valve stem HONDA CIVIC 1998 6.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 563 of 2189

Emission Control System

Evaporative Emission (EVAPI Controls (cont'd)

Evaporative Emission (EVAPI Two Way Valve Testing

l'96 DIGYS engine lcoupel,'97 Dl6Y7 engine (coupe: KL

model, sedan: KL (LX) modoll,'97 Dl6Y8 engine {coup€:

alt models, sedan: KL model, '98-all modelsll:

1. Remove the fuel fill cap.

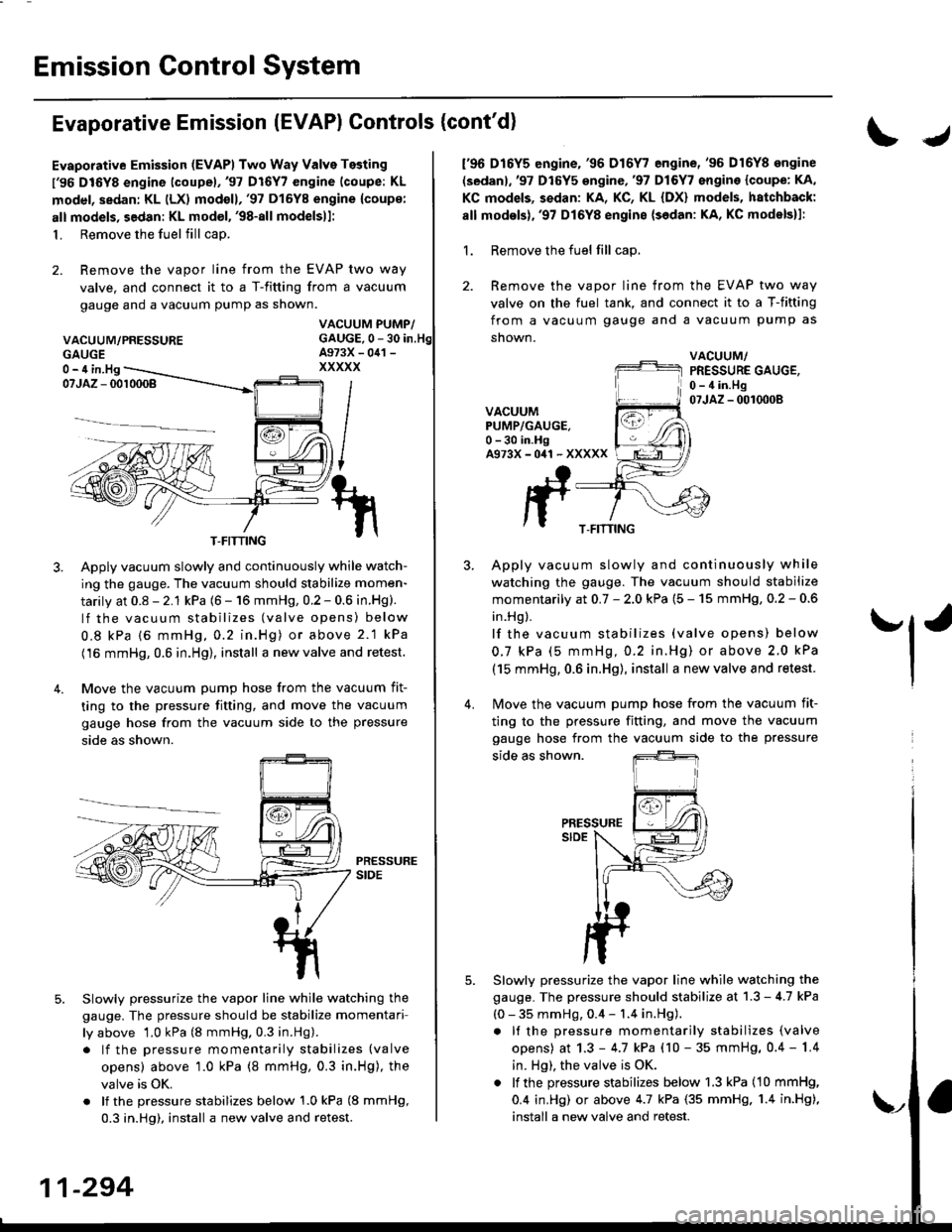

2. Remove the vapor line from the EVAP two way

valve. and connect it to a T-fitting from a vacuum

gauge and a vacuum pump as shown.

