clutch GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 72 of 425

Transmission-33

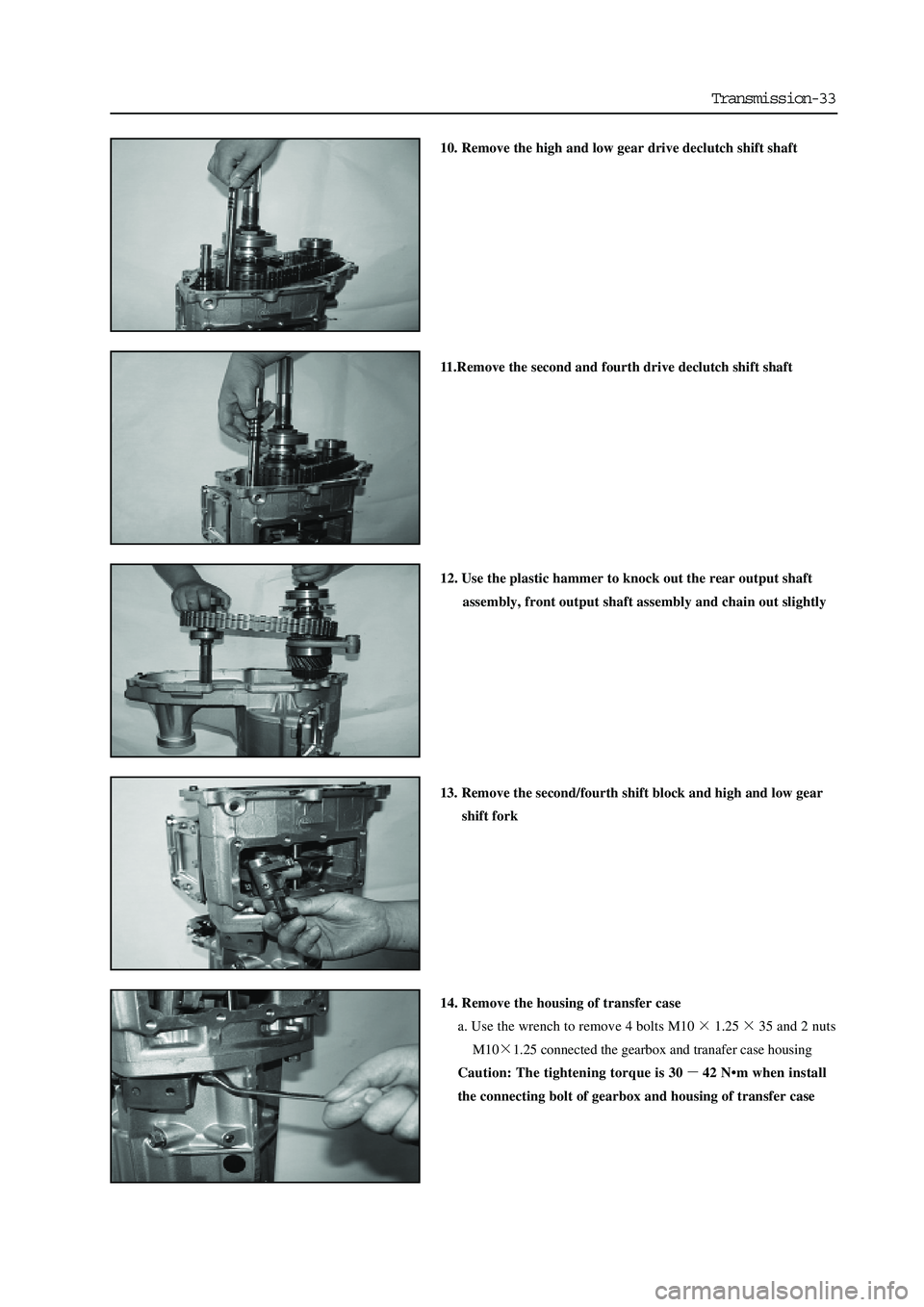

10. Remove the high and low gear drive declutch shift shaft

11.Remove the second and fourth drive declutch shift shaft

12. Use the plastic hammer to knock out the rear output shaft

assembly, front output shaft assembly and chain out slightly

13. Remove the second/fourth shift block and high and low gear

shift fork

14. Remove the housing of transfer case

a. Use the wrench to remove 4 bolts M10

1.2535 and 2 nuts

M10

1.25 connected the gearbox and tranafer case housing

Caution: The tightening torque is 30

42 N•m when install

the connecting bolt of gearbox and housing of transfer case

Page 81 of 425

Automatic transmission-5

Table 2.1 Gear selection and its function

Gear selection function

1st-Gear

(manual 1

st-Gear ) The first gear is using for climbing and braking. It is a function which limits the speed of

the car. The speed limitation by engine is realized by reduce the opening degree of

throttle position.

