valve stem HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

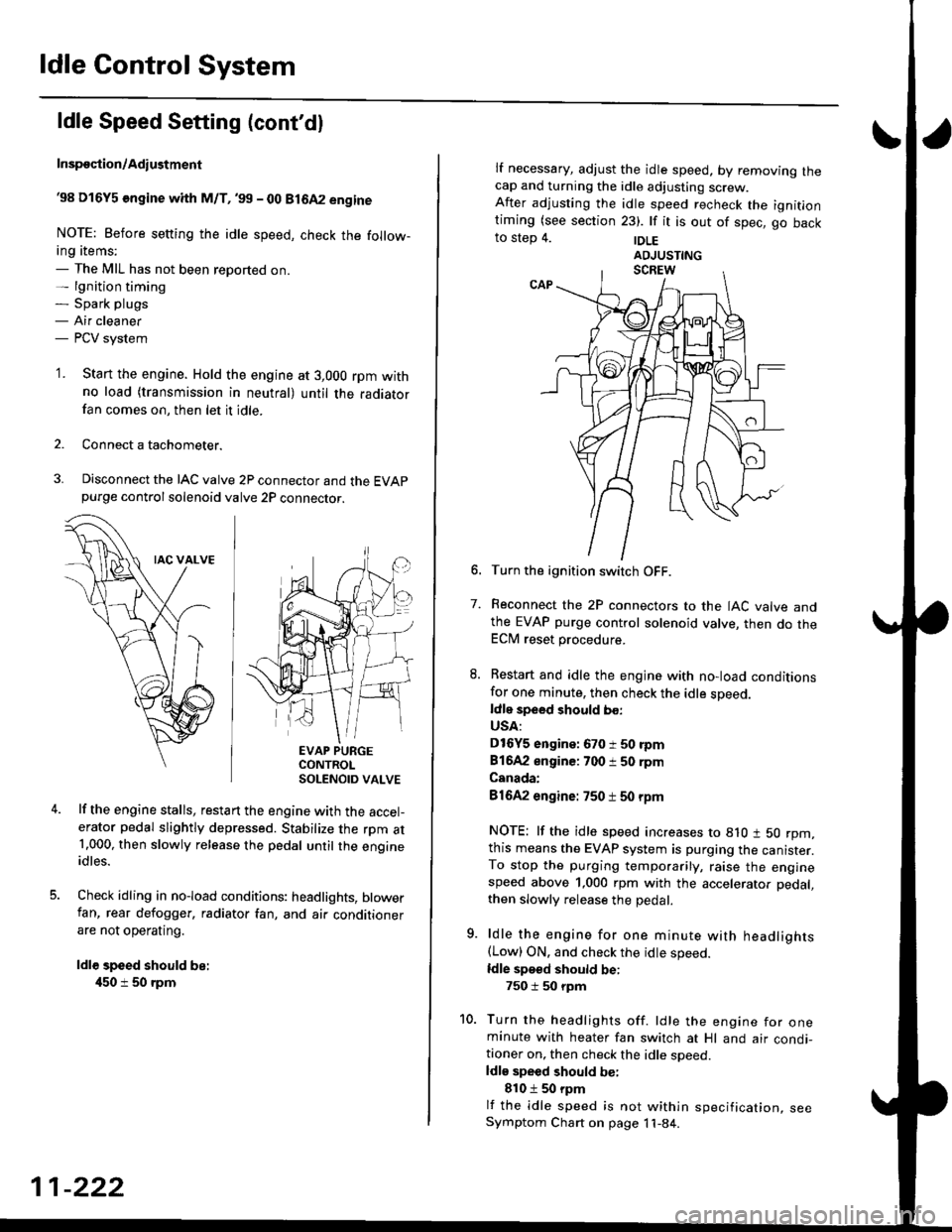

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

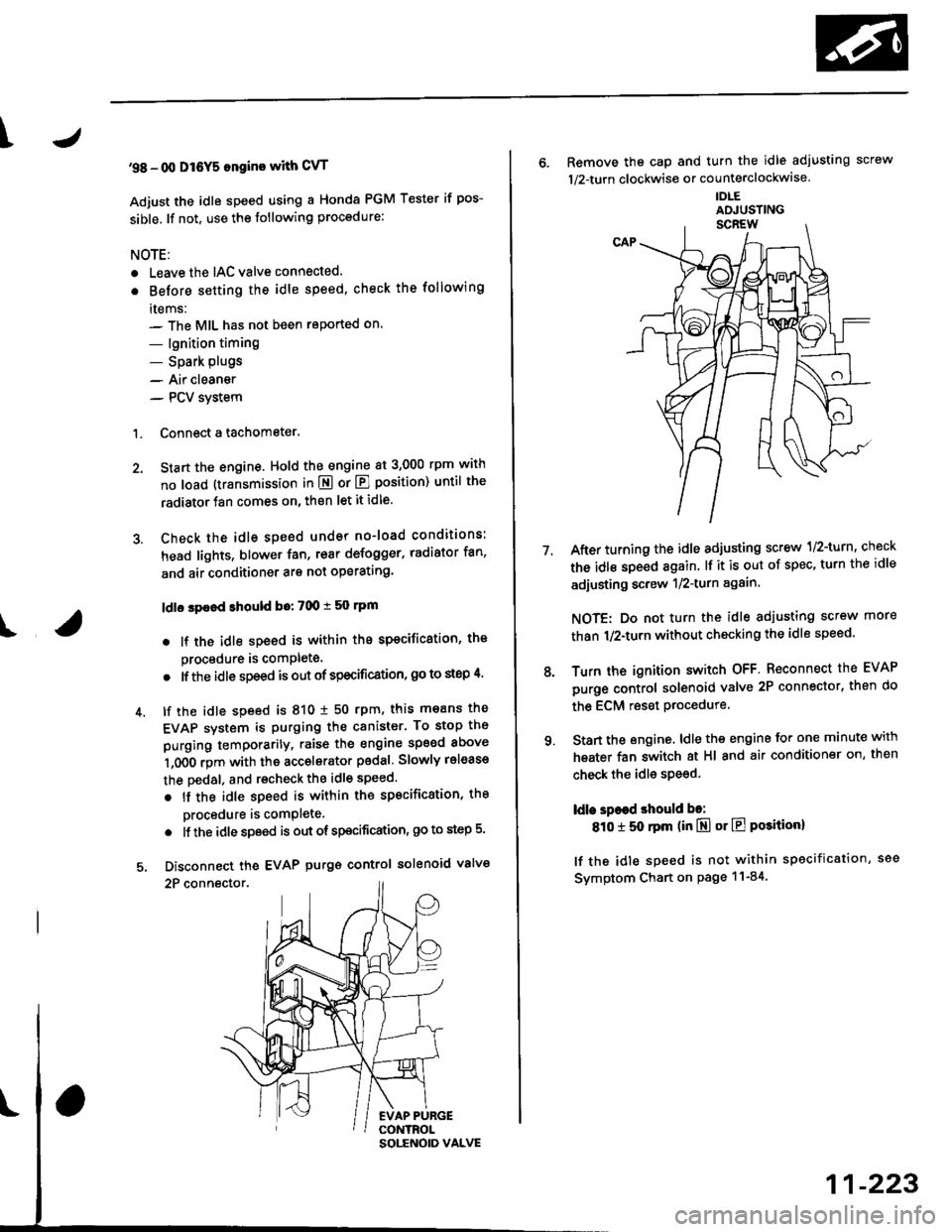

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 495 of 2189

Fuel Supply System

