switch HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 532 of 1139

DTC tli|: Motor Driven Current is Excessively

Hish

1. Clear the DTC.

2. Start the engine.

3. Turn the steering wheel from lock-to-lock several

times, and wait '10 seconds or more.

Does the EPS indicator come on?

YES Go to step 4.

NO-Check for loose wires or poor connections. lf

the connections are good, the system is OK at this

ttme.I

4. Stop the engine, and verify the DTC.

ls DTC 43 indicated?

YES Go to step 5.

NO-Perform the appropriate troubleshooting for

the code indicated.I

5. Make sure the ignition switch is OFF, then

disconnect EPS control unit connector B (2P) and

the motor 2P connector.

6. Turn the ignition switch ON (ll).

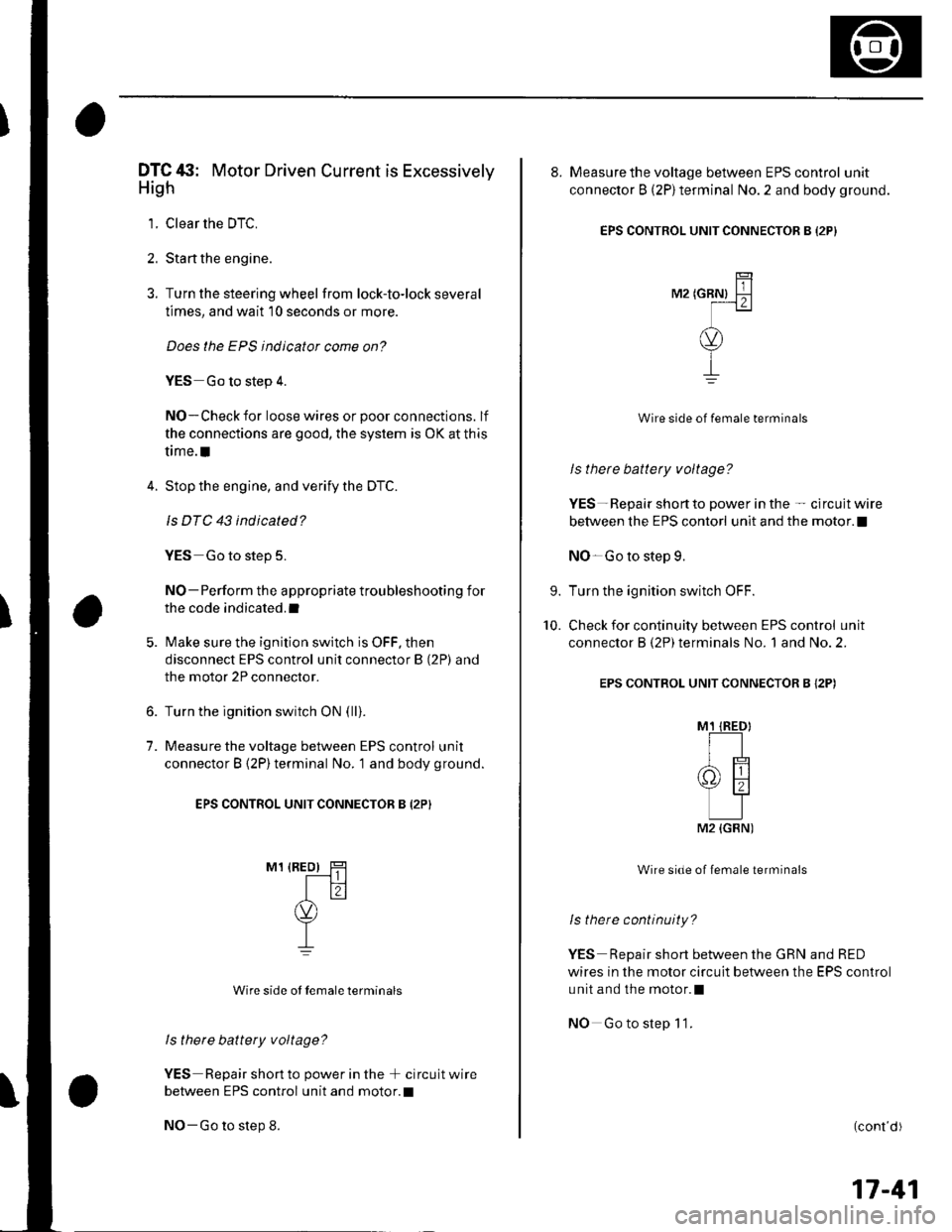

7. Measure the voltage between EPS control unit

connector B (2P)terminal No. '1 and body ground.