2nd-Gear (automatic, manual

2

nd-Gear) In economic mode, it can process the 1

st and 2nd shifting operation when engage the 2nd

–Gear. The limitation of vehicle speed by engine is realized through reducing the

opening of throttle position. in 4WD 4 high, , the transmission will maintain 2

nd-Gear

position The manual mode and winter-Mode will only maintain 2nd-Gear 。

3rd-Gear

(automatic, manual 3rd-Gea) In economic mode and dynamic mode, it can process the shifting operation of 1

st, 2nd

and 3rd-Gear when engage the 3rd-Gear, and can reaches the very high vehicle speed. At

this time the locking clutch can process the locking action, refer to vehicle user manual.

The limitation of vehicle speed by engine is realized by reduce the opening of throttle

position. In 4WD 4 low, the transmission should be maintained in 3

rd –Gear position.

Under manual mode, the transmission will be kept in 3rd-Gear.

D-gear

(drive) It can process the 1

st, 2nd, 3rd and 4th –Gear position operation and gear-shifting operation

of (1-2), (1-3), (2-3), (2-4), (3-4), (4-3), (4-2), (3-1) and (2-1). This shifting operation is

processed by taking the vehicle speed, throttle position, throttle position switching

frequency (or forced Gear-decreasing) as the parameter. The locking clutch can process

the locking action in 3rd –Gear, 4

th-Gear according to the type of vehicle. Refer to user

manual of vehicle.

N-Gear

(neutral gear) Only the rear brake belt is engaged at this time. It determines whether the function can

be realized according to the vehicle speed, engine speed and throttle position. But the

gear-position sensor allows the starting of engine. Allow the slide of N-Gear.

R-Gear

(reverse gear) Set the anti-misoperation in forward function according to the vehicle speed, engine

speed and throttle position opening to realize the reverse operation. The gear-position

sensor can start the revers e lamp.

P-gear

(parking gear) Only the rear brake belt is engaged at this time. The function can be determined

according to the vehicle speed, engine speed and throttle position. The output shaft of

transmission is locked. The gear-position sensor can start the engine.

Page 83 of 425

Automatic transmission-7

Indicator lamp

Figure 2.2

control system

General

The transmission has two sets of control system, a electric control system and a hydraulic control system. The electric control

system monitors the vehicle parameter and adjusts the transmission performance; the hydraulic control system executes the

command of electric control system.