Fuel Lines (cont'dl

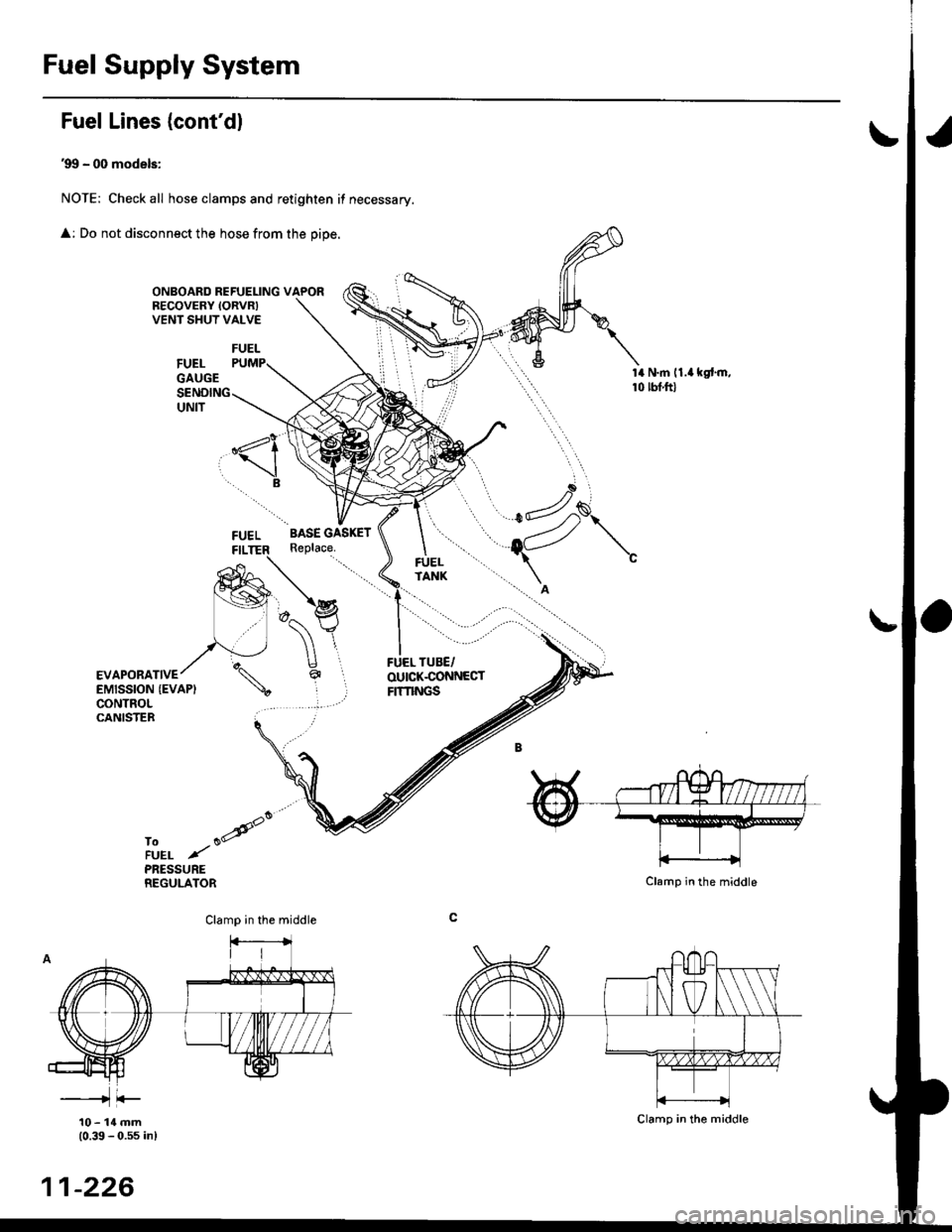

.99 - 00 models:

NOTE: Check all hose clamps and retighten if necessary.

: Do not disconnect the hose from the pipe.

ONBOARD REFUELING VAPORBECOVERY IORVRIVENT SHUT VALVE

B

FUELGAUGElt N.rn l1.a kgt.m,r0 lbt ftl

ftr, n'fo'PRESSUREREGULATOR

