glove box HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 720 of 1139

Dashboard

Dashboard Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

NOTE:. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts to prevent damage.. Have an assistant help you when removing and

installing the dashboa rd.. Take care not to scratch the dashboard, body, and

other related parts.

. Put on gloves to protect your hands.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

Disconnect the negative cable from the battery, and

wait at least three minutes before beginning work.

Remove these items:

. Driver's dashboard lower cover (see page 20-59). Driver's dashboard under cover (see page 20-60). Passenger's dashboard lower cover (see page

20-63). Glove box (see page 20-63). Consoles, front and rear (see page 20-57). Shift lever trim {see page 20-61). Center panel (see page 20-62). Kick panels, both sides (see page 20-50). A-pillar trim. both sides (see page 20-50). Steering column (see page 17-9)

20-66

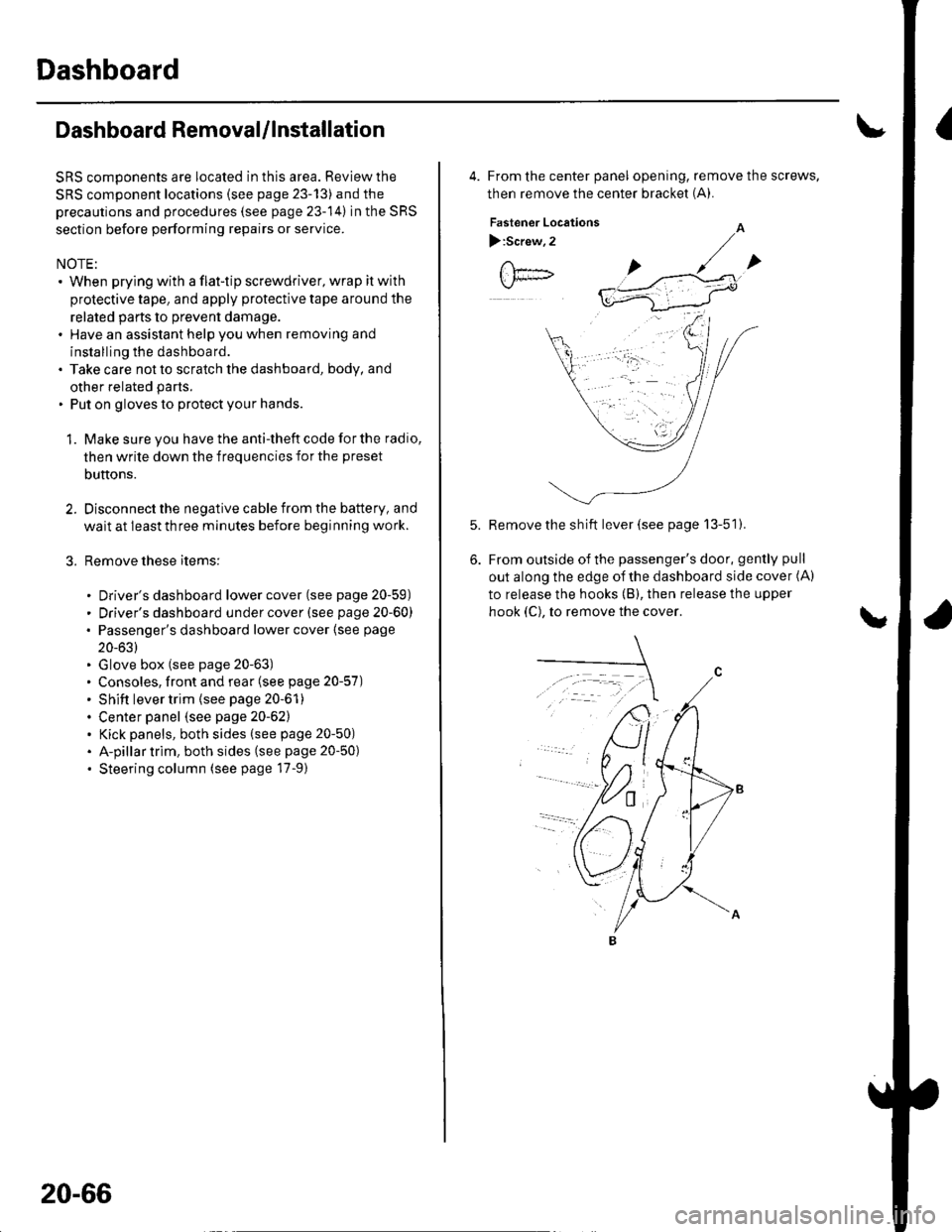

4. From the center panel opening, remove the screws,

then remove the center bracket (A).

Fastener Locations

):Screw,2

Remove the sh ift lever (see page 13-51).

From outside of the passenger's door, gently pull

out along the edge of the dashboard side cover (A)

to release the hooks (B), then release the upper

hook (C), to remove the cover.

Page 722 of 1139

Dashboard

Dashboard Removal/lnstallation

(cont'd)

