service HONDA CIVIC 2002 7.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 176 of 1139

Engine Lubrication

Oil Pump Overhaul {cont'dl

Oil Pump Inspection

1. Remove the pump housing.

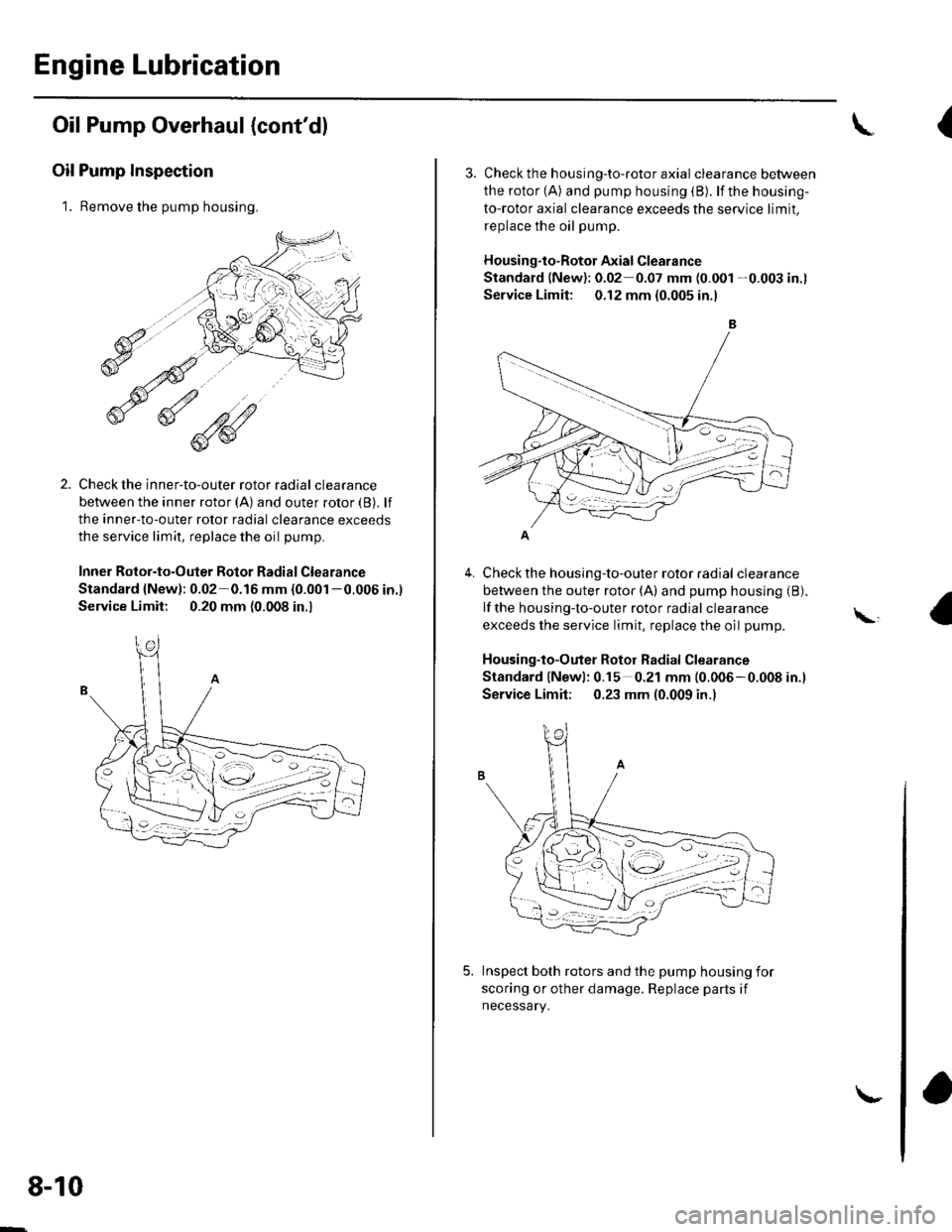

Check the inner-to-outer rotor radial clearance

between the inner rotor (A) and outer rotor {B). lf

the inner-to-outer rotor radial clearance exceeds

the service limit, replace the oil pump.

Inner Rotor-to-Outer Botor Radial Clearance

Standard {New): 0.02 0.16 mm (0.001 -0.006 in.)

Service Limit: 0.20 mm (0.008 in.,

1'[1e-\1.-,-2

1 'a - :.: ,-'r'

8-10

\-

{

4.

3. Check th e h ousing-to-roto r axia I clearance between

the rotor (A) and pump housing (B). lf the housing-

to-rotor axial clearance exceeds the service limit.

replace the oil pump.

Housing"to-Rotor Axial Clearance

Standard (New): 0.02 0.07 mm (0.001 -0.003 in.l

Service Limit: 0.12 mm (0.005 in.l

Check the housing-to-outer rotor radial clearance

between the outer rotor (A) and pump housing (B).

lf the housing-to-outer rotor radial clearance

exceeds the service limit, replace the oil pump.

Housing-to-Outer Rotor Radial Clearance

Standard lNewl: 0.15 0.21 mm (0.006-0.008 in.l

Service Limit; 0.23 mm (0.009 in.)

Inspect both rotors and the pump housing for

scoring or other damage. Replace parts if

necessary.

\,

Page 177 of 1139

1.