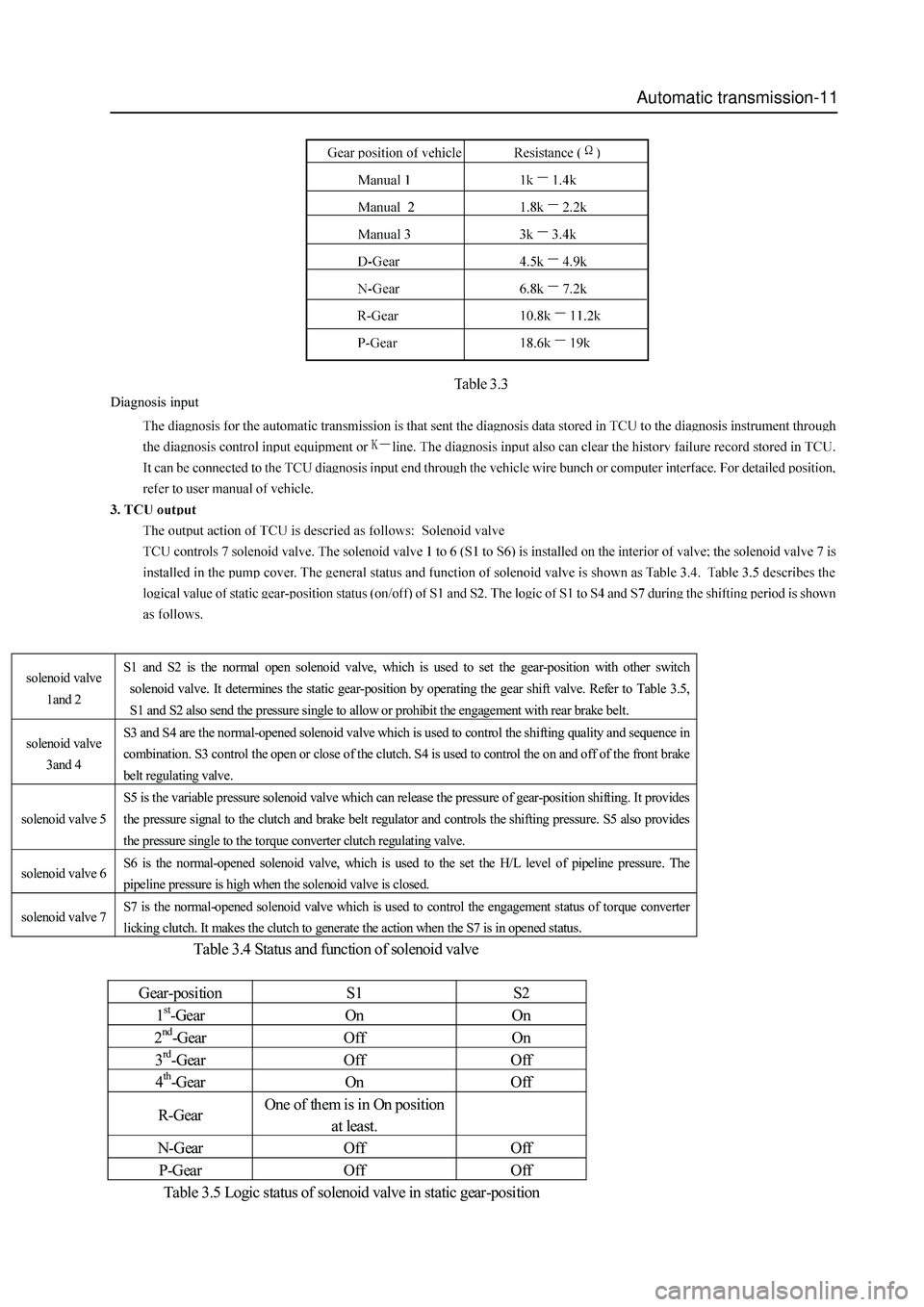

Electric control system

The electric control system consists of the sensor, TCU and 7 solenoid valves. TCU read in the data and make the output under the

control of software based on the value stored in Read Only Memory (ROM).

TCU controls the hydraulic control system and the control is realized through the valve and pump assembly. The system includes

7 solenoid valves, in which 6 valves are used to control the line pressure, operate the shift valve and hydraulic torque converter lock

clutch and switch on and off two regulating valves (Two regulating valves control the shift feel). The seventh solenoid valve is the

pressure regulating solenoid valve (VPS) which controls the shift feel with other three regulating valves. Figure 3.1 is the typical TCU

control system plan.

The figure includes all elements of electric control system involved in the section.

throttle position

open sensor

Engine speed

vehicle speed

Transmission

fluid temperature

mode selection

(instrument panel

/console )

Gear sensor

Forced step-

decreasingK line

shifting

logic

shifting

sensing

line

pressurehydraulic

control

system

Solenoid valve 1

Solenoid valve 2

Solenoid valve 3

Solenoid valve 4

Solenoid valve 5

Solenoid valve 6

Solenoid valve 7

pressure regulating

solenoid valve

Mode indicator lamp

Gear indicator lamp

set and other

necessary equipment

indication

Page 87 of 425

Automatic transmission-11

Diagnosis input

solenoid valve

1and 2 S1 and S2 is the normal open solenoid valve, which is used to set the gear-position with other switch

solenoid valve. It determines the static gear-position by operating the gear shift valve. Refer to Table 3.5,

S1 and S2 also send the pressure single to allow or prohibit the engagement with rear brake belt.

solenoid valve

3and 4 S3 and S4 are the normal-opened solenoid valve which is used to control the shifting quality and sequence in

combination. S3 control the open or close of the clutch. S4 is used to control the on and off of the front brake

belt regulating valve.

solenoid valve 5 S5 is the variable pressure solenoid valve which can release the pressure of gear-position shifting. It provides

the pressure signal to the clutch and brake belt regulator and controls the shifting pressure. S5 also provides

the pressure single to the torque converter clutch regulating valve.

solenoid valve 6 S6 is the normal-opened solenoid valve, which is used to the set the H/L level of pipeline pressure. The

pipeline pressure is high when the solenoid valve is closed.

solenoid valve 7 S7 is the normal-opened solenoid valve which is used to control the engagement status of torque converter

licking clutch. It makes the clutch to generate the action when the S7 is in opened status.

Table 3.4 Status and function of solenoid valve

Gear-position S1 S2

1st-Gear On On

2nd-Gear Off On

3rd-Gear Off Off

4th-Gear On Off

R-Gear One of them is in On position

at least.

