fork HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 591 of 2189

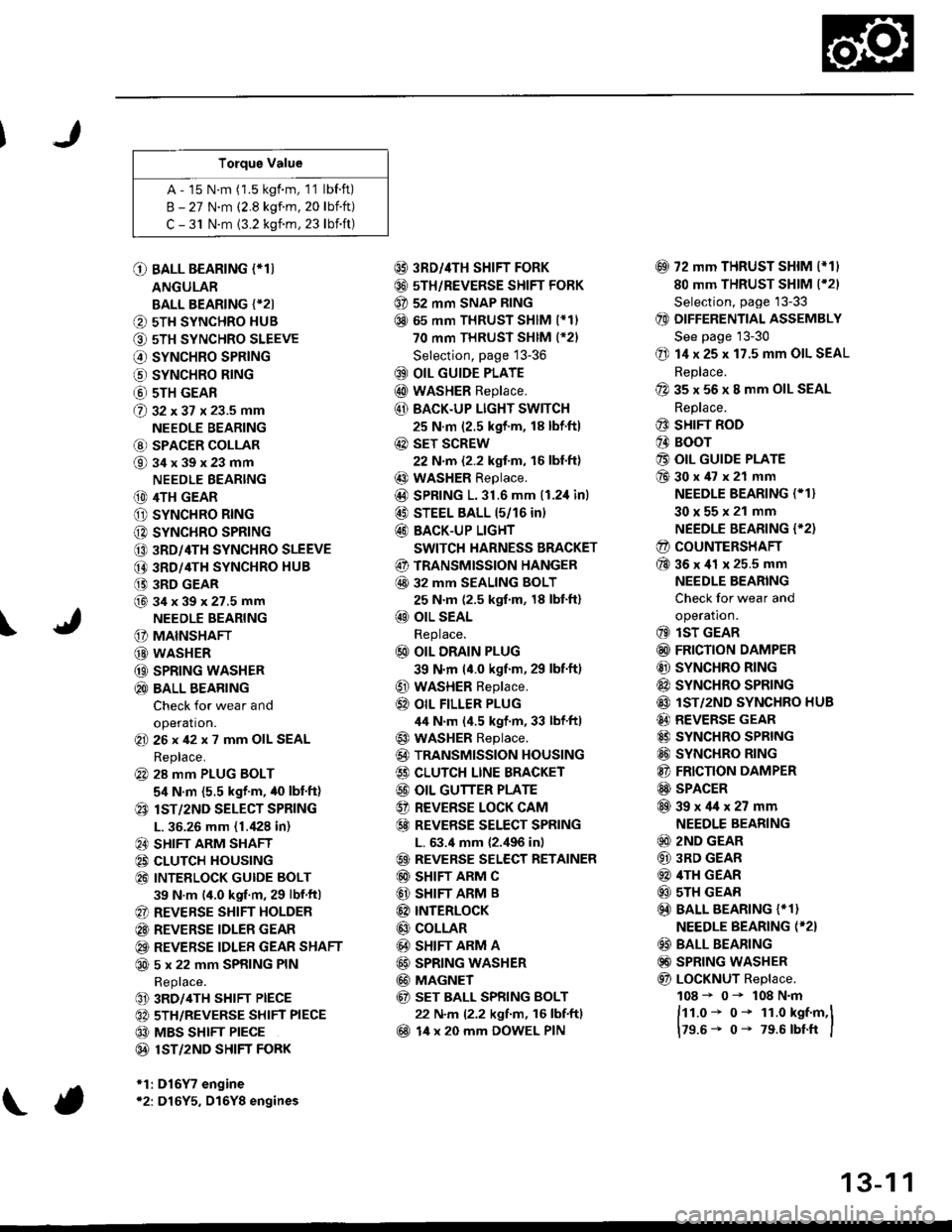

Torque Value

A - 15 N.m (1.5 kgf.m, 1'1 lbf.ft)

B - 27 N.m (2.8 kgf.m. 20 lbift)

C - 31 N.m {3.2 kgnm, 23 lbift)

\

O BALL BEARING (*T)

ANGULAR

BALL BEARING {*2I

O 5TH SYNCHRO HUB

O 5TH SYNCHRO SLEEVE

€) SYNCHRO SPRING

o SYNCHRO B|NG

@ 5TH GEAR

@ gz xgt x 23.5 mm

NEEDLE BEARING

@ SPACER COLLAR

@34x39x23mm

NEEDLE BEARING

(D 4TH GEAR

O SYNCHRO RING

C) SYNCHRO SPRING

CO 3RD/4TH SYNCHRO SLEEVE

@ 3RD/4TH SYNCHRO HUB

(} 3RD GEAR

@34x39x27.5mmNEEDLE BEARING

G) MAINSHAFT

G) WASHER

@ SPRING WASHER

@ BALL BEARING

Check for wear and

operation.(E 26x42x7 mm OIL SEAL

Replace.

@ 28 mm PLUG BOLT

5,1 N.m {5.5 kgf'm, /t0 lbt'ft)

@ lsT/zND SELECT SPRING

L. 36.26 mm (1./P8 in)

@ SHIFT ARM SHAFT

@ CLUTCH HOUSING

@ INTEELOCK GUIDE BOLT

39 N.m (4.0 kgf.m, 29 lbf.ftl

@ REVERSE SHIFT HOLDER

@ REVERSE IDLER GEAR

@ REVERSE IDLER GEAR SHAFT

@ 5 x 22 mm SPRING PIN

Replace.

@ 3RD/4TH SHIFT PIECE

@ 5TH/REVERSE SHIFT PIECE

@ MBS SHIFT PIECE

@ 1ST/2ND SHIFI FORK

*1:D16Y7 engine*2: D16Y5, D16Y8 engines

@ 3RD//|TH SHIFT FORK

@ 5TH/REVERSE SHIFT FORK

@ 52 mm SNAP RING

@ 65 mm THRUST SHIM (*11

70 mm THRUST SHIM (*21

Selection, page 13-36

@ OIL GUIDE PLATE

@ wASHER Replace.

@ BACK.UP LIGHT SWITCH

25 N.m (2.5 kgf'm, 18 lbf'ft)

@ sET SCREW

22 N.m {2.2 kgf.m, 16 lbl.ft}

@ WASHER Replace.

@D SPRING 1.31.6 mm (1.2,1inl

@ STEEL BALL 15/16 in)

@ BACK-UP LIGHT

SWITCH HARNESS BRACKET

@ TRANSMISSION HANGER

@ 32 MM SEALING BOLT

25 N.m (2.5 kgf.m, 18 lbt'ft)

@ OIL SEAL

Replace.

@ OIL DRAIN PLUG

39 N.m (4.0 kgf.m, 29 lbf.ft)

@ WASHER Replace.

