belt GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 221 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual214

Areas of Importance

1. While performing maintenance on the SRS airbag, make sure to work in accordance with this

chapter's steps and notes.

2. Be sure to use the specified test apparatus and SST (Special Service Tools) which are mentioned in this

chapter.

3. While performing maintenance on the following mentioned components, if there is any problem with a

component, be sure to replace it with a new one.

• Airbag ECU assembly.

• Clock spring assembly.

• Driver side airbag assembly.

• Front passenger side airbag module.

• Driver side preload seat belt.

• Front passenger side preload seat belt.

• Airbag wire harness.

4. While performing maintenance, please disconnect the battery's negative terminal connector, and then

after waiting for 60 s, commence operation. Furthermore, wrap up the removed negative terminal with

insulating tape.

After the battery power is cut off, the capacitor in the airbag ECU will still maintain a set amount of electrical

energy. If used without waiting a sufficient amount of time, it may lead to serious injury and accidents due to

the airbag's faulty deployment.

5. When painting the vehicle, excessive heat may influence the components, in which case the SRS-ECU,

airbag module, clock spring, etc., should first be removed and set aside\

.

Use a diagnostic scanner to clear the trouble code after the SRS airbag is repaired, as to ensure the warning

lamp will continue to work normaly.

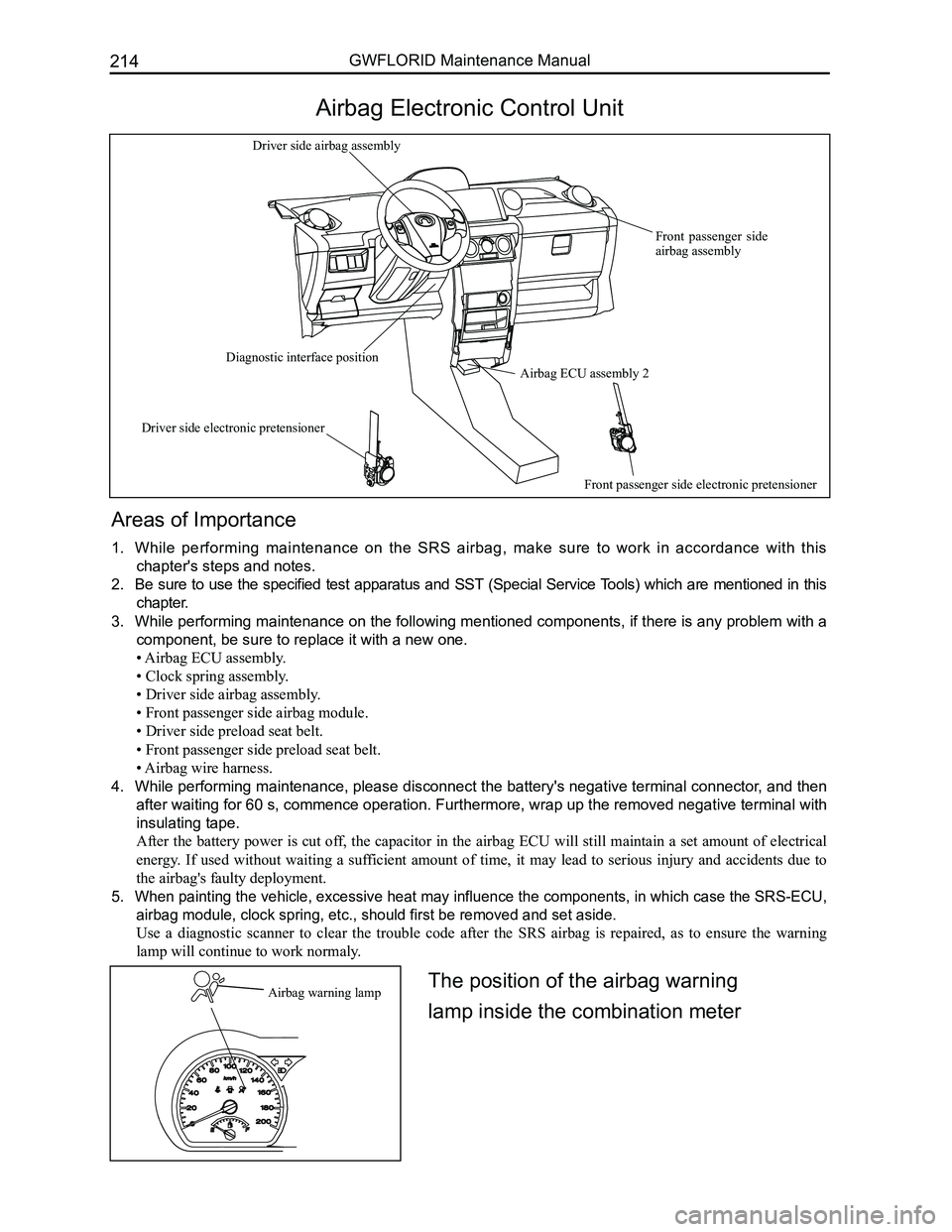

Airbag Electronic Control Unit

Airbag warning lamp

Airbag ECU assembly 2

