service HONDA CIVIC 2002 7.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 615 of 1139

Conventional Brake Components

Rear Brake Pads Inspection and Replacement

Frequent inhalation of brake pad dust, regardless ofmaterial composition, could be hazardous to your

hea hh.. Avoid breathing dust particles.. Never use an air hose or brush to clean brake

assemblies, Use an OSHA-approved vacuum

cleaner.

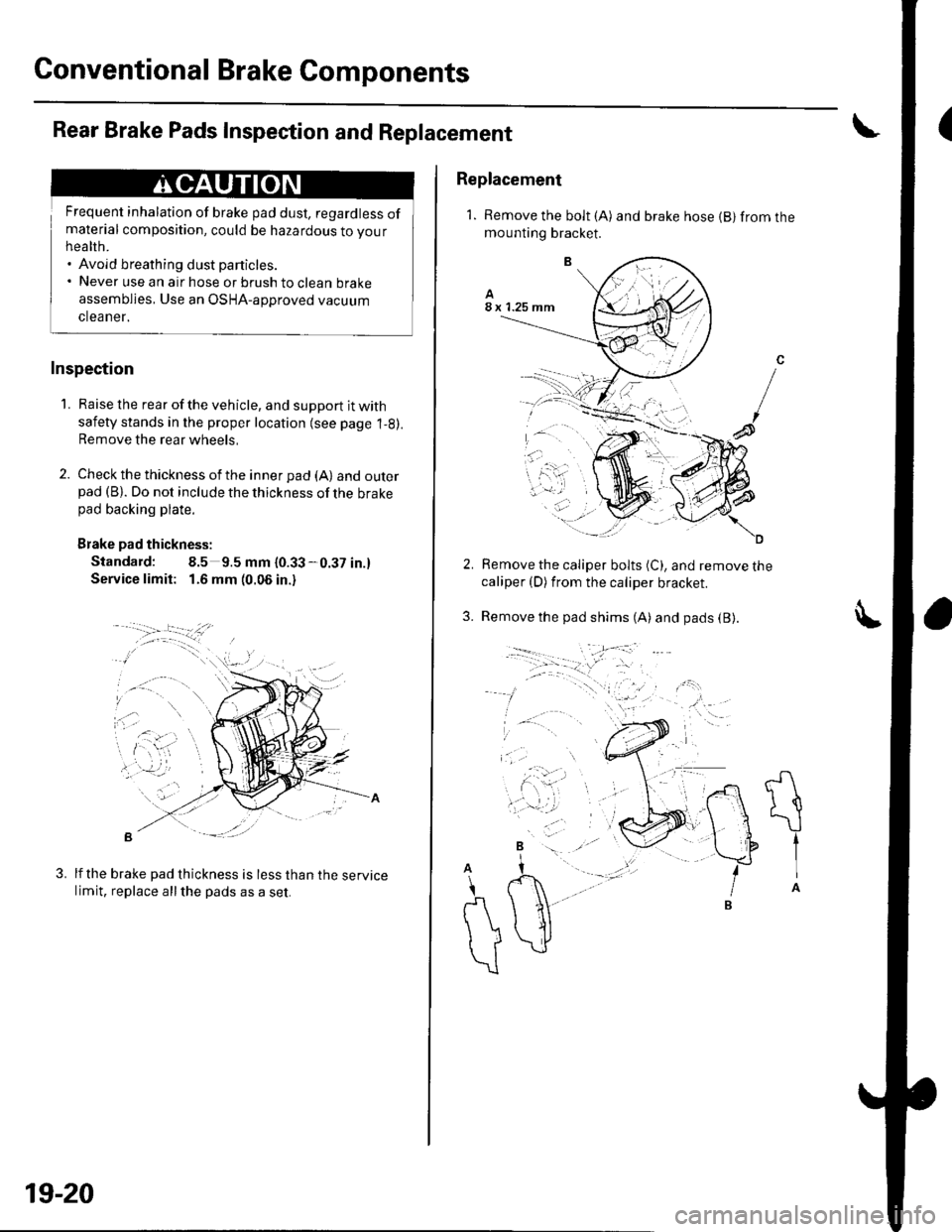

Inspection

'1. Raise the rear of the vehicle, and support jt with

safety stands in the proper location (see page 1-8).Remove the rear wheels,

2. Check the thickness of the inner pad (A) andouterpad (B). Do not include the thickness of the brakepad backing plate.

Brake pad thickness:

Standard: 8.5 9.5 mm {0.33-0.37 in.}

Service limit: 1.6 mm (0.06 in.)

B -::--

lf the brake pad thickness is less than the servicelimit, replace allthe pads as a set.

3.

19-20

Replacement

1. Remove the bolt (A) and brake hose {B} from themounting bracket.

Remove the caliper bolts (C), and remove thecaliper (D) from the caliper bracket.

Remove the pad shims (A) and pads (B).3.

A

t{

\

tIA

A

\

r\

))