N-Gear Off Off

P-Gear Off Off

Table 3.5 Logic status of solenoid valve in static gear-position

Page 88 of 425

Automatic transmission-12

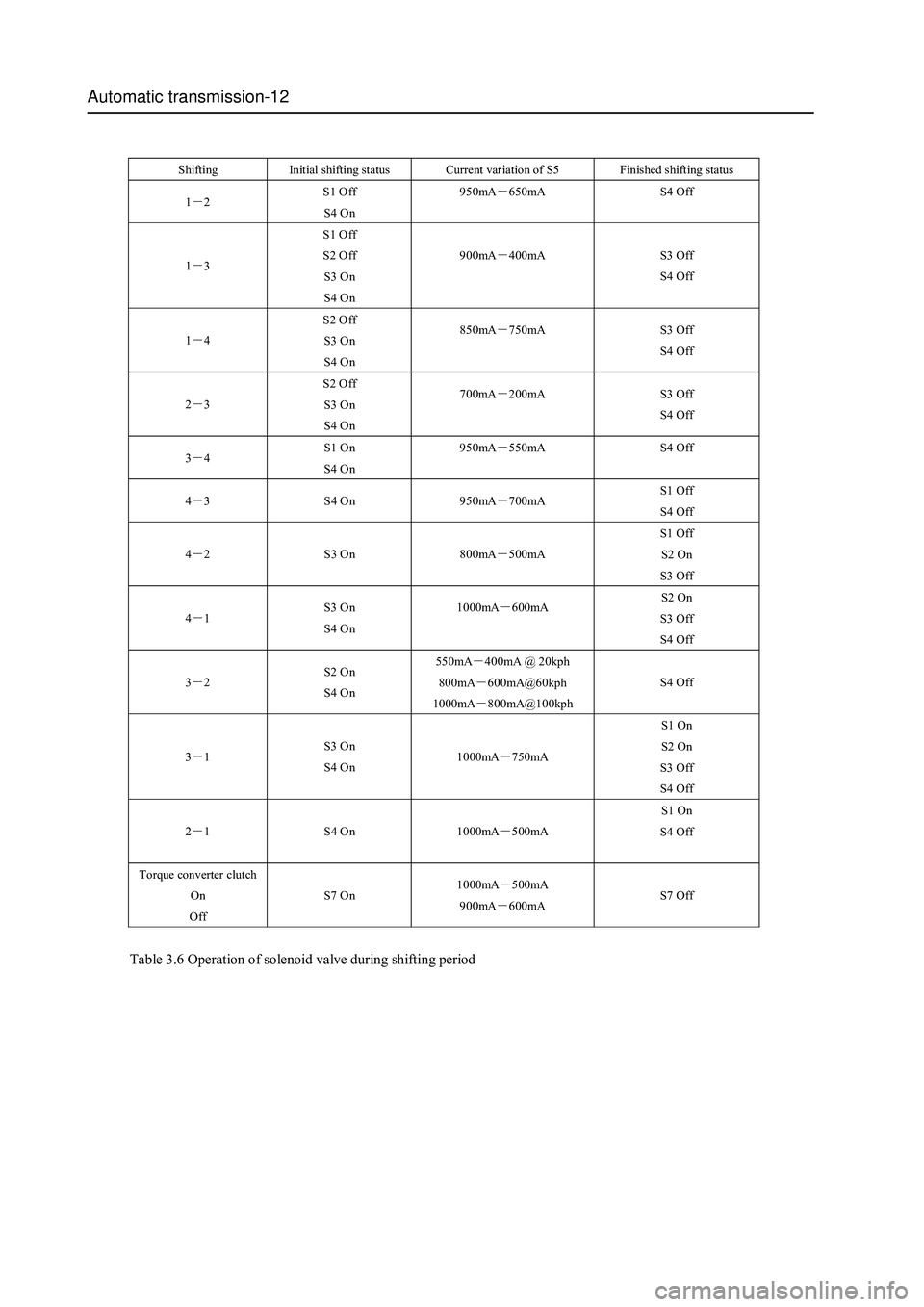

Shifting Initial shifting status Current variation of S5 Finished shifting status

