brake light GMC CANYON 2008 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2008, Model line: CANYON, Model: GMC CANYON 2008Pages: 428, PDF Size: 5.82 MB

Page 300 of 428

Brake Wear

Your vehicle has front disc brakes and rear drum

brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound

can come and go or be heard all the time your vehicle

is moving, except when you are pushing on the

brake pedal �rmly.

{CAUTION:

The brake wear warning sound means that

soon the brakes will not work well. That

could lead to an accident. When you hear

the brake wear warning sound, have your

vehicle serviced.Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates can cause a

brake squeal when the brakes are �rst applied or

lightly applied. This does not mean something is

wrong with the brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated,

inspect brake pads for wear and evenly tighten wheel

nuts in the proper sequence to torque speci�cations

inCapacities and Specifications on page 5-116.

Rear drum brakes do not have wear indicators, but if

you ever hear a rear brake rubbing noise, have the

rear brake linings inspected immediately. Also, the rear

brake drums should be removed and inspected each

time the tires are removed for rotation or changing.

When you have the front brake pads replaced, have

the rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

5-40

Page 303 of 428

Notice:Ignoring these steps could result in costly

damage to your vehicle that would not be covered

by your warranty.

Trying to start your vehicle by pushing or pulling it

will not work, and it could damage your vehicle.

1. Check the other vehicle. It must have a 12-volt

battery with a negative ground system.

Notice:If the other vehicle’s system is not a 12-volt

system with a negative ground, both vehicles can

be damaged. Only use vehicles with 12-volt systems

with negative grounds to jump start your vehicle.

2. Get the vehicles close enough so the jumper cables

can reach, but be sure the vehicles are not touching

each other. If they are, it could cause a ground

connection you do not want. You would not be able

to start your vehicle, and the bad grounding could

damage the electrical systems.To avoid the possibility of the vehicles rolling, set the

parking brake �rmly on both vehicles involved in the

jump start procedure. Put an automatic transmission

in PARK (P) or a manual transmission in NEUTRAL

before setting the parking brake. If you have a

four-wheel-drive vehicle, be sure the transfer case

is not in NEUTRAL.

Notice:If you leave your radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered

by your warranty. Always turn off your radio and

other accessories when jump starting your vehicle.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or the accessory power outlets. Turn off

the radio and all lamps that are not needed.

This will avoid sparks and help save both batteries.

And it could save the radio!

5-43

Page 329 of 428

The TPMS sensor matching procedure is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the

engine off.

3. Turn the exterior lamp switch from AUTO to OFF

four times within three seconds. A double horn

chirp will sound and the TPMS low tire warning light

starts �ashing. The double horn chirp and �ashing

TPMS warning light indicates the TPMS matching

process has started. The TPMS warning light

should continue �ashing throughout the matching

procedure. The LOW TIRE message displays on

the Driver Information Center (DIC).

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within

15 seconds, con�rming that the sensor identi�cation

code has been matched to this tire and wheel

position. If you do not hear the con�rming single

horn chirp, turn the ignition switch to LOCK and

start over beginning with Step 2.6. Proceed to the passenger side front tire, and repeat

the procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat

the procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the

procedure in Step 5.

9. After hearing the con�rming horn chirp for the driver

side rear tire, check to see if the TPMS low tire

warning light and the DIC LOW TIRE messages

have turned off. If yes, the TPMS sensors have

been relearned. Turn the ignition switch to

LOCK/OFF.

If the low tire warning light and the SERV TPM

message on the DIC are on after completing

Step 5 for the driver side rear tire, the sensor

relearn process has not been successful.

Turn the ignition switch to LOCK/OFF and repeat

the matching process beginning with Step 2.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.

5-69

Page 334 of 428

Different Size Tires and Wheels

If you add wheels or tires that are a different size than

your original equipment wheels and tires, this may

affect the way your vehicle performs, including its

braking, ride and handling characteristics, stability,

and resistance to rollover. Additionally, if your vehicle

has electronic systems such as, anti-lock brakes,

traction control, and electronic stability control, the

performance of these systems can be affected.

{CAUTION:

If you add different sized wheels, your

vehicle may not provide an acceptable

level of performance and safety if tires not

recommended for those wheels are selected.

