EPS HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 453 of 1139

Mainshaft Thrust Clearance Adiustment

Special Tools Required. Mainshaft base 07GAJ-PG20130. Mainshaft holder 07GAJ-PG20110

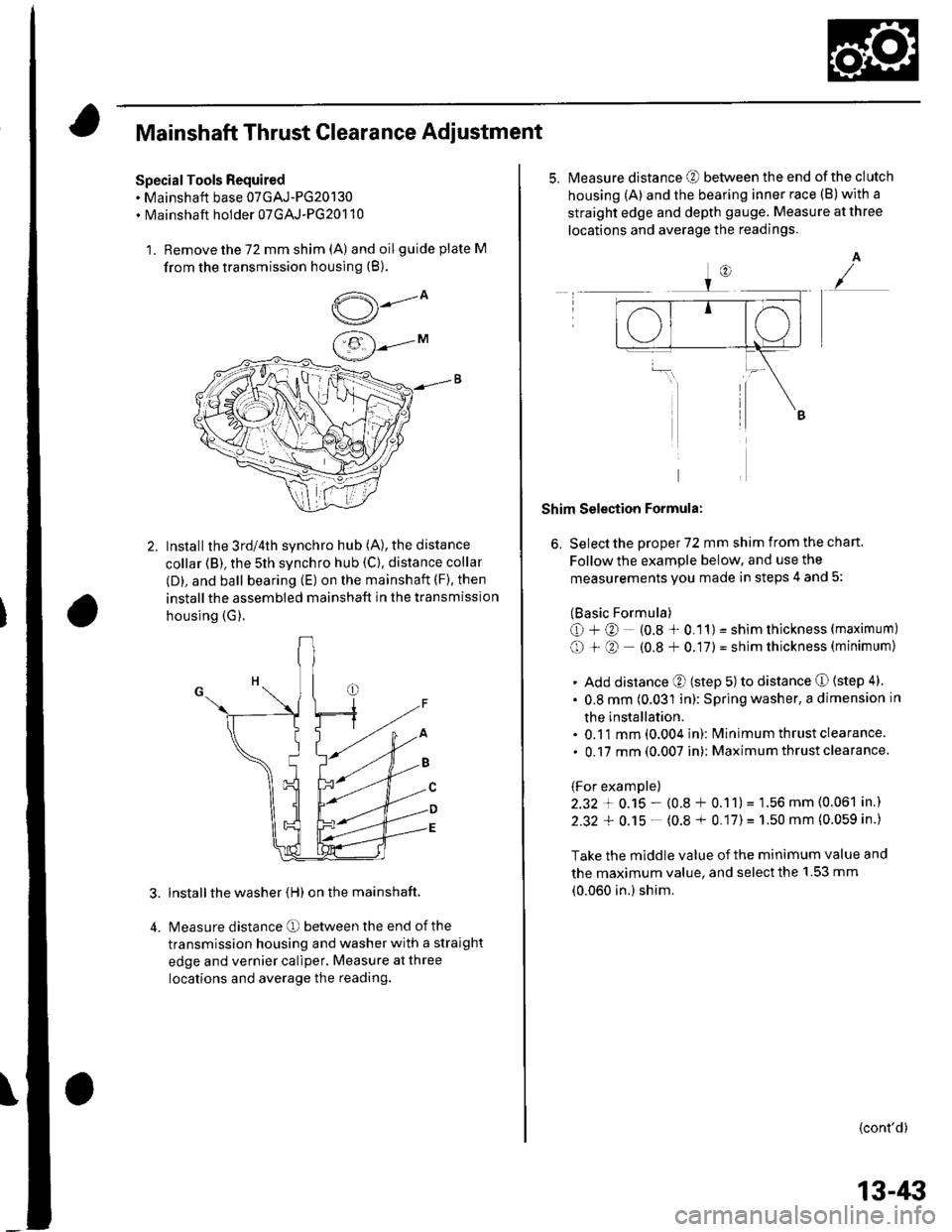

1. Remove the 72 mm shim (A) and oilguide plate M

from the transmission housing (B).

,5---ov/

Installthe 3rd/4th synchro hub (A), the distance

collar (B), the 5th synchro hub {C). distance collar

(D), and ball bearing (E) on the mainshaft (F), then

installthe assembled mainshaft in the transmission

housing (G).

lnstall the washer (H) on the mainshaft.

