ect HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 960 of 2189

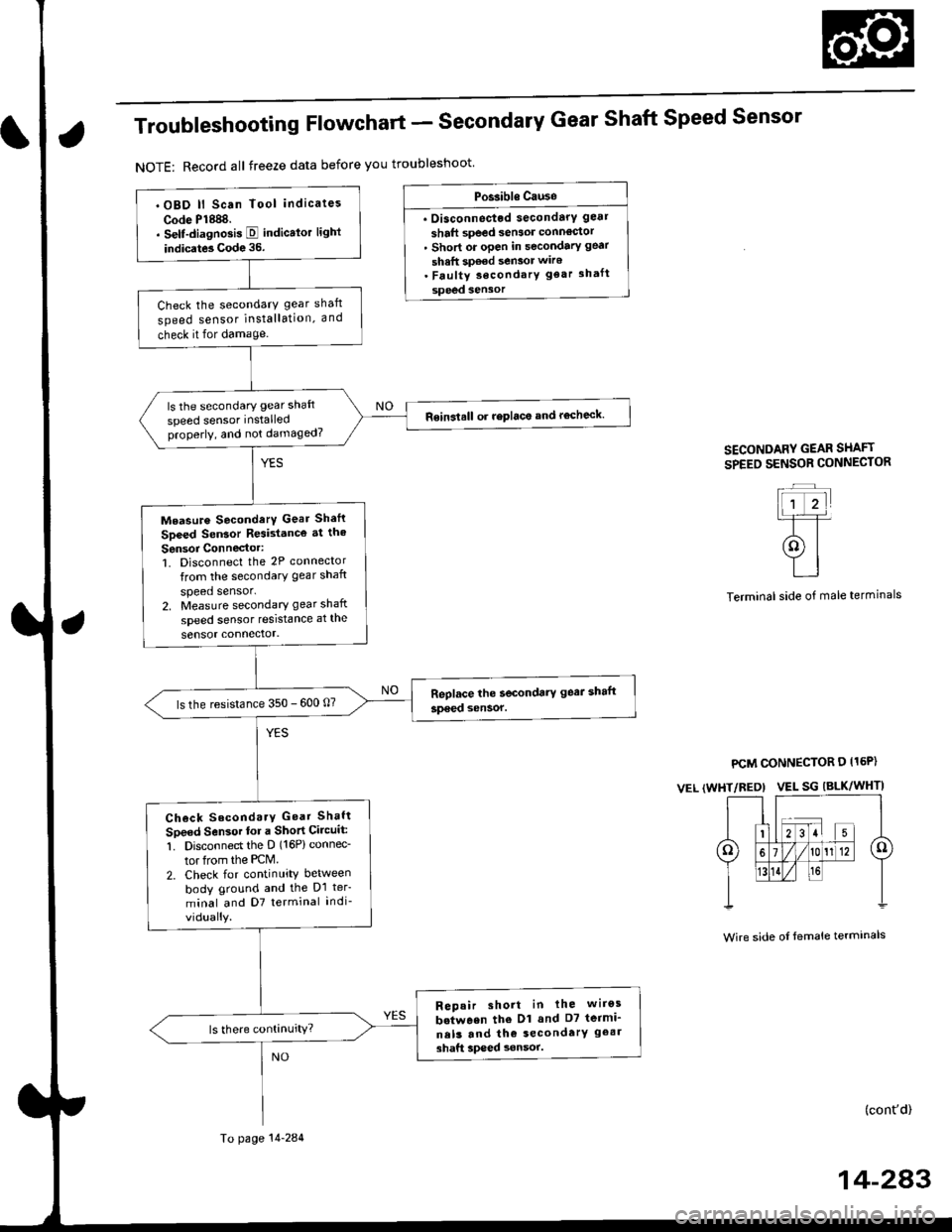

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor

NOTE: Record all freeze data before you troubleshoot

Po$ible Causo

. Oisconnectod secondarY gear

shaft speed sensor conn66or' short or open in secondary gear

shaft spe€d sensor wiro. Faulty secondarY gear 3haft

sPeed sensor

SECONDARY GEAR SHAFT

SPEEO SENSOR CONNECTOR

Terminal side of male terminals

PCM CONNECTOR D I15P)

VEL (WHT/REO) VEL SG IALK/WHTI

Wire side oI female terminals

(cont'd)

14-243

' OBD ll Scan Tool indicates

Code P1888.. Self-diagnosis E indicalor light

indicats Code 35.

Check the secondarY gear shaft

speed sensor installation, and

check it for damage.

ls the secondary gear shaft

speed sensor installedproperly, and not damaged?

Reinatall or replace and rocheck.

Measure SocondarY Gear Sh.ft

Speed Sen3or Resistance at the

Sensor Connector:1. Disconnect the 2P connector

trom the secondary gear shaft

speed sensor.2. Measure secondary gear shaft

speed sensor resistance at the

sensor connector.

ls the resistance 350 - 600 0?

Check SecondarY Gear Shaft

Speed Sensor lor a Short Circuit:

1. Disconned the D (16P) connec-

tor from the PCM.

2. Check for continuity between

body ground and the D1 ter-

minal and D7 terminal indi-

vidually.

Repair short in the wiros

b.tween the Dl and D7 termi_

ne13 and th€ secondarY geal

3haft lpeed sonsor.

