CABLE HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1059 of 2189

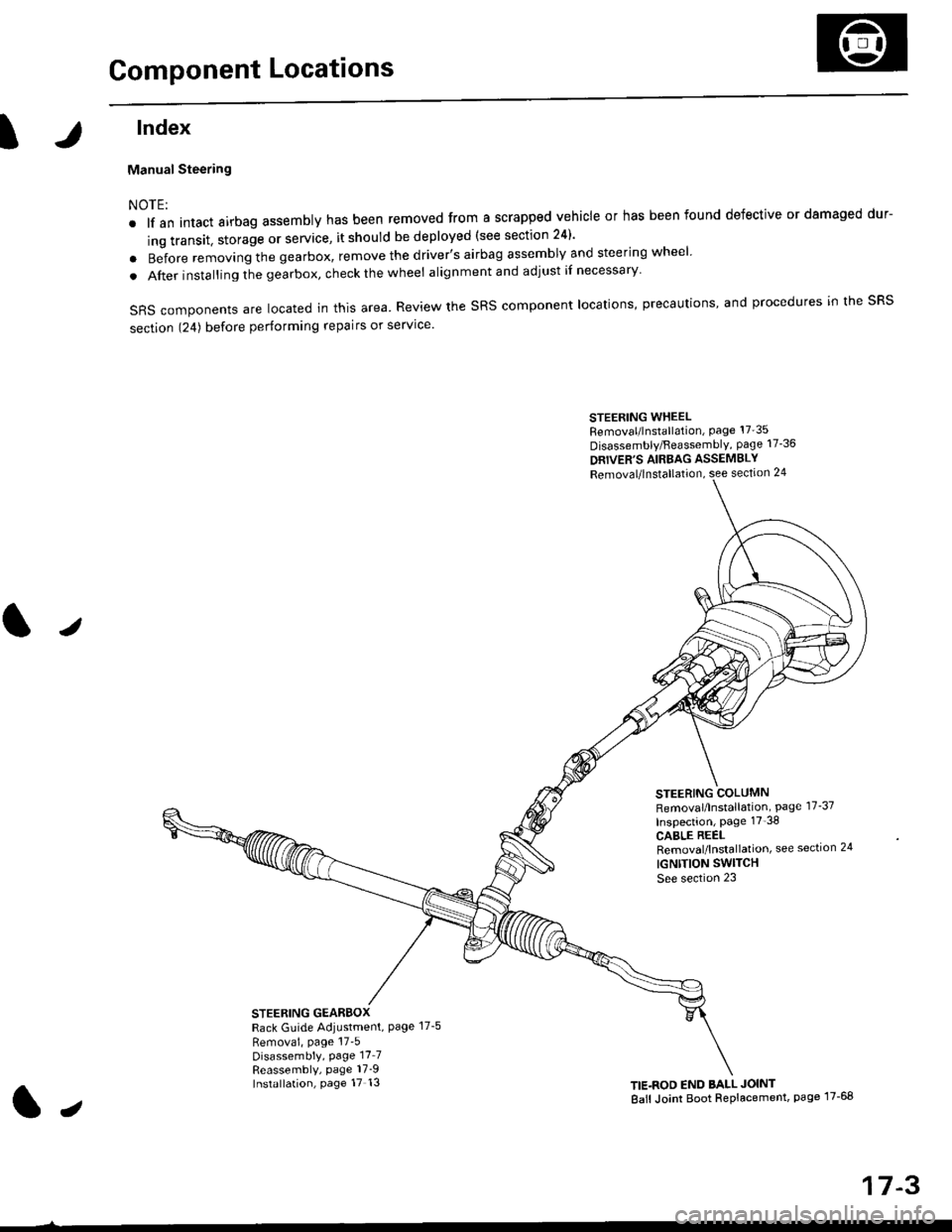

Component Locations

tlndex

Manual Steering

NOTE:

. lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-

ing transit. storage or service, it should be deployed (see section 24)'

o Before removing the gearbox, remove the driver's airbag assembly and steering wheel

. After insta lling the gearbox, check the wheel alignmentand adjust if necessary

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section 124) before performing repairs or service'

STEERING WHEELRemoval/lnstallation, Page 17'35

Disassembly/FeassemblY, page 17-36

DRIVER'S AIRBAG ASSEMBLY

Removal/lnstallation, see section 24

STEERING COLUMNRemoval/lnstallation, Page 17-37

Inspection, page 17'38

CABLE REELRemoval/lnstallation, see section 24

IGNTTION SWITCH

See section 23

STEERING GEARBOXRack Guide Adiustment, Page 17-5

Removai, page 17'5Disassembly, Page 17_7Reassembly, page 17_9Installation, page 17 13TIE.ROD END BALL JOINT