Measure distance O between the end of the

transmission housing and washer with a straight

edge and vernier caliper. Measure at three

locations and average the reading.

5.Measure distance @ between the end of the clutch

housing (A) and the bearing inner race (B)with a

straight edge and depth gauge. Measure at three

locations and average the readings.

A

Shim Selection Formula:

6, Select the proper 72 mm shim from the chan.

Follow the example below, and use the

measurements you made in steps 4 and 5:

(Basic Formula)

O+@ (0.8 * 0.11) = shim thickness (maximum)

O + O (0.8 + 0.17) = shim thickness (minimum)

. Add distance O (step 5) to distance O (step 4)

. 0.8 mm (0.031 in): Spring washer, a dimension in

the installation.. 0.11 mm (0.004 in): lvlinimum thrust clearance

. 0.17 mm (0.007 in): Maximum thrust clearance.

(For example)

2.32 + 0.15 - (0.8 + 0.11)= 1.56 mm (0.061 in.)

2.32 + 0.15 - (0.8 + 0.17)= 1.50 mm (0.059 in.)

Take the middle value of the minimum value and

the maximum value, and select the 1.53 mm

(0.060 in.) shim.

{cont'd)

13-/li|

Page 463 of 1139

\

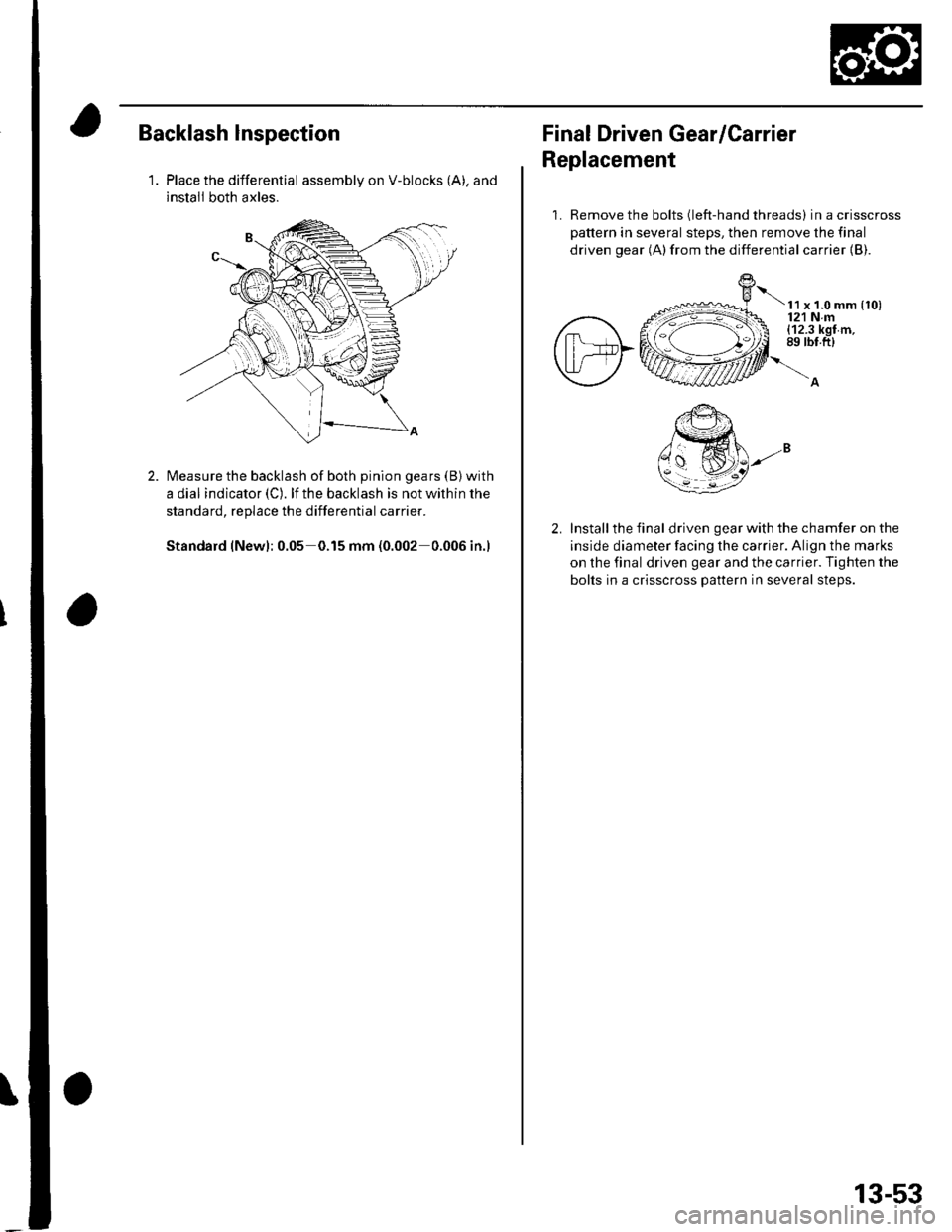

Backlash lnspection

1.Place the differential assembly on V-blocks (A), and

install both axles.

Measure the backlash of both pinion gears (B) with

a dial indicator (C). lf the backlash is not within the

standard, replace the differential carrier.

Standard (New): 0.05 0.15 mm (0.002 0.006 in.)

Final Driven Gear/Carrier

Replacement

1. Remove the bolts (left-hand threads) in a crisscross

pattern in several steps, then remove the final

driven gear (A)from the differential carrier {B).

t x t.o mm {to)121 Nm(12.3 kgf m,89 rbt.ft)

Install the final driven gear with the chamfer on the

inside diameter facing the carrier. Align the marks

on the final driven gear and the carrier. Tighten the

bolts in a crisscross pattern in several steps.