1-2 S1 Off

S4 On 950mA-650mA

S4 Off

1-3 S1 Off

S2 Off

S3 On

S4 On 900mA-400mA

S3 Off

S4 Off

1-4 S2 Off

S3 On

S4 On 850mA-750mA

S3 Off

S4 Off

2-3 S2 Off

S3 On

S4 On 700mA-200mA

S3 Off

S4 Off

3-4 S1 On

S4 On 950mA-550mA

S4 Off

4-3 S4 On 950mA-700mA S1 Off

S4 Off

4-2 S3 On 800mA-500mA S1 Off

S2 On

S3 Off

4-1 S3 On

S4 On 1000mA-600mA

S2 On

S3 Off

S4 Off

3-2 S2 On

S4 On 550mA-400mA @ 20kph

800mA-600mA@60kph

1000mA-800mA@100kph S4 Off

3-1 S3 On

S4 On 1000mA-750mA S1 On

S2 On

S3 Off

S4 Off

2-1 S4 On 1000mA-500mA S1 On

S4 Off

Torque converter clutch

On

Off S7 On 1000mA-500mA

900mA-600mA S7 Off

Table 3.6 Operation of solenoid valve during shifting period

Page 89 of 425

Automatic transmission-13

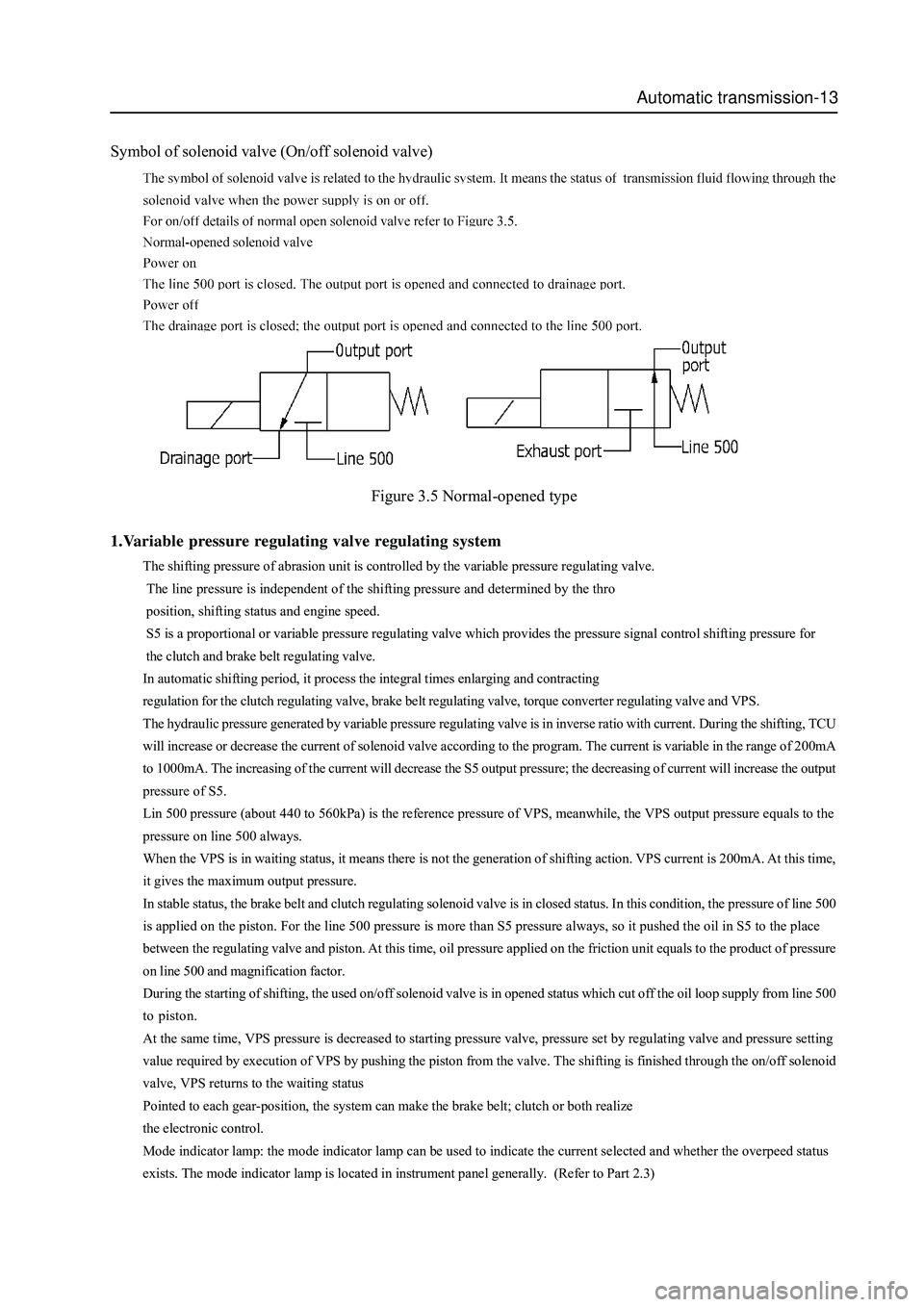

Symbol of solenoid valve (On/off solenoid valve)

Figure 3.5 Normal-opened type

1.Variable pressure regulating valve regulating system

The shifting pressure of abrasion unit is controlled by the variable pressure regulating valve.

The line pressure is independent of the shifting pressure and determined by the thro

position, shifting status and engine speed.

S5 is a proportional or variable pressure regulating valve which provides the pressure signal control shifting pressure for

the clutch and brake belt regulating valve.

In automatic shifting period, it process the integral times enlarging and contracting

regulation for the clutch regulating valve, brake belt regulating valve, torque converter regulating valve and VPS.

The hydraulic pressure generated by variable pressure regulating valve is in inverse ratio with current. During the shifting, TCU

will increase or decrease the current of solenoid valve according to the program. The current is variable in the range of 200mA

to 1000mA. The increasing of the current will decrease the S5 output pressure; the decreasing of current will increase the output

pressure of S5.

Lin 500 pressure (about 440 to 560kPa) is the reference pressure of VPS, meanwhile, the VPS output pressure equals to the

pressure on line 500 always.

When the VPS is in waiting status, it means there is not the generation of shifting action. VPS current is 200mA. At this time,

it gives the maximum output pressure.

In stable status, the brake belt and clutch regulating solenoid valve is in closed status. In this condition, the pressure of line 500

is applied on the piston. For the line 500 pressure is more than S5 pressure always, so it pushed the oil in S5 to the place

between the regulating valve and piston. At this time, oil pressure applied on the friction unit equals to the product of pressure

on line 500 and magnification factor.

During the starting of shifting, the used on/off solenoid valve is in opened status which cut off the oil loop supply from line 500

to piston.

At the same time, VPS pressure is decreased to starting pressure valve, pressure set by regulating valve and pressure setting

value required by execution of VPS by pushing the piston from the valve. The shifting is finished through the on/off solenoid

valve, VPS returns to the waiting status

Pointed to each gear-position, the system can make the brake belt; clutch or both realize

the electronic control.

Mode indicator lamp: the mode indicator lamp can be used to indicate the current selected and whether the overpeed status

exists. The mode indicator lamp is located in instrument panel generally. (Refer to Part 2.3)

Page 90 of 425

Automatic transmission-14

The main box includes:

�z BIR blow-off valve

1. Valve

Figure 3.7 shows the valve unit in the view of transmission fluid tank. Figure 3.8 illustrates the pump cover.