@} OIL FILLER PLUG

44 N.m (4.5 kgf.m, 33 lbf'ftl

@ WASHER Replace.

@) TRANSMISSION HOUSING

€) CLUTCH LINE BRACKET

@ OIL GUTTER PLATE

@ REVERSE LOCK CAM

@ REVEBSE SELECT SPRING

L. 63.4 mm {2.,196 in)

@ REVERSE SELECT RETAINER

@ SHIFT ARM C

@ SHIFT ARM B

@ INTERLoCK

@ COLLAR

@ SHIFT ARM A

@ SPRING WASHER

@ MAGNET

@ sET BALL SPRING BOLT

22 N.m (2.2 kgf.m, 16 lbf.ftl

@ 14 x 20 mm DOWEL PIN

@ 72 mm THRUST SHIM l*11

80 mm THRUST SHIM (*21

Selection, page '13-33

@ DIFFERENTIAL ASSEMBLY

See page 13-30

@ 14 x 25 x 17.5 mm OIL SEAL

Replace.

@ 35 x 56 x 8 mm OIL SEAL

Replace.

@ SHIFT ROD

@ BOOr

@ OIL GUIDE PLATE

@30x47x21 mm

NEEDLE BEARING (* 1}

30x55x21 mm

NEEDLE BEARING {'2)

@ COUNTERSHAFT

@36x41 x 25.5 mm

NEEDLE BEARING

Check for wear and

operatron.

@ lsT GEAR

@ FRICTION DAMPER

@ SYNCHRO RING

@ SYNCHRO SPRTNG

@ lST/2ND SYNCHRO HUB

@ REVERSE GEAR

@ SYNCHRO SPRING

@ SYNCHRO RING

@ FRICTION DAMPER

@ SPACER

@39x4lx27mm

NEEDLE BEARING

@ 2ND GEAR

@ 3RD GEAR

@ 4TH GEAR

@ sTH GEAR

@) BALL BEARING {* 1}

NEEDLE BEARING (*2}

@ BALL BEARING

@) SPRING WASHER

@ LoCKNUT Replace.

108 - 0- 108 N.m

ftt.o* o- 1r.o kst.m,l

179.6- 0- 79.6 rbtft I

13-1 1

Page 593 of 2189

Reverse Shift Holder

)

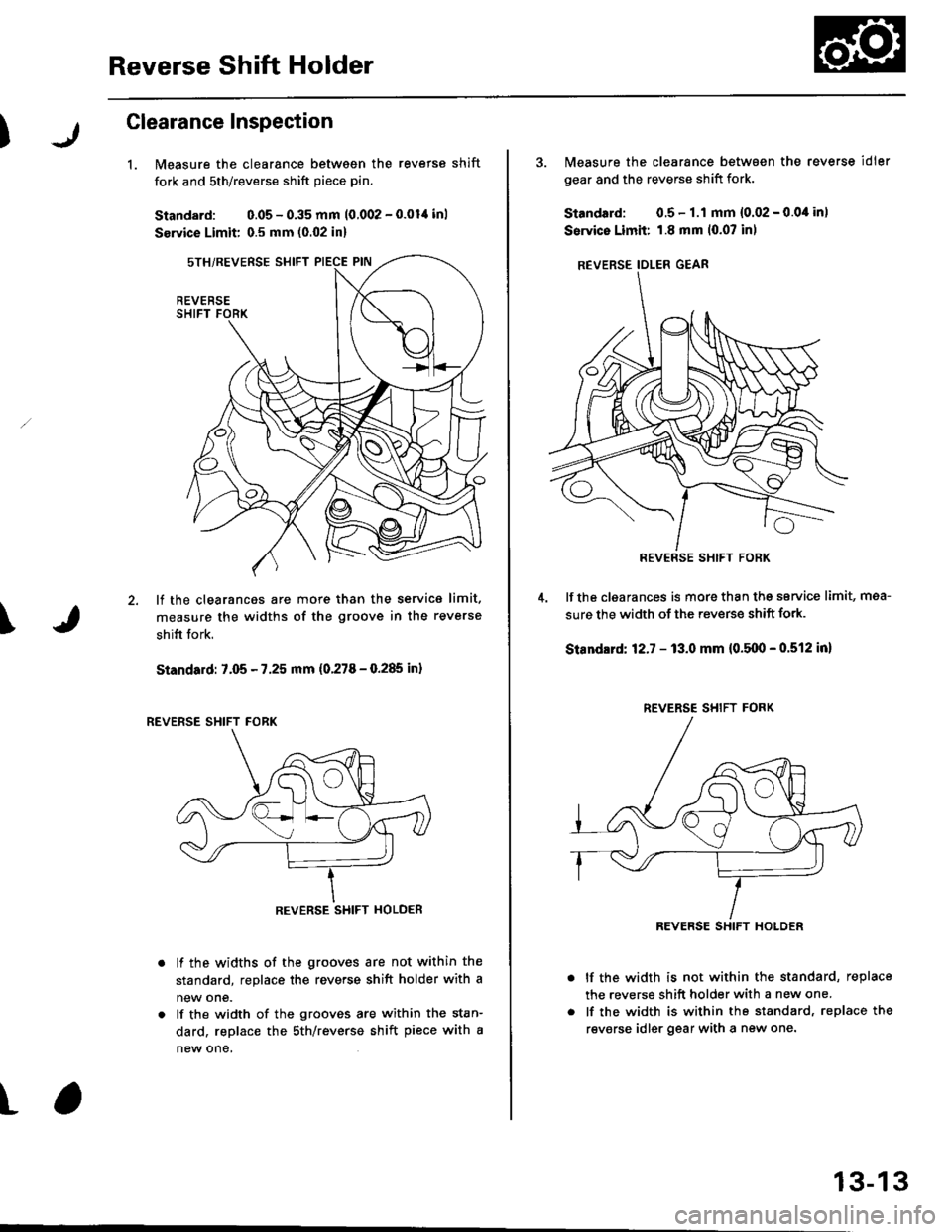

Glearance Inspection

1.Measure the clearance between the reverse shift

fork and sth/reverse shift piece pin.

Standard: 0.05 - 0.35 mm 10.002 - 0.01,1 inl

Service Limit 0.5 mm (0.02 in)

lf the clearances are more than the service limit.

measure the widths of the groove in the reverse

shifi fork.

Standard: 7.05 - 7.25 mm (0.278 - 0.285 inl

lf the widths of the grooves are not within the

standard, replace the reverse shift holder with a

new one.

lf the width of the grooves are within the stan-

dard, replace the sth/reverse shift piece with a

new one,

\

t

REVERSE

REVERSE SHIFT HOLDER

3. Measure the clearance between the reverse idler

gear and the reverse shift fork.