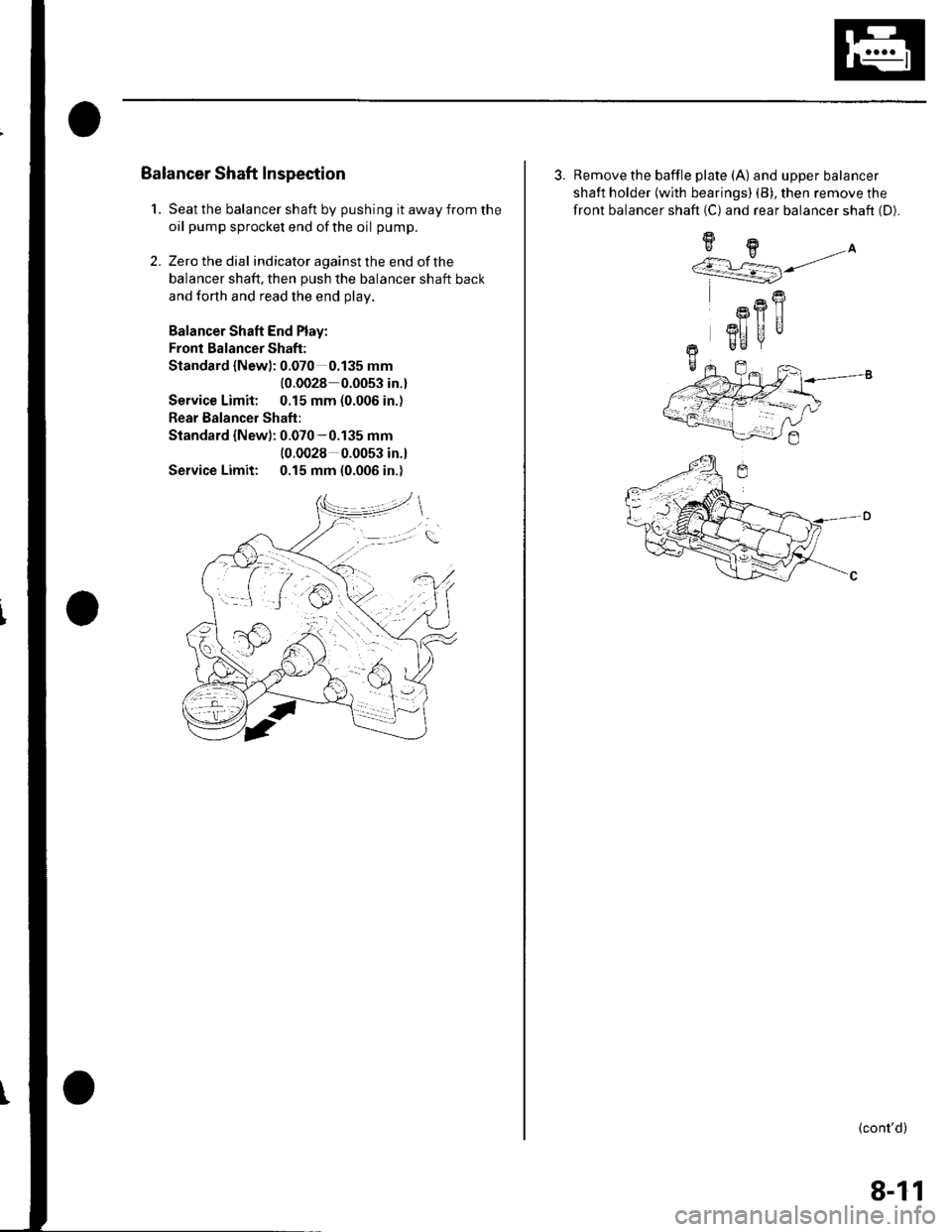

Balancer Shaft Inspection

Seat the balancer shaft by pushing it away from the

oil pump sprocket end ofthe oil pump.

Zero the dial indicator against the end of the

balancer shaft, then push the balancer shaft back

and forth and read the end olav.

Balancer Shaft End Play:

Fronl Balancer Shaft:

Standard {Newl: 0.070 0.135 mm

{0.0028 0.0053 in.}

Service Limit: 0.15 mm (0.006 in.)

Rear Balancer Shaft:

Standard {New): 0.070-0.135 mm(0.0028 0.0053 in.l

Service Limit: 0.15 mm (0.006 in.)

2.

3. Remove the baffle plate (A) and upper balancer

shaft holder {with bearings) (B), then remove the

front balancer shaft (C) and rear balancer shaft (D).

9H.A''/.r L=] j/

R

Rfl|]

3I] UUr Be

+-

(cont'd)

8-11

Page 178 of 1139

Engine Lubrication

Oil Pump Overhaul (cont'dl

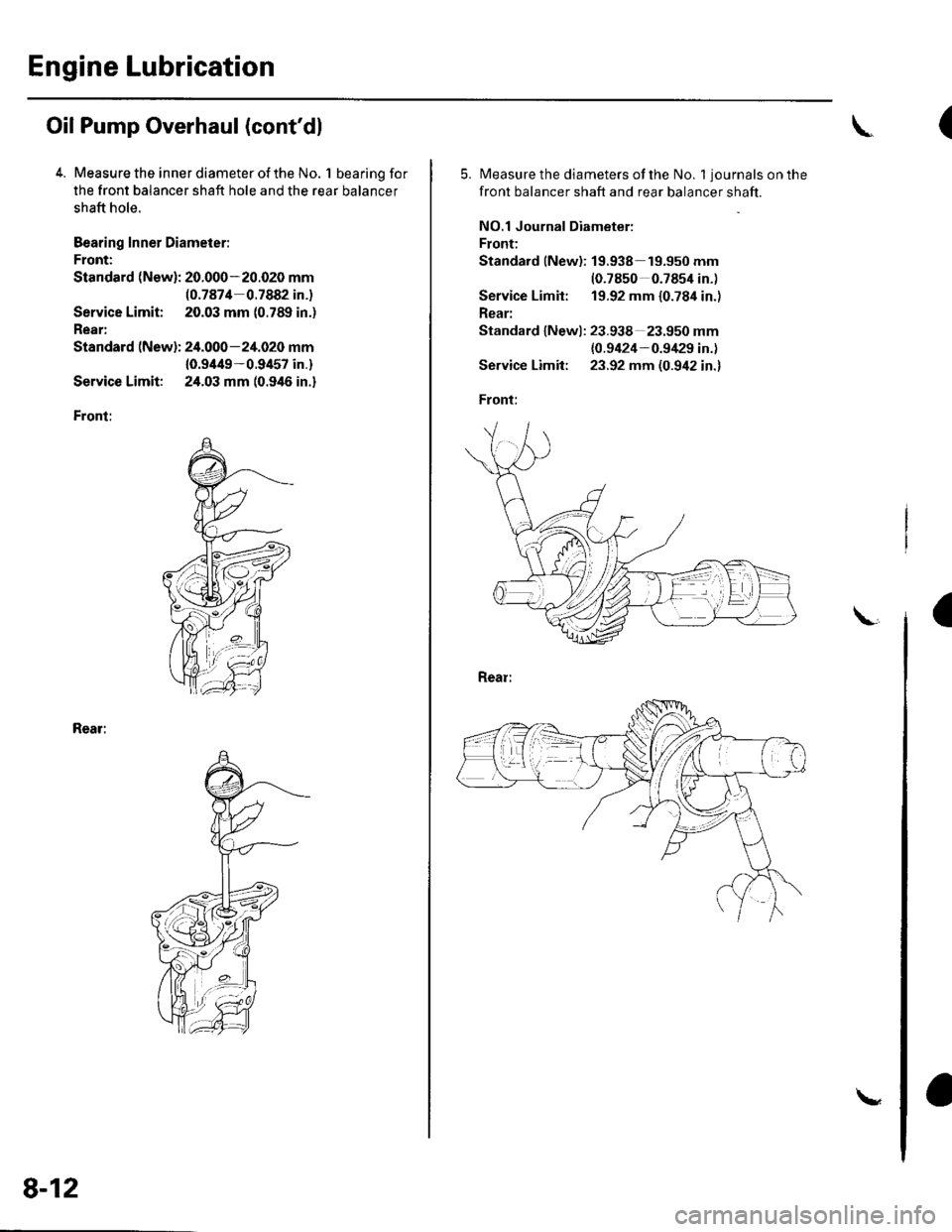

4. Measure the inner diameter of the No. 1 bearing for

the front balancer shaft hole and the rear balancer

shaft hole.