EPS CONTROL UNIT CONNECTOR B {2P}

M1 {REo) HT------t I I

Itr(v)

T-L

Wire side ot Iemale terminals

ls therc battery voltage?

YES Repair short to power in the + circuit wire

between EPS control unit and motor.l

NO-Go to step 8.

8. Measure the voltage between EPS control unit

connector B (2P)terminal No. 2 and body ground.

EPS CONTROL UNIT CONNECTOR B I2PI

TilM2 tcRNl F-lf---1 z I

(v)

Y

I

Wire side of female terminals

ls there battety voltage?

YES- Repair short to power in the - circuit wire

between the EPS contorl unit and the motor. !

NO-Go to step 9.

Turn the ignition switch OFF.

Check for continuity between EPS control unit

connector B (2P) terminals No. 1 and No. 2.

EPS CONTROL UNIT CONNECTOR B {2P)

Wire side of female terminals

ls there continuity?

YES Repair short between the GRN and RED

wires in the motor circuit between the EPS control

unit and the motor.l

NO Gotostep 11.

9.

10.

(cont d)

17-41

M2 {GBN)

Page 538 of 1139

EPS Indicator Circuit Troubleshooting

1.Turn the ignition switch ON (ll), start the engine,

and watch the EPS indicator.

Does the EPS indicator come on?

YES lf the EPS indicator comes on and goes off, it's

OK. lf the EPS indicator stays on or blinks. go to

step 12.

NO Go to step 2.

Turn the ignition switch OFF, then ON (ll) again,

and watch the brake system indicator,

Does the brake system indicator come on?

YES-Go to step 3.

NO Repair open in the indicator power source

circuit.l. Blown No. 10 (7.5A)fuse.

. Open in the wire between the No. 10 (7.5A) fuse

and gauge assembly.. Open circuit inside the under-dash fuse/relay box,. Faulty gauge assembly.