Standard: 0.5- 1.1 mm {0.02 - 0.0,1in)

Service Limii: 1.8 mm 10.07 inl

REVERSE IDLER GEAR

lf the clgarances is more than thg service limit, mea-

sure the width of the reverse shift fork.

Standlrd: 12.7 - 13.0 mm {0.5110 - 0.512 in}

lf the width is not within the standard, replace

the reverse shift holder with a new one.

lf the width is within the standard, replace the

revsrse idler gear with a new one.

REV€RSE SHIFT FORK

REVERSE SHIFT FORK

REVERSE SHIFT HOLOER

13-13

Page 594 of 2189

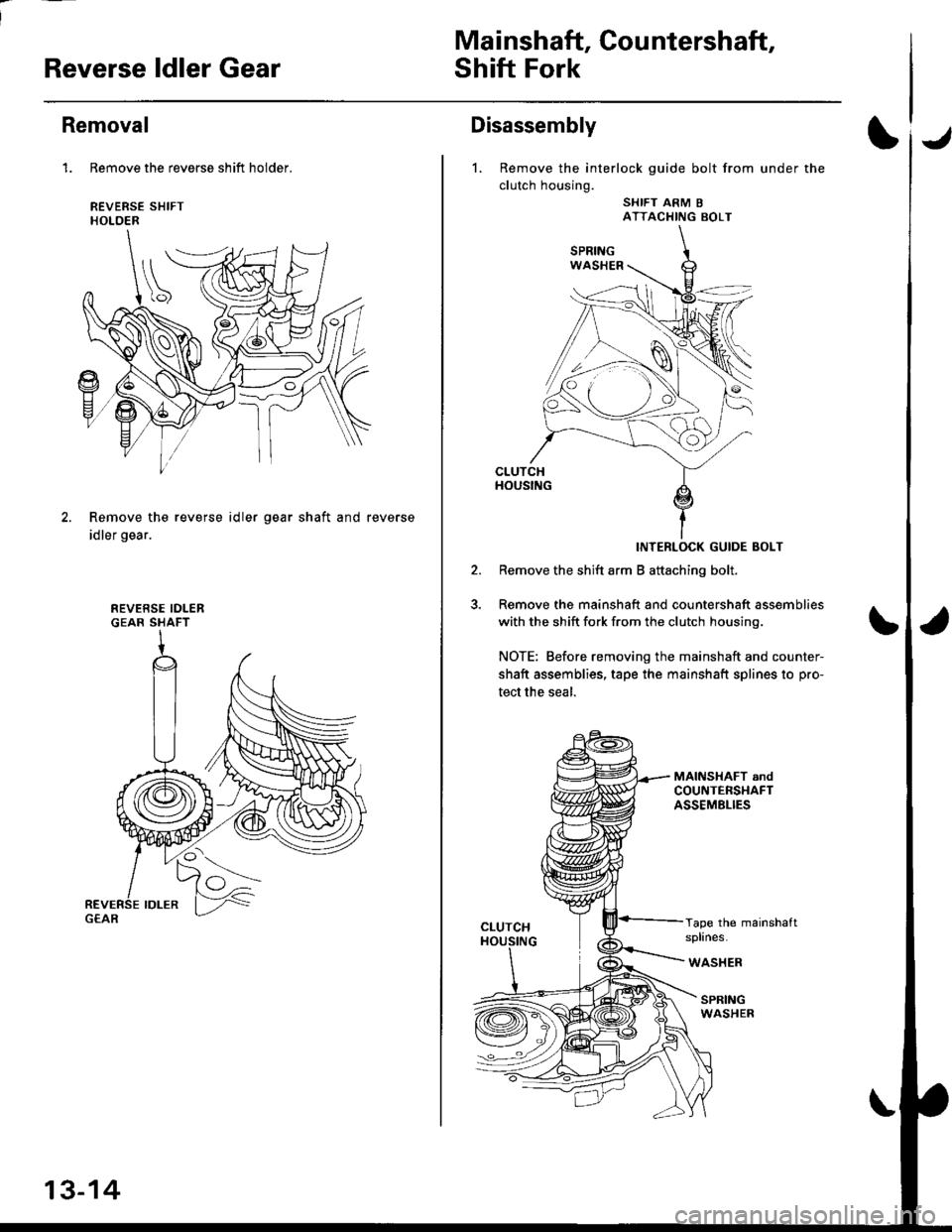

Reverse ldler Gear

Mainshaft, Cou ntershaft,

Shift Fork

Removal

1. Remove the reverse shift holder.

REVERSE SHIFTHOLOER

Remove the reverse id ler

idler gear.

gear shaft and reverse

REVERSE IDLERGEAR SHAFT

13-14

Disassembly

1. Remove the interlock guide bolt from under the

clutch housing.

SHIFT ARM 8ATTACHING BOLT

CLUTCHHOUSING

INTERLOCK GUIDE BOLT

Remove the shift arm B attaching bolt.

Remove the mainshaft and countershaft assemblies

with the shift fork from the clutch housinq.

NOTE: Before removing the mainshaft and counter-

shaft assemblies, tape the mainshaft splines to pro-

tect the seal.

Tape the mainshaftsplines.