Bearing Inner Diameier:

Front:

Standard (New): 20.000-20.020 mm(0.7874 0.7882 in.)

Service Limit; 20.03 mm (0.789 in.)

Rear:

Standard (New): 24.000-24.020 mm

10.9/t49-0.9457 in.)

Service Limit: 24.03 mm (0.946 in.)

Front:

Rear:

8-12

\

(

5.Measure the diameters of the No. 1 journals on the

front balancer shaft and rear balancer shaft.

NO.1 Journal Diameter:

Front:

Standard lNew): 19.938 19.950 mm(0.7850 0.7854 in.)

Service Limit: 19.92 mm {0.784 in.)

Rear:

Standard lNewl: 23.938 23.950 mm

{0.9424-0.9/129 in.)

Service Limit: 23.92 mm (0.942 in.)

Front:

a

Page 179 of 1139

8.

9.

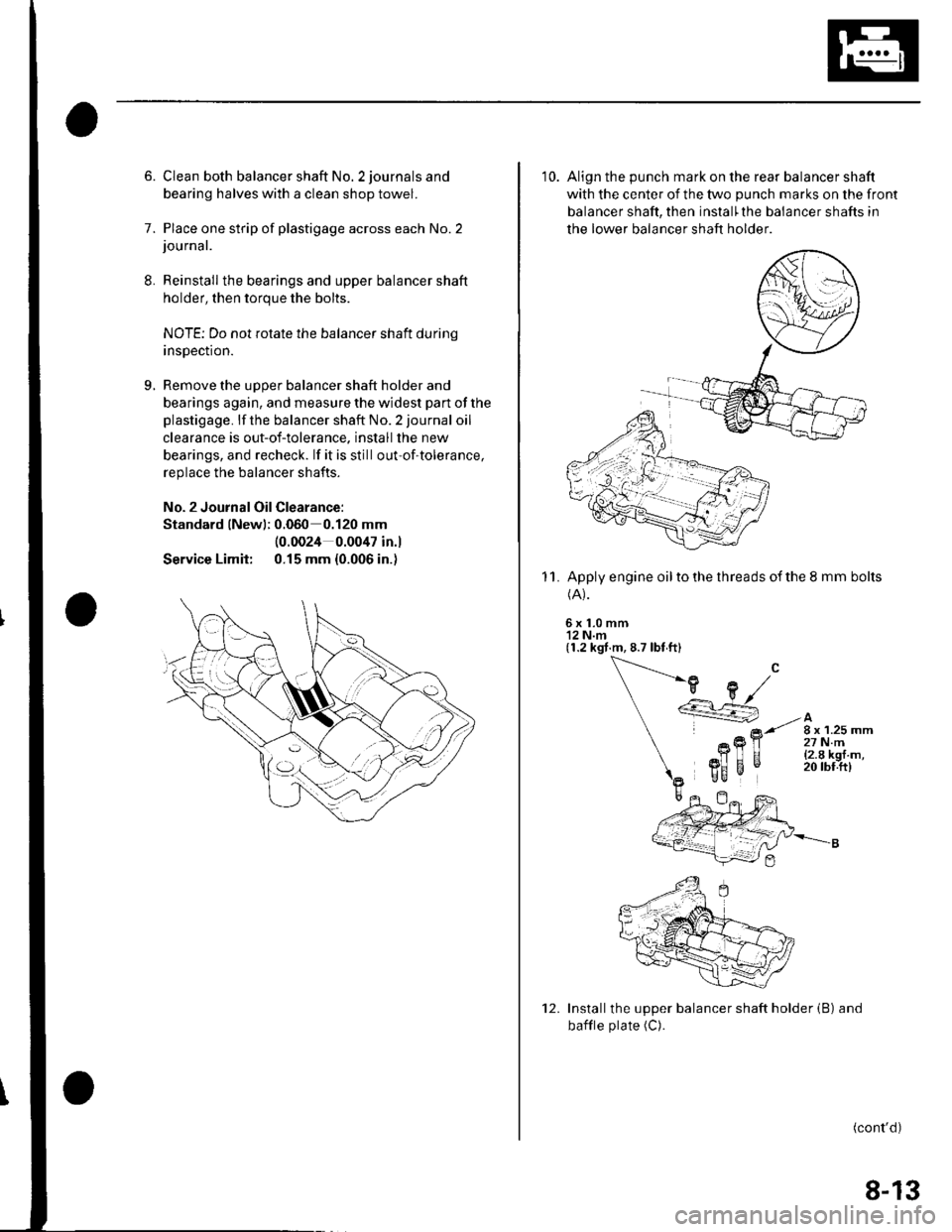

6. Clean both balancer shaft No. 2 journals and

bearing halves with a clean shop towel.

7. Place one strip of plastigage across each No.2journal.

Reinstall the bearings and upper balancer shaft

holder, then torque the bolts.

NOTE; Do not rotate the balancer shaft durinq

insDection.

Remove the uooer balancer shaft holder and

bearings again, and measure the widest part of the

plastigage. lf the balancer shaft No. 2 journal oil

clearance is out-of-tolerance. install the new

bearings, and recheck. lf it is still out-of-tolerance,

replace the balancer shafts.

No. 2 Journal Oil Clearance:

Standard lNewl; 0.060 0.120 mm

Service Limit:

(0.0024 0.0047 in.l

0.15 mm {0.006 in.)

10. Align the punch mark on the rear balancer shaft

with the center of the two punch marks on the front

balancer shaft, then install'the balancer shafts in

the lower balancer shaft holder

Apply engine oil to the threads of the 8 mm bolts(A).

6x1.0mm'12 N.m(1.2 kgt.m, 8.7 lbt ft)

11.

Installthe upper balancer shaft holder (B) and

bafile plate (C).

(cont'd)

12.