Ball Joint Boot Replacement, page 17-68

J

t,

17-3

Page 1070 of 2189

Steering Gearbox

Installation (cont'dl

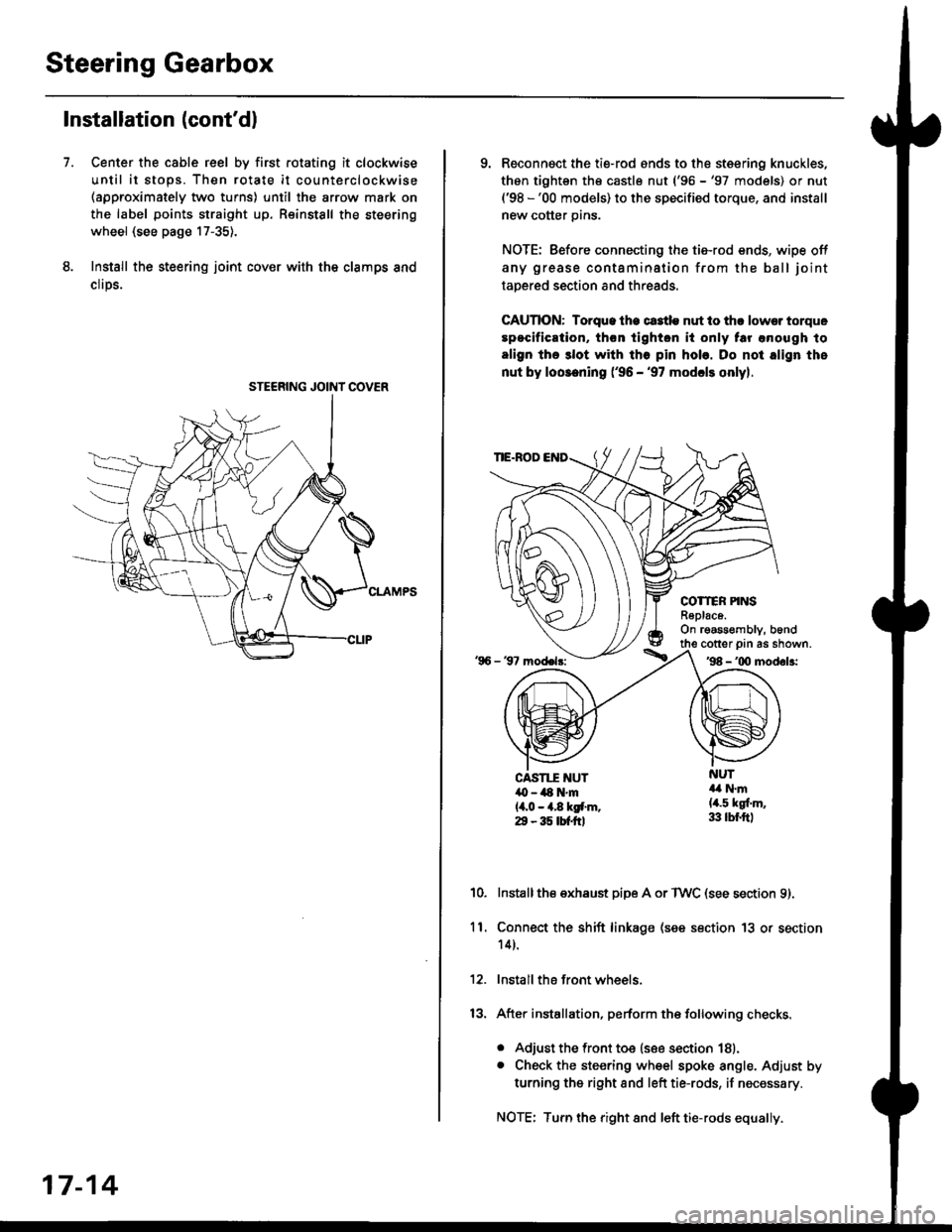

Center the cable reel by first rotating it clockwise

until it stops. Then rotate it counterclockwise(approximately two turns) until the arrow mark on

the label points straight up. Reinstall the steering

wheel (see page 17-35).

Install the steering joint cov€r with the clamps and

clrps.

7.

STEERING JOINI COVER

17-14

9. Reconnsct the ti€-rod ends to the steering knuckles,

thon tightsn th€ castle nut ('96 -'97 models) or nut('98 -'00 models) to the specified torque, and install

new cotter pins.

NOTE: Before connecting the tie-rod ends, wipe off

any grease contamination from the ball joint

tapered section and threads.

CAUTION: Torque lhe ct3tle nut to thr lowsr torque

spocification, th€n tighton it only tar anough to

align the 3lot with tho pin hob. Do not align the

nut by loosening ('96 - '97 modcls onlyl.

TIE.ROD

COTTER PINSR6plac6.On rgassombly, b6nd

'96 - 37 model3:

cotter prn as shown.'98 - '00 modol3:

NUT4a N.m(4.5 kgf.m,33 lbr.ftl

CAST1T NUT,O - ilt N'm{4,0 - 4.8 kgf.m.29 - 35 tbtftl

10.Installthe exhaust pipe A or TWC (see section 9).

Connect the shift linkage (see section 13 or section

14).

Install the front wheels.

After installation, perform the following checks.

. Adjust the front toe (see section 18).. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

NOTE: Turn the right and left tie-rods equally.

ll.