Turn the ignition switch OFF,

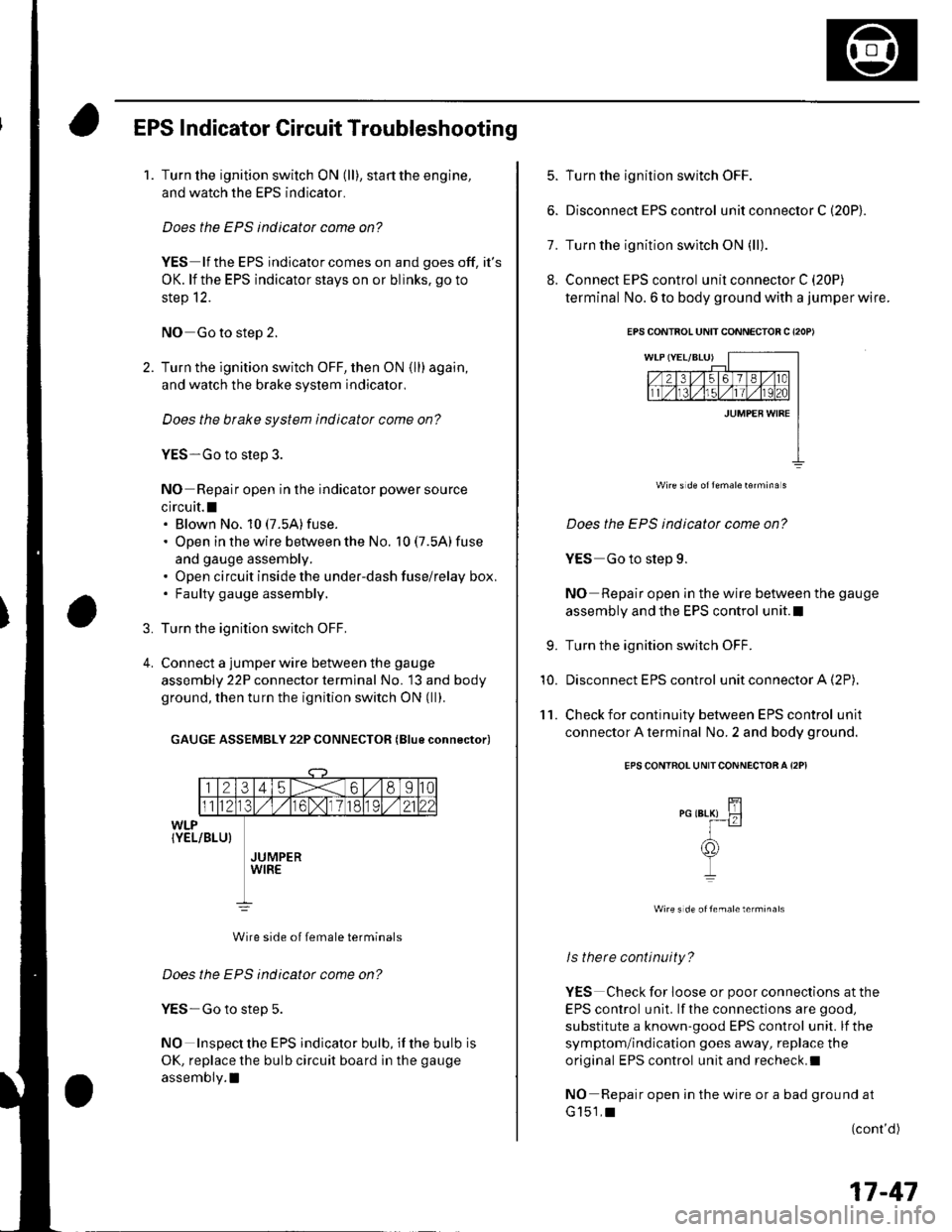

Connect a jumper wire between the gauge

assembly 22P connector terminal No. 13 and body

ground, then turn the ignition switch ON (ll).

GAUGE ASSEMBLY 22P CONNECTOR (Blue connector)

Wire side of female terminals

Does the EPS indicator come on?

YES-Go to step 5.

NO Inspect the EPS indicator bulb, if the bulb is

OK, replace the bulb circuit board in the gauge

assembly.l

3.

4.

5. Turn the ignition switch OFF.

6. Disconnect EPS control u n it connector C (20P).

7. Turn the ignition switch ON (ll).

8. Connect EPS control unit connector C (20P)

terminal No. 6 to body ground with a jumper wire.

Wire s d€ oflemale16rmina s

Does the EPS indicatot come on?

YES Go to step 9.

NO Repair open in the wire between the gauge

assembly and the EPS control unit.l

Turn the ignition switch OFF.

Disconnect EPS control unit connector A (2P),

Check for continuity between EPS control unit

connector A terminal No. 2 and body ground.

EPS CONTROL UNITCONNECTOA A I2PI

wire s de oftemale terminals

ls there continuity?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.I

NO Repair open in the wire or a bad ground at

G151,t(cont'd)

9.

10.

'l 1.

EPS CONTBOL UNIT CONNECTOB C {2OP)

17-47

Page 539 of 1139

EPS Components

I

12.

EPS Indicator Circuit Troubleshooting (cont'dl

Turn the ignition switch OFF.

Disconnect EPS control unit connector C (20P).

Turn the ignition switch ON (ll).

Does the EPS indicator come on?

YES-Repair short to ground in the YEUBLU wire

between the gauge assembly and the EPS control

unit, or replace the bulb circuit board in the gauge

assembly.l

NO-Go to step 15.