8-13

Page 214 of 1139

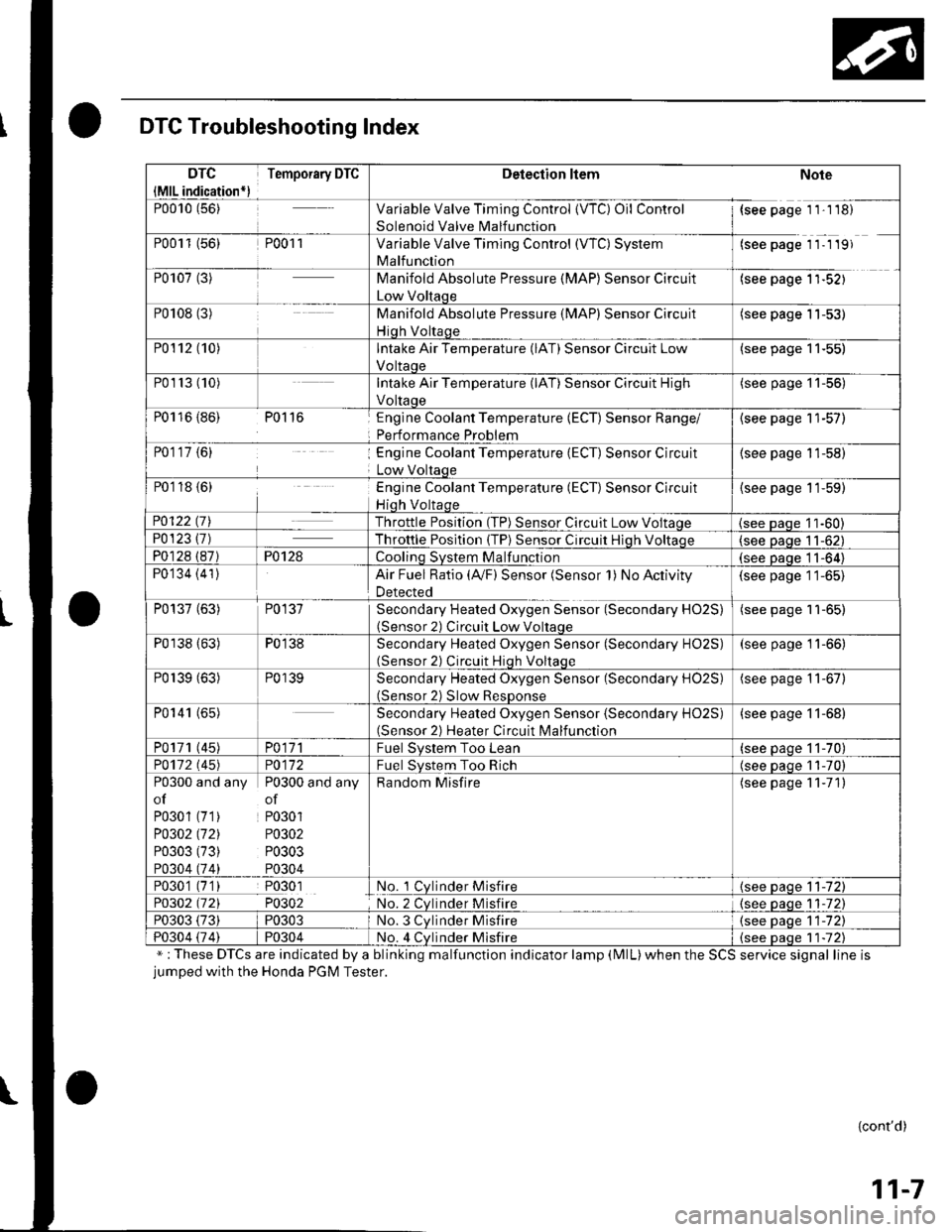

DTC Troubleshooting Index

";These DTCs are indicated by a blinking malfunction indicator lamp (MlL)when the SCS service signal line isjumped with the Honda PGM Tester.

{cont'd)

11-7

DTC

{MlL indication*)

Temporary DTCDetection ltemNote

P0010 (56)Variable Valve Timing Control {VTC) Oil Control

Solenoid Valve Malfunction

{see page 1 1'1 18)

P0011 (56)P001 1Variable Valve Timing Control (WC) System

Malfunction

(see page 11- 1 19)

P0107 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Low Voltaqe

(see page 1'l-521

P0108 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Hiqh Voltaqe

(see page 11-53)

P0112 (10)Intake Air Temperature (lAT) Sensor Circuit Low

Voltaoe

(see page 11-55)

P01r3 (10)Intake Air Temperature (lAT) Sensor Circuit High

Voltaoe

(see page '11-56)

P0116 {86) P0116Englne Coolant Temperature (ECT) Sensor Range/

Performance Problem

{see page 11-57)

P0117 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Low Voltaqe

(see page 11-58)

P0118 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Hiqh Voltaqe

{see page 11-59)

P0122 t7\Throttle Position (TP) Sensor Circuit Low Voltaqe(see Daqe 11-60)P0123 {7)Throttle Posltion (TP) Sensor Circuit Hiqh Voltaoe(see paqe 11-62)

P0128 (87)P0128Coolinq SVStem Malfunction(see Daqe 11-64)

P0134 (41)Air Fuel Ratio (Ay'F) Sensor (Sensor 1) No Activity

Detected

(see page 11-65)

P0137 (63)P0137Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Low Voltaqe

(see page 11-65)

P0138 (63)P0138Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Hiqh Voltaqe

(see page 11-66)

P0139 (63)P0139Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Slow ResDonse

(see page 11-67)

P0141 (65)Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Heater Circuit Malfunction

(see page 11-68)

P0171 (45)PO\11Fuel Svstem Too Lean(see paqe 11-70)

PO112 l'45)PO\l2Fuel System Too Rich(see oaoe 11-70)

P0300 and any P0300 and any

of of

P0301 (71) P0301

PO302 (721 P0302

P0303 (73) P0303

P0304 (74) P0304

Random Misfire(see page 11-71)

P0301 (7'1) P0301No. 1 Cylnder Misfire{see page 11-72)

P0302 (721 P0302No. 2 Cvlnder Misfire{see paqe 1 1-72)

P0303 (73)P0303No. 3 Cvlnder Misfire(see oaqe 11-72)

P0304 {74)P0304No. 4 Cvlnder Misfire{see Daqe 1 1-72)