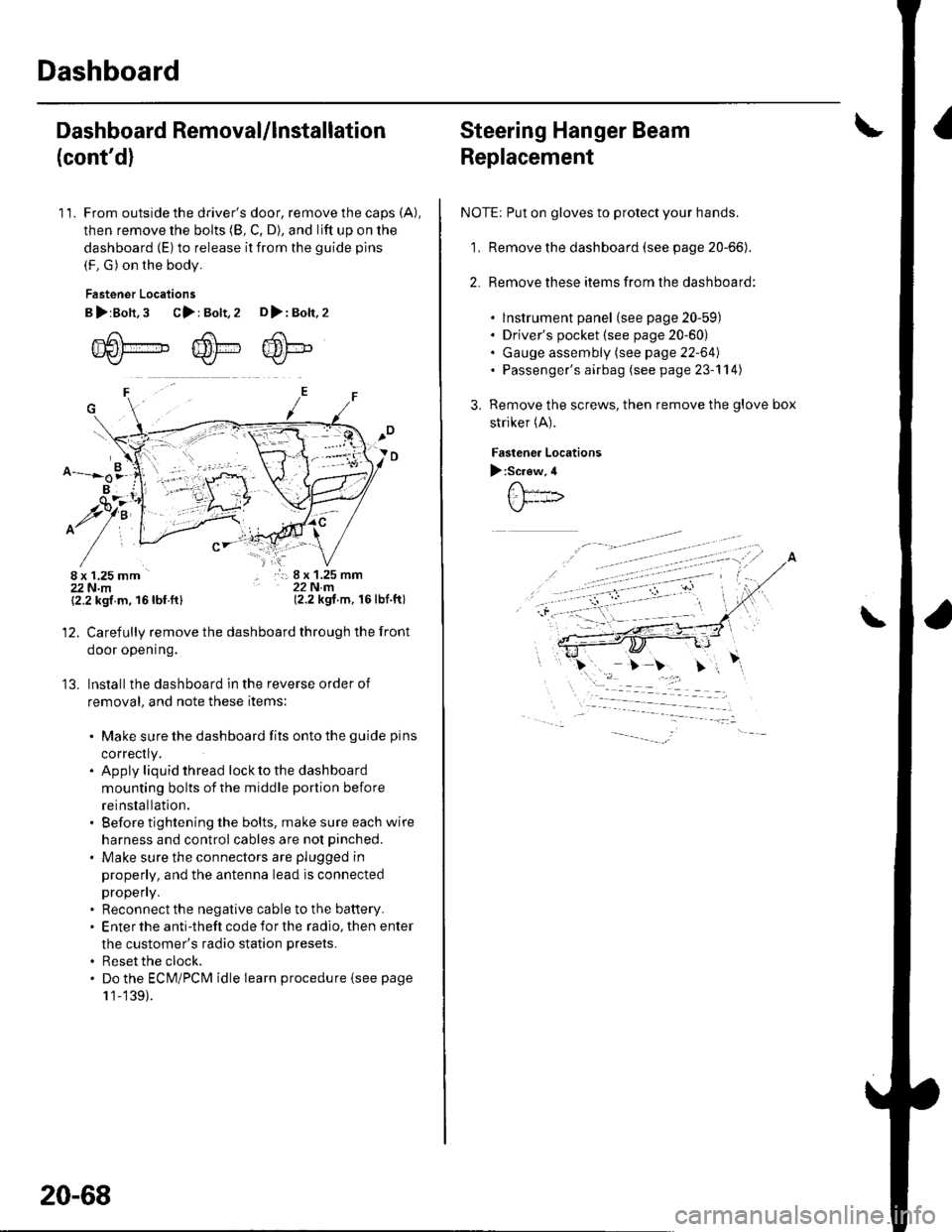

11. From outside the driver's door, remove the caps (A),

then remove the bolts (8, C, D), and lift up on the

dashboard (E) to release it from the guide pins

(F. G) on the body.

Fastener Locations

B>rBolt.3 C>: Bolt,2 D>: Bolt,2

m6[-,,,,",",,-,F6't---'' ffi'!--v{/- Kr* w-

B

$7:

^/761:

/,-,. r:; 8 x 1.25 mm22Nm(2.2 kgf.m, 16lbf.ft)

13.

{2.2 kgf m, 16lbf.ftl

Carefully remove the dashboard through the front

door opening.

lnstall the dashboard in the reverse order of

removal, and note these items:

. Make sure the dashboard fits onto the guide pins

correctly.. Apply liquid thread lock to the dashboard

mounting bolts of the middle portion before

reinstallation.. Before tightening the bolts, make sure each wire

harness and control cables are not pinched.

. Make sure the connectors are plugged in

properly, and the antenna lead is connected

propeny.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure isee page

1 '1-139).

20-68

Steering Hanger Beam

Replacement

NOTE: Put on gloves to protect your hands.

1, Remove the dashboard (see page 20-66).

2. Remove these items from the dashboard:

. lnstrument panel (see page 20-59). Driver's pocket (see page 20-60). Gauge assembly (see page 22-64). Passenger's airbag (see page 23-'l 14)

Remove the screws, then remove the glove box

striker (A).

Fastenea Locations

):Screw,4

\

Page 810 of 1139

Dust and Pollen Filter Replacement

The dust and pollen filters should be replaced every

30,000 miles (48.000 km) or 24 months whichever

comes first. Replace the filters more often if the air flow

is less than usual.

1. Open the glove box. Remove both glove box stops,

then let the glove box hang down (see page 20 63).

