EPS HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 229 of 1139

![HONDA CIVIC 2002 7.G User Guide Fuel and Emissions Systems

System Descriptions (contdl

ECM lnputs and Outputs at Connector E (31P}

L

u

1iMoFPR

2sr-{]zs3LG34SG3

6$1025HTC

1M RLY

8AFSHTCR

I

14FTP15ELD

16EPSLD

18ACC20Z/VBS21VSV

22BKSW HONDA CIVIC 2002 7.G User Guide Fuel and Emissions Systems

System Descriptions (contdl

ECM lnputs and Outputs at Connector E (31P}

L

u

1iMoFPR

2sr-{]zs3LG34SG3

6$1025HTC

1M RLY

8AFSHTCR

I

14FTP15ELD

16EPSLD

18ACC20Z/VBS21VSV

22BKSW](/img/13/5744/w960_5744-228.png)

Fuel and Emissions Systems

System Descriptions (cont'dl

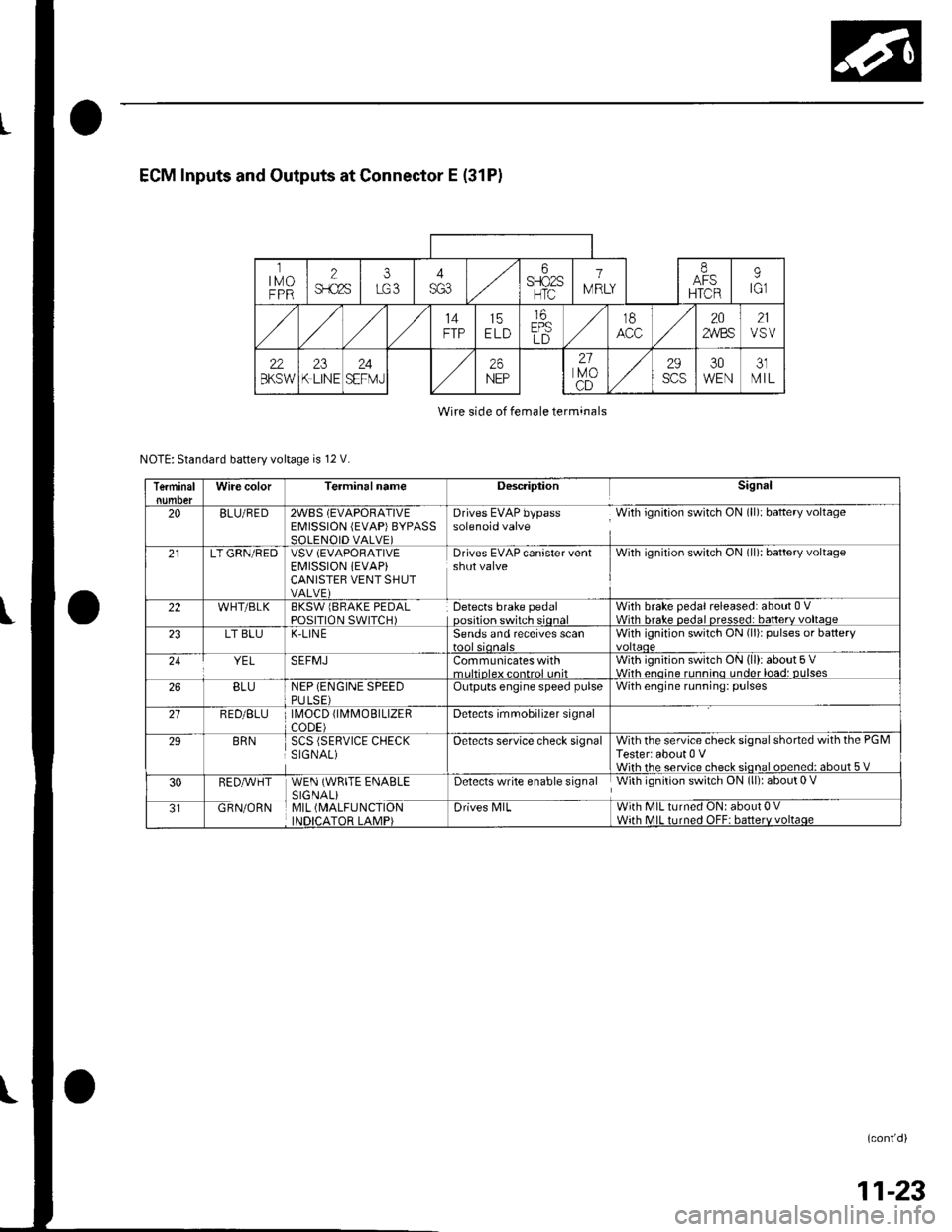

ECM lnputs and Outputs at Connector E (31P}

L

u

1iMoFPR

2sr-{]zs3LG34SG3

6$1025HTC

1M RLY

8AFSHTCR

I

14FTP15ELD

16EPSLD

18ACC20Z/VBS21VSV

22BKSW23K-LINE24SEFMJ26NEP

21rMoCD

29scs30WEN31MIL

Wire side of female terminals

NOTE: Standard battery voltage is '12 V.