To page 14-284

Page 961 of 2189

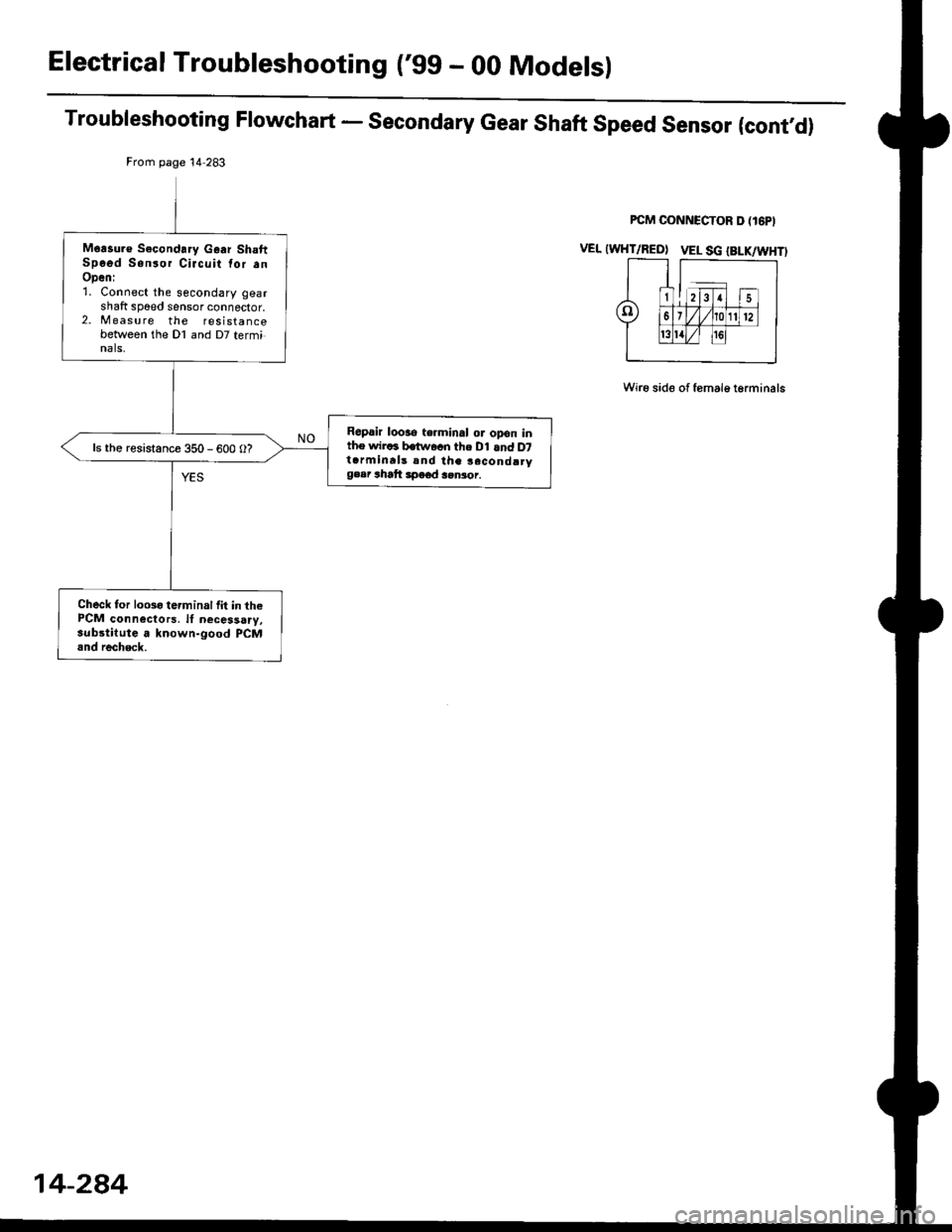

Electrical Troubleshooting ('gg - 00 Modelsl

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor (cont'd)

Wi16 side of female t6rminals

From page 14 283

Moasu.€ Secondary Gaar ShaftSpo6d Sonsor Circuit tor anOpeni1. Connect the secondary gearshaft sp6ed sensor connector,2. M easu re the resistancebetween the Dl and D7 terminals,

Repair looao terminal or opon inthe wiraa batuvacn the Dl and D7t.rminrls snd the second!rygeer rhatt 3peod 3.nior.

ls the resistance 350 - 600 O?

Check for looso terminal lit in thePCM connectors. lf necessary,substilute a known-good PCM.nd recheck.