You may increase the chance that you will

crash and suffer serious injury. Only use

GM speci�c wheel and tire systems developed

for your vehicle, and have them properly

installed by a GM certi�ed technician.

SeeBuying New Tires on page 5-72andAccessories

and Modifications on page 5-3for additional information.

Uniform Tire Quality Grading

Quality grades can be found where applicable

on the tire sidewall between tread shoulder

and maximum section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National

Highway Traffic Safety Administration (NHTSA),

which grades tires by treadwear, traction, and

temperature performance. This applies only

to vehicles sold in the United States. The grades

are molded on the sidewalls of most passenger

car tires. The Uniform Tire Quality Grading

(UTQG) system does not apply to deep tread,

winter-type snow tires, space-saver, or temporary

use spare tires, tires with nominal rim diameters

of 10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

5-74

Page 373 of 428

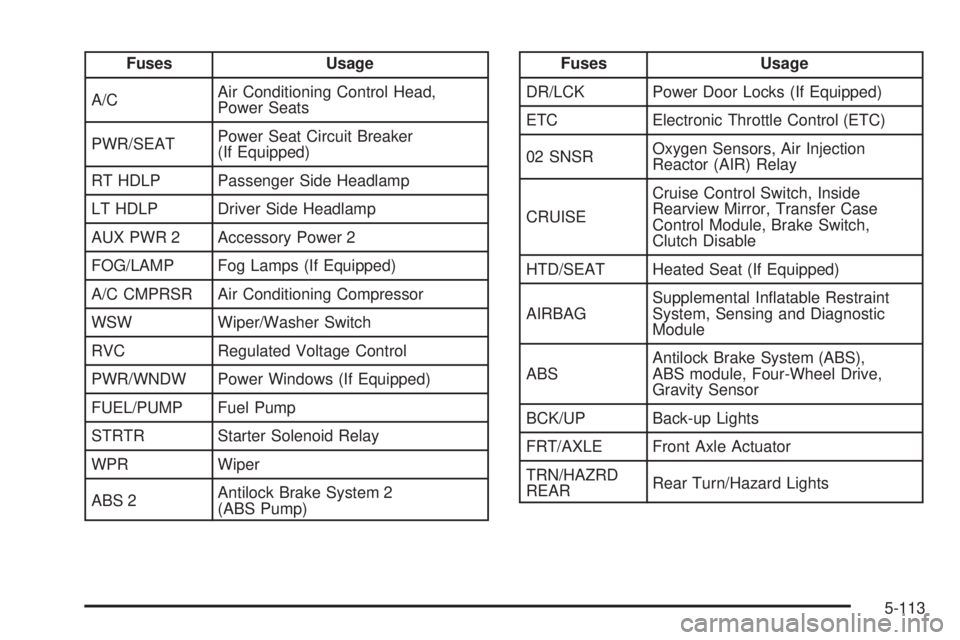

Fuses Usage

A/CAir Conditioning Control Head,

Power Seats

PWR/SEATPower Seat Circuit Breaker

(If Equipped)

RT HDLP Passenger Side Headlamp

LT HDLP Driver Side Headlamp

AUX PWR 2 Accessory Power 2

FOG/LAMP Fog Lamps (If Equipped)

A/C CMPRSR Air Conditioning Compressor

WSW Wiper/Washer Switch

RVC Regulated Voltage Control

PWR/WNDW Power Windows (If Equipped)

FUEL/PUMP Fuel Pump

STRTR Starter Solenoid Relay

WPR Wiper

ABS 2Antilock Brake System 2

(ABS Pump)Fuses Usage

DR/LCK Power Door Locks (If Equipped)

ETC Electronic Throttle Control (ETC)

02 SNSROxygen Sensors, Air Injection

Reactor (AIR) Relay

CRUISECruise Control Switch, Inside

Rearview Mirror, Transfer Case

Control Module, Brake Switch,

Clutch Disable

HTD/SEAT Heated Seat (If Equipped)