\

Page 617 of 1139

Conventional Brake Components

Rear Brake Disc Inspection

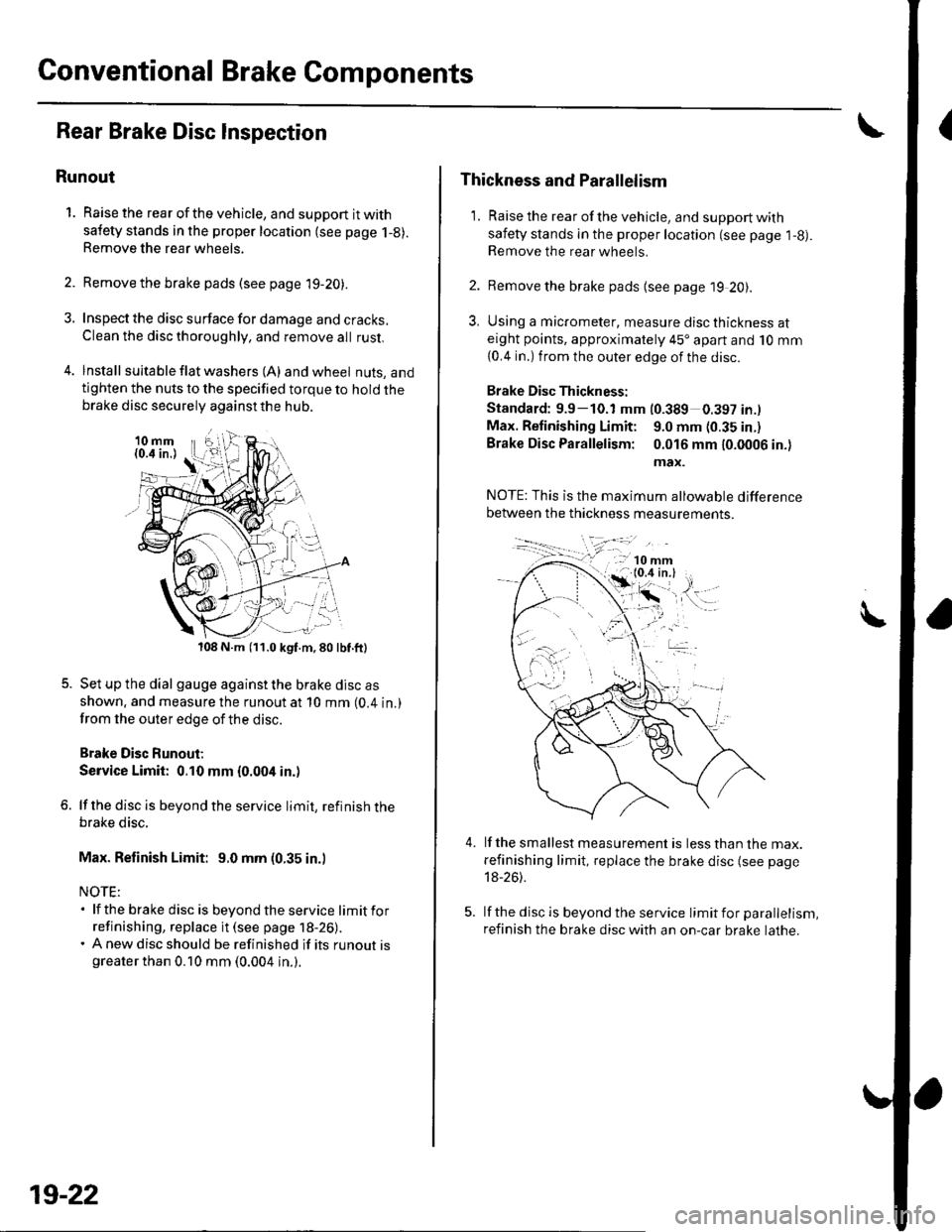

Runout

1. Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).Remove the rear wheels,

2. Remove the brake pads (see page 19-20).

3. Inspect the disc surface for damage and cracks.

Clean the disc thoroughly, and remove all rust,

4. lnstall suita ble f lat washers (A) and wheel nuts, andtighten the nuts to the specified torque to hold thebrake disc securely against the hub.

108 N.m (11.0 kgf.m,80lbf.ft)

Set up the dial gauge against the brake disc as

shown. and measure the runout at 10 mm (0.4 in.)

from the outer edge of the disc.

Brake Disc Runout;

Service Limit: 0.10 mm {0.004 in.)

lf the disc is beyond the service limit, refinish thebrake disc.

Max. Refinish Limit: 9.0 mm (0.35 in.)

NOTE:. lf the brake disc is beyondtheservice limitfor

refinishing, replace it (see page 18-26).. A new disc should be refinished if its runout isgreater than 0.10 mm (0.004 in.).

19-22

Thickness and Parallelism

1. Raise the rear of the vehicle, and support with

safety stands in the proper location (see page l-g).Remove the rear wheels.

2. Remove the brake pads {see page 19 20).

3, Using a micrometer, measure disc thickness ateight points, approximately 45'apart and 10 mm

{0.4 in.) from the outer edge of the disc.

Brake Disc Thickness:

Standard: 9.9-10.1 mm (0.389 0.397 in.l

Max. Retinishing Limit: 9.0 mm (0.35 in.)

Brake Disc Parallelism: 0.016 mm 10.0006 in.)

max.

4.lf the smallest measurement is less than the max.

refinishing limit, replace the brake disc (see page

18-26).

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.