14-284

Page 963 of 2189

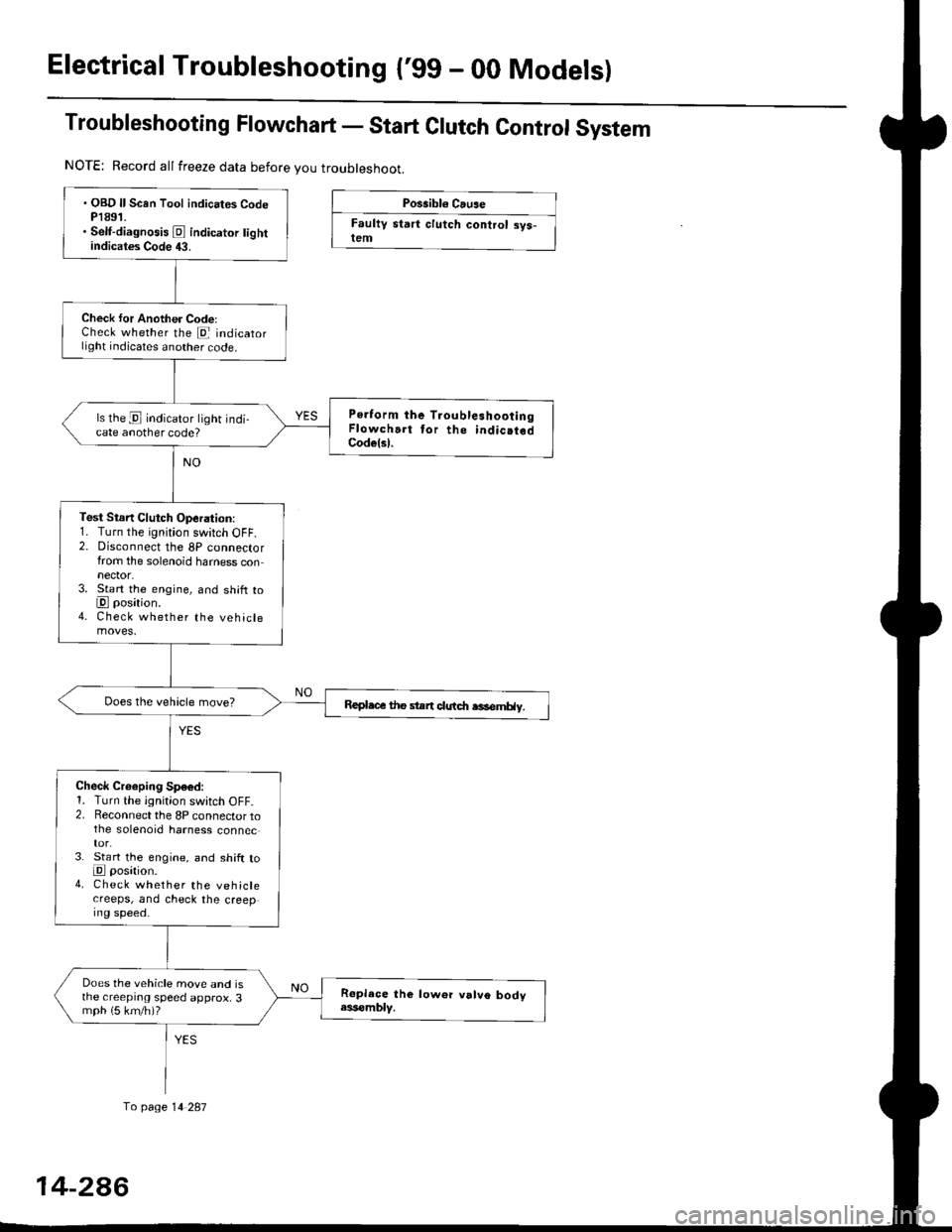

Electrical Troubleshootang ('gg - 00 Models)

Troubleshooting Flowchart - Start Clutch Control System

Possibl€ Cause

Faultv start clutch control sys-lem

NOTE: Record allfreeze data before you troubleshoot.

fo page 14 287

. OBD ll Scan Tool indicates CodeP1891.. Self-diagnosis E indicator tightindicates Code 43.

Check for Another CodelCheck whether the E indicatorlight indicates another code.

Perform the TroubleshootingFlowchart tor the indic.tedCodelsl.

ls the E indicator light indi-cate another code?

Test Stsn Clutch Operation:1. Turn the ignition switch OFF.2. Disconnect the 8P connectorfrom the solenoid harness connector.3. Start the engine, and shift toE position.4. Check whether the vehiclemoves.

Repl.c€ the stan clutdt rasemHy.

Check Croeping Sp€6d:1. Turn the ignition switch OFF.2. Reconnect the 8P connector tothe solenoid harness connec

3. St€rt the engine, and shift toE posation.4. Check whether the vehiclecreeps, and check the creeping speed.

Does the vehicle move and isthe creeprng speed approx, 3mph (5 km/h)?

14-2A6

Page 965 of 2189

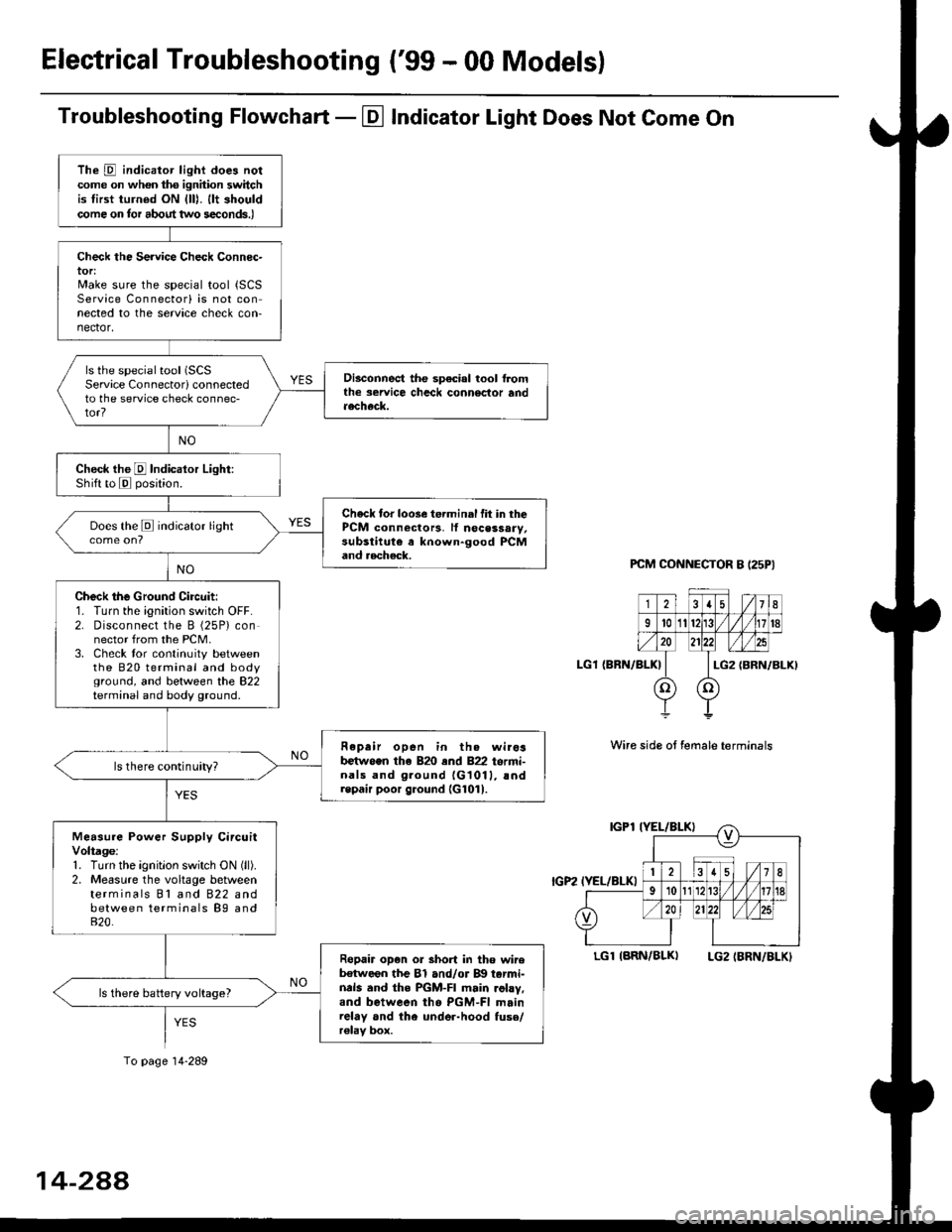

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - El Indicator Light Does Not Come On

PCM CONNECTOR B I25PI

LGl {BRN/BLK)

Wire side ot female terminals

LGlIARN/BLK) LG2IBRN/BLKI

The D indicator light does notcome on whon ths ignhion switchis tirst turned ON {lll. llt shouldcome on tor about two s€conds.)