Page 1091 of 2189

Steering Wheel

l,/

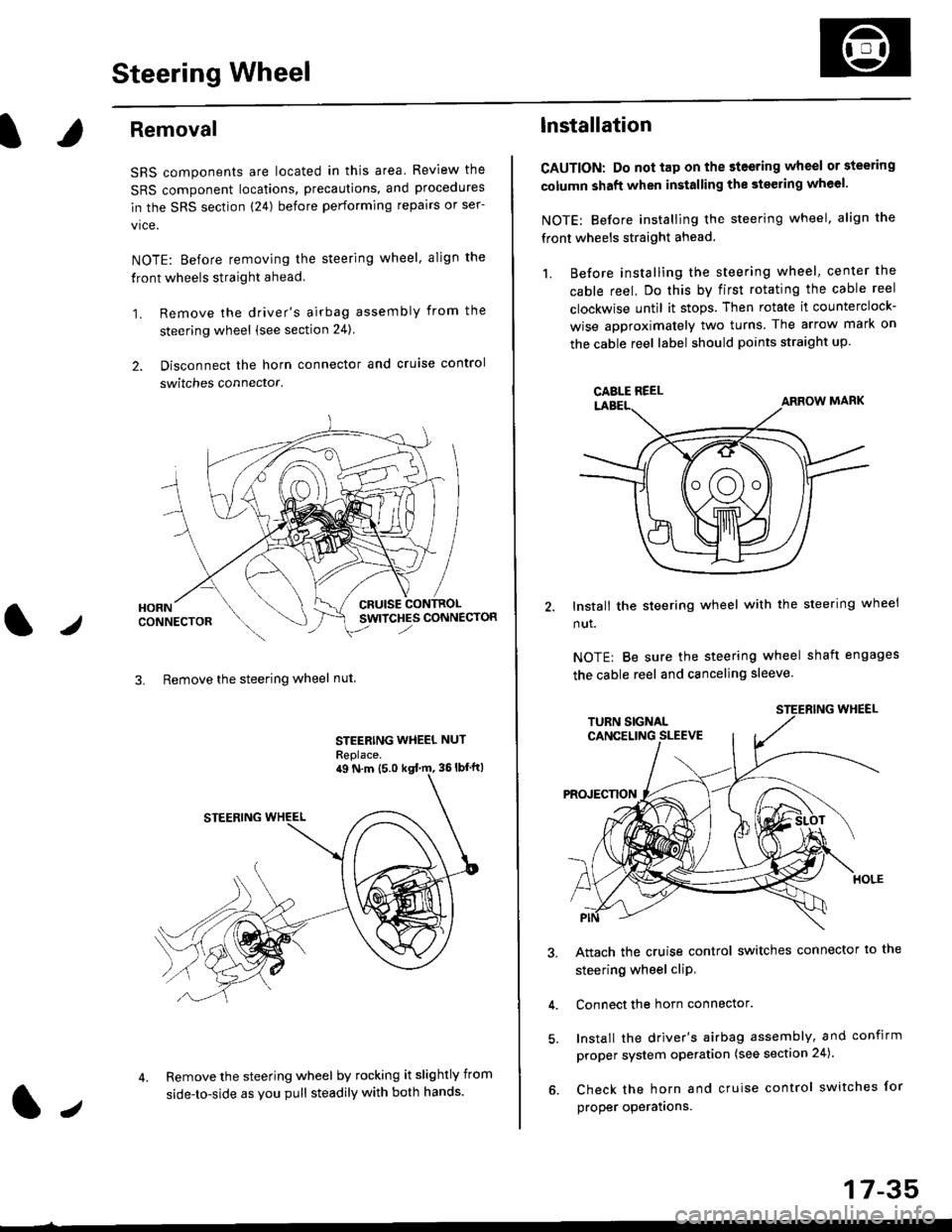

Removal

SRS components are located in this area Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

NOTE: Before removing the steering wheel. align the

front wheels straight ahead.

1. Remove the driver's airbag assembly from the

steering wheel (see section 24)

2. Disconnect the horn connector and cruise control

switches connector.

CRUISESWITCHES CONNECTOR

3. Remove the steering wheel nut

STEERING WHEEL NUT

Replace.

Remove the steering wheel by rocking it slightly from

side-to-side as you pull steadily with both hands.

ag N.m {5.0 kgt rn, 36lbfft)

1.,

17-35

lnstallation

CAUTION: Do not tap on the steering wheel or steering

column shaft when installing the stsering wheel.

NOTE: Before installing the steering wheel, align the

front wheels straight ahead.

1. Before installing the steering wheel, center the

cable reel, Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns The arrow mark on

the cable reel label should points straight up.

Install the steering wheel with the steering wheel

nut.

NOTE: Be sure the steering wheel shaft engages

the cable reel and canceling sleeve.

Attach the cruise control switches connector io the

steering wheel cliP,

Connect the horn connector.

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

Check the horn and cruise control switches for

proper operatrons.

CAELE REEL

Page 1093 of 2189

Steering Column

I

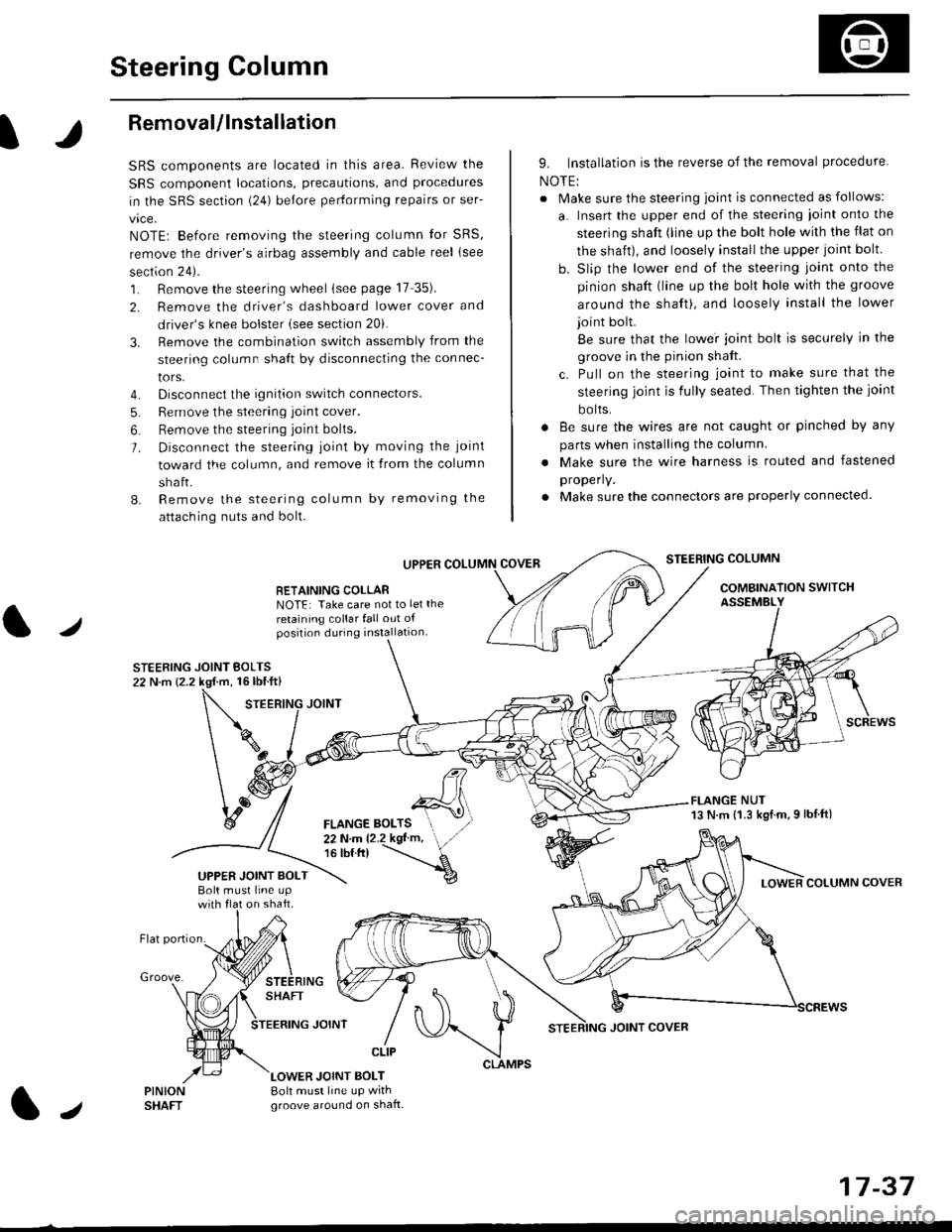

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and proceclures

in the SRS sectron (24) before pertorming repairs or ser-

vice.