TerminalnumberWire colorferminal nameDescription Signal

GRNI/ELIMO FPR (IMMOBILIZERFLJEL PUMP RELAYIDrives PGM Fl main relay 20Vfor2 seconds after turning ignition switch ON{ll). then batterv voltaoe2WHT/REDSHO2S (SECONDARYHEATED OXYGEN SENSOR(SECONDARY HO2S),SENSOR 2r

Detects secondary HO2S{sensor 2) signalWith throttle Jully opened from idle with fullywarmed up engine: above 0.6VWith throttle quickly closed: below 0.4 V

3BRN/YELLG3 (LOGIC GROUND)cround forthe ECM/PCMcontrolcircuitLess than 1.0 V at all times

4PNKSG3 {SENSOR GBOUND)Sensor oroundLess than 1.0 V at all times5YEUELUVCC3 {SENSOR VOLTAGE)Provides sensor voltageWith ignition switch ON (ll): about 5 VWith ionition switch OFF: about 0 V6BLKATr'HTSO25HTC (SECONDARYHEATED OXYGEN SENSOR(SECONDARY H02S)HEATER CONTROL)

Drives secondary HO2SheaterWith ignition switch ON (ll): baftery voltageWilh fullv warmed up engine running: dul,controlled

1REDA/ELMRLY (PGM.FI MAINRELAY}Drives PGM-Flmain relay 1Power source forthe DTCWith ignition switch ON (ll): about 0 VWith ignition switch OFF: battery voltage

IORNAFSHTCR {AIR FUEL BATIO(Iy'F)SENSOR HEATERCONTROL RELAY)

Drives air fuel ratio sensorheater relayWith ignition swirch ON {ll): 0 V

IYEUBLKIGl (IGNITION SIGNAL)Detecrs ignition signalWith ignition switch ON (ll): battery voltageWith iqnition switch OFF: about 0 V't4LT GRNFIP lFUEL TANKPRESSURE (FTP) SENSOR)Detects FTP sensor signalWith ignition switch ON (ll) and fuel fill cap open:about 2.5 VGRN/REDELD (ELECTRICAL LOADDETECTOF)Detects ELD signalWith ignition swjtch ON itt):aOoutO.t V l-gV(deDendino on electrical load)LT GRN/8LKEPSLD (ELECIRICALPOWEB STEEBING LOADDETECT)

Detects Power steering loadsrgnalAt idle with steering wheel in straight aheadposition: about 0 VAt idle with steering wheelatfull lock: momentary

'18REDACC (Ay'C CLUTCH RELAY)Drives P,/C clutch relayWith compressor ON: about 0 VWith comoressor OFF: batterv voltaoe

11-22

\-

Page 230 of 1139

ECM Inputs and Outputs at Connector E (31P)

ltMoFPR

2$.c2s

i6SFIO2SHTC

1

IV RLY

IAFSHTCR

9tGl

14FTP15ELD

16EPSLD

t8202,4/BS21VSV

22BKSW23K LINE24SEFMJ26NEP

21lvoCD

29scs30WEN31MIL

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

TerminalWire colorTerminalnameDescriptionSignal

20BLU/RED2WBS (EVAPORATIVEEMISSION (EVAP)BYPASSSOLENOID VALVE)

Drives EVAP bypass With ignition switch ON (ll): baftery voltagesolenoid valve

21LT GRN/REDVSV (EVAPORATIVE

EI\4ISSION iEVAP)CANISTEB VENT SHUTVALVE)

Drives EVAP canister ventshut valveWith ignilion switch ON (ll): battery voltage

22WHT/BLKBKSW lBRAKE PEDALPOSITION SWITCH)Detects brake pedaloosition switch sionalWith brake pedal released: about 0 VWith hrake nedal nresse.l: batterv voltaoe23LT BLUK-LIN ESends and receives scanWith ignition switch ON (li)r pulses or battery

YELSEFMJCommunicates withmrltinleY eontrol unitWith ignition switch ON (ll): about 5 VWith enoine runnino under load: DUlses26BLUNEP (ENGINE SPEEDPULSE)Outputs engine speed pulseWith engine running: pulses

21RED/BLU \40CD fl\4MOBTLTZERCODE)Detects imrnobilizer signal

29BRNSCS (SERVICE CHECKSIGNAL)Oetects service check signalWith the service check signal shorted with the PGMTester: about 0 VWiih rhe service check sional ooened: about 5 V

30RED,A/VHTWEN (WRITE ENABLESIGNALiDetects write enable signal With ignition switch ON (ll): about 0 V

GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP)Drives N4lLWith MIL turned ON: about 0 VWith MIL turned OFF: batterv voltaqe

(cont'd)