Clamp in the middle

Clamp in the middle

11-226

Page 501 of 2189

Fuel Supply System

Fuel Injectors

Replacement

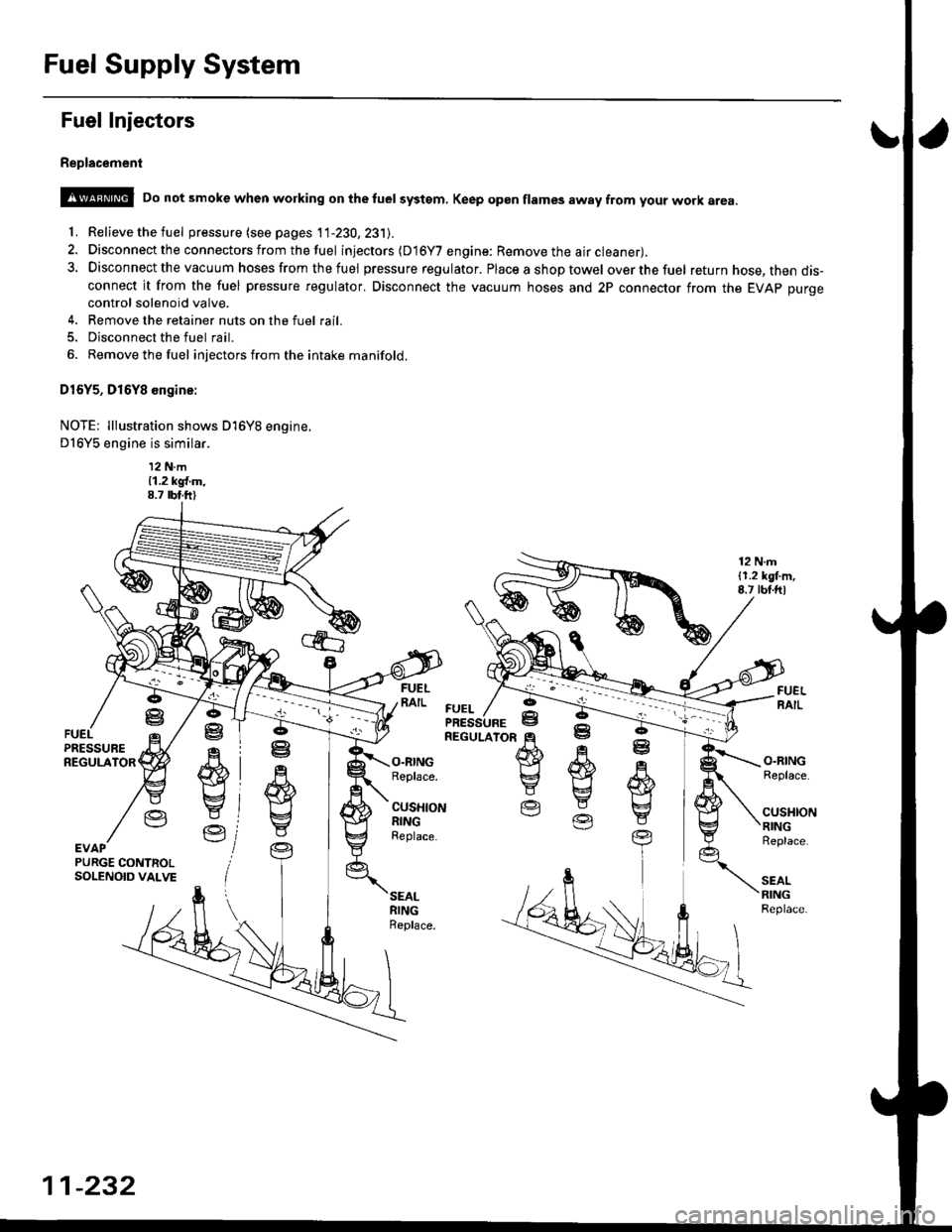

@ Do not smoke when working on the tuel systgm, Keep gp6n flames away from your work area

'f. Relieve the fuel pressure (see pages 11-230,231J.