13-53

Page 466 of 1139

M/T Differential

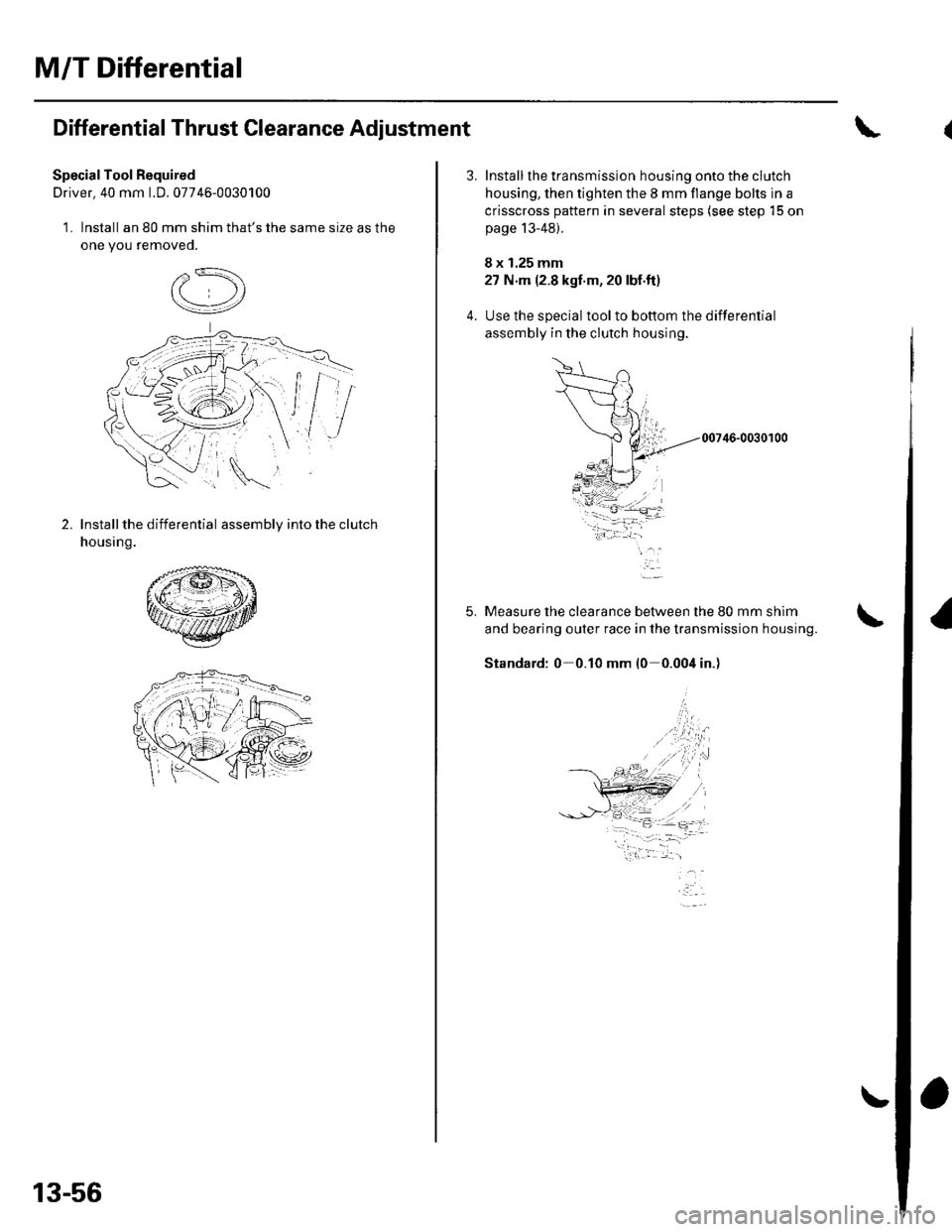

Differential Thrust Clearance Adjustment

SpecialTool Required

Driver. 40 mm LD. 07746-0030100

1. Install an 80 mm shim that's the same size as the

one you removeo.

2.Install the differential assembly into the clutch

housing.

13-56

5.

Install the transmission housing onto the clutch

housing, then tighten the 8 mm flange bolts in a

crisscross pattern in several steps (see step 15 on

page 13-48).

8 x 1.25 mm

27 N m (2.8 kgf'm, 20 lbf.ft)

Use the special toolto bottom the differential

assembly in the clutch housing.

00746-0030100

Measure the clearance between the 80 mm shim

and bearing outer race in the transmission housing.

Standard: 0 0.10 mm l0 0.004 in.)

-i.w.t ..1-- -- :,- -=.