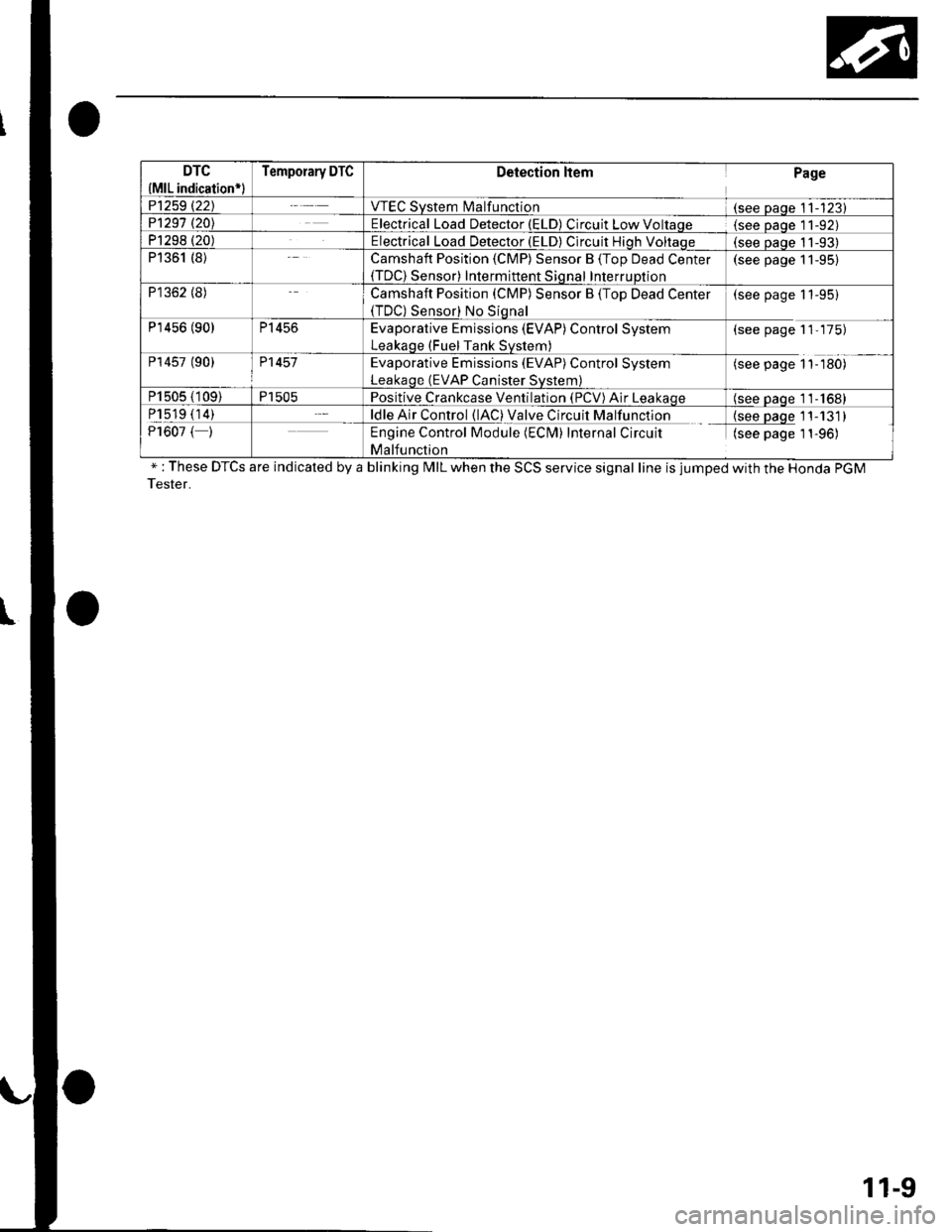

Page 216 of 1139

DTC

{MlL indication*l

Temporary DTCDetection ltemPage

P1259 t22JVTEC System l\4alfunction(see Daqe 11-123)P1291 t20\Electrical Load Detector (ELD) Circuit Low Voltaqe(see Daqe l1-92)P1298 (20)Electrical Load Detector (ELD) Circuit Hiqh Voltaqe(see oaoe 11-93)P1361 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) Intermittent Sional InterruDtion

(see page 11-95)

P1362 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) No Siqnal

(see page 11-95)

P'r456 (90)P1456Evaporative Emissions (EVAP) Control System

Leakaqe (Fuel Tank Svstem)

(see page 11-175)

P14s7 (90)P1457Evaporative Emissions (EVAP) Control System

Leakaqe (EVAP Canister Svstem)

(see page 1'l-180)

P1505 (109)P1505Positive Crankcase Ventilation (PCV) Air Leakaqe(see oaqe 11-1681

P1519 (14)ldle Air Control (lAC) Valve Circuit Malfunction{see paqe 11-131)P1607 ( )Engine Control Module (ECM) Internal Circuit

Malfunction

(see page 1 1-96)

" : These DTCS are indicated by a blinking MIL when the SCS service signal line is jumped with the Honda PGM

Tester.