Check the Service Check Connec-tor:Make sure the special tool {SCSService Connectorl is not connected to the service check con-nector,

ls the special tool (SCS

Service Connectorl connectedto the service check connec-tor?

Disconnect the sp€cial tool f]omthe seruice chcck connoclor andaecheck.

Check the E Indicalor Light:Shift to E posjtion.

Check tor loose te.minal fit in thePCM connectors, lf nocessary,substitute a known-good PCMand aecheck.

Does the E indicator light

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) connector from the PCM.3. Check tor continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Fepair open in th. wirosb€tw.en the 820 end 822 termi-nals and ground {G1011, !ndrepair poor ground {G1011.

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignitlon switch ON (ll).

2. Measure the voltage betweenterminals Bl and 822 andbetween terminals B9 and820.

Ropair op€n or short in tho wireb€tween the Bl and/or B!| tarmi-nds and the PGM-FI main .ohy,and between tho PGM-FI mainrelay and the under-hood fuso/r€lav box.

ls there battery voltage?

To page 14-289

14-2AA

Page 966 of 2189

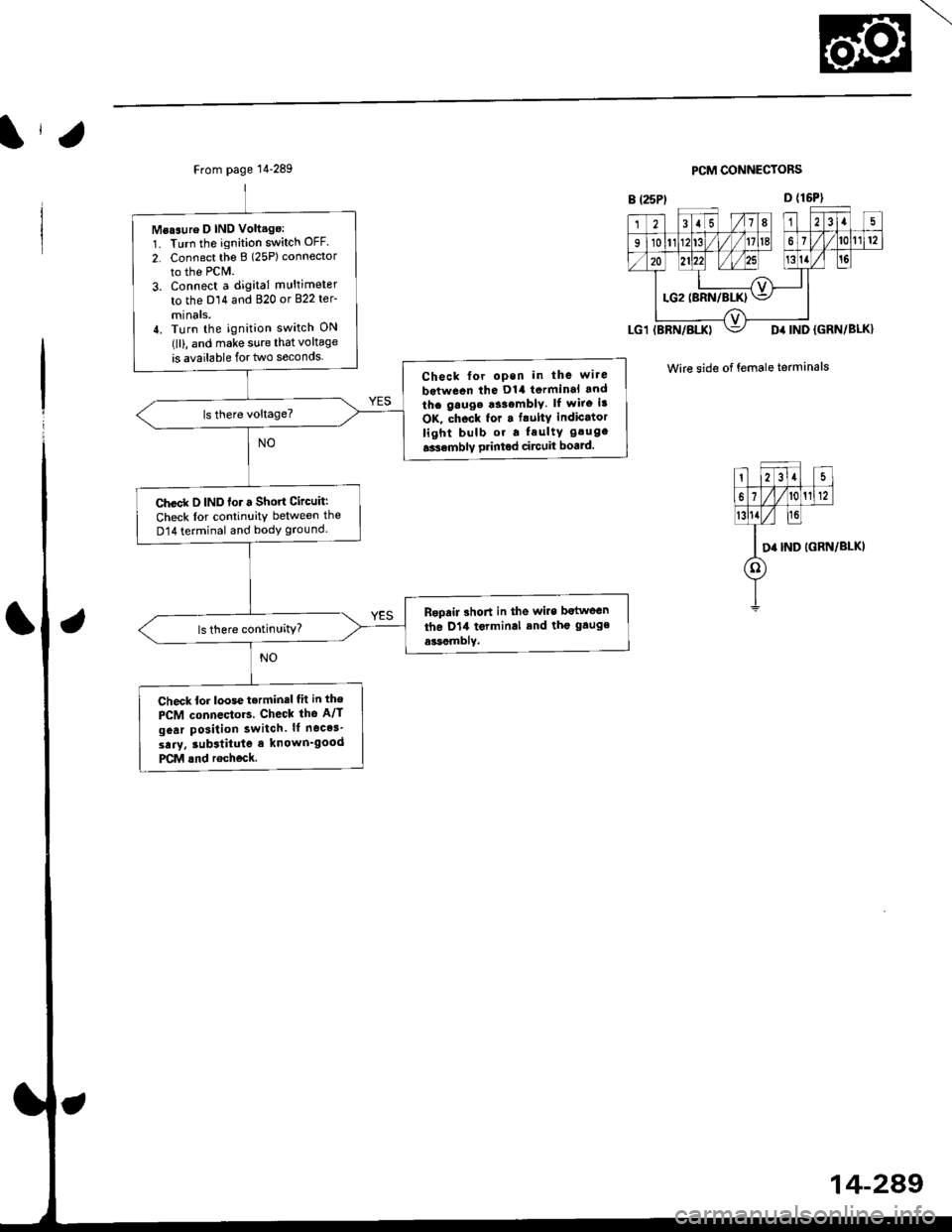

From page 14-289

Msaaure D IND Volt.ge:1. Turn the ignition switch OFF.

2. Connect tho B (25Plconnector

to the PCM.

3. Connect a digital multimeter

to the D14 and 820 or 822 ter-

mtnals.il. Turn the ignition switch ON(lll, and make sure that voltage

is available for two seconds

Check for open in the wire

between tha D14 terminal rnd

the gauge a33emblY. lf wiro ia

OK, chock for . frulty indicator

light bulb or a Iaulty gaug.

a3r6mbly printod circuit board.

Check D IND for a Short Circuit:

Check lor continuitY between the

D14 terminal and body ground.

Rgpair 3hort in the wire b.tween

the D14 tcrminal and tho gauge

a*somblY.

Check for loose terminsl fh in the

PCM connectors Check tho A/T

goar posilion switch. It neces'

saiy, iubstitute a known_good

PCM rnd rochock.

