Connector a HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1222 of 2189

tt

(From page 19-68)UNDER.HOOD ABSFUSE/RELAY 8()X

TERMINAL TERMINAL

PUMP MOTOR 2P CONNECTOR

MOTOR +8 lWHTl,$

rv) -

Y

Wire side ot female terminals

\lt

MOTOR +B {RED}MOTOR GND (BLK)

ABS CONTROL UNIT 22P CONNECTOR

(cont'dl

19-69

JUMPER WIRE

Wire side oI female terminals

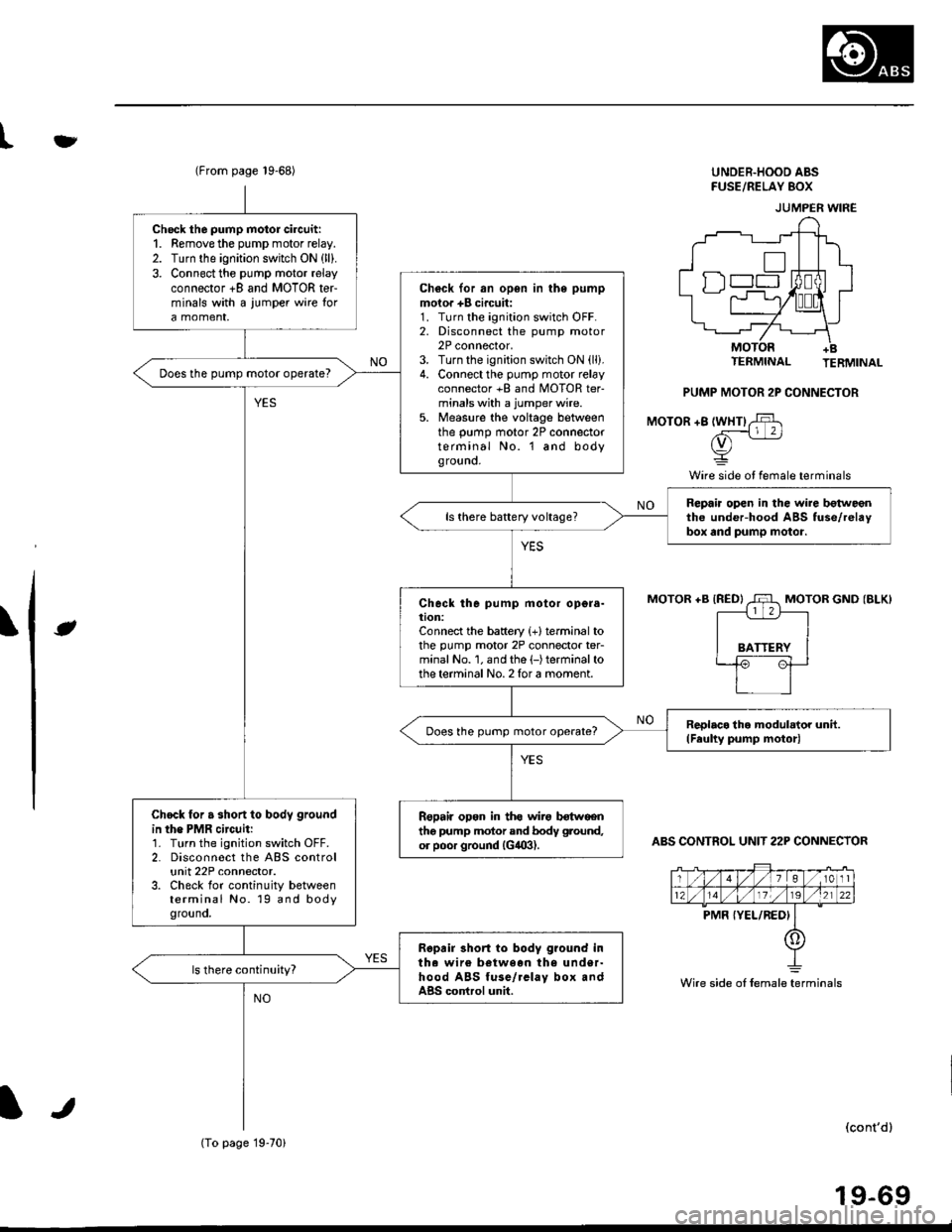

Check the pump motor circuit:1. Remove the pump motor relay.2. Turn the ignition switch ON (ll).

3. Connect the pump motor relayconnector +8 and MOTOR terminals with a iumper wire tora momenr,

Ch€ck for an open in the pump

moior +B circuit:1. Turn the ignition switch OFF.2. Disconnect the pump motor2P connector,3. Turn the ignition switch ON (ll).

4. Connect the pump motor relayconnector +B and MOTOR ter-minals with a jumper wire.5. Measure the voltage betweenthe pump motor 2P connectorterminal No. l and bodyground.

Does the pump motor operate?

Repaia open in the wire botweentho under-hood ABS fuse/relaybox and pump motor.ls there battery voltage?

Check the pump motor opgra-tion:Connect the battery {+}terminal tothe pump motor 2P connector ter-minal No. 1. and the (-)terminalto

the terminal No. 2 for a moment.

ReDlaco lho modulator unit.(Feulty pump motor)Does the pump motor operate?

Chock for a short to body ground

in the PMR circuit:1. Turn the ignition switch OFF.2. Disconnect the ABS controlunit 22P connector.3. Check for continuity betweenterminal No. 19 and bodygrouno,

Repail opon in ths wirg botwgentho pump motor and bodv ground,

or poor ground (G,!09).

Ropair 3hort to body g?ound intha wire between the under-hood ABS fuse/rclay box andABS cortrol unit.