NOTE: Before removing the steering column for SRS,

remove the driver's airbag assembly and cable reel lsee

section 24).

1. Remove the steering wheel (see page 17 35).

2. Remove the driver's dashboard lower cover and

driver's knee bolster (see section 20).

3. Remove the combination switch assembly from the

steering column sha{t by disconnecting the connec-

tors.

4. Disconnect the ignition switch connectors.

5. Remove the steering joint cover.

6. Bemove the steering joint bolls.

7. Disconnect the steering ioint by moving the joint

toward the column, and remove it from the column

shaft.

8. Remove the steering column by removing the

attaching nuts and bolt.

UPPER

RETAINING COLLABNOTE: Take care not to let the

retaining collar fall out ofposition during installation.

STEERING JOINT BOLTS22 N.m {2.2 kgf.m, 16lbtft}

9. Installation is the reverse of the removal procedure

NOTE:

. Make sure the steering joint is connected as follows:

a. Insert the upper end of the steering ioint onto the

steering shaft (line up the bolt hole with the flat on

the shait), and loosely install the upper joint bolt.

b. Slip the lower end of the steering joint onto the

pinion shaft (line up the bolt hole with the groove

around the shaft), and loosely install the lower

joint bolt.

Be sure that the lowei joint bolt is securely in the

groove in the pinion shaft.

c. Pull on the steering joint to make sure that the

steering joint js fully seated. Then tighten the ioint

bolts.

. 8e sure the wires are not caught or pinched by any

parts when installing the column

. Make sure the wire harness is routed and fastened

properly.

. Make sure the connectors are properly connected.

STEERING COLUMN

COMBINATION SWITCHASSEMBLY

FLANGE NUT13 N.m {1.3 kgl.m.9 lbf ft)

COLUMN COVER

FLANGE BOLTS22Nm12.2kgl'm,16 tbt.tr)

UPPER JOINT BOLTBolt musl line upon shaft.

Groove.

LOWER JOINT BOLT8oh must line up wrthgroove around on shaft.

CLIP

J

JOINT COVER

17-37

Page 1122 of 2189

Steering Gearbox

Installation (cont'dl

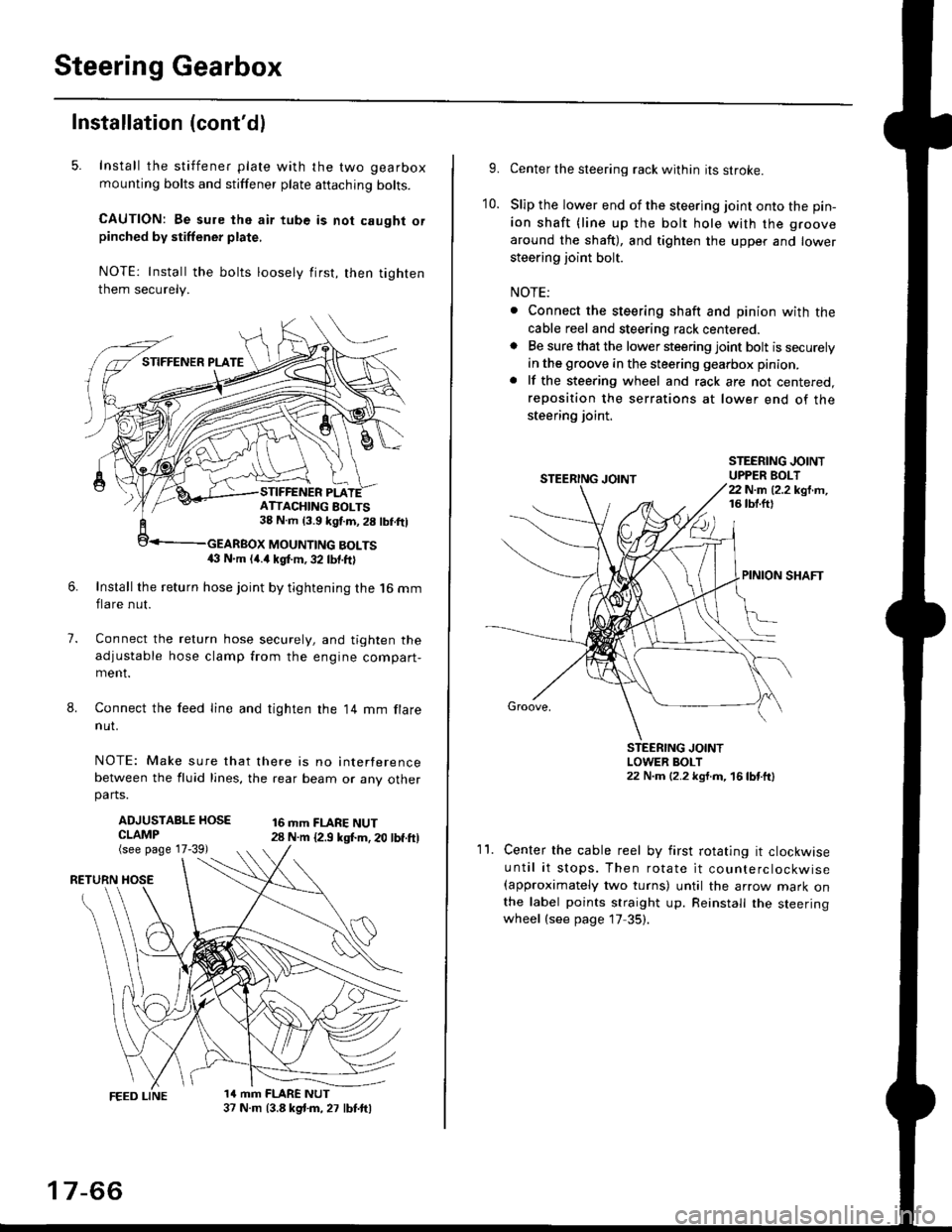

5. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate aftaching bolts.