2. Disconnect the connectors from thefuel injectors (D16Y7 engine: Remove the air cleaner).

3. Disconnect the vacuum hoses from thefuel pressure regulator. Placeashoptowel overthefuel return hose, then dis-connect it from the fuel pressure regulator. Disconnect the vacuum hoses and 2P connector from the EVAp purgecontrol solenoid valve.

4. Remove the retainer nuts on the fuel rail.

5. Disconnect the fuel rail.

6. Removethefuel injectors from the intake manifold.

D16Y5, D16Y8 engine:

NOTE: lllustration shows D16Y8 engine.

D16Y5 engine is similar.

12 N.m11.2 kgl.m,8.7 rbt.ft)

12 N.m11.2 lgl.m,8.7 rbt.ftl

.q

wE4

Y

Ve

ffi}Yg

E

O.RINGReplace.

CUSHIONRINGReplace.

O.RINGReplace.

cusl{toNRINGReplace.

SEALRINGReplace.

ffi

E

EV

R

w

t

YEVAPPURGE CONTNOLSOLENOID VALVE

FUEL

11-232

Page 512 of 2189

Intake Air System

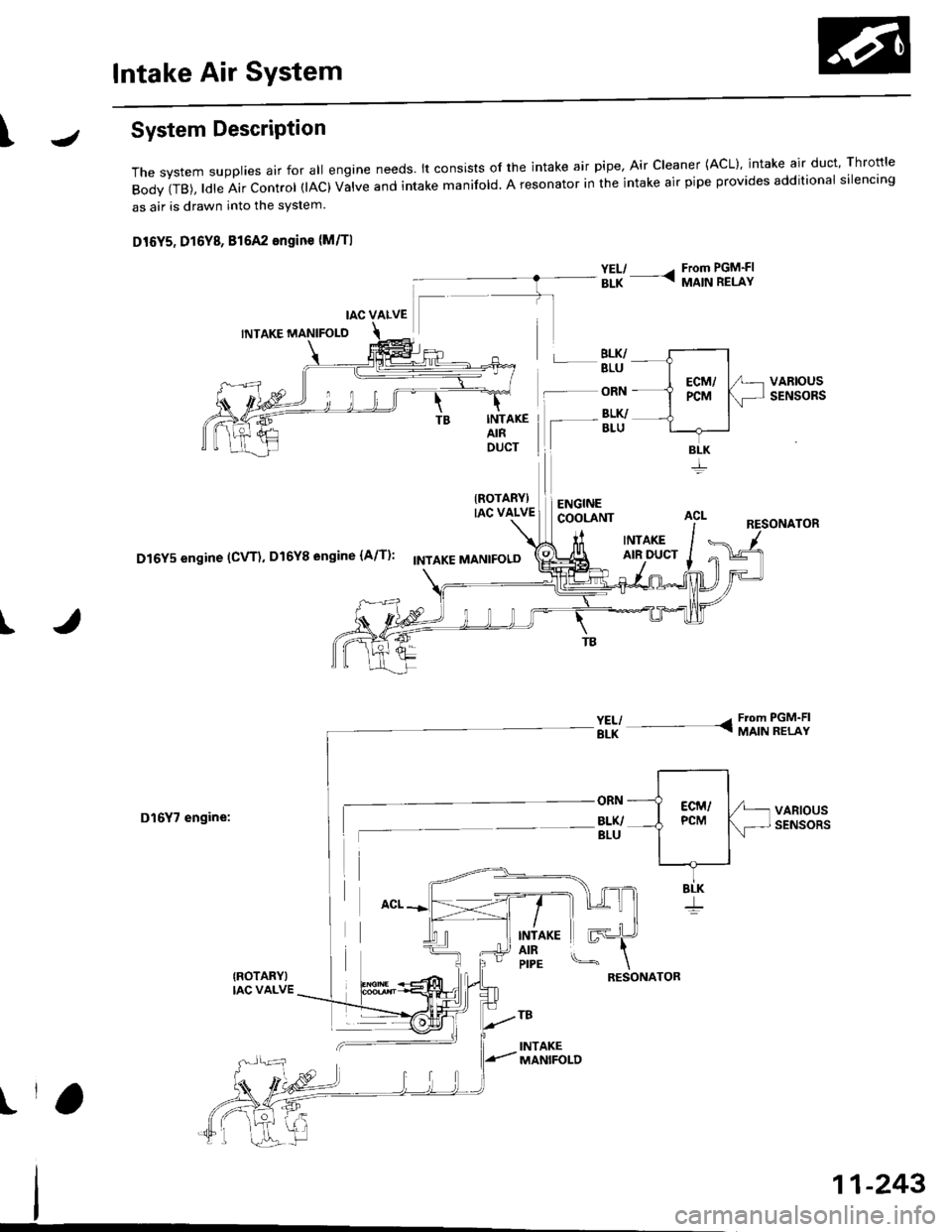

\JSystem DescriPtion

The system supp|ies air for a|| engine needs' |t consists of the intake air pipe' Air C|eaner (ACL}, intake air duct, Thrott|e

Body (TB), ldle Air control (lAc) valve and intake manifold. A resonator in the intake air pipe provides additional silencing

as air is drawn into the system.