(To page 19-70)

Page 1223 of 2189

Troubleshooting

ABS Pump Motor (cont'dl

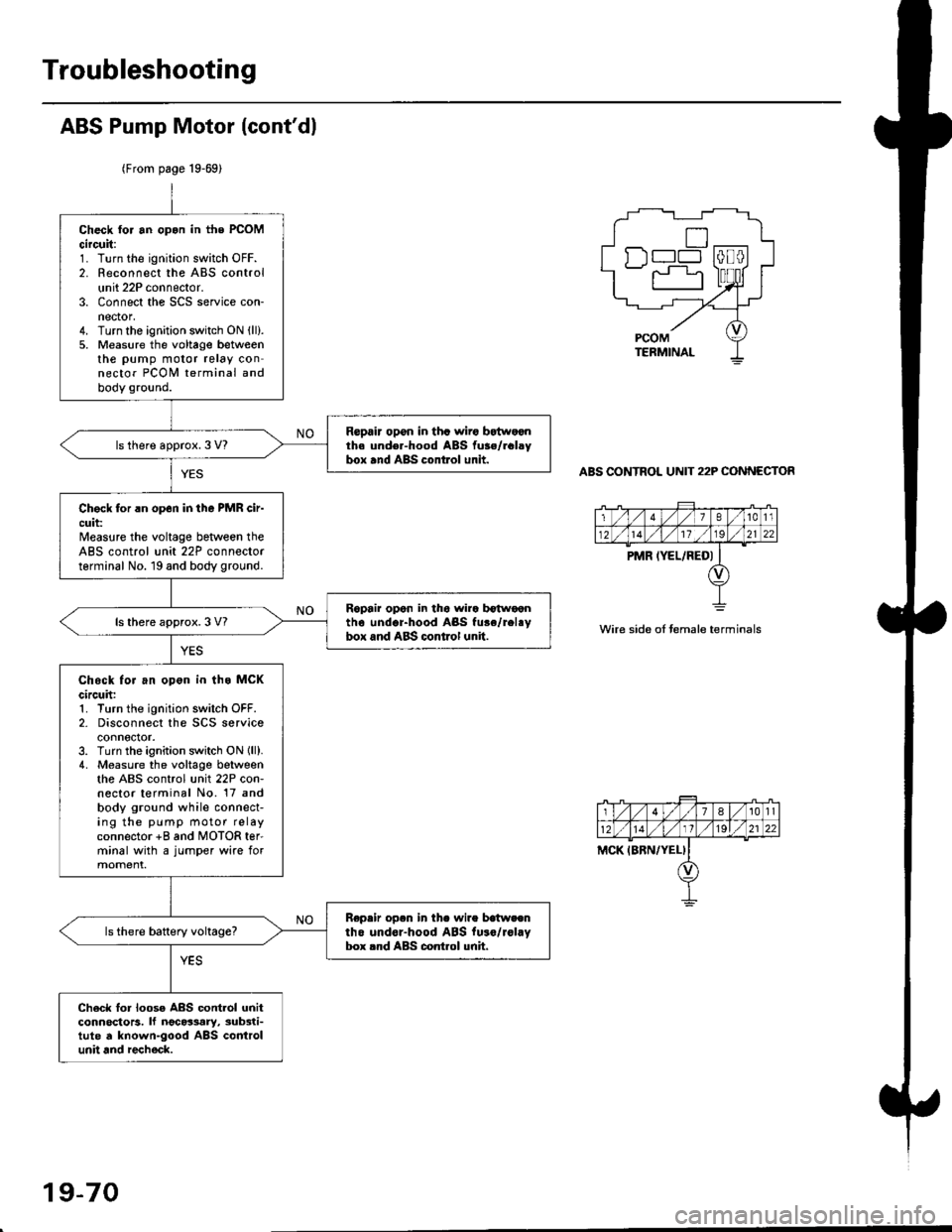

(From page 19-69)

ABS CONTROL UNIT 22P CONNECTOR

Check tor an opon in the PCOMcircuit:1. Turn the ignition switch OFF.2. Reconnect the ABS controlunit 22P connector.3. Connect the SCS service con-nector,4. Turn the ignition switch ON (ll).

5. Measure the voltage betweenthe pump motor relay connector PCOI,I terminal andbody ground.

Repair opon in tha wiro bEtwoonth. und€r-hood ABS fu3./rclsybox and ABS control unit.ls there approx. 3 V?

Chock for rn op6n in tho PMR cir-cuit:Measure the voltage beNveen theABS control unit 22P connectorterminal No. 19 and body ground.

Ropair opon in tho wira b€twoontho undor-hood ABS fu.e/rel.ybox and ABS control unit.ls there approx. 3 V?

Chock for an opon in ths MCKcircuh:1. Turn the ignition switch OFF.2- Disconnect the SCS serviceconnector.3. Turn the ignition switch ON lll).4. Measure the voltage betweenthe ABS control unit 22P con-nector terminal No. 17 andbody ground while connect-ing the pump motor relayconnector +8 and MOTOR ter'minal with a jumper wire formoment.

Repeir op.n in th. wire batweentho undor-hood ABS fu.o/rol.Vbox rnd ABS control unh.