CAUTION: Be sure the air tube is not caught orpinched by stiffener plate,

NOTE: Install the bolts loosely first, then tighten

them securely.

7.

8.

6.Install the return hose joint by tightening the l6 mm

flare nut.

Connect the relurn hose securely, and tighten the

adjustable hose clamp from the engine compart-ment.

Connect the feed line and tighten the 14 mm flare

nut.

NOTE: Make sure that there is no interference

between the fluid lines, the rear beam or any otherparts.

ADJUSTABLE HOSECLAMP(see page 17-39)

16 mm FLARE NUT28 N.m {2.9 ksl.m. 20 lbf.ft)

RETURN

1a mm FLARE NUT37 N.m (3.8 kg{.m, 27 lbt.ftl

ATTACHING AOLTS38 N.m 13.9 kgf.m, 28 lbf.ftl

MOUNTING BOLTS(} N.m (4.a kgt m, 32 lbf.ftl

17-66

9.Center the steering rack within its stroke.

Slip the lower end of the steering joint onto the pin-

ion shaft (line up the bolt hole with the groove

around the shaft), and tighten the upper and lower

steering joint bolt.

NOTE:

. Connect the steering shaft and pinion with the

cable reel and steering rack centered.. Be sure that the lower steering joint bolt is securely

in the groove in the steering gearbox pinion.

. lf the steering wheel and rack are not centered,

reposition the serrations at lower end of the

steering joint.

10.

STEERING JOINTUPPER BOLT22 N.m (2.2 kgf.m,16 tbt.ftl

PINION SHAFT

Groove,

STEERING JOINTLOWER BOLT22 N.m (2.2 kgt.m, 16lbtttl

11.Center the cable reel by first rotating it clockwise

until it stops. Then rotate it counterclockwise(approximately two turns) until the arrow mark onthe label points straight up. Reinstall the steeringwheel (see page 17 35).

Page 1155 of 2189

t

Conventional Brake

Speciaf Tools .............19'2

Component Locations

lndex ................ ...... 19-3

Inspection and Adiustment

Brake System Rubber Parts

and Brake Booster ...........,.,............. 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19-7