WASHER

SPRINGWASHER

Page 605 of 2189

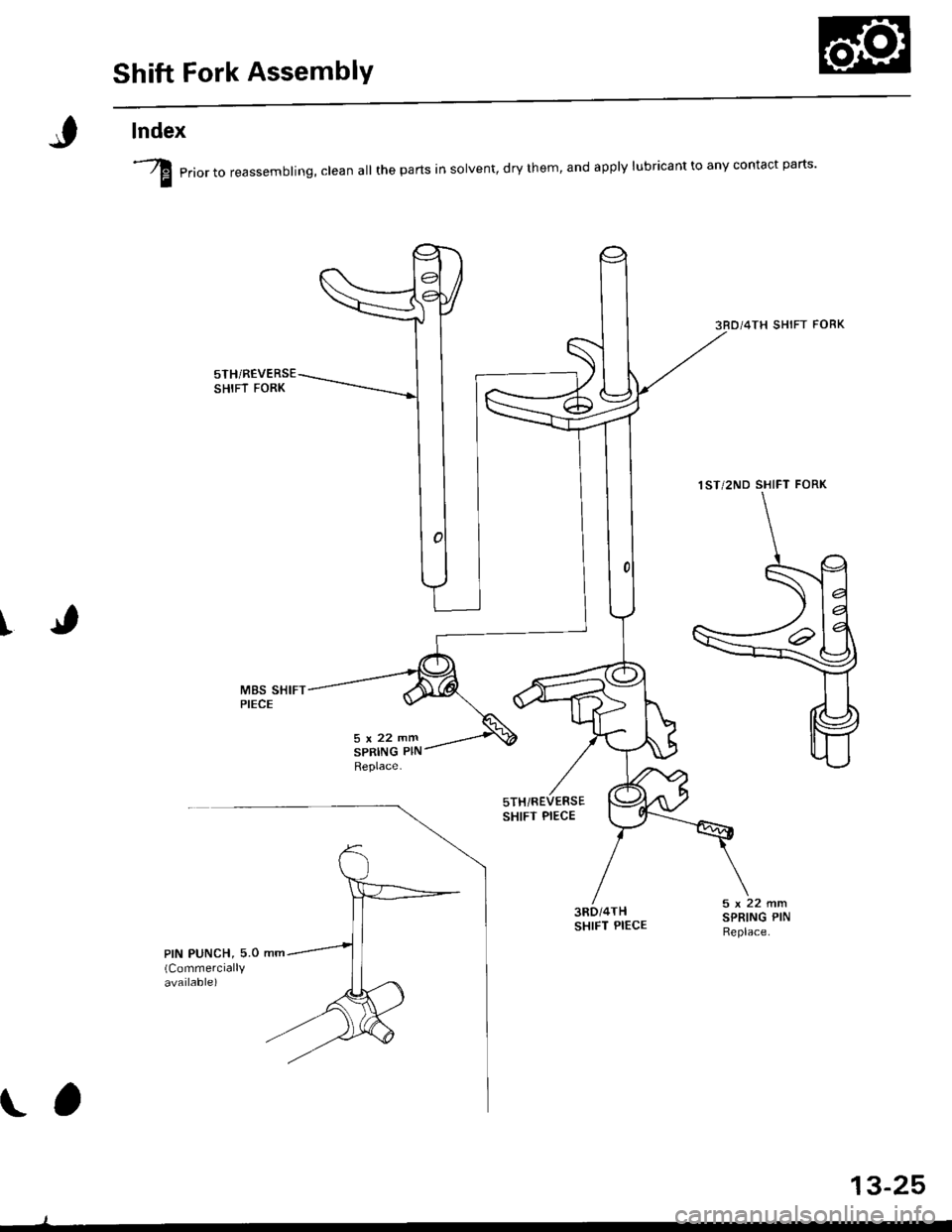

Shift Fork AssemblY

lndex

I

I erio, ,o reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts'

3RD/4TH SHIFT FORK

5THi REVERSESHIFT FORK

5TH/REVERSESHIFT PIECE

M8S SHIFTPIECE

3RD/4THSHIFT PIECE

1ST/2ND SHIFT FORK

\a

13-25

Page 606 of 2189

Shift Fork Assembly

Clearance Inspection

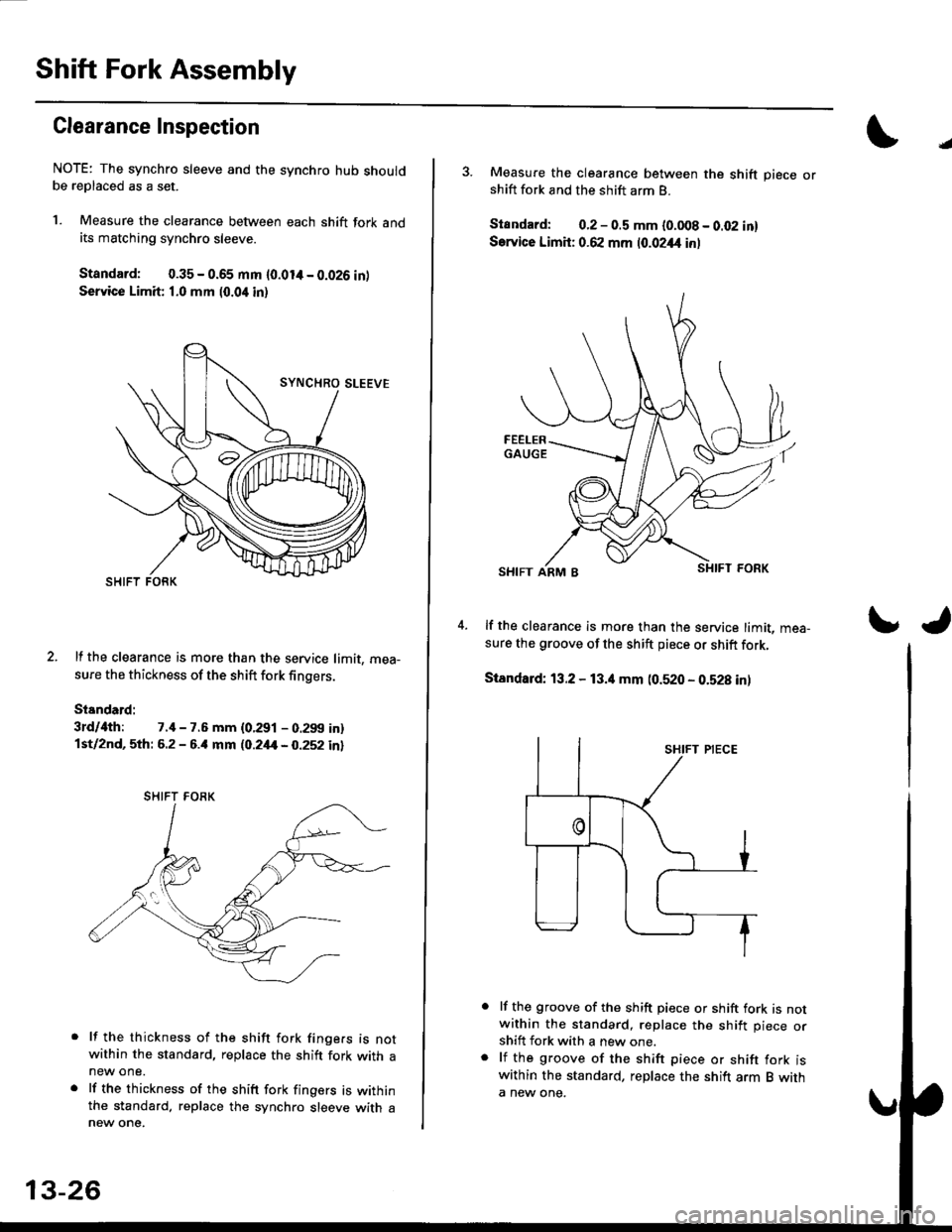

NOTE: The synchro sleeve and the synchro hub shouldbe replaced as a set.

l. Measure the clearance between each shift fork andits matching synchro sleeve.

Standard: 0.35 - 0.65 mm {0.014 - 0.026 intService Limit 1.0 mm (0.04 in)

2. lf the clearance is more than the service limit, mea-

sure the thickness of the shift fork fingers.