D16Y5, D16Y8, 816A2 engine {M/Tl

YEL/ - From PGM-FIaLK - MA|N RELAY

BLK/BLU

-- ORN

INTAKEAIRDUCT

IROTARYIIAC VALVE

Iaru

ENGINECOOLANT

BLK/

INTAKEAIR DUCT

I

D16Y5 engine (CVT), D16Y8 engine (A/T)' f'ttlxr ,tla"tpoto

D16Y7 engine:

{ROTARY)IAC VALVE

VARIOUSSENSORS

INTAKEAIRPIPE

tr

RESONATOR

!r,

IAC VALVE

BLK

11-243

Page 515 of 2189

Intake Air System

Throttle Cable (cont'dl

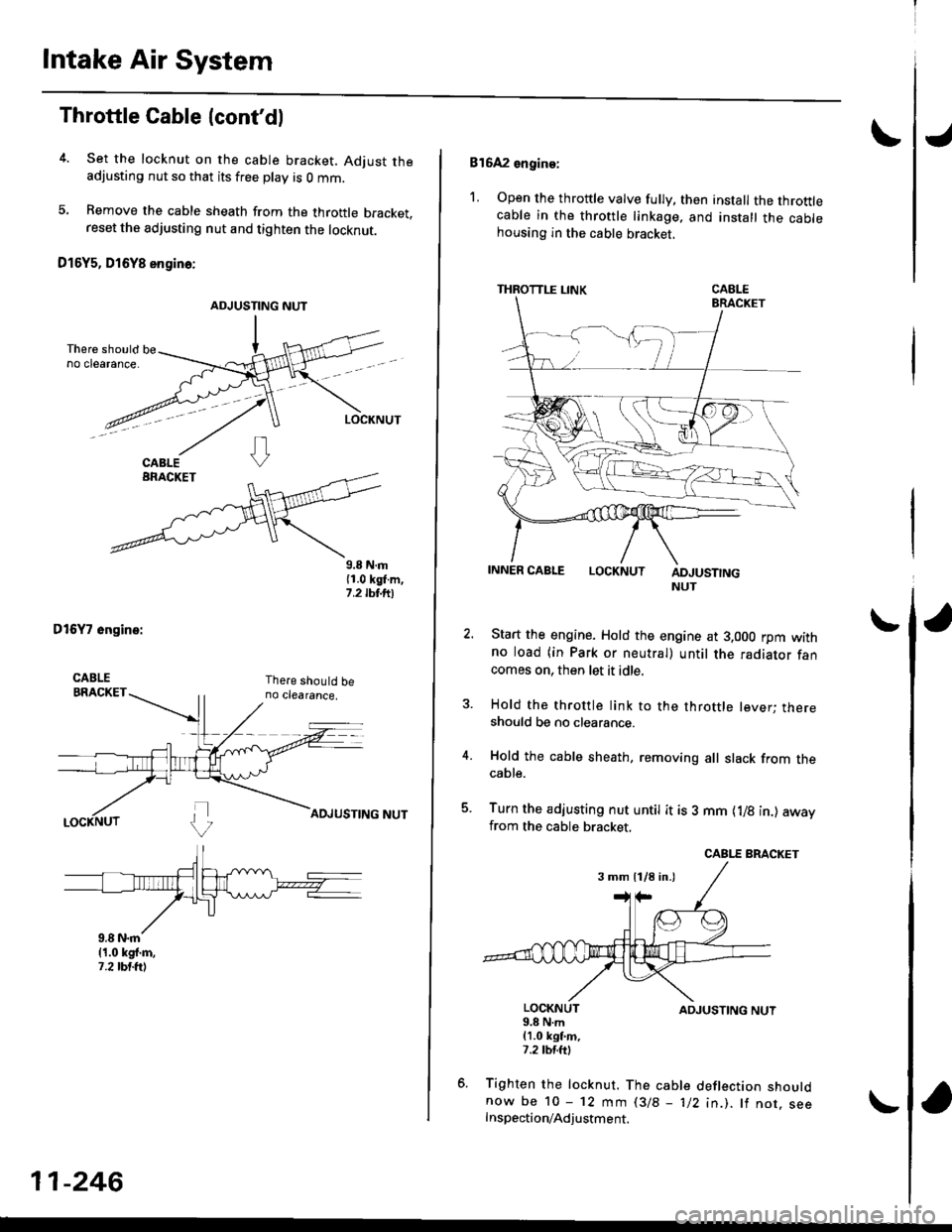

4. Set the locknut on the cable bracket. Adjust theadjusting nut so that its free play is O mm.

5. Bemove the cable sheath from the throttle bracket,reset the adjusting nut and tighten the locknut.

O16Y5, D16Y8 engino:

ADJUSTING NUT

9.8 N.m{1.0 kgl.m,1.2 tbt.ttl

DtGYT 6ngine:

11-246

816A2 engine:

1. Open the throttle valve fully, then install the throttlecable in the throttle linkage. and install the cablehousing in the cable bracket,

THROTTLE LINK

LOCKNUTADJUSTINGNUT

Start the engine. Hold the engine at 3.000 rpm withno load (in Park or neutral) until the radiator fancomes on, then let it idle.

Hold the throttle link to the throttle lever; thereshould be no clearance.