AIRBAGSupplemental In�atable Restraint

System, Sensing and Diagnostic

Module

ABSAntilock Brake System (ABS),

ABS module, Four-Wheel Drive,

Gravity Sensor

BCK/UP Back-up Lights

FRT/AXLE Front Axle Actuator

TRN/HAZRD

REARRear Turn/Hazard Lights

5-113

Page 374 of 428

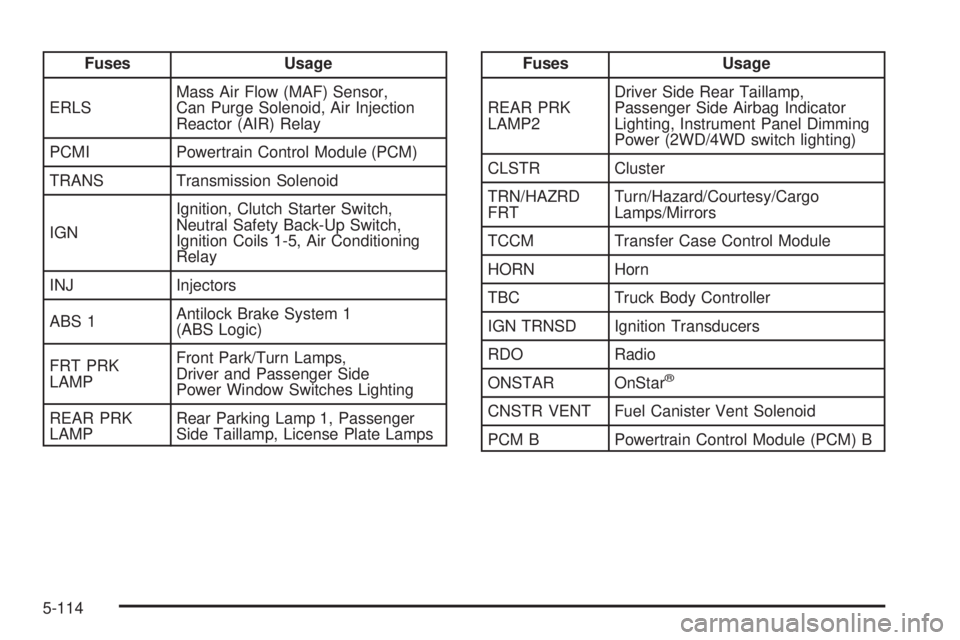

Fuses Usage

ERLSMass Air Flow (MAF) Sensor,

Can Purge Solenoid, Air Injection

Reactor (AIR) Relay

PCMI Powertrain Control Module (PCM)

TRANS Transmission Solenoid

IGNIgnition, Clutch Starter Switch,

Neutral Safety Back-Up Switch,

Ignition Coils 1-5, Air Conditioning

Relay

INJ Injectors

ABS 1Antilock Brake System 1

(ABS Logic)

FRT PRK

LAMPFront Park/Turn Lamps,

Driver and Passenger Side

Power Window Switches Lighting

REAR PRK

LAMPRear Parking Lamp 1, Passenger

Side Taillamp, License Plate LampsFuses Usage

REAR PRK

LAMP2Driver Side Rear Taillamp,

Passenger Side Airbag Indicator

Lighting, Instrument Panel Dimming

Power (2WD/4WD switch lighting)

CLSTR Cluster

TRN/HAZRD

FRTTurn/Hazard/Courtesy/Cargo

Lamps/Mirrors

TCCM Transfer Case Control Module

HORN Horn

TBC Truck Body Controller

IGN TRNSD Ignition Transducers

RDO Radio

ONSTAR OnStar

®

CNSTR VENT Fuel Canister Vent Solenoid

PCM B Powertrain Control Module (PCM) B

5-114

Page 385 of 428

Maintenance Footnotes

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect drum brake linings/shoes for wear or

cracks. Inspect other brake parts, including drums, wheel

cylinders, calipers, parking brake, etc. Check parking

brake adjustment.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing parts or

signs of wear. Inspect power steering lines and hoses

for proper hook-up, binding, leaks, cracks, chafing,

etc. Visually check constant velocity joints, rubber boots,

and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if

they are cracked, swollen, or deteriorated. Inspect

all pipes, fittings, and clamps; replace with genuine parts

as needed. To help ensure proper operation, a pressure

test of the cooling system and pressure cap and cleaning

the outside of the radiator and air conditioning condenser

is recommended at least once a year.(d)Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and wiper blades, if

contaminated. Replace wiper blades that are worn or

damaged. See Windshield Wiper Blade Replacement on

page 5-54andWindshield and Wiper Blades on

page 5-105for more information.