VACUUM/PRESSURE

IJ

f96 D16Y5 engine,'96 D16Y7 engine,'96 D16Y8 ongine

(sedanl,'97 D16Y5 engine,'97 Dl6Y7 engine {coupe: KA,

KC models, sedan: KA, KC, KL {DX} models, hatchback:

all modsls),'97 D16Y8 engine {sedan: KA, KC models}l:

1. Remove the fuel fill cap,

2. Remove the vapor line from the EVAP two way

valve on the fuel tank, and connect it to a T-fitting

from a vacuum gauge and a vacuum pump as

snown.

VACUUM/PRESSURE GAUGE,0 - 4 in.Hg07JAZ - 0010008VACUUMPUMP/GAUGE.0 -30 in.HgA973X-041 -XXXXX

Apply vacuum slowly and continuously while watch-

ing the gauge. The vacuum should stabilize momen-

tarily at 0.8 - 2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).

lf the vacuum stabilizes (valve opens) below

0.8 kPa {6 mmHg, 0.2 in.Hg) or above 2.1 kPa

(16 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

ting to the pressure fitting, and move the vacuum

gauge hose from the vacuum side to the pressure

side as shown.

Slowlv pressurize the vapor line while watching the

gauge. The pressure should be stabilize momentari

ly above 1.0 kPa (8 mmHg. 0.3 in.Hg).

. lf the pressure momentarily stabilizes (valve

opens) above '1.0 kPa (8 mmHg, 0.3 in.Hg), the

valve is OK.

. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.7 - 2.0 kPa (5 - 15 mmHg, 0.2 - 0.6

in.Hg ).

lf the vacuum stabilizes (valve opens) below

0.7 kPa (5 mmHg,0.2 in.Hg) or above 2.0 kPa

(15 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

'l'

4.

5.

ting to the pressure fitting, and move the

gauge hose from the vacuum side to the

side as shown.

PRESSURESIDE

Slowly pressurize the vapor line while watching the

gauge. The pressure should stabilize at 1.3 - 4.7 kPa

(0 - 35 mmHg, 0.4 - 1.4 in.Hg).

. It the pressure momentarily stabilizes (valve

opens) at 1.3 - 4.7 kPa (10 - 35 mmHg, 0.4 - 1.4

in. Hg), the valve is OK.

. lf the pressure stabilizes below 1.3 kPa (10 mmHg,

0.4 in.Hg) or above 4.7 kPa (35 mmHg. 1.4 in.Hg),

install a new valve and retest.