Page 619 of 1139

Conventional Brake Components

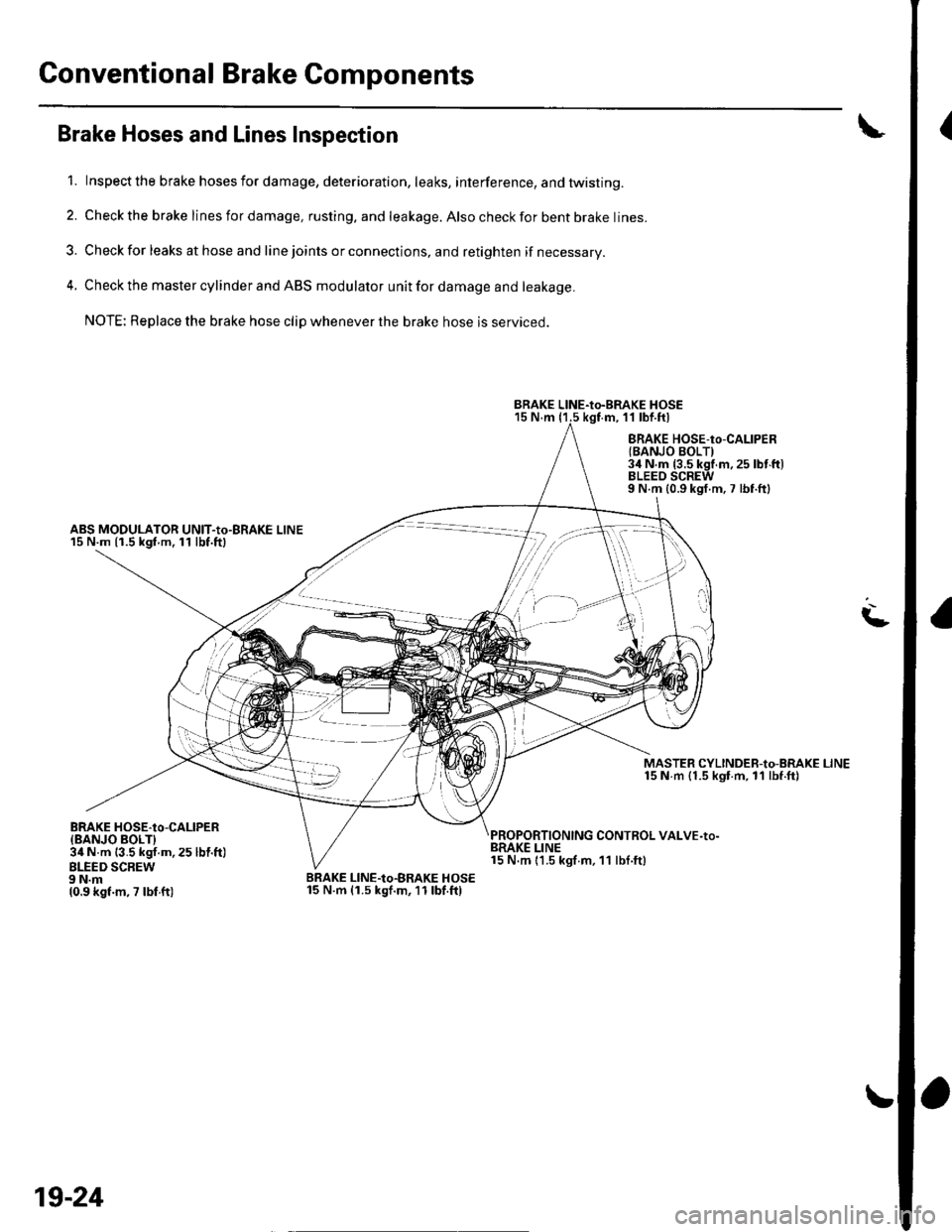

{Brake Hoses and Lines Inspection

1. Inspect the brake hosesfordamage, deterioration, leaks, interference, andtwisting.

2. Check the brake lines for damage, rusting. and leakage. Also check for bent brake lines.

3. Check for leaks at hose and line joints or connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit for damage and leakage.

NOTE: Replace the brake hose clip whenever the brake hose is serviced.

15 N.m (1.5 kgf.m, 11 lbf.ftl

ABS MODULATOR UNIT-Io-BRAKE LINE15 N.m {1.5 kgf m.11 lbf.ftl

BRAKE HOSE-to-CALIPERlBANJO BOLTI3il N.m {3.5 kgf.m.25 lbt'ft)BLEEO SCREW9 N.m {0.9 kgf.m,7 lbf.ftl

MASTER CYLINDEB-to-BRAKE LINE15 N m {1.5 kgt.m, ll lbf.ft)

CONTROL VALVE-to-

L

BRAKE HOSE.tO-CALIPER{BANJO BOLTI34 N.m {3.5 kgf.m, 25 lbl.ft)BLEED SCBEW9 N.m10.9 kgf.m, 7 lbf ft)

BRAKE LINE15 N.m 11.5 kgf m, 11 lbf.ft)

BRAKE LINE-Io-BRAKE HOSE15 N.m (1.5 kgf.m,11lbf.ftl

BRAKE LINE-to-BRAKE HOSE

t''/,i'i'

,/ ,l

t t,.. -)

19-24

Page 626 of 1139

ABS Components

General Troubleshooting Information (cont'd)

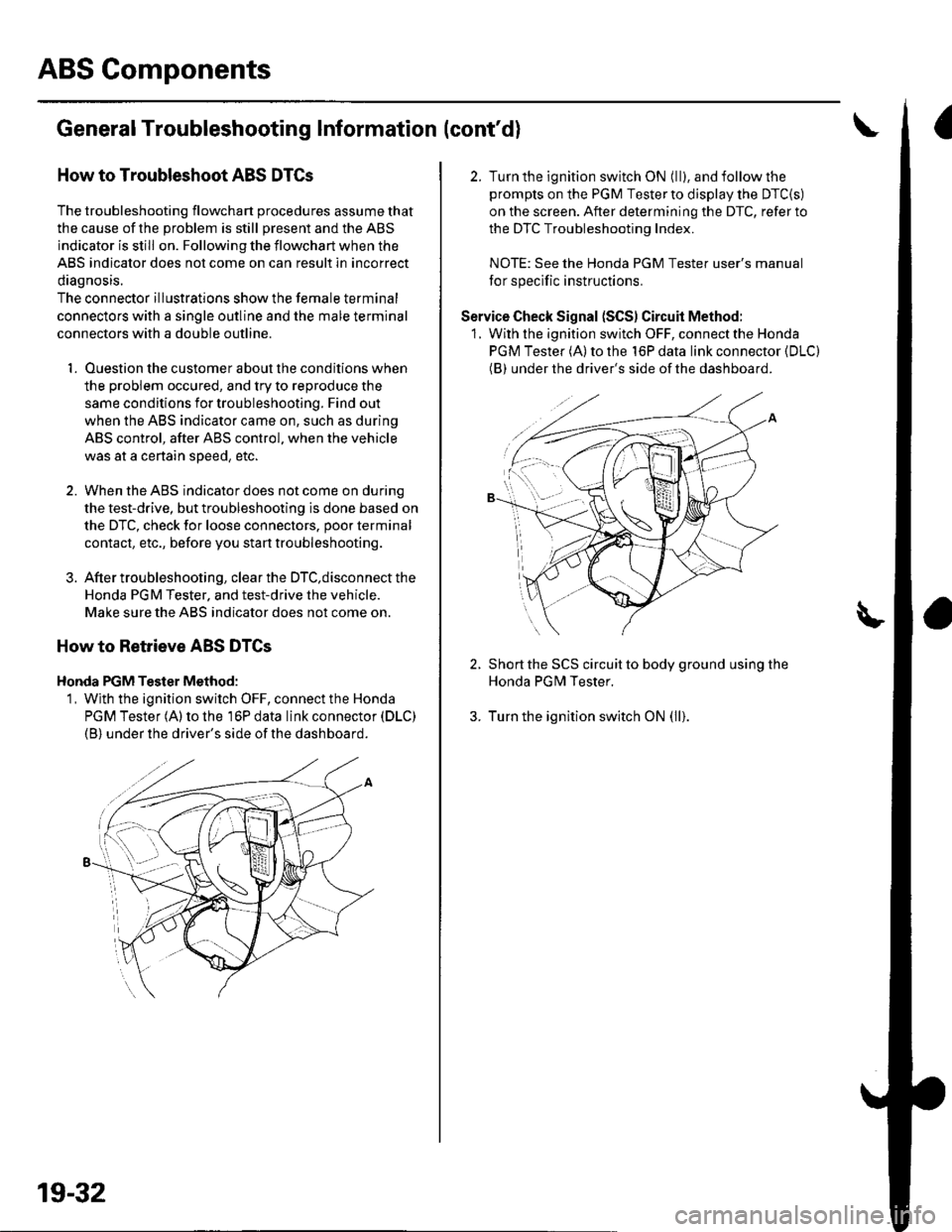

How to Troubleshoot ABS DTCs

The troubleshooting flowchart procedures assume that

the cause of the oroblem is still Dresent and the ABS

indicator is still on. Following the flowchart when the

ABS indicator does not come on can result in incorrect

diagnosis.