11-23

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

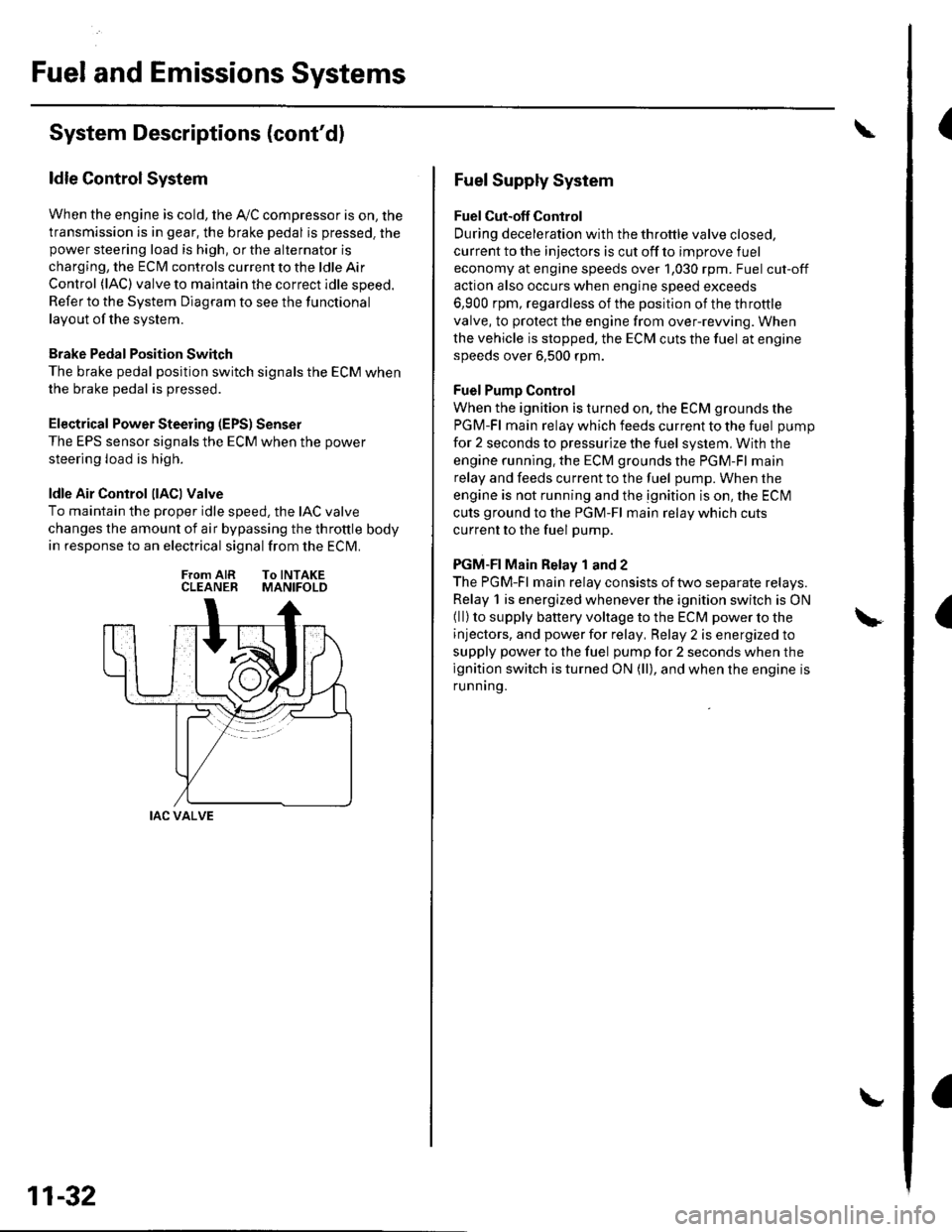

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.

Page 342 of 1139

15. Check for continuity between body ground and

ECIM connector terminal 813.

ECM CONNECTOR B I24P}

Wire side of female terminals

ls there continuity?

YES Repair short in the wire between the ECM

(813) and the alternator.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck lsee page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