vacuum

pressure

GAUGE0- 4 in.Hg

T-FITTINGT-FITTING

11-294

\,

Page 565 of 2189

Emission Gontrol System

Evaporative Emission (EVAP) Controls (cont'dl

ORVR Vent Shut Valve Test

Float Test

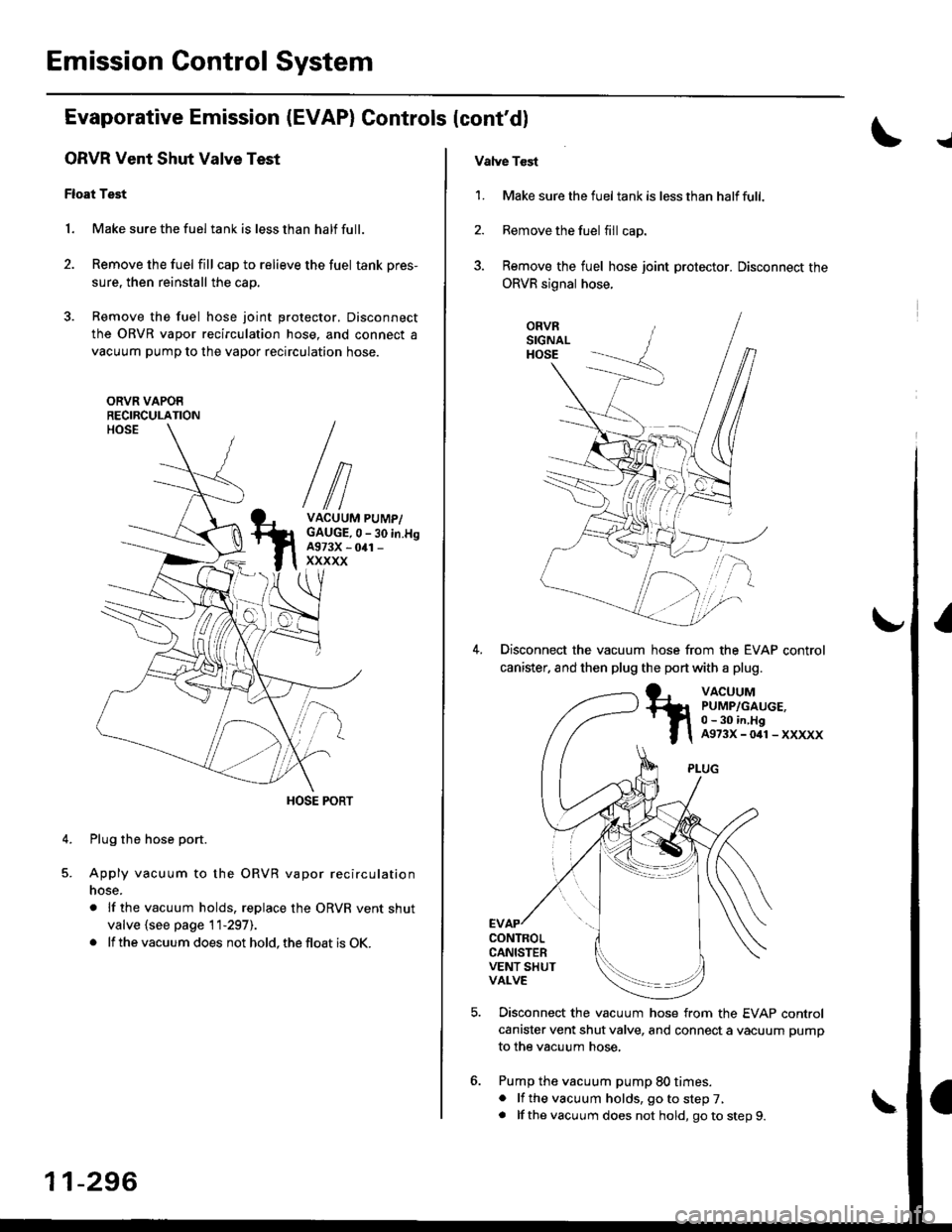

1. Make sure the fuel tank is less than half full.

2. Remove the fuel fill cap to relieve the fuel tank pres-

sure, then reinstall the cap.

3. Remove the fuel hose joint protector. Disconnect

the ORVR vapor recirculation hose, and connect a

vacuum pump to the vapor recirculation hose.

ORVR VAPOERECIRCULATION

VACUUM PUMP/GAUGE,0 - 30 in.H9A973X - 041 -

xxxxx

Plug the hose port.

Apply vacuum to the ORVR vapor recirculation

nose.

. lf the vacuum holds, replace the ORVR vent shut

valve {see page 11-297).

. lf the vacuum does not hold, the float is OK.

4.

11-296

Vatve Tcst

1. Make sure the fueltank is lessthan halffull.

2. Remove the fuel fill cap.

3. Remove the fuel hose joint protector. Disconnect the

ORVR signal hose.

ORVRSIGNALHOSE

Disconnect the vacuum hose from the EVAP control

canister. and then plug the port with a plug.

VACUUMPUMP/GAUGE,0 - 30 in,HgA973X-041-XXXXX

CONTROLCANISTERVENT SHUTVALVE

Disconnect the vacuum hose from the EVAP control

canister vent shut valve, and connect a vacuum pump

to the vacuum hose,

Pump the vacuum pump 80 times.. lf the vacuum holds, go to step 7,. lf thevacuum does not hold, goto step9.