Standard:

3rd/ilth: 7.il - 7.6 mm {0.291 - 0.299 in}lst/2nd, 5th: 6.2 - 6.il mm (O.2,tt - 0.252 in)

lf the thickness of the shift fork finge.s is notwithin the standard, replace the shift fork with anew one.

lf the thickness of the shift fork fingers is withinthe standard. replace the synchro sleeve with a

SHIFT FORK

13-26

J

3. Measure the clearance between the shift piece orshift fork and the shift arm B.

Standard: 0.2 - 0.5 mm {0.008 - 0.02 in}

Sarvice Limit: 0.62 mm 10.0244 inl

4. lf the clearance is more than the service limit, mea-sure the groove of the shift piece or shift fork,

Standard: 13.2 - 13.4 mm (0.520 - 0.b28 inl

lf the groove of the shift piece or shift fork is notwithin the standard, replace the shift piece orshift fork with a new one.

lf the groove of the shift piece or shift fork iswithin the standard, replace the shift arm B witha new one.

\J

Page 620 of 2189

Transmission

Reassembly lcont'dl

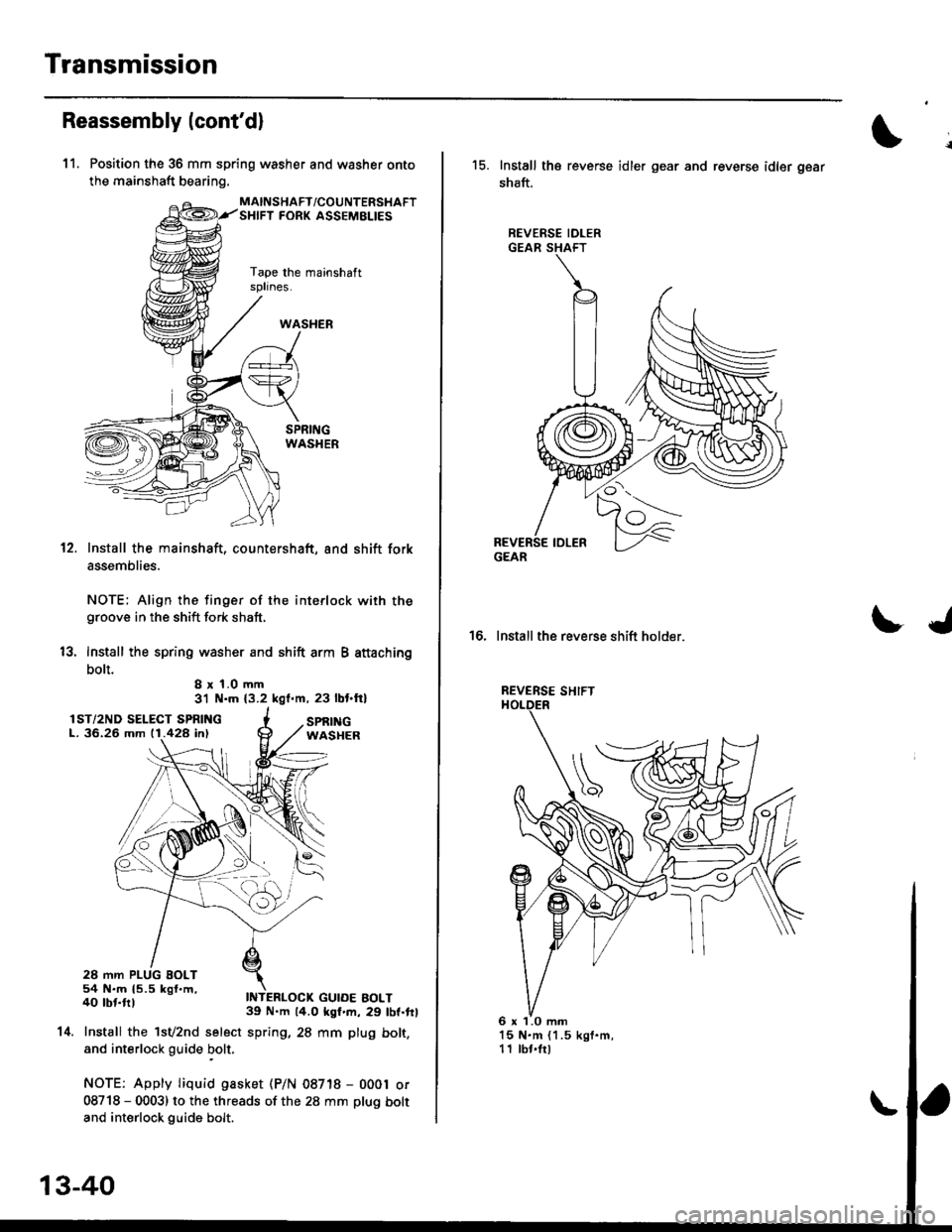

11. Position the 36 mm spring washer and washer onto

the mainshaft bearing.

MAINSHAFT/COUNTERSHAFTSHIFT FORK ASSEMELIES

Tape the mainshaftsplines.

12.

13.

Install the mainshaft, countershaft, and shift fork

assemblies.

NOTE; Align the finger of the interlock with thegroove in the shift fork shaft,

lnstall the spring washer and shift arm B attaching

bolt.I x 1.0 mm31 N.m (3.2 kgl.m, 23 lbt.ft)

IST/2ND SELECT SPRINGL. 36.26 mm 11.428 in)

54 N.m 15.5 kgf.m,40 tbt.ftl

SPf,INGWASHER

GUIDE BOLT

14.

39 N.m 14.0 kgf.m, 29 lbf.frl

Install the 1sv2nd select spring, 28 mm plug bolt.

and interlock guide bolt,

NOTE: Apply Iiquid gasket (P/N 08718 - 0001 or

08718 - 0003) to the threads of the 28 mm plug bolt

and interlock guide bolt.

13-40

15. Install the reverse idler gear and reverse idler gear

shaft.

REVERSE IDLERGEAR SHAFT

LJ16. Install the reverse shift holder.