Ch6ck lor loose ABS contlol unitconnoctors. lf ngc63ary, sub3ti-tute d known-good ABS controlunit and recheck.

n--l

wire side oI temale terminals

19-70

Page 1224 of 2189

tfMain Relay

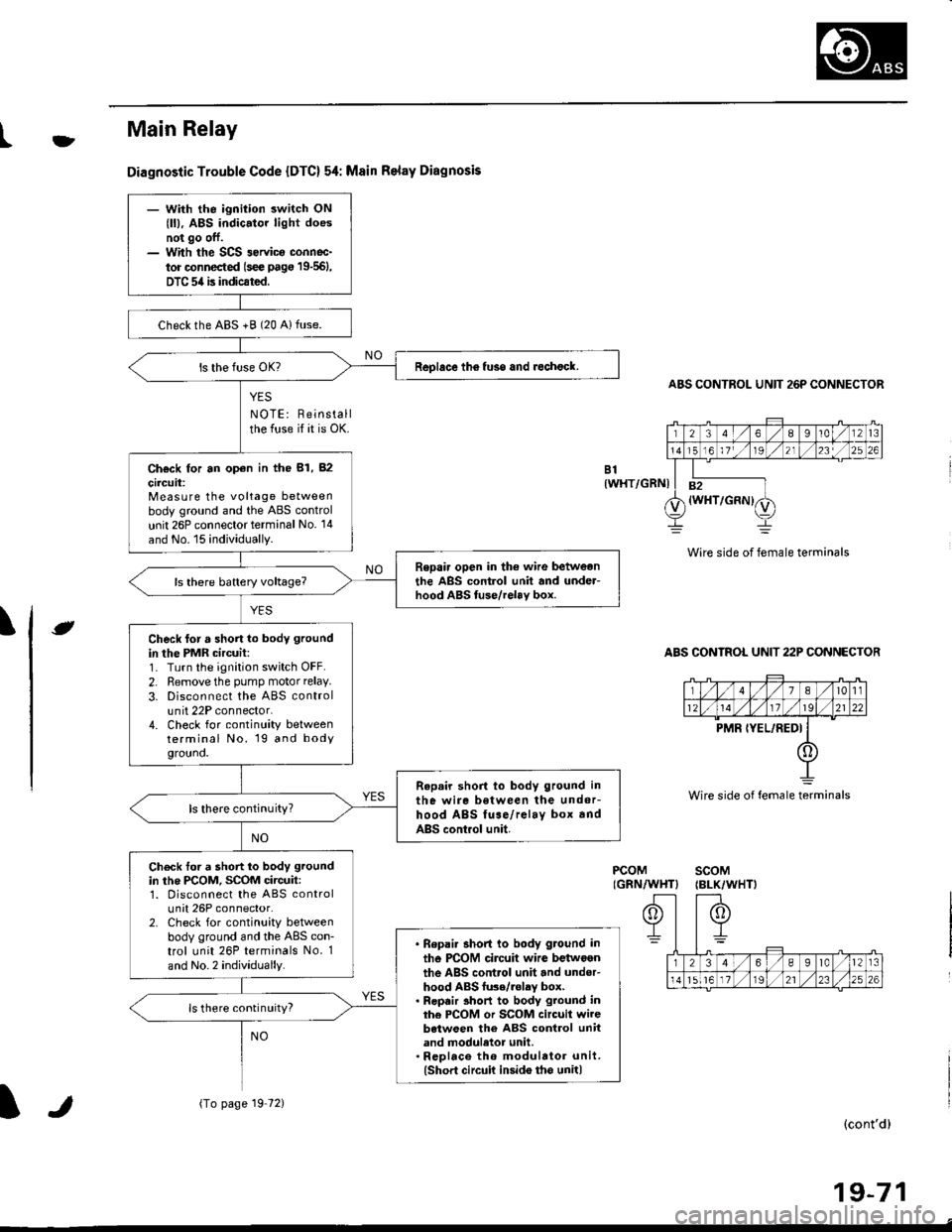

Diagnostic Trouble Code {DTC} 54: Msin Relay Diagnosis

YES

NOTE: Reinstallthe fuse if it is OK.

ABS CONTROL UNIT 26P CONNECTOR

Wire side of female terminals

ABS CONTROL UNIT 22P CONNECTOR

B1{WHT/GRNI

\e

PCOMIGRN/WHT}scoM{BLK/WHTI

(cont'd)

19-71

Wire side of female terminals

- With the ignition switch ON

{ll), ABS indic.tor light doesnot go off.- With the SCS 3ervica connoc-

tor connected (s€e pag€ 19-561,

DTC 54 is indicated.

checkthe ABS +B (20 Alfuse.

Replace th6 fuso and rechock.

Ch€ck for an op€n in the 81, 82

circuit:Measure the voltage betweenbody ground and the ABS control

unit 26P connector terminal No. '14

and No. 15 individually.

Repair open in the wire betweonthe ABS control unit and under-hood ABS tuse/relav box.

Check for a short lo body ground

in the PMR circuit:1- Turn the ignition switch OFF.

2. Remove the pump motor relay.

3. Disconnect the ABS controlunit 22P connector.4. Check for continuity betweenterminal No. 19 and bodygrouno.

Repair short to body ground in

the wire between the undor-hood ABS fuse/relay box andABS control unit.

ls there continuity?

Check tor a short to body ground

in the PCOM, SCOM circuit:1. Disconnect the ABS controlunit 26P connector.2. Check for continuity betweenbody ground and the ABS con-trol unit 26P terminals No. 1

and No.2 individually.

. Bepai. short to body ground in

tho PCOM circuit wire betwoenthe ABS control unit and under-hood ABS fu3e/.olay box.. Repair 3hort to body ground inthe PCOM or SCOM circuit wirebetween the ABS control unitand moduletor unit.. Rcplace th6 modulator unit.(Short circuit insido tho unit)

ls there continuity?