(e)Make sure the safety belt reminder light and safety

belt assemblies are working properly. Look for any

other loose or damaged safety belt system parts. If you

see anything that might keep a safety belt system from

doing its job, have it repaired. Have any torn or frayed

safety belts replaced. Also see Checking the Restraint

Systems on page 1-75.

(f)Lubricate all key lock cylinders, body door and fuel

door hinges, latches and locks (including glove box and

console doors), hood latch assembly, secondary latch,

pivots, spring anchor, release pawl, and any moving seat

hardware. Lubricate hood safety lever pivot and prop rod

pivot and tailgate latch bolt, handle assembly pivot points,

and hinges. More frequent lubrication may be required

when exposed to a corrosive environment. Applying

silicone grease on weatherstrips with a clean cloth will

make them last longer, seal better, and not stick

or squeak.

6-7

Page 415 of 428

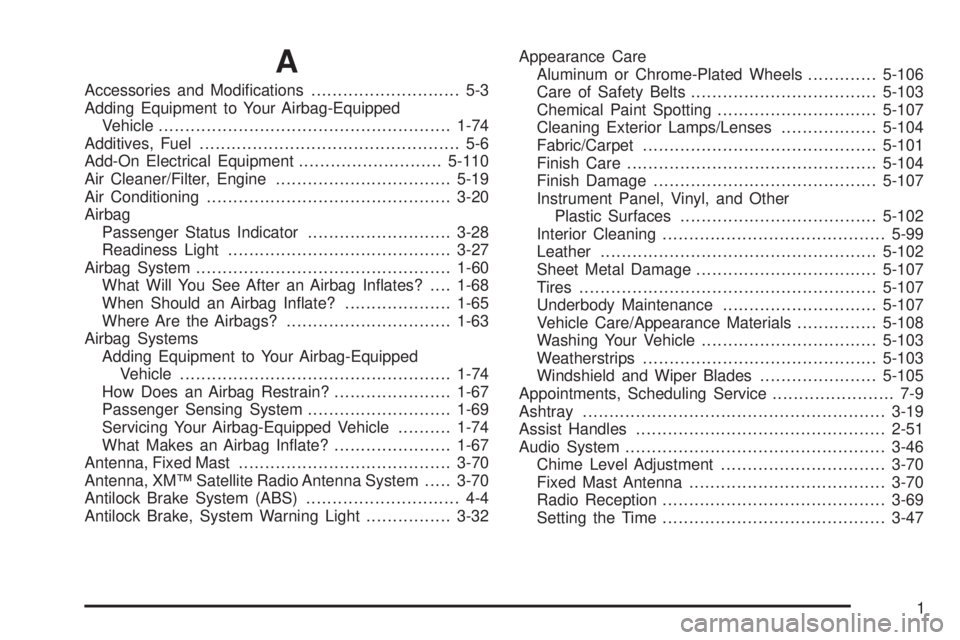

A

Accessories and Modi�cations............................ 5-3

Adding Equipment to Your Airbag-Equipped

Vehicle.......................................................1-74

Additives, Fuel................................................. 5-6

Add-On Electrical Equipment...........................5-110

Air Cleaner/Filter, Engine.................................5-19

Air Conditioning..............................................3-20

Airbag

Passenger Status Indicator...........................3-28

Readiness Light..........................................3-27

Airbag System................................................1-60

What Will You See After an Airbag In�ates?....1-68

When Should an Airbag In�ate?....................1-65

Where Are the Airbags?...............................1-63

Airbag Systems

Adding Equipment to Your Airbag-Equipped

Vehicle...................................................1-74

How Does an Airbag Restrain?......................1-67

Passenger Sensing System...........................1-69

Servicing Your Airbag-Equipped Vehicle..........1-74

What Makes an Airbag In�ate?......................1-67

Antenna, Fixed Mast........................................3-70

Antenna, XM™ Satellite Radio Antenna System.....3-70

Antilock Brake System (ABS)............................. 4-4

Antilock Brake, System Warning Light................3-32Appearance Care

Aluminum or Chrome-Plated Wheels.............5-106

Care of Safety Belts...................................5-103

Chemical Paint Spotting..............................5-107

Cleaning Exterior Lamps/Lenses..................5-104

Fabric/Carpet............................................5-101

Finish Care...............................................5-104

Finish Damage..........................................5-107

Instrument Panel, Vinyl, and Other

Plastic Surfaces.....................................5-102

Interior Cleaning..........................................5-99

Leather....................................................5-102

Sheet Metal Damage..................................5-107

Tires........................................................

