ect GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 219 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual212

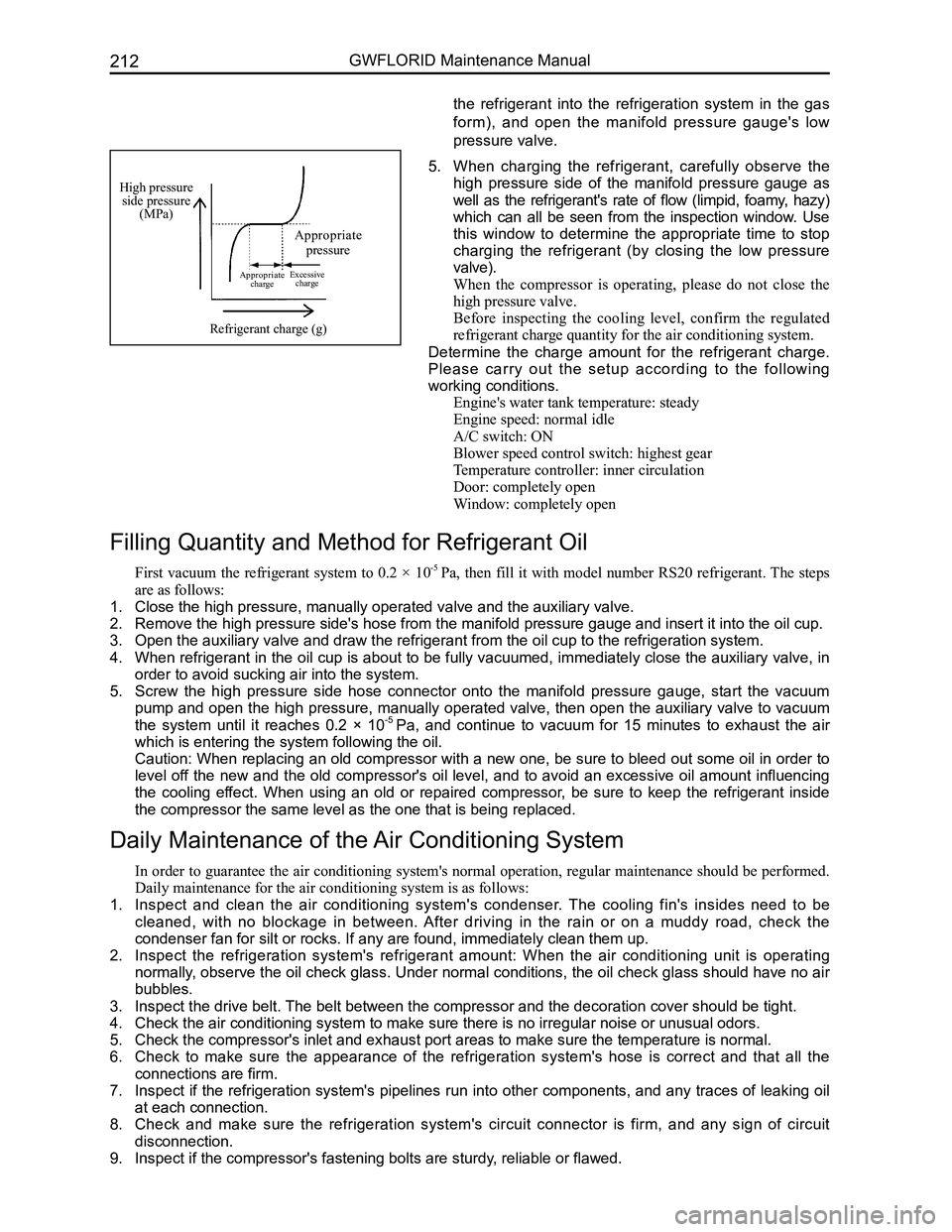

High pressure side pressure(MPa)

Appropriate pressure

Appropriate chargeExcessive charge

Refrigerant charge (g)

5. When charging the refrigerant, carefully observe the

high pressure side of the manifold pressure gauge as

well as the refrigerant's rate of flow (limpid, foamy, hazy)

which can all be seen from the inspection window. Use

this window to determine the appropriate time to stop

charging the refrigerant (by closing the low pressure

valve).

When the compressor is operating, please do not close the

high pressure valve.

Before inspecting the cooling level, confirm the regulated

refrigerant charge quantity for the air conditioning system.

Determine the charge amount for the refrigerant charge.

Please carry out the setup according to the following

working conditions.

Engine's water tank temperature: steady

Engine speed: normal idle

A/C switch: ON

Blower speed control switch: highest gear

Temperature controller: inner circulation

Door: completely open

Window: completely open

Filling Quantity and Method for Refrigerant Oil

First vacuum the refrigerant system to 0.2 × 10-5 Pa, then fill it with model number RS20 refrigerant. The steps

are as follows:

1. Close the high pressure, manually operated valve and the auxiliary valve\

.

2. Remove the high pressure side's hose from the manifold pressure gauge an\

d insert it into the oil cup.

3. Open the auxiliary valve and draw the refrigerant from the oil cup to th\

e refrigeration system.

4. When refrigerant in the oil cup is about to be fully vacuumed, immediately close the auxiliary valve, in

order to avoid sucking air into the system.

5. Screw the high pressure side hose connector onto the manifold pressure gauge, start the vacuum

pump and open the high pressure, manually operated valve, then open the auxiliary valve to vacuum

the system until it reaches 0.2 × 10-5 Pa, and continue to vacuum for 15 minutes to exhaust the air

which is entering the system following the oil.

Caution: When replacing an old compressor with a new one, be sure to bleed out some oil in order to

level off the new and the old compressor's oil level, and to avoid an excessive oil amount influencing

the cooling effect. When using an old or repaired compressor, be sure to keep the refrigerant inside

the compressor the same level as the one that is being replaced.

Daily Maintenance of the Air Conditioning System

In order to guarantee the air conditioning system's normal operation, regular maintenance should be performed.

Daily maintenance for the air conditioning system is as follows:

1. Inspect and clean the air conditioning system's condenser. The cooling fin's insides need to be

cleaned, with no blockage in between. After driving in the rain or on a muddy road, check the

condenser fan for silt or rocks. If any are found, immediately clean the\

m up.

2. Inspect the refrigeration system's refrigerant amount: When the air conditioning unit is operating

normally, observe the oil check glass. Under normal conditions, the oil check glass should have no air

bubbles.

3. Inspect the drive belt. The belt between the compressor and the decoration cover should be tight\

.

4. Check the air conditioning system to make sure there is no irregular noi\

se or unusual odors.

5. Check the compressor's inlet and exhaust port areas to make sure the tem\

perature is normal.