Front passenger side airbag assembly

Driver side airbag assembly

Diagnostic interface position

Driver side electronic pretensioner

Front passenger side electronic pretensioner

The position of the airbag warning

lamp inside the combination meter

Page 222 of 281

Downloaded from www.Manualslib.com manuals search engine 215Airbags

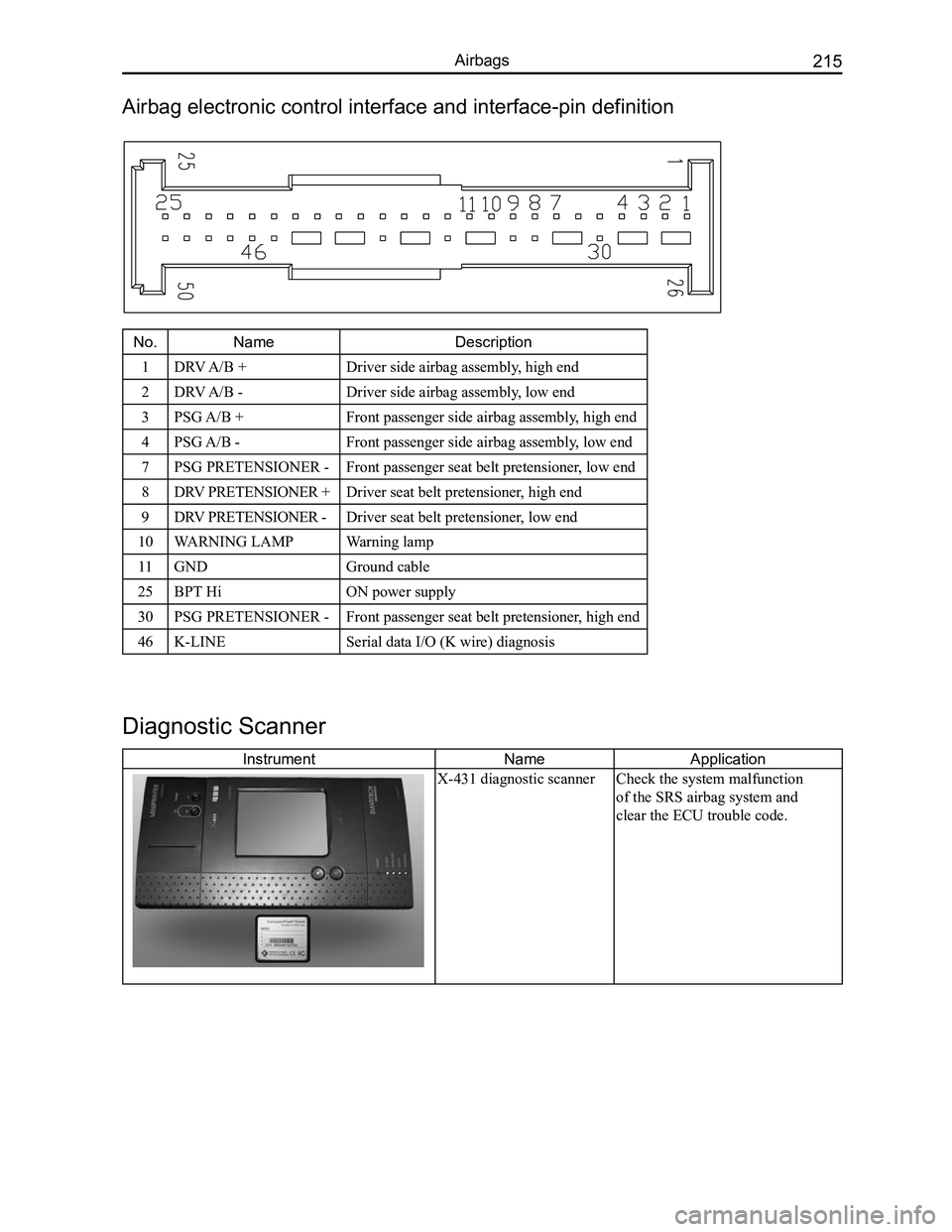

Airbag electronic control interface and interface-pin definition

No. NameDescription

1DRV A/B + Driver side airbag assembly, high end

2DRV A/B -Driver side airbag assembly, low end

3PSG A/B +Front passenger side airbag assembly, high end

4PSG A/B -Front passenger side airbag assembly, low end

7PSG PRETENSIONER -Front passenger seat belt pretensioner, low end

8DRV PRETENSIONER +Driver seat belt pretensioner, high end

9DRV PRETENSIONER -Driver seat belt pretensioner, low end

10WARNING LAMPWarning lamp

11GNDGround cable

25BPT Hi ON power supply

30PSG PRETENSIONER -Front passenger seat belt pretensioner, high end

46K-LINESerial data I/O (K wire) diagnosis

Diagnostic Scanner

InstrumentNameApplication

X-431 diagnostic scannerCheck the system malfunction

of the SRS airbag system and

clear the ECU trouble code.

Page 224 of 281

Downloaded from www.Manualslib.com manuals search engine 217Airbags

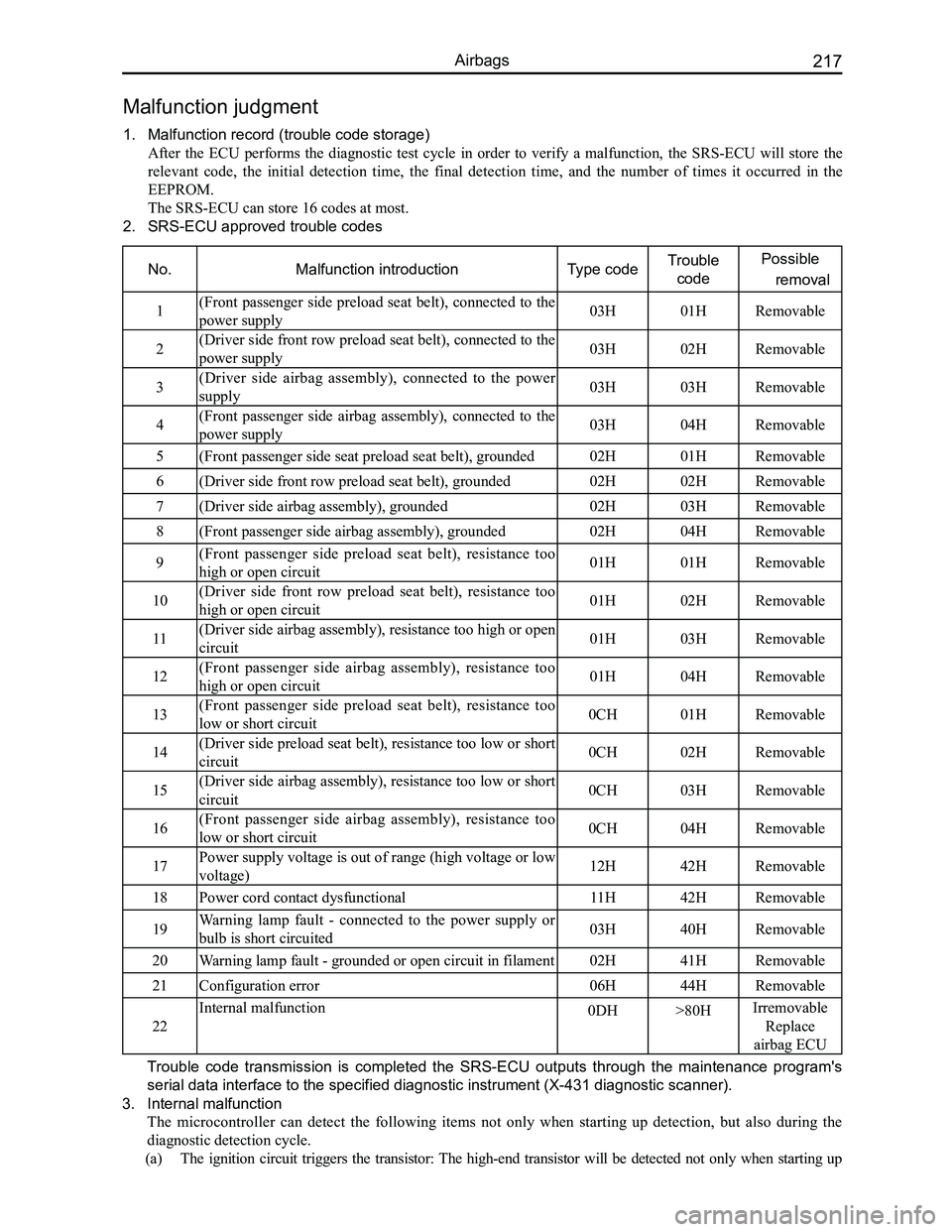

Malfunction judgment

1. Malfunction record (trouble code storage)

After the ECU performs the diagnostic test cycle in order to verify a malfunction, the SRS-ECU will store the

relevant code, the initial detection time, the final detection time, and the number of times it occurred in the

EEPROM.

The SRS-ECU can store 16 codes at most.