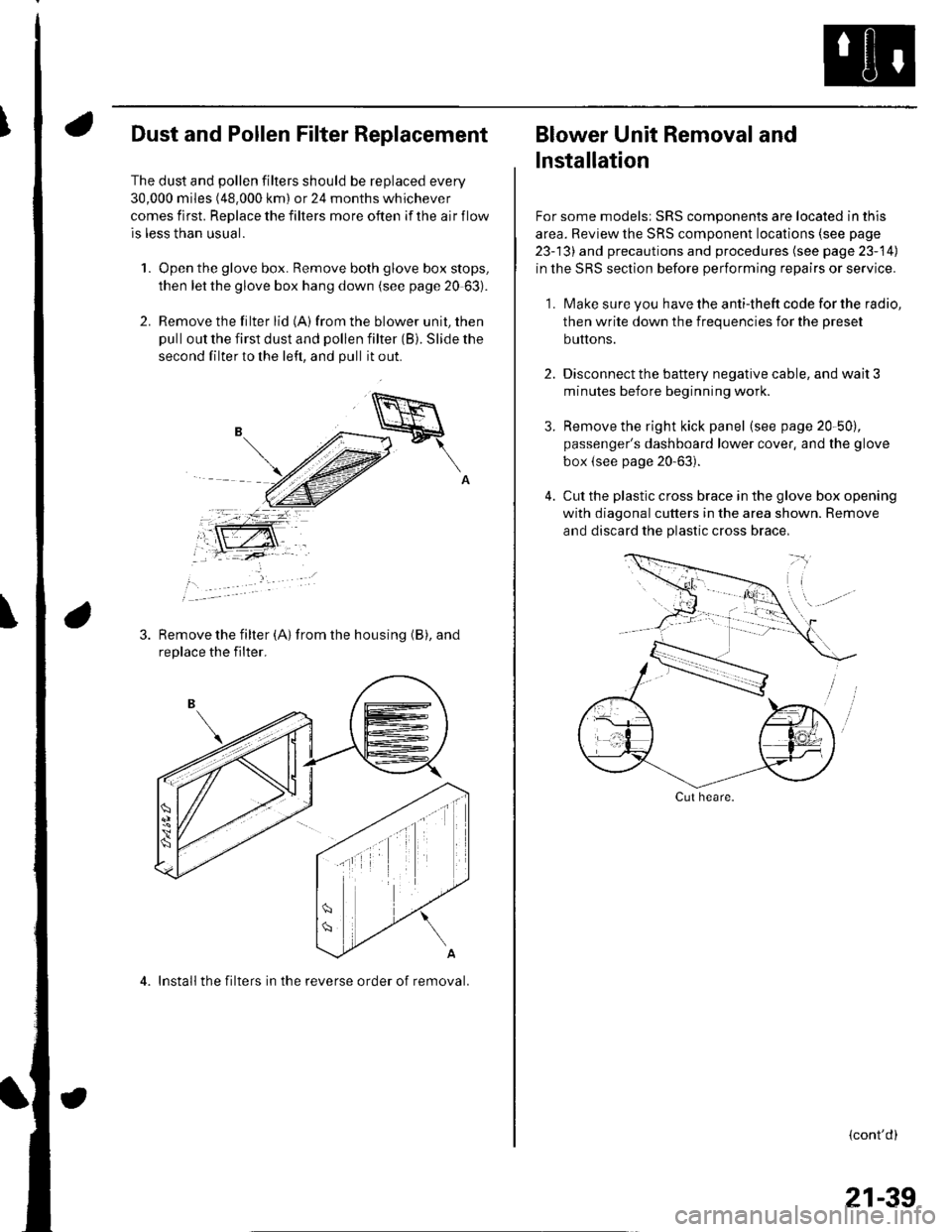

2. Remove the filter lid (A)from the blower unit, then

pull out the first dust and pollen filter (B). Slide the

second filter to the left, and pull it out.

Remove the filter {A) from the housing (B), and

replace the filter.

4. Install the filters in the reverse order of removal.

Blower Unit Removal and

lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-13) and precautions and procedures (see page 23-14)

in the SRS section before performing repairs or service.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the battery negative cable, and wait 3

minutes before beginning worK.

3. Remove the right kick panel (see page 20-50),

passenger's dashboard lower cover, and the glove

box {see page 20-63).

4. Cut the plastic cross brace in the glove box opening

with diagonal cutters in the area shown. Remove

and discard the plastic cross brace,

Cut heare.

{cont'd)