{To page 19 72)lr

Page 1225 of 2189

Troubleshooting

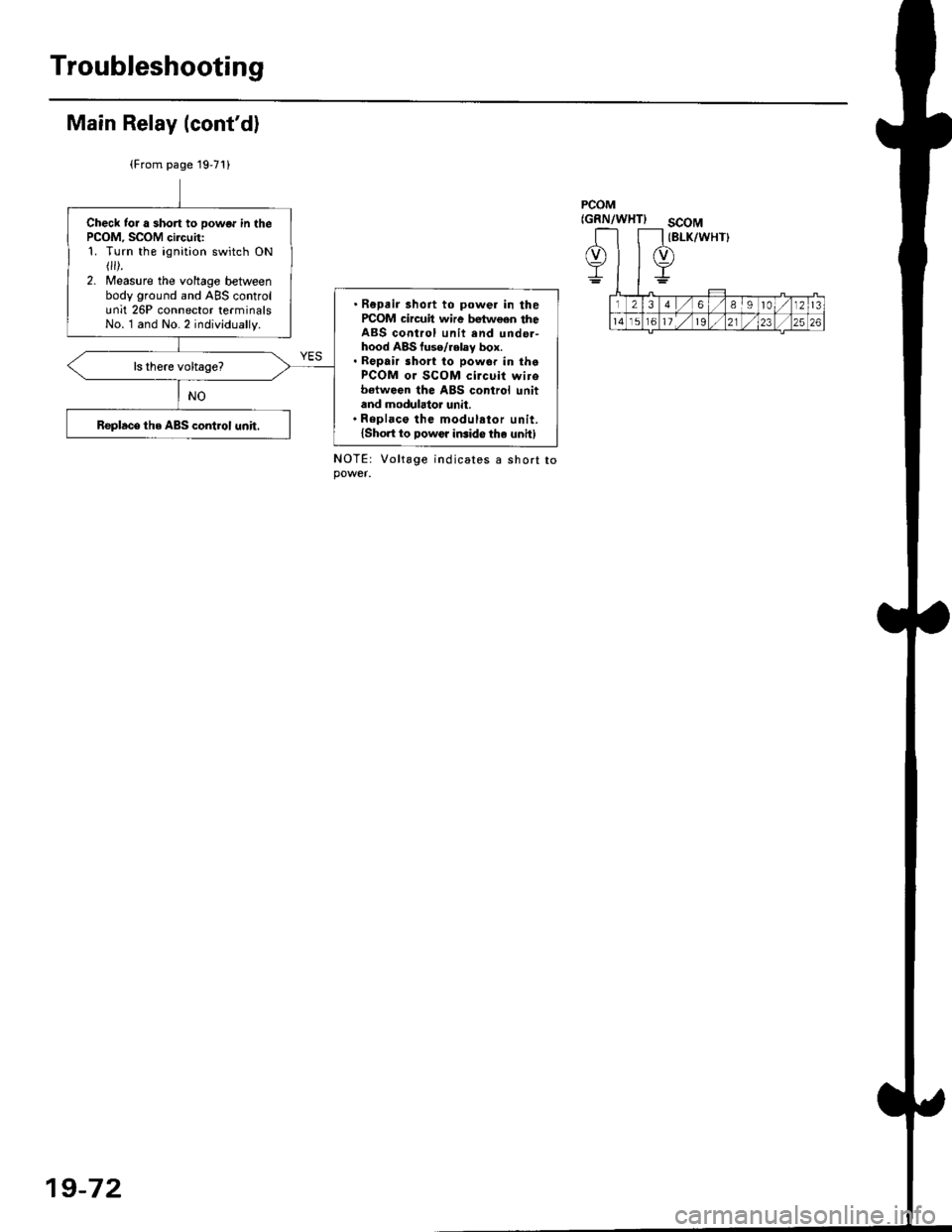

Main Relay (cont'd)

(From page 19'71)

PCOM(GRN/WHTIscoM(BLK/WHT}Check tor a short to powor in thePCOM, SCOM circuit:1. Turn the ignition switch ON r).2. Measure the voltage betweenbody ground and ABS controlunit 26P connector terminalsNo. l and No.2 individually.

. Repair 3hoit to power in ihercOM circuil wire bgtween theABS control unit end unde.-hood ABS fuse/relay box.. Repair sho to powor in thaPCOM oJ SCOM circuit wirobetwoen the ABS control unitand modulator unit.' Repl.co the modul.tor unit.lshort to Dowcr iGido the unit)Replace the ABS control unit.

Vo lta ge

19-72

Page 1226 of 2189

![HONDA CIVIC 1996 6.G Workshop Manual lgnition Voltage

Diagnostic Trouble Code (DTC) 61: lgnhion Voltage Diagno3is

A8S CONTROL UNIT 26P CONNECTOR

IG2IBLK/BLU}

]Wire side of lemale terminals

- With tha engin€ running, ABSindicator lighl HONDA CIVIC 1996 6.G Workshop Manual lgnition Voltage

Diagnostic Trouble Code (DTC) 61: lgnhion Voltage Diagno3is

A8S CONTROL UNIT 26P CONNECTOR

IG2IBLK/BLU}

]Wire side of lemale terminals

- With tha engin€ running, ABSindicator lighl](/img/13/6068/w960_6068-1225.png)

lgnition Voltage

Diagnostic Trouble Code (DTC) 61: lgnhion Voltage Diagno3is

A8S CONTROL UNIT 26P CONNECTOR

IG2IBLK/BLU}

]Wire side of lemale terminals

- With tha engin€ running, ABSindicator lighl is ON.- With the SCS s€rvice connec-to. conn€ctod ls€€ page 19-561,DTC 61 is indicated.

Problem v€rification:1. Erase the DTC.2. Start the engine.3. Make sure that the ABS ind;cator light comes on and DTC61 is indicated.

ls DTC 61 indicated?The system b OK .t this time.

Check the lG2 cilcuii:Measure the voltage between theABS control unit 26P connectorterminal No. 3 and body ground.

ls there 18 V or above?

lf the vohage is 0 V, check lor anopon in the lG2 circuit.It there is 12 - 17 V. substitute aknown-good ABS colrtrol unit andJecheck.