11-9

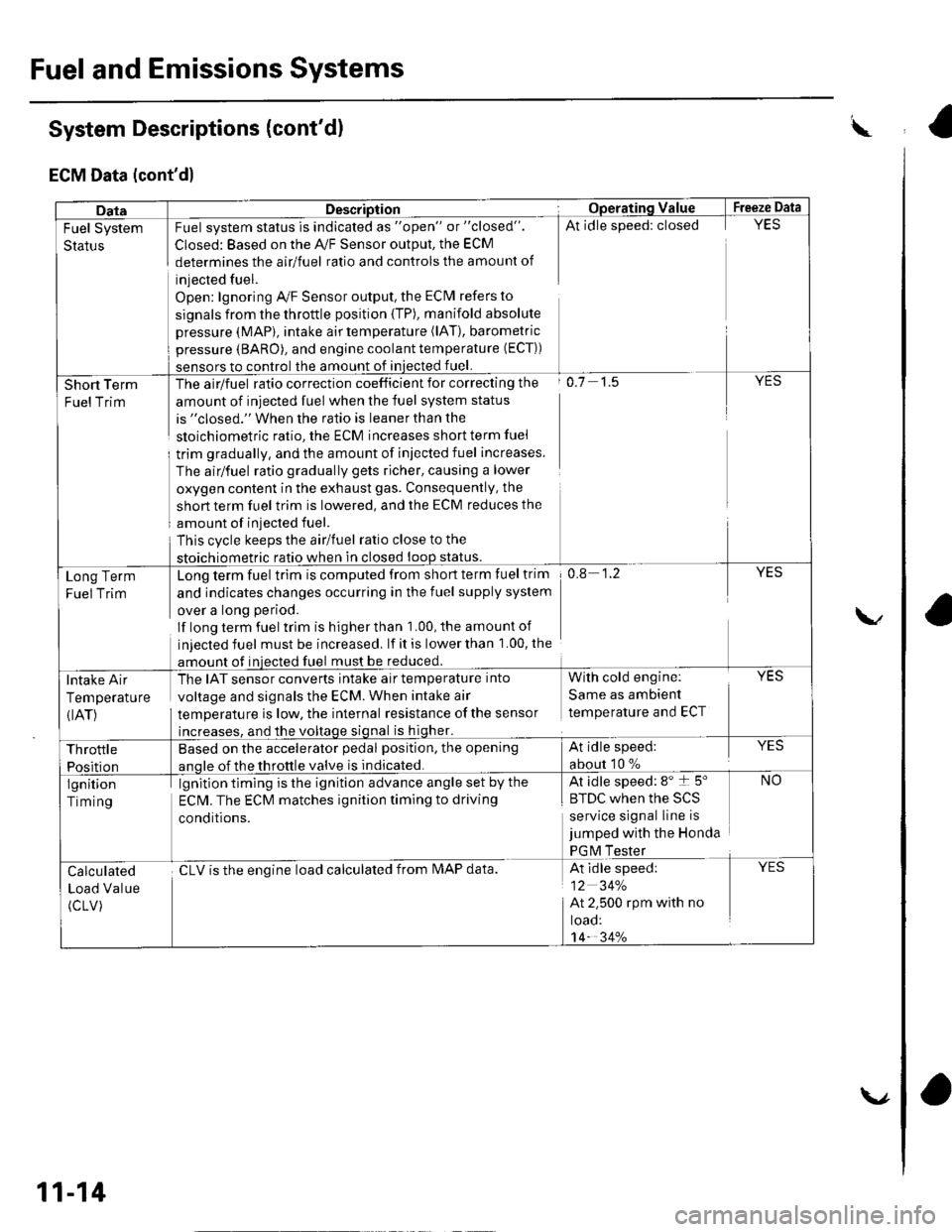

Page 221 of 1139

Fuel and Emissions Systems

System Descriptions (cont'd)

ECM Data (cont'd)

w

DataDescriptionOpera'ting ValueFreeze Data

Fuel System

Status

Fuel system status is indicated as "open" or "closed".

Closed: Based on the A,/F Sensor output, the ECM

determines the airlfuel ratio and controls the amount of

injected fuel.

Open: lgnoring Ay'F Sensor output, the ECM refers to

signals from the throttle position {TP), manifold absolute

pressure (MAP), intake air temperature (lAT), barometric

pressure (BARO), and engine coolant temperature (ECT))

sensors to control the amount of iniected fuel.

At idle speed: closedYES

Short Term

FuelTrim

The airlfuel ratio correction coefficient for correcting the

amount of injected fuel when the fuel system status

is "closed." When the ratio is leaner than the

sloichiometric ratio, the ECM increases short term fuel

trim gradually, and the amount of iniected fuel increases.

The airlfuel ratio gradually gets richer, causing a lower

oxygen content in the exhaust gas. Consequently, the

short term fuel trim is lowered, and the ECM reduces the

amount of injected fuel.

This cvcle keeps the airlfuel ratio close to the

stoichiometric ratio when in closed loop status.

o.7 1.5YES

Long Term

Fuel Trim

Long term fuel trim is computed from short term fuel trim

and indicates changes occurring in the fuel supply system

over a long period.

lf long term fuel trlm is higher than 1.00, the amounl of

injected fuel must be increased. lf it is lower than 1.00, the

amount of injected fuel must be reduced.

0.8 1.2YES

Intake Air

Temperature

{IAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air

temperature is low, the internal resistance ofthe sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient

temperature and ECT

YES

Throttle

Position

Based on the accelerator pedal position, the opening

anole of the throttle valve is indicated.

At idle speed:

about 10 %

YES

lgnition

Timing

lgnition timing is the ignition advance angle set by the

ECM. The ECM matches ignition timing to driving

conditions.

At idle speed: 8" t 5"

|' tuL wnen rne >L)

service signal line is

jumped with the Honda

PGM Tester

NO

Calculated

Load Value

(cLV)

cLV is the enoine load calculated from IMAP data.At idle speed:

12 34%

At 2.500 rpm with no

toao:'t4- 34%

YES

11-14

\.,

ra

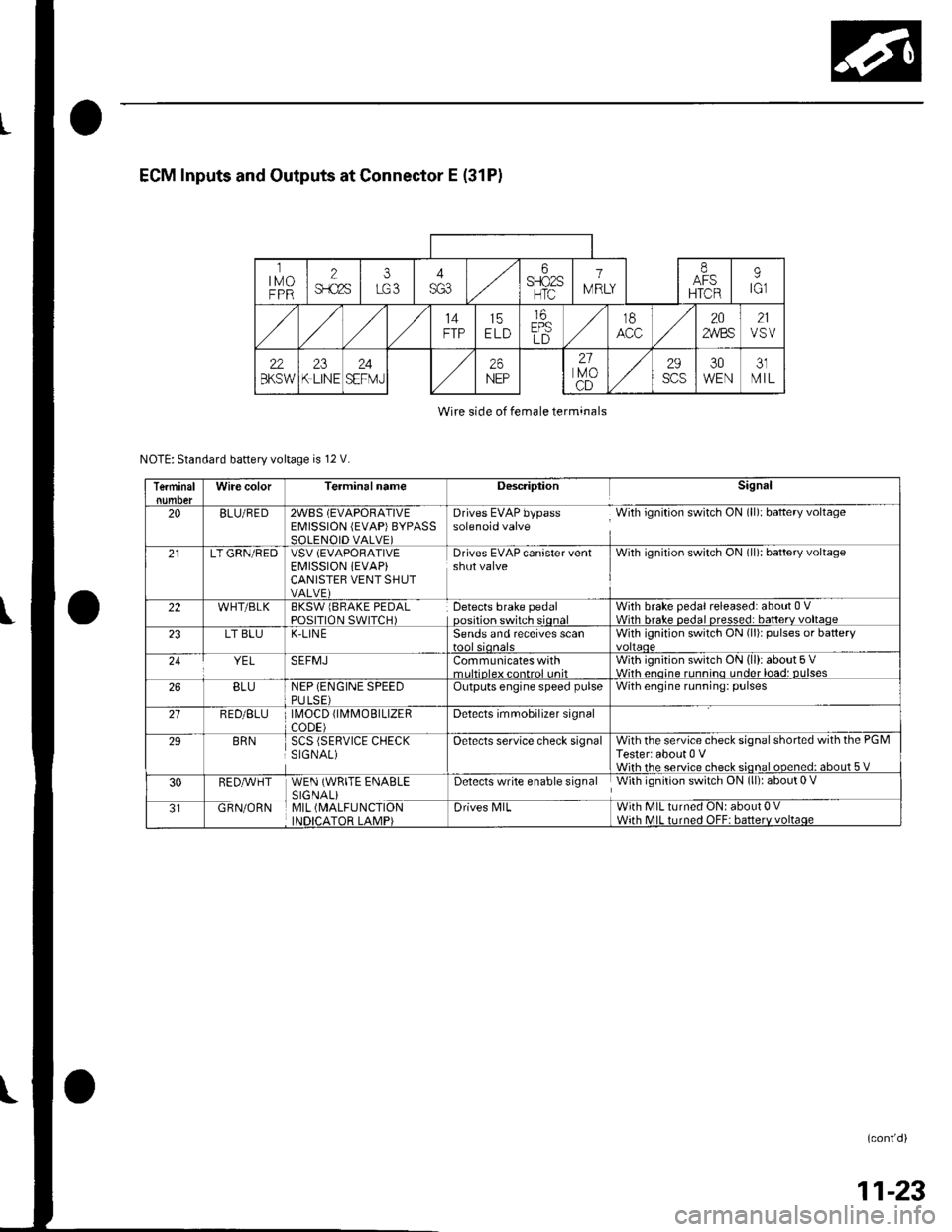

Page 230 of 1139

ECM Inputs and Outputs at Connector E (31P)

ltMoFPR

2$.c2s

i6SFIO2SHTC

1

IV RLY

IAFSHTCR

9tGl

14FTP15ELD

16EPSLD

t8202,4/BS21VSV

22BKSW23K LINE24SEFMJ26NEP

21lvoCD

29scs30WEN31MIL

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

TerminalWire colorTerminalnameDescriptionSignal

20BLU/RED2WBS (EVAPORATIVEEMISSION (EVAP)BYPASSSOLENOID VALVE)

Drives EVAP bypass With ignition switch ON (ll): baftery voltagesolenoid valve

21LT GRN/REDVSV (EVAPORATIVE

EI\4ISSION iEVAP)CANISTEB VENT SHUTVALVE)

Drives EVAP canister ventshut valveWith ignilion switch ON (ll): battery voltage

22WHT/BLKBKSW lBRAKE PEDALPOSITION SWITCH)Detects brake pedaloosition switch sionalWith brake pedal released: about 0 VWith hrake nedal nresse.l: batterv voltaoe23LT BLUK-LIN ESends and receives scanWith ignition switch ON (li)r pulses or battery

YELSEFMJCommunicates withmrltinleY eontrol unitWith ignition switch ON (ll): about 5 VWith enoine runnino under load: DUlses26BLUNEP (ENGINE SPEEDPULSE)Outputs engine speed pulseWith engine running: pulses

21RED/BLU \40CD fl\4MOBTLTZERCODE)Detects imrnobilizer signal

29BRNSCS (SERVICE CHECKSIGNAL)Oetects service check signalWith the service check signal shorted with the PGMTester: about 0 VWiih rhe service check sional ooened: about 5 V

30RED,A/VHTWEN (WRITE ENABLESIGNALiDetects write enable signal With ignition switch ON (ll): about 0 V

GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP)Drives N4lLWith MIL turned ON: about 0 VWith MIL turned OFF: batterv voltaqe

(cont'd)

11-23

Page 406 of 1139

Clutch Replacement

Spscial Tools Required. Clutch alignment disc 07JAF-PM701 1A. Ring gear holder 07LAB-PV00100 or

07924-PD20003. Clutch alignment shaft 07ZAF-PR8A100. Remover handle 07936-3710100

