fuse HONDA CIVIC 2002 7.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 340 of 1139

A/G Signal Circuit Troubleshooting

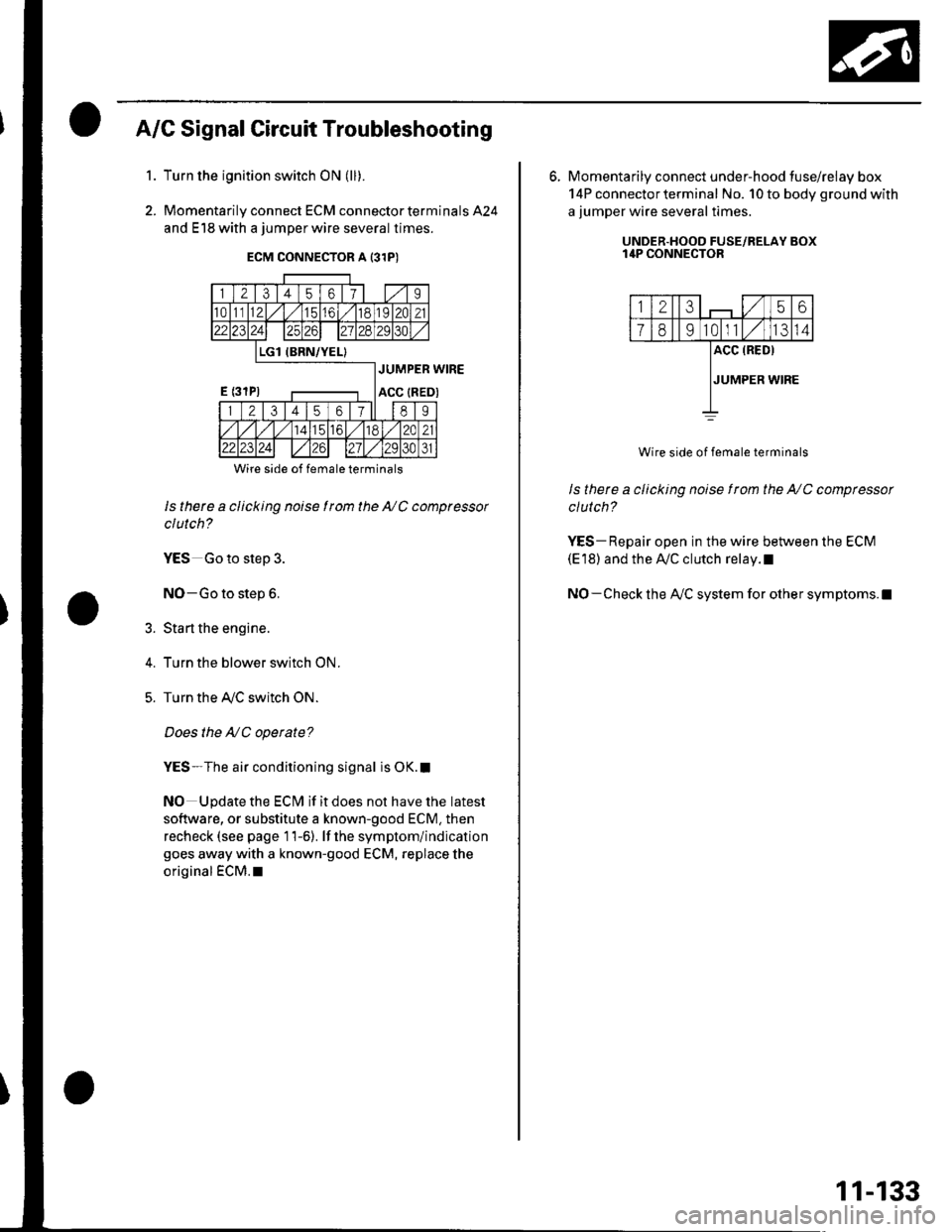

Turn the ignition switch ON (ll).

Momentarily connect ECM connector terminals 424

and E18 with a jumper wire several times.

1.

2.

5.

Wire side of female terminals

ls there a clicking noise I rom the NC compressor

clutch?

YES Go to step 3.

NO-Go to step 6.

Sta rt the engine.

Turn the blower switch ON.

Turn the Ay'C switch ON.

Does the NC operate?

YES-The air conditioning signal is OK.I

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM. then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original €CM.l

6. Momentarily connect under-hood tuse/relay box

14P connector terminal No. 10 to body ground with

a jumper wire several times.

UNDER.HOOD FUSE/RELAY BOXI4P CONNECTOR

12356

1891011IJ14

ACC (RED)

JUMPER WIRE

Wire side of female terminals

ls there a clicking noise f rom the NC compressor

clutch?