Page 679 of 2189

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

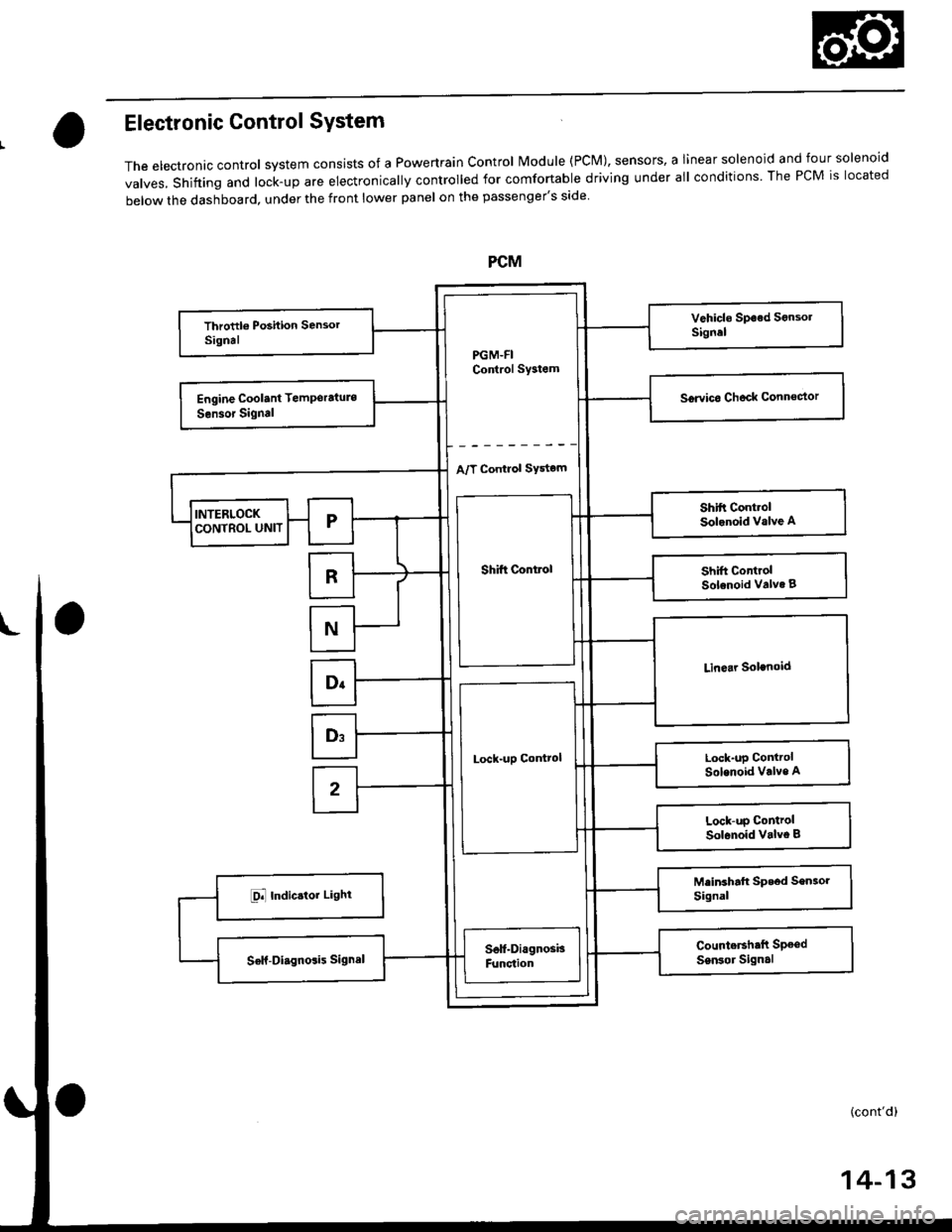

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 691 of 2189

Electronic Control SYstem

The electronac controt system consrsts of a Powertrain control Module (PcM), sensors, a Iinear solenoid and four solenoid

valves, shifting and lock-up are electronically controlled for comfortable driving under all conditions The PCM is located

below the dashboard, under the front lower panel on the passenger's side

PGM-FIControl Sy3tem

A/T Control SYstom

Shift Control

Lock-uD Control

14-13

Page 692 of 2189

Description

Electronic Control System (cont'd)