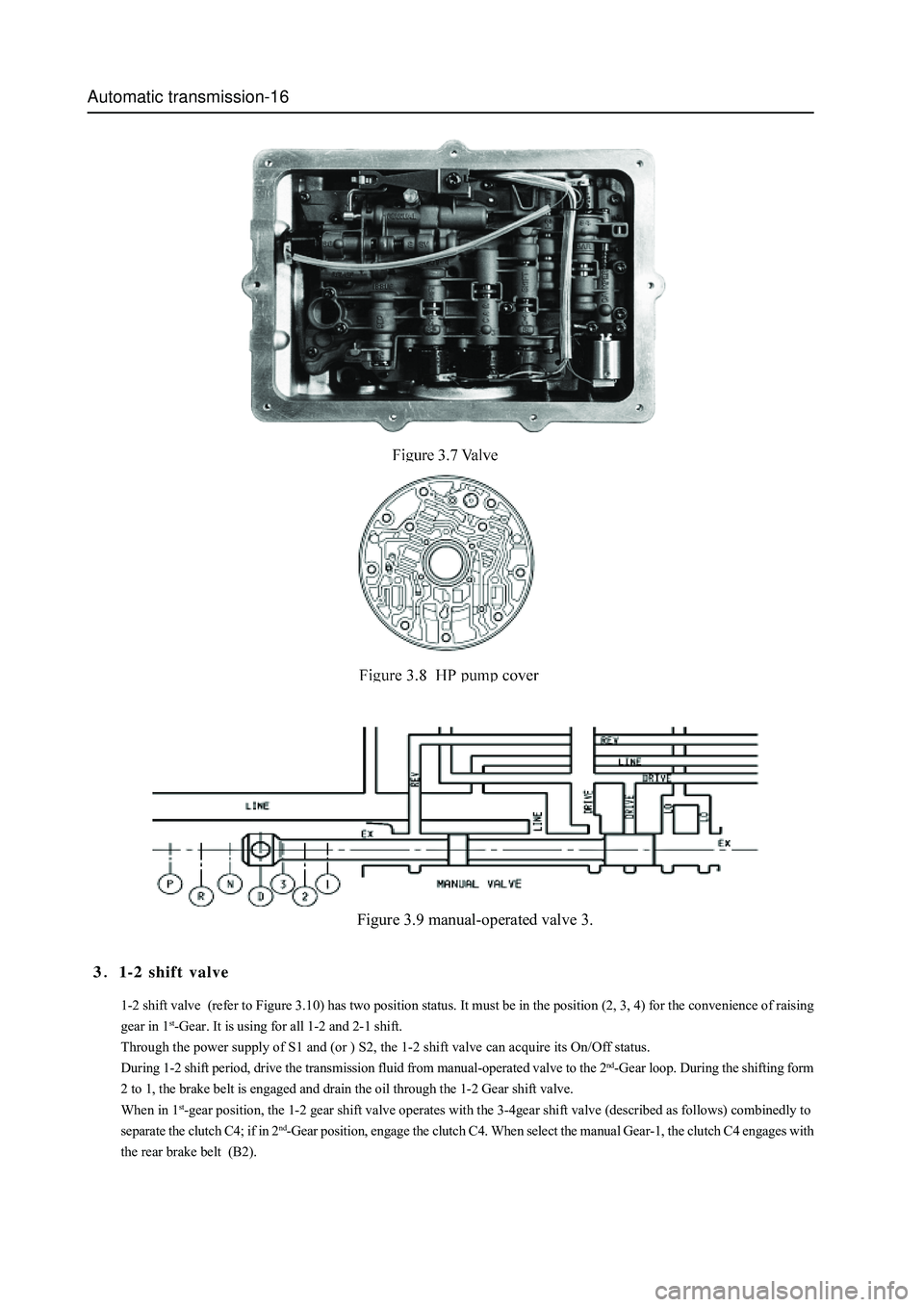

2. Manual-operated valve

The manual-operated valve (refer to Figure 3.9) is connected to the car gear selection mechanism. It controls the transmission

fluid flow to the forward or reverse loop. Except in manual 1st-Gear position, the function of manual-operated valve is same

in all forward gear. In manual 1st-Gear, the transmission fluid will enter into the shift valve 1

2 to make the rear brake belt

and C4 overspeed gear clutch is engaged respectively. The hydraulic control system is located in the valve, pump and main box.

The valve includes the following types:

�zManual-operated valve

�z Three shift valves

�zsequence valve

�z electromagnetic pressure control valve

�zline pressure control valve

�zclutch connection regulating valve

�zbrake belt connection regulating valve

�zsolenoid valve 1 to solenoid valve 6

�zreverse lock valve

The pump includes the following types:

�zprimary regulating valve (control line pressure)

�ztorque converter clutch regulating valve

�ztorque converter clutch control valve

�z

solenoid valve 7 Hydraulic control system

Page 92 of 425

Automatic transmission-16

Figure 3.9 manual-operated valve 3.

