Code 38 HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 945 of 2189

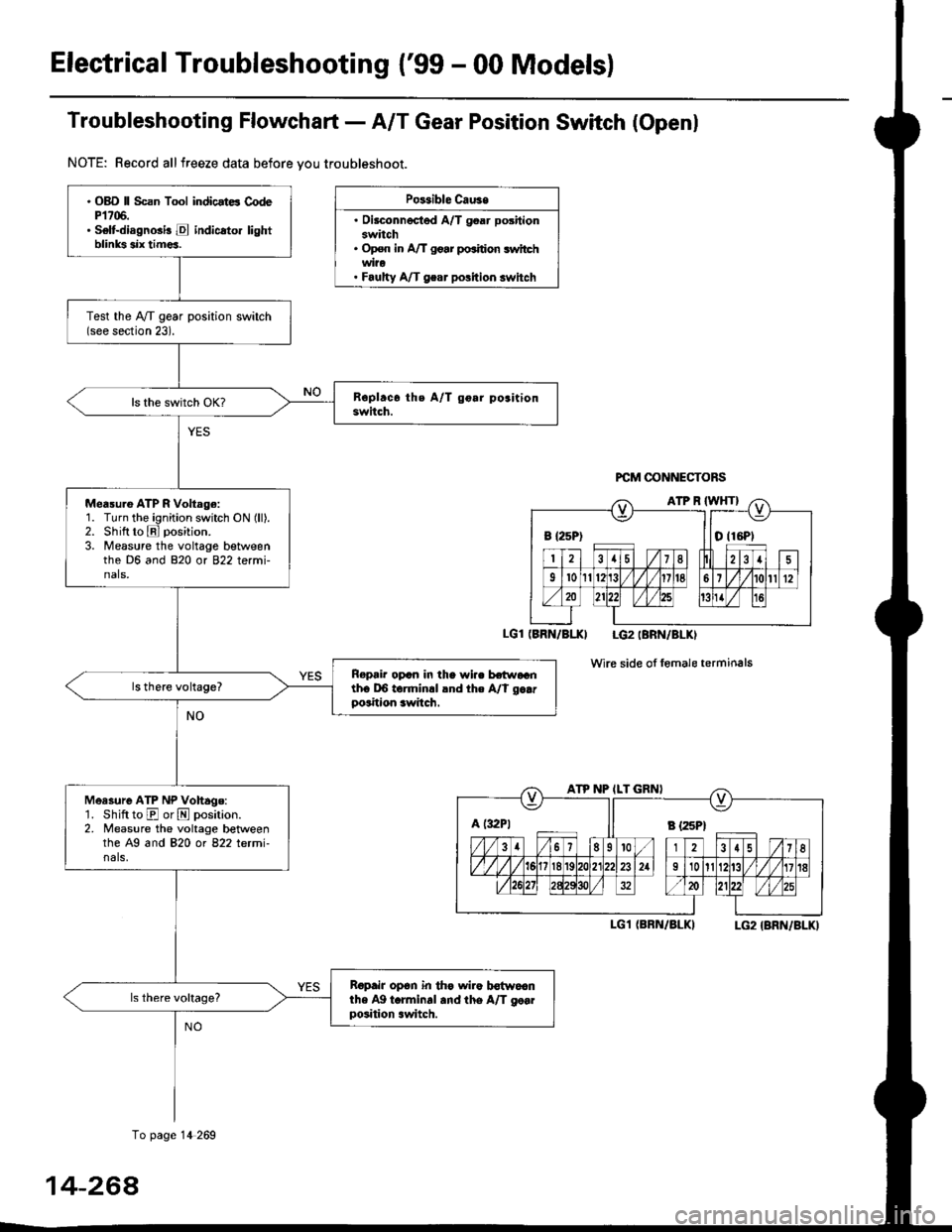

Electrical Troubleshooting {'99 - 00 Models)

Troubfeshooting Flowchaft- AIT Gear Position Switch (Openl

NOTE: Record allfreeze data before vou troubleshoot.

Po$ible Cau3e

. Oilconnected A/T goar positionswitch. Op€n in A/T go.r po.ition switchwi?o. Faulty A/T gear polition switch

PCM @NNECTORS

(BRN/BI.XI LG2IBRN/BLKI

wire side of fomale terminals

I-G1 (BRN/BLKILG2 {BRN/BLK)

B {25P) I tO (16P1

ATP NP ILT GRNI

A t:r2Pt Il s tzspt

. OBD ll Scan Tool indicstE CodeP1706.. Selt-diagnGi! E indicato. lightblinks six tim€a.

Test the IVT gear position switch(see section 23).

Measu.e ATP R Voltage:1. Turn the ignition switch ON (ll).2. Shift to E position.

3. Measure the voltage betweenthe D6 and 820 or 822 termi-nals,

Ropair opcn in the wi.. hr.raGnth6 DO torminrl lnd the A/t g..rposition awitch.

Measure ATP NP Vohage:'1. Shift to E or N position.2. Measure the voltage betweenthe A9 and 820 ot 822 letmi-nals,

Ropair op6n in th€ wiro b€{woanthe Ag t.rminal and the A/T go..position .witch.