The connector illustrations show the female terminal

connectors with a single outline and the male terminal

connectors with a double outline.

1. Ouestion the customer about the conditions when

the problem occured, and try to reproduce the

same conditions for troubleshooting. Find out

when the ABS indicator came on, such as during

ABS control, after ABS control, when the vehicle

was at a certain speed, etc.

2. When the ABS indicator does not come on during

the test-drive, but troubleshooting is done based on

the DTC, check for loose connectors. poor terminal

contact, etc., before you start troubleshooting.

3. After troubleshooting, clear the DTC,disconnect the

Honda PGM Tester. and test-drive the vehicle.

Make sure the ABS indicator does not come on.

How to Retrieve ABS DTCs

Honda PGM Tester Method:

1, Wjth the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) under the driver's side of the dashboard.

19-32

2. Turn the ignition switch ON (ll), and follow the

prompts on the PGM Tester to display the DTC{S)

on the screen. After determining the DTC, refer to

the DTC Troubleshooting Index.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.

Service Check Signal (SCS) Circuit Method:

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(BI under the driver's side of the dashboard.

2. Short the SCS circuit to body ground using the

Honda PGM Tester.

3. Turn the ignition switch ON (ll).

Page 709 of 1139

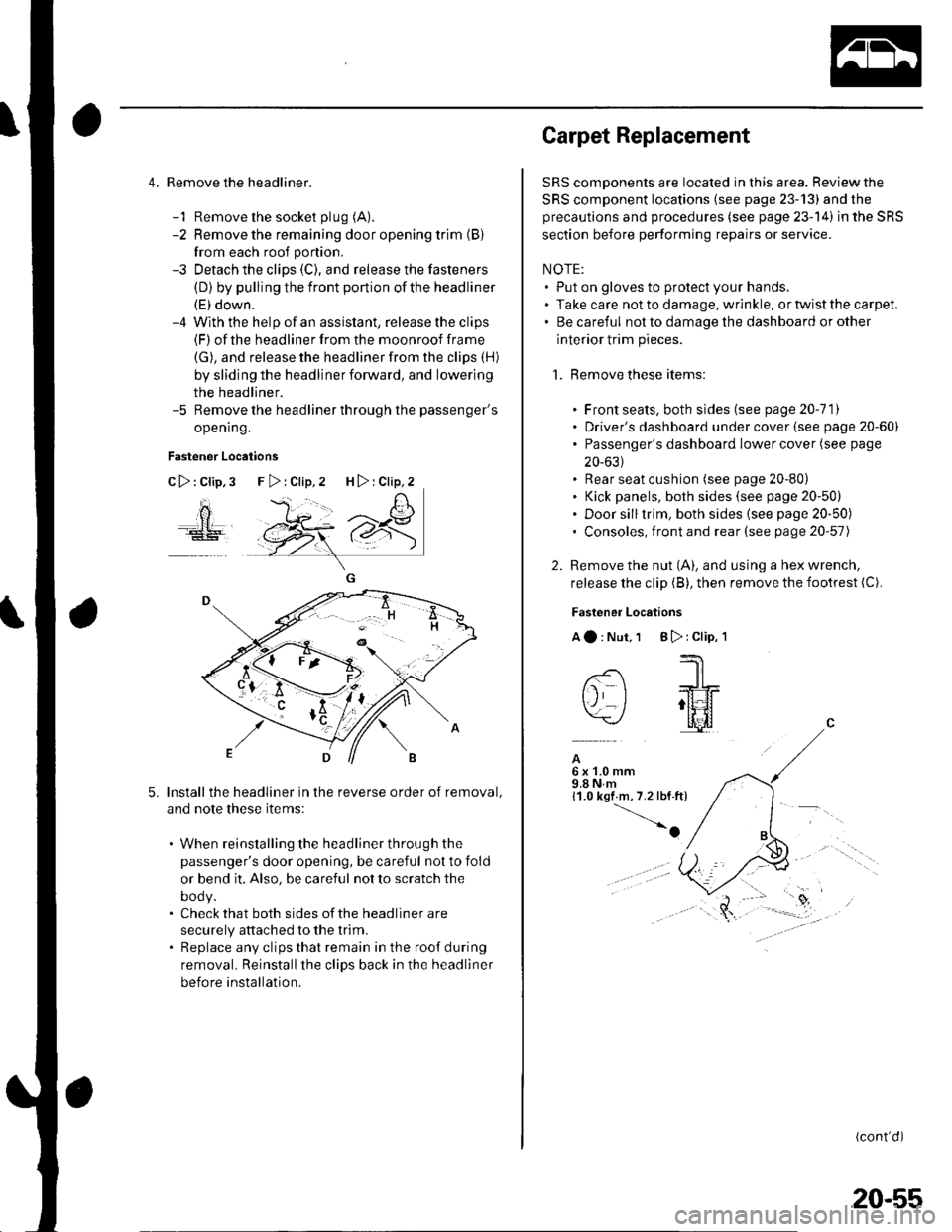

4. Remove the headliner.

-1 Remove the socket plug (A).

-2 Remove the remaining door opening trim {B}

from each roof portion.

-3 Detach the clips (C), and release the fasteners

(D) by pulling the front portion ofthe headliner

(E) down.-4 With the help of an assislant, release the clips(F) of the headliner from the moonroof frame

(G), and release the headliner from the clips (H)

by sliding the headliner forward, and lowering

the headliner.-5 Remove the headliner through the passenger's

opening.