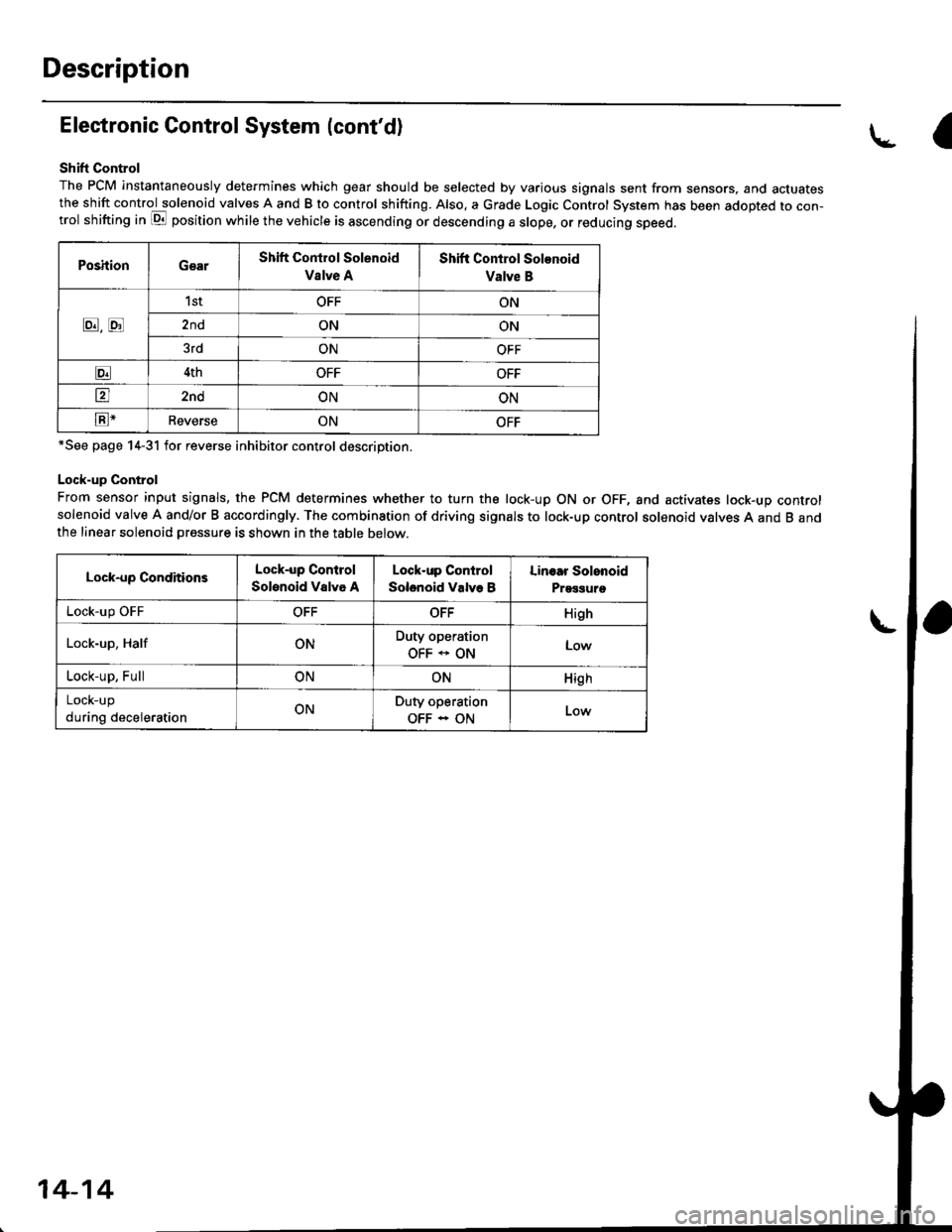

Shift Control

The PCM instantaneously determines which gear should be selected by various signals sent from sensors, and actuatesthe shift control solenoid valves A and B to control shifting. Also. a Grade Logic Control System has been adopted to con-trol shifting in E position while the vehicle is ascending or descending a slope, or reducing speed.

PoshionGearShift Control Solenoid

Vslve A

Shift Control Solenoid

Valve B

8,tr

1stOFFON

2ndONON

3rdONOFF

E4thOFFOFF

tr2ndONON

E-ReverseONOFF

*See page 14-31 for reverse inhibitor control description.

Lock-up Control

From sensor input signals, the PCM determines whether to turn the lock-up ON or OFF, and activates lock-up controlsolenoid valve A and/or B accordingly. The combination of driving signals to lock-up control solenoid valves A and B andthe linear solenoid pressure is shown in the table below.