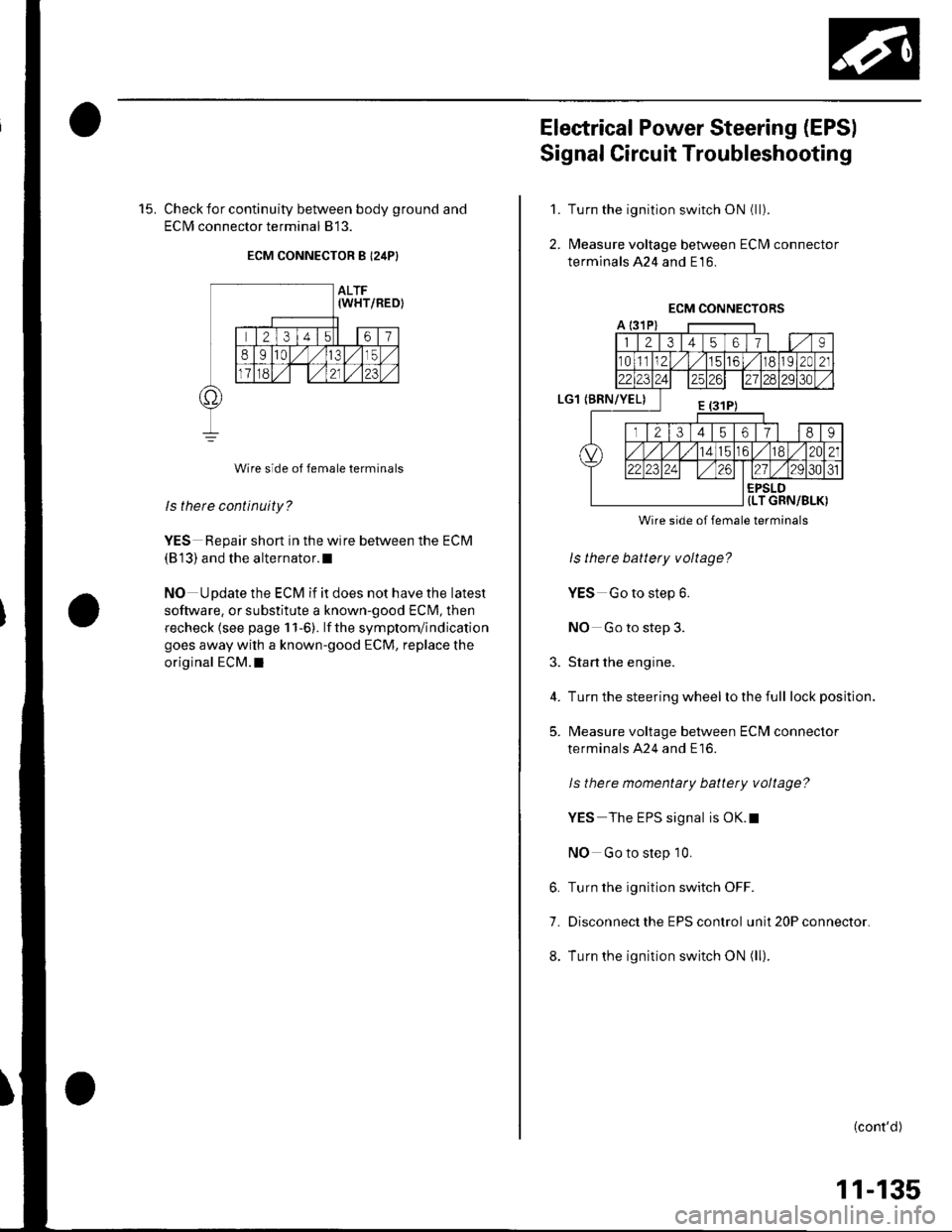

Electrical Power Steering (EPSI

Signal Circuit Troubleshooting

Turn the ignition switch ON (ll).

l\4easure voltage between ECM connector

terminals 424 and E16.

1.

2.

3.

4.

5.

Wire side of female terminals

ls there battery voltage?

YES Go to step 6.

NO Go to step 3.

Start the engine.

Turn the steering wheel lo the full lock position.

l\4easure voltage between ECM connector

terminals A24 and E16.

ls there momentaty battery voltage?

YES The EPS signal is OK.t

NO Go to step 10.

6. Turn the ignition switch OFF.

7. Disconnect the EPS control unit 20P connector.

8. Turn the ignition switch ON (ll).

(cont'd)

11-135

Page 343 of 1139

ldle Control System

Electrical Power Steering (EPSI Signal Circuit Troubleshooting (cont'd)

9. Measure voltage between EPS control unitterminal

No.l7 and body ground.

EPS CONTROL UNIT 2OP CONNECTOR

Wire side of female terminals

ls there battety voltage?

YES-Substitute a known-good EPS control unit

and recheck.I

NO- Repair open in the wire between the ECM(E 16) and the EPS control unit.l

Turn the ignition switch OFF.

Disconnect the EPS control unit 20P connector.

Turn the ignition switch ON (ll).

10.

I '�I.

12.

11-136

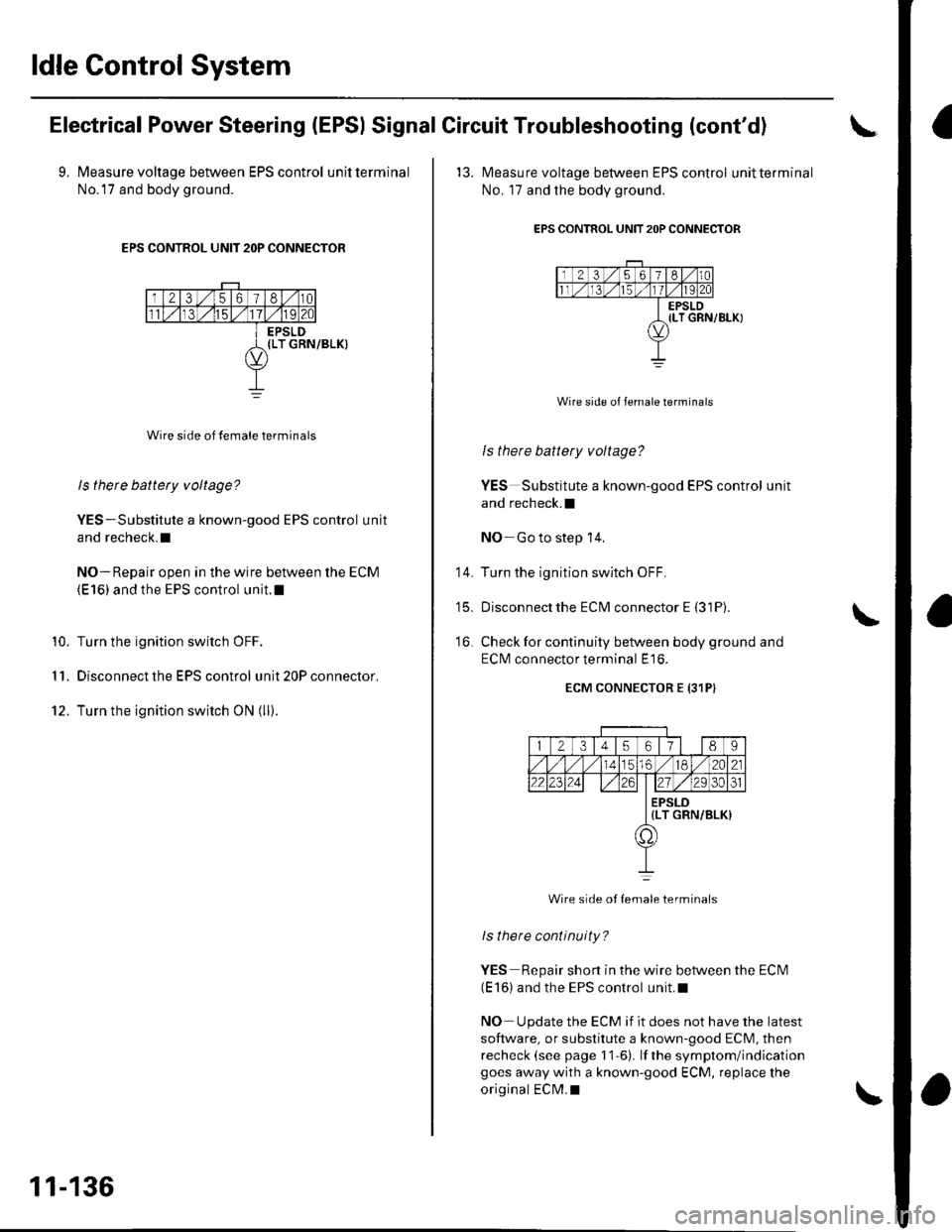

'13. l\4easure voltage between EPS control unitterminal

No. 17 and the body ground.