6. Check to make sure the appearance of the refrigeration system's hose is correct and that all the

connections are firm.

7. Inspect if the refrigeration system's pipelines run into other components, and any traces of leaking oil

at each connection.

8. Check and make sure the refrigeration system's circuit connector is firm, and any sign of circuit

disconnection.

9. Inspect if the compressor's fastening bolts are sturdy, reliable or flawed.

the refrigerant into the refrigeration system in the gas

form), and open the manifold pressure gauge's low

pressure valve.

Page 220 of 281

Downloaded from www.Manualslib.com manuals search engine 213Airbags

Airbags

Airbag Electronic Control Unit ..........................................214

Diagnostic Scanner ..........................................................215

Troubleshooting ................................................................216

Vehicle Collision Diagnostics ............................................226

Removal Method for Individual Components....................227

Driver Side Airbag Module (DAB), Front Passenger Side

Airbag Module (PAB), Clock Spring, and Steering Wheel ....228

Airbag Module Disposal....................................................230

Airbag’s Diagnostic Methods Without a

Diagnostic Scanner ..........................................................232

Page 221 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual214

Areas of Importance

1. While performing maintenance on the SRS airbag, make sure to work in accordance with this

chapter's steps and notes.

2. Be sure to use the specified test apparatus and SST (Special Service Tools) which are mentioned in this

chapter.

3. While performing maintenance on the following mentioned components, if there is any problem with a

component, be sure to replace it with a new one.

• Airbag ECU assembly.

• Clock spring assembly.

• Driver side airbag assembly.

• Front passenger side airbag module.

• Driver side preload seat belt.

• Front passenger side preload seat belt.

• Airbag wire harness.

4. While performing maintenance, please disconnect the battery's negative terminal connector, and then

after waiting for 60 s, commence operation. Furthermore, wrap up the removed negative terminal with

insulating tape.

After the battery power is cut off, the capacitor in the airbag ECU will still maintain a set amount of electrical

energy. If used without waiting a sufficient amount of time, it may lead to serious injury and accidents due to

the airbag's faulty deployment.

5. When painting the vehicle, excessive heat may influence the components, in which case the SRS-ECU,

airbag module, clock spring, etc., should first be removed and set aside\

.

Use a diagnostic scanner to clear the trouble code after the SRS airbag is repaired, as to ensure the warning

lamp will continue to work normaly.