Fastener Locations

C>:Clip,3

ao

5.Install the headliner in the reverse order of removal,

and note these items:

. When reinstalling the headliner through the

passenger's door opening, be careful not to fold

or bend it, Also, be careful not to scratch the

DOOy.. Check that both sides of the headliner are

securely attached to the trim.. Replace any clips that remain in the roof during

removal. Reinstallthe clips back in the headliner

before installation.

F>:Clip,2 H>:Clip,2

Carpet Replacement

SRS components are located in this area. Reviewthe

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

NOTE:. Put on gloves to protect your hands.. Take care not to damage, wrinkle. or twist the carpet.. Be careful not to damage the dashboard or other

interior trim pieces.

1. Remove these items:

. Front seats, both sides (see page 20-111. Driver's dashboard under cover (see page 20-60). Passenger's dashboard Iower cover (see page

20-631. Rear seat cushion (see page 20-80). Kick panels, both sides (see page 20-50). Door silltrim, both sides (see page 20-50). Consoles, front and rear (see page 20-57)

2. Remove the nut (A), and using a hex wrench,

release the clip (B), then remove the footrest (C).

Fastener Locations

Aa:Nut,1 B):Clip,'l

--'1 I

-- -JrL

tj I ;tt4f=\-/ l[il

A6x1.0mm9.8Nm11.0 kgf m,7.2 lbf.ft)

-o

(cont'd)

20-55

Page 717 of 1139

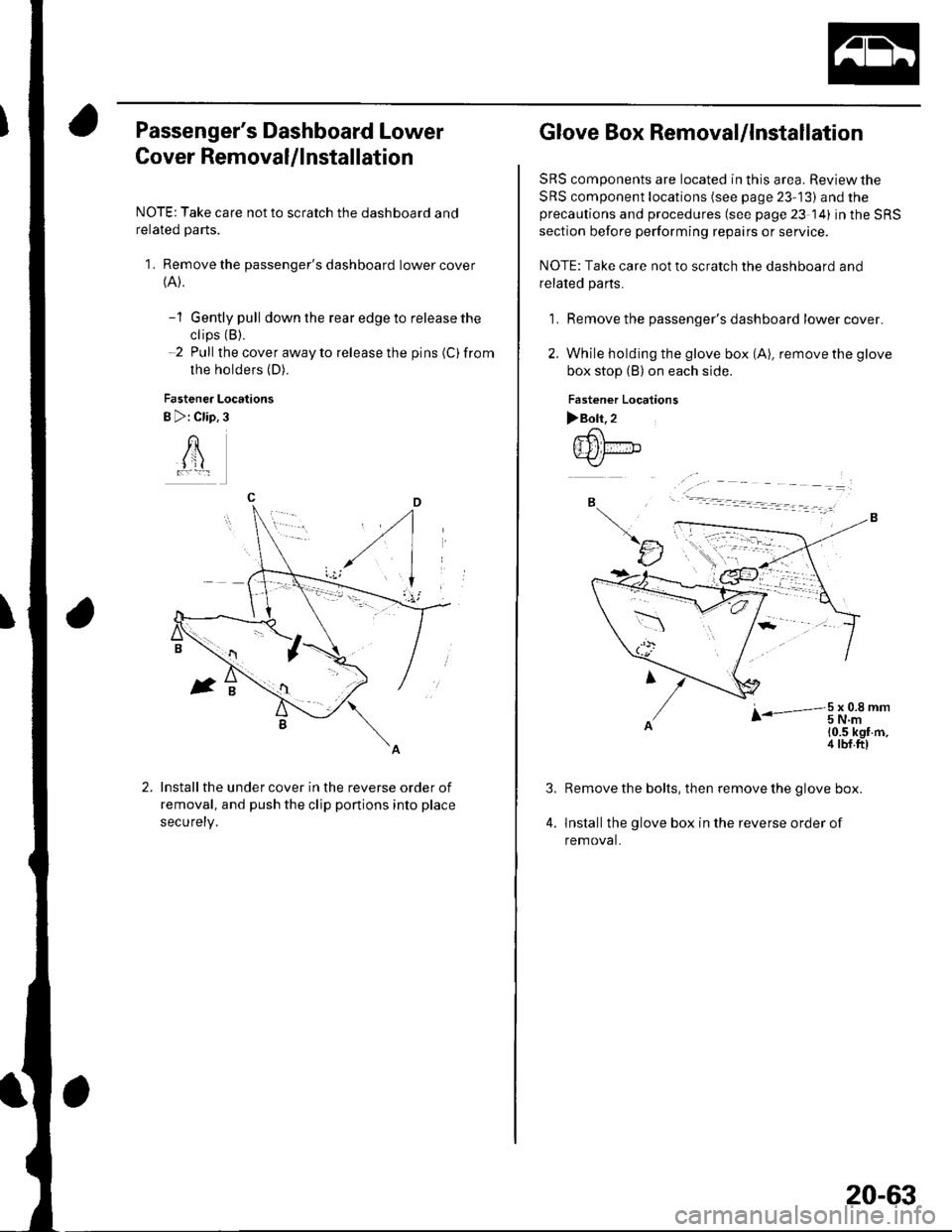

Passenger's Dashboard Lower

Cover Removal/lnstallation

NOTE: Take care not to scratch the dashboard and

related parts.

1. Remove the passenger's dashboard lower cover(A).

-1 Gently pull down the rear edge to release the

ctips (B).

-2 Pull the cover away to release the pins (C)from

the holders (D).

Fastener Locations

B >: Clip,3

AI jl

Install the under cover in the reverse order of

removal, and push the clip ponions into place

securety.

Glove Box Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations (see page 23-13) and theprecautions and procedures (see page 23 14) in the SRS

section before performing repairs or service.

NOTE: Take care not to scratch the dashboard and

related pa rts.

1. Remove the passenger's dashboard lower cover.

2. While holding the glove box (A), remove the glove

box stop (B) on each side.

Fastener Localions

>Boh.2.-6\

{Ill fir-"b.-<,/

B

tJ

r-3t.oi,t-'

10.5 kgf m,4 tbf.ft)

4.

Remove the bolts, then remove the glove box.

lnstallthe glove box in the reverse order of

removal.