EPS CONTROL UNIT 2OP CONNECTOR

Wire side of female terminals

ls there battery voltage?

YES Substitute a known-good EPS control unit

and recheck.l

NO-Go to step 14,

Turn the ignition switch OFF.

Disconnectthe ECM connector E {31P).

Check for continuity between body ground and

ECI\4 connector terminal E16.

ECM CONNECTOR E {31PI

14.

t5_

16.

12345617l 189

56./182A21

2223zi ./29 30ol

EPSLD{LT GRN/BLK)

a,

Wire side ot Iemale terminals

lsthere continuity?

YES Repair short in the wire between the ECN4(E 16) and the EPS control unit.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

Page 363 of 1139

Fuel Supply System

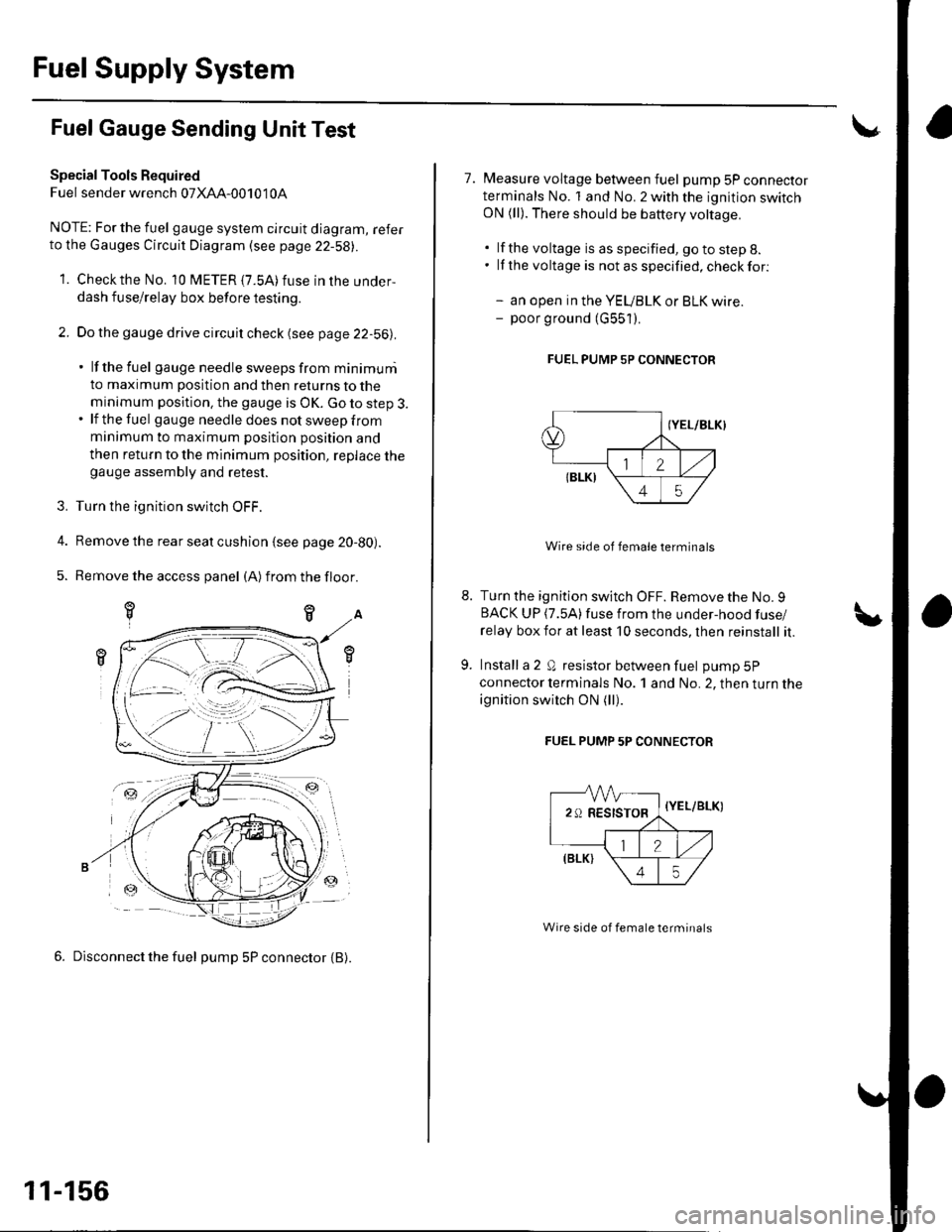

Fuel Gauge Sending Unit Test

Special Tools Required

Fuel sender wrench 07XAA-001010A

NOTE; For the fuel gauge system circuit diagram, referto the Gauges Circuit Diagram (see page 22-58||.

1. Checkthe No. 10 fUETER {7.5A)fuse in the under-

dash fuse/relay box before testing.

2. Do the gauge drive circuit check (see page 22-56|l.

' lf the fuel gauge needle sweeps from minimuni

to maximum position and then returns to the

minimum position. the gauge is OK. Go to step 3.. lf the fuel gau ge need le does not sweep from

minimum to maximum position position and

then return to the minimum position, replace thegauge assembly and retest.