5-107

Underbody Maintenance.............................5-107

Vehicle Care/Appearance Materials...............5-108

Washing Your Vehicle.................................5-103

Weatherstrips............................................5-103

Windshield and Wiper Blades......................5-105

Appointments, Scheduling Service....................... 7-9

Ashtray.........................................................3-19

Assist Handles...............................................2-51

Audio System.................................................3-46

Chime Level Adjustment...............................3-70

Fixed Mast Antenna.....................................3-70

Radio Reception..........................................3-69

Setting the Time..........................................3-47

1

Page 416 of 428

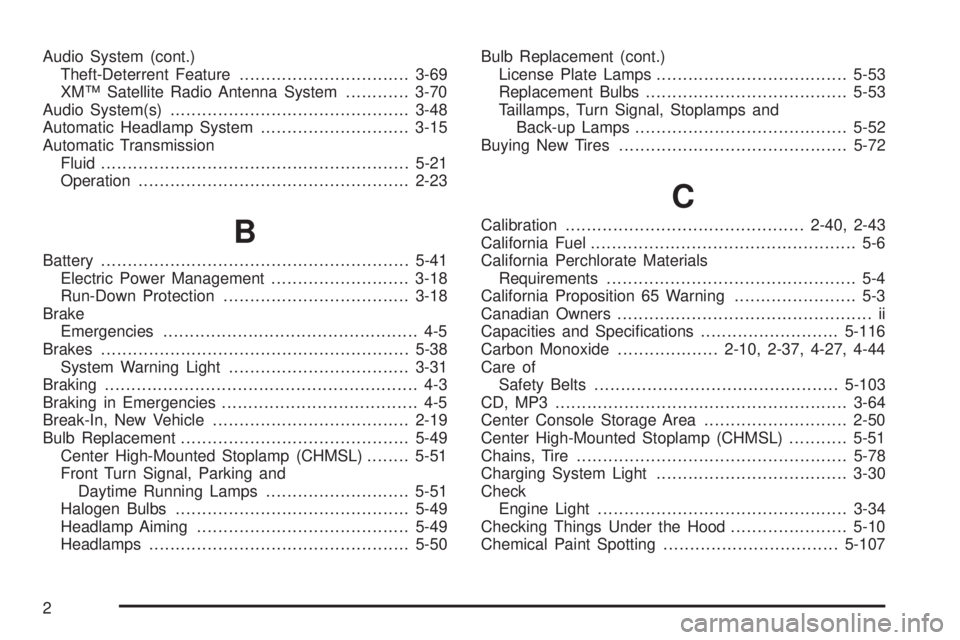

Audio System (cont.)

Theft-Deterrent Feature................................3-69

XM™ Satellite Radio Antenna System............3-70

Audio System(s).............................................3-48

Automatic Headlamp System............................3-15

Automatic Transmission

Fluid..........................................................5-21

Operation...................................................2-23

B

Battery..........................................................5-41

Electric Power Management..........................3-18

Run-Down Protection...................................3-18

Brake

Emergencies................................................ 4-5

Brakes..........................................................5-38

System Warning Light..................................3-31

Braking........................................................... 4-3

Braking in Emergencies..................................... 4-5

Break-In, New Vehicle.....................................2-19

Bulb Replacement...........................................5-49

Center High-Mounted Stoplamp (CHMSL)........5-51

Front Turn Signal, Parking and

Daytime Running Lamps...........................5-51

Halogen Bulbs............................................5-49

Headlamp Aiming........................................5-49

Headlamps.................................................5-50Bulb Replacement (cont.)