It

19-73

Page 1228 of 2189

\il

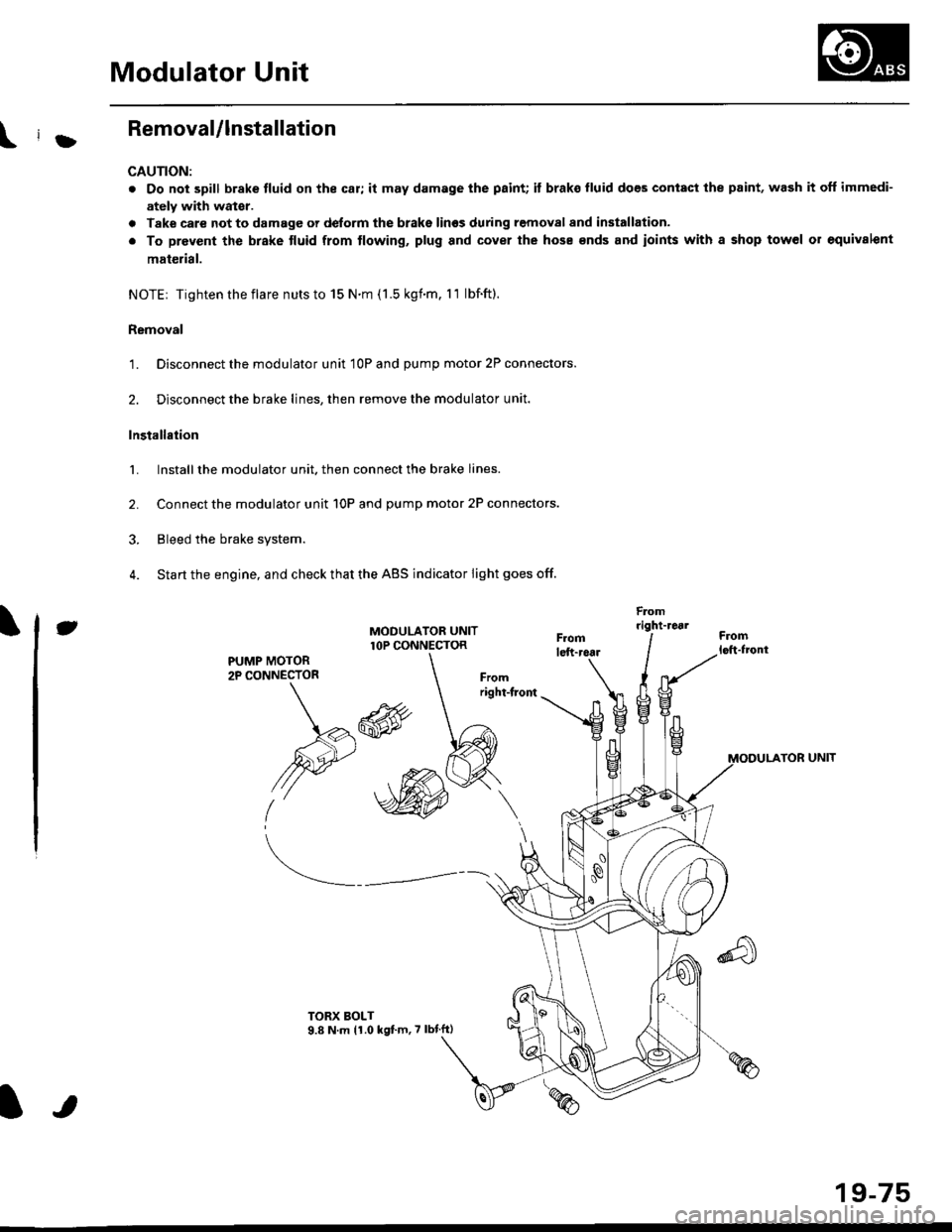

Modulator Unit

RemovaUlnstallation

CAUTION:

. Do not spill brake tluid on the car; it may damage the paint; it brako lluid does contact the paint, wash it off immedi-

ately with wator.

a Take care not to damage or delorm the brake lin€s during removal and installation.

. To prevent the brake tluid from tlowing, plug and cover the hose €nds and ioints with a shop tow6l or equivalent

mat€rial.

NOTE| Tightentheflare nutsto 15 N.m (1.5 kgnm. l1 lbf.ft).

Removal

'1. Disconnect the modulator unit 10P and Dump motor 2P connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installaiion

1. Install the modulator unit. then connect the brake lines.

2. Connect the modulator unit 10P and oumD motor 2P connectors.

3. Bleed the brake system.

4. Start the engine, and check that the ABS indicator light goes off.

Fomright-1461

PUMP MOTOR2P CONNECTOR

J

-R

/2e'

t'