YES- Repair open in the wire between the ECM(E'18) and the Ay'C clutch relay.l

NO- Check the A/C system for other symptoms.l

11-133

Page 344 of 1139

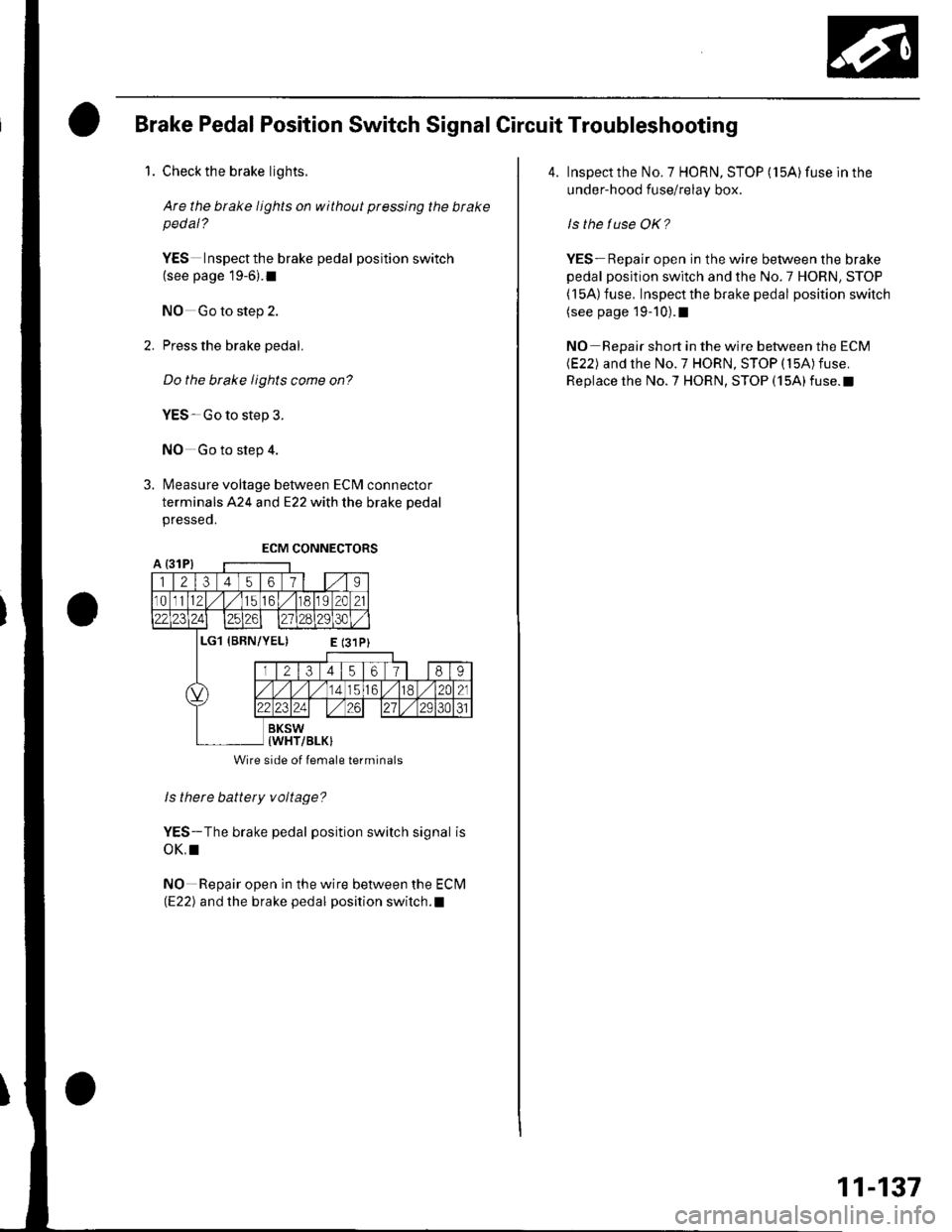

Brake Pedal Position Switch Signal Circuit Troubleshooting

1. Check the brake lights.

Are the brake lights on without pressing the brakepedal?

YES Inspectthe brake pedal position switch(see page 19-6).I

NO Go to step 2.

2. Press the brake pedal.

Do the brake lights come on?

YES-Go to step 3.

NO Go to step 4.

3. Measure voltage between ECM connector

terminals A24 and E22 with the brake pedal

presseo.

ls there battery voltage?

YES-The brake pedal position switch signal is

oK,I

NO Repair open in the wire between the Eclvl(E22) and the brake pedal position switch.l

Wire side of lemale terminals

4. Inspect the No. 7 HORN, STOP (15A) fuse ln the

under-hood fuse/relay box.

ls the tuse OK?

YES- Repair open in the wire between the brake

pedal position switch and the No.7 HORN, STOP( l5A) fuse, Inspect the brake pedal position switch(see page 19-10).1

NO Repair short in the wire between the ECM(E22) and the No.7 HORN, STOP (15A)fuse.

Replace the No.7 HORN, STOP (15A)fuse.t

11-137

Page 346 of 1139

ECM ldle Learn Procedure

The idle learn procedure must be done so the ECM can

learn the engine idle characteristics.

Do the idle learn procedure whenever you do any of

these actions:. Disconnect the battery.

Replace the ECM or disconnect its connector.

Reset the ECM.

NOTE: Erasing DTCS with the Honda PGM Tester

does not require you to do the idle learn procedure.

Remove the No.6 ECU {ECM) ( 15A) fuse from the

under-hood fuse/relay box.

Remove the No.19 baftery (80A) fuse from the under-

hood fuse/relay box.

Remove PGM-FI main relay 1.

Remove any of the wires from the under-hood fuse/

retay Dox.

Disconnect any of the connectors from the under

hood fuse/relay box.

Disconnect the connector between the engine

compartment wire harness and ECM wire harness.

Disconnect the G2 terminal from the transmission

ho u srng.

Disconnectthe G'l terminal from the body.

Disconnectthe G101 terminal from the cylinder head

cover.