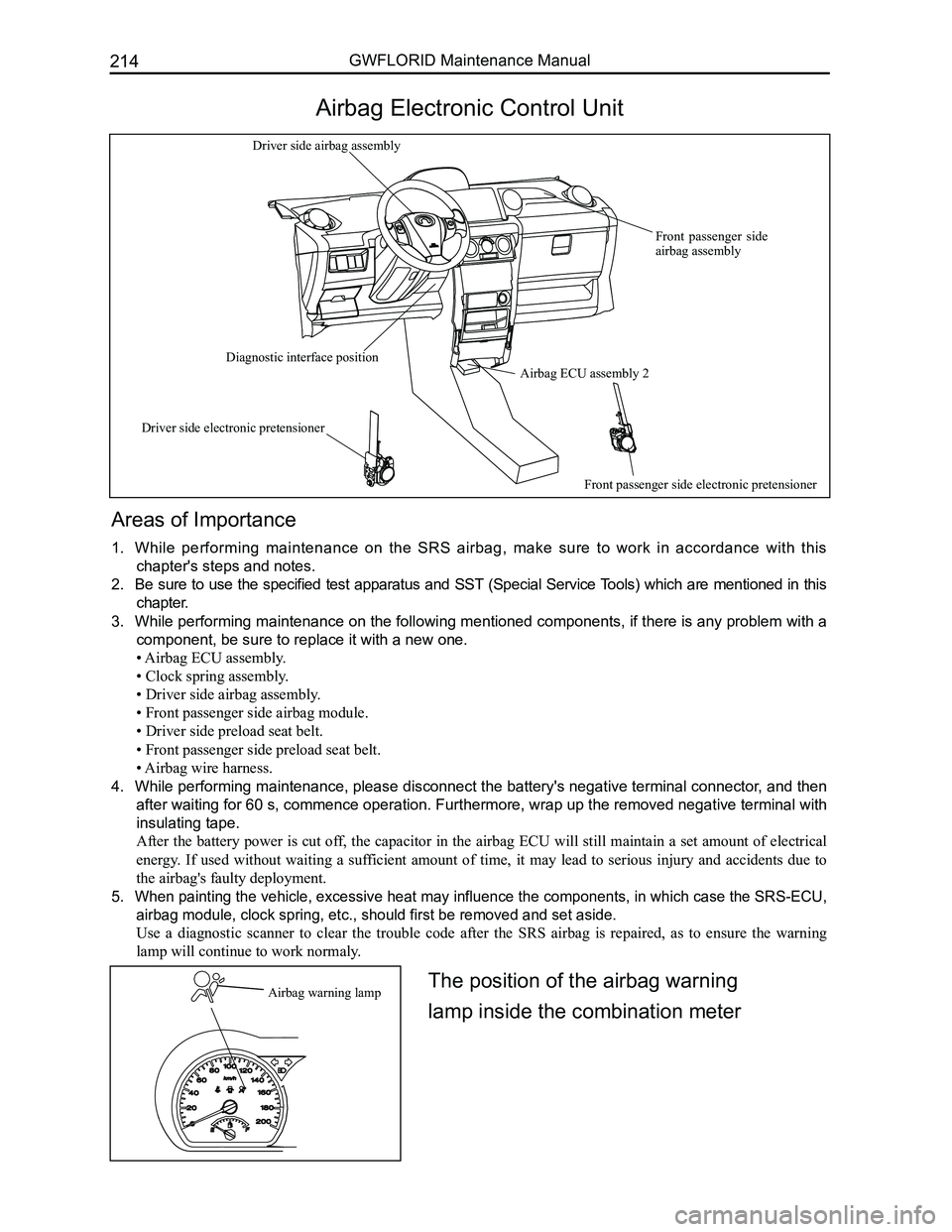

Airbag Electronic Control Unit

Airbag warning lamp

Airbag ECU assembly 2

Front passenger side airbag assembly

Driver side airbag assembly

Diagnostic interface position

Driver side electronic pretensioner

Front passenger side electronic pretensioner

The position of the airbag warning

lamp inside the combination meter

Page 222 of 281

Downloaded from www.Manualslib.com manuals search engine 215Airbags

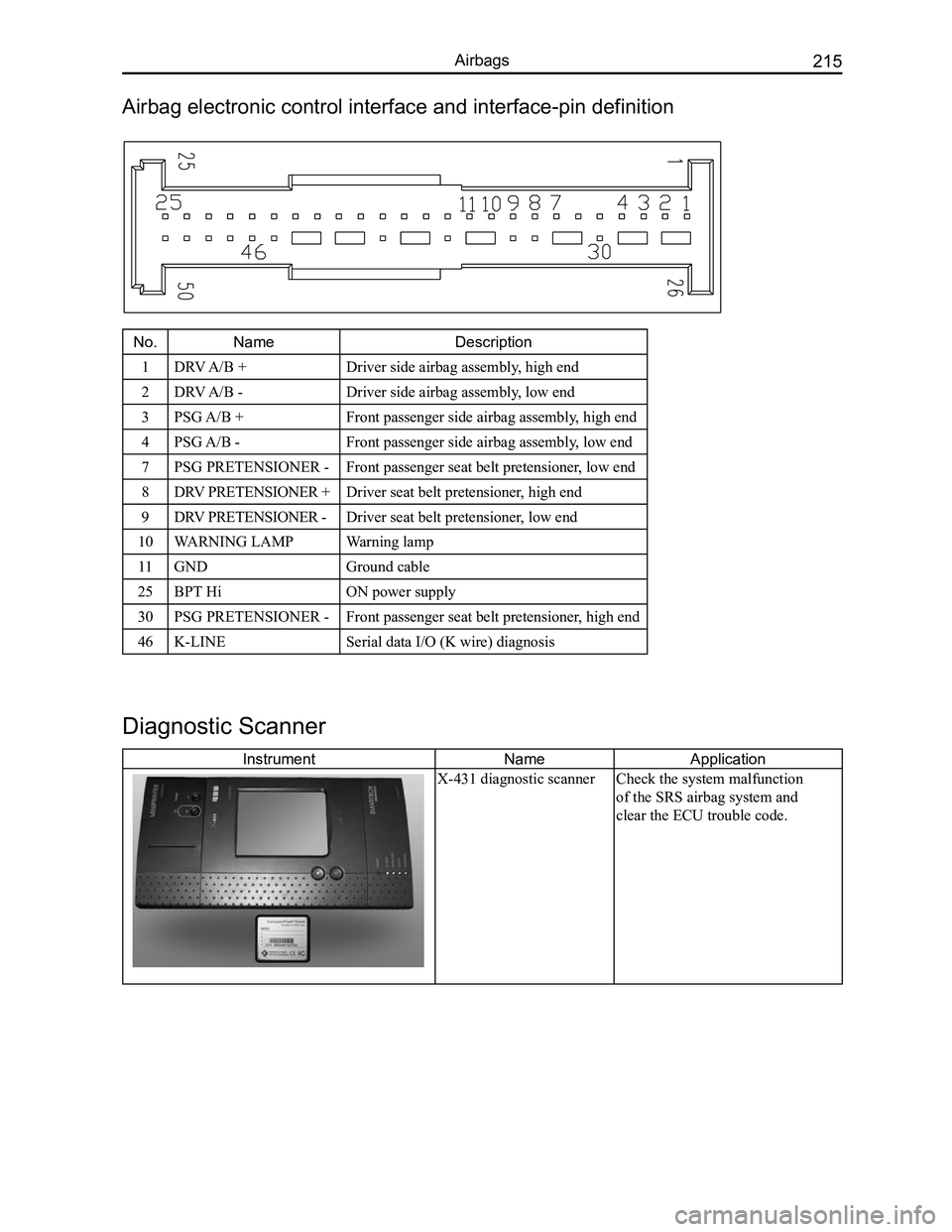

Airbag electronic control interface and interface-pin definition

No. NameDescription

1DRV A/B + Driver side airbag assembly, high end

2DRV A/B -Driver side airbag assembly, low end

3PSG A/B +Front passenger side airbag assembly, high end

4PSG A/B -Front passenger side airbag assembly, low end

7PSG PRETENSIONER -Front passenger seat belt pretensioner, low end

8DRV PRETENSIONER +Driver seat belt pretensioner, high end

9DRV PRETENSIONER -Driver seat belt pretensioner, low end

10WARNING LAMPWarning lamp

11GNDGround cable

25BPT Hi ON power supply

30PSG PRETENSIONER -Front passenger seat belt pretensioner, high end

46K-LINESerial data I/O (K wire) diagnosis

Diagnostic Scanner

InstrumentNameApplication

X-431 diagnostic scannerCheck the system malfunction

of the SRS airbag system and

clear the ECU trouble code.

