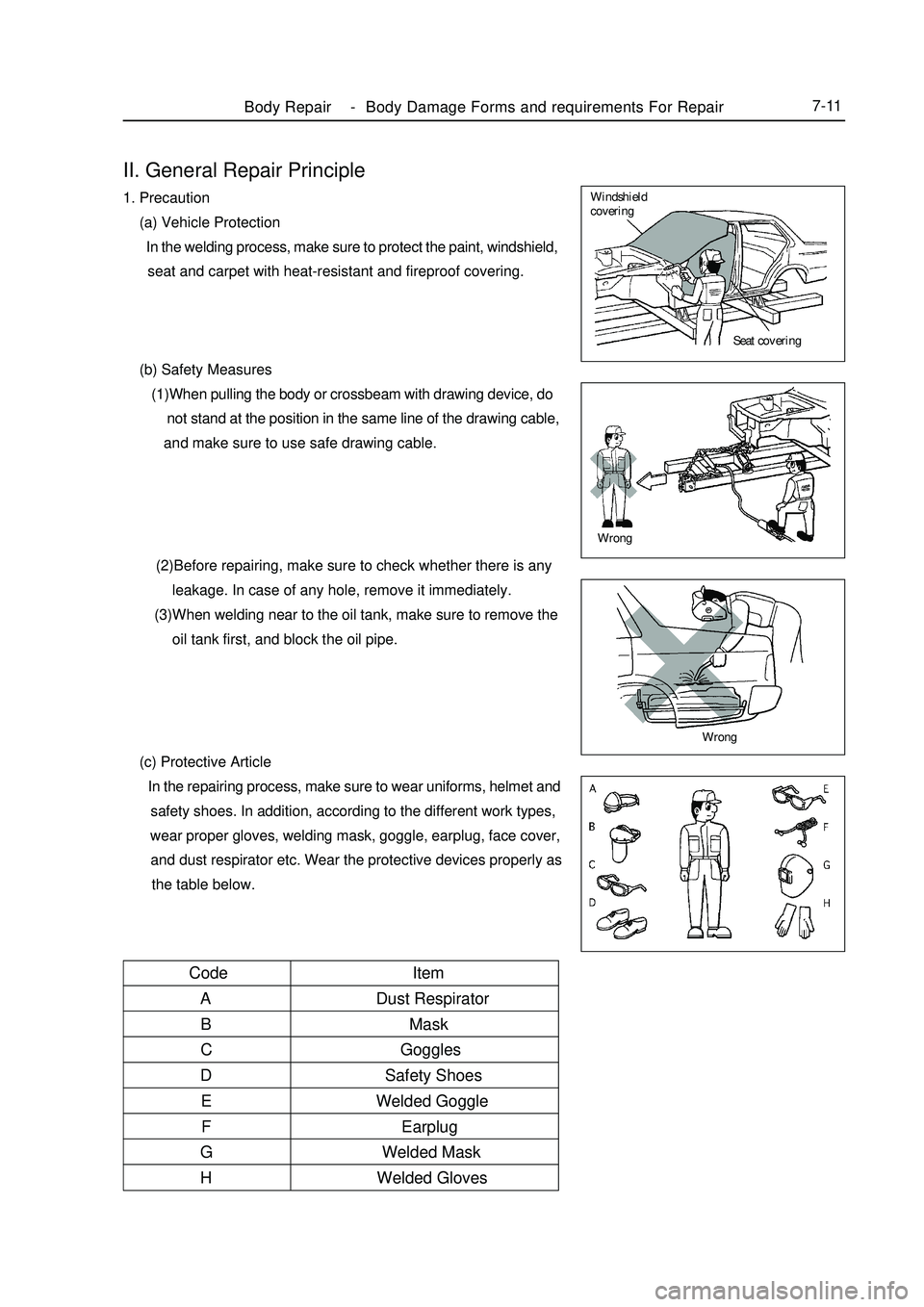

II. General Repair Principle1. Precaution

(a) Vehicle Protection

In the welding process, make sure to protect the paint, windshield,

seat and carpet with heat-resistant and fireproof covering.