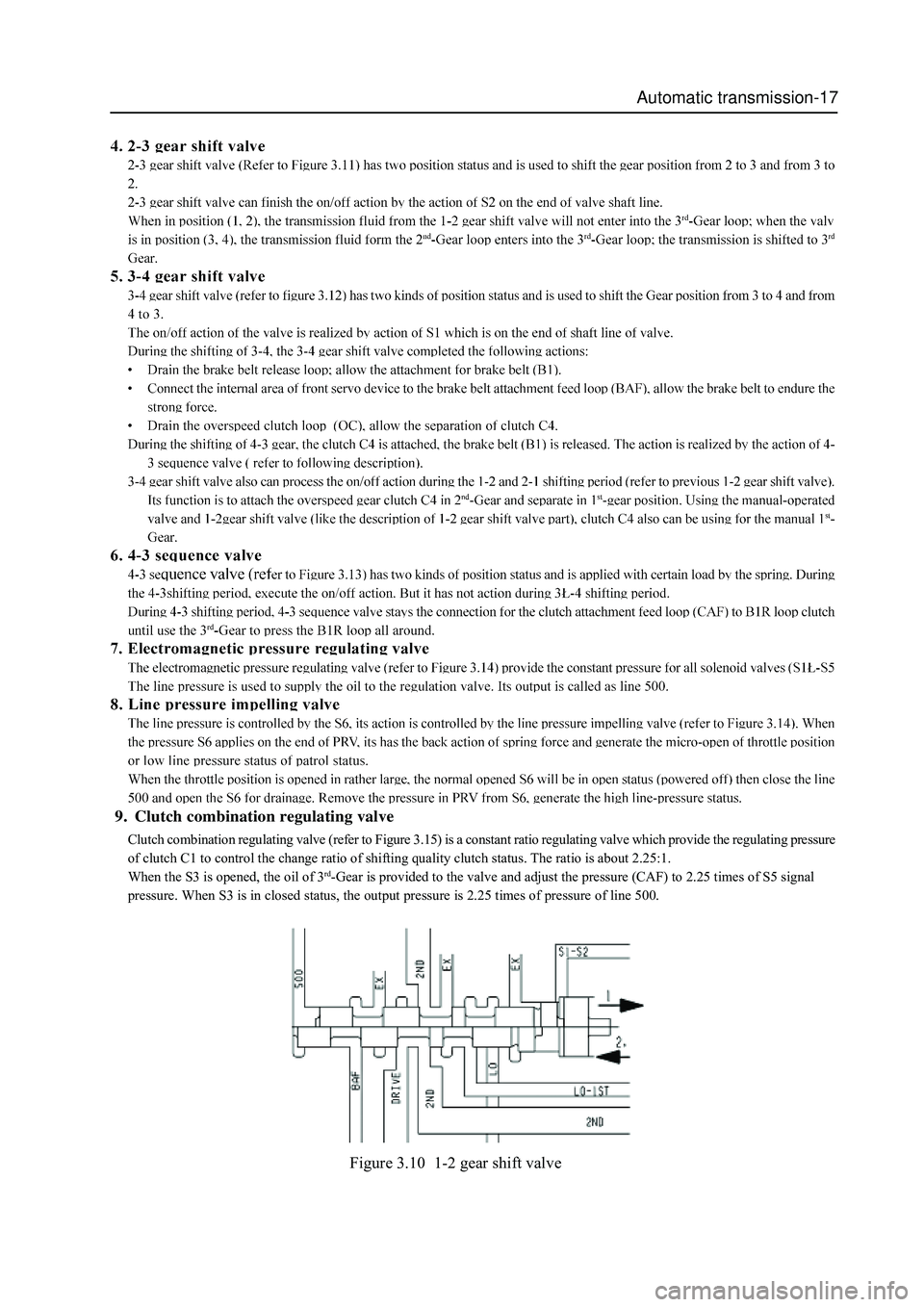

1-2 shift valve (refer to Figure 3.10) has two position status. It must be in the position (2, 3, 4) for the convenience of raising

gear in 1

st-Gear. It is using for all 1-2 and 2-1 shift.

Through the power supply of S1 and (or ) S2, the 1-2 shift valve can acquire its On/Off status.

During 1-2 shift period, drive the transmission fluid from manual-operated valve to the 2

nd-Gear loop. During the shifting form

2 to 1, the brake belt is engaged and drain the oil through the 1-2 Gear shift valve.

When in 1

st-gear position, the 1-2 gear shift valve operates with the 3-4gear shift valve (described as follows) combinedly to

separate the clutch C4; if in 2

nd-Gear position, engage the clutch C4. When select the manual Gear-1, the clutch C4 engages with

the rear brake belt (B2).