Lock-up ConditionsLock-up Control

Solenoid Valvo A

Lock-up Control

Solenoid Valve B

Linoar Solonoid

Prggguro

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF * ONLow

Lock-up, FullONONHigh

LOCK-Up

during decelerationONDuty operation

OFF - ON

a

14-14

Page 696 of 2189

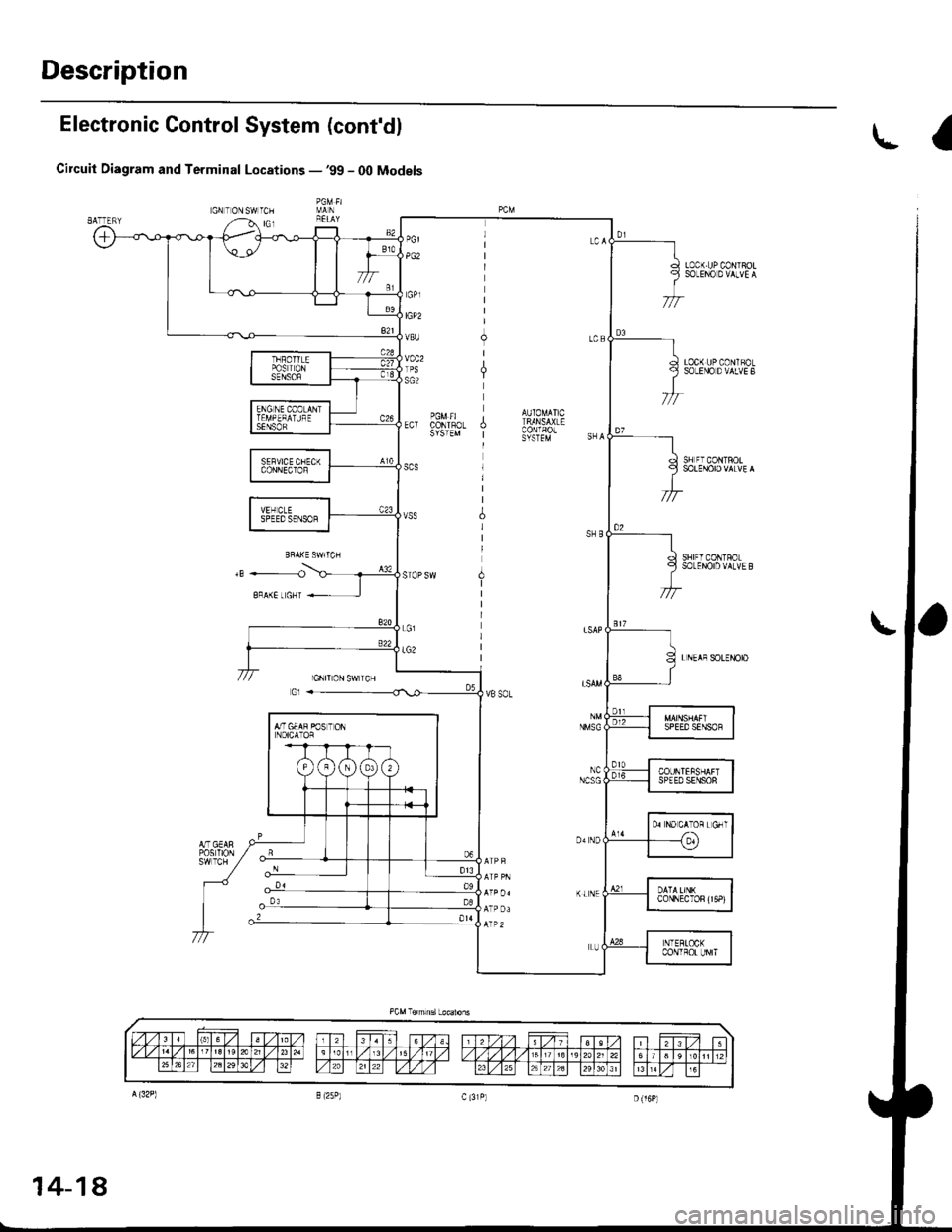

Description

Electronic Control System (cont'dl

Circuit Diagram and Terminal Locations -'99 - O0 Models

GNTONSWICH,,--b. rcj

LI

LOCK.UPCONIFOLSOLEI\Q D VALVE A

LOCK UP CON'IROLSOLENODVALVEB

SH FI CONTROL

SHIFTCONTFOLSOLENOIDVALVEE

L NEAF SOLEIOIO

PG2

IGP2

v3u

vcc2

sc2

6NII ON SWICH

14-18

Page 697 of 2189

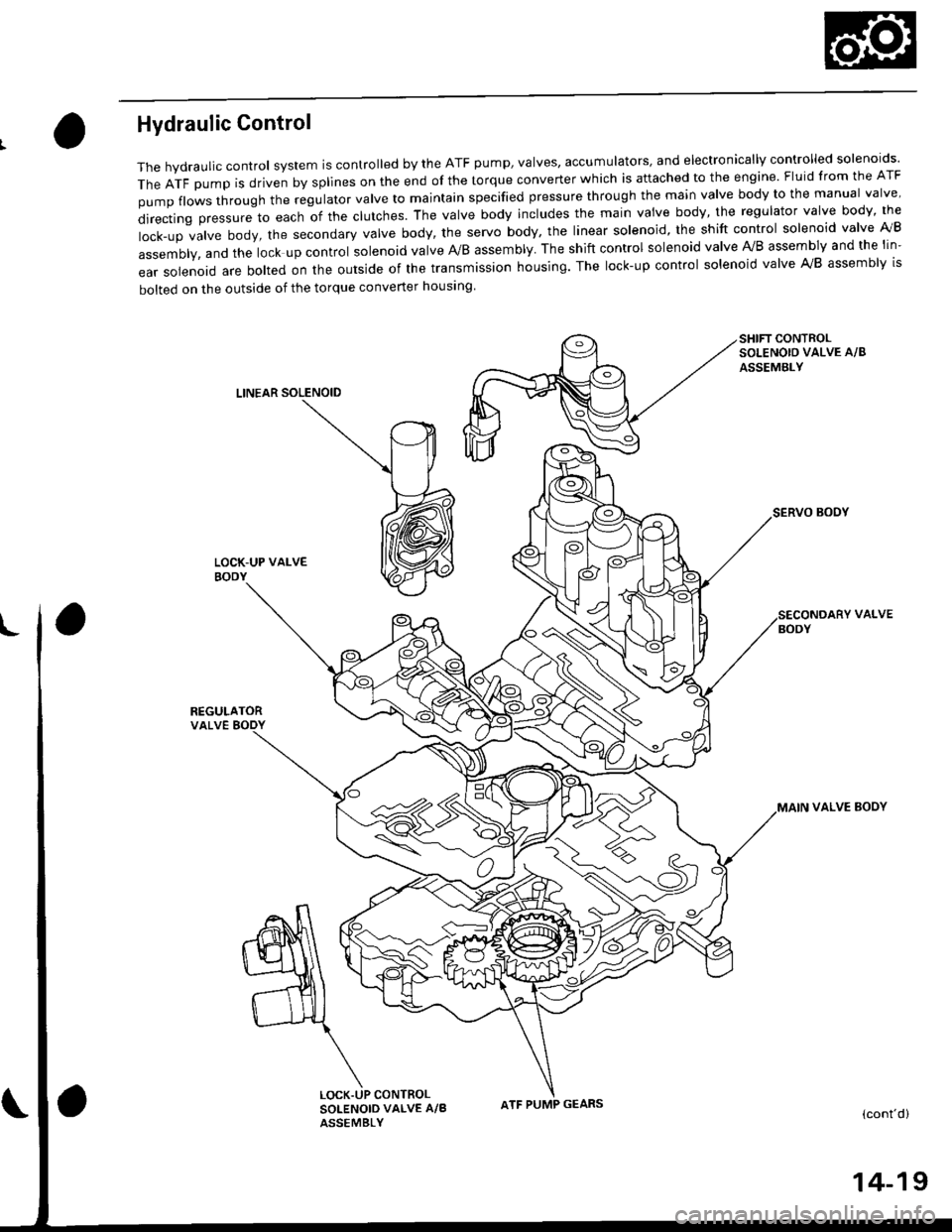

Hydraulic Control

The hydraulic control system is controlled by the ATF pump, valves, accumulators, and electronically controlled solenoids'

TheATFpUmpisdrivenbysp||nesontheendofthetorqueconverterWhichisattachedtotheengine.F|uidfromtheATF

pumpf|owsthroughtheregu|atorva|vetomajntainspecifiedpressurethroughthemainva|vebodytothemanuaIva|ve'

directingpressuretoeachofthec|utches.Theva|vebodyinc|udesthemainvaivebody,theregu|atorvalvebody,the

|ock-upva|vebody,thesecondaryVa|vebody,theservobody,theIinearso|enoid,theshiftcontro|so|enoidva|velVB