Front Brake Pads

Inspection and Replacement .......... 19-8

Front Erake Disc

Disc Runout Inspection ................... 19-12

Disc Thickness and Parallelism

Inspection .......... 19-12

Front Brake Caliper

Disassembly .......... 19'13

Reassembly ........... 19-16

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-21

Pushrod Clearance Adiustment ...... 19-22

Brake Booster Inspection ................ 19-23

Rear Brake Pads

Inspection and Replacement ,,........ 19-24

Rear Brake Disc

Disc Runout lnspection ................... 19-26

Disc Thickness and Parallelism

Inspection .......... 19-26

Rear Brake Caliper

Disassembly ...........19-27

Reassembly ........." 19-31

Rear Drum Brake

Index/lnspection .............................. 19-35

Inspection ....,.,....... 19-36

Brake Shoe Disassembly ..............." 19-37

Brake Shoe Reassembly ...............'.. 19-37

Brake Hoses/Lines

Inspection/Torque Specifications ..... 19-39

Hose Replacement ........................... 19-40

Parking Brake Cable

lnspection and Replacement ........,. 19-41

l-l

Page 1178 of 2189

Rear Brake Pads

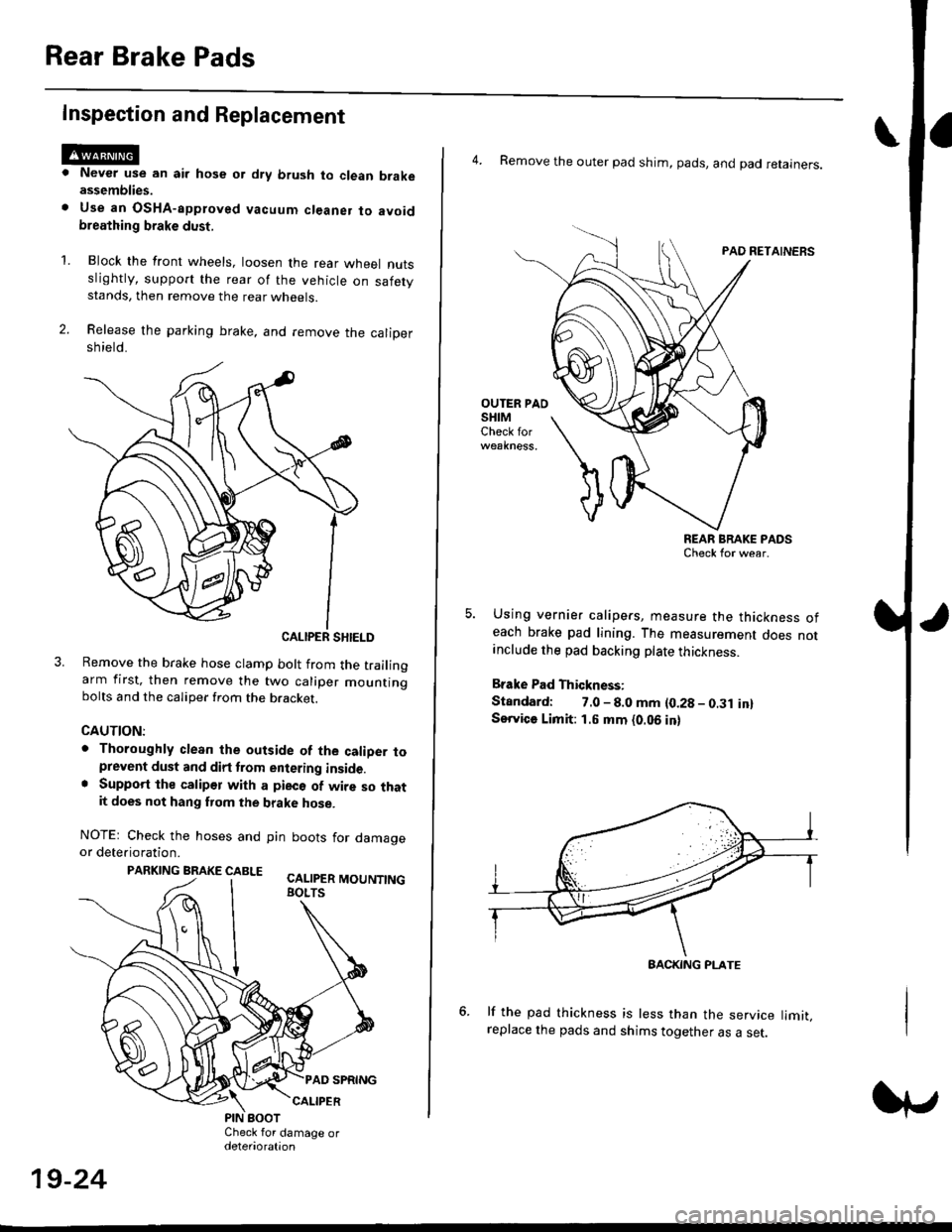

Inspection and Replacement

Never use an air hose or dry brush to clean brakeassemblies.

Use an OsHA-apptoved vacuum cl€aner to avoidbreathing brake dust,

Block the front wheels, loosen the rear wneet nutsslightly, support the rear of the vehicle on safetystands, then remove the rear wheels.

Release the parking brake, and remove the calioersh ield.

CALIPER SHIELD

Remove the brake hose clamp bolt from the trailingarm first, then remove the two caliper mountingbolts and the caliper from the bracket.

CAUTION:

. Thoroughly clean the outside of the caliDer toprevent dust and dirt trom entering inside.. Support the calipor with a pieco of wire so thatit does not hang fuom the brake hose.

NOTEr Check the hoses and pin boots for damageor deterioration.

PARKING BRAKE CABLE ^.. ._-_ ---.

'L

19-24

4. Remove the outer pad shim, pads, and pad retainers.

PAO RETAINERS

OUTER PAOSHIMCheck for

REAR BRAKE PADSCheck for wear.

Using vernier calipers, measure the thickness ofeach brake pad lining. The measurement does notanclude the pad backing plate thickness.

Brake Pad Thickness:

Standard: 7.0 - 8.0 mm {0.28 - 0.31 in}Service Limit: 1.5 mm {0.06 in}

lf the pad thickness is less than the service limit,replace the pads and shims together as a set.

BACKING PI-ATE

Page 1181 of 2189

Rear Brake Caliper

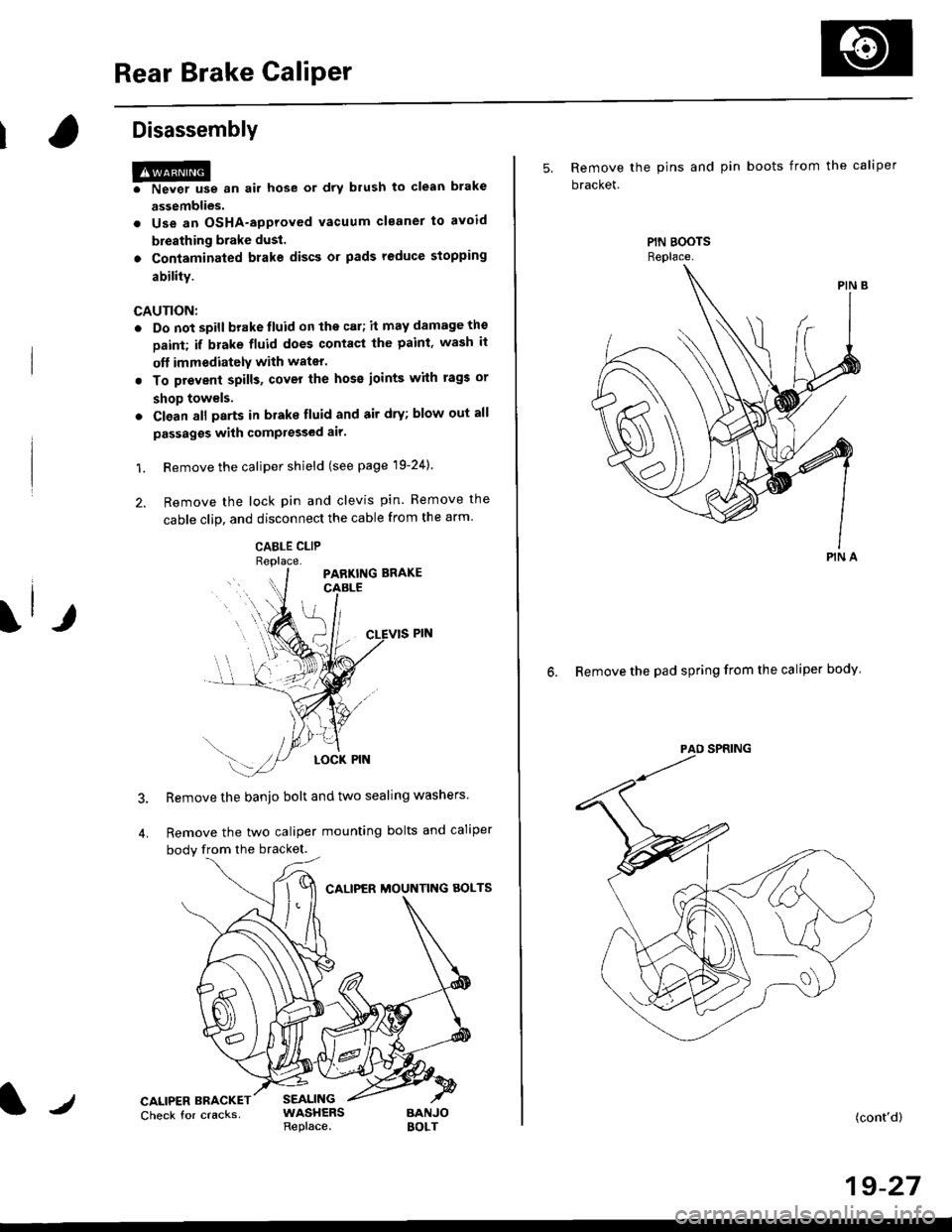

Disassembly

@f l',lever use an air hose or dry brush to clean

assemblies.