REVERSE SHIFT

l5 N.m (1.5 kgf.m,11 lbt.trl

GEAR

6 x 1.0 mm

Page 625 of 2189

S4C Model ('99 - 00 2-door Si, SiR)

Manual Transmission

Special Tools ............' 13-46

Maintenance

Transmission Oi1 ...................'.......... 13-47

Back-up Light Switch

Repfacement ...""" 13'47

Transmission Assembly

Removal ......'.......... 13-/tB

lnstallation ............. 13-52

lllustrated lndex ................................... 13-54

Transmission Housing

Removal ................. 13-55

Beverse Shift Holder, Reverse ldler Gear

Clearance lnspection ...................".. 13-57

Removal ................. 13-58

Change Holder Assembly

Clearance lnspection .................".... 13-59

Removal ....,,........... 13-61

Disassembly/Reassembly ............... 1 3-62

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-63

Shift Rod

Removal .........."'.... 13-64

Shift Fork Assembly

lndex ................ ...... 13-65

Clearance lnspection .............'......... 13'66

Mainshaft Assembly

lndex ............"" ...... 13-67

Clearance lnspection ....................... 13-68

Disassembly .......... 13-71

fnspection '."'.......', 13'72

Reassembly .......'... 13-73

Countershaft Assembly

fndex ................ "....13-71

Glearance Inspection'......'...........'... 1 3'75

Disassembly .......... 13-76

fnspection .'............13'77

Reassembly "......... 13'78

Synchro Sleeve, Synchro Hub

Inspection .............. 13'8C

Installation ............. 13-80

Synchro Ring, Gear

Inspection .'............ 13-81

Differential

lndex ................ ...... 13-82

Backlash Inspection ..."..........."'...... 1 3-82

Final Driven Gear Replacement ...... 13-83

Bearing Replacement ....."'.......""'.. 13-83

Thrust Shim Adiustment ......""'..... 13-84

Clutch Housing Bearing

Replacement ..'...... 13-86

Mainshaft Thrust Glearance

Adiustment '.........'. 13-88

Transmission

Reassembly ."'....... 13-91

Oil Seals

Replacement ..'...... 13-96

Gearshift Mechanism

Overhaul ................ 13-97

\

Page 629 of 2189

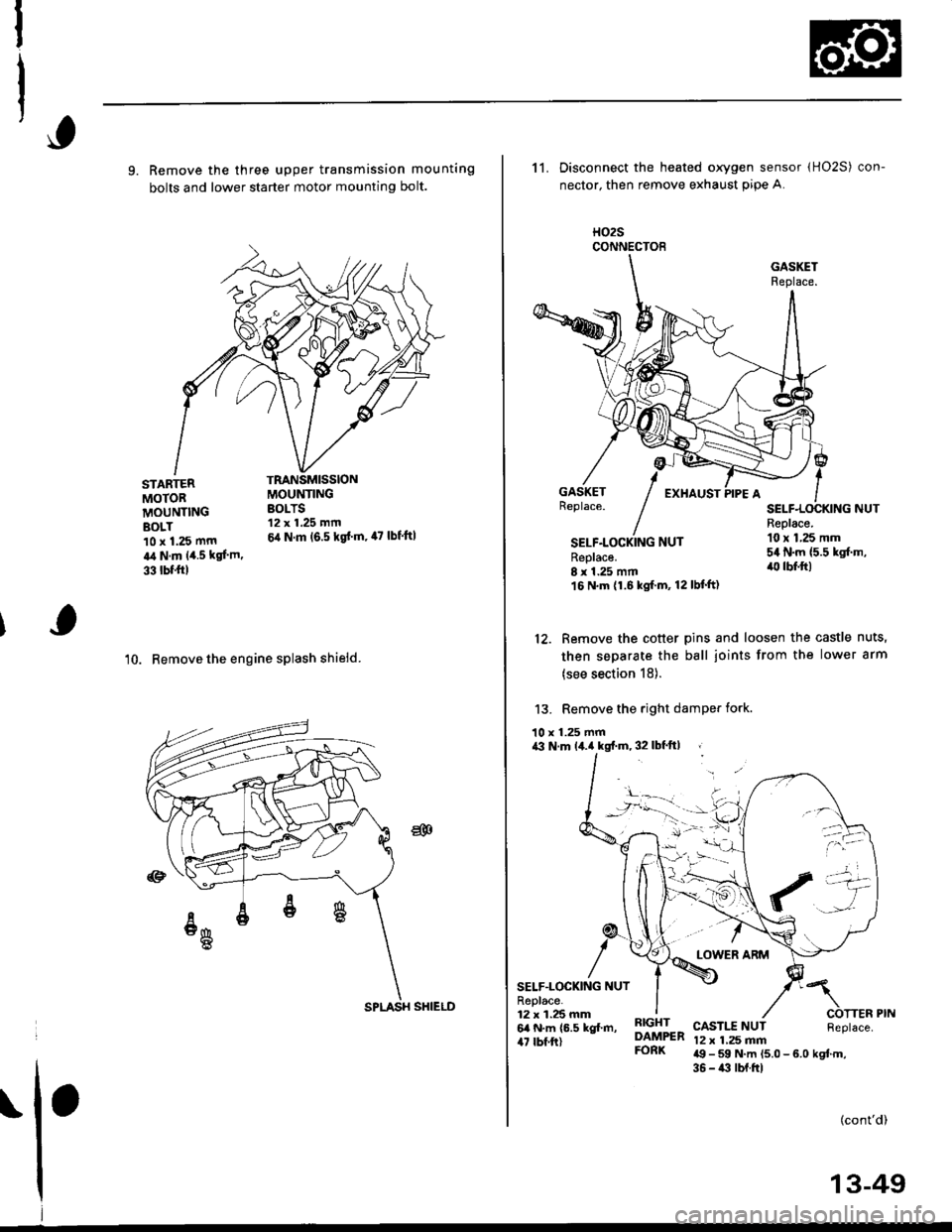

9. Remove the three upper transmission mounting

bolts and lower starter motor mounting bolt.

'10. Remove the engine splash shieid.

TRANSMISSIONMOUNTINGBOLTS12 x 1.25 mm

6,1 N.m (6.5 kgd m, 47 lbf'ft|

STARTERMOTORMOUNTINGBOLT10 x 1.25 mm

a,t N.m 14.5 kgl.m.

33 tbf.trl

CONNECTOE

11. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove exhaust pip€ A.

H02S

SELF.LOCKING NUTReplace.8 r 1.25 mm16 N.m (1.6 kgf.m, 12lbf'ft)

Replace.10 x 1,25 mm54 N.m {5.5 kgf.m,'lll lbf.ft)

12. Remove the cotter pins and loosen the castle nuts,

then separate the ball joints from the lower arm

(see section 18).