assembly, and the lock up control solenoid valve A/B assembly. The shift control solenoid valve Ay'B assembly and the lin-

ear solenoid are bolted on the outside of the transmission housing. The lock-up control solenoid valve A,/B assembly is

bolted on the outside of the torque converter housing

SHIFT CONTROLSOLENOIO VALVE A/8

ASSEMBLY

LINEAR SOLENOID

SERVO BOOY

REGULATORVALVE BODY

VALVE

VALVE BOOY

(cont'd)

CONTROLSOLENOID VALVE A/BASSEMBLY

ATF PUMP GEARS

14-19

Page 698 of 2189

Description

Hydraulic Control (cont'dl

Msin Valve Body

The main valve body houses the manual valve, the 1-2 shift valve, the 2nd orifice control valve, the cpB valve, the modu-lator valve' the servo control valve, and the relief valve. The primary functions of the main valve body are to swatch fluidpressure on and off and to control the hydraulic pressure going to the hydraulic control svstem.

2ND ORIFICE CONTROTVALVE

1-2 SHIFT VALVE

RELIEF VALVE

CPC VAL

3-4 SHTFT V

VALVE

Socondary Valve Body

The secondary valve body is located on the main valve body. The secondary valve body houses the 2-3 shift vatve, the 3-4shift valve, the 3-4 orifice control valve, the 4th exhaust valve, and the CpC valve.