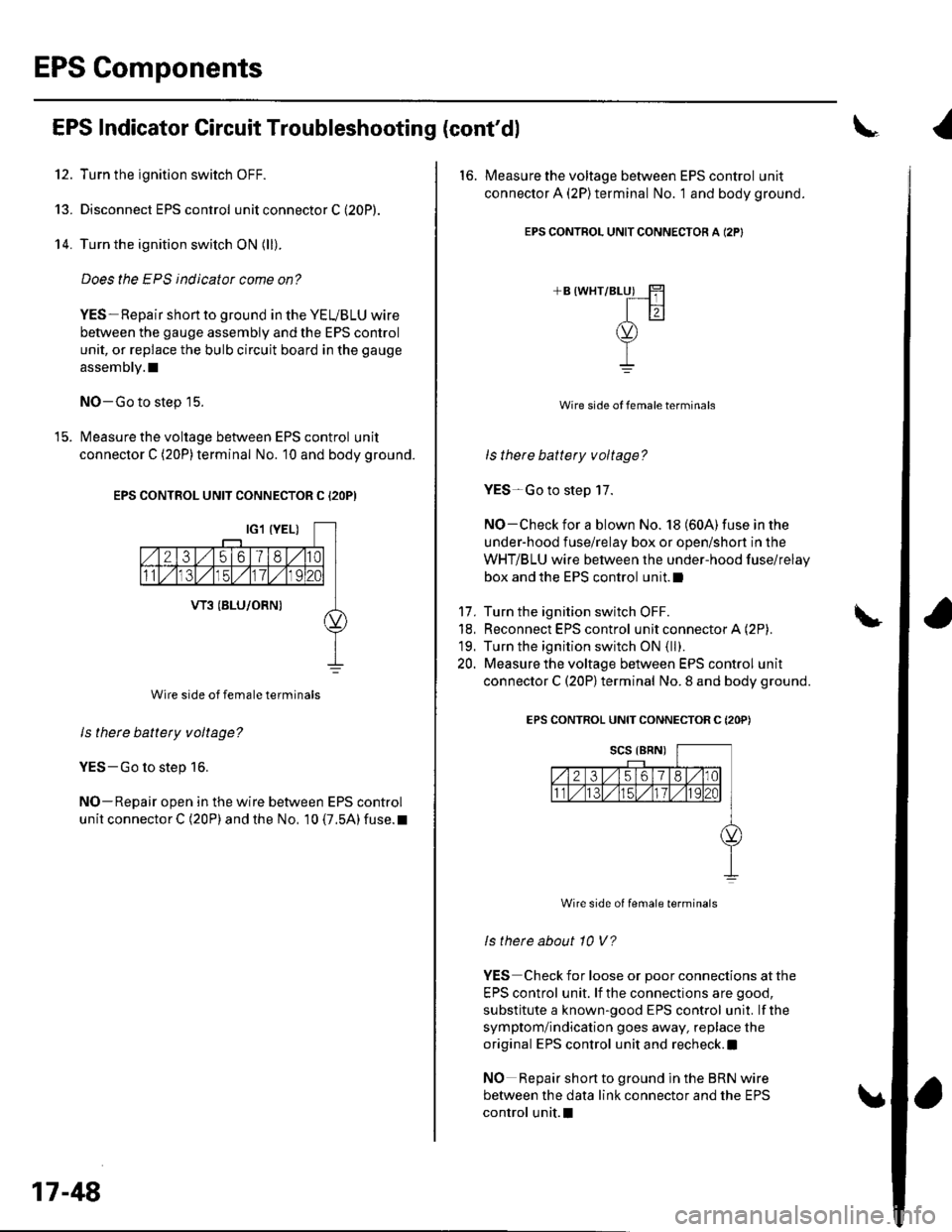

Measure the voltage between EPS control unit

connector C (20P)terminal No. 10 and body ground.

EPS CONTROL UNIT CONNECTOR C I2OP)

Wire side of female terminals

ls there battery voltage?

YES-Go to step 16.

NO-Repair open in the wire between EPS control

unit connector C (20P) and the No, 10 (7.5A) fuse. t

13.

14.

17-48

16. Measure the voltage between EPS control unit

connector A (2P)terminal No. '1 and body ground.

EPS CONTROL UNITCONNECTON A (2P}

+B (WHT/BLUI H

Itr

v-L

17.

18,

19.

20.

Wire side of female terminals

ls there battery voltage?

YES-Go to step 17.

NO-Check for a blown No. 18 (604) fuse in the

under-hood fuse/relay box or open/short in the

WHT/BLU wire between the under-hood fuse/relay

box and the EPS control unit.l

Turn the ignition switch OFF.

Reconnect EPS control unit connector A (2P).

Turn the ignition switch ON (ll).

Measure the voltage between EPS control unit

connector C (20P)terminal No. 8 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side of female terminals

ls therc about 10 V?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.l

NO Repair short to ground in the BRN wire

between the data link connector and the EPS

control unit.I

Page 596 of 1139

Brakes

Conventional Brake Components

Special Tools ... ..... ... l9-2

Component Location Index ......................................... 19-3

Brake System Inspection and

Tests ............... .......... 19-4

Brake Pedal and Brake Pedal Position Switch

Adjustment .............. 19-6

Parking Brake Check and

Adjustment .............. 19-7

Brake System Bleeding ...................... 19-8

Brake System Indicator Circuit

Diagram ................... 19-9

Parking Brake Switch Test ................. 19-10

Brake Fluid Level Switch Test ...................................... 19-10

Front Brake Pads lnsoection and

Replacement ........... 19-11

Front Brake Disc Inspection ............... 19-13

Front Brake Calioer Overhaul ...................................... 19-14

Master Cylinder Replacement ........... 19-15

Master Cylinder Inspection ................ 19-16

Brake Booster

Pushrod Clearance Adjustment ................................ 19-16

Brake BoosterTest ................... .......... 19-18

Brake Booster Reolacement .............. 19-19

Rear Brake Pads Inspection and

Reolacement ........... 19-20

Rear Brake Disc Inspection ................ 19-22

Rear Brake Caliper Overhaul ....................................... 19-23

Brake Hoses and Lines Insoection .... 19-24

Brake Hose Reolacement ................... 19-25

Parking Brake Cable Replacement .............................. 19-26

ABS (Anti-lock Brake System)

Gomponents ... 19-29

Page 598 of 1139