21-39

Page 811 of 1139

Heating and Air Gonditioning

Blower Unit Removal and Installation {cont'd}

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

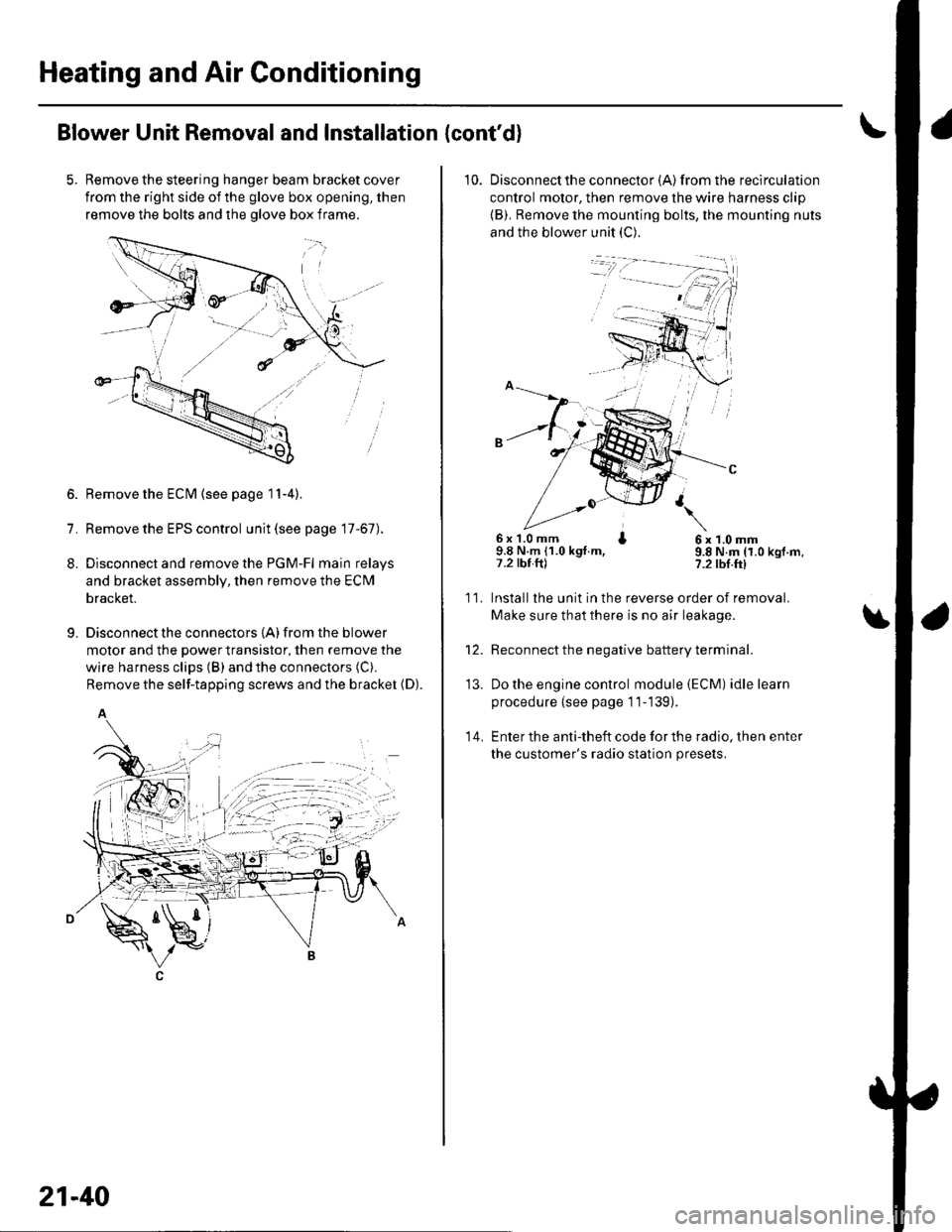

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 829 of 1139

Heating and Air Conditioning

A/C System Tests (cont'd)

1.

Performance Test

Air conditioning refrigerant or lubricant vapor

can irritate your eyes, nose, or throar.

Be carefulwhen connecting service equipment.

Do not breathe refrigerant or vapor.

The performance test will help determine if the air

conditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is

cenified to meet the requirements of SAE J2210 toremove HFC-134a (R-134alfrom the air conditioning

system.

lf accidental system discharge occurs, ventilate the

work area before resuming service

R-134a service equipment or vehicle air conditioning

systems should not be pressure tested or leak testedwith compressed air.

Additional health and safety information may be

obtained from the refrigerant and lubricant

manufacturers.

Connect a R-134a refrigerant recover/recycling/

charging station to the high-pressure service port

and the low-pressure service port, following the

equipment manufacturer's instructions.

Determine the relative humidity and air

Iemperaru re.

' Compressed air mixed with R-134a forms a

combustible vapor.. The vapor can burn or explode causing serious

Injury.. Never use compressed air to pressure test

R-134a service equipment or vehicle air

conditioning systems.

21-58

4.