2. SRS-ECU approved trouble codes

No.Malfunction introductionType codeTrouble

code

Possible

removal

1(Front passenger side preload seat belt), connected to the

power supply03H01HRemovable

2(Driver side front row preload seat belt), connected to the

power supply03H02HRemovable

3(Driver side airbag assembly), connected to the power

supply03H03HRemovable

4(Front passenger side airbag assembly), connected to the

power supply03H04HRemovable

5(Front passenger side seat preload seat belt), grounded02H01HRemovable

6(Driver side front row preload seat belt), grounded02H02HRemovable

7(Driver side airbag assembly), grounded02H03HRemovable

8(Front passenger side airbag assembly), grounded02H04HRemovable

9(Front passenger side preload seat belt), resistance too

high or open circuit01H01HRemovable

10(Driver side front row preload seat belt), resistance too

high or open circuit01H02HRemovable

11(Driver side airbag assembly), resistance too high or open

circuit01H03HRemovable

12(Front passenger side airbag assembly), resistance too

high or open circuit01H04HRemovable

13(Front passenger side preload seat belt), resistance too

low or short circuit0CH01HRemovable

14(Driver side preload seat belt), resistance too low or short

circuit0CH02HRemovable

15(Driver side airbag assembly), resistance too low or short

circuit0CH03HRemovable

16(Front passenger side airbag assembly), resistance too

low or short circuit0CH04HRemovable

17Power supply voltage is out of range (high voltage or low

voltage)12H42HRemovable

18Power cord contact dysfunctional11H42HRemovable

19Warning lamp fault - connected to the power supply or

bulb is short circuited03H40HRemovable

20Warning lamp fault - grounded or open circuit in filament02H41HRemovable

21Configuration error06H44HRemovable

22

Internal malfunction0DH>80HIrremovable

Replace

airbag ECU

Trouble code transmission is completed the SRS-ECU outputs through the maintenance program's

serial data interface to the specified diagnostic instrument (X-431 dia\

gnostic scanner).

3. Internal malfunction

The microcontroller can detect the following items not only when starting up detection, but also during the

diagnostic detection cycle.

(a) The ignition circuit triggers the transistor: The high-end transistor will be detected not only when starting up

Page 226 of 281

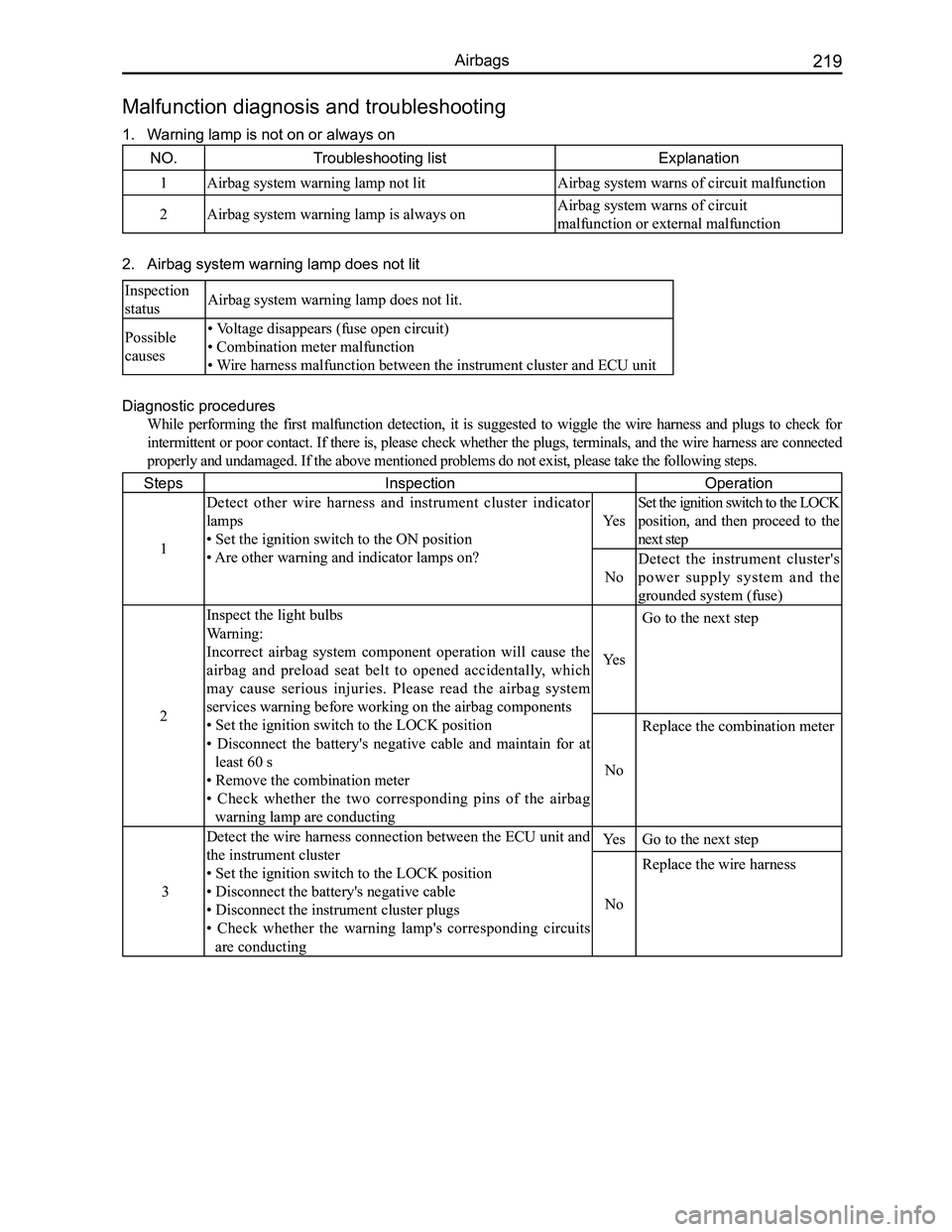

Downloaded from www.Manualslib.com manuals search engine 219Airbags

NO.Troubleshooting listExplanation

1Airbag system warning lamp not litAirbag system warns of circuit malfunction

2Airbag system warning lamp is always onAirbag system warns of circuit

malfunction or external malfunction

2. Airbag system warning lamp does not lit

Inspection

statusAirbag system warning lamp does not lit.

Possible

causes

• Voltage disappears (fuse open circuit)

• Combination meter malfunction

• Wire harness malfunction between the instrument cluster and ECU unit

Diagnostic procedures

While performing the first malfunction detection, it is suggested to wiggle the wire harness and plugs to check for

intermittent or poor contact. If there is, please check whether the plugs, terminals, and the wire harness are connected

properly and undamaged. If the above mentioned problems do not exist, pl\

ease take the following steps.

StepsInspectionOperation

1

Detect other wire harness and instrument cluster indicator

lamps

• Set the ignition switch to the ON position

• Are other warning and indicator lamps on?