Page 481 of 1139

Driveline/Axle

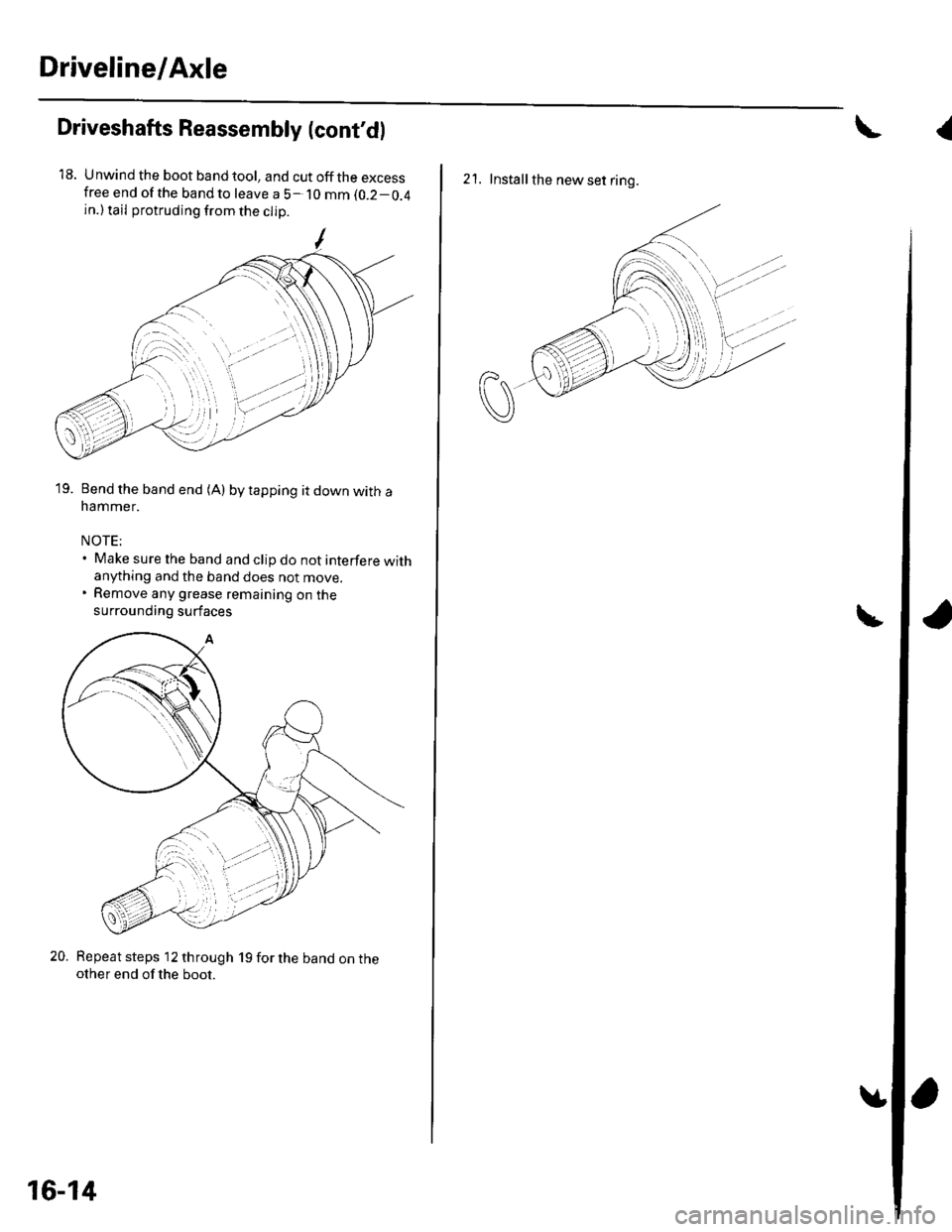

Driveshafts Reassembly (cont'dl

18. Unwind the boot band tool, and cut off the excessfree end of the bandto leave a 5- 10 mm (0.2-0.4

in.) tail protruding from the clip

19. Bend the band end (A) by tapping it down with anammer.

NOTE;. Make sure the band and clip do not interfere withanything and the band does not move.. Remove any grease remaining on the

surrounding surfaces

20. Repeat steps 12 through 19 for the band on theother end of the boot.

16-14

{

2'1. Installthe new set ring.