Page 223 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual216

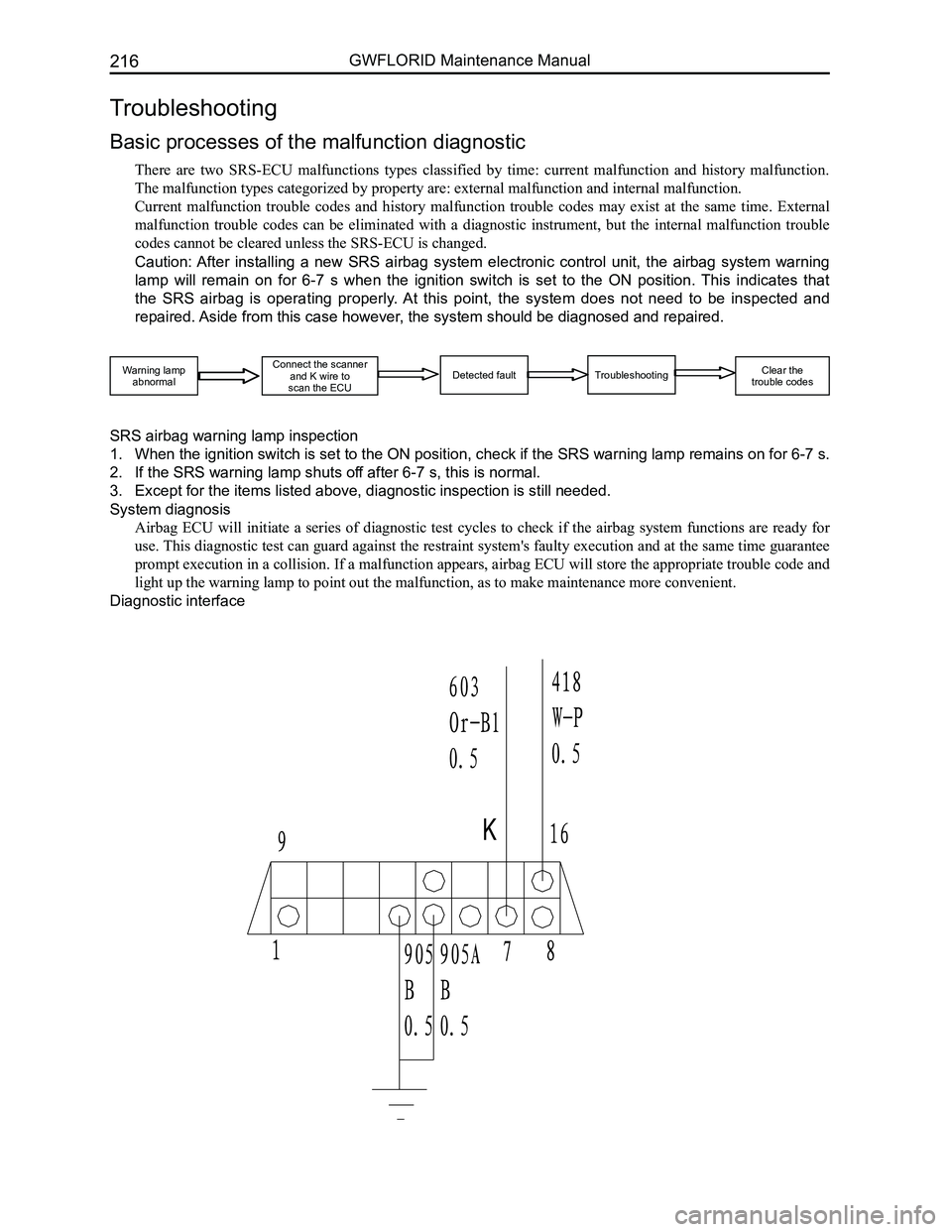

SRS airbag warning lamp inspection

1. When the ignition switch is set to the ON position, check if the SRS warning lamp remains on for 6-7 s.

2. If the SRS warning lamp shuts off after 6-7 s, this is normal.

3. Except for the items listed above, diagnostic inspection is still needed\

.

System diagnosis

Airbag ECU will initiate a series of diagnostic test cycles to check if the airbag system functions are ready for

use. This diagnostic test can guard against the restraint system's faulty execution and at the same time guarantee

prompt execution in a collision. If a malfunction appears, airbag ECU will store the appropriate trouble code and

light up the warning lamp to point out the malfunction, as to make maint\

enance more convenient.

Diagnostic interface

Troubleshooting

Basic processes of the malfunction diagnostic

There are two SRS-ECU malfunctions types classified by time: current malfunction and history malfunction.

The malfunction types categorized by property are: external malfunction \

and internal malfunction.

Current malfunction trouble codes and history malfunction trouble codes may exist at the same time. External

malfunction trouble codes can be eliminated with a diagnostic instrument, but the internal malfunction trouble

codes cannot be cleared unless the SRS-ECU is changed.

Caution: After installing a new SRS airbag system electronic control unit, the airbag system warning

lamp will remain on for 6-7 s when the ignition switch is set to the ON position. This indicates that

the SRS airbag is operating properly. At this point, the system does not need to be inspected and

repaired. Aside from this case however, the system should be diagnosed and repaired.

Warning lampabnormal

Connect the scannerand K wire to scan the ECUDetected faultTroubleshooting Clear the trouble codes

Page 224 of 281

Downloaded from www.Manualslib.com manuals search engine 217Airbags

Malfunction judgment

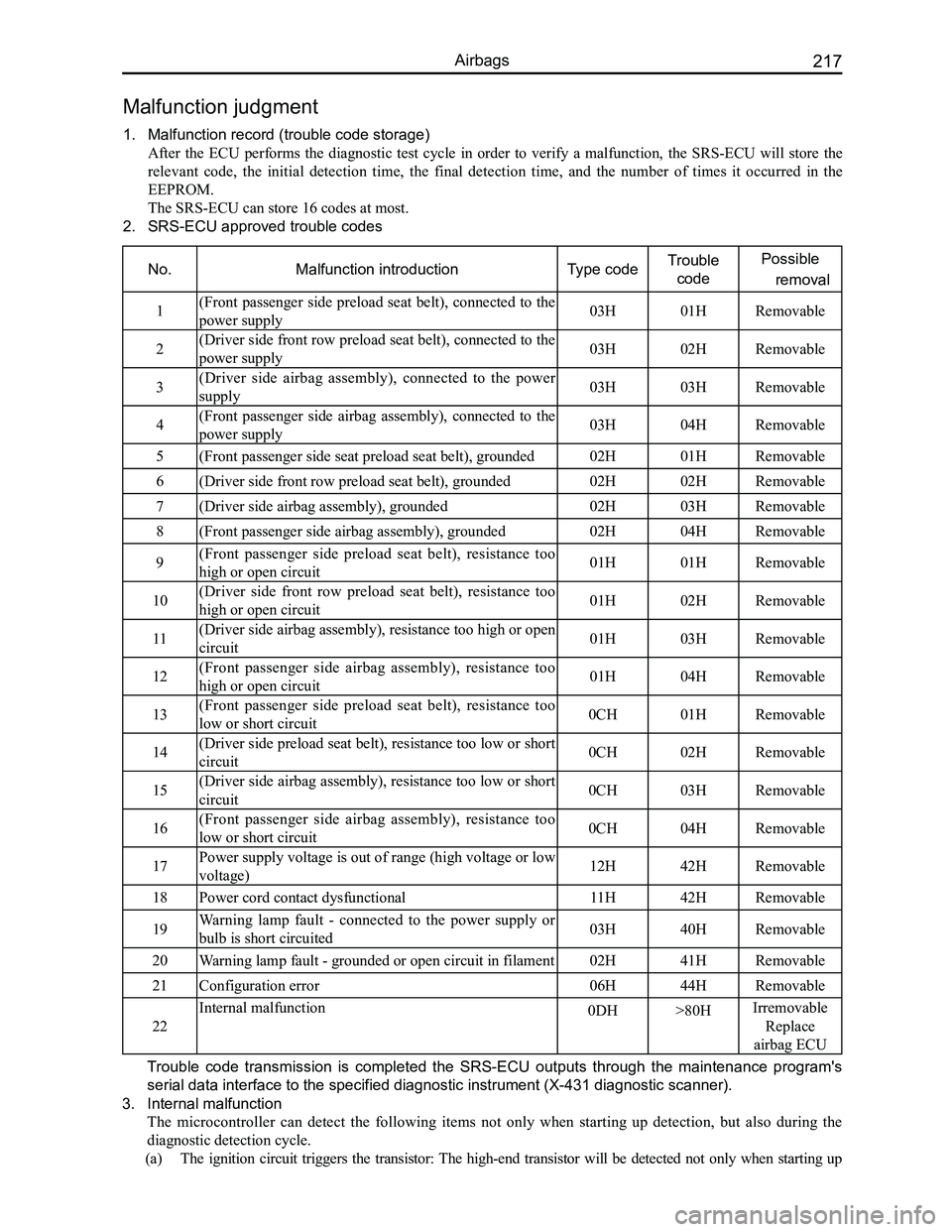

1. Malfunction record (trouble code storage)

After the ECU performs the diagnostic test cycle in order to verify a malfunction, the SRS-ECU will store the

relevant code, the initial detection time, the final detection time, and the number of times it occurred in the

EEPROM.