To page 14 269

14-264

Page 948 of 2189

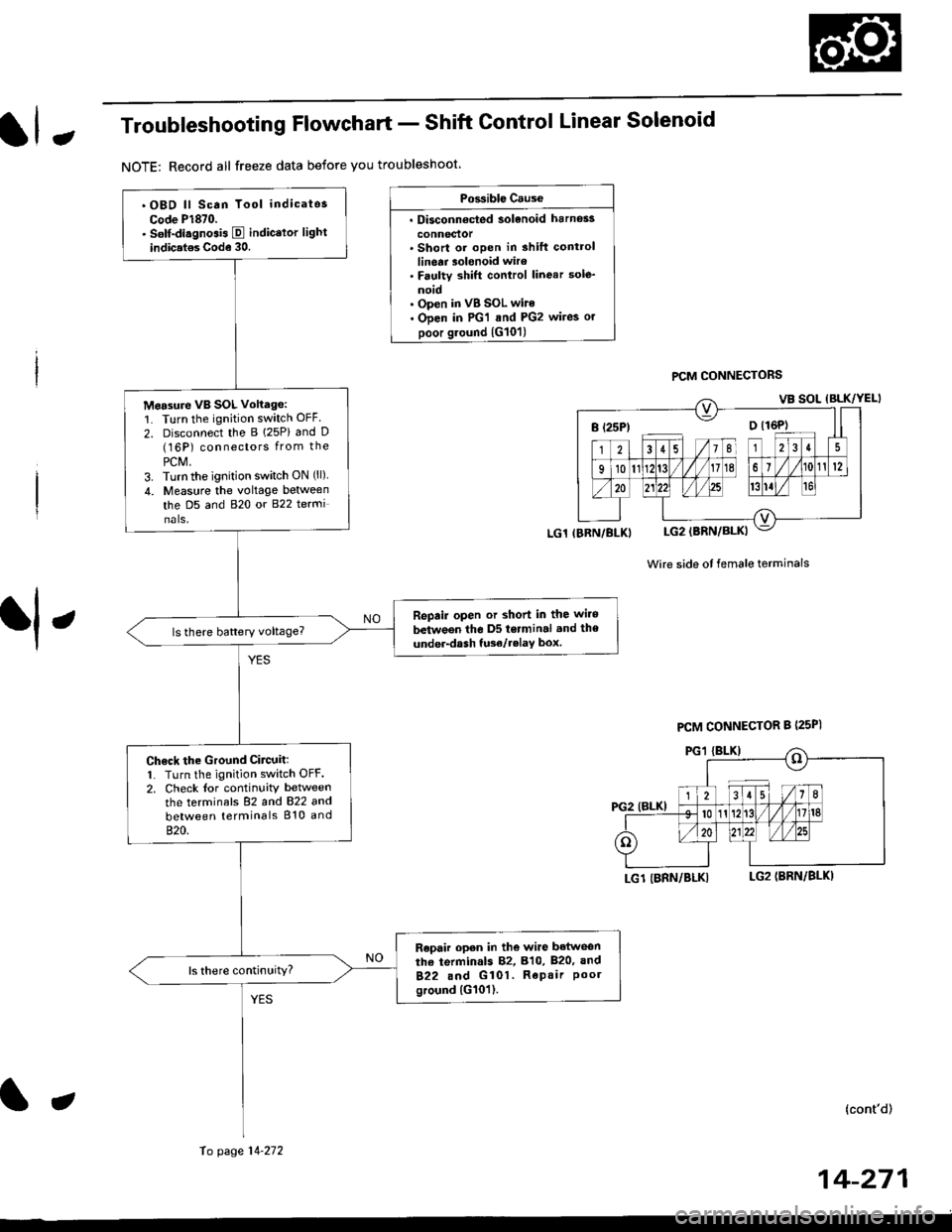

JTroubleshooting Flowchart - Shift Control Linear Solenoid

NOTE: Record all freeze data before you troubleshoot

Possiblc Cause

. Disconn€cted solenoid harnos3

connectol. Short or oDen in shilt controllinetr solonoid wiro. Faulty shift control linear sole_

noid. Op€n in VB SOL wite. ODen in PG'l and PG2 wires or

poor ground {G10'l)

f,

wire side ot female terminals

LG1 IBRN/BLKILG2IBRN/BLK)

{cont'd)

14-271

PCM CONNECTORS

B(25P) - Dll6P)

.OBD ll Scan Tool indicatos

Code P1870.. Solf-diagnosis E indic.lor light

indic.t€s Code 30.

M6a3ure VB SOL voltage:1. Turn the ignition switch OFF.

2. Disconnect the B 125P) and D(16P) connectors from the

PCM,3. Turn the ignition switch ON (ll).

4. Measure the voltage between

the D5 and 820 or 822 terminals.

Repair open or shod in the wire

between the D5 terminal and the

under-dash tuso/telay box.

Check the Ground Circuitl1. Turn the ignition switch OFF.2. Check lor continuity between

the terminafs 82 and 822 and

between terminals 810 and

820.

Repair open in the wi.e betwoen

the termin.ls 82, B10, B20, and

822 and G101. Repair Poolground (G101).

LG1 IBRN/BLKI

PCM CONNECTOR B PsPI

PG,I IBLK)