Page 484 of 1139

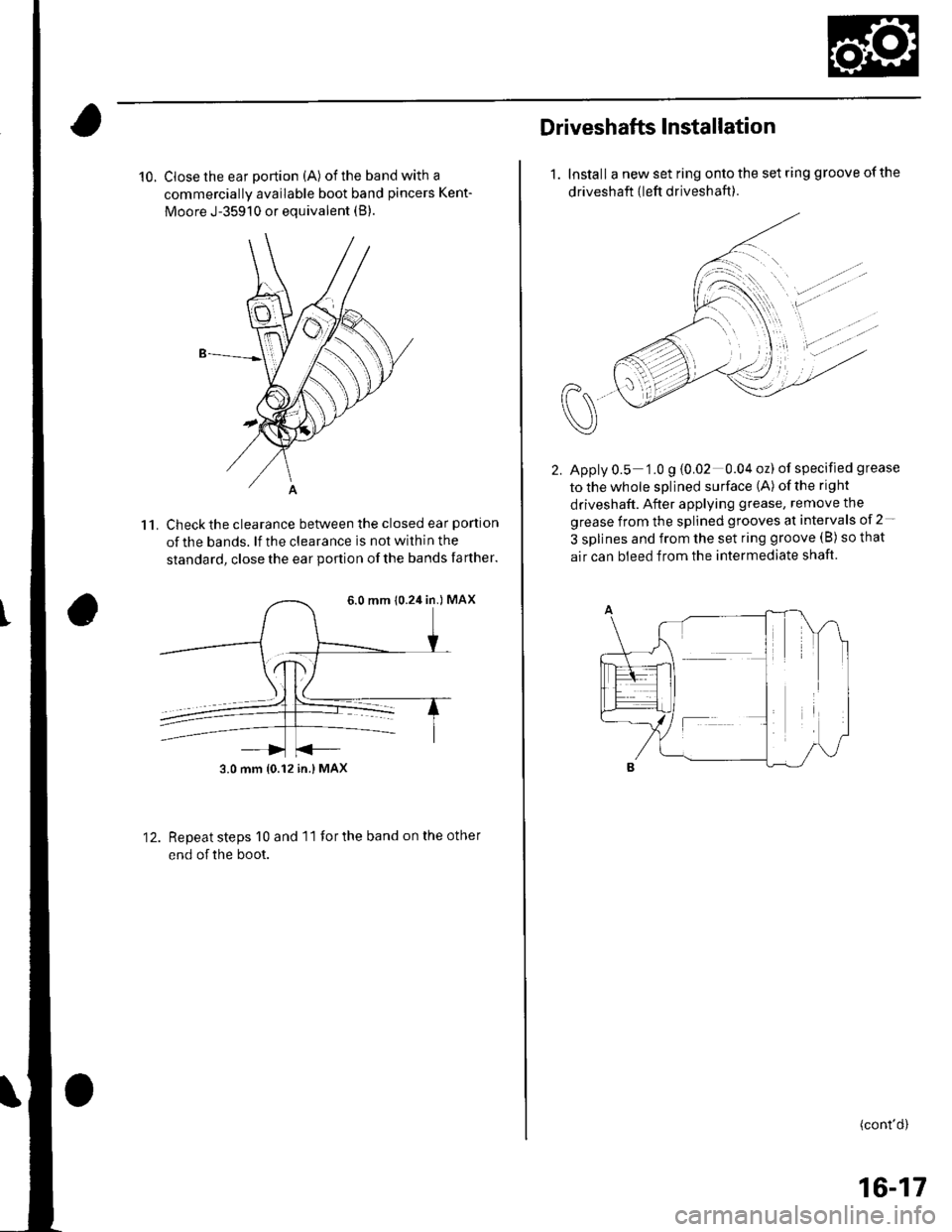

10. Close the ear portion (A) of the band with a

commercially available boot band pincers Kent-

Moore J-35910 or equivalent (B).

Check the clearance between the closed ear portlon

of the bands. lf the clearance is not within the

standard, close the ear podion of the bands farther.

11.

12.Repeat steps 10 and 11 for the band on the other

end of the boot.

6.0 mm 10.24 in.) MAX

3.0 mm {0.12 in.} MAX

Driveshafts Installataon

1. Install a new set ring onto the set ring groove of the

driveshaft {left driveshaft ).

Apply 0.5 1.0 g {0.02 0.04 oz) of specified grease

tothewhole splined surface (A) ofthe right

driveshaft. After applying grease, remove the

grease from the splined grooves at intervals of 2-

3 splines and from the set ring groove (B) so that

air can bleed from the intermediate shaft.

(cont'd)