3. Turn the ignition switch OFF.

4. Remove the rear seat cushion {see page 20-80).

5. Remove the access panel (A)from the floor.

6. Disconnect the fuel pump 5P connector {B).

-ztr

11-156

7. Measure voltage between fuel pump 5P connectorterminals No. 1 and No. 2 with the ignition switchON (ll). There should be battery voltage.

. lf the voltage is as specified, go to step 8.. lf the voltage is notasspecified,checkfor:

- an open in the YEUBLK or BLK wire.- poor ground (G551).

FUEL PUMP 5P CONNECTOR

Wire side of female terminals

Turn the ignition switch OFF. Remove the No. 9BACK UP (7.5A)fuse from the under-hood fuse/

relay box for at least 10 seconds, lhen reinstall it.

Install a 2 Q resistor between fuel pump 5P

connector lerminals No. 1 and No. 2, then turn the

ignition switch ON (ll).

FUEL PUMP 5P CONNECTOR

-VVV-

29RESISTOR,

=-a

{Y

\

//,(elrt \

\45/

{YEL/BLK)

Wire side of female terminals

Page 374 of 1139

Catalytic Converter System

DTC Troubleshooting

DTC P0420: Catalytic System Efficiency

Below Threshold

NOTE: lf some of the DTCS listed below are stored at

the same time as DTC P0420, troubleshoot those DTCS

first, then recheck for DTC P0420.

P0137, P0138: Secondary Heated Oxygen Sensor(secondary HO2S) (Sensor 2)

P0141: Secondary HO2S (Sensor 2) heater

1. Reset the ECM {see page 1'l-4}, then continue to

step 2 through 5 to reset the readiness code.

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) untilthe radiator fan comes on.

Drive for about l0 minutes without stopping. Your

speeo can vary.

With the transmission in 4th gear, drive at a steady

speed between 50 62 mph (80-'100 km/h) for

30 seconds.

Repeat step 4 three times. Between each repetition,

close the throttle completely for 1 2 seconds. lf

the engine is stopped during this part of the

procedure, repeat steps 3, 4 and 5.

Check for a Temporary DTC with the scan tool.

Does the scan tool indicate Temporaty DTC

P0420?

YES Check the TWC. lf necessary, replace the

TWC.I

NO Check for readiness code completion. lfthe

readiness is complete, it was a interminent failure,

and the system is OK at this time. lf the readiness

code is incomplete, repeat steps 2 through 5.1

4.

11-167

Page 406 of 1139

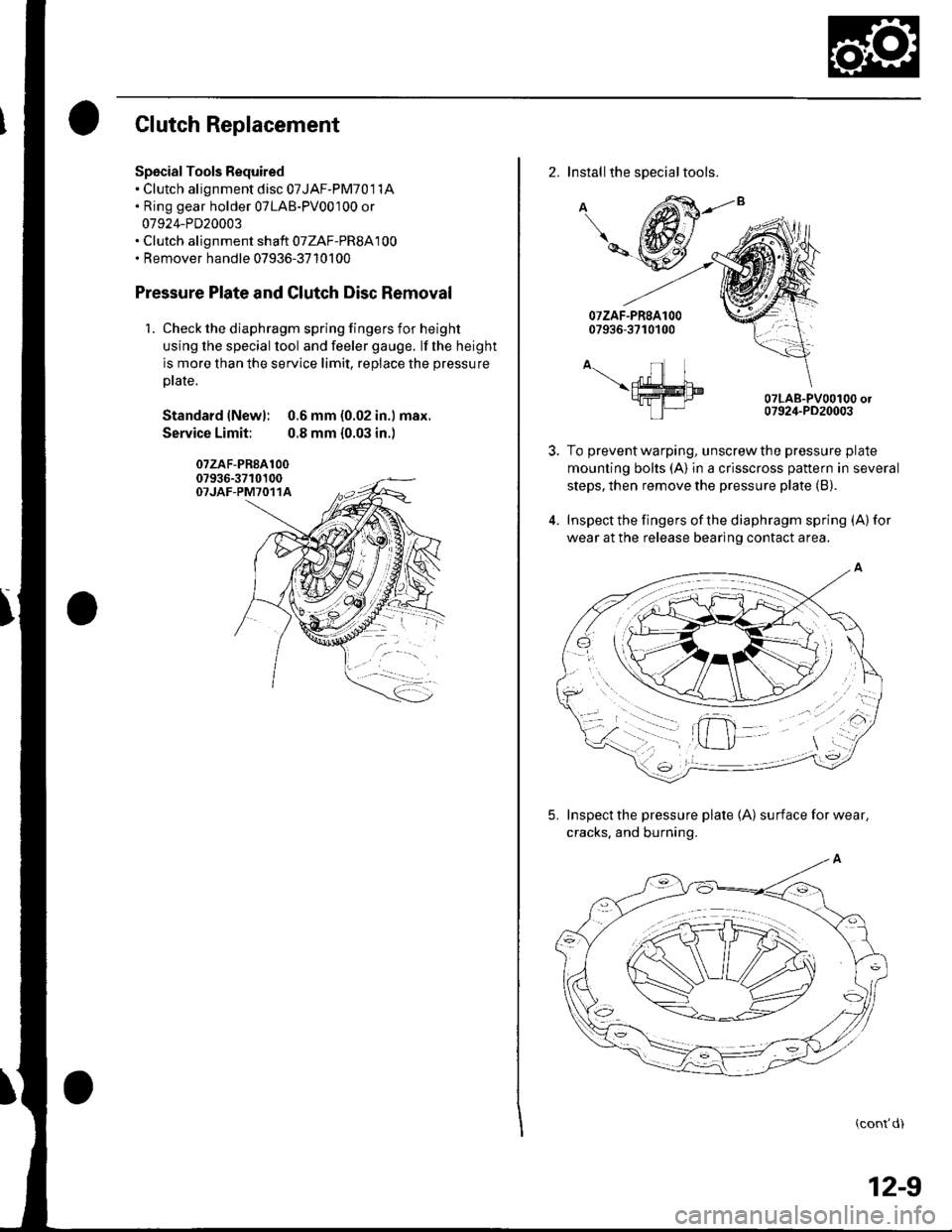

Clutch Replacement

Spscial Tools Required. Clutch alignment disc 07JAF-PM701 1A. Ring gear holder 07LAB-PV00100 or