PCM CONNECTORS

D {16P1

(BRN/BI.X)D4 IND (GRN/BLK}

Wire side of female terminals

123rs 1/7I215

910nn fT /fl6l112

o lzlzz ,rl/zs 1311- -T---=4'+:l

LG2IBRN/BLKI\=/ |

r lz35

6i /l/t01112

l0

D' IND

o

IGRN/BLKI

4-289

Page 967 of 2189

ElectricalTroubleshooting ('gg - 00 Models)

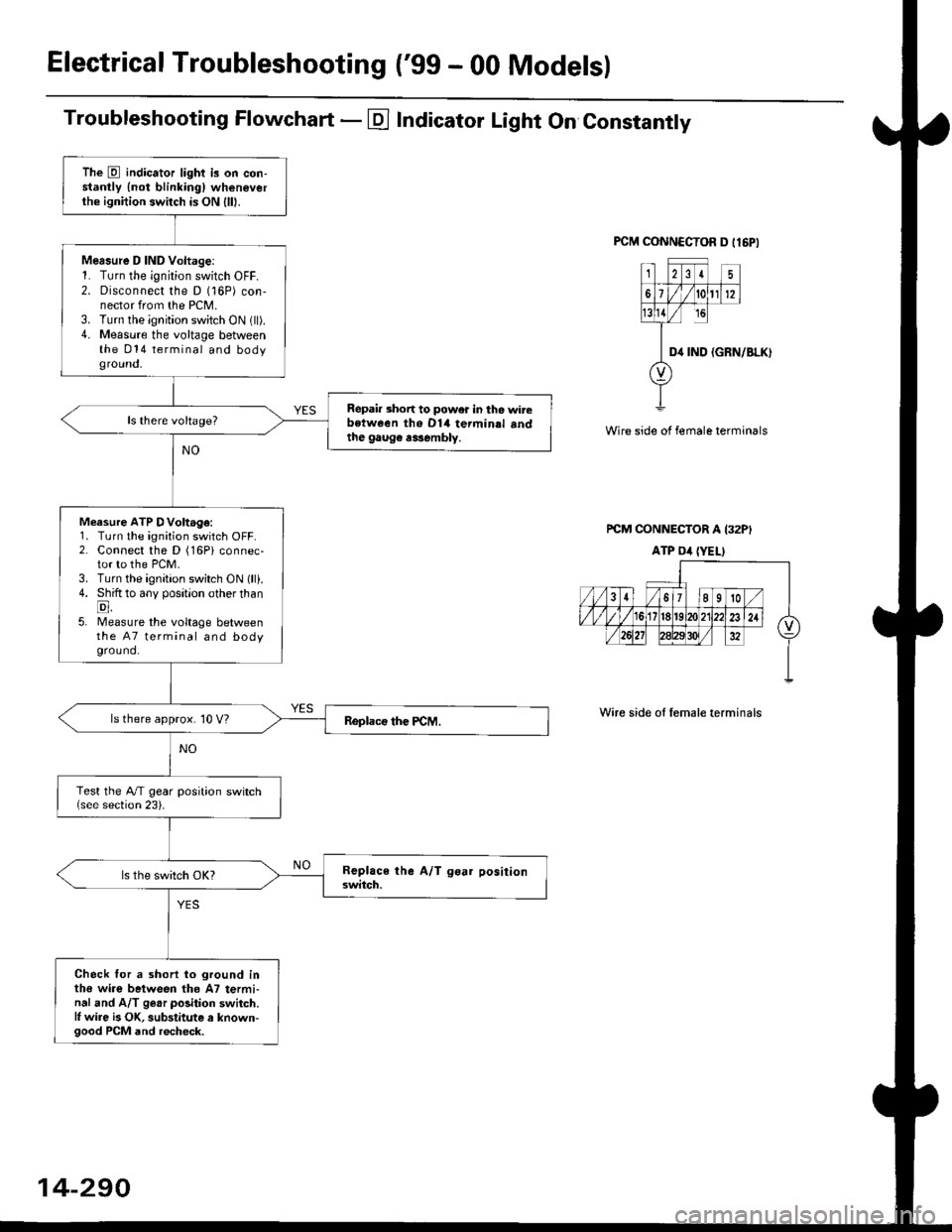

Troubleshooting Flowchart - E Indicator Light On Constantly

FCM CONNCCTOR D tl6PI

23I5

61t012

tsll / rc

II D4 rND

o

(GRN/BLK)

Wire side of female terminals

rcM CONNECTOR A I32PI

ATP Dil {YELI

Wire side of lemale terminals

The E indicator light is on con-stantly {not blinkingl wheneverthe ignition switch is ON lll|.

Mersure D IND Voltage:1. Turn the ignition switch OFF.2. Disconnect the D (16P) con-nector from the PCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe 014 terminal and bodyground,

Repair short to power in tho wirebstween the Dl4 termin.l sndthe gaug€ r3sembly.

Measure ATP DVoltage:1. Turn the ignition switch OFF.2. Connect the D (16Pi connec-tor to the PCM.3. Turn the ignition switch ON lll).4. Shift to any position other thanE,5. lMeasure the voltage betweenthe 47 terminal and bodyground.

ls there approx. 10 V?

Test the A/T gear position switch{see section 23).

Check for a shorl lo ground inthe wire between tho A7 termi-nal and A/T ge.r polition switch.l, wire is OK, substitute a known-good PCM and recheck.