10 page 14-272

a

Page 950 of 2189

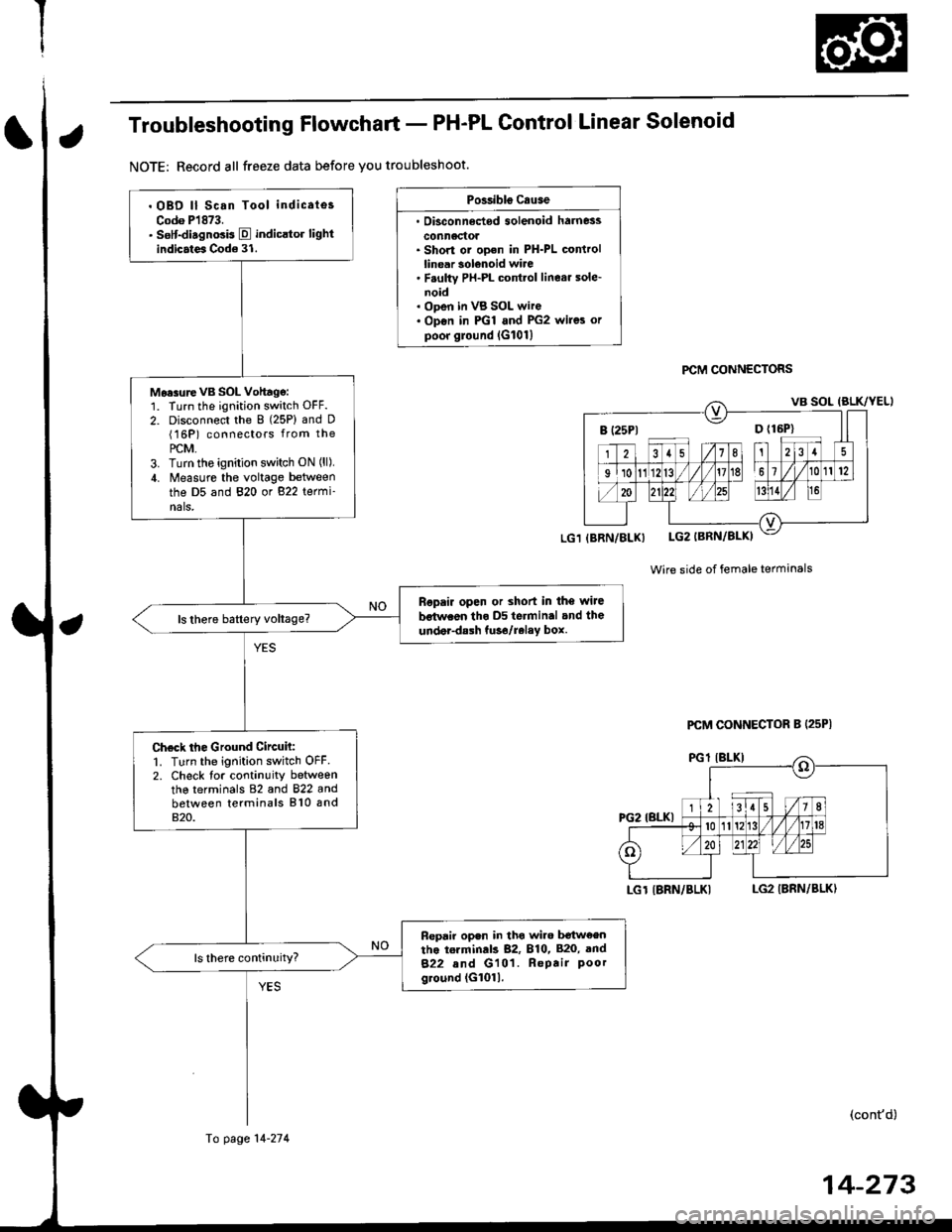

Troubleshooting Flowchart - PH-PL Control Linear Solenoid

NOTE: Record all freeze data before you troubleshoot.

Possibls c.use

. Oisconn6dod solenoid harness

conn6ctol. Short or ooen in PH-PL controllinear solenoid wire. F.ulty PH-PL cont.ol linear sole-noid. ODen in VB SOL wire. Op€n in PGl and PG2 wires orpoor ground lG101l

PCM CONNECTORS

Wire side of female terminals

LGT IBRN/BLKILG2 IBRN/BLK)

(cont'd)

B (25P1 D {16P}

. OBD ll Scan Tool indicates

Codo P1873.. sslt-disgnosis E indicltor lightindicates Code 31.

Mo.surevB SOL Vohagg:1. Turn the ignition switch OFF.

2. Disconnect the 8 (25P) and D(16P) connectors from the

PCM,3. Turn tho ignition switch ON (ll),

4. Measure the voltage between

the D5 and 820 or 822 termi-nals,

Ropair open or shod in the wiJe

bstwaon tho D5 terminal and the

under-dalh tuso/relay box.

Check the Ground Circuh:1. Turn the ignition switch OFF2. Check tor continuity betweenthe terminals 82 and 822 andbetween terminals 810 and820.

Fepair open in tho wiro b€tw€entho torminds 82, 810, 820, and

822 and G101. Repair Poorground (G1011.

(BRN/BLX)

Fo page 14-274

PCM CONNECTOR B (25P|

14-273

Page 952 of 2189

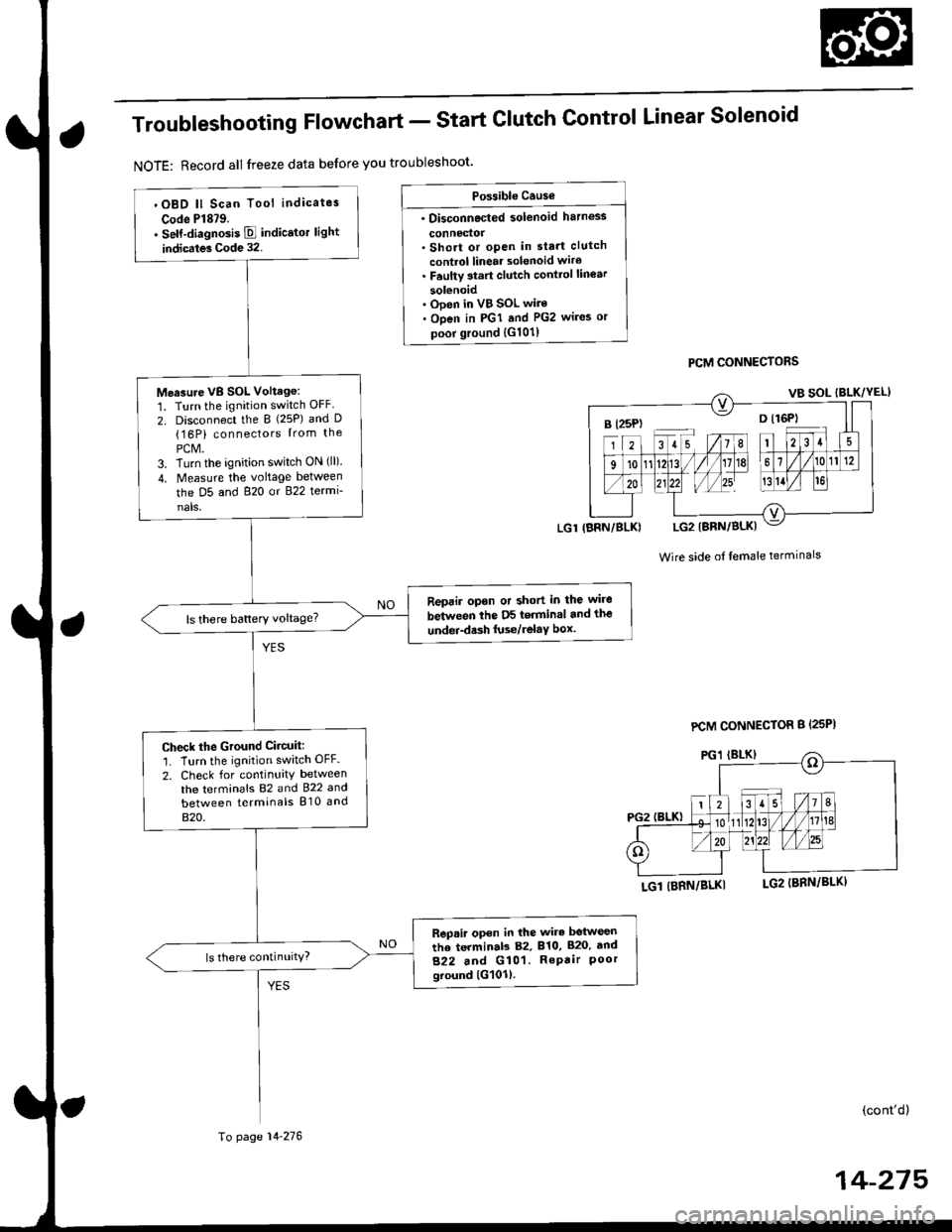

Troubleshooting Flowchart - Start

NOTE: Record all freeze data before you troubleshoot'

Clutch Control Linear Solenoid

PCM CONNECTORS

Wire side of lemale terminals

LGl (BRN/BLKI

(cont'd)

14-215

Po$ible Cause

. Disconnected solenoid harness

connedol. Short or open in sta.t clutch

control linear solenoid wiro. Faulty 3tart clutch conttol lin€ar

solenoid' Ooen in VB SOL wire. Open in PGI and PG2 wires or

poor ground {G101)

B l25P) -- o l16P)

'OBD ll Scan Tool indicates

Code Pl879.. self-diagnosis E indicstor light

indicates Code 32.