20-63

Page 720 of 1139

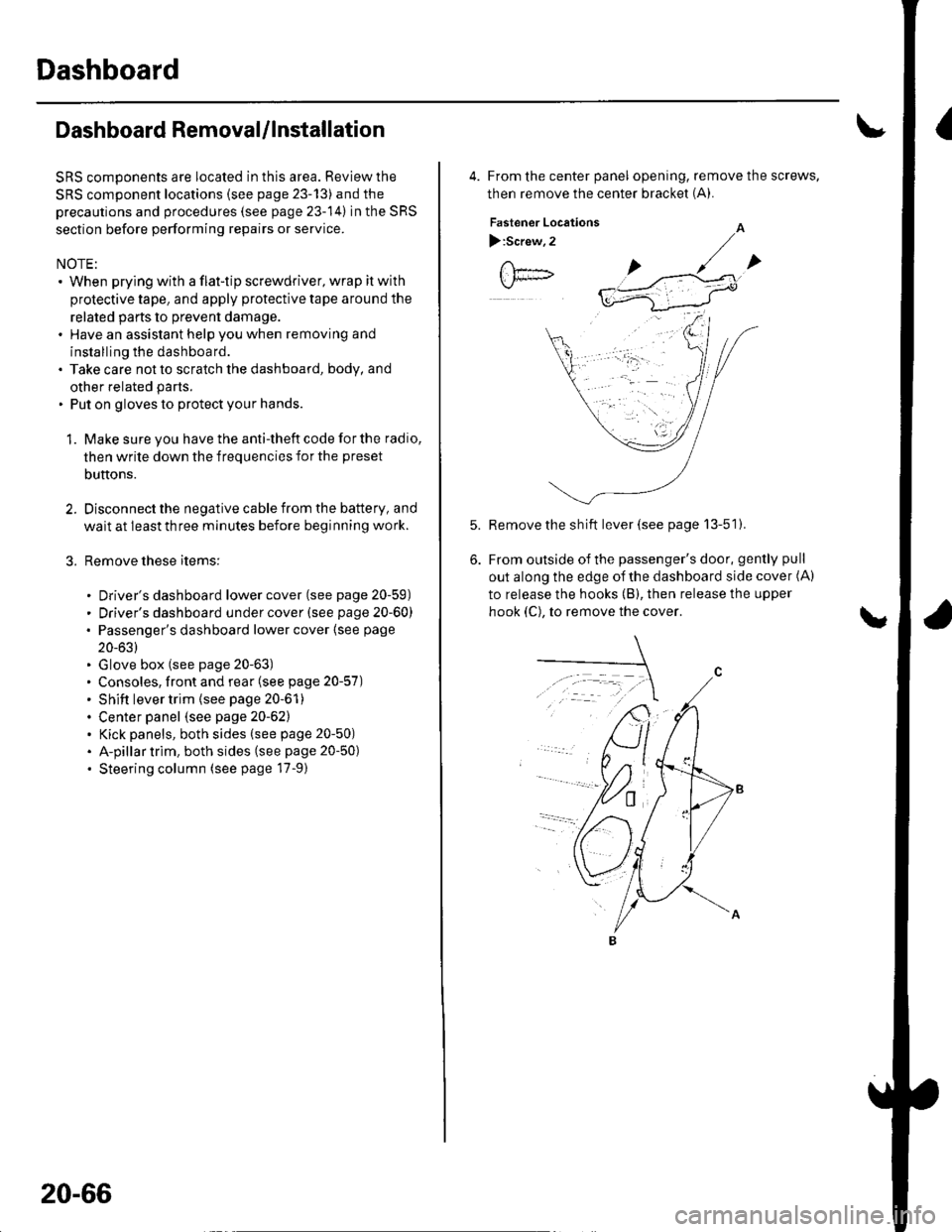

Dashboard

Dashboard Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

NOTE:. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts to prevent damage.. Have an assistant help you when removing and

installing the dashboa rd.. Take care not to scratch the dashboard, body, and

other related parts.

. Put on gloves to protect your hands.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

Disconnect the negative cable from the battery, and

wait at least three minutes before beginning work.

Remove these items:

. Driver's dashboard lower cover (see page 20-59). Driver's dashboard under cover (see page 20-60). Passenger's dashboard lower cover (see page

20-63). Glove box (see page 20-63). Consoles, front and rear (see page 20-57). Shift lever trim {see page 20-61). Center panel (see page 20-62). Kick panels, both sides (see page 20-50). A-pillar trim. both sides (see page 20-50). Steering column (see page 17-9)

20-66

4. From the center panel opening, remove the screws,

then remove the center bracket (A).

Fastener Locations

):Screw,2

Remove the sh ift lever (see page 13-51).

From outside of the passenger's door, gently pull

out along the edge of the dashboard side cover (A)

to release the hooks (B), then release the upper

hook (C), to remove the cover.