Procedure:

To complete the idle learn procedure, do this:

1. Make sure all electrical items (Ay'C, audio, rear

defogger, l:ghts, etc.,) are off.

2. Start the engine, and hold it at 3,000 rpm with no

load {in neutral) until the radiator fan comes on, or

until the engine coolanttemperature reaches 194"F(90'c).

3. Let the engine idle for about 5 minutes with the

throttle fully closed.

NOTE: lf the radiator fan comes on, do not include its

running time in the 5 minutes.

11-139

Page 348 of 1139

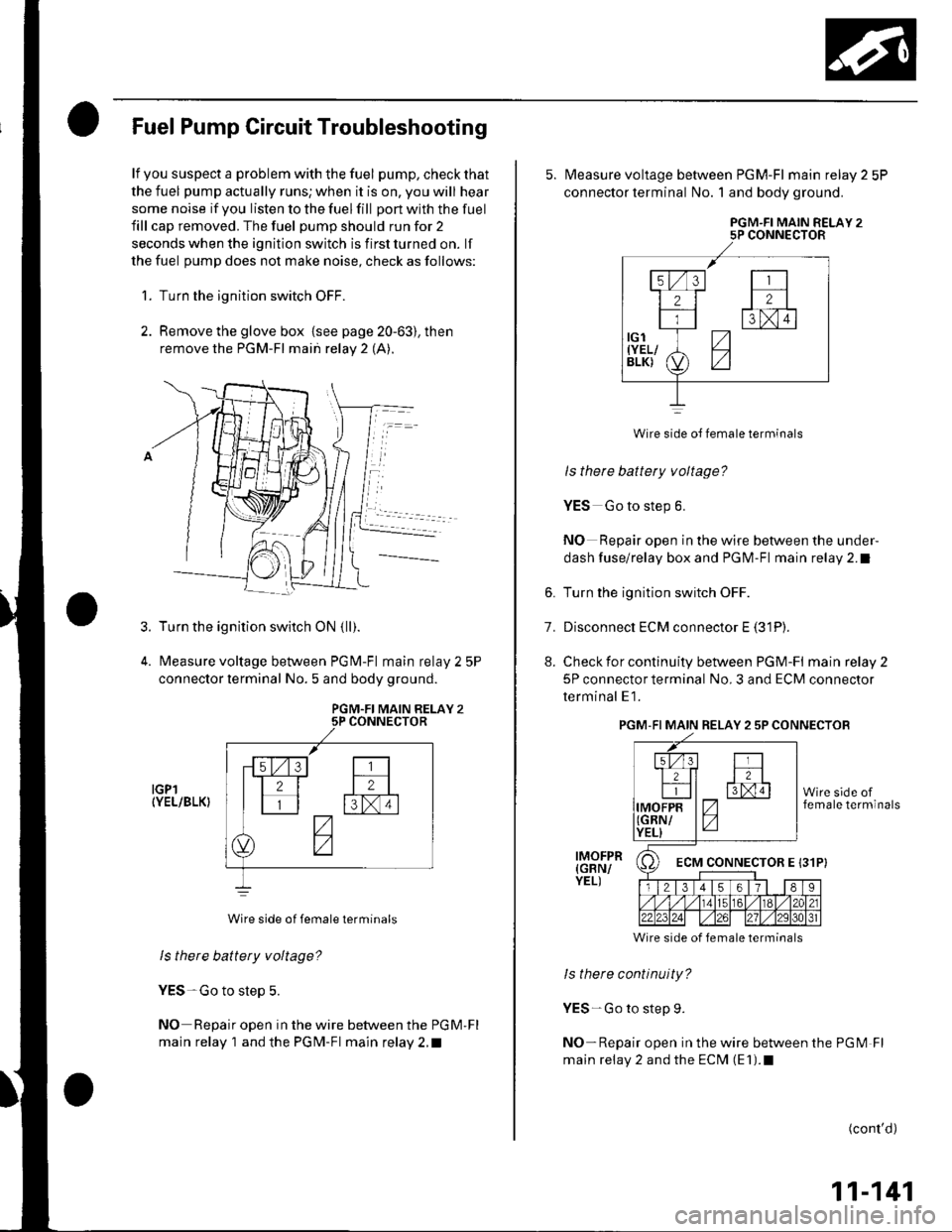

Fuel Pump Circuit Troubleshooting

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is on, you will hear

some noise if you listen to the fuel fill port with the fuel

fill cap removed. The fuel pump should run for 2

seconds when the ignition switch is first turned on. lf

the fuel pump does not make noise, check as follows:

1. Turn the ignition switch OFF.

2. Remove the glove box {see page 20-63), then

remove the PGM-FI main relay 2 (A).

Turn the ignition switch ON {ll).

Measure voltage between PGM-Fl main relay 2 5P

connector lerminal No. 5 and body ground.

PGM.FI MAIN RELAY 25P CONNECTOR

IGPl(YEL/BLK}

Wire side of female terminals

ls there battery voltage?

YES-Go to step 5.

NO Repair open in the wire between the PGM'Fl

main relay 1 and the PGM-Fl main relay 2.t

3.

5. N4easure voltage between PGM-Fl main relay 2 5P

connector terminal No. 1 and body ground.

PGM.FI MAIN RELAY 25P CONNECTOR

Wire side oJ female terminals

ls there battery voltage?