Pressure Plate and Glutch Disc Removal

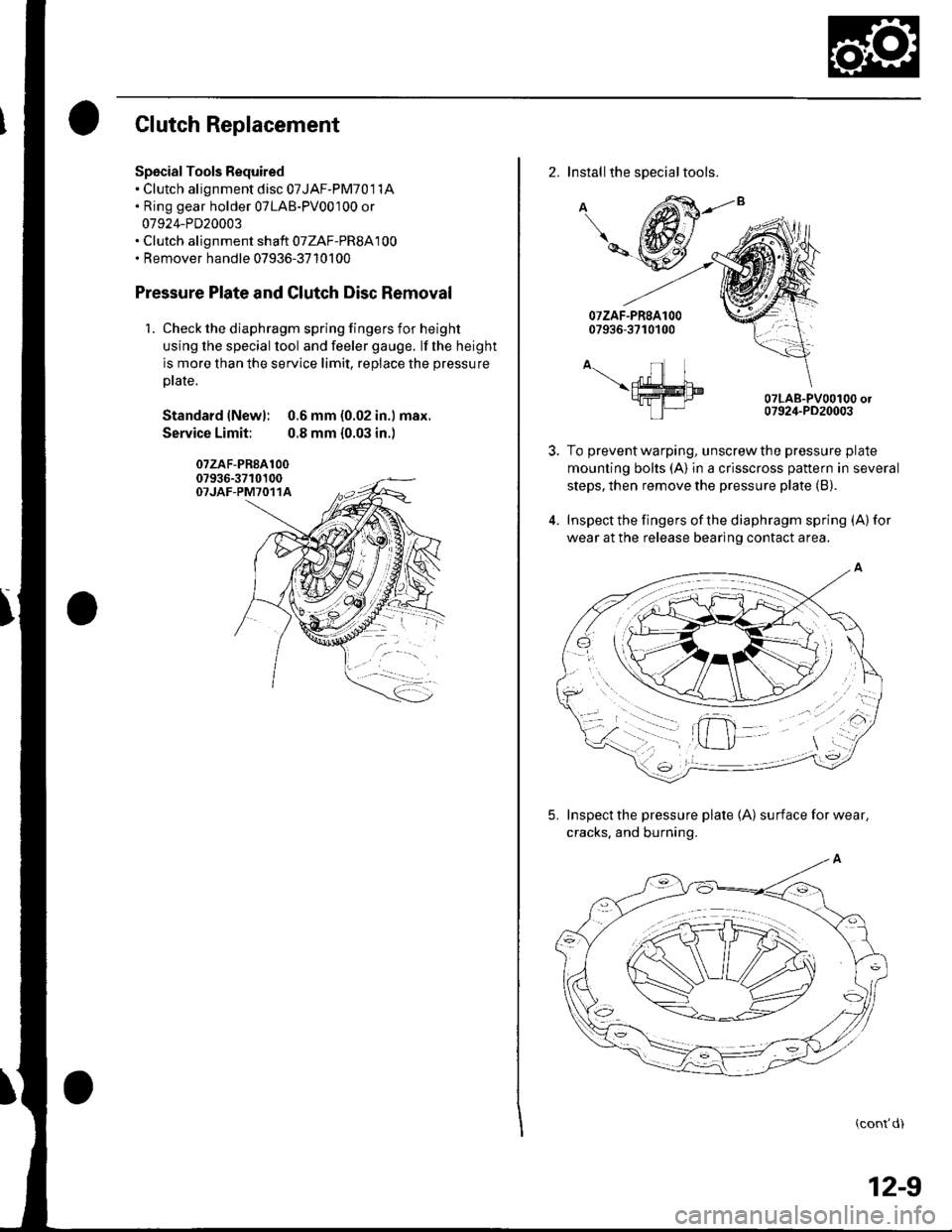

1. Check the diaphragm spring fingers for height

using lhe special lool and feeler gauge. lf the height

is more than the service limit, replace the pressure

ptate.

Standard lNewl: 0.6 mm (0.02 in.) max.

Service Limit: 0.8 mm {0.03 in.)

07zAF-PR8A10007936-3710100OTJAF-PM7O11A

2. Installthe special tools.

A

\-

A-.- nl I\ffim9fra-I tP|-

07LAB-PV00100 or07924-PD20003

To prevent warping, unscrew the pressure plate

mounting bolts (A) in a crisscross pattern in several

steps, then remove the pressure plate (B).

Inspect the fingers of the diaphragm spring (A) for

wear at the release bearing contact area.

5. Inspect the pressure plate 1A) surfaceforwear,

cracks. and burning.

(cont'd)

12-9

Page 407 of 1139

Clutch

Clutch Replacement (cont'd)

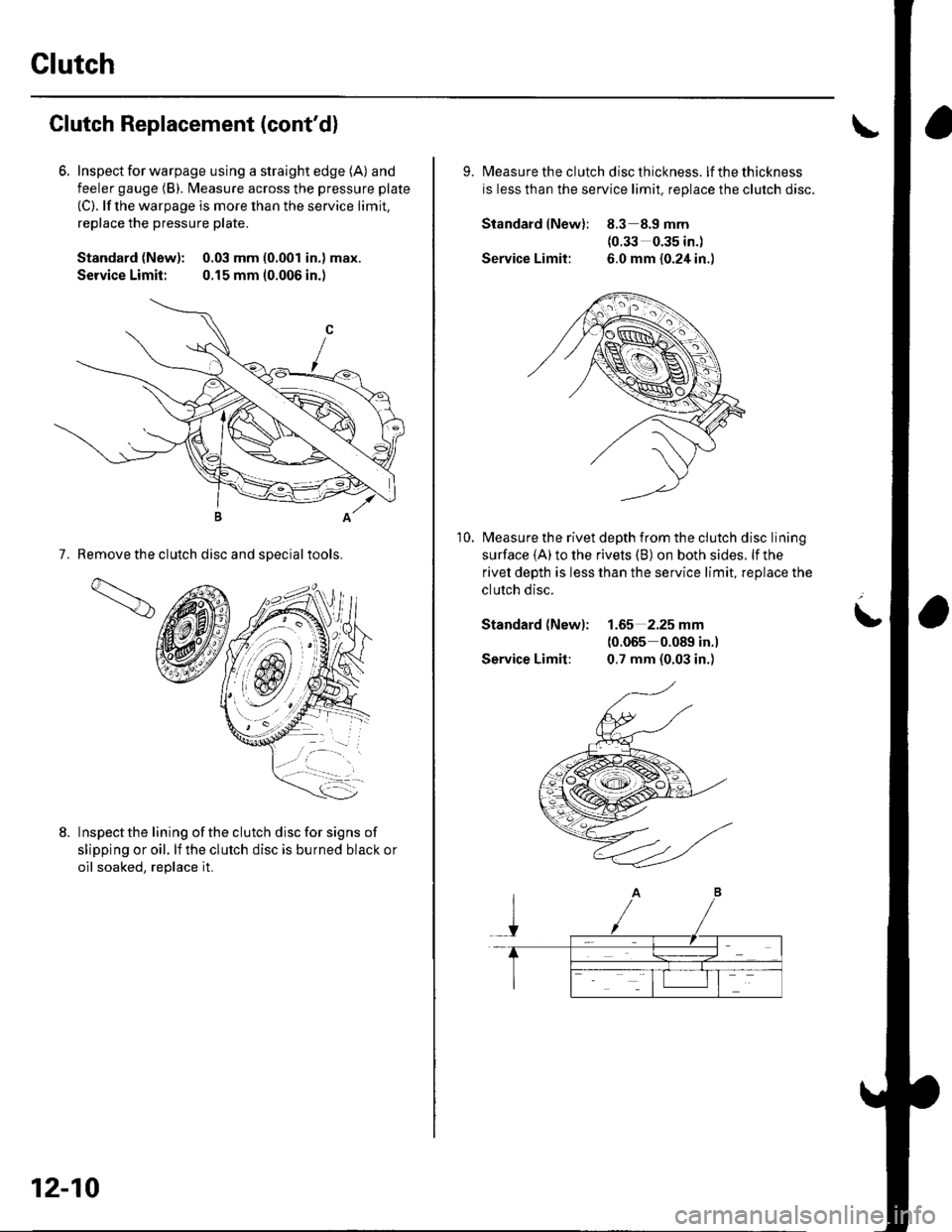

6. Inspecl for warpage using a straight edge (A) and

feeler gauge (B). l\4easure across the pressure plate

(C). lf the warpage is more than the service limit,

replace the pressure plate.

Standard {New): 0.03 mm (0.001 in.) max.

Service Limit: 0.15 mm (0.006 in.)

7. Remove the clutch disc and sDecialtools.

Inspectthe lining ofthe clutch disc for signs of

slipping or oil. lf the clutch disc is burned black or

oil soaked. reolace it.

1d

12-10

9. lvleasu re th e clutch d isc th ickness. lfthethickness

is less than the service limit, replace the clutch disc.

Standard lNew): 8.3 8.9 mm(0.33 0.35 in.)

Service Limit: 6.0 mm {0.24 in.)

Measure the rivet depth from the clutch disc lining

surface (A) to the rivets (B) on both sides. lf the

rivet depth is less than the service limit, replace the

clutch disc.

Standard (New): 1.65 2.25 mm(0.065 0.089 in.)

Service Limit: 0.7 mm (0.03 in.)

10.

L