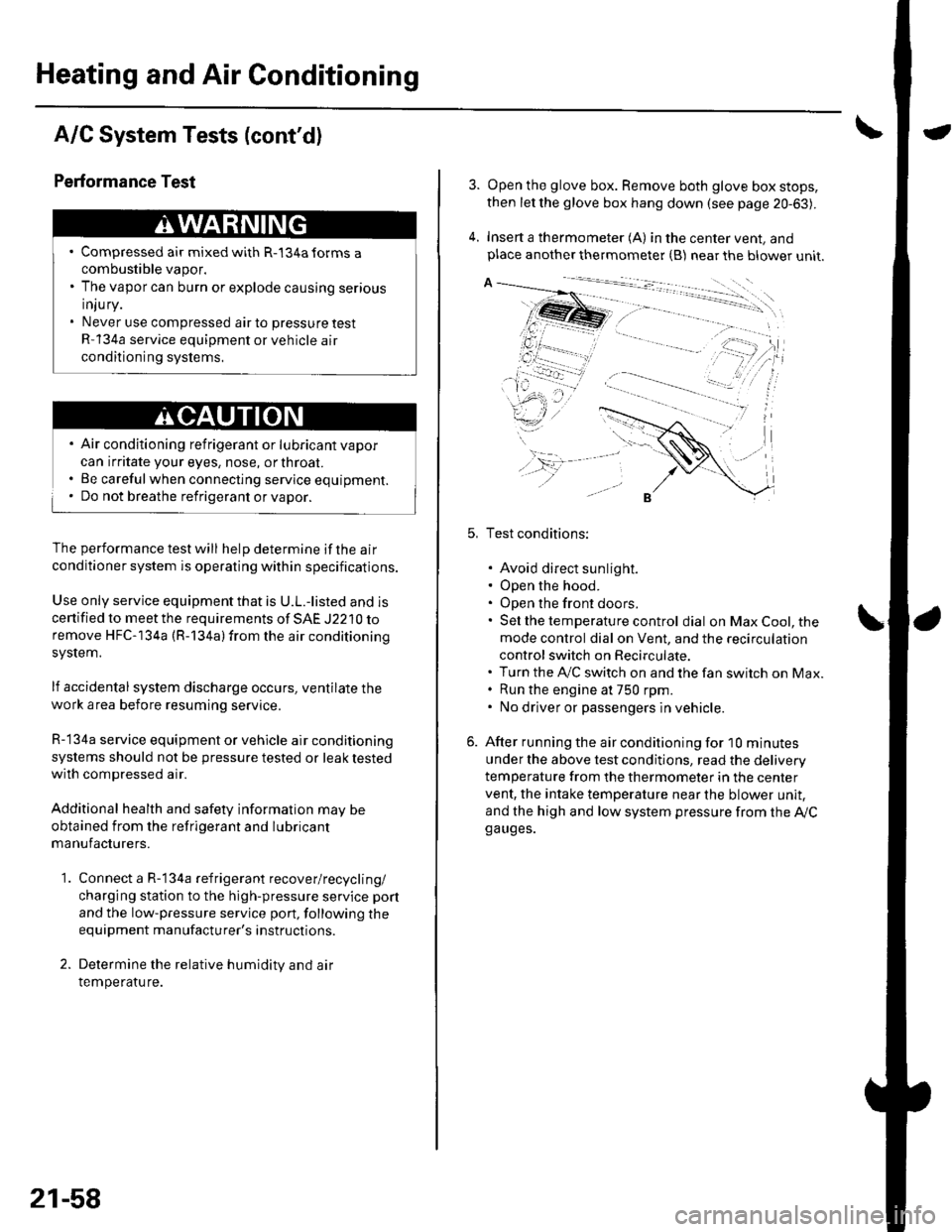

Open the glove box. Remove both glove box stops,

then let the glove box hang down (see page 20-63).

Insert a thermometer (A) in the center vent, andplace another thermometer {B) near the blower unit.

Test conditions:

. Avoid direct sunlight.. Open the hood.. Open the front doors.. Sel the temperature control dial on Max Cool, the

mode control dial on Vent, and the recirculation

control switch on Recirculate.. Turn the A,/C switch on and the fan switch on Max.. Run the engine at 750 rpm.. No driver or passengers in vehicle.

After running the air conditioning for I0 minutes

under the above test conditjons, read the delivery

temperature from the thermometer in the center

vent, the intake temperature near the blower unit,

and the high and low system pressure from the Ay'Cga uges.

Page 847 of 1139

Connectors and Harnesses

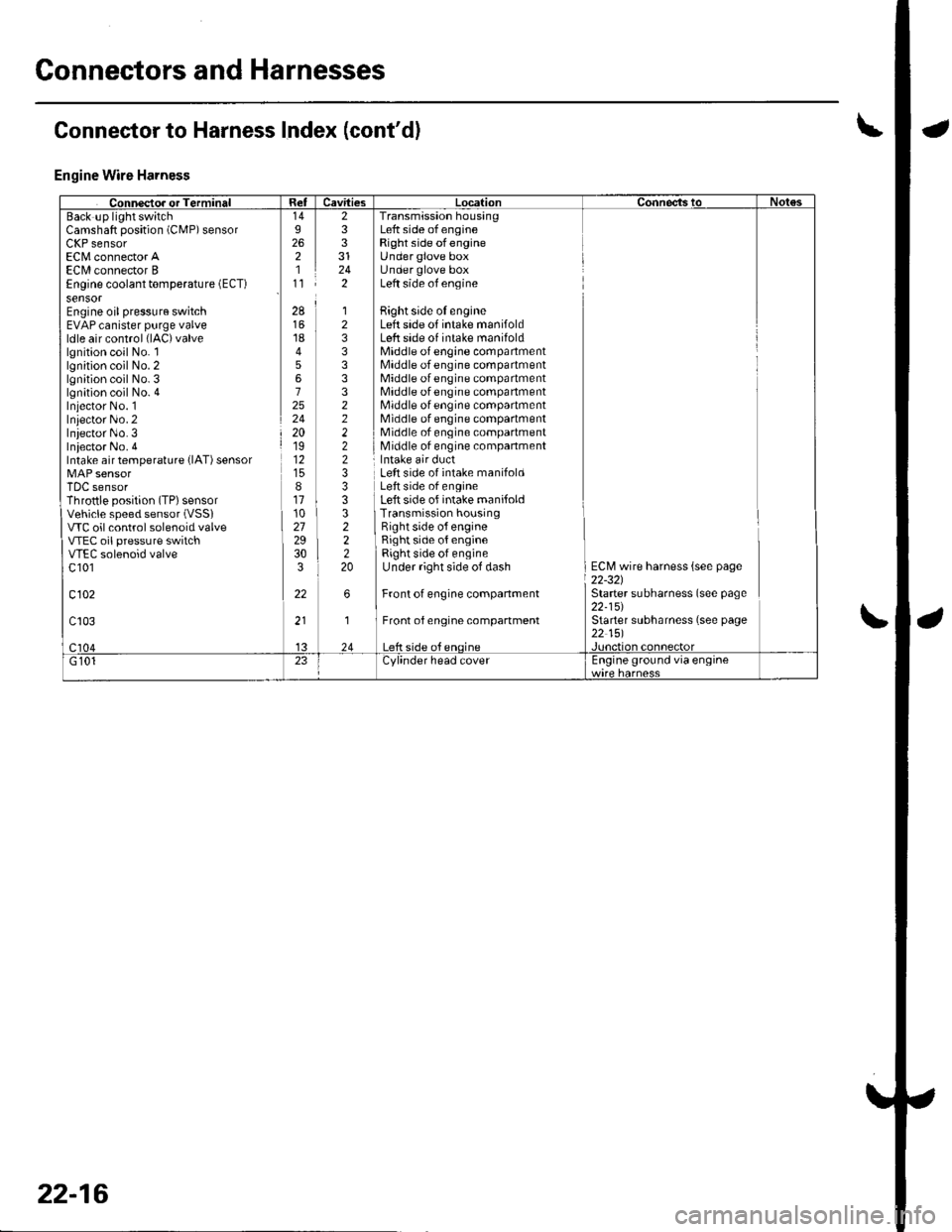

Engine Wire Harness

Camshaft position (CMP) sensorLllr sensorEC[,4 connector AECI/l connector BEngine coolant temperature (ECT)

sensorEngine oil pressure switchEVAP canister purge valveldle air control (lAC)valve

lgnition coil No. llgnition coil No. 2lgnition coil No. 3lgnition coil No. 4Iniector No. 1Inlector No.2Iniector No.3Iniector No. 4Intake air temperature {lAT) sensor