Page 725 of 1139

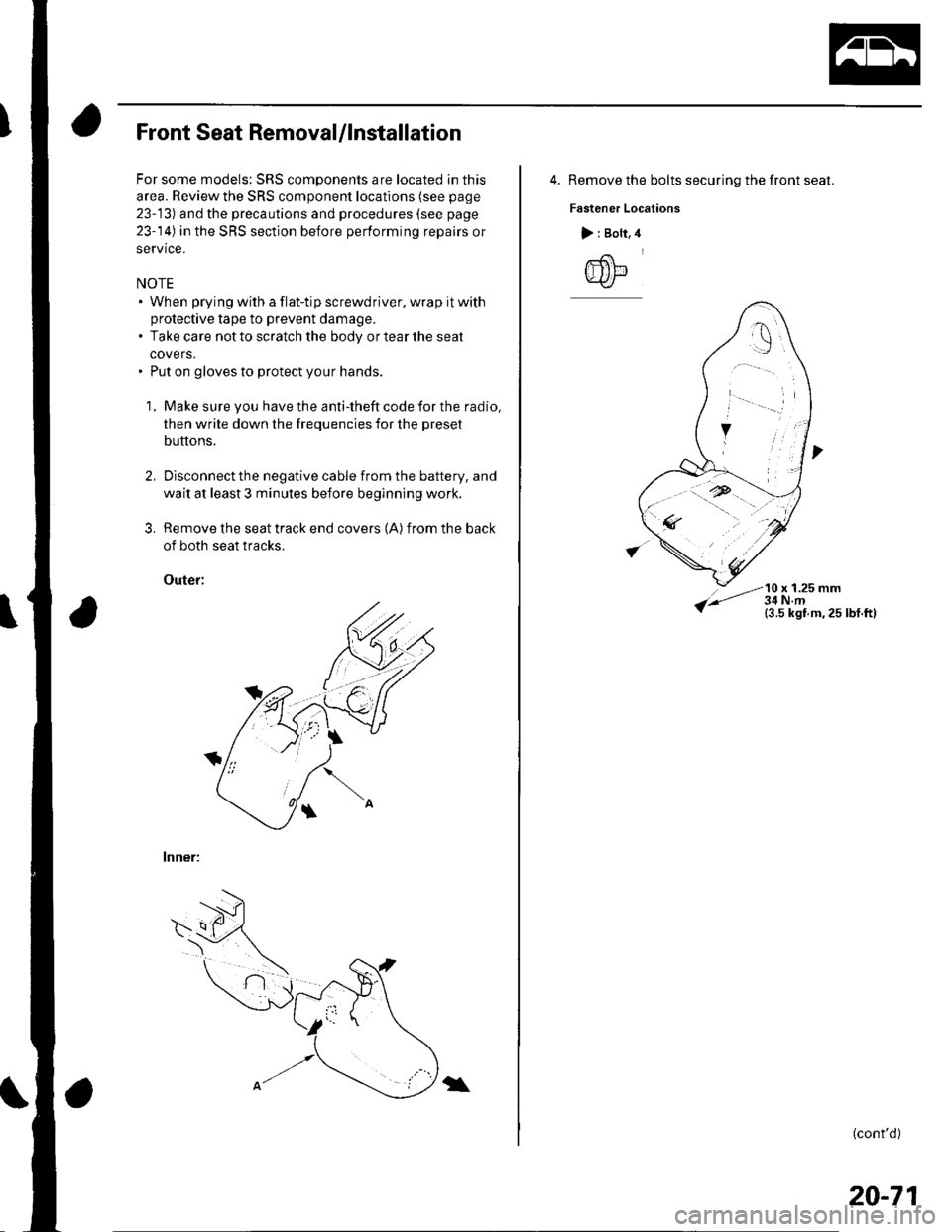

Front Seat Removal/lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-'13) and the precautions and procedures (see page

23-14) in the SRS section before performing repairs or

service.

NOTE. When prying with a flat-tip screwdriver, wrap it with

protective tape to prevent damage.. Take care not to scratch the body or tear the seat

covers.. Put on gloves to protect your hands.

1, Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

butlons.

Disconnect the negative cable from the battery, and

wait at least 3 minutes before beginning work.

Remove the seat track end covers (A) from the back

of both seat tracks.

Outef:

lnner:

3.

\

4. Remove the bolts securing the front seat.

Fastener Locations

10 x 1.25 mm

> : Bolt,

@

(cont'd)

20-71

Page 727 of 1139

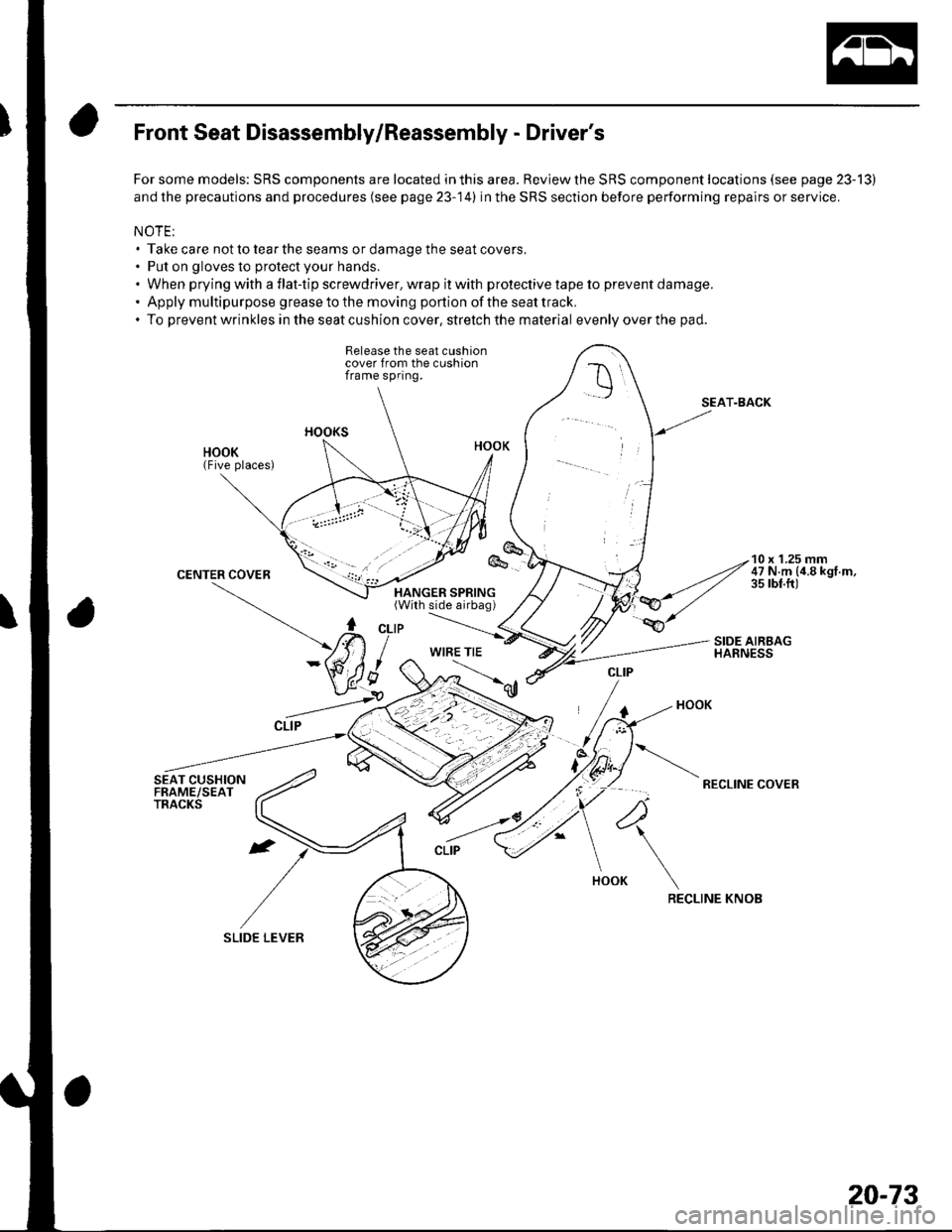

Front Seat Disassembly/Reassembly - Driver's

For some models: SRS components are located in this area. Review the SRS component locations (see page 23-13)

and the precautions and procedures (see page 23-14) in the SRS section before performing repairs or service.