Measure VB SOL Voltag6:

1. Turn the ignition switch OFF

2. Disconnect the B {25P) and D(16P) connectors {rom the

PCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage between

the D5 and 820 or 822 termi-

nals,

Reprir opon or short in the wire

between the D5 terminal and the

undei-d.sh luse/relaY box.ls there battery voltage?

Check the Ground Ciicuit:'1. Turn the ignition switch OFF.

2. Check for continuity between

the terminafs 82 and 922 and

between terminals 810 and

820.

Rep.ir open in the wire betwesn

the terminab 82, 810, 820. tnd

822 and G101. RePair Poorground lG101l.

ls there continuity?

LGl IBRN/BLK)

To page 14-276

PCM CONNECTOR B {25PI

Page 954 of 2189

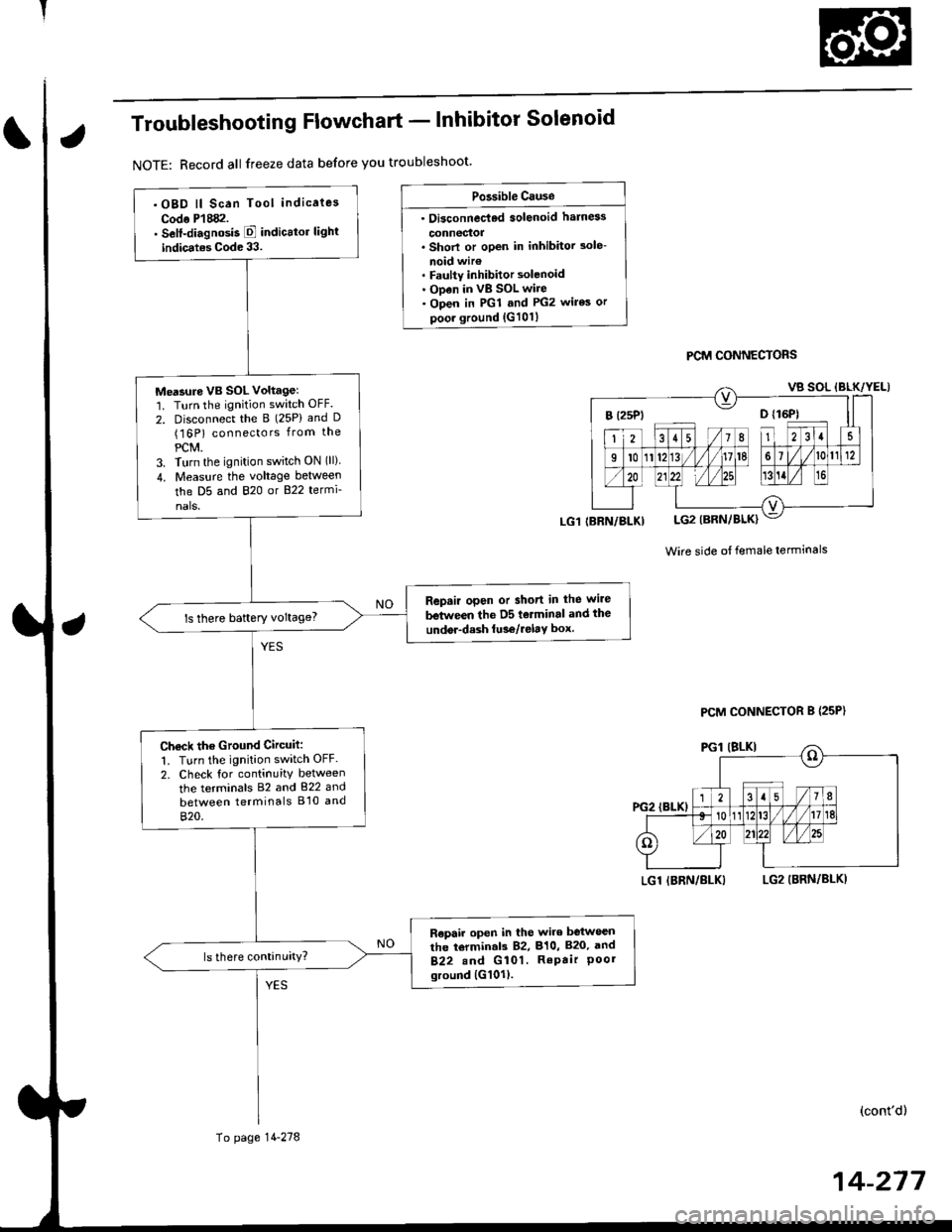

Troubleshooting Flowchart - lnhibitor Solenoid

NOTE: Record all freeze data before you troubleshoot'

Po3sible Cause

. Oi3connec'ted solenoid harn6s

connectoa. Shorl or open in inhibitor 3ole-

noid wir€. Faulty inhibitor solenoid. ODen in vB SOL wire. Open in PGl and PG2 wires or

poor ground {G101}

PCM CONNECTORS

Wire side ot female terminals

LGl IBRN/BLKILG2 (BRN/BLKI

(cont'd)

14-217

.OBD ll Scan Tool indicaies

Codo P'l882.. Self-diagnosis E indicttor light

indic.tes Code 33.

Me'sure VB SOL voltagel'1. Turn the ignition switch OFF.

2. Disconnect the B (25P) and D(16P) connectors from the

PCM.3. Turn the ignition switch ON (ll)

4. Measu.e the voltage between

the D5 and 820 or B22 termi-

nals.

Repair open or short in the wire

between the D5 tolminal and the

undor-dash lu36/relay box.ls there baftery voltage?

Ch€ck the Ground Circuit:

1. Turn the ignition switch OFF.

2. Check tor continuity between

the terminals 82 and 822 and

between terminals B'10 and

820.