YES Go to step 6.

NO Repair open in the wire between the under-

dash fuse/relay box and PGM-Fl main relay 2.1

6. Turn the ignition switch OFF.

7. Disconnect ECM connector E (31P).

8. Check for continuity between PGM-FI mainrelay2

5P connector terminal No. 3 and ECM connector

terminal E1.

PGM-FI MAIN RELAY 2 5P CONNECTOB

Wire side of female terminals

ls there continuity?

YES-Go to step 9.

NO-Repair open in the wire between the PGM Fl

main relay 2 and the ECM (E1).1

IMOFPR(GBN/YEL)

(cont'd)

11-141

Et2lFtxm

7-

z

ECM CONNECTOR E 131P}

Page 363 of 1139

Fuel Supply System

Fuel Gauge Sending Unit Test

Special Tools Required

Fuel sender wrench 07XAA-001010A

NOTE; For the fuel gauge system circuit diagram, referto the Gauges Circuit Diagram (see page 22-58||.

1. Checkthe No. 10 fUETER {7.5A)fuse in the under-

dash fuse/relay box before testing.

2. Do the gauge drive circuit check (see page 22-56|l.

' lf the fuel gauge needle sweeps from minimuni

to maximum position and then returns to the

minimum position. the gauge is OK. Go to step 3.. lf the fuel gau ge need le does not sweep from

minimum to maximum position position and

then return to the minimum position, replace thegauge assembly and retest.

3. Turn the ignition switch OFF.

4. Remove the rear seat cushion {see page 20-80).

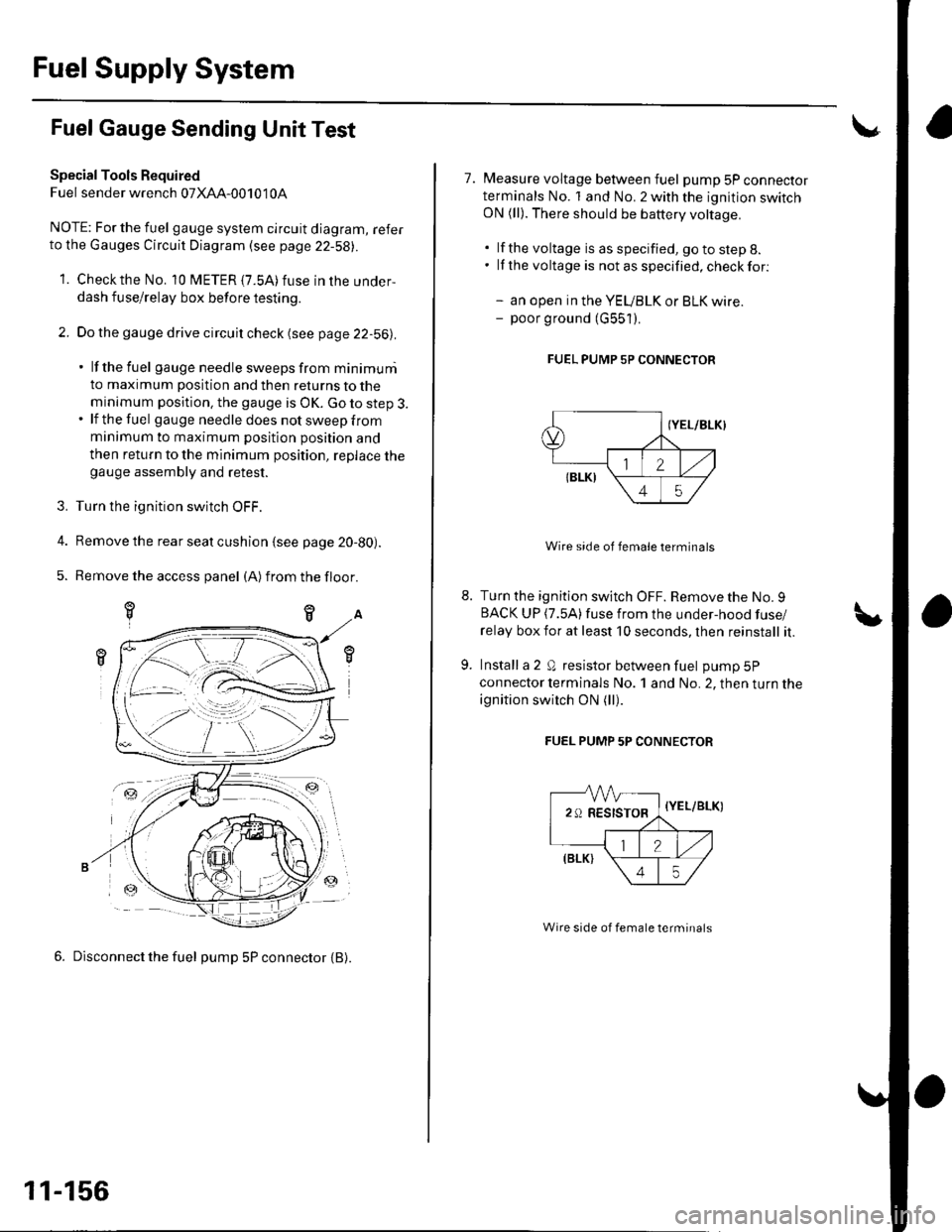

5. Remove the access panel (A)from the floor.

6. Disconnect the fuel pump 5P connector {B).

-ztr

11-156

7. Measure voltage between fuel pump 5P connectorterminals No. 1 and No. 2 with the ignition switchON (ll). There should be battery voltage.