16-17

Page 493 of 1139

Steering

Steering

Special Tools ............. 17-2

Comoonent Location Index ......................................... 17-3

Steering Wheel Rotational Play Check .....................". 17-4

Power Assist Check .................. .......... 17-4

Steering Linkage and Gearbox Inspection ................. 17-5

Steering Wheel Removal .........................,................... 17-6

Steering Wheel Disassembly/Reassembly ................ 17-7

Steering Wheel Installation ............... 17-8

Steering Column Removal and Installation ...........'... 17-9

Steering Column Inspection .............. 17-11

Steering Lock Replacement .......................................'. 17-'12

Rack Guide Adiustment ....."........'..'.. 17-13

Electrical Power Steering (EPS)17-15

Page 496 of 1139

Steering

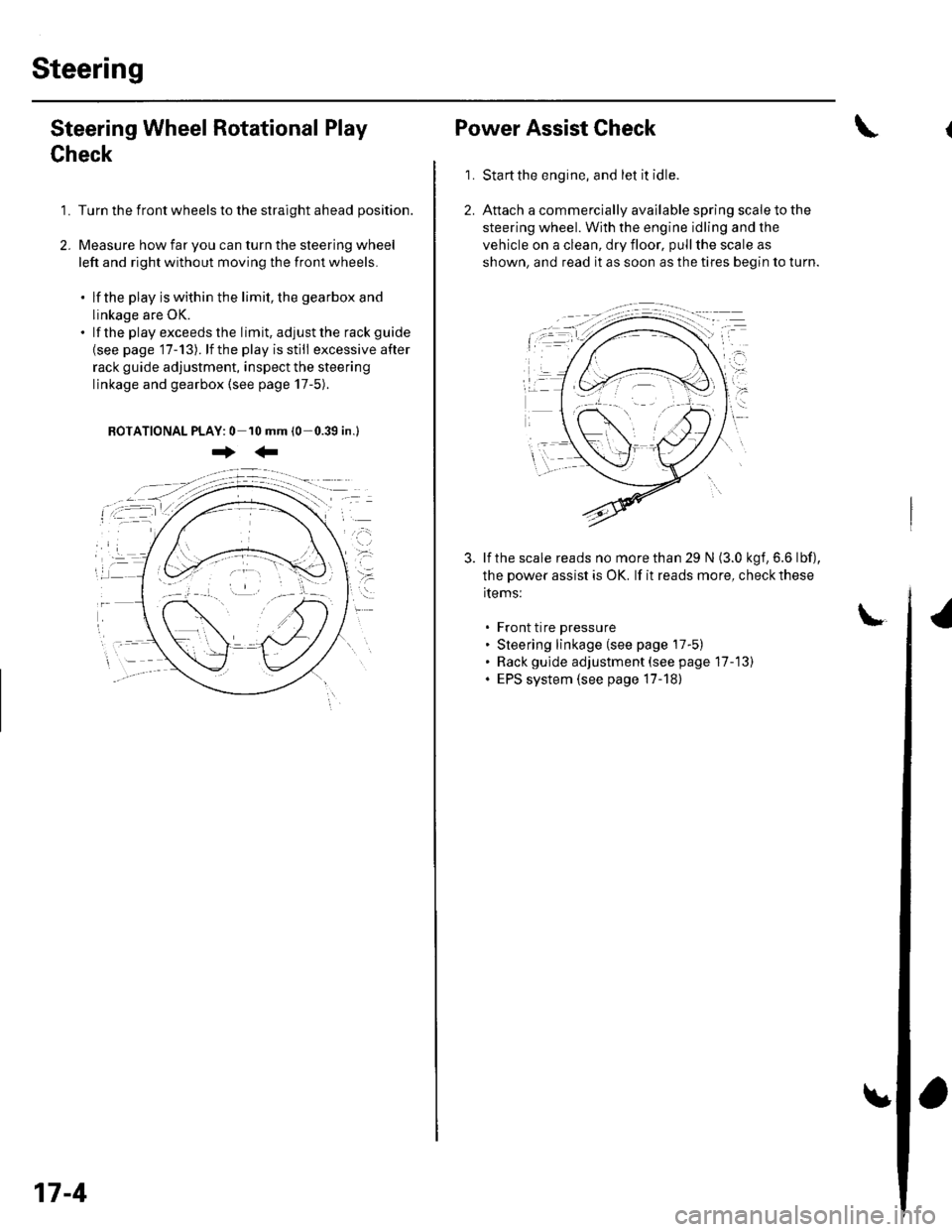

Steering Wheel Rotational Play

Check

1. Turn the front wheels to the straight ahead position.

2. Measure how far you can turn the steering wheel

left and right without moving the front wheels.

. lf the play is within the limit, the gearbox and

linkage are OK.. lf the playexceedsthe limit, adjustthe rack guide

{see page '17-13). lf the play is still excessive after

rack guide adjustment, inspect the steering

linkage and gearbox {see page 17-5).

BOTATIONAL PLAY: 0 10 mm (0-0.39 in.l

+:

17-4

Power Assist Check

Start the engine, and let it idle.

Attach a commercially available spring scale to the

steering wheel. With the engine idling and the

vehicle on a clean, dry floor, pull the scale as

shown, and read it as soon as the tires begin to turn.

\

1.

3. lf the scale reads no morethan 29 N (3.0 kgf,6.6 lbf),

the power assist is OK. lf it reads more, check these

items:

. Front tire pressure. Steering linkage (see page 17-5). Rack gulde adjustment (see page 17-13). EPS system (see page 17-18)