R€pair open in the wire between

the torminal3 82, 810, B20, and

B22.nd G 101. RePair Poorground {G101).

(BRN/BLKI

To page 14-278

PCM CONNECTOR B {25P}

Page 956 of 2189

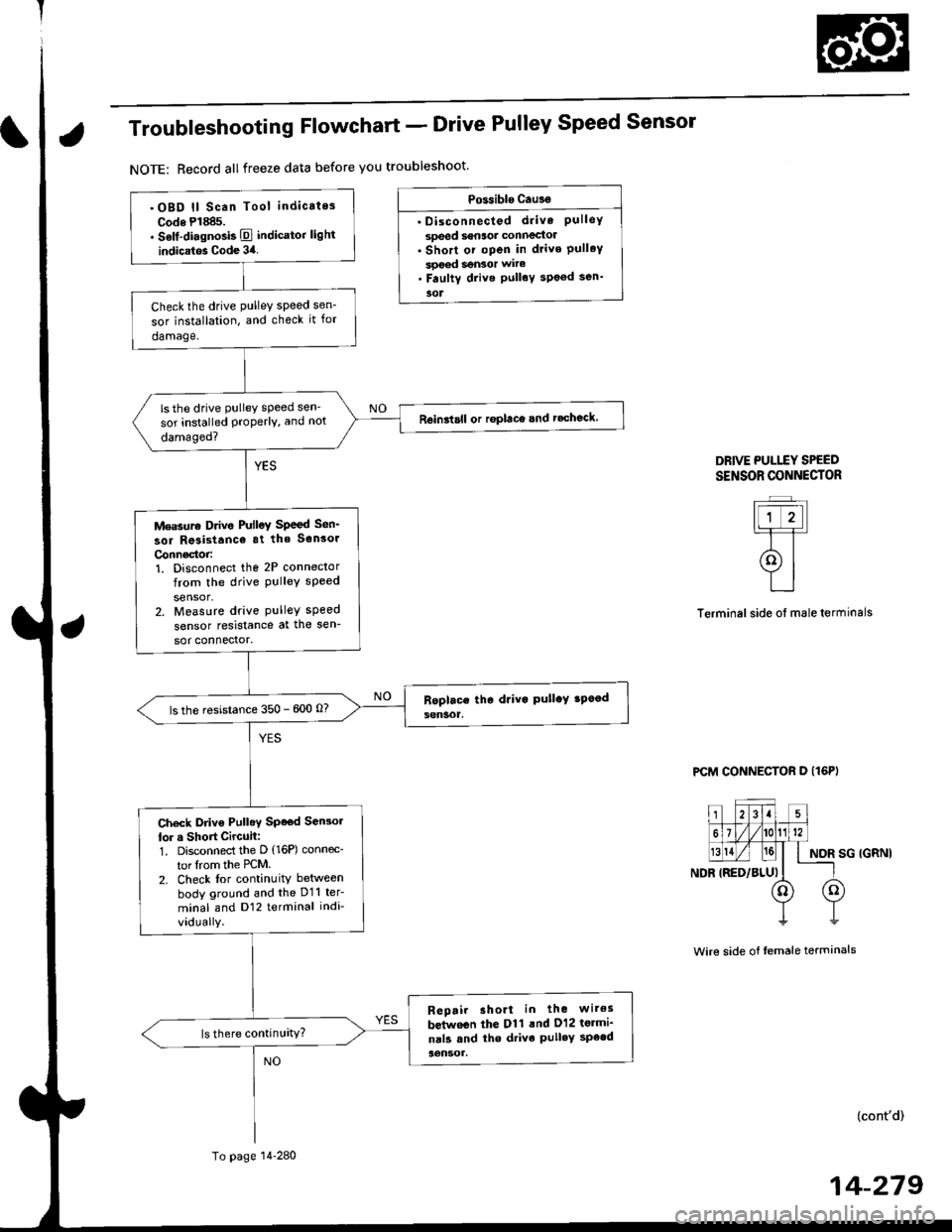

Troubleshooting Flowchart - Drive Pulley Speed Sensor

NOTE: Record allfreeze data before you troubleshoot'

Possible Cau3€

. Disconnected diive PulleYsoeed s6n3or connectol. Short or open in drive Pull.Ysooed sonsor wire. FaultY drive PulleY spo€d sen'

301

DRIVE PULEY SPEED

SENSOR @NNEfiOR

Terminal side of male terminals

PCM CONNECTOR D (16PI

NDR SG IGRNI

Wire side o{ Iemale terminals

(cont'd)

14-279

.OBD ll Scan Tool indicates

Code Pl885.. Selt-diagnosb E indicator light

indicatos Code 34

check the drive pulleY sPeed sen-

sor installation, and check it for

damage.

ls the drive PulleY speed sen-

sor installed properly, and not

damaged?

Rein3tall or roplace and techeck

Measuro Drive PulleY Speed Sen_

sor Ro3istanco at the Sonsol

Connector:1. Disconnect the 2P conneclor

from the drive Pulley speed

sensor,2. Measure drive Pulley speed

sensor resislance at the sen-

sor connecror.

ls the resistance 350 - 600 O?

Check Drivo PulleY SP6€d Sen3o.

lor . Short Circuit:1. Disconnect the D {16P) connec-

torlrom the PCM.

2. Check lor continuity between

body ground and the D11 ter

minal and D'l2 terminal indi

vidually.