Yes

Set the ignition switch to the LOCK

position, and then proceed to the

next step

No

Detect the instrument cluster's

power supply system and the

grounded system (fuse)

2

Inspect the light bulbs

Warning:

Incorrect airbag system component operation will cause the

airbag and preload seat belt to opened accidentally, which

may cause serious injuries. Please read the airbag system

services warning before working on the airbag components

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 60 s

• Remove the combination meter

• Check whether the two corresponding pins of the airbag

warning lamp are conducting

Yes

Go to the next step

No

Replace the combination meter

3

Detect the wire harness connection between the ECU unit and

the instrument cluster

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable

• Disconnect the instrument cluster plugs

• Check whether the warning lamp's corresponding circuits

are conducting

YesGo to the next step

No

Replace the wire harness

Malfunction diagnosis and troubleshooting

1. Warning lamp is not on or always on

Page 227 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual220

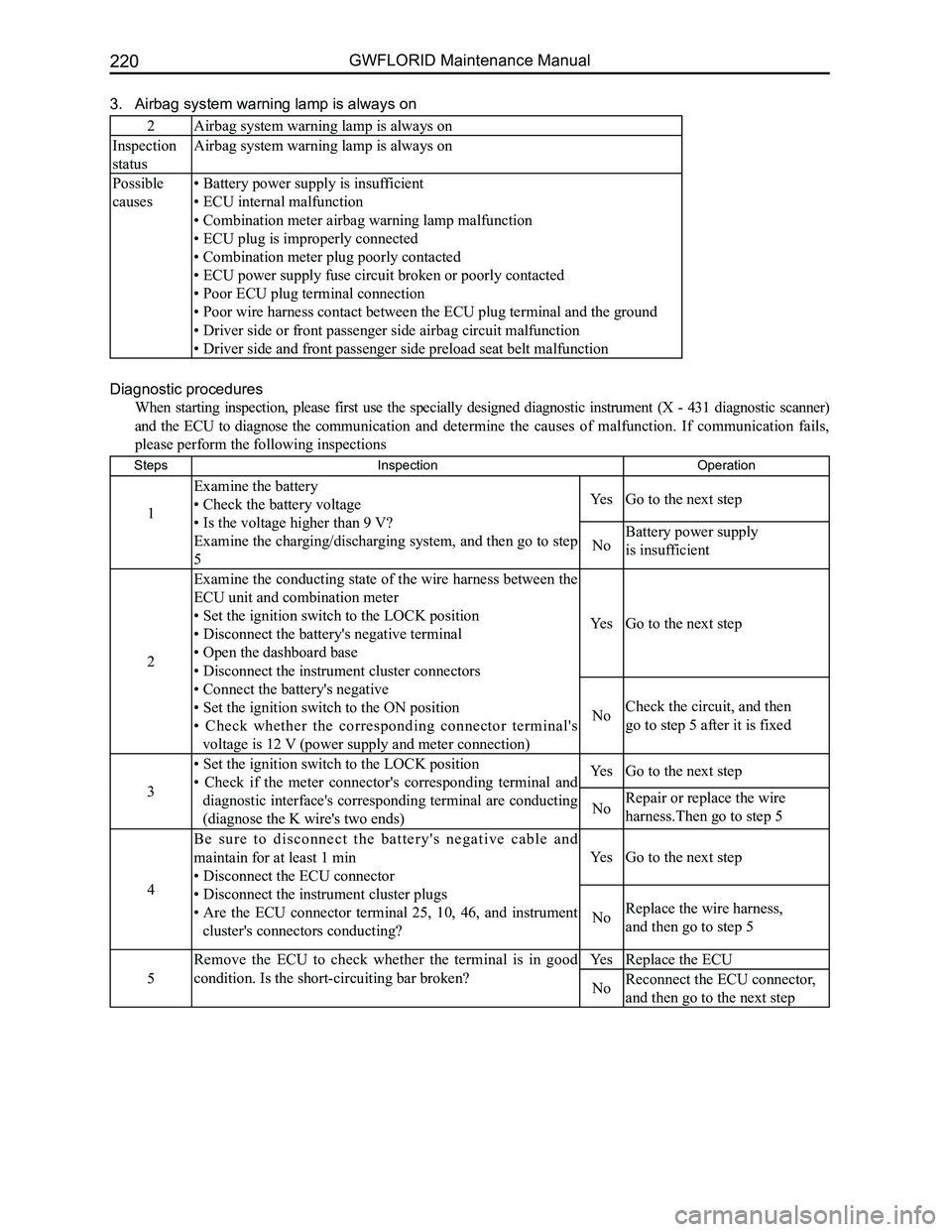

3. Airbag system warning lamp is always on

2Airbag system warning lamp is always on

Inspection

status

Airbag system warning lamp is always on

Possible

causes

• Battery power supply is insufficient

• ECU internal malfunction

• Combination meter airbag warning lamp malfunction

• ECU plug is improperly connected

• Combination meter plug poorly contacted

• ECU power supply fuse circuit broken or poorly contacted

• Poor ECU plug terminal connection

• Poor wire harness contact between the ECU plug terminal and the ground

• Driver side or front passenger side airbag circuit malfunction

• Driver side and front passenger side preload seat belt malfunction

Diagnostic procedures

When starting inspection, please first use the specially designed diagnostic instrument (X - 431 diagnostic scanner)

and the ECU to diagnose the communication and determine the causes of malfunction. If communication fails,

please perform the following inspections

StepsInspection Operation

1

Examine the battery

• Check the battery voltage

• Is the voltage higher than 9 V?

Examine the charging/discharging system, and then go to step

5

YesGo to the next step

NoBattery power supply

is insufficient

2

Examine the conducting state of the wire harness between the

ECU unit and combination meter

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative terminal

• Open the dashboard base

• Disconnect the instrument cluster connectors

• Connect the battery's negative

• Set the ignition switch to the ON position

• Check whether the corresponding connector terminal's

voltage is 12 V (power supply and meter connection)

YesGo to the next step

NoCheck the circuit, and then

go to step 5 after it is fixed

3

• Set the ignition switch to the LOCK position

• Check if the meter connector's corresponding terminal and

diagnostic interface's corresponding terminal are conducting

(diagnose the K wire's two ends)

YesGo to the next step

NoRepair or replace the wire

harness.Then go to step 5

4

B e s u r e t o d i s c o n n e c t t h e b a t t e r y ' s n e g a t i v e c a b l e a n d

maintain for at least 1 min

• Disconnect the ECU connector

• Disconnect the instrument cluster plugs

• Are the ECU connector terminal 25, 10, 46, and instrument

cluster's connectors conducting?

YesGo to the next step

NoReplace the wire harness,

and then go to step 5

5

Remove the ECU to check whether the terminal is in good

condition. Is the short-circuiting bar broken?