The SRS-ECU can store 16 codes at most.

2. SRS-ECU approved trouble codes

No.Malfunction introductionType codeTrouble

code

Possible

removal

1(Front passenger side preload seat belt), connected to the

power supply03H01HRemovable

2(Driver side front row preload seat belt), connected to the

power supply03H02HRemovable

3(Driver side airbag assembly), connected to the power

supply03H03HRemovable

4(Front passenger side airbag assembly), connected to the

power supply03H04HRemovable

5(Front passenger side seat preload seat belt), grounded02H01HRemovable

6(Driver side front row preload seat belt), grounded02H02HRemovable

7(Driver side airbag assembly), grounded02H03HRemovable

8(Front passenger side airbag assembly), grounded02H04HRemovable

9(Front passenger side preload seat belt), resistance too

high or open circuit01H01HRemovable

10(Driver side front row preload seat belt), resistance too

high or open circuit01H02HRemovable

11(Driver side airbag assembly), resistance too high or open

circuit01H03HRemovable

12(Front passenger side airbag assembly), resistance too

high or open circuit01H04HRemovable

13(Front passenger side preload seat belt), resistance too

low or short circuit0CH01HRemovable

14(Driver side preload seat belt), resistance too low or short

circuit0CH02HRemovable

15(Driver side airbag assembly), resistance too low or short

circuit0CH03HRemovable

16(Front passenger side airbag assembly), resistance too

low or short circuit0CH04HRemovable

17Power supply voltage is out of range (high voltage or low

voltage)12H42HRemovable

18Power cord contact dysfunctional11H42HRemovable

19Warning lamp fault - connected to the power supply or

bulb is short circuited03H40HRemovable

20Warning lamp fault - grounded or open circuit in filament02H41HRemovable

21Configuration error06H44HRemovable

22

Internal malfunction0DH>80HIrremovable

Replace

airbag ECU

Trouble code transmission is completed the SRS-ECU outputs through the maintenance program's

serial data interface to the specified diagnostic instrument (X-431 dia\

gnostic scanner).

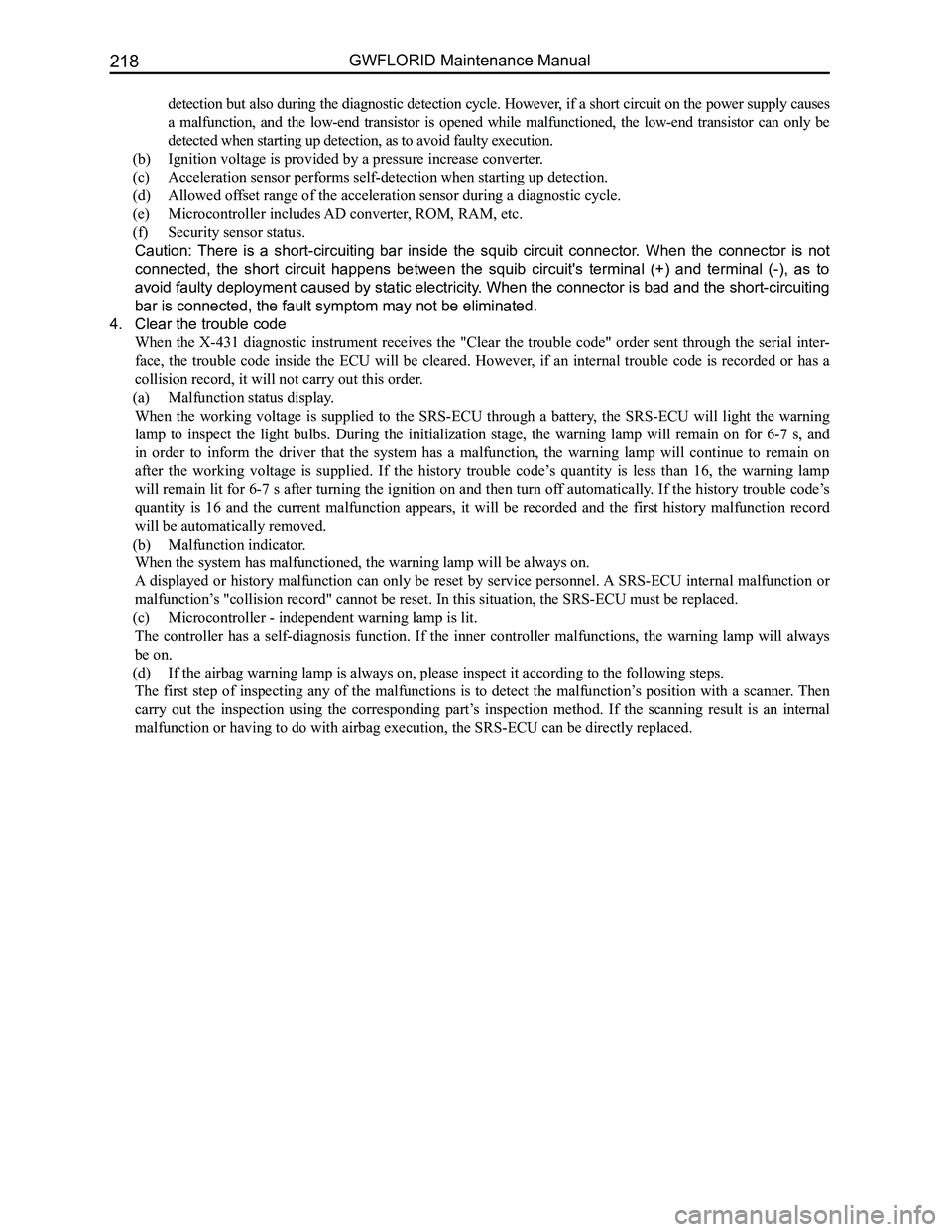

3. Internal malfunction

The microcontroller can detect the following items not only when starting up detection, but also during the

diagnostic detection cycle.

(a) The ignition circuit triggers the transistor: The high-end transistor will be detected not only when starting up

Page 225 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual218

detection but also during the diagnostic detection cycle. However, if a short circuit on the power supply causes

a malfunction, and the low-end transistor is opened while malfunctioned, the low-end transistor can only be

detected when starting up detection, as to avoid faulty execution.