13. Remove the right damPer fork.

10 x 1.25 mma3 N.m lil.a kgf.m, 32 lbf'ft| ,

SELF.LOCKING NUTR6place.12 x 1.25 mm6a N.m (6.5 kgl.m,47 rbf ft)

RIGHTDAMPERFORK

CASTI.T NUT12 x 1,25 mma9 - 59 N.m (5.0 - 6.0 kgtm,36 - i(t lbf.ftl

(cont'd)

!-

ria -11: \/-/

't'''-a

SPLASH SHIELD

13-49

Page 632 of 2189

Transmission Assembly

lnstallation

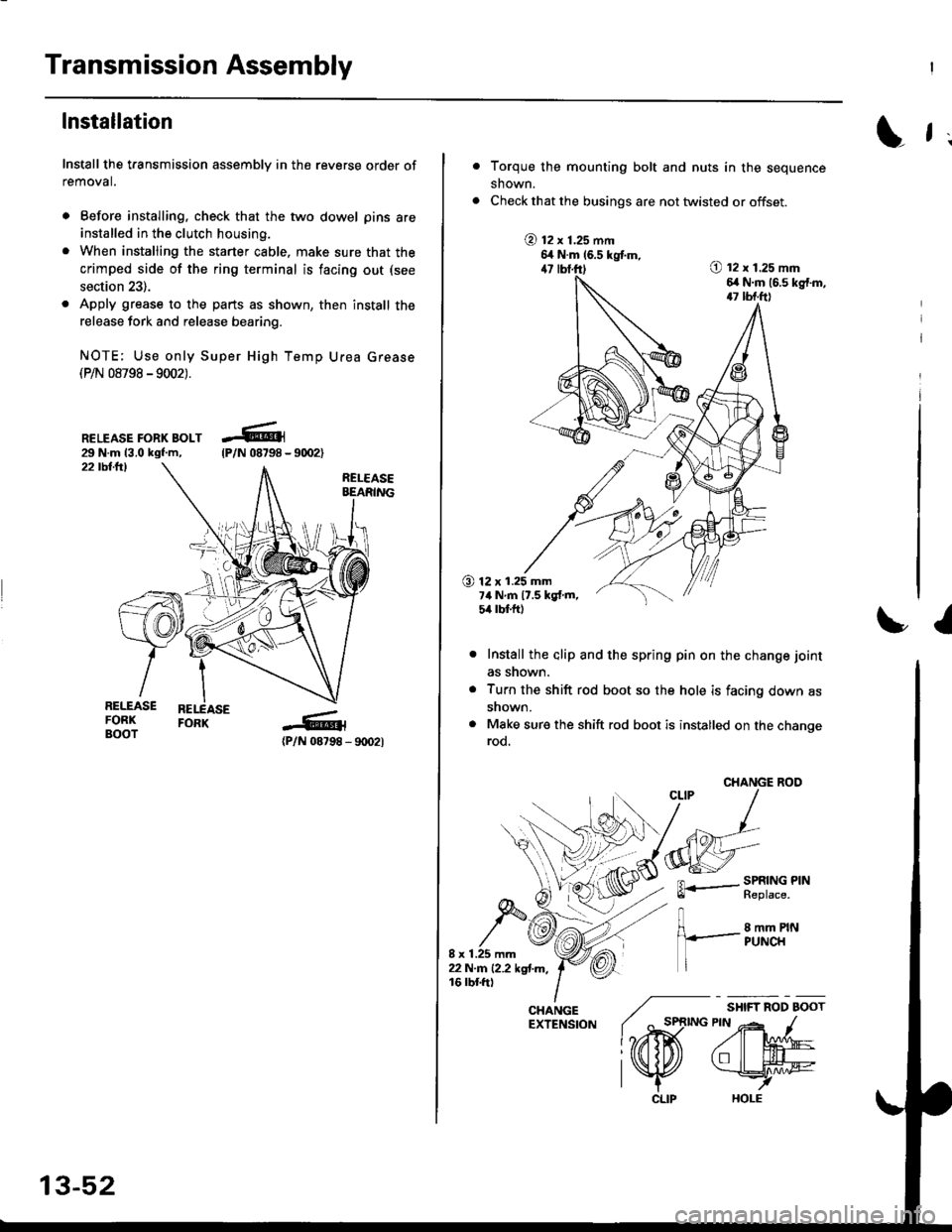

Install the transmission assembly in the reverse order of

removal.

. Before installing, check that the two dowel pins are

installed in the clutch housing.

. When installing the starter cable. make sure that the

crimped side of the ring terminal is facing out (see

section 23).

. Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE; Use only Super High Temp Urea Grease(P/N 08798 -9002).

RELEASE FORK BOLT29 N.m 13.0 kgf.m,22 tbllrl

(P/N 08798 - 9rD2l

-R1

tP/N 08798 -

13-52

CLIP

L f ;

Torque the mounting bolt and nuts in the sequence

shown.

Check that the busings are not twisted or offset.

@ t2 x 1.25 mm6,t N.m 16.5 kgtm,47 lbf.ft)O t2 x 1.25 mm6,r N.m (6.s kg{.m,17 tbf.ft)

O 12 x 1.25 mm7ilNm17.5kgf.m,5it lbt ft)

I

Install the alip and the spring pin on the change joint

as snown.

Turn the shift rod boot so the hole is facing down as

snown.

Make sure the shift rod boot is installed on the changerod.