. lf the voltage is as specified, go to step 8.. lf the voltage is notasspecified,checkfor:

- an open in the YEUBLK or BLK wire.- poor ground (G551).

FUEL PUMP 5P CONNECTOR

Wire side of female terminals

Turn the ignition switch OFF. Remove the No. 9BACK UP (7.5A)fuse from the under-hood fuse/

relay box for at least 10 seconds, lhen reinstall it.

Install a 2 Q resistor between fuel pump 5P

connector lerminals No. 1 and No. 2, then turn the

ignition switch ON (ll).

FUEL PUMP 5P CONNECTOR

-VVV-

29RESISTOR,

=-a

{Y

\

//,(elrt \

\45/

{YEL/BLK)

Wire side of female terminals

Page 364 of 1139

10. Checkthatthe pointerof thefuel gauge indicates"F".

. lf the pointer does not indicate "F", replace the

ga uge.. lf the pointer indicates "F", inspect the fuel

gauge sending unit.

NOTE: The pointer of the fuel gauge retu rns to the

bottom of the gauge dial when the ignition switch

is OFF, regardless of the fuel level. -

11. Relieve the fuel pressure (see page 11-144\.

12. Remove the fuelfill cap.

13. Disconnect the quick-connect fittings from the fuel

pump.

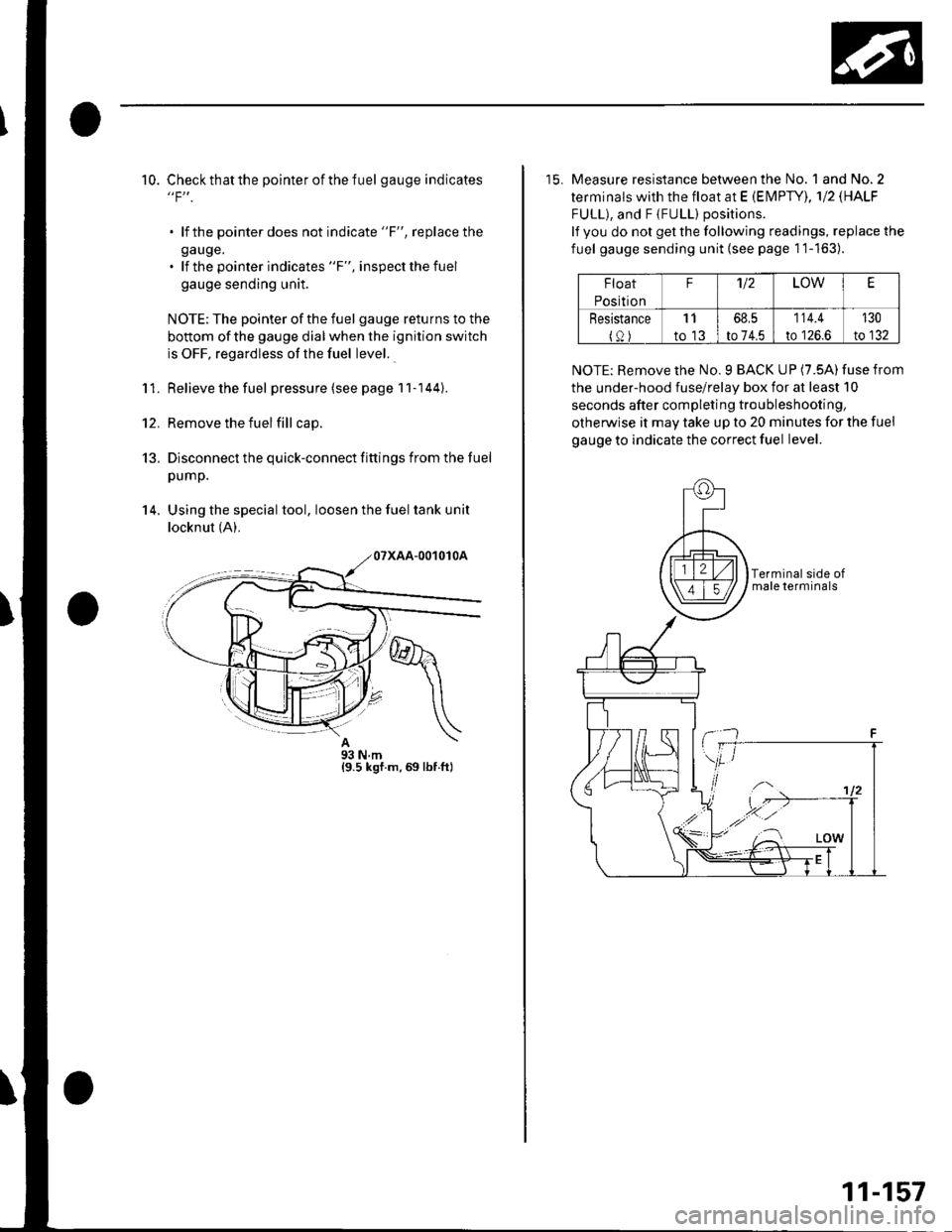

14. Using the special tool, loosen the fuel tank unit

locknut (A).