(b) Safety Measures

(1)When pulling the body or crossbeam with drawing device, do

not stand at the position in the same line of the drawing cable,

and make sure to use safe drawing cable.

(2)Before repairing, make sure to check whether there is any

leakage. In case of any hole, remove it immediately.

(3)When welding near to the oil tank, make sure to remove the

oil tank first, and block the oil pipe.

(c) Protective Article

In the repairing process, make sure to wear uniforms, helmet and

safety shoes. In addition, according to the different work types,

wear proper gloves, welding mask, goggle, earplug, face cover,

and dust respirator etc. Wear the protective devices properly as

the table below.Body Repair -Body Damage Forms and requirements For Repair7-11Seat covering Windshield

coveringWrongWrongItem

Dust Respirator

Mask

Goggles

Safety Shoes

Welded Goggle

Earplug

Welded Mask

Welded Gloves Code

A

B

C

D

E

F

G

H

Page 386 of 416

7-14 (b) Precaution

(1) For the number of spot welding, it depends on the following

principles.

S pot welding:1.3 times of the number specified by the manufacturer

Hole-filling welding: more than the number specified by the

manufacturer

(2) When carrying out the hole-filling welding, MIG welder

shall be used. It is not allowed to use the oxyacetylene

welding or braze welding outside the specified area.

(c) Abrasion after welding

(1) After the welding, make sure to check the welding position

whether it is welded firmly.

(2) When abrading the welding position with disc abrader,

never abrade it too much, which may weakens the strength

of the welding position.

(d) Precaution of spot welding

(1) The shape of the spot welder head may affect the strength

of the welding.

(2) Make sure to remove the paint film on the surface of the spot

welding and the contact surface of the welder head.

(e) Position of spot welding

In the spot welding process, overlap with the old welding

position shall be avoided.

4. Anti-rust Processing

(a) Apply sealant

In the waterproof and antirust part operation, make sure to

apply the sealant on the joint of the steel plates,door,and engine

hood corner.Wrong CorrectWrong

Spot welding head scraper

New welding position

Old welding

positionSealant gunBody Repair -Body Damage Forms and requirements For Repair

Page 387 of 416

5. Base Anti-rust Processing

Impact-proof Coat

In order to avoid corrosion and protect the body from being damaged by bouncing stone on the road, a layer

of impact-proof coat is applied on the door threshold plate, arc area and balancing plate etc.

Tips: There are two types of painting: impact-resistant coat on the electrophoresis primer or on the surface paint

according to different types and painting positions. (See Fig.5-22)7-15IV. Repair Requirement 1. As the body is an integral structure and the steel plates used are not thick, special attention shall be paid to

reinforce the parts acted in the reshaping process in the plate work processing. For the parts that burden the stress

intensively, measures shall be taken to lower the local stress.

2. After the plate work processing, note to apply the antirust primer on the inside and outside surfaces to avoid

corrosion.

3. In the body repair process, repair the old parts; or remove the parts with serious defects and order new parts

from the manufacturer.

4. When making body reshaping or parts welding, make sure that all main control points of the body are within

the specified scope in the design.

5. The strength and serviceability of the repaired body shall not be lower than those of the new vehicle.

6. The outside decoration of the repaired body shall meet the requirements by the new vehicle body and the

drivers in various aspects, such as modern aesthetics and ergonomics etc. (b) Apply primer

In order to prevent rust and protect the body steel plate from

being damaged by the bouncing stone, sufficient primer is

applied onto the body base and inner wheel cup.