License Plate Lamps....................................5-53

Replacement Bulbs......................................5-53

Taillamps, Turn Signal, Stoplamps and

Back-up Lamps........................................5-52

Buying New Tires...........................................5-72

C

Calibration.............................................2-40, 2-43

California Fuel.................................................. 5-6

California Perchlorate Materials

Requirements............................................... 5-4

California Proposition 65 Warning....................... 5-3

Canadian Owners................................................ ii

Capacities and Speci�cations..........................5-116

Carbon Monoxide...................2-10, 2-37, 4-27, 4-44

Care of

Safety Belts..............................................5-103

CD, MP3 .......................................................3-64

Center Console Storage Area...........................2-50

Center High-Mounted Stoplamp (CHMSL)...........5-51

Chains, Tire...................................................5-78

Charging System Light....................................3-30

Check

Engine Light...............................................3-34

Checking Things Under the Hood......................5-10

Chemical Paint Spotting.................................5-107

2

Page 421 of 428

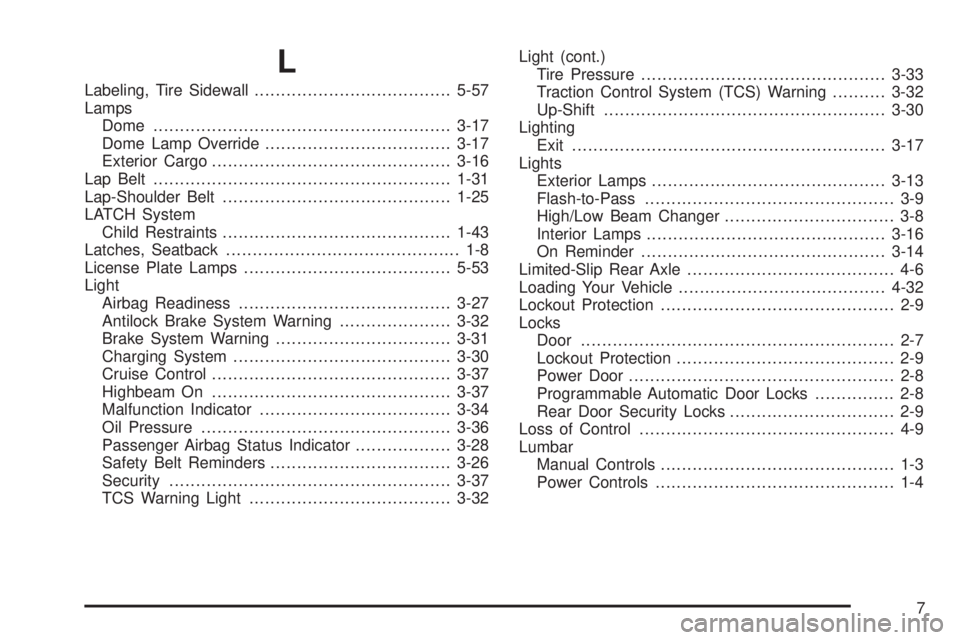

L

Labeling, Tire Sidewall.....................................5-57

Lamps

Dome........................................................3-17

Dome Lamp Override...................................3-17

Exterior Cargo.............................................3-16

Lap Belt........................................................1-31

Lap-Shoulder Belt...........................................1-25

LATCH System

Child Restraints...........................................1-43

Latches, Seatback............................................ 1-8

License Plate Lamps.......................................5-53

Light

Airbag Readiness........................................3-27

Antilock Brake System Warning.....................3-32

Brake System Warning.................................3-31

Charging System.........................................3-30

Cruise Control.............................................3-37

Highbeam On.............................................3-37

Malfunction Indicator....................................3-34

Oil Pressure...............................................3-36

Passenger Airbag Status Indicator..................3-28

Safety Belt Reminders..................................3-26

Security.....................................................3-37

TCS Warning Light......................................3-32Light (cont.)

Tire Pressure..............................................3-33

Traction Control System (TCS) Warning..........3-32

Up-Shift.....................................................3-30

Lighting

Exit...........................................................3-17

Lights

Exterior Lamps............................................3-13

Flash-to-Pass............................................... 3-9

High/Low Beam Changer................................ 3-8

Interior Lamps.............................................3-16

On Reminder..............................................3-14

Limited-Slip Rear Axle....................................... 4-6

Loading Your Vehicle.......................................4-32

Lockout Protection............................................ 2-9

Locks

Door........................................................... 2-7

Lockout Protection......................................... 2-9

Power Door.................................................. 2-8

Programmable Automatic Door Locks............... 2-8

Rear Door Security Locks............................... 2-9

Loss of Control................................................ 4-9

Lumbar

Manual Controls............................................ 1-3

Power Controls............................................. 1-4

7