A93Nm{9.5 ksf.m,69 lbf.ft}

15. Measure resistance between the No. 1 and No.2

terminals with the float at E (EN4PTY), 'l12 \HALF

FULL), and F {FULL) positions.

lf you do not get the following readings, replace the

fuel gauge sending unit {see page 1'1-163).

Float

Position

F'U2LOWE

Resistance

{0)

11

to 13

68,5

to 74.5

114.4

to 126.6

130

to 132

NOTE: Remove the No. 9 BACK UP (7.5A) fuse from

the under-hood fuse/relay box for at least 10

seconds after completing troubleshooting,

otherwise it may take up to 20 minutes for the fuel

gauge to indicate the correct fuel level.

11-157

Page 365 of 1139

Fuel Supply System

1.

4,

Low Fuel Indicator Test

Do the fuel gauge sending unit test (see page 11,

rcol.

. lf the system is OK, go to step 2.. lf the system has any malfunction, repair it.

Turn the ignition switch OFF. Remove the No. 9

BACK UP (10A) fuse from the under-hood fuse/

relay box for at least 30 seconds, then reinstall it.

Turn the ignition switch ON (ll) with the float at the

E (EMPry) position.

. lf the low fuel indicator is on, go to step 4.. lf the low fuel indicator is not on, refer to the low

fuel indicator Circuit Diagram (see page 22-58)

and check the circuit.

Turn the ignition switch OFF. Remove the No. 9

BACK UP (10A) fuse from the under-hood fuse/

relay box for at least 30 seconds, then reinstall it.

Lift the float above the LOW position.

. lf the lowfuel indicatorgoes off,the system is OK.. lf the low fuel indicator is still on, refer to the low

fuel indicator Circuit Diagram {see page 22-58),

and check the circuit.

11-158

\,

Page 384 of 1139

15.

to.

Turn the ignition switch OFF.

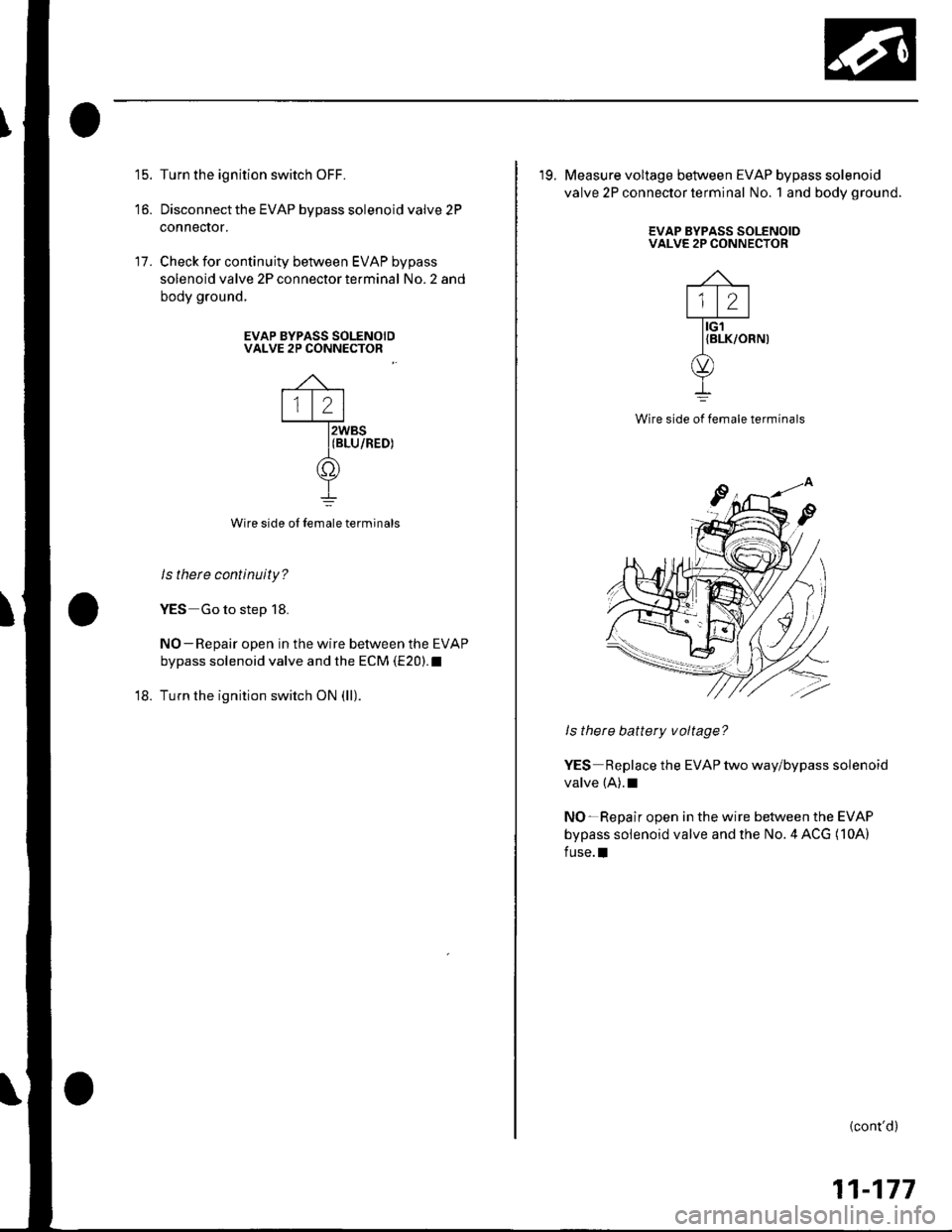

Disconnect the EVAP bypass solenoid valve 2P

connecror.