TOR UNIT

tt

19-75

Page 1229 of 2189

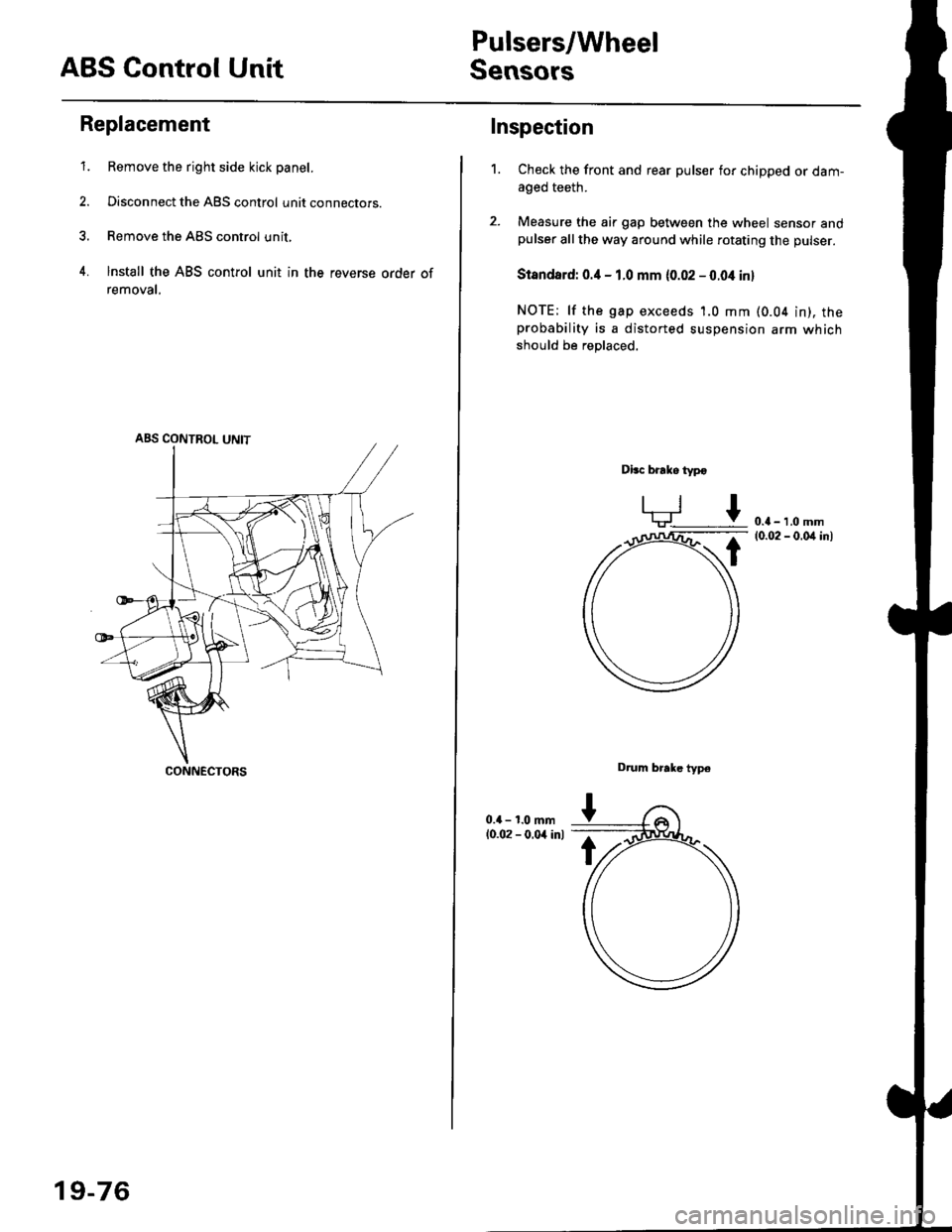

ABS Control Unit

Pulsers/Wheel

Sensors

Replacement

1. Remove the right side kick panel.

2. Disconnect the ABS control unit connecrors.

3. Remove the ABS control unit,

4. lnstall the ABS control unit in the reverse order of

removal,

CONNECTORS

19-76

Inspection

Check the front and rear pulser for chipped or dam-aged teeth.

Measure the air gap between the wheel sensor andpulser all the way around while rotating the pulser.

Slandard: 0.4 - 1.0 mm (0.02 - 0.04 in,

NOTE; lf the gap exceeds 1.0 mm (0.04 in), theprobability is a distorted suspension arm which

should be replaced.

Dbc brake typo

0.{ - 1.0 mm(0.02 - 0.04 in)

Drum brake typ6

1.