YesReplace the ECU

NoReconnect the ECU connector,

and then go to the next step

Page 228 of 281

Downloaded from www.Manualslib.com manuals search engine 221Airbags

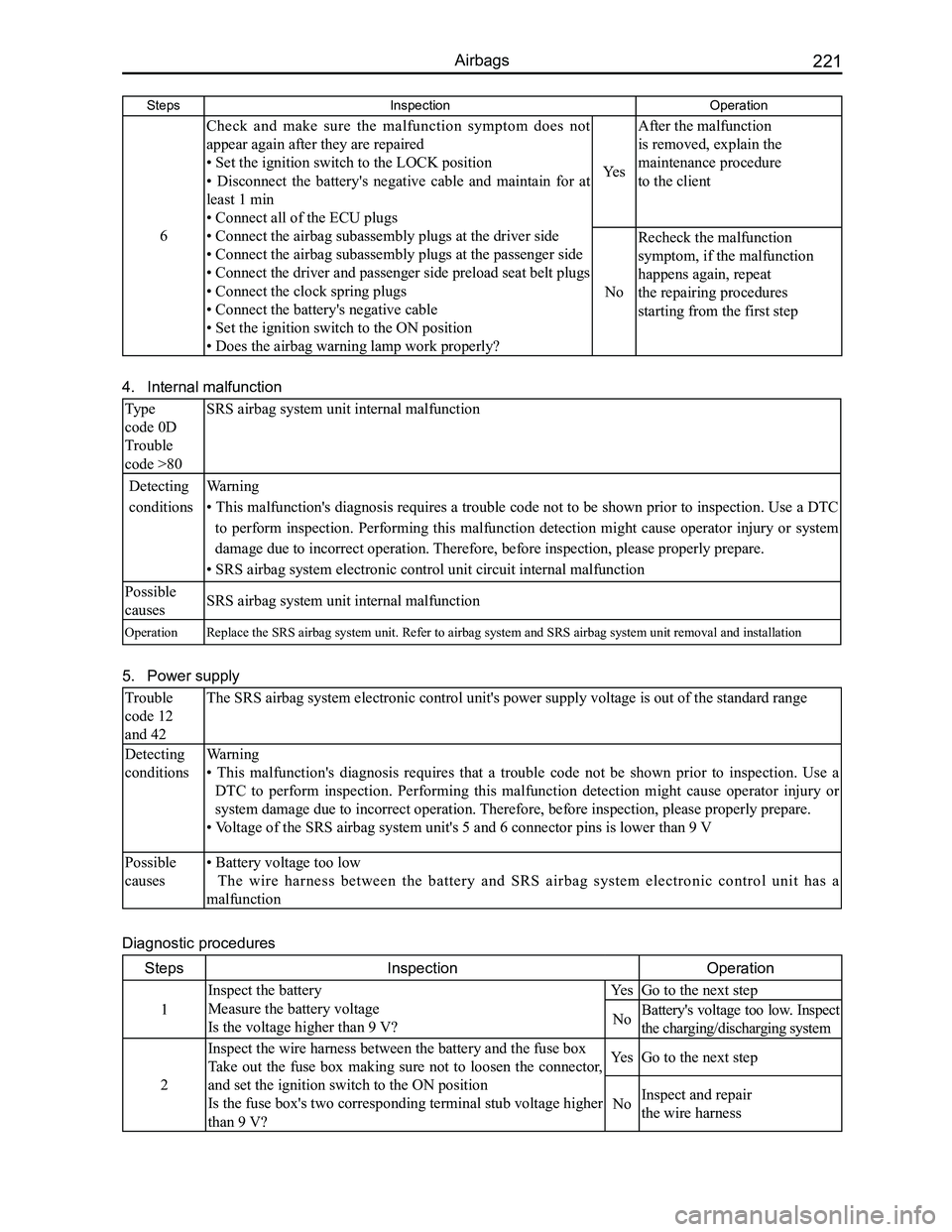

StepsInspection Operation

6

Check and make sure the malfunction symptom does not

appear again after they are repaired

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 1 min

• Connect all of the ECU plugs

• Connect the airbag subassembly plugs at the driver side

• Connect the airbag subassembly plugs at the passenger side

• Connect the driver and passenger side preload seat belt plugs

• Connect the clock spring plugs

• Connect the battery's negative cable

• Set the ignition switch to the ON position

• Does the airbag warning lamp work properly?

Yes

After the malfunction

is removed, explain the

maintenance procedure

to the client

No

Recheck the malfunction

symptom, if the malfunction

happens again, repeat

the repairing procedures

starting from the first step

4. Internal malfunction

Type

code 0D

Trouble

code >80

SRS airbag system unit internal malfunction

Detecting

conditions

Warning

• This malfunction's diagnosis requires a trouble code not to be shown prior to inspection. Use a DTC

to perform inspection. Performing this malfunction detection might cause operator injury or system

damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• SRS airbag system electronic control unit circuit internal malfunction

Possible

causesSRS airbag system unit internal malfunction

OperationReplace the SRS airbag system unit. Refer to airbag system and SRS airba\

g system unit removal and installation

5. Power supply

Trouble

code 12

and 42

The SRS airbag system electronic control unit's power supply voltage is \

out of the standard range

Detecting

conditions

Warning

• This malfunction's diagnosis requires that a trouble code not be shown prior to inspection. Use a

DTC to perform inspection. Performing this malfunction detection might cause operator injury or

system damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• Voltage of the SRS airbag system unit's 5 and 6 connector pins is lower than 9 V

Possible

causes

• Battery voltage too low

The wire harness between the battery and SRS airbag system electronic control unit has a

malfunction

Diagnostic procedures

StepsInspectionOperation

1

Inspect the battery

Measure the battery voltage

Is the voltage higher than 9 V?

YesGo to the next step

NoBattery's voltage too low. Inspect

the charging/discharging system

2

Inspect the wire harness between the battery and the fuse box

Take out the fuse box making sure not to loosen the connector,

and set the ignition switch to the ON position

Is the fuse box's two corresponding terminal stub voltage higher

than 9 V?