14-290

Page 968 of 2189

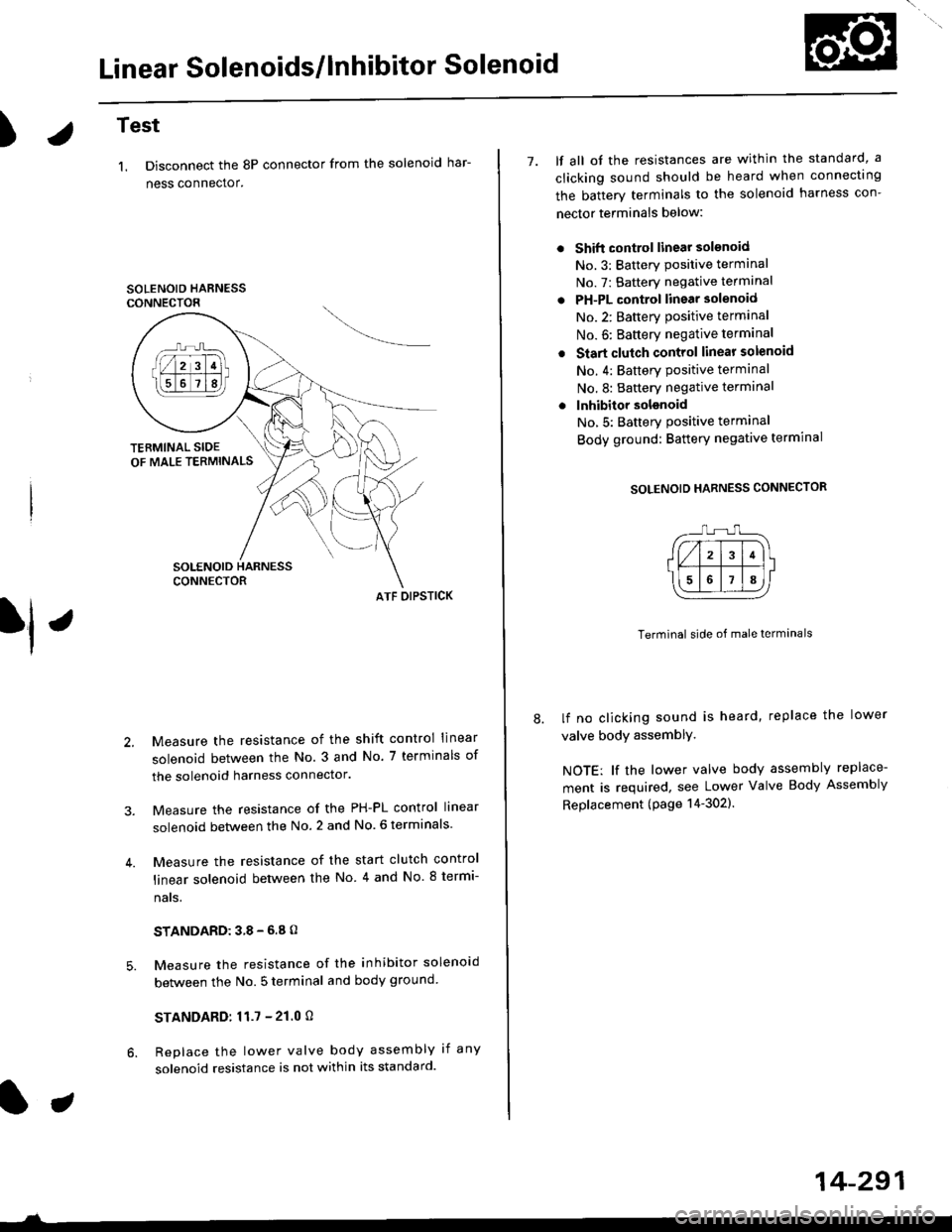

Linear Solenoids/lnhibitor Solenoid

)Test

1. Disconnect the 8P connector from the solenoid har-

ness connector.

SOLENOID HARNESSCONNECTOR

ATF OIPSTICK

Measure the resistance of the shift control linear

solenoid between the No. 3 and No. 7 terminals of

the solenoid harness connector.

Measure the resistance of the PH-PL control linear

solenoid between the No. 2 and No. 6 terminals

Measure the resistance of the start clutch control

linear solenoid between the No 4 and No. 8 termi-

nats,

STANDARD:38-6.8O

Measure the resistance of the inhibitor solenoid

between the No. 5 terminal and body ground

STANDARD:11.7 - 21.0 O

Replace the lower valve body assembly if any

solenoid resistance is not within its standard.

7. lf all ot the resistances are within the standard, a

clicking sound should be heard when connectrng

the batterv terminals to the solenoid harness con-

nector terminals below:

Shift control linear solsnoid

No.3: Batterv Positive terminal

No. 7: Battery negative terminal

PH-PL control linear solenoid

No.2: Batterv oositive terminal

No. 6: Baftery negative terminal

Start clutch control linear solenoid

No. 4: Battery Positive terminal

No.8: Battery negative terminal

lnhibitor solsnoid

No,5: Batterv Positive terminal

Body ground: Battery negative termrnal

SOLENOID HARNESS CONNECTOR

Terminal side of male terminals

lf no clicking sound is heard, replace the lower

valve body assemblY,

NOTE: lf the lower valve body assembly replace-

ment is required, see Lower Valve Body Assembly

Replacement (page 14-302).