Page 1234 of 2189

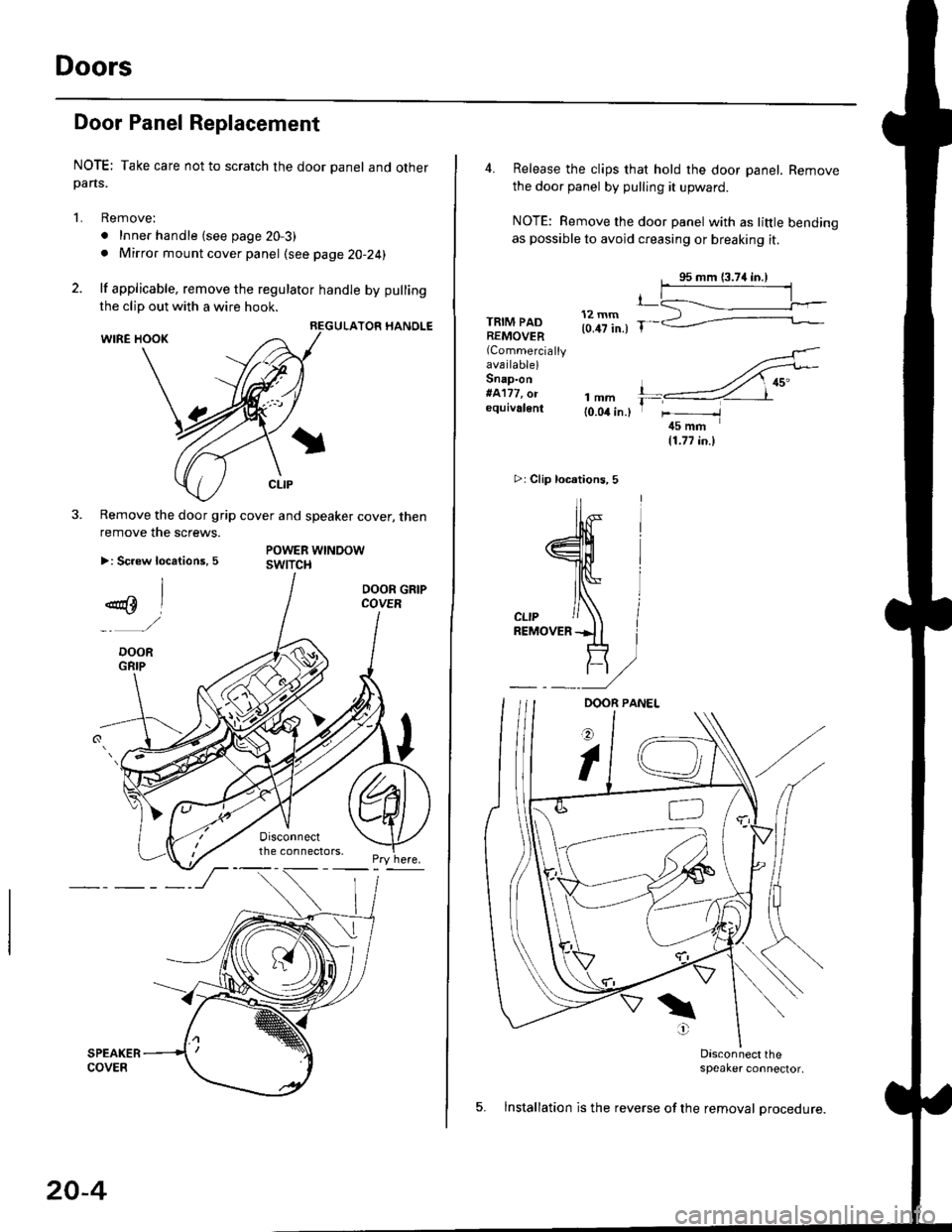

Doors

Door Panel Replacement

NOTE; Take care not to scratch the door panel and otherpans.

1. Remove:

. Inner handle (see page 20-3)

. Mirror mount cover panel (see page 20-24)

2. lf applicable, remove the regulator handle by pulling

HANOLE

3. Remove the door grip cover and speaker cover, thenremove the screws.

>: Screw locations, 5POWER WTNOOWswtTct{

the clip out with a wire hook.

20-4

4. Release the clips that hold the door panel. Remove

the door panel by pulling it upward.

NOTE: Remove the door panel with as little bending

as possible to avoid creasing or breaking it.

95 mm {3.74 in.)

.L12 mm(0.47 in.) fTRIM PADREMOVER(Commercially

availablelSnap-on#A'177, o.equivalenllmm(0.04 in.l

r_

rr-l

45 mm(1.77 in.l

>i Clip loc.tions, 5

lu-i

J$- I

:fe i

cL,P / IREMovERil I

_ _t/

Dasconnect the;peaker connector,

5. lnstallation is the reverse of the removal procedure.

Page 1236 of 2189

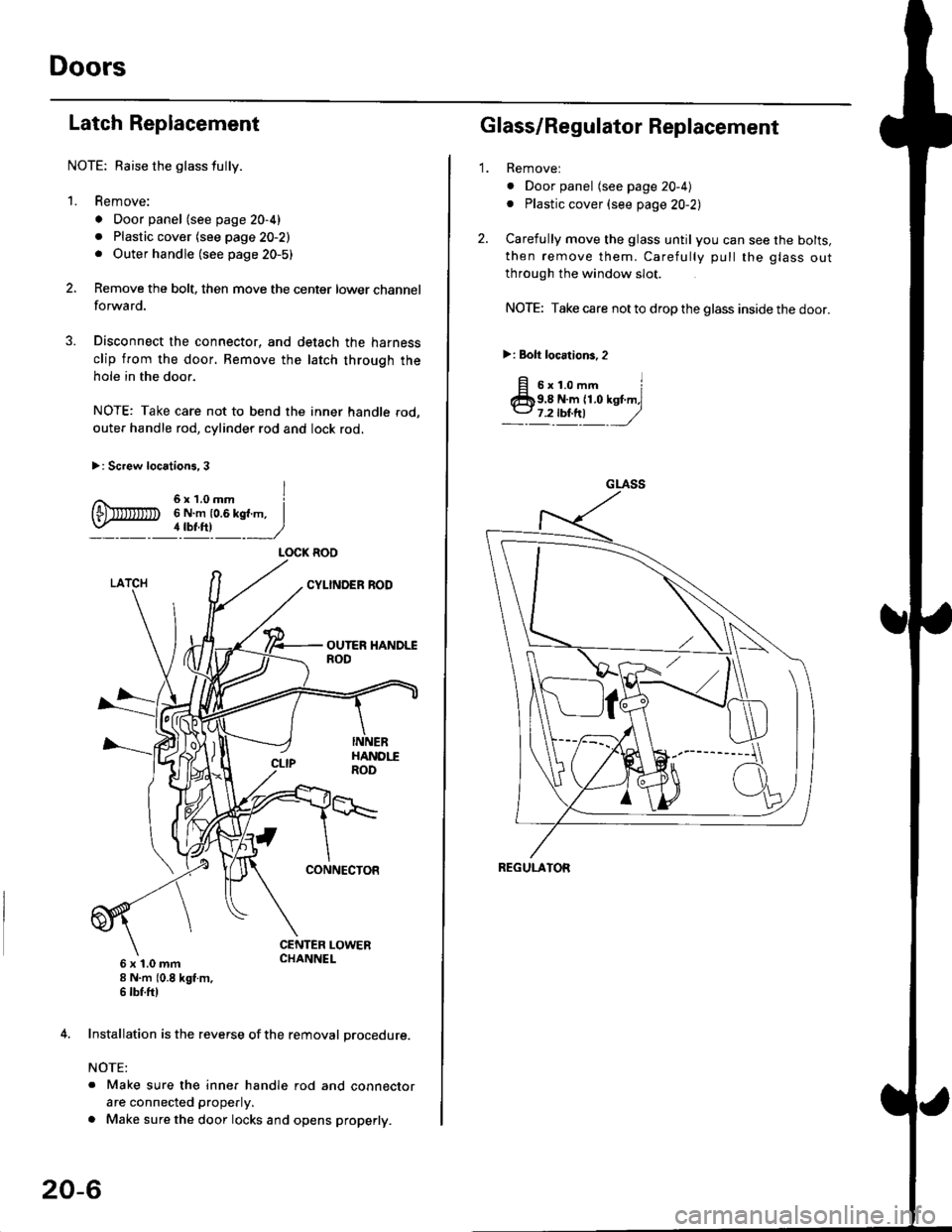

Doors

Latch Replacement

NOTE: Baise the glass fully.