TDC sensorThrottle position (TP) sensorVehicle speed sensor (VSSI

VTC oil control solenoid valveVTEC oil pressure switchVTEC solenoid valvec 101

c102

233

242

Transmission housingLeft side of engineRight side ofengineUnder glove boxUnder glove boxLeft side of engine

Bight side oI engineLeft side of intake manifoldLeft side of intake manifoldMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine companment

28

1845672524201912

811102729303

22

12333332222233

322220

Left side of intake manifoldLeft side of engineLeft side of intake manifoldTransmission housingRight side o{ engineRight side of engineRight side of engineUnder right side of dash

Front of engine companment

Front of engine compartment

ECM wire harness {see page22-321Starter subharness (see page22-15)Starter subharness (see page22 151

Connector to Harness Index (cont'dl

22-16

Page 863 of 1139

Connectors and Harnesses

Connector to Harness Index (cont'd)

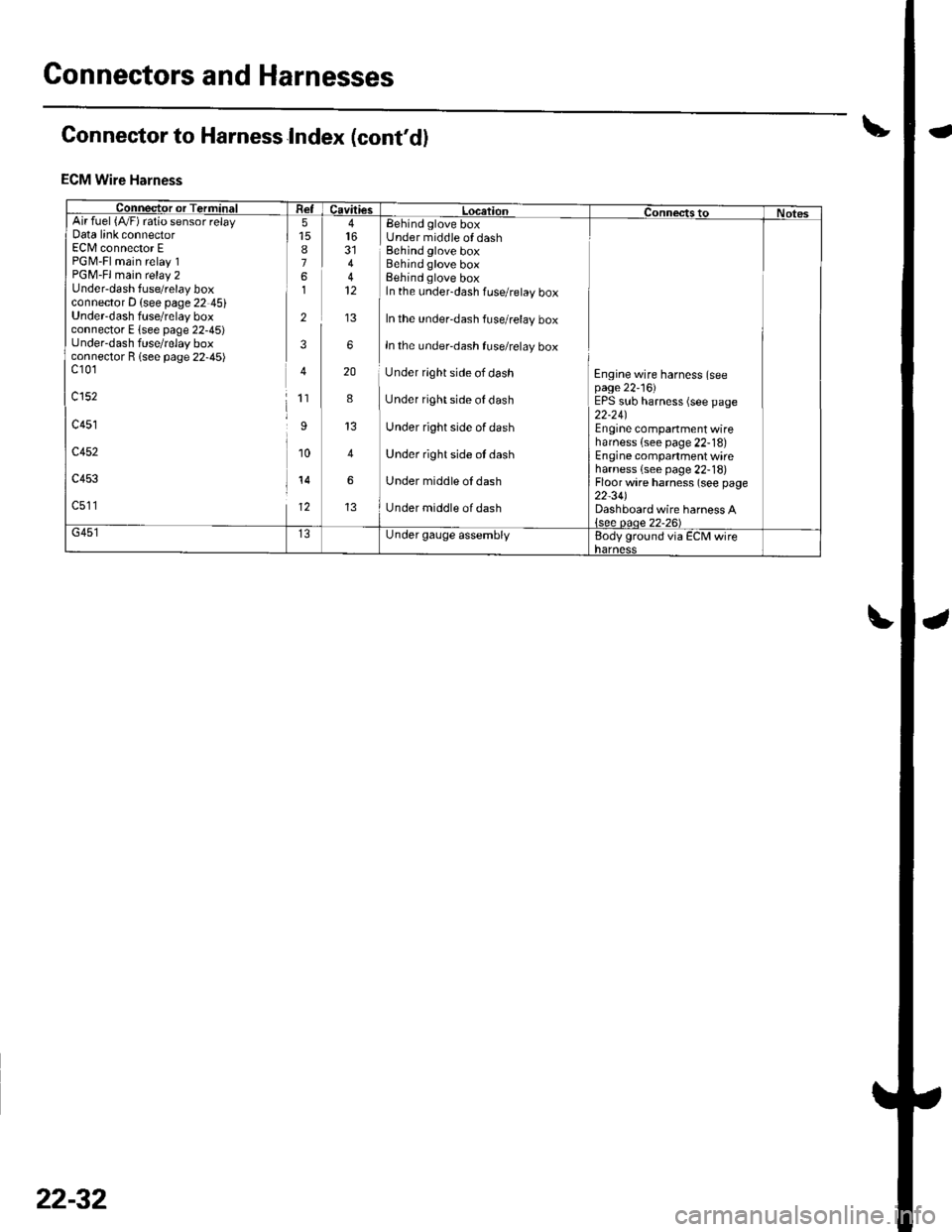

ECM Wire Harness

Connector or TerminiFI Re-lcavitiesL LocationConnectstoNotesArr ruer t/vrl ralo sensor retayData link connectorEC[/l connector EPGM-Fl main relay 1PGM-Fl main relay 2Under-dash fuse/relay boxconnector D (see page 22 45)Underdash fuse/relay boxconnector E lsee page 22-45)under-dash fuse/relay boxconnector R lsee page 22-45)c10'1

c152

c451

c452

c453

c511

8761

2

3

4

1'�I

I

10

14

12

44

6

20

8

4

6

Eehind glove boxUnder middle of dashBehind glove boxBehind glove boxBehind glove boxIn the under-dash fuse/relay box

In the under-dash fuse/relay box

In the under-dash fuse/relay box

Under rlght side of dash

Under right side of dash

Under right side of dash

Under right side ot dash

Under middle oI dash

Under middle of dash

Engine wire harness (seepage 22'16)EPS sub harness (see page22-24)Engine companment wireharness {see page 22-18)Engine compartment wireharness {see page 22-18)Floor wire harness (see page22-34)Dashboard wire harness A{see oaoe 22-26)G451Under gauge assemblyBody ground via ECM wireharness