Repai. short in the wiles

between the Dll lnd D12 termi-

nals and iho drive Pull.Y speed

To page 14-280

Page 958 of 2189

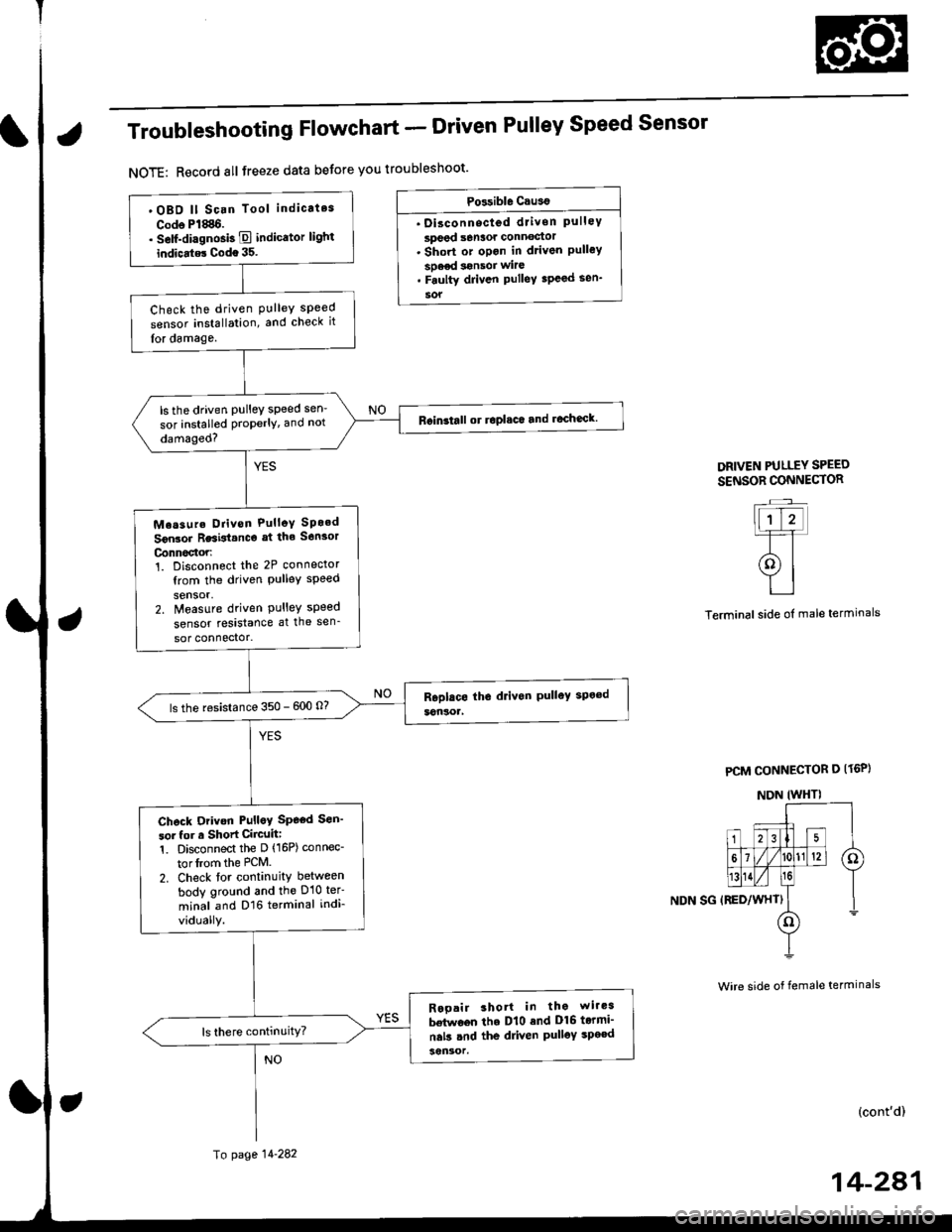

Troubleshooting Flowchart - Driven Pulley Speed Sensor

NOTE: Record all freeze data betore you troubleshoot'

Po3sible Caus€

' Oisconnected driven PulleYspeed s6nlor connoctor. Short or opon in d.iven Pulleysoeed sonsol wirc. Faulty driven Pulley speed sen_

sor

DRIVEN PULLEY SPEED

SENSOR CONNECTOR

Terminal side ol male terminals

FCM CONNECTOR D If6P)

NDN IWHTI

Wire side of female terminals

(cont'd)

'OBD lt Sc.n Tool indicates

Code Pl886.. Self-diagnosb E indicator light

indicrt€. Codo 35.

Check the driven Pulley speed

sensor installation, and check it

Ior damage.

lsthe driven pulleY speed sen'

sor installed ProPerly, and not

damaged?

Boin3tall or ropl.ca and recheck.

M..sure Drivon PulloY SPoed

Sonsor Rosblanco at the S6n3or

Conn6ctori1. Disconnect the 2P connector

trom the driven PUlley sPeed

sensor,2. lveasure driven Pulley speed

sensor resistance at the sen_

sor connector.

ls the resistance 350 - 600 0?

Check Dtivon Pulloy SP€ed Sen'

sor for a Short Circuit:

1. Disconnect the D (16P) connec-

torfrom the PCM.

2. Check tor continuity between

body ground and the D10 ter'

minal and Dl6 terminal indi-

vidually.

Raoair shott in tho wi.6s

betwoon th. Dlo end D16 tormi'