CHANGE ROO

FL.- SPRING PINll heptace,

8 mm PINPUNCH

/ "*,*

lo,iD(

CHANGE ./EXTENSfoN ( ^ st

l?rffi

l\K

Page 635 of 2189

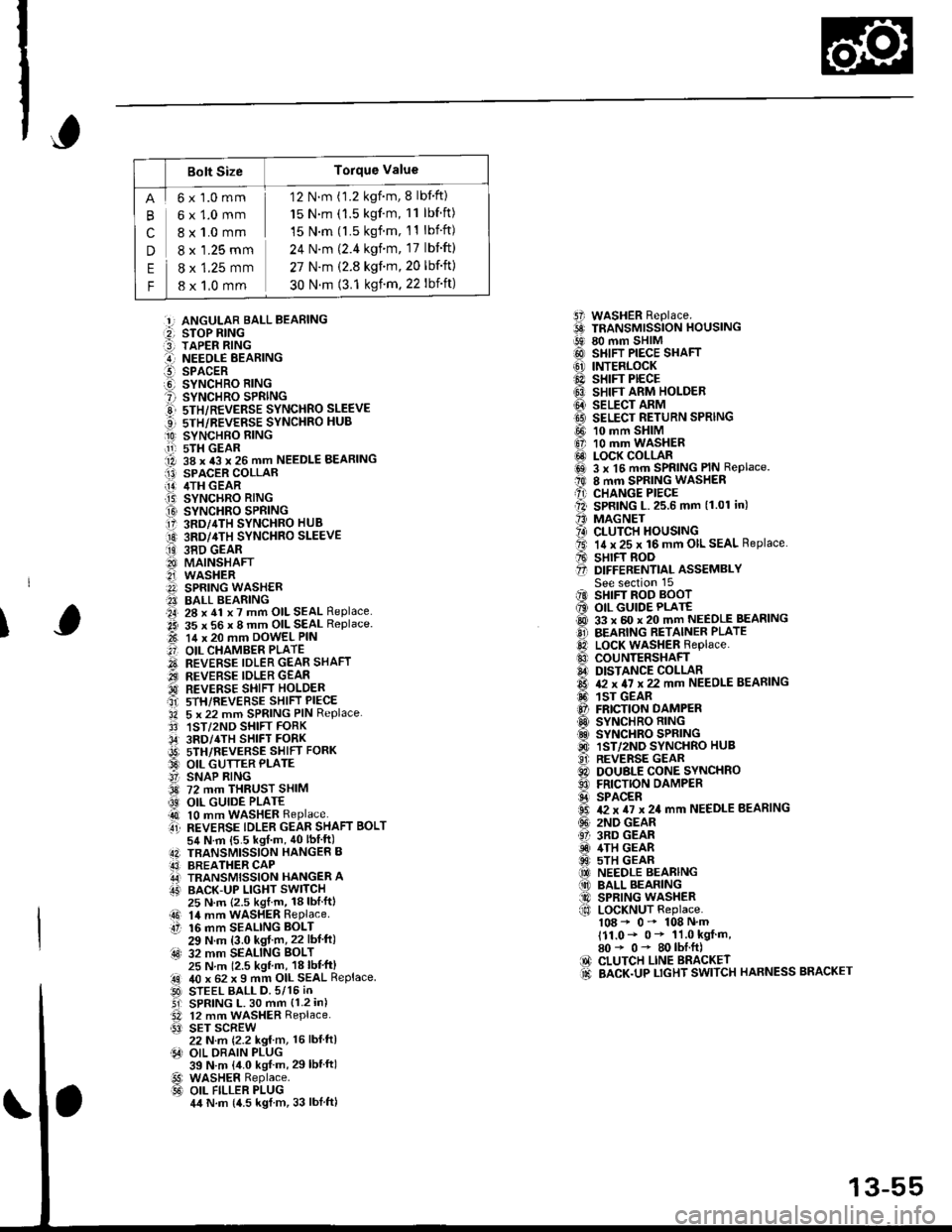

Bolt SizeTorque Value

cn

E

F

6x1.0mm

6x1.0mm

8 x 1.0 mm

8 x '1.25 mm

8 x 1.25 mm

8 x 1,0 mm

12 N.m (1.2 kgnm, 8 lbf'ft)

15 N.m (1.5 kgf'm, 11 lbf ft)

15 N.m (l.5 kgf.m, 11 lbift)

24 N'm (2.4 kgim, 17 lbift)

27 N.m (2.8 kgf.m,20 lbf'ft)

30 N.m (3.1 ksf m. 22 lbift)

5i WASHER Replace.6 TRANSMrssioN HouslNG!9 80 mm SHIM@ SHIFT PIECE SHAFT(6' INTERLOCK@ sHrFr PECE6} SHIFT ARM HOLDER@ seucr nnrvtI9 SELECT RETURN SPRING

@ 10 mm SHIM6, 10 mm WASHER@ LOCK COLLARi6sl 3 x l5 mm SPRING PIN Replace.t0 8 mm SPRING WASHERA) CHANGE PIECEll SPRING L.25.6 mm (1.01 in)'' MAGNET?4) CLUTCH HOUSINGta. 14 x 25 x 16 mm OIL SEAL Replace.A sHrFT BooO D|FFERENT|aL ASSEMBLYSee section 15iIO SHIFT ROD BOOT6 OIL GUIDE PLATE@ 33 x 60 x 20 mm NEEDLE BEASINGO BEARING RETAINER PLATElD LocK WASHER Replace..0 couNTERSHAFIA DISTANCE COLLAR6 & x 4I x 22 mm NEEDLE BEARING6. 1sr GEAR@ FRICTION DAMPERO SYNCHRO RING.d SYNCHRO SPRING@ 1ST/2ND SYNCHRO HUB..9i. REVERSE GEARC) DOUBLE CONE SYNCHROO FRICTION DAMPERS SPACER6 T2 x TI x 24 mm NEEDLE BEARING(!' 2ND GEAR61 3RD GEARiD 4TH GEAR@ 5TH GEAR(O NEEDLE BEARING(10 BALL BEARING@ SPRING WASHERf,o LoCKNUT Replace.108 - 0- 108 N'm111.0- 0* 11.0 kgf m,80* 0- 80lbI.ft)IO CLUTCH LINE BRACKET.d BACK.UP LTGHT SWITCH HARNESS BRACKET

:!, ANGULAR BALL BEABING:2, STOP RING:3] TAPER RING..-I NEEOLE BEARINGl!-- SPACERO SYNCHRO RING? SYNCHRO SPRINGE 5TH/REVERSE SYNCHRO SLEEVE...] sTH/REVERSE SYNCHRO HUB

O SYNCHBO EING.11-r sTH GEAR1A 38 x 43 x 26 mm NEEDLE BEARINGI13) SPACER COLLAR[!] /ITH GEAR.T5) SYNCHRO RING

O SYNCHRO SPRING17 3RD/4TH SYNCHRO HUB

O 3RD/4TH sYNcHRo SLEEVE

ii9 38D GEAR8I MAINSHAFT2i WASHERA SPRING WASH€R?I BALL BEARING.a4, 28 x 41 x 7 mm OIL SEAL Replace..2i 35 x 56 x 8 mm OIL SEAL Replace.t-t 14 x 20 mm DowEL PIN

.'] OIL CHAMBER PLATE

O REVERSE IDLER GEAR SHAFT.iI.., REVERSE IDLER GEAR'd REVERSE SHIFI HOLDERait srH/REVERSE sHIFT PIECE'34 5 x 22 mm SPRING PIN Replace.3' 1ST/2ND SHIFT FORK,34' 3RD/4TH SHIFT FORKi9t) srH/nevense sstrr ronx33 OIL GUTTER PLATE!' SNAP RING3d 72 mm THRUST SHIM

@ OIL GUIDE PLATE4t 10 mm WASHER Replaceti REVERSE TDLER GEAR SHAFT BoLT54 N.m {5.5 kgf m, 40lbIft)4N TBANSMISSION HANGER B43] BREATHER CAPA,J TRANSMISSION HANGER AIT' BACK-UP LIGHT SWITCH

I

25 N.m {2.5 kgl.m, 18lblftl14 mm WASHER RePlaceaO 14 mmtt 16 mm16 mm SEALING BOLT29 N.m (3.0 kgf m,22 lbf ft):4s) 32 mm SEALING BoLT25 N m 12.5 kgl m, 18 lbl'ft)40 x 62 x I mm OIL SEAL ReplaceSTEEL BALL D.5/15 iNSPRING L. 30 mm {1.2 in)12 mm WASHER Replace.SET SCREW22 N.m {2.2 kg{ m, 16 lbl ftlOIL DRAIN PLUG39 N.m {4.0 kgf m, 29lbtftlWASHER Replace.OIL FILLER PLUG4,t N.m {4.5 kgl m, 33 lblftl

.!rl00

@l

13-55