CONTROL

2.3 SHIFT VALVE

4TH EXHAUST VALV€

VALVE

14-20

VALVE

Page 700 of 2189

Description

Hydraulic Control (cont'dl

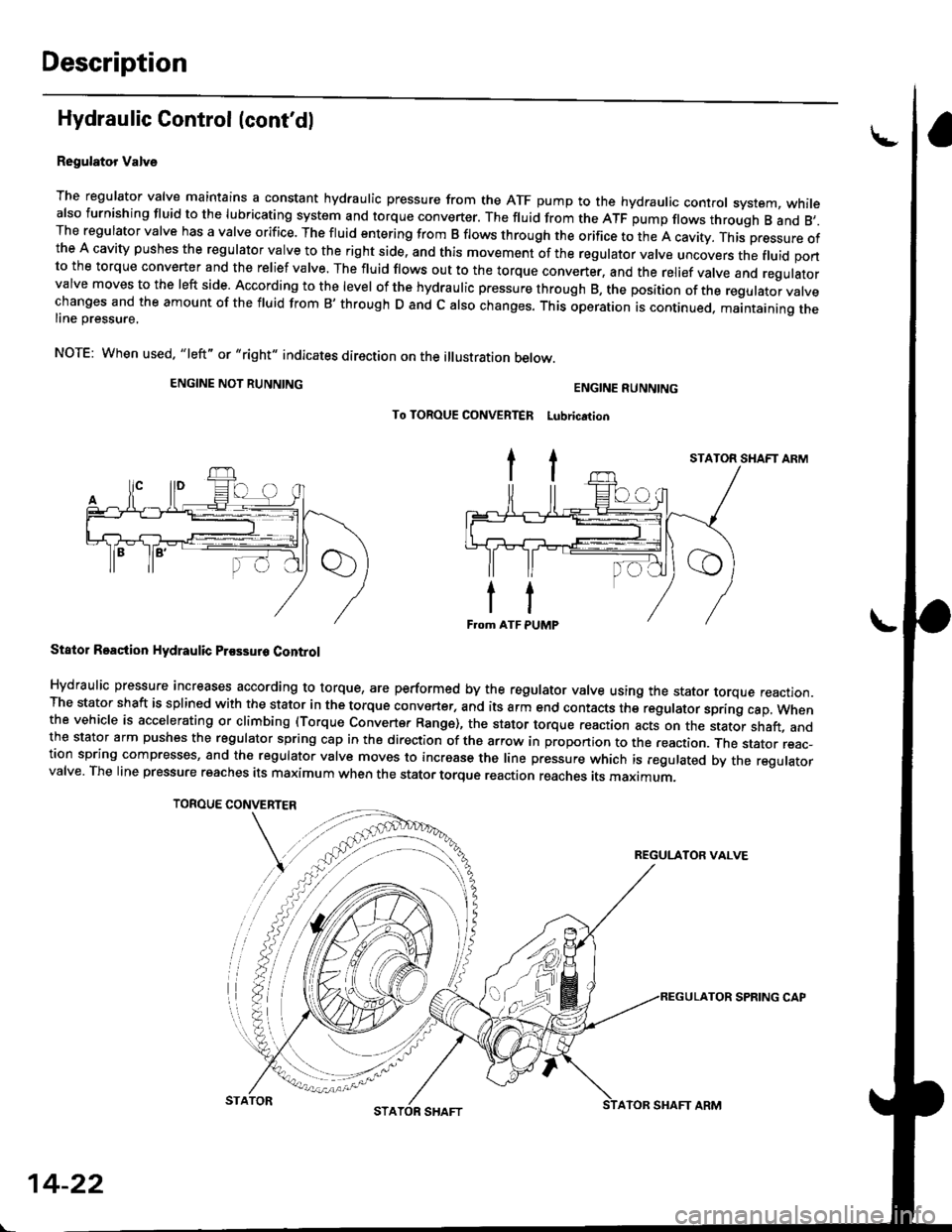

Regulator Valve

The regulator valve maintains a constant hydraulic pressure from the ATF pump to the hydraulic control system, whitealso furnishing fluid to the lubricating system and torque converter. The fluid from the ATF pump flows through B and 8,.The regulator valve has a valve orifice. The fluid entering from B flows through the orifice to the A cavity. This pressure ofthe A cavity pushes the regulator valve to the right side, and this movement of the regulator valve uncovers the fluid portto the torque converter and the relief valve. The fluid flows out to the torque converter, and the relief valve and regulatorvalve moves to the left side. According to the level of the hydraulic pressure through B, the position of the regutator vatvechanges and the amount of the fluid from B' through D and c also changes. This operation is continued. maantaining theline pressure,

NOTE: When used. "|eft" or "right" indicates direction on the illustration betow.

ENGINE NOT RUNNING

TOROUE CONVERTER

ENGINE RUNNING

To TOROUE CONVERTER Lubrication

Stator Roaction Hydraulic Prossur6 Control

Hydraulic pressure increases according to torque, are performed by the regulator valve using the stator torque reaction.The stator shaft is splined with the stator in the torque converter, and its arm end contacts the regulator sprang cap. whenthe vehicle is accelerating or climbing (Torque Convert€r Range), the stator torque reaction acts on the stator shaft, andthe stator arm pushes the regulator spring cap in the direction of the arrow in proponion to the reaction. Jne stator reac-tion spring compresses, and th€ reoulator valve moves to increase the line pressure which is regulated by the regulatorvalve. The line pressure reaches its maximum when the stator torque reaction reaches its maximum.

STATOR SHAFT ARM

REGULATOR VALVE

14-22

STATORATOR SHAFT ARM

SPRING CAP