14-291

Page 969 of 2189

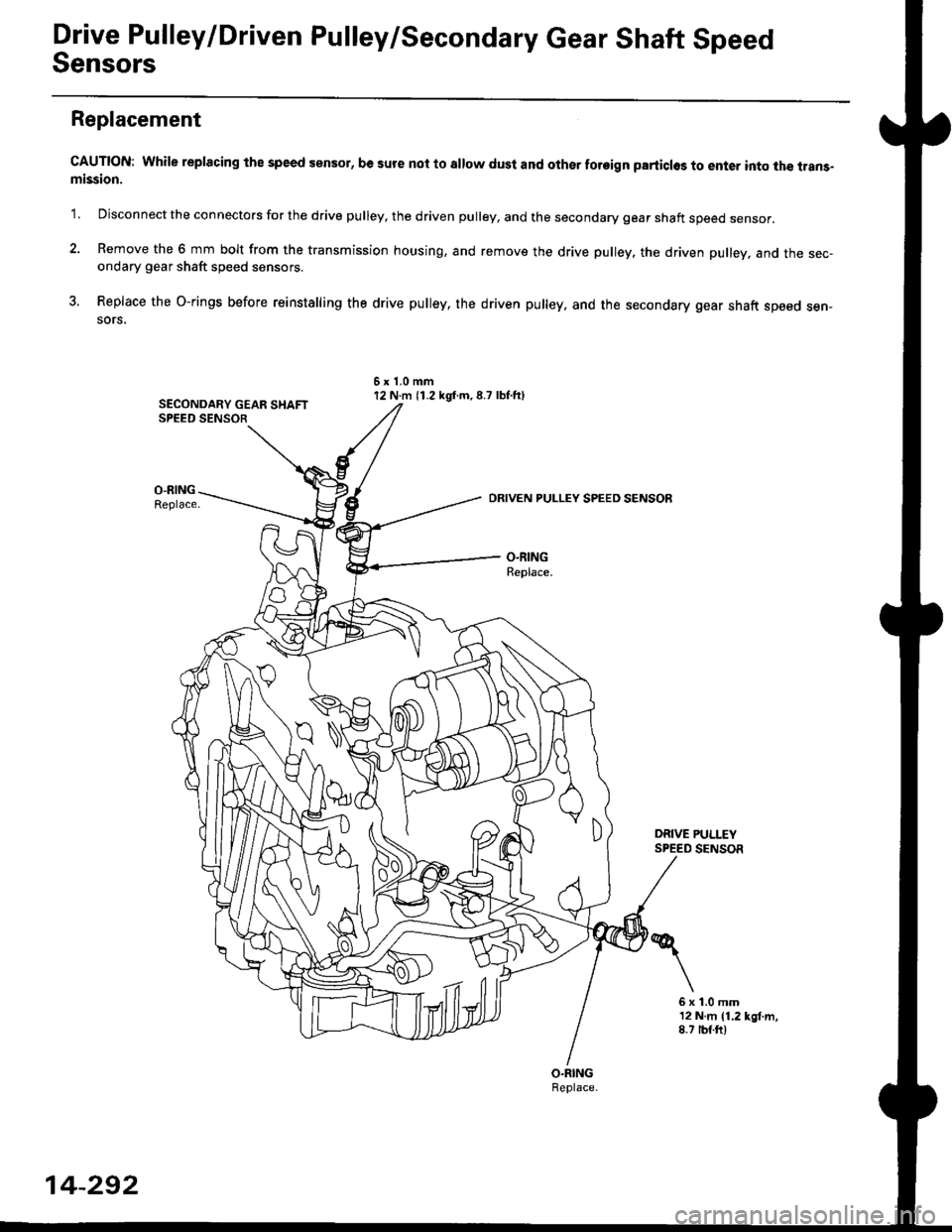

Drive Pulley/Driven Pulley/Secondary Gear Shaft Speed

Sensors

Replacement

CAUTION: While replacing the speed sensor, be sure not to allow dust and other foreign parliclos to enter into the trans-mission.

'1. Disconnect the connectors for the drive pulley, the driven pulley, and the secondary gear shaft speed sensor.

2. Remove the 6 mm bolt from the transmission housing, and remove the drive pulley. the driven pulley, and the sec-ondary gear shaft speed sensors.

3. Replace the O-rings before reinstalling the drive pulley, the driven pulley, and the secondary gear shaft sp€ed sen-sors.

6x1.0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

6x1.0mm12 N.m (1.2 kgt.m,8.7 tbf.ft)

DRIVEN PULLEY SPEED SENSOB

14-292

Page 970 of 2189

Start Clutch Control@

T

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

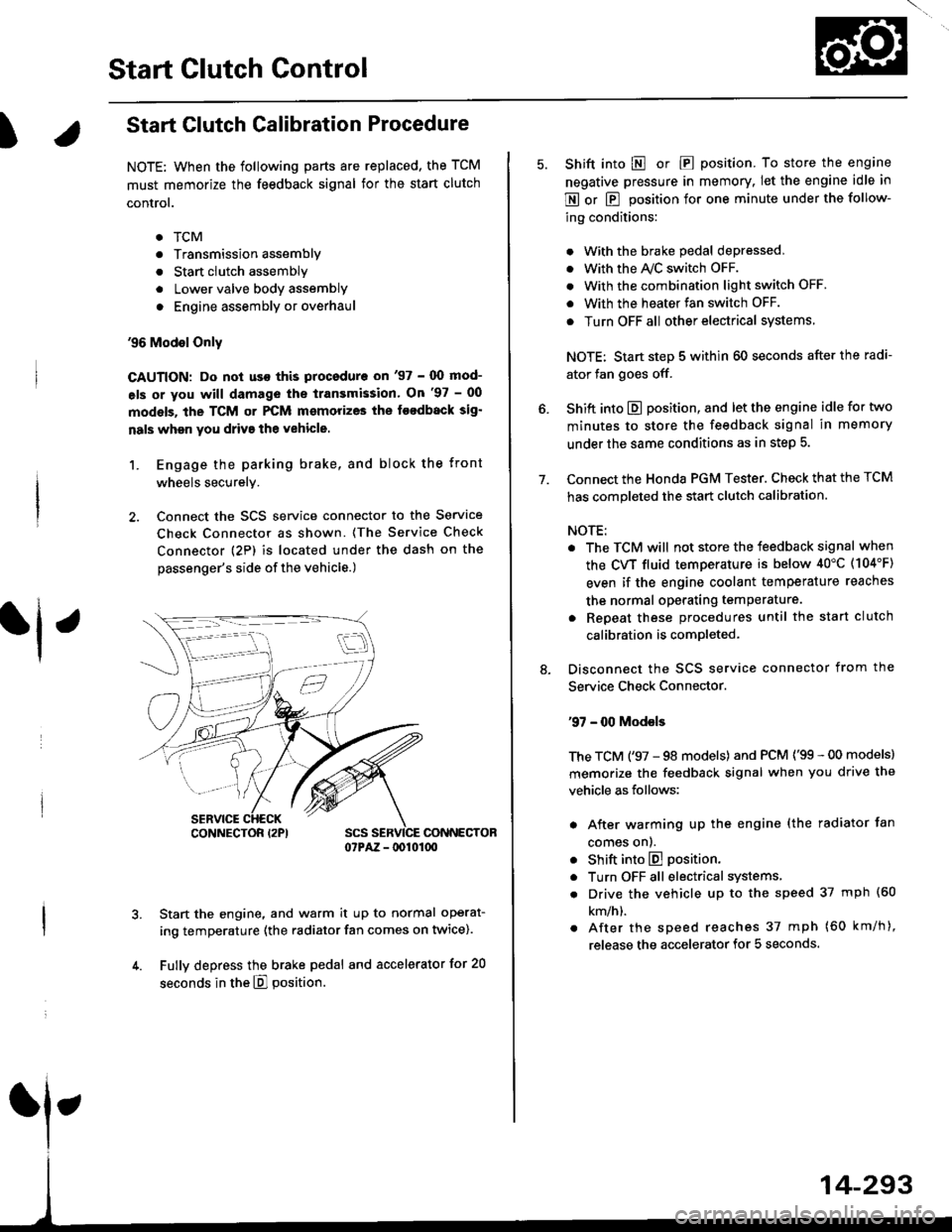

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 972 of 2189

t.