. Use an OsHA-approved vacuum cleaner to

brake

avoid

breathing brake dust.

. Contaminated brake discs or pads reduce stopping

ability.

CAUTION:

. Do not spill brake tluid on the cal; h may damage the

paint; if brake fluid does contact the paint, wash ii

ofl immediatelY with water.

. To prevent spills, cover the hose ioints whh rags or

shop tow€ls.

. Clean all parts in brake fluid and air dry; blow out all

passagss with complessed air.

1. Remove the caliper shield (see page 19-24).

2. Remove the lock pin and clevis pin. Remove the

cable clip, and disconnect the cable from the arm

CABLE CLIP

Remove the banjo bolt and two sealing washers

Remove the two caliper mounting bolts and caliper

body from the bracket.

CALIPER MOUNTNG AOLTS

CALIPER BRACKETCheck for cracksSEALINGWASHERSReplace.BANJOBOLT

5, Remove the pins and pin boots from the caliper

bracket.

6. Remove the pad spring from the caliper body

PIN A

(cont'd)

19-27

Page 1188 of 2189

Rear Brake Caliper

Reassembly (cont'dl

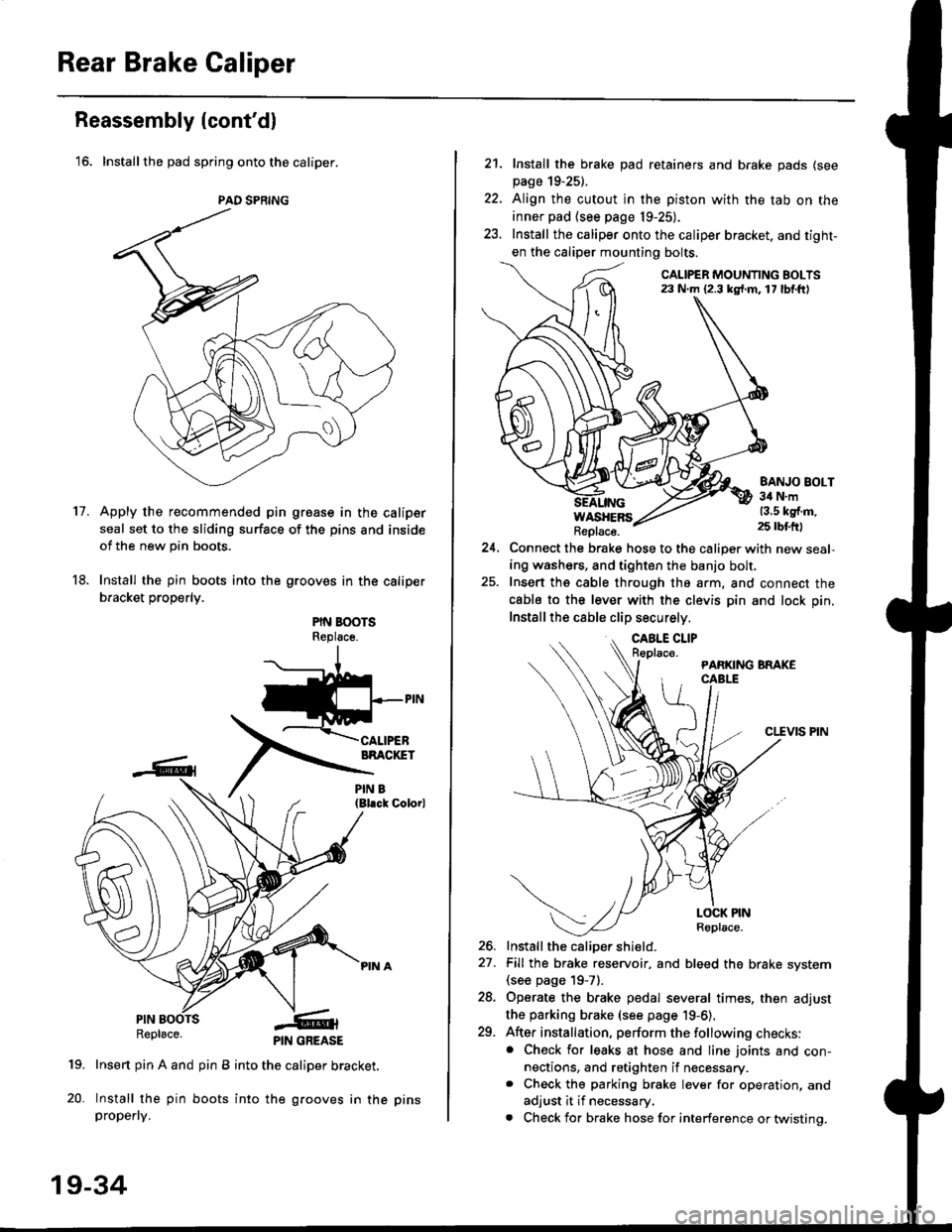

'16. Installthe pad spring onto the caliper.

Apply the recommended pin groase in the caliper

seal set to the sliding surface of the pins and inside

of the new pin boots.

Install the pin boots into the grooves in the caliper

bracket properly.

PIN BOOTSReplsce.

(Bl.ck Colorl

PINRepl6ce.

19. Insert pin A and pin B into the caliper bracket.

20. Install the pin boots into the grooves in thepropefly.

PAD SPRING

11.

PIN GREASE

19-34

pr ns

22.

21. Install the brake pad retainers and brake pads (see

page 19-25).

Align the cutout in the piston with the tab on the

inner pad (see page 19-25).