YesGo to the next step

NoInspect and repair

the wire harness

Page 229 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual222

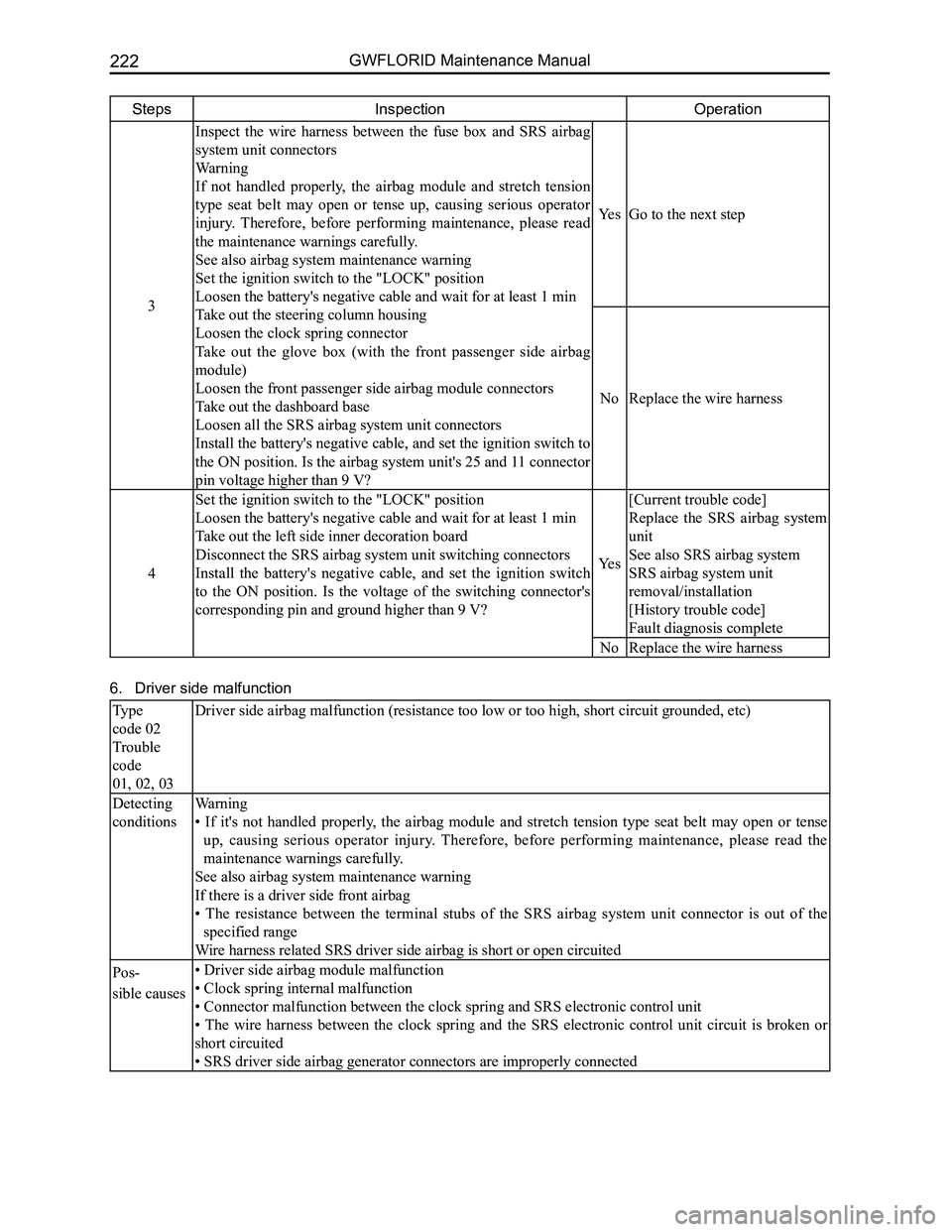

StepsInspectionOperation

3

Inspect the wire harness between the fuse box and SRS airbag

system unit connectors

Warning

If not handled properly, the airbag module and stretch tension

type seat belt may open or tense up, causing serious operator

injury. Therefore, before performing maintenance, please read

the maintenance warnings carefully.

See also airbag system maintenance warning

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the steering column housing

Loosen the clock spring connector

Take out the glove box (with the front passenger side airbag

module)

Loosen the front passenger side airbag module connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Install the battery's negative cable, and set the ignition switch to

the ON position. Is the airbag system unit's 25 and 11 connector

pin voltage higher than 9 V?

YesGo to the next step

NoReplace the wire harness

4

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the left side inner decoration board

Disconnect the SRS airbag system unit switching connectors

Install the battery's negative cable, and set the ignition switch

to the ON position. Is the voltage of the switching connector's

corresponding pin and ground higher than 9 V?

Yes

[Current trouble code]

Replace the SRS airbag system

unit

See also SRS airbag system

SRS airbag system unit

removal/installation

[History trouble code]

Fault diagnosis complete

NoReplace the wire harness

6. Driver side malfunction

Type

code 02

Trouble

code

01, 02, 03

Driver side airbag malfunction (resistance too low or too high, short c\

ircuit grounded, etc)

Detecting

conditions

Warning

• If it's not handled properly, the airbag module and stretch tension type seat belt may open or tense

up, causing serious operator injury. Therefore, before performing maintenance, please read the

maintenance warnings carefully.

See also airbag system maintenance warning

If there is a driver side front airbag

• The resistance between the terminal stubs of the SRS airbag system unit connector is out of the

specified range

Wire harness related SRS driver side airbag is short or open circuited

Pos-

sible causes

• Driver side airbag module malfunction

• Clock spring internal malfunction

• Connector malfunction between the clock spring and SRS electronic control unit

• The wire harness between the clock spring and the SRS electronic control unit circuit is broken or