1. Remove:

. Door panel (see page 20-4)

. Plastic cover (see page 20-2). Outer handle (see page 20-5)

Remove the bolt, then move the center lower channel

forwa rd.

Disconnect the connector, and detach the harness

clip from the door. Bemove the latch through the

hole in the door.

NOTE: Take care not to bend the inner handle rod,

outer handle rod, cylinder rod and lock rod.

>: Screw locations, 3

6 x 't.0 mm8 N.m (0.8 kgt m,6 tbf.ftl

4. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the inner handle rod and connector

are connected properly.

. Make sure the door locks and opens properly.

LOCK ROO

20-6

'1.

Glass/Regulator Replacement

Removel

o Door panel (see page 20-4)

. Plastic cover (see page 20-2l,

Carefully move the glass until you can see the bolts,

then remove them. Carefully pull the glass out

through the window slot.

NOTE: Take care not to drop the glass inside the door.

>i Bolt loc.tions,2

fi s'r.o-. iClb9.8 N.m 11.0 kst m,l

_-l't!!t ,/

GLASS

REGULATOR

Page 1237 of 2189

\L

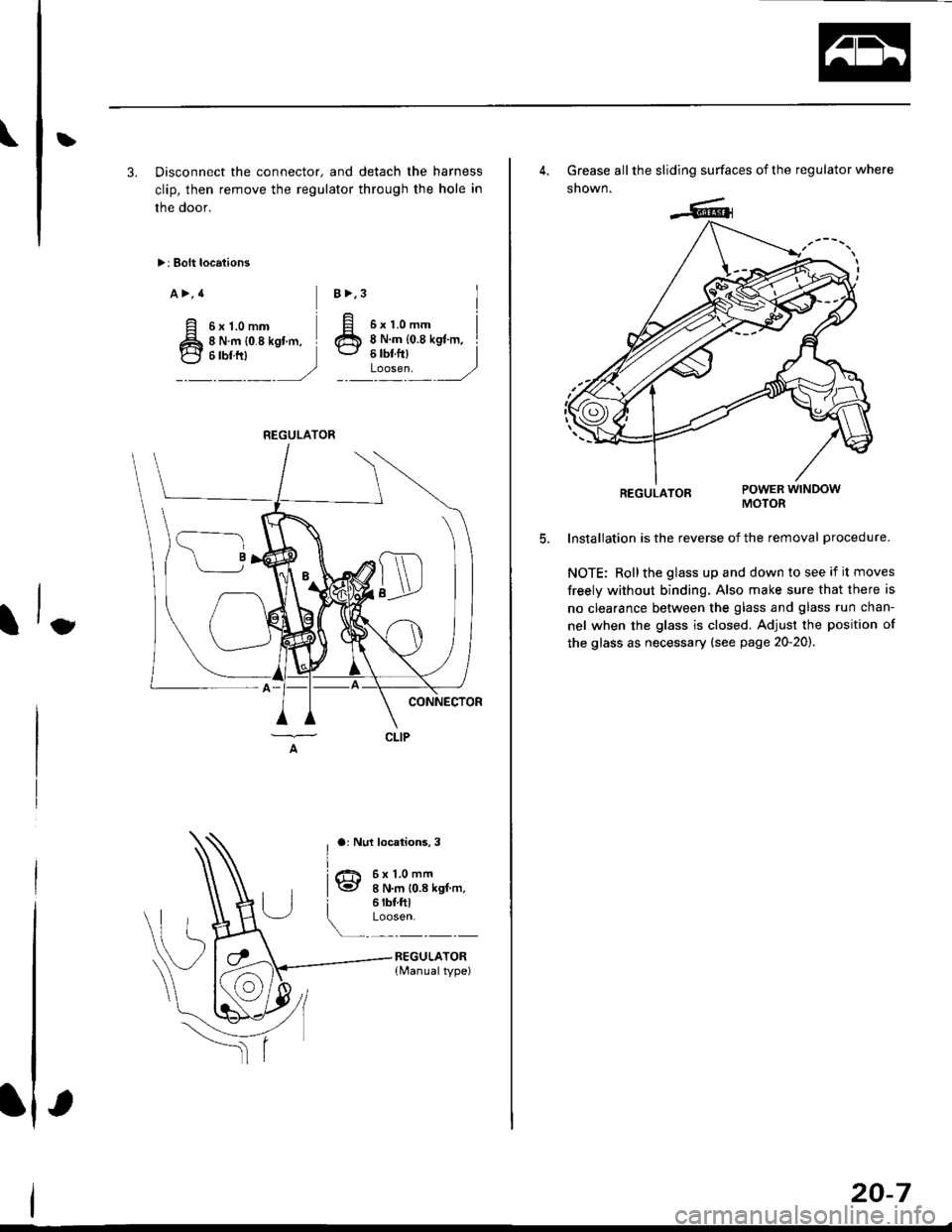

3. Disconnect the connector, and detach the harness

clip, then remove the regulator through the hole in

the door,

>: Bolt locations

a>,4

ttt*,

)

6x1.0mm8 N.m {0.8 kgl m,

B>,3

ar Nul locations, 3

It

6x1.0mm8 N.m 10.8 kgf m,6 rbt.ftlLoosen.

REGULATOR{Manualtype)

REGULATOR

4. Grease all the sliding surfaces of the regulator where

snown.

REGULATORMOTOR

lnstallation is the reverse of the removal procedure.

NOTE: Rollthe glass up and down to see if it moves

freely without binding. Also make sure that there is

no clearance between the glass and glass run chan-

nel when the glass is closed. Adjusr the position of

the glass as necessary (see page 20-20).

20-7