07924-PD20003. Clutch alignment shaft 07ZAF-PR8A100. Remover handle 07936-3710100

Pressure Plate and Glutch Disc Removal

1. Check the diaphragm spring fingers for height

using lhe special lool and feeler gauge. lf the height

is more than the service limit, replace the pressure

ptate.

Standard lNewl: 0.6 mm (0.02 in.) max.

Service Limit: 0.8 mm {0.03 in.)

07zAF-PR8A10007936-3710100OTJAF-PM7O11A

2. Installthe special tools.

A

\-

A-.- nl I\ffim9fra-I tP|-

07LAB-PV00100 or07924-PD20003

To prevent warping, unscrew the pressure plate

mounting bolts (A) in a crisscross pattern in several

steps, then remove the pressure plate (B).

Inspect the fingers of the diaphragm spring (A) for

wear at the release bearing contact area.

5. Inspect the pressure plate 1A) surfaceforwear,

cracks. and burning.

(cont'd)

12-9

Page 408 of 1139

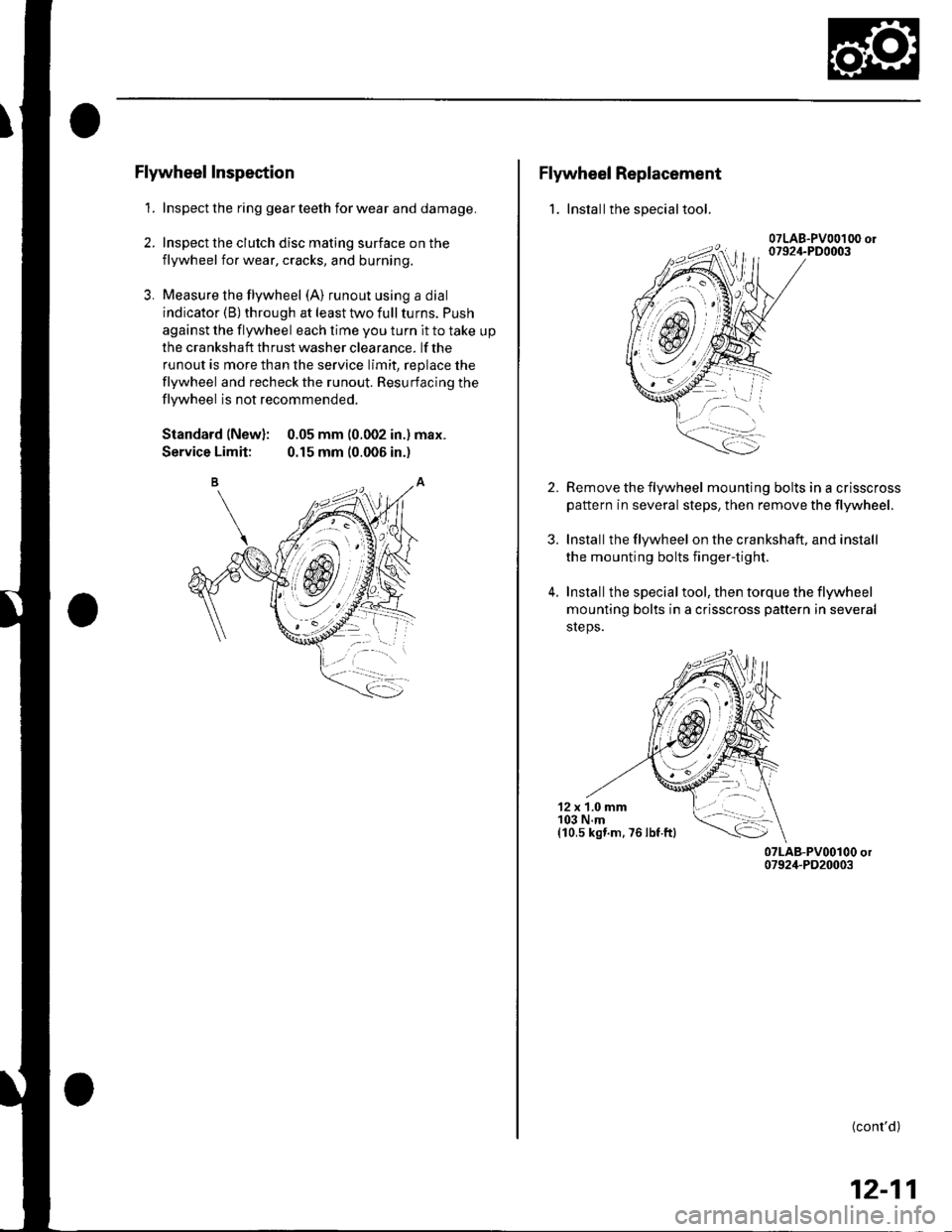

Flywheel Inspection

1. Inspect the ring gear teeth for wear and damage.

2. Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

3. Measure the flywheel (A) runout using a dial

indicator (B) through at least two full turns. Push

against the flywheel each time you turn it to take up

the cra nksh aft th rust washer clea rance. lf the

runout is more than the service limit, replace the

flywheel and recheck the runout. Resurfacing the

flywheel is not recommended.