short circuited

• SRS driver side airbag generator connectors are improperly connected

Page 231 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual224

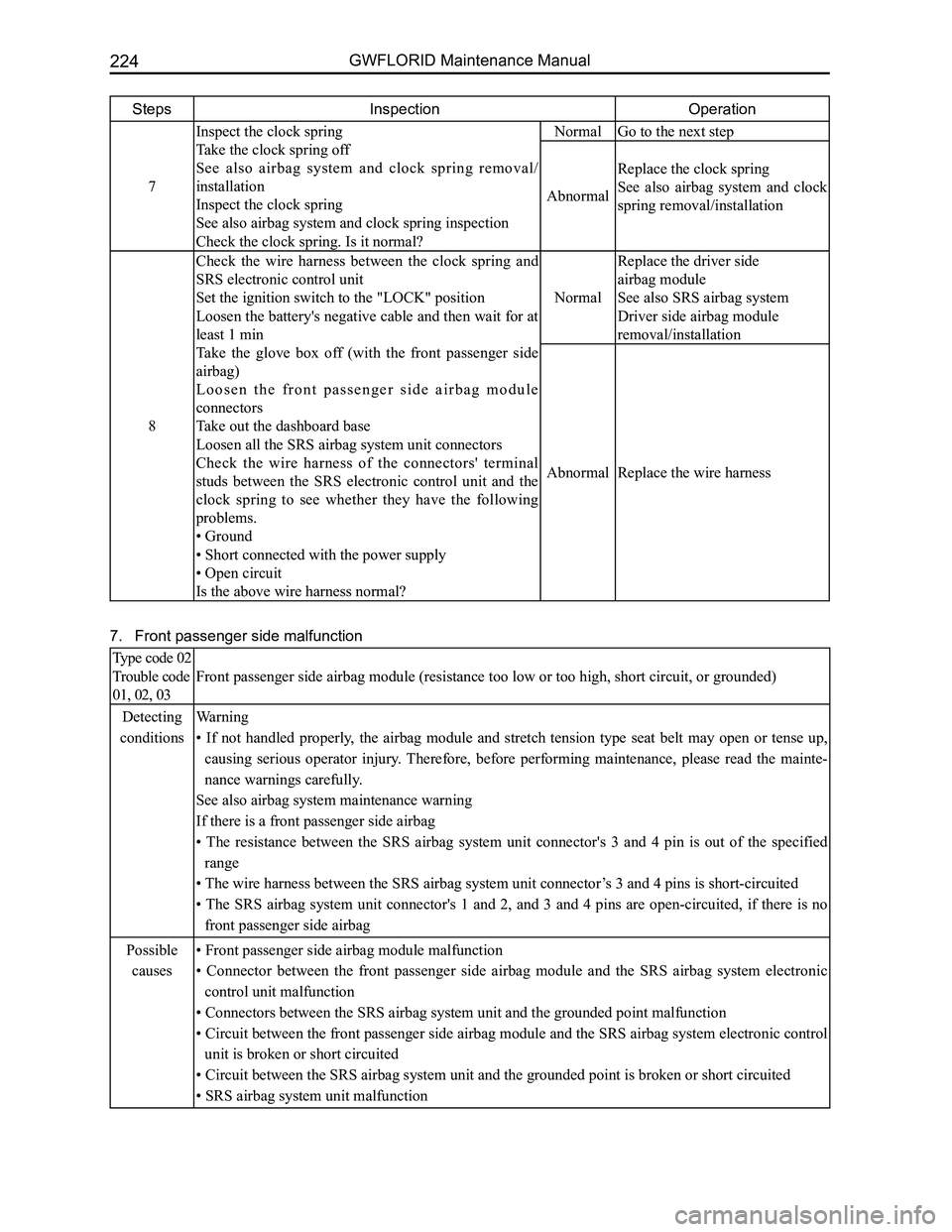

StepsInspectionOperation

7

Inspect the clock spring

Take the clock spring off

See also airbag system and clock spring removal/

installation

Inspect the clock spring

See also airbag system and clock spring inspection

Check the clock spring. Is it normal?

NormalGo to the next step

Abnormal

Replace the clock spring

See also airbag system and clock

spring removal/installation

8

Check the wire harness between the clock spring and

SRS electronic control unit

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and then wait for at

least 1 min

Take the glove box off (with the front passenger side

airbag)

L o o s e n t h e f r o n t p a s s e n g e r s i d e a i r b a g m o d u l e

connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Check the wire harness of the connectors' terminal

studs between the SRS electronic control unit and the

clock spring to see whether they have the following

problems.

• Ground

• Short connected with the power supply

• Open circuit

Is the above wire harness normal?

Normal

Replace the driver side

airbag module

See also SRS airbag system

Driver side airbag module

removal/installation

AbnormalReplace the wire harness

7. Front passenger side malfunction

Type code 02

Trouble code

01, 02, 03

Front passenger side airbag module (resistance too low or too high, sho\

rt circuit, or grounded)

Detecting

conditions

Warning

• If not handled properly, the airbag module and stretch tension type seat belt may open or tense up,

causing serious operator injury. Therefore, before performing maintenance, please read the mainte-

nance warnings carefully.

See also airbag system maintenance warning

If there is a front passenger side airbag

• The resistance between the SRS airbag system unit connector's 3 and 4 pin is out of the specified

range

• The wire harness between the SRS airbag system unit connector’s 3 and 4 pins is short-circuited

• The SRS airbag system unit connector's 1 and 2, and 3 and 4 pins are open-circuited, if there is no

front passenger side airbag

Possible

causes

• Front passenger side airbag module malfunction

• Connector between the front passenger side airbag module and the SRS airbag system electronic

control unit malfunction

• Connectors between the SRS airbag system unit and the grounded point malfunction

• Circuit between the front passenger side airbag module and the SRS airbag system electronic control

unit is broken or short circuited

• Circuit between the SRS airbag system unit and the grounded point is broken or short circuited

• SRS airbag system unit malfunction

Page 233 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual226

Vehicle Collision Diagnostics

Whether the airbag is deployed or not, vehicle collision diagnostic and maintenance must be conducted

according to the following procedures.

1. Check the SRS-ECU diagnostic signal

(a) Connect the diagnostic connector (X-431 diagnostic scanner).

(b) Read the diagnostic result with the X-431 diagnostic.

Caution: Due to impact, and when the battery's power supply is insufficient, the scanner will be unable

to communicate with the SRS-ECU. At this time, use an external power supply, or make sure to

perform inspection and maintenance on the dashboard's wire harness.

2. Maintenance sequence

When the airbag is deployed, the following components should be replaced\

.

(a) Driver side airbag module.

(b) Front passenger side airbag module.

(c) SRS-ECU.

(d) Driver side and front passenger side preload seat belts.

Inspect the following components, if anything is abnormal, replace with \

a new one.

(a) Clock spring.

(b) Steering wheel, steering column, and steering lower shaft components.

Installation status of the driver side airbag module regarding the steer\

ing wheel.

(a) Inspect whether the steering wheel's noise is abnormal, for improper movement, or abnormal cleara\

nce.

(b) Inspect whether the wire harness connectors are broken and whether the terminals are deformed.