22-32

Page 1121 of 1139

sRs

Front Passenger's Airbag Replacement

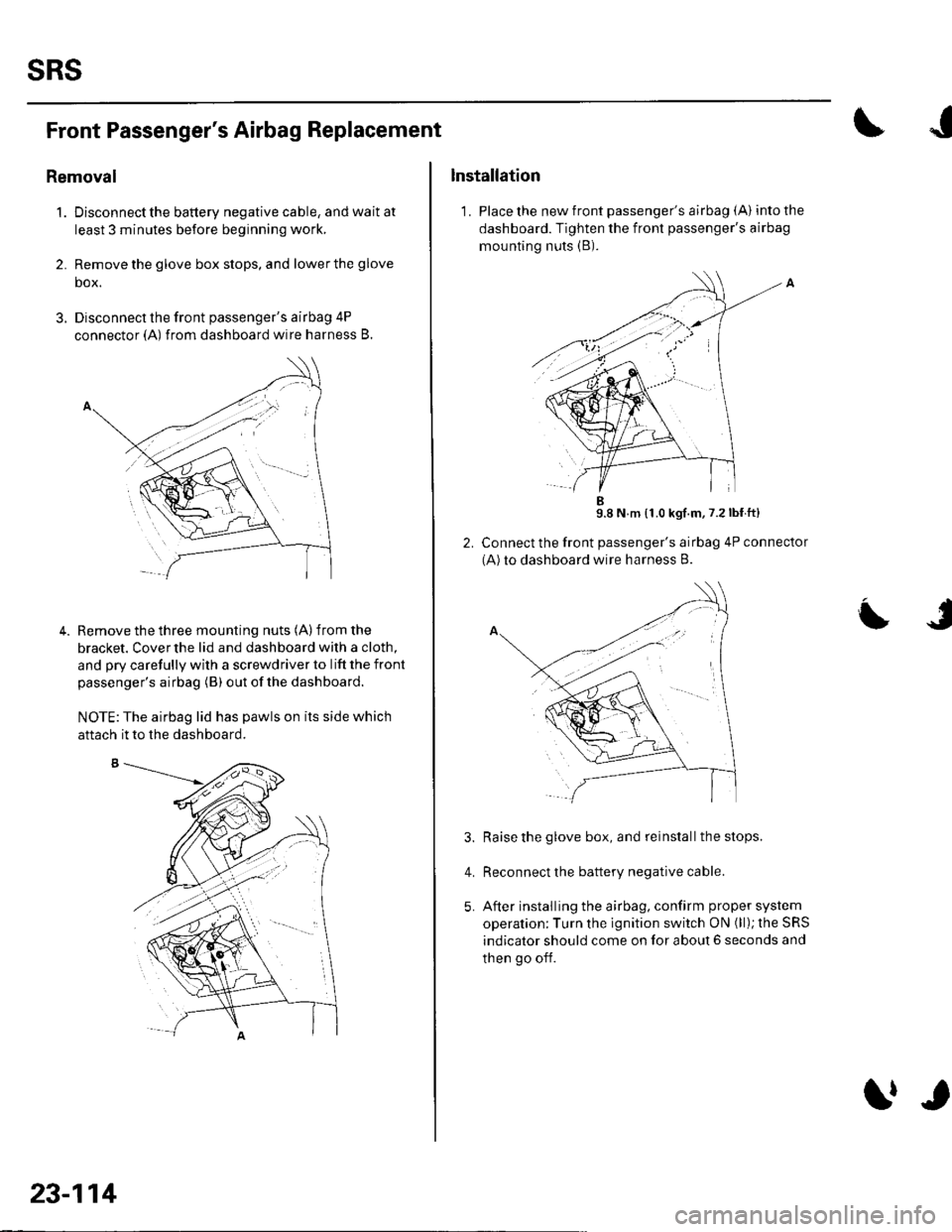

Removal

1. Disconnectthe battery negative cable, and wait at

least 3 minutes before beginning work,

2. Remove the glove box stops, and lower the glove

box.

3. Disconnect the front passenger's airbag 4P

connector (A) from dashboard wire harness B.

Remove the three mounting nuts (A) from the

bracket. Cover the lid and dashboard with a cloth,

and pry carefully with a screwdriver to lift the front

passenger's airbag (B) out ofthe dashboard.

NOTE:The airbag lid has pawls on its side which

4.

aftach it to the dashboard.

23-114

trr

Installation

1. Place the new front passenger's airbag (A) into the

dashboard. Tighten the front passenger's airbag

mounting nuts (B).

9.8 N m {1.0 kgf.m,7.2lbf ft}

Connect the front passenger's airbag 4P connector

(A)to dashboard wire harness B.

Raise the glove box, and reinstall the stops.

Reconnect the battery negative cable.

After installing the airbag, confirm proper system

operation; Turn the ignition switch ON (ll); the SRS

indicator should come on for about 6 seconds and

then go off.

L

4.

Page 1123 of 1139

sRs

Airbag Disposal

Special Tool Required

Deployment tool 07HAz-SG00500

Before scrapping any airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners (including

those in a whole vehicle to be scrapped), the airbags,

side airbags, seat belt tensioners, or seat belt buckle

tensioners must be deployed. lf the vehicle is still within

the warranty period, the Honda District Service

Manager must give approval and/or special instruction

before deploying the airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners. Only after the

airbags, side airbags, seat belt tensioners, or seat belt

buckle tensioners have been deployed (as the result of

vehicle collision, for example), can they be scrapped.

lf the airbags, side airbags, seat belt tensioners, and

seat belt buckle tensioners appear intact (not deployed),

treat them with extreme caution. Follow this Drocedure.