Hold the cable sheath, removing all slack from thecable.

Turn the adjusting nut untit it is 3 mm {1/8 in.) awayfrom the cable bracket,

LOCKNUT9.8 N.m(1.0 kgt m,7.2 tM.ttl

ADJUSTING NUT

Tighten the locknut. The cable deflection shouldnow be 10 - 12 mm l3/B - 1/2 in.). lf nor. seeInspection/Adjustment.

3 mm 11/8 in.)

Page 519 of 2189

![HONDA CIVIC 1998 6.G Repair Manual Intake Air System

Fuel Injection Air (FlA) Controt System I99 - 00 Dl6yg enginel

Dsscription

When the engine running lengine coolant below 149oF (6S"C)], the fuel Injection Air (FtA) Control Valve se HONDA CIVIC 1998 6.G Repair Manual Intake Air System

Fuel Injection Air (FlA) Controt System I99 - 00 Dl6yg enginel

Dsscription

When the engine running lengine coolant below 149oF (6S"C)], the fuel Injection Air (FtA) Control Valve se](/img/13/6068/w960_6068-518.png)

Intake Air System

Fuel Injection Air (FlA) Controt System I'99 - 00 Dl6yg enginel

Dsscription

When the engine running lengine coolant below 149oF (6S"C)], the fuel Injection Air (FtA) Control Valve sends intake air tothe fuel iniectors.

E> : INTAKEAIR

FUELINJECTOB

11-250

Page 520 of 2189

\J

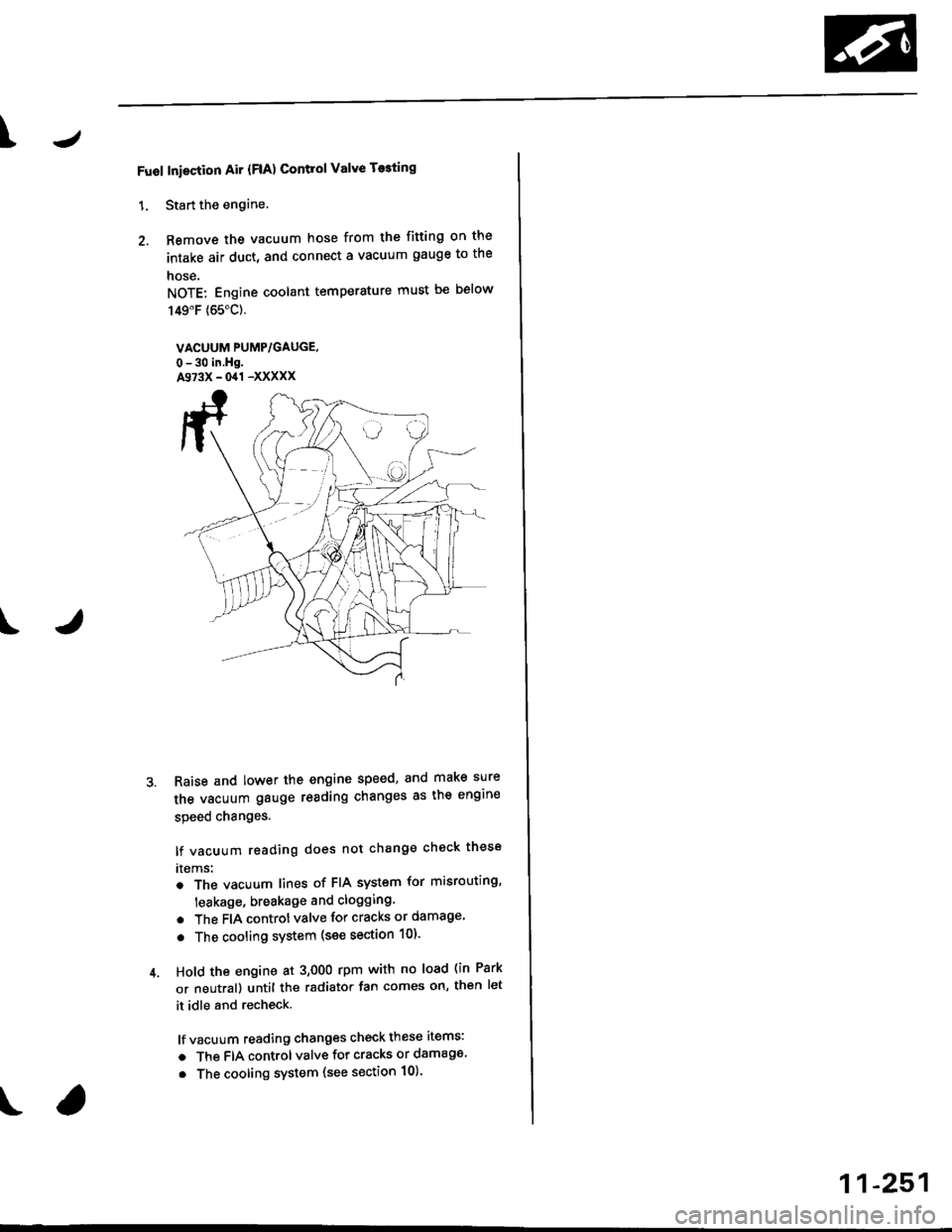

Fuol Iniection Air {FlA) Contlol Valve T$ting

1. Start the engine.

2. Remove the vacuum hose from the fitting on the

intake air duct, and connect a vacuum gauge to the

nose.