Install the caliper onto the caliper bracket. and tight-

en the caliper mounting bolts.

CALIPER MOUNTING BOLTS23 N.m {2.3 kg{.m. 17 lbf.ft)

WASHERSReplace.

BANJO BOLT34 N.m13.5 kg{.m.25 rbtft)

24.Connect the brake hose to the caliper with new seal,

ing washers, and tighten the banjo bolt,

Insert ths cable through the arm, and connect the

cabls to the lever with the clevis pin and lock pin.

Install the cable clip securely.

CLEVIS PIN

-t

//t

LOCK PINRoplace.

26. Install the caliDer shield.

27. Fill the brake reservoir, and bleed the brake svstem(see page 19-71.

28. Operate the brake pedal several times, then adjust

the parking brake (see page 19-6).

29. After installation, perform the following checks:. Check for leaks at hose and line joints and con-nections, and retighten if necessary.. Check the parking brake lever for operation, and

adjust it if necessary.

. Check for brake hose for interference or twistinq.

Page 1191 of 2189

t-

Brake Shoe Disassembly

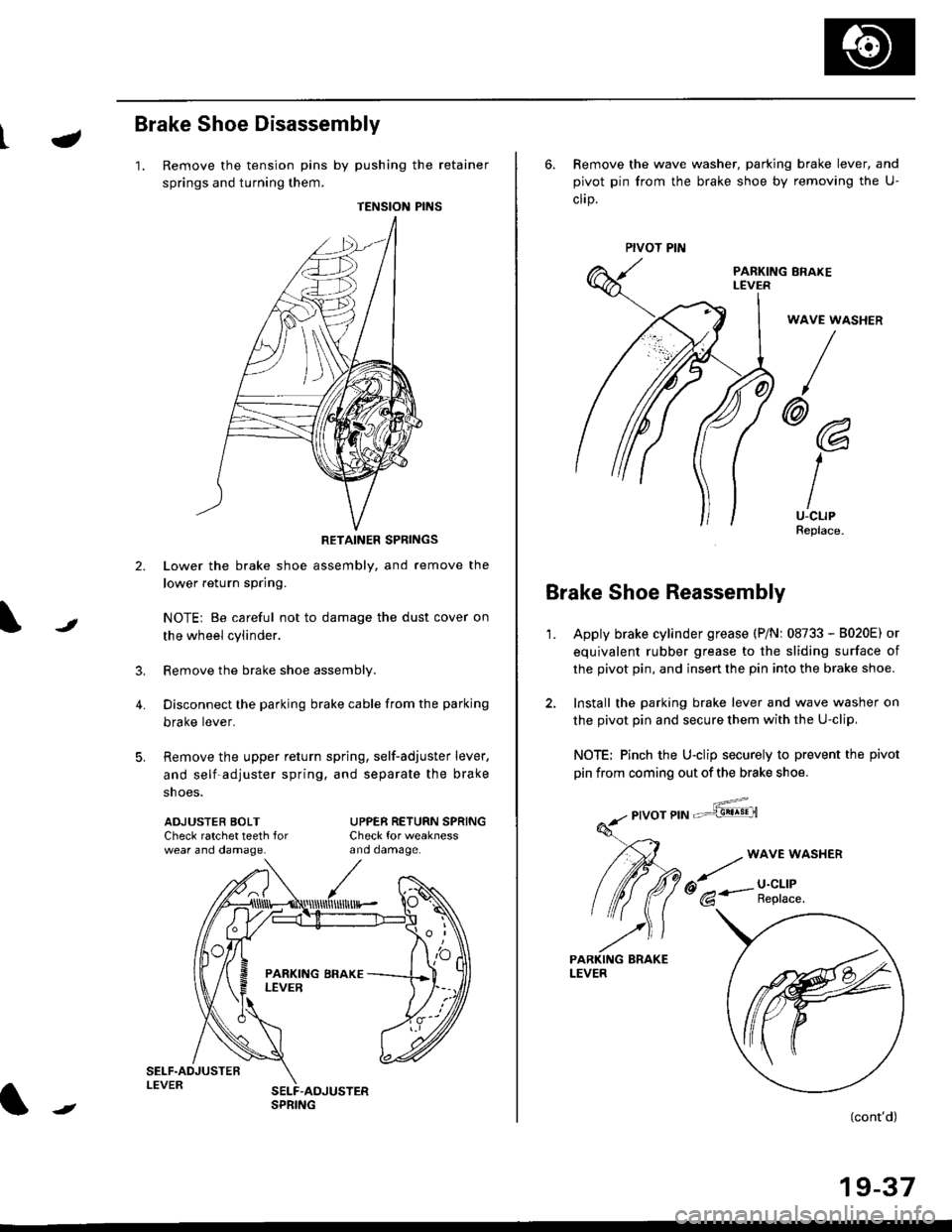

1. Remove the tension pins by pushing the retainer

springs and turning them.

TENSION PINS

RETAINER SPRINGS

Lower the brake shoe assembly, and remove the

lower return spring.

NOTEi Be careful not to damage the dust cover on

the wheel cylinder.

Remove the brake shoe assembly.

Disconnect the parking brake cable from the parking

brake lever.

Remove the upper return spring, self-adjuster lever,

and self-adjuster spring, and separate the brake

snoe5.

t

3.

4.

ADJUSTEB BOLTCheck ratchet teeth forwear ano oamage.

UPPER RETURN SPRINGCheck for weaknessano oamage.

ll

,'/

N

r

//

t

6. Remove the wave washer, parking brake lever, and

pivot pin from the brake shoe by removing the U-

clrp.

PARKING ERAKEI-EVER

WAVE WASHER

/

@@

I

IU-CLIPReplace.

Brake Shoe Reassembly

1.Apply brake cylinder grease (P/Nr 08733 - B020E) or

equivalent rubber grease to the sliding surface of

the pivot pin, and insert the pin into the brake shoe.

Install the parking brake lever and wave washer on

the pivot pin and secure them with the U-clip,

NOTE: Pinch the U-clip securely to prevent the pivot

pin from coming out of the brake shoe.

,6;::"'

(cont'd)

19-37

LEVER