Deploying Airbags in the Vehicle

lf an SRS equipped vehicle is to be entirely scrapped, its

airbags, side airbags. seat belt tensioners. and seat belt

buckle tensioners should be deoloved while still in the

vehicle. The airbags, side airbags, seat belttensioners,

and seat belt buckle tensioners should not be

considered as salvageable parts and should never be

installed in another vehicle.

1. Turn the ignition switch OFF, then disconnect the

battery negative cable, and wait at least 3 minutes.

2. Confirm that each airbag, side airbag, or seat belt

tensioner is securely mounted.

3. Conf irm that the specia I tool isfunctioning properly

by following the check procedure on the tool label.

23-116

$J

Driver's Airbag:

4. Remove the access panel f rom the steering wheel,

then disconnect the driver's airbag 4P connector

from the cable reel (see step 2 on page 23-21).

Front Passenger's Airbag:

5. Lowerthe glove box, then disconnectthe front

passenger's airbag 4P connector from dashboard

wire harness B (see step 3 on page 23-211.

Side Airbag:

6. Disconnect the side airbag 2P connectors from the

floor wire harness (see step 4 on page 23-211.

Seat belt tensioner:

7. Disconnect the seat belt tensioner 2P connectors

from the floor wire harness {see step 5 on page 23-

22). Pull the seat belt out all the way, and cut it off.

Seat belt buckle tensioner:

8, Disconnect the seat belt buckle tensioner 4P

connectors from the floor wire harness (see step 6

on page 23-221.

Page 1136 of 1139

Service Manual Index

(cont'dl

Gauge A3semblyReplacement......................................... 22 64

Gaug€sComponent Location Index ..........-...... 22 54How-to lnformation ........................22-56Circuit Diagram22-54

Heater Valve CableAdjustment ...................... .................... ?1-46

High Mount Brake Light8ep|acement......................................... 22 82

Hood

lmmobilizer SystemComponent Location In dex .............. 22-162

\

G

Description

Genoral Information(See seclion 1)

Glove BoxRemoval/1nsta11ation .......................-.... 20-63

GrilleReplacement...........-............................. 20-94

Hood lnsulatorReplacement......................................... 20-89

Hood LatchRep1acement................... ..........20 108

Hood Opener CableComponentLocation Index ..............20 105Replacement ................ . . ........... .....20 106

Hood SealBeplacement.-...........................-........... 20-88

HornTesVReplacement . . ................ ...... 22-122

CircuitDiagram ...........................22-164Troubleshooting ............................ 22,165

Inner Fender, FronlRepf acemenl....................................... 20-102

Inside Rearview MirrorReplacement..........-.............................. 20 16

Instrument PanelRemoval/1nsta11ation................. ....... 20-59

Intake Air Bypass ControlThermal ValveTesr................................ ..... ..11-161

Intake Air SystemComponent Location Index ...-.-........ 11-159

Intake ManitoldRemoval/1nsta11ation ................................ I 2

lntermediate Shaft AssemblyRemova1 ................-.-...-......................... 16-19Disassemb|y................... ... ......-.... 16,20Resassemb|y ........................................ 16 22Installation .........-...-.............................. 16-24

Keyless Entry Transmitter

Adjuslment

H

Adiustment .......

Hatch Handle

Horn SwitchTest ............-........

HornsComponent Location IndexCirc!it Diagram

H02S. SecondaryReplacement

..............22-120Replacement

22-122

22 12120-110

20-'110Hatch LatchReplacement$

K

Hatch Latch Switch

.... 11 113

HubsReplacement. ... .................................. 1A 26Test

Test

Replacement

Hatch Support StrutsBeplacement.....

Hatch WeatherstrioReplacement....

Hazard Warning Switchtest

ldle ControlSystemComponentLocation Index .............. 11-129Inspection,.,.........-.......,.,.,,,,,,.,,,.,.,..... 1'l 138

lgnition CoillslBemoval/lnstallation ...............-.............. 4 18

22-161Test ...................................................... 22 161

Keyless Entry/Security Alarm SystemComponenl Location Index .............. 22 150Circuil Diagram ................. . .............. 22 151

Keyless Receiver Unitlnput Test ............................................ 22-153

Knock SensorReplacement......-................................ 1 1 115

KnucklesReplacementFront Suspensron ............................. 18-1 1Rear Suspension ........ .................-... 18-28

Repair ...............

H.tch Lock Actuator22-159

Hatch Lock CylinderRep|acement....................................... 20,111

Hatch SpoilerIAT {lntake Air Temperature} SensorReplacement.,.........-...'11 115

20-91

20-92

.................... 22_88lgnition Key LightTest,,.,,,,.,...,......-.

H6adlightAdjustmentlgnition Key Switch

....................... 22-91

....................... 22-91..22-78TestReQ\ace$entlgnition SwitchTest .,,,.,.,.,,,,.,.,.......22-53License Plate LightReplacement...........-... - ... .....22-83

License TrimReplacement..................-...-..........-....... 20-98

Lights, ExteriorComponent Localion Index.................22 68

Lights,InteriorComponent Location Index................. 22-94CircuitDiagram .. .. ...... .... 22-95

HcadlightsCircuit Diagram .............................. 22-71, 72

HeadlinerRemoval/lnstallalion ............................ 20-54

Heater ControlPanelRemoval/1nsta11ation ............................ 21-38

Heater Control Power and Ground CircuitsTroubfeshooting......... .......................21-27

lgnition SystemComponent Location Index ................... 4-15CircuitDia9ram .................................... 4'161nspection ............................................... 4-17

lmmobilizer Control Unit-Receiver

J

22-161