NOTE:. Take care not to tear the seams or damage the seat covers,. Put on gloves to protect your hands.. When prying with a flat-tip screwdriver. wrap it with protective tape to prevent damage.' Apply multipurpose greasetothe moving portion of the seattrack.. To preventwrinkles in the seat cushion cover, stretch the material evenlyoverthe pad.

Release the seat cushioncover from the cushionframe spring.

SEAT-BACK

RECLINE COVER

RECLINE KNOB

10 x 'l.25 mm47 N.m {4.8 kgf.m,35 rbt.ft)

WIRE TIE

4

20-73

Page 728 of 1139

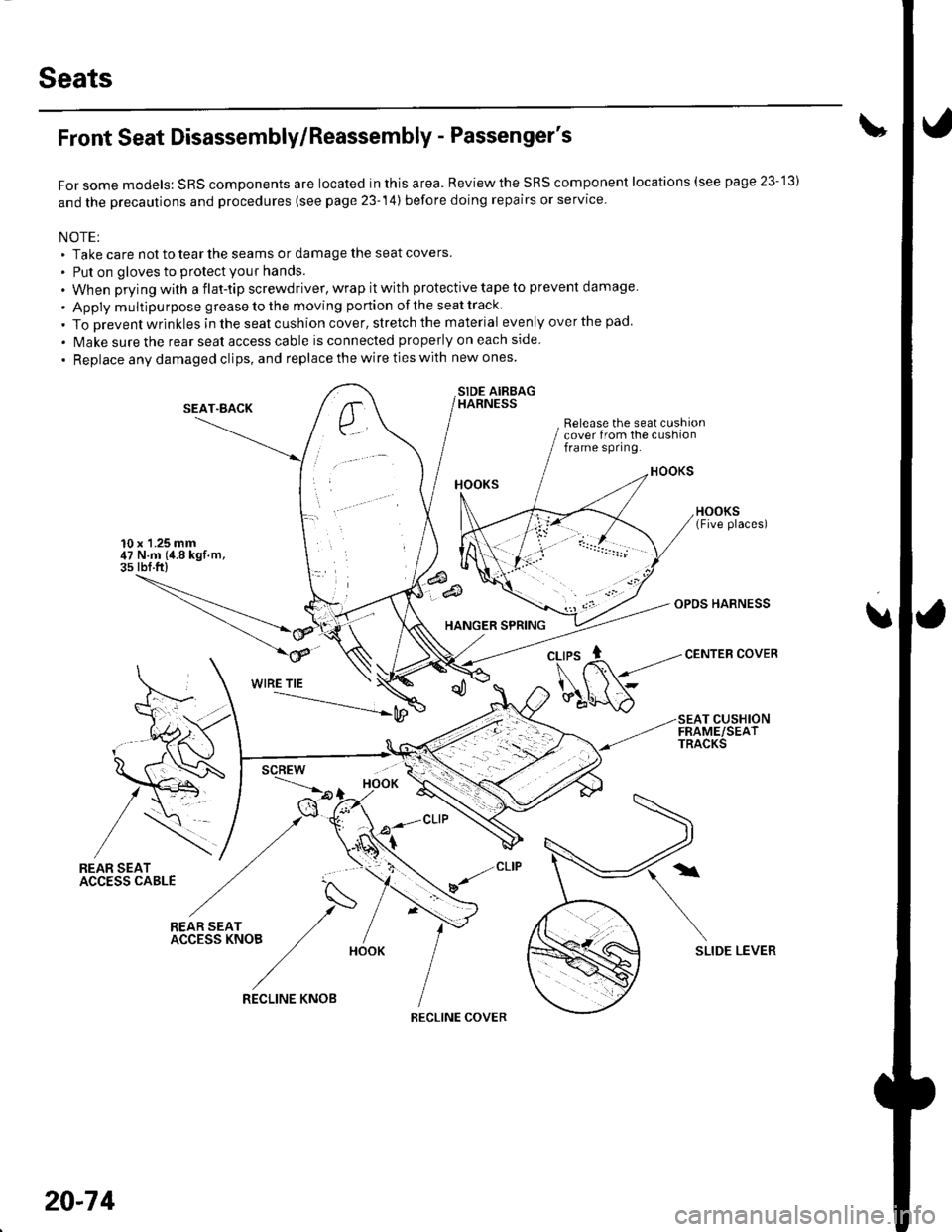

Seats

Front Seat Disassembly/Reassembly - Passenger's

For some models: SRS components are located in this area. Reviewthe SRS component locations (see page 23-'13)

and the precautions and procedures (see page 23-14) before doing repairs or service.

NOTE;. Take care not to tear the seams or damage the seat covers

. Put on gloves to protect your hands.

. When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage

. Apply multipu rpose grease to the moving portion of the seat track

. To Drevent wrinkles in the seat cushion cover, stretch the material evenly over the pad.

. lvlake sure the rear seat access cable is connected properly on each side

. Replace any damaged clips, and replace the wire ties with new ones

SIDE AIRBAGHARNESS

Release the seat cushioncover from the cushionframe spring.

10 x 1.25 mm47 N.m (4.8 kgf.m,3s rbf.ft)

SEAT"BACK

HANGER SPRING

OPDS HARNESS

CENTEB COVER

u

WIRE TIE

SEAT CUSHIONFRAME/SEATTRACKS

/REAR SEATACC€SS CABLE

N

*r(".o, /- IACCESSKNOB ,/ /

/HooK

SLIDE LEVER

,/CLIP

v/

20-74

RECLINE KNOB

RECLINE COVER