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

17.

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

'18.

Wire side oI Iemale terminals

ls there continuity?

YES Go to step 18.

NO-Repair open in the wire bet\iveen the EVAP

bypass solenoid valve and the ECM (E20).1

Turn the ignition switch ON (ll).

2

tG'l

'19. Measure voltage between EVAP bypass solenoid

valve 2P connector terminal No. 1 and body ground.

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

{BLK/ORN)

Wire side ol lemale terminals

ls there battery voltage?

YES Replace the EVAP two way/bypass solenoid

valve (A).1

NO-Repair open in the wire between the EVAP

bypass solenoid valve and the No. 4 ACG (10A)

fuse.l

{cont'd)

11-177

Page 388 of 1139

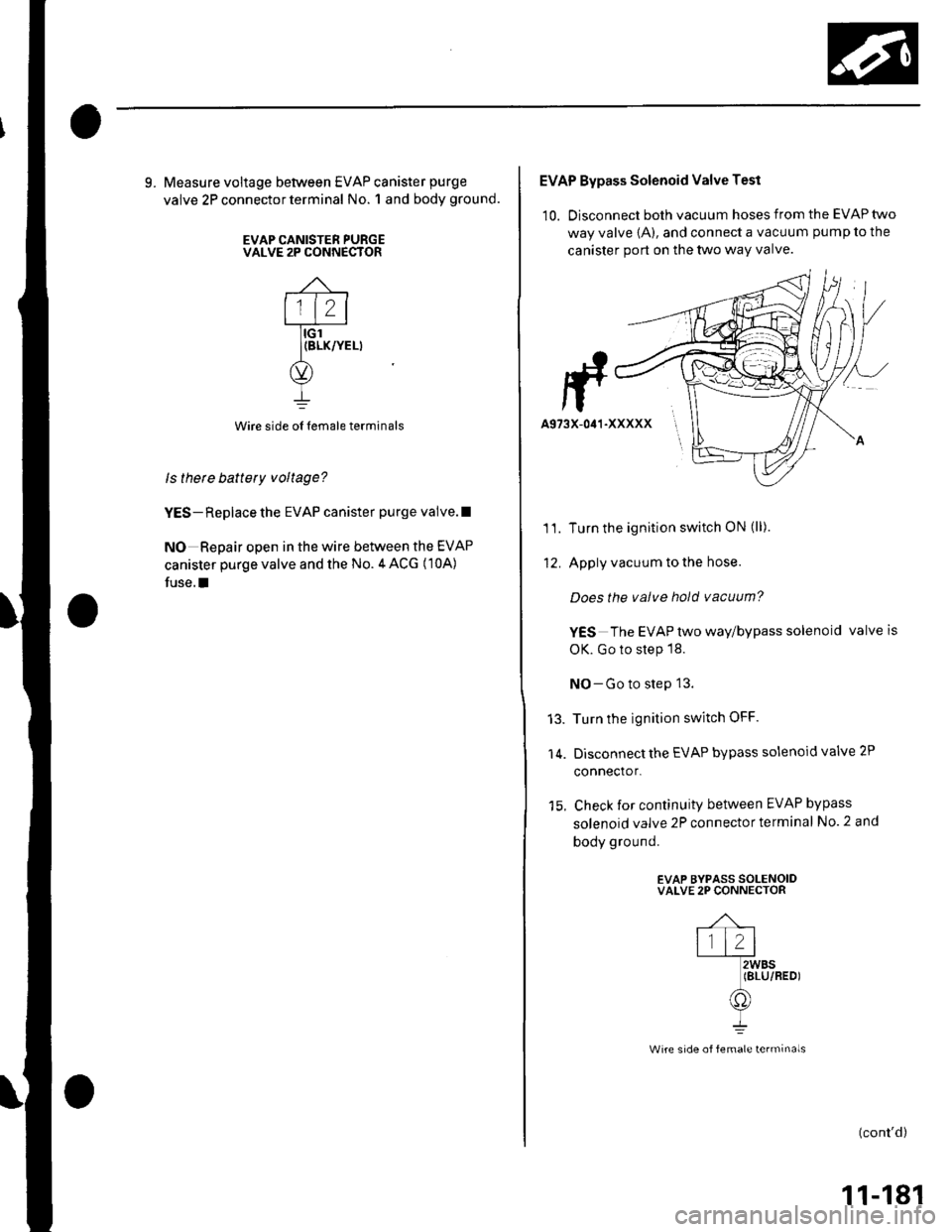

9. Measure voltage between EVAP canister purge

valve 2P connector terminal No. 1 and body ground.

EVAP CANISTER PURGEVALVE 2P CONNECTOR

Wire side oI lemale terminals

ls thete battery voltage?

YES- Replace the EVAP canister purge valve.l

NO Repair open in the wire between the EVAP

canister purge valve and the No.4 ACG (10A)

fuse.I

EVAP Bypass Solenoid Valve Test

10. Disconnect both vacuum hoses from the EVAP two

way valve {A), and connect a vacuum pump to the

canister port on the two way valve.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES The EVAP two way/bypass solenoid valveis

OK. Go to step 18.