rl,

fl,

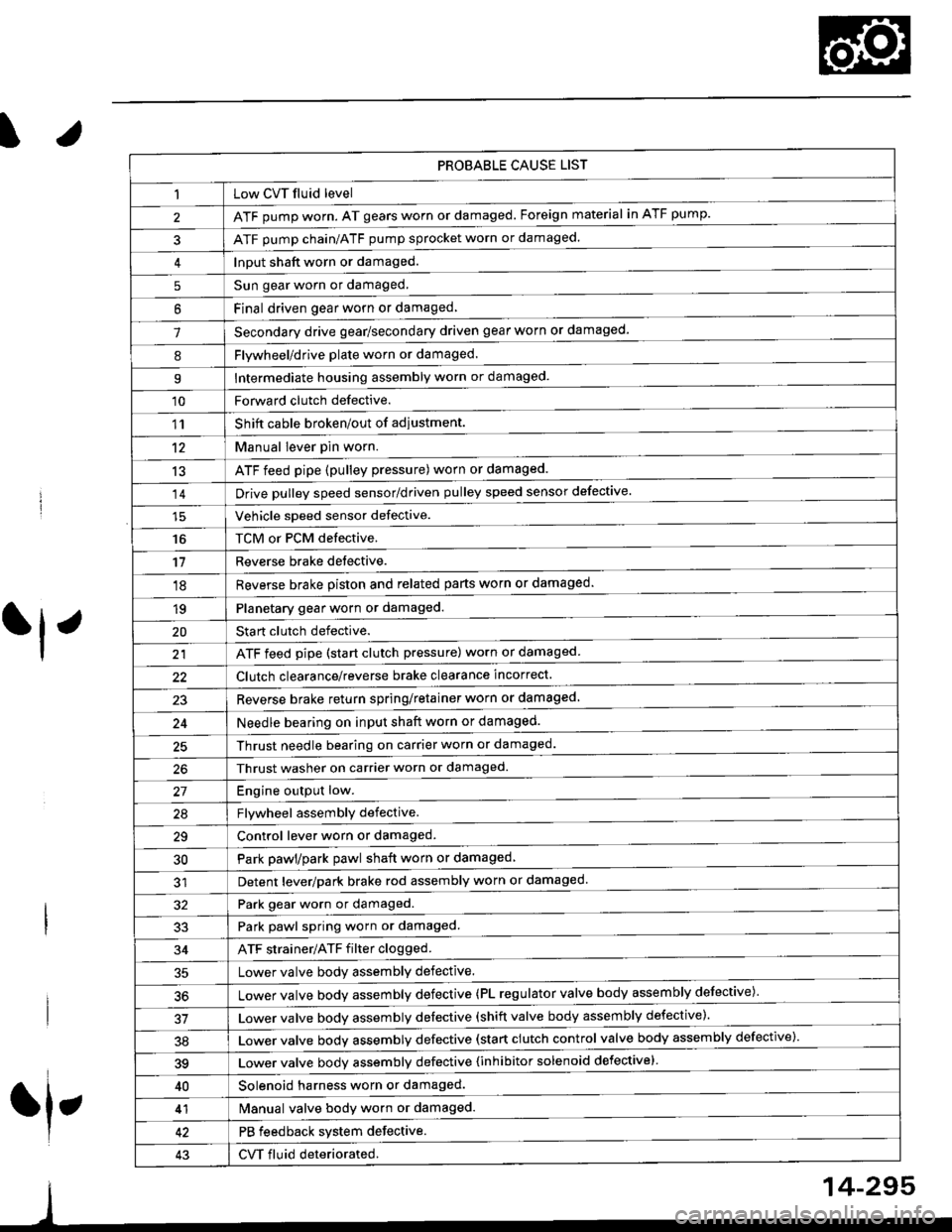

PROBABLE CAUSE LIST

Low CVT fluid level

ATF pump worn. AT gears worn or damaged. Foreign material in ATF pump.

ATF pump chain/ATF pump sprocket worn or damaged.

Input shaft worn or damaged.

Sun gear worn or damaged.

Final driven oear worn or damaqed,

Secondary drive gear/secondary driven gear worn or damaged-

5

6

1

8Flywheel/drive plate worn or damaged.

Intermediate housing assembly worn or damaged.9

'10Forward clutch defective.

Shift cable broken/out of adiustment.

M"nu"t t"uffi

ATF feed pipe (pulley pressure) worn or damaged.

Vchiclc speed sensor defective.

TCM or PCM defective.

Reverse brake detective.

1'�r

't2

13

14

16

'11

'18

1qPlanetary gear worn or damaged.

Sta rt clutch defective.

ATF feed pipe (start clutch pressure) worn or damaged

20

t't

Clutch clearance/reverse brake clearance incorrect.

23Reverse brake return spring/retainer worn or damaged

24Needle bearing on input shaft worn or damaged.

25Thrust needle bearing on carrier worn or damaged.

Thrust washer on carrier worn or damaged.

Enoine outout low.------------------------

Flvwhcel assemblv defective.

Control lever worn or damaged.

Park pawl/park pawl shaft worn or damaged

Detent lever/park brake rod assembly worn or damaged

27

29

30

32Park gear worn or damaged.

Park pawl spring worn or damaged.

ATF strainer/ATF filter clogged.

Lower valve body assembly defective.

Lower valve bodv assemblv defective (PL regulator valve body assembly defective)'

33

34

50

Lower valve bodv assembly defective (shift valve body assembly defective).

Lower valve bodv assemblv defective (start clutch control valve body assembly defective)'

39Lower valve bodv assemblv defective {inhibitor solenoid defective}

40Solenoid harness worn or damaged.

Manual valve body worn or damaged.

PB feedback system defective.

CVT fluid deteriorated.

41

43

14-295