(b) Ignition voltage is provided by a pressure increase converter.

(c) Acceleration sensor performs self-detection when starting up detection.

(d) Allowed offset range of the acceleration sensor during a diagnostic cycle.

(e) Microcontroller includes AD converter, ROM, RAM, etc.

(f) Security sensor status.

Caution: There is a short-circuiting bar inside the squib circuit connector. When the connector is not

connected, the short circuit happens between the squib circuit's terminal (+) and terminal (-), as to

avoid faulty deployment caused by static electricity. When the connector is bad and the short-circuiting

bar is connected, the fault symptom may not be eliminated.

4. Clear the trouble code

When the X-431 diagnostic instrument receives the "Clear the trouble code" order sent through the serial inter-

face, the trouble code inside the ECU will be cleared. However, if an internal trouble code is recorded or has a

collision record, it will not carry out this order.

(a) Malfunction status display.

When the working voltage is supplied to the SRS-ECU through a battery, the SRS-ECU will light the warning

lamp to inspect the light bulbs. During the initialization stage, the warning lamp will remain on for 6-7 s, and

in order to inform the driver that the system has a malfunction, the warning lamp will continue to remain on

after the working voltage is supplied. If the history trouble code’s quantity is less than 16, the warning lamp

will remain lit for 6-7 s after turning the ignition on and then turn off automatically. If the history trouble code’s

quantity is 16 and the current malfunction appears, it will be recorded and the first history malfunction record

will be automatically removed.

(b) Malfunction indicator.

When the system has malfunctioned, the warning lamp will be always on.

A displayed or history malfunction can only be reset by service personnel. A SRS-ECU internal malfunction or

malfunction’s "collision record" cannot be reset. In this situation, the SRS-ECU mus\

t be replaced.

(c) Microcontroller - independent warning lamp is lit.

The controller has a self-diagnosis function. If the inner controller malfunctions, the warning lamp will always

be on.

(d) If the airbag warning lamp is always on, please inspect it according to the following steps.

The first step of inspecting any of the malfunctions is to detect the malfunction’s position with a scanner. Then

carry out the inspection using the corresponding part’s inspection method. If the scanning result is an internal

malfunction or having to do with airbag execution, the SRS-ECU can be di\

rectly replaced.

Page 226 of 281

Downloaded from www.Manualslib.com manuals search engine 219Airbags

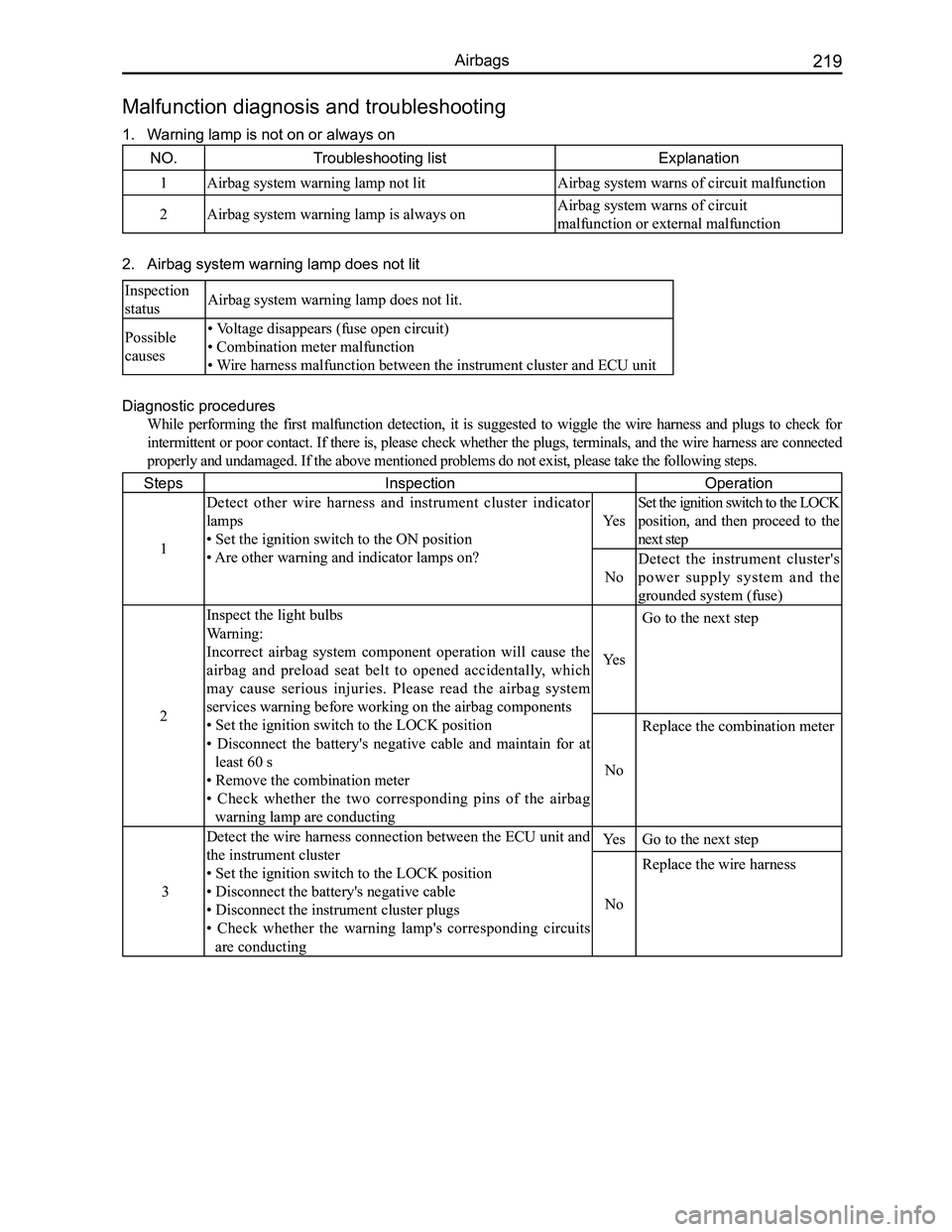

NO.Troubleshooting listExplanation

1Airbag system warning lamp not litAirbag system warns of circuit malfunction

2Airbag system warning lamp is always onAirbag system warns of circuit

malfunction or external malfunction

2. Airbag system warning lamp does not lit

Inspection

statusAirbag system warning lamp does not lit.