NOTE: Engine coolant temperature must be below

149"F (65"C).

VACUUM PUMP/GAUGE,

0-30 in.Hg.A973X - 041 -XXXXX

Raise and lower the engine speed, and make sure

the vacuum gauge reading changes as the engine

speed changes.

lf vacuum reading does not change check these

rtems:

. The vacuum lines of FIA system for misrouting,

leakage, breakage and clogging.

. The FIA controt valve for cracks or damage

. The cooling system (see section 10).

Hold the engine at 3,OOO rpm with no load (in Park

or neutral) until the radiator fan comes on, th€n let

it idle and recheck.

lf vacuum reading changes check these items:

a The FIA control valve for cracks or damage.

. The cooling system (see section 10).

11-251

Page 523 of 2189

Emission Control System

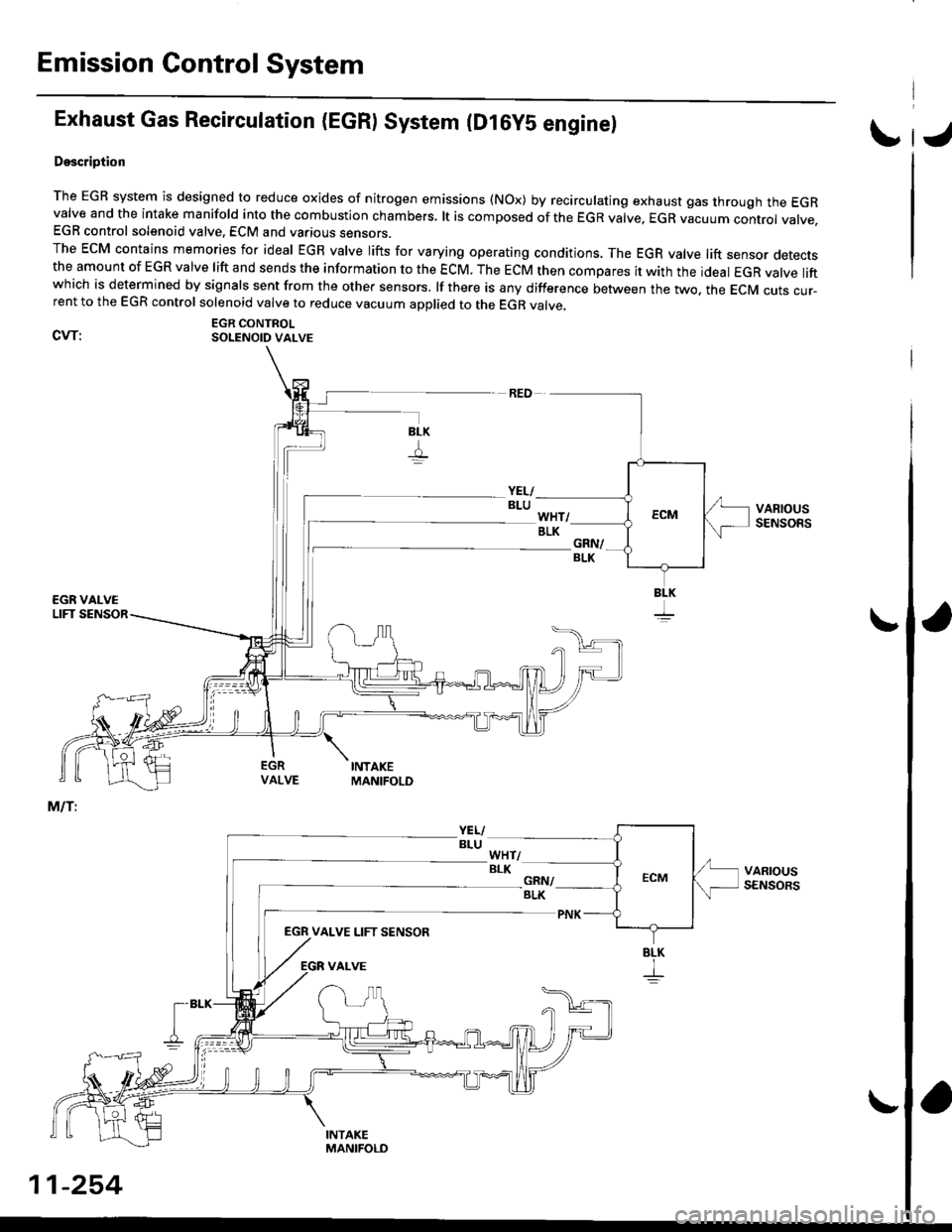

Exhaust Gas Recirculation (EGR) System (D16yS engine)

Doscription

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGRvalve and the intake manifold into the combustion chambers. lt is composed of the EGR valve. EGR vacuum conrrot vatve.EGR control solenoid valve. ECM and various sensors.The EcM contains memories for ideal EGR valve lifts for varying operating conditions, The EGR valve lift sensor detectsthe amount of EGR valve lift and sends the information to the ECM. The ECM then compares it with the ideat EGR valve liftwhich is determined by signals sent from the other sensors. lf there is any difference between the two. the EcM cuts cur-rent to the EGR control solenoid valve to reduce vacuum applied to the EGR valve.