Page 506 of 1139

Electrical Power Steering (EPSI

SpecialTools ............. 17 -16

Component Location Index ......................................... 17-17

General Troubleshooting Information ....................... 17-18

DTC Troubleshooting Index .............. 17-22

Symptom Troubleshooting Index ............................... 17 -23

System Description ................. ........... 17-24

Circuit Diagram ......... 17-26

DTC Troubleshooting ............... .......... 17-28

EPS lndicator Circuit Troubleshooting ....................... 17-47

Motor Removal/lnstallation ............... 17-49

Steering Gearbox Removal ............... 17-51

Steering Gearbox Overhaul ............... 17-55

Steering Gearbox Installation ........... 17-63

EPS Control Unit Remova l/lnsta llation ....................... 17-67

Tie-rod Ball Joint Boot Replacement .......................... 17-67

Page 507 of 1139

EPS Components

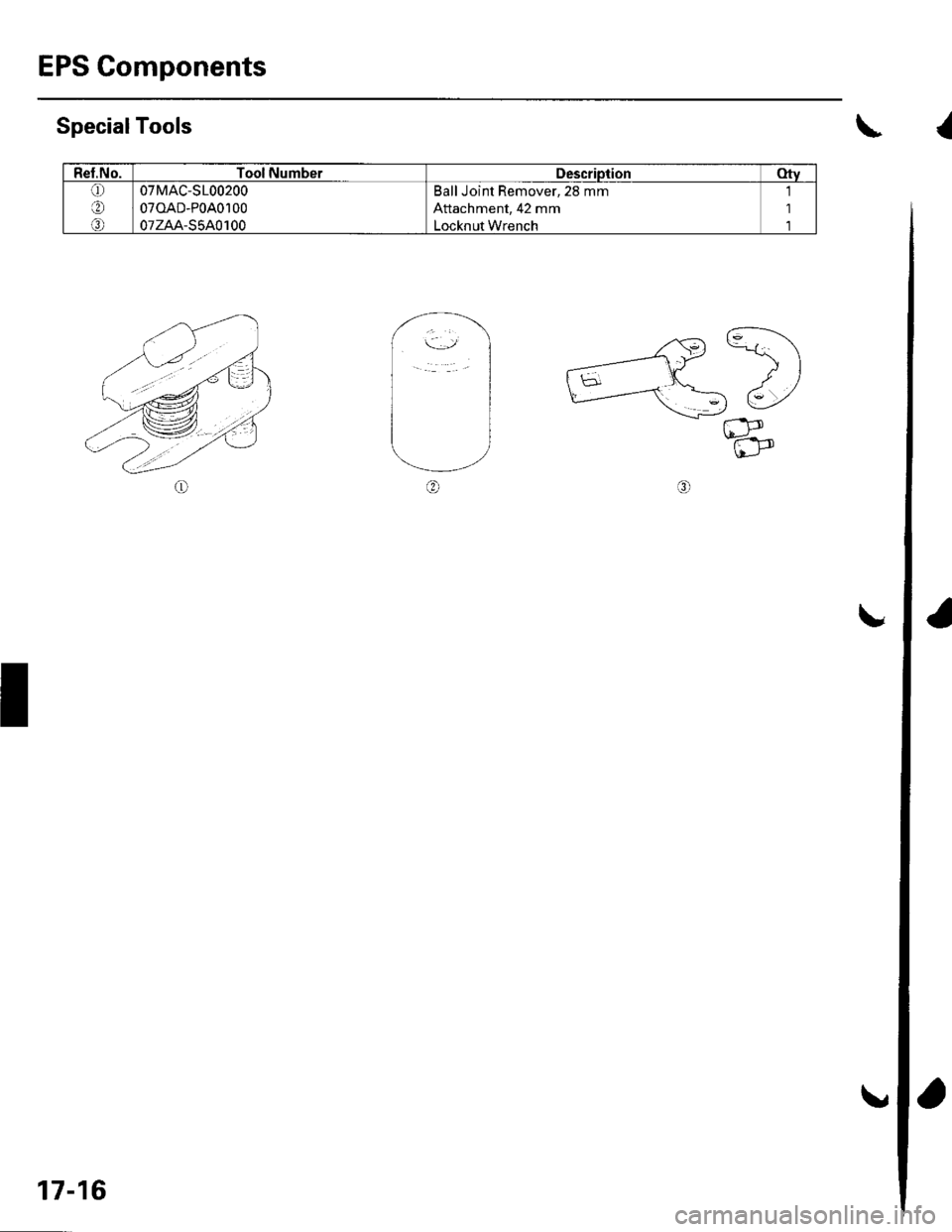

Rel.No.Tool NumberDescriptionotv(!)

at'

o

07MAC-S100200

070AD-P0A0100

07zAA-S5A0100

Ball Joint Remover, 28 mm

Attachment, 42 mm

Locknut Wrench

'1

1'l

SpecialTools\

,.^G) C\

_---1t

-)

)

h5--d-'

u_r-.c_-tt)\L-,

t

I

17-16

a

Page 508 of 1139

![HONDA CIVIC 2002 7.G Owners Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS HONDA CIVIC 2002 7.G Owners Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS](/img/13/5744/w960_5744-507.png)

Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,'/.,....

'.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENSOR

STEERING GEARBOXSteering Gearbox Removal, page 17-51Steering Gearbox Overhaul, page 17-55Steering Gearbox Installation, page 17-63

Removal/lnstallation,page l7-49

GAUGE ASSEMBLY

MOTOR

17-17