31-2 shift valve

Page 93 of 425

Automatic transmission-17

Figure 3.10 1-2 gear shift valve

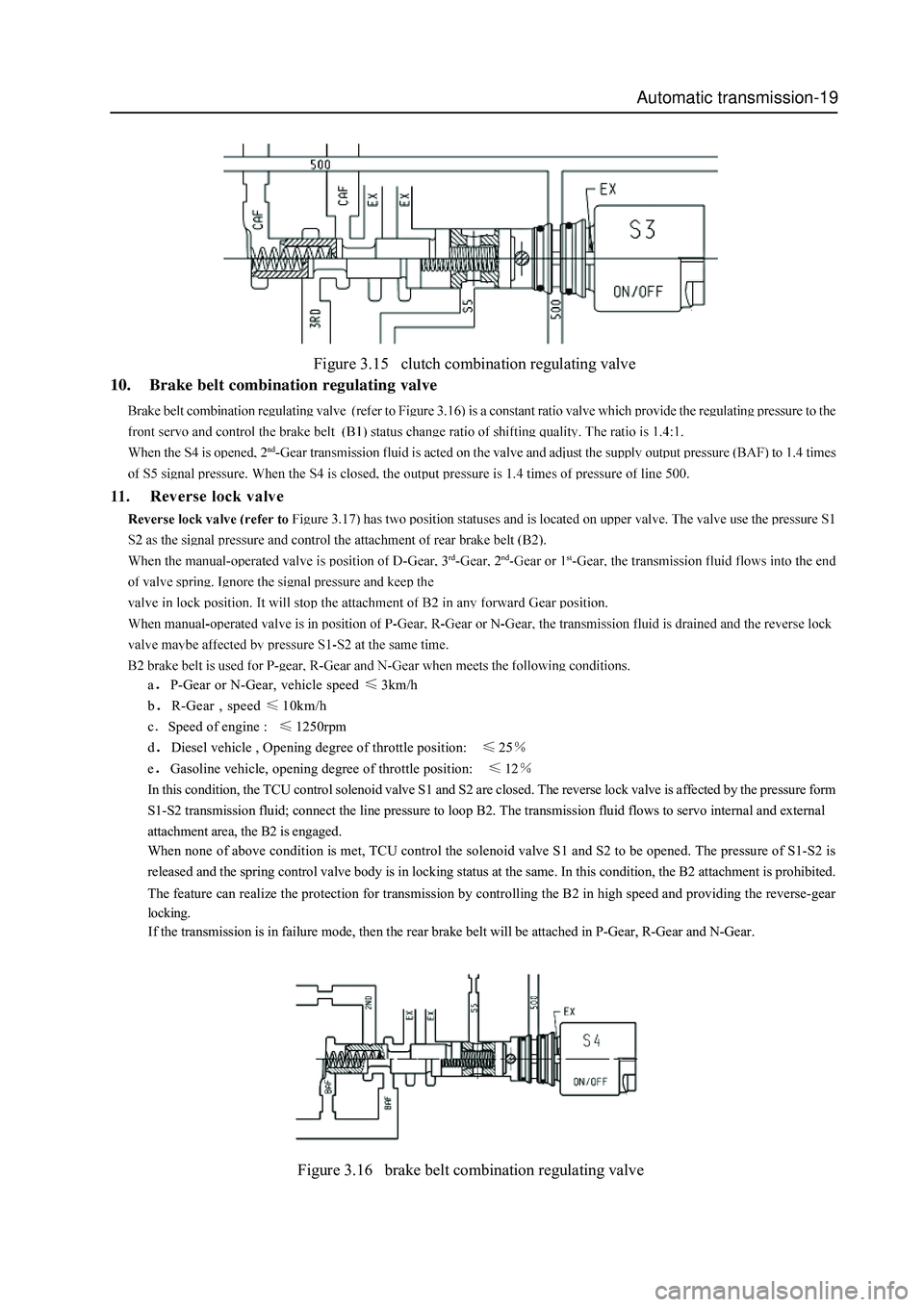

Clutch combination regulating valve (refer to Figure 3.15) is a constant ratio regulating valve which provide the regulating pressure

of clutch C1 to control the change ratio of shifting quality clutch status. The ratio is about 2.25:1.

When the S3 is opened, the oil of 3

rd-Gear is provided to the valve and adjust the pressure (CAF) to 2.25 times of S5 signal

pressure. When S3 is in closed status, the output pressure is 2.25 times of pressure of line 500.

9. Clutch combination regulating valve

Page 95 of 425

Automatic transmission-19

Figure 3.15 clutch combination regulating valve

10. Brake belt combination regulating valve

aP-Gear or N-Gear, vehicle speed 3km/h

b

R-Gear , speed 10km/h

c

Speed of engine : 1250rpm

d

Diesel vehicle , Opening degree of throttle position: 25

eGasoline vehicle, opening degree of throttle position: 12

In this condition, the TCU control solenoid valve S1 and S2 are closed. The reverse lock valve is affected by the pressure form

S1-S2 transmission fluid; connect the line pressure to loop B2. The transmission fluid flows to servo internal and external

attachment area, the B2 is engaged.

When none of above condition is met, TCU control the solenoid valve S1 and S2 to be opened. The pressure of S1-S2 is

released and the spring control valve body is in locking status at the same. In this condition, the B2 attachment is prohibited.

The feature can realize the protection for transmission by controlling the B2 in high speed and providing the reverse-gear

locking.

If the transmission is in failure mode, then the rear brake belt will be attached in P-Gear, R-Gear and N-Gear.

Figure 3.16 brake belt combination regulating valve