EGR CONTROLCVT: SOLENoID vALvE

EGN VALVE LIFT SENSOR

BLK

I

I

11-254

Page 524 of 2189

4

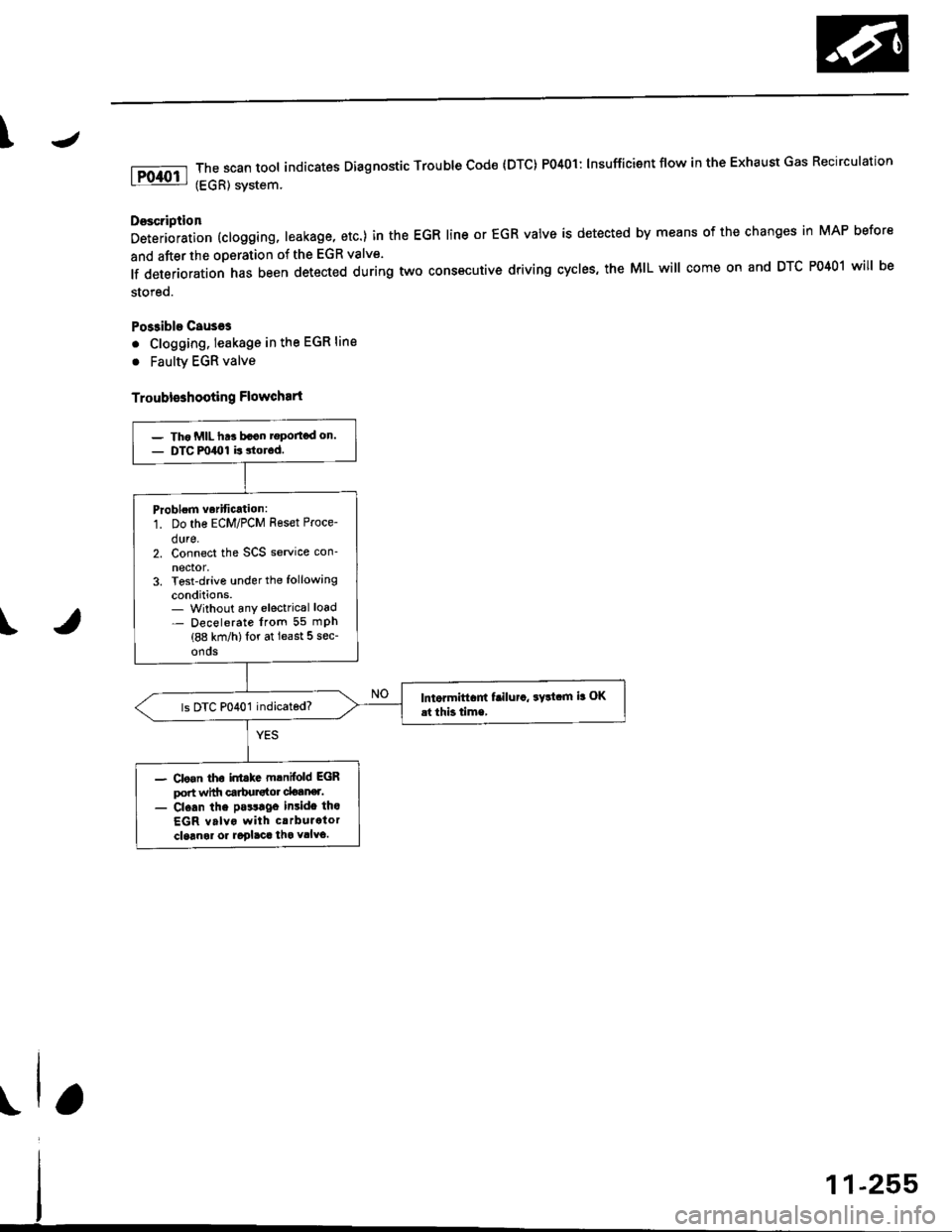

The scan tool indicates Dlagnostic Trouble cod€ {DTc} Po4ol: lnsufficient flow in the Exhaust Gas Recirculation

(EGR) svstem.

Doscription

Deterioration (clogging, leakage, etc.) in the EGR line or EGR valve is detected by means of the changes in MAP before

and after the operation of the EGR valve.

lf deterioration has been detected during two cons€cutive driving cycles, the MIL will come on and DTC P0401 will be

stored.

Po$ible Causeg

. Clogging. leakage in the EGR line

. Faulty EGR valve

Troubleshooting Flowchart

\

- Tho MIL ht! bacn rgportod on.- DTC m40l is 3torod.

Problom vorification:

1. Do the ECM/PCM Reset Proce-

dure.2. Connect the SCS service con-

nector,3. Tost-drive under the following

conditions.- Without any electrical load- Decelerate lrom 55 mPh(88 km/h)lor at least 5 sec-

onos

lntormiftam f!ilu.a, ayltam ia OK

.t thb time,

- Clo.n tho inttkc mlnifold EGRport wittr carbursto. clotner.- Cl.an the pa$lgo insido tho

EGR valvo with crrburator

cloanol or aoglaca tha vllvo.