nak .nd the ddven Pulley spo€d

Fo page 14'282

14-2A1

Page 960 of 2189

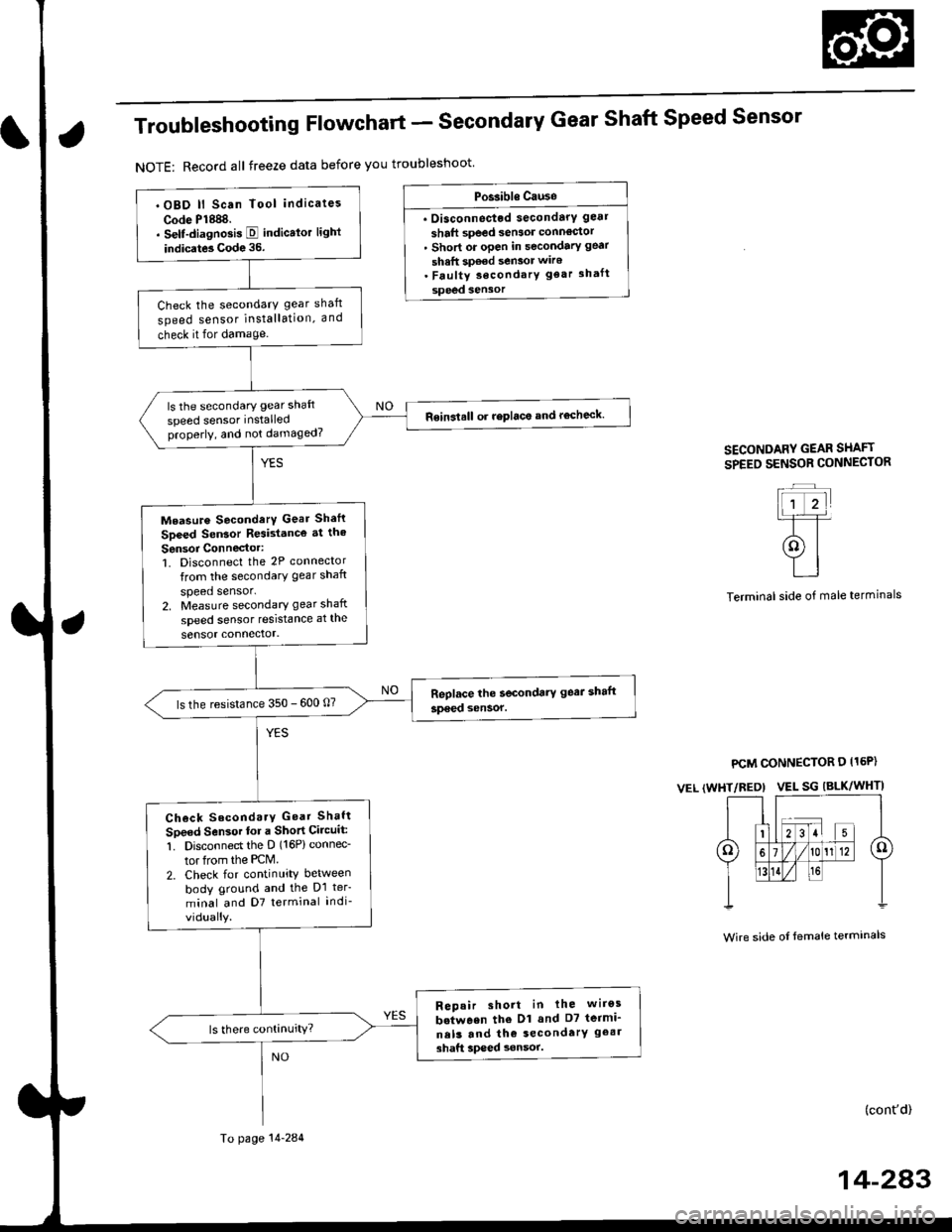

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor

NOTE: Record all freeze data before you troubleshoot

Po$ible Causo

. Oisconnectod secondarY gear

shaft speed sensor conn66or' short or open in secondary gear

shaft spe€d sensor wiro. Faulty secondarY gear 3haft

sPeed sensor

SECONDARY GEAR SHAFT

SPEEO SENSOR CONNECTOR

Terminal side of male terminals

PCM CONNECTOR D I15P)

VEL (WHT/REO) VEL SG IALK/WHTI

Wire side oI female terminals

(cont'd)

14-243

' OBD ll Scan Tool indicates

Code P1888.. Self-diagnosis E indicalor light

indicats Code 35.

Check the secondarY gear shaft

speed sensor installation, and

check it for damage.

ls the secondary gear shaft

speed sensor installedproperly, and not damaged?

Reinatall or replace and rocheck.

Measure SocondarY Gear Sh.ft

Speed Sen3or Resistance at the

Sensor Connector:1. Disconnect the 2P connector

trom the secondary gear shaft

speed sensor.2. Measure secondary gear shaft

speed sensor resistance at the

sensor connector.

ls the resistance 350 - 600 0?

Check SecondarY Gear Shaft

Speed Sensor lor a Short Circuit:

1. Disconned the D (16P) connec-

tor from the PCM.

2. Check for continuity between

body ground and the D1 ter-

minal and D7 terminal indi-

vidually.

Repair short in the wiros

b.tween the Dl and D7 termi_

ne13 and th€ secondarY geal

3haft lpeed sonsor.

To page 14-284

Page 962 of 2189

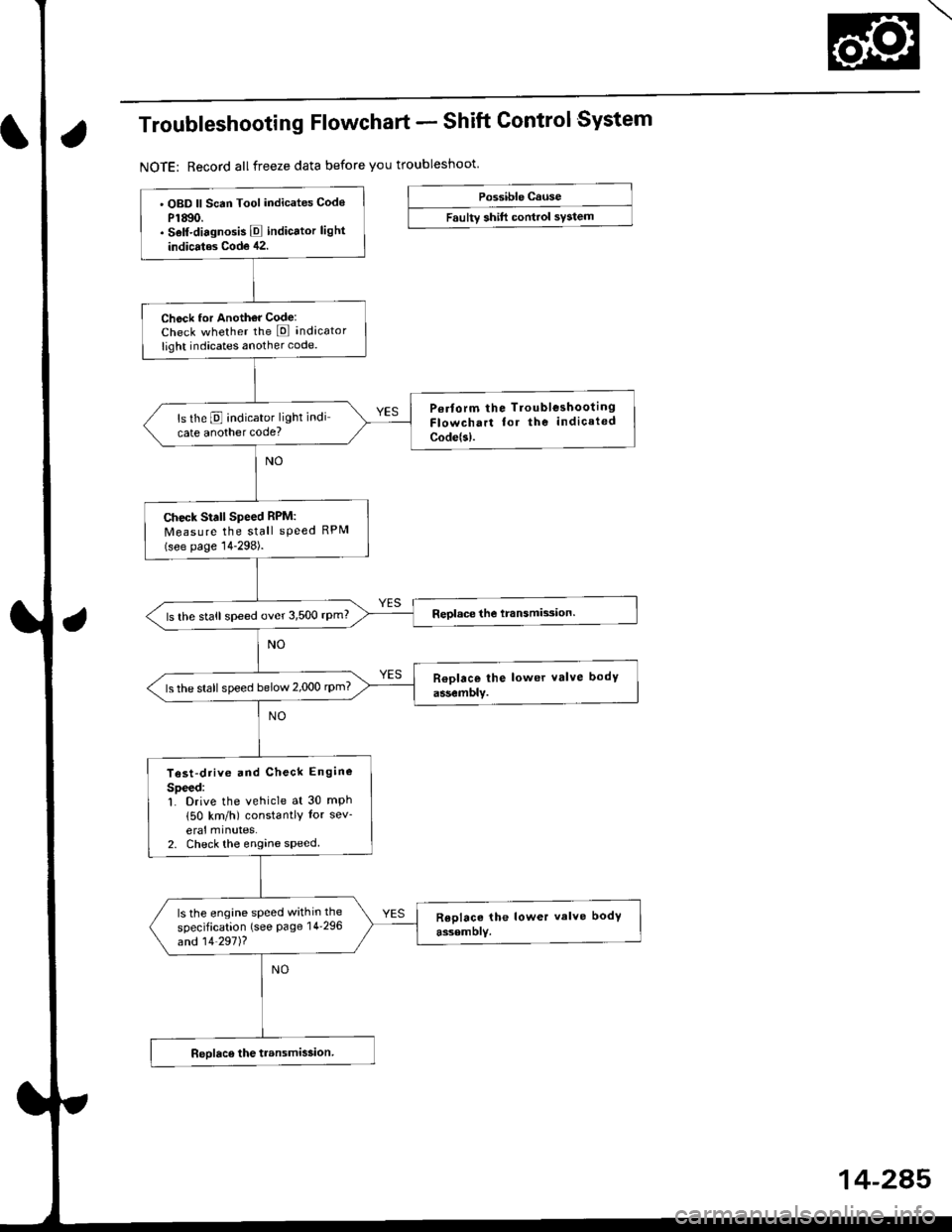

Troubleshooting Flowchart - Shift Control System

NOTE: Record allfreeze data before you troubleshoot

Possible cause

Faultv shift control svstem' OBD ll Scan Tool indicates Codo

P1Ato.. Self-diagnosis E indicator light

indicatos Code 42.