(c) Apply antirust (wax)

In order to prevent the painting part from rusting, sufficient

antirust is applied on the engine cover, door inner corner, hinge

ambiance, or in the inside welding part of the box section

structures such as side beam, body post.Fig. 5-22 Apply the impact-proof coat on the surface paint

Impact-proof coat

Surface paint

Intermediate primer

Electrophoresis primer

Steel sheet Apply the impact-proof coat on the electrophoresis primer

Surface paint

Intermediate primer

Impact-proof coat

Electrophoresis primer

Steel sheetBody Repair -Body Damage Forms and requirements For Repair

Page 397 of 416

2. Shock Absorption & Noise Isolation

(1) Body structure (Fig. 5-37)

a. Arrange the reinforced bar reasonably to improve the parts' rigidity, reduce the shock and lower the noise.

b. Apply the sealant in the floor seam to improve the floor sealing and reduce the noise in the cabin.Fig. 5-37 Front Wall Panel

1. Front wall bridge reinforced panel

2. Front wall mid-frame panel

3. Front wall lower main panel

4. Heat-isolated pad

Fig. 5-38 (a) Body floor

1. Front mud guard 2. Rear side wall 3. Rear wheel housing 4.Floor sides (2) Deadening

It is an interactive and systemic work to make the body isolate heat, shock and noise. Besides the measures

carried out to improve the body's stiffness and sealing performance, the following measures shall be taken in the

design and manufacture process.

a. Sound isolation material: add sound isolation pad on the front wall and floor.

b. Sound absorption material: add molded carpet on the front floor and rear floor.

3. Sealing

Special consideration has been given to the sealing of the body both in design process and in manufactureprocess. Sealing plays an important role in many aspects, such as dust resistance, water resistance, corrosionresistance, heat resistance, heat preservation, and noise reduce etc. Especially when the body floor and front wall

stay in a tough external condition, the mud, dust, noises (from the tire and engine) and hot air will invade into the

cabin any time.

After the body assembly is welded, sealant will be employed on all joints to prevent the water and steam

penetrating into the metal seam and ensure the quality of subsequent painting.

In addition, a thick layer of impact-proof PVC coat is applied on the base of the body, which has excellentsealing performance. For the sealing to those assemblies, the traditional sealing method is used, such as rubber sealBody Repair -Features and Composition of Automobile Body7-251

123Front4

Page 406 of 416

4. Surface Treatment

Surface treatment shall be strict, careful and all-around. Though this car is not a deluxe sedan, it nearly has no

difference with the deluxe sedan in the surface treatment.

a. Phosphoric acid processing

Phosphoric acid processing is also called pretreatment before painting. After removing the grease on the body

by washing, apply zinc phosphate onto the body, with a thickness under 3

but also can help to increase adhesion in the next coating process.

b. Cathode electrophoresis

In the practical application, the electrophoresis painting shows many advantages, such as high efficiency, good

quality, safety and cost effectiveness. It is accompanied with four electrochemical phenomena including

electroanalysis, electrophoresis, electrodeposition and electroosmosis. The cathode electrophoresis is much better

than the anode electrophoresis both in the features and advantages. Incomparably, the process is strict extremely.

c. Intermediate coat

The intermediate coat is also called intermediate layer, which is located between the primer and the surface

paint. Its function is to improve the evenness of the painted work piece and the primer and provide the surface paint

with a good base to improve the paint's brightness and richness and improve the decoration of the entire coat.

d. Surface paint

The surface paint is the last coat in the multiple coats, which directly affect the vehicle's decoration,

weatherability and appearance etc. Great attention shall be made when selecting the surface paint, including its

adaptability, cost-effectiveness and usability. All performance indexes shall meet the national standard and

industrial standard. The paint shall be even and smooth.

e. Protective coat

For those vehicles parked outside for a long time (more than three months) or used for shipping, water-soluble

protective wax shall be applied on the outside surface of the body. This agent contains ultraviolet absorbent. Before

selling the vehicle, wash it with soap detergent and flush it with clean water, to make the paint brighter.7-34Fig. 5-38 (j) Painting Position of Impact-proof CoatPVC Impact-proof Coat Body Repair -Features and Composition of Automobile Body m. It not only can protect the work piece,

1U

Page 408 of 416

Section 6 Service Data For for BodyI. Technical Repair Data (Table 5-1)Item (Clearance)