Standard (New): 0.05 mm (0.002 in.) max.

Service Limit: 0.15 mm (0.006 in.)

Flywheel Replacement

1. Installthe special tool.

2.

3.

4.

Remove the flywheel mounting bolts in a crisscross

pattern in several steps, then remove the tlywheel.

Installthe flywheel on the crankshaft, and install

the mounting bolts fingertight.

Installthe specialtool, then torque the flywheel

mounting bolts in a crisscross pattern in several

sreps.

12 x 1.0 mm103 N.m(10,s kst.m. 76 lbf ftl

(cont'd)

12-11

Page 409 of 1139

Glutch

Clutch Replacement (cont'dl

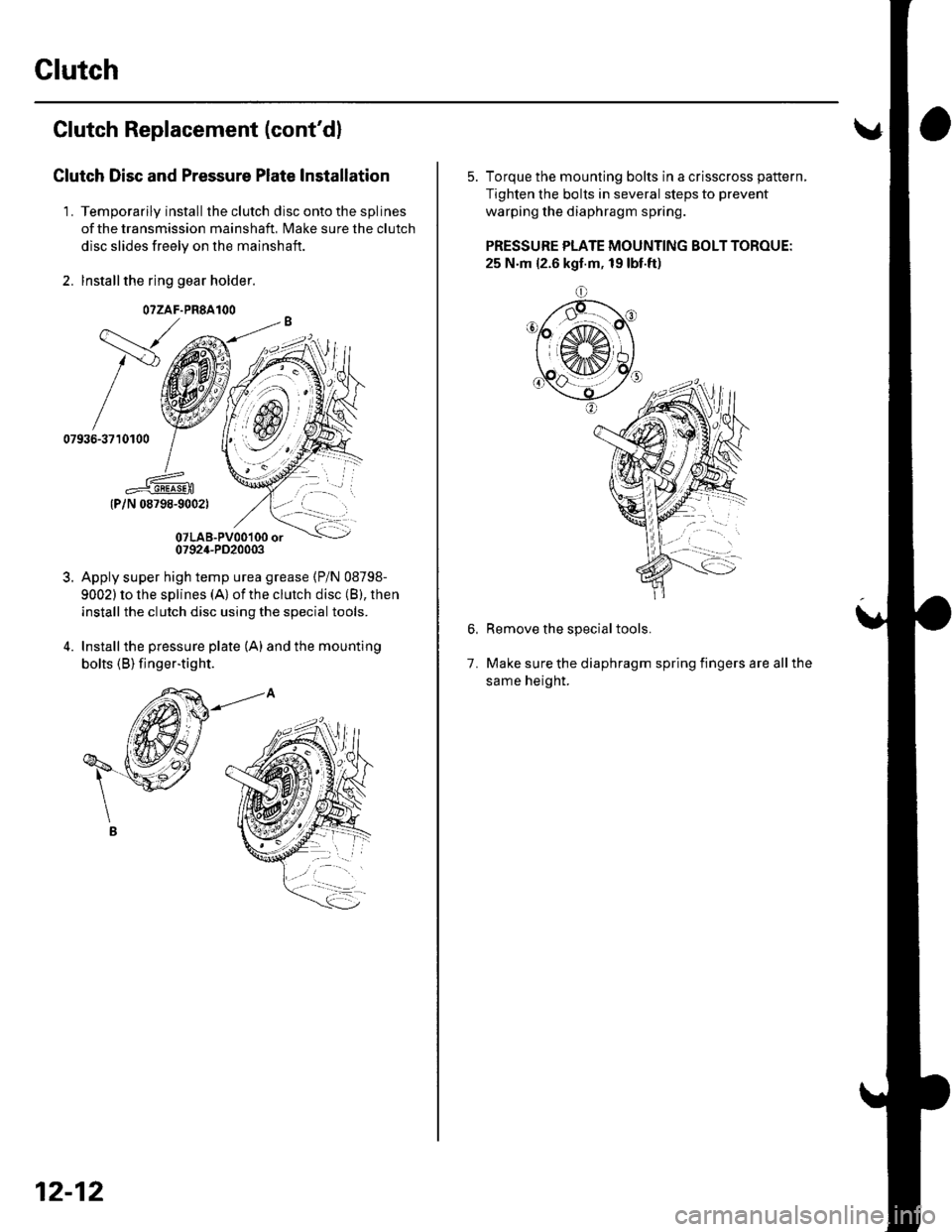

Clutch Disc and Pressure Plate Installation

'L Temporarily install theclutch disc ontothesplines

of the transmission mainshaft, Make sure the clutch

disc slides freely on the mainshaft.

2. lnstallthe ring gear holder.

{P/N 08798-9002)

07LAB-PVo0'100 or0792,1-PD20003

Apply super high temp urea grease (P/N 08798-

9002) to lhe splines (A) of the clutch disc (B), then

install the clutch disc using the special tools.

Installthe pressure plate (A) and the mounting

bolts (B) finger-tig ht.

\---,

/v

07936-3710100

3.

O?ZAF.PRSAIOO

12-12

5. Torque the mounting bolts in a crisscross pattern,

Tighten the bolts in several steps to prevent

warping the diaphragm spring.

PRESSURE PLATE MOUNTING BOLT TOROUE:

25 N.m {2.6 kgt.m, 19 lbt.ft)

o

Remove the special tools.

Make sure the diaphragm spring fingers are all the

same height.

1.