Check for Anoth€r Code:Check whether the E indicator

light indicates another code.

P€rform the Tloubleshooting

Flowchart for the indicated

Code(sl.

ls the E indicator light indi

cate another code?

Check Stall Speed RPM:

Measure the stall sPeed RPM(see page 14-298).

ls the stall speed over 3,500 rpm?

ls the stall speed below 2,000 rpm?

Test-drive and Check Engine

Speed:L Drive the vehicle at 30 mph

150 km/h) constantly for sev-

eral mlnutes.2. Check the engine speed

ls the engine speed within the

specification (see Page 14'296

and 14'297)?

14-245

Page 963 of 2189

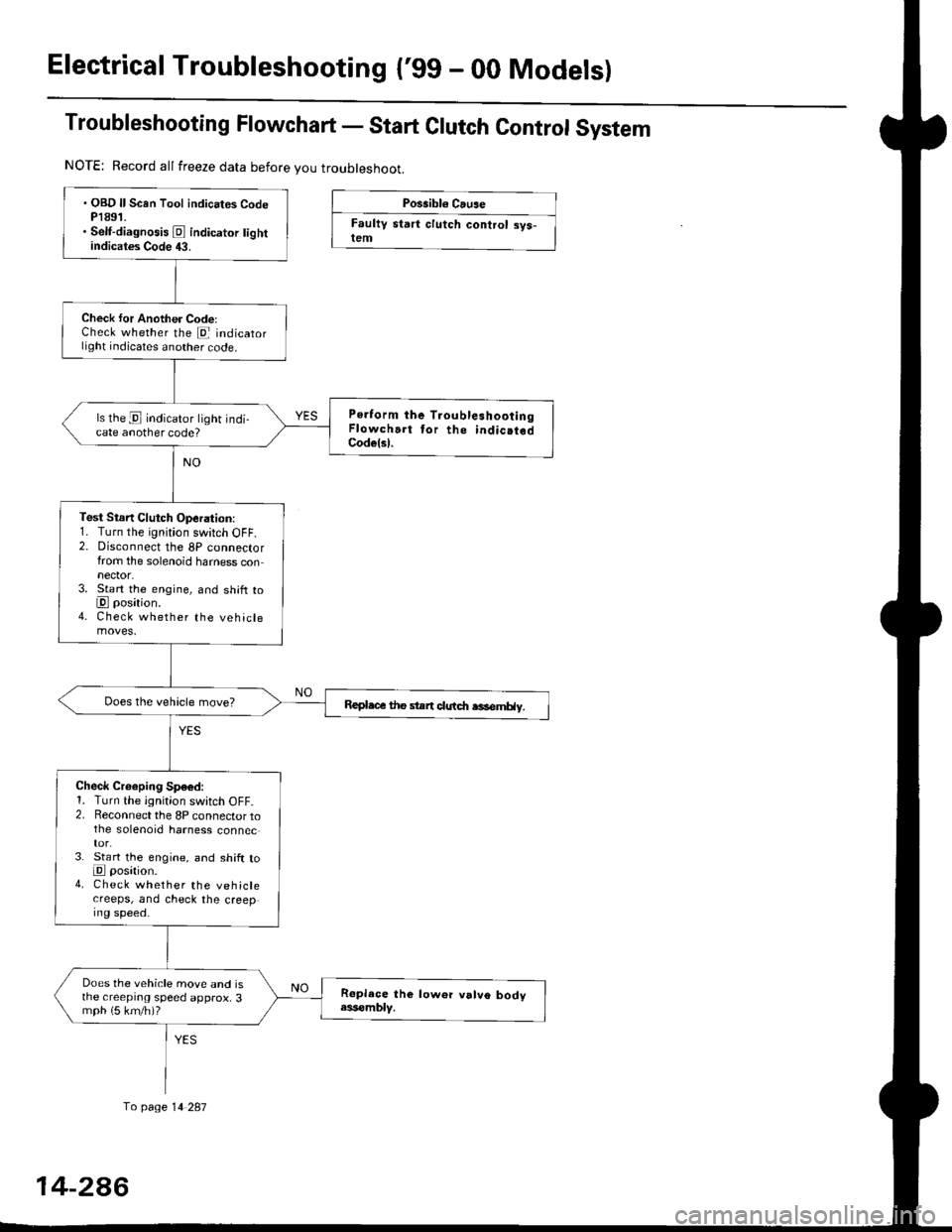

Electrical Troubleshootang ('gg - 00 Models)

Troubleshooting Flowchart - Start Clutch Control System

Possibl€ Cause

Faultv start clutch control sys-lem

NOTE: Record allfreeze data before you troubleshoot.

fo page 14 287

. OBD ll Scan Tool indicates CodeP1891.. Self-diagnosis E indicator tightindicates Code 43.

Check for Another CodelCheck whether the E indicatorlight indicates another code.

Perform the TroubleshootingFlowchart tor the indic.tedCodelsl.

ls the E indicator light indi-cate another code?

Test Stsn Clutch Operation:1. Turn the ignition switch OFF.2. Disconnect the 8P connectorfrom the solenoid harness connector.3. Start the engine, and shift toE position.4. Check whether the vehiclemoves.

Repl.c€ the stan clutdt rasemHy.

Check Croeping Sp€6d:1. Turn the ignition switch OFF.2. Reconnect the 8P connector tothe solenoid harness connec

3. St€rt the engine, and shift toE posation.4. Check whether the vehiclecreeps, and check the creeping speed.

Does the vehicle move and isthe creeprng speed approx, 3mph (5 km/h)?

14-2A6