Front fender and side wall outside plate

Front fender and front door outside plate

Side wall outside plate and front/rear door

Door outside plate and side wall outside plate

Front door and rear door

Rear windshield and side wall outside plate

Luggage outside plate and side wall outside plate

Side wall outside plate and taillight & bumper

Luggage outside panel and rear taillight

Taillight and rear bumper

Side wall outside plate and refill opening

Front bumper and headlight

Left fender and front bumper

Engine cover outside plate and left front fender

Roof and front windshield

Roof and rear windshield

Left front fender and headlight

Engine cover outside plate and headlight

Side wall outside plate and front windshield Table 5-1Body Repair -Service Data For for Body7-36Technical Repair Data

Repair Data

2.5mm(+1,0mm)

5mm±1mm

5.5mm±1.5mm, Height Difference 2 mm±1.5mm

6mm±1.5mm, Height Difference 2.5mm±1.5mm

5.5mm±1mm

7mm±1.5mm

4.5mm±1.5mm

2mm±0.5

5.5mm±0.5mm

3mm(1,-0.5mm)

3.5mm(1,0mm)

3mm±1mm

1mm(1,0mm)

4mm±1mm

4mm±0.5mm

3mm±0.5mm

3mm±0.5mm

4.5mm±1mm

11mm±0.5mm

Page 410 of 416

Appendix: Body Key Dimensions1. Engine CompartmentAppendix-Body Key Dimensions7-38

(mm)

Item Description

Diameter of Hole

XY Z

A,a

Front fender installetion hole(Front)

7(M6 nut) -336.18 +/-652.5 580.69

B,b

Front absorber spring support hole(Inside)

10 1.09 +/-519.51 641.4

C,c

Front fender installetion hole(Rear)

7(M6 nut) 62.3 +/-661.71 665.72

D Cowl panel drip charnel fixing hole 7(M6 nut) 66.13 -1.2 648.7

E,e Collision sensor installation hole 9(M8 nut) -445.74 +/-436.17 273.26

F Braking pipe instaltion hole 7(M6 nut) -49 -418.74 309.12

f

ABS actuator installatim hole(front)

9(M8 nut) -48.64 417.53 291

G,g

Radiator upper crossmermber installation hole(front)

7(M6 nut) -589.94 +/-397 452.84

H,h

Radiator side insulation gasket installation hole

10x8-621.82 +/-403.33 94.99

I Hood lock bracket installation hole 7(M6 nut) -662.61 0 36.34

J,j

FR bumper horizontal installation hole

9(M8 nut) -651.68 -487.41 275.57

K,k

Windscreen fastener installation hole

11.5x8.7-849.35 +/-357.86 111.07

L,l

Radiator uppor crossmenber installation hole

7(M6 nut) -553.26 +/-392.02 502.18

M,m Hood hinge hole(Rear) 9(M8 nut) 149.64 +/-668.27 678.44

N,n Front fender support hole 10 -368.55 +/-704.84 379.94

O,o

Joint between side outerpanel and roof panel

£ 202.21 +/-636.33 736.57

P,p

Joint between side outer panel and dash panel

- 851.59 +/-508.37 1092.37

A-D 771±2.5

4

a-D 771±2.5

B-c 1183±2.5

4

b-C 1183±2.5

B-D 522±2.5

4

b-D 552±2.5

C-M 89±2.5

c-m 89±2.5

D-E 771±2.5

4

D-e 777±2.5

D-L 746±2.5

4

D-l 746±2.5

N-O 1410±2.5

A-c 1376±2.5

4

a-C 1376±2.5

I-j 547±2.5

4

I-J 547±2.5

I-H 410±2.5

4

I-h 410±2.5

O-p 1360±2.5

4

o-P 1360±2.5

A-o 1408±2.5

4

a-O 1408±2.5

I-g 580±2.5

4

i-G 580±2.5

F-b 997±2.5

f-B 1088±2.5

L-c 1231±2.5

4

l-C 1231±2.5

Measuring

point

Value

ToleranceMeasuring

point

Value

ToleranceMeasuring

point

Value

Tolerance

Measuring

point

Value

Tolerance