Possible

causes

• Voltage disappears (fuse open circuit)

• Combination meter malfunction

• Wire harness malfunction between the instrument cluster and ECU unit

Diagnostic procedures

While performing the first malfunction detection, it is suggested to wiggle the wire harness and plugs to check for

intermittent or poor contact. If there is, please check whether the plugs, terminals, and the wire harness are connected

properly and undamaged. If the above mentioned problems do not exist, pl\

ease take the following steps.

StepsInspectionOperation

1

Detect other wire harness and instrument cluster indicator

lamps

• Set the ignition switch to the ON position

• Are other warning and indicator lamps on?

Yes

Set the ignition switch to the LOCK

position, and then proceed to the

next step

No

Detect the instrument cluster's

power supply system and the

grounded system (fuse)

2

Inspect the light bulbs

Warning:

Incorrect airbag system component operation will cause the

airbag and preload seat belt to opened accidentally, which

may cause serious injuries. Please read the airbag system

services warning before working on the airbag components

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 60 s

• Remove the combination meter

• Check whether the two corresponding pins of the airbag

warning lamp are conducting

Yes

Go to the next step

No

Replace the combination meter

3

Detect the wire harness connection between the ECU unit and

the instrument cluster

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable

• Disconnect the instrument cluster plugs

• Check whether the warning lamp's corresponding circuits

are conducting

YesGo to the next step

No

Replace the wire harness

Malfunction diagnosis and troubleshooting

1. Warning lamp is not on or always on

Page 227 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual220

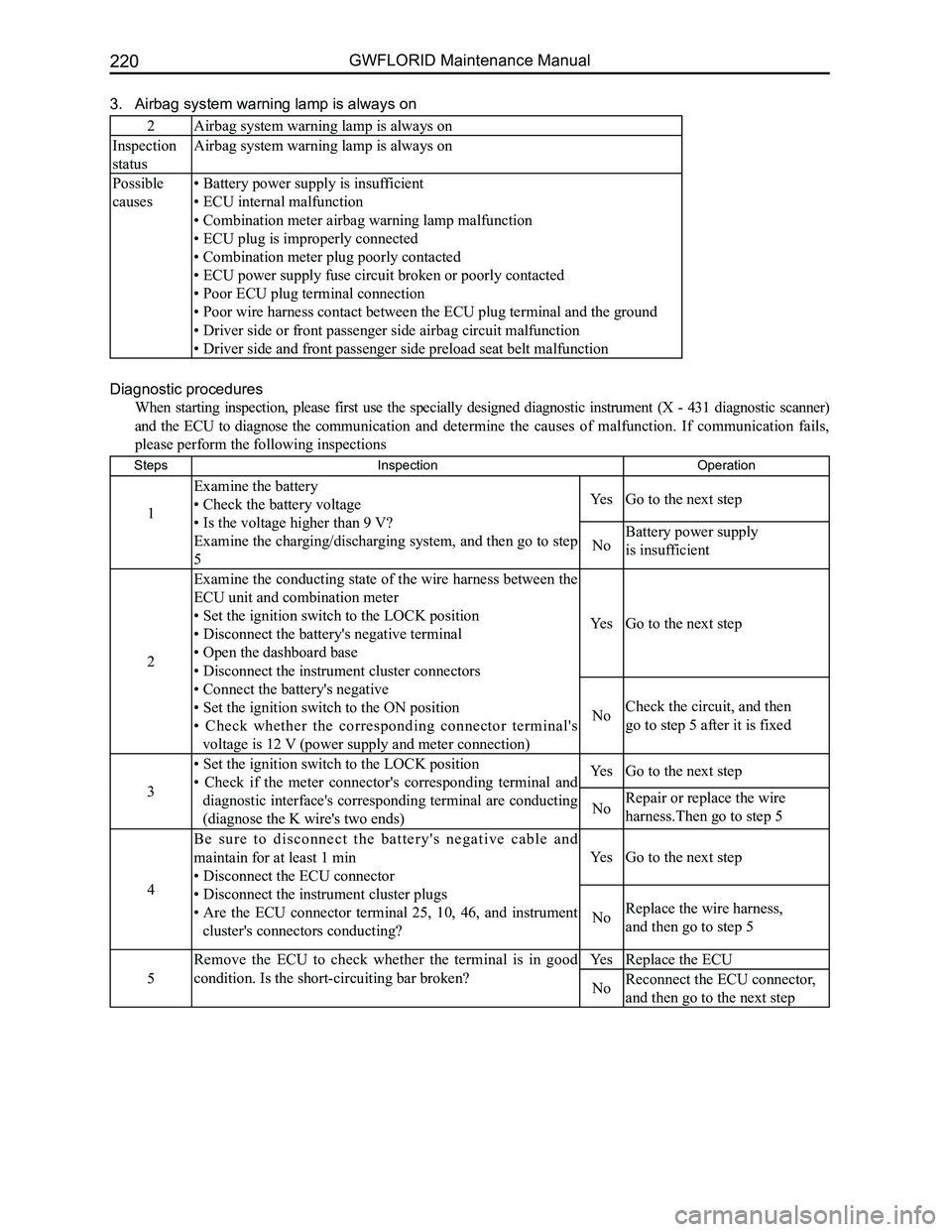

3. Airbag system warning lamp is always on

2Airbag system warning lamp is always on

Inspection

status

Airbag system warning lamp is always on

Possible

causes

• Battery power supply is insufficient

• ECU internal malfunction

• Combination meter airbag warning lamp malfunction

• ECU plug is improperly connected

• Combination meter plug poorly contacted

• ECU power supply fuse circuit broken or poorly contacted

• Poor ECU plug terminal connection

• Poor wire harness contact between the ECU plug terminal and the ground

• Driver side or front passenger side airbag circuit malfunction

• Driver side and front passenger side preload seat belt malfunction

Diagnostic procedures

When starting inspection, please first use the specially designed diagnostic instrument (X - 431 diagnostic scanner)

and the ECU to diagnose the communication and determine the causes of malfunction. If communication fails,

please perform the following inspections

StepsInspection Operation

1

Examine the battery

• Check the battery voltage

• Is the voltage higher than 9 V?

Examine the charging/discharging system, and then go to step

5

YesGo to the next step

NoBattery power supply

is insufficient

2

Examine the conducting state of the wire harness between the

ECU unit and combination meter

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative terminal

• Open the dashboard base

• Disconnect the instrument cluster connectors

• Connect the battery's negative

• Set the ignition switch to the ON position

• Check whether the corresponding connector terminal's

voltage is 12 V (power supply and meter connection)

YesGo to the next step

NoCheck the circuit, and then

go to step 5 after it is fixed

3

• Set the ignition switch to the LOCK position

• Check if the meter connector's corresponding terminal and

diagnostic interface's corresponding terminal are conducting

(diagnose the K wire's two ends)

YesGo to the next step

NoRepair or replace the wire

harness.Then go to step 5

4

B e s u r e t o d i s c o n n e c t t h e b a t t e r y ' s n e g a t i v e c a b l e a n d

maintain for at least 1 min

• Disconnect the ECU connector

• Disconnect the instrument cluster plugs

• Are the ECU connector terminal 25, 10, 46, and instrument

cluster's connectors conducting?