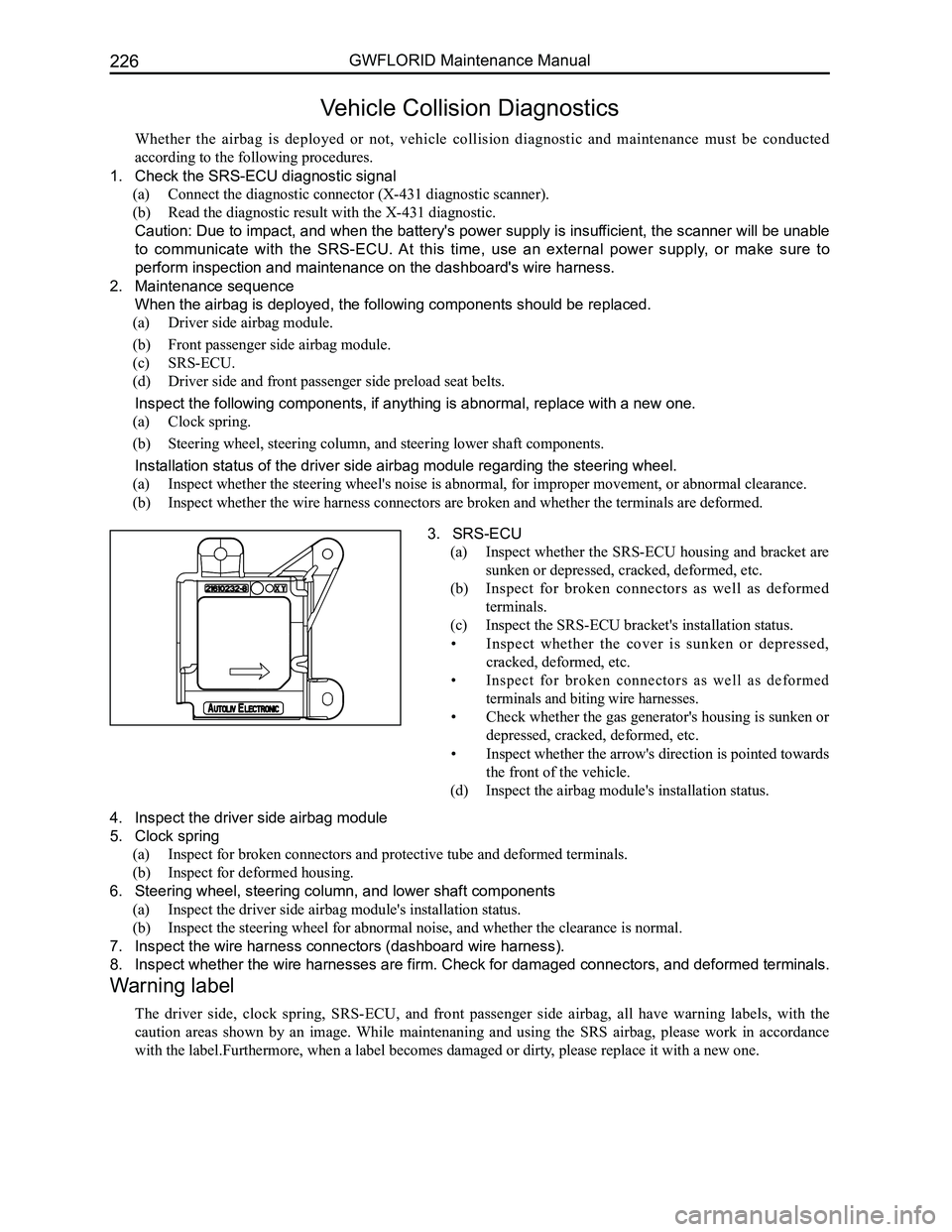

3. SRS-ECU

(a) Inspect whether the SRS-ECU housing and bracket are

sunken or depressed, cracked, deformed, etc.

(b) Inspect for broken connectors as well as deformed

terminals.

(c) Inspect the SRS-ECU bracket's installation status.

• Inspect whether the cover is sunken or depressed,

cracked, deformed, etc.

• Inspect for broken connectors as well as deformed

terminals and biting wire harnesses.

• Check whether the gas generator's housing is sunken or

depressed, cracked, deformed, etc.

• Inspect whether the arrow's direction is pointed towards

the front of the vehicle.

(d) Inspect the airbag module's installation status.

4. Inspect the driver side airbag module

5. Clock spring

(a) Inspect for broken connectors and protective tube and deformed terminals.

(b) Inspect for deformed housing.

6. Steering wheel, steering column, and lower shaft components

(a) Inspect the driver side airbag module's installation status.

(b) Inspect the steering wheel for abnormal noise, and whether the clearance is normal.

7. Inspect the wire harness connectors (dashboard wire harness).

8. Inspect whether the wire harnesses are firm. Check for damaged connectors, and deformed terminals.

Warning label

The driver side, clock spring, SRS-ECU, and front passenger side airbag, all have warning labels, with the

caution areas shown by an image. While maintenaning and using the SRS airbag, please work in accordance

with the label.Furthermore, when a label becomes damaged or dirty, please replace it with a new one.

Page 239 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual232

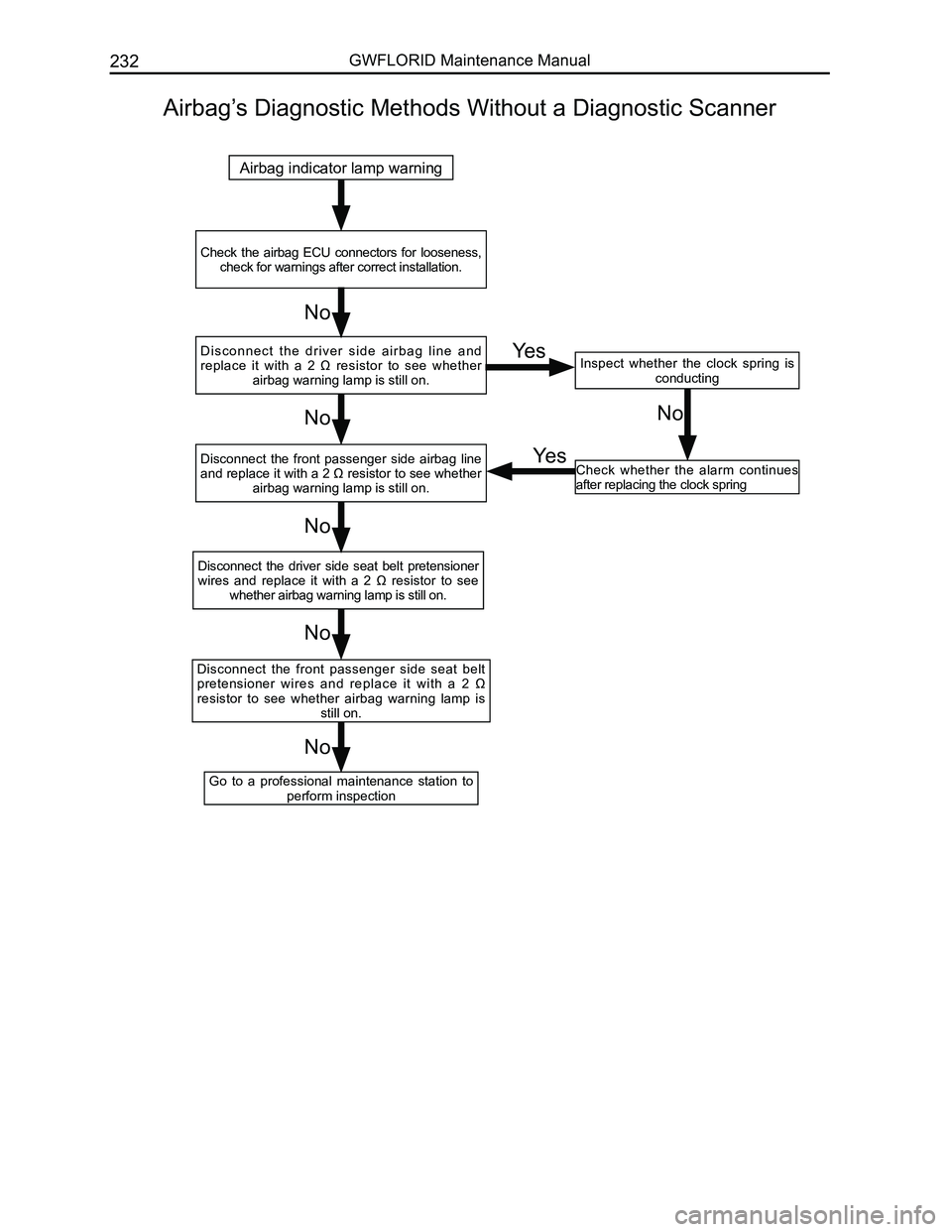

Airbag’s Diagnostic Methods Without a Diagnostic Scanner

Airbag indicator lamp warning

Check the airbag ECU connectors for looseness, check for warnings after correct installation.

Inspect whether the clock spring is conducting

Go to a professional maintenance station to perform inspection

Disconnect the front passenger side seat belt pretensioner wires and replace it with a 2 Ω resistor to see whether airbag warning lamp is still on.

Disconnect the driver side seat belt pretensioner wires and replace it with a 2 Ω resistor to see whether airbag warning lamp is still on.

Disconnect the front passenger side airbag line and replace it with a 2 Ω resistor to see whether airbag warning lamp is still on.

D i s c o n n e c t t h e d r i v e r s i d e a i r b a g l i n e a n d replace it with a 2 Ω resistor to see whether airbag warning lamp is still on.

Check whether the alarm continues after replacing the clock spring

No

No

No

No

NoNo

Yes

Yes