NO-Go to step 13.

Turn the ignition switch OFF.

Disconnect the EVAP bypass solenoid valve 2P

connector.

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

11.

'It

14.

(cont'd)

11-181

Wire side of female terminals

Page 390 of 1139

25.

26.

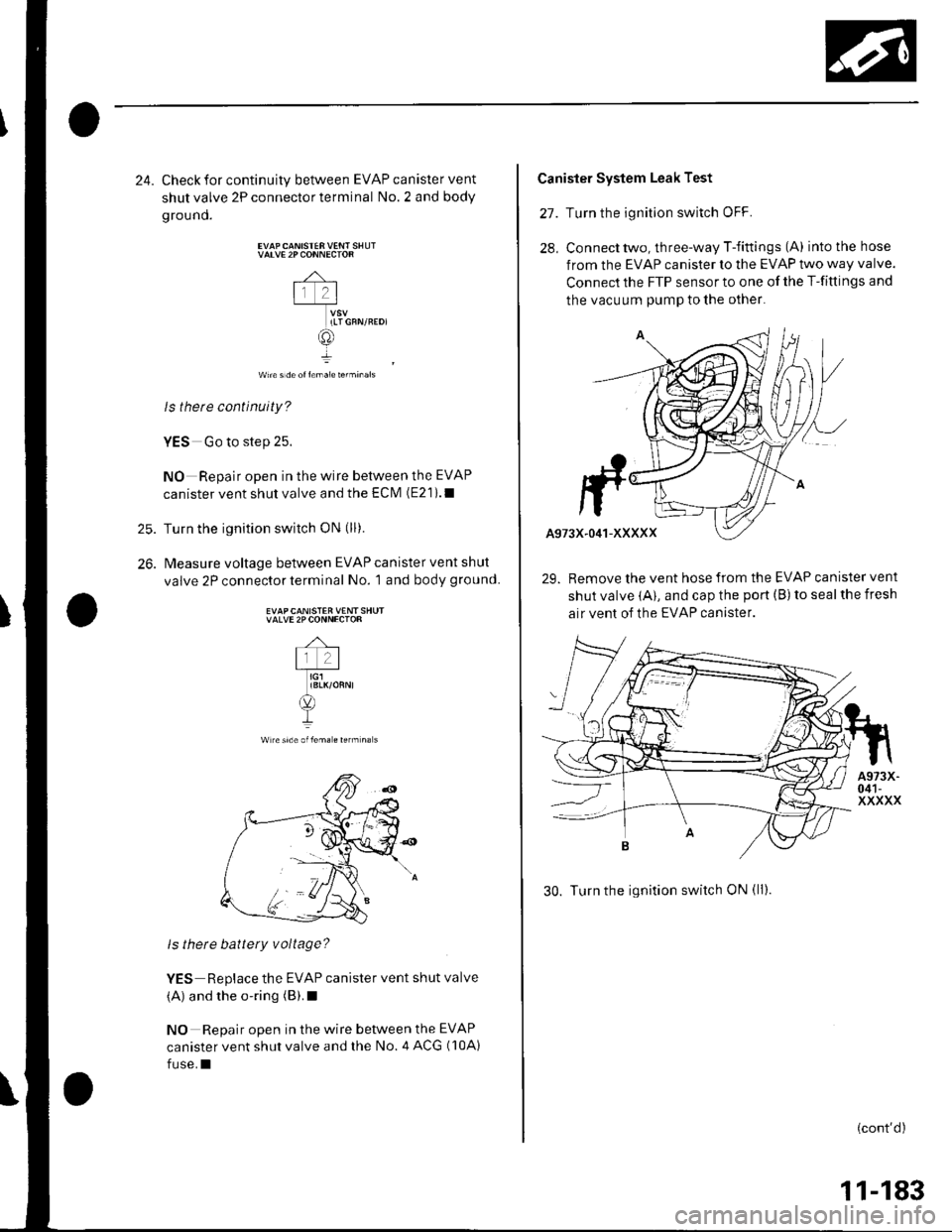

24. Check for continuity between EVAP canister vent

shutvalve 2Pconnectorterminal No.2 and body

ground.

VATVE 2P CONNECTOR

-4-

lr 2l-T_*u

ILTGFN/REDI

@

wn€ s de ol l€ma1e terminals

ls therc continuity?

YES Go to step 25.

NO Repair open in the wire between the EVAP

canister vent shut valve and the ECIVI (E21).1

Turn the ignition switch oN (ll).

Measure voltage between EVAP canister vent shut

valve 2P connector terminal No. 1 and body ground.

EVAPCANISTER VENT SHUTVALVE 2PCONNECTOR

Wlreside oflem. € rerm na s

ls there battery voltage?

YES Replace the EVAP canister vent shut valve

(A) and the o-ring (B).I

NO Repair open in the wire between the EVAP

canister vent shut valve and the No. 4 ACG (10A)

fuse.I

Canister System Leak Test

27. Turn the ignition switch oFF.

28, Connecttwo, three-way T-fittings (A) intothehose

from the EVAP canister to the EVAP two way valve.

Connect the FTP sensor to one of the T-fittings and

the vacuum pump to the othel

29. Remove the vent hose from the EVAP canister vent

shut valve (A), and cap the port (B) to seal the fresh

air vent of the EVAP canister.

30. Turn the ignition switch ON (ll).

(cont'd)

11-183