YesGo to the next step

NoReplace the wire harness,

and then go to step 5

5

Remove the ECU to check whether the terminal is in good

condition. Is the short-circuiting bar broken?

YesReplace the ECU

NoReconnect the ECU connector,

and then go to the next step

Page 228 of 281

Downloaded from www.Manualslib.com manuals search engine 221Airbags

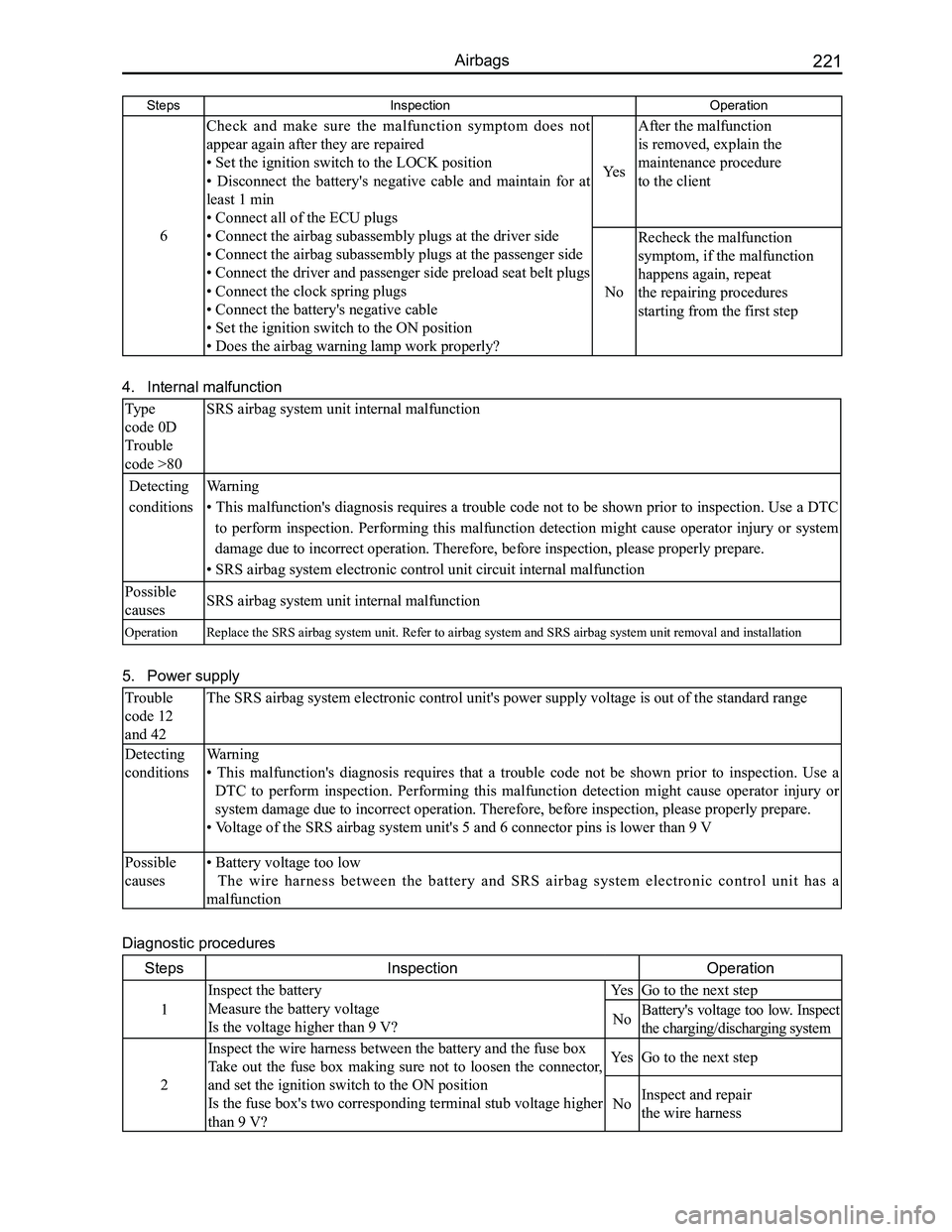

StepsInspection Operation

6

Check and make sure the malfunction symptom does not

appear again after they are repaired

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 1 min

• Connect all of the ECU plugs

• Connect the airbag subassembly plugs at the driver side

• Connect the airbag subassembly plugs at the passenger side

• Connect the driver and passenger side preload seat belt plugs

• Connect the clock spring plugs

• Connect the battery's negative cable

• Set the ignition switch to the ON position

• Does the airbag warning lamp work properly?

Yes

After the malfunction

is removed, explain the

maintenance procedure

to the client

No

Recheck the malfunction

symptom, if the malfunction

happens again, repeat

the repairing procedures

starting from the first step

4. Internal malfunction

Type

code 0D

Trouble

code >80

SRS airbag system unit internal malfunction

Detecting

conditions

Warning

• This malfunction's diagnosis requires a trouble code not to be shown prior to inspection. Use a DTC

to perform inspection. Performing this malfunction detection might cause operator injury or system

damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• SRS airbag system electronic control unit circuit internal malfunction

Possible

causesSRS airbag system unit internal malfunction

OperationReplace the SRS airbag system unit. Refer to airbag system and SRS airba\

g system unit removal and installation

5. Power supply

Trouble

code 12

and 42

The SRS airbag system electronic control unit's power supply voltage is \

out of the standard range

Detecting

conditions

Warning

• This malfunction's diagnosis requires that a trouble code not be shown prior to inspection. Use a

DTC to perform inspection. Performing this malfunction detection might cause operator injury or

system damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• Voltage of the SRS airbag system unit's 5 and 6 connector pins is lower than 9 V

Possible

causes

• Battery voltage too low

The wire harness between the battery and SRS airbag system electronic control unit has a

malfunction

Diagnostic procedures

StepsInspectionOperation

1

Inspect the battery

Measure the battery voltage

Is the voltage higher than 9 V?

YesGo to the next step

NoBattery's voltage too low. Inspect

the charging/discharging system

2

Inspect the wire harness between the battery and the fuse box

Take out the fuse box making sure not to loosen the connector,

and set the ignition switch to the ON position

Is the fuse box's two corresponding terminal stub voltage higher

than 9 V?

YesGo to the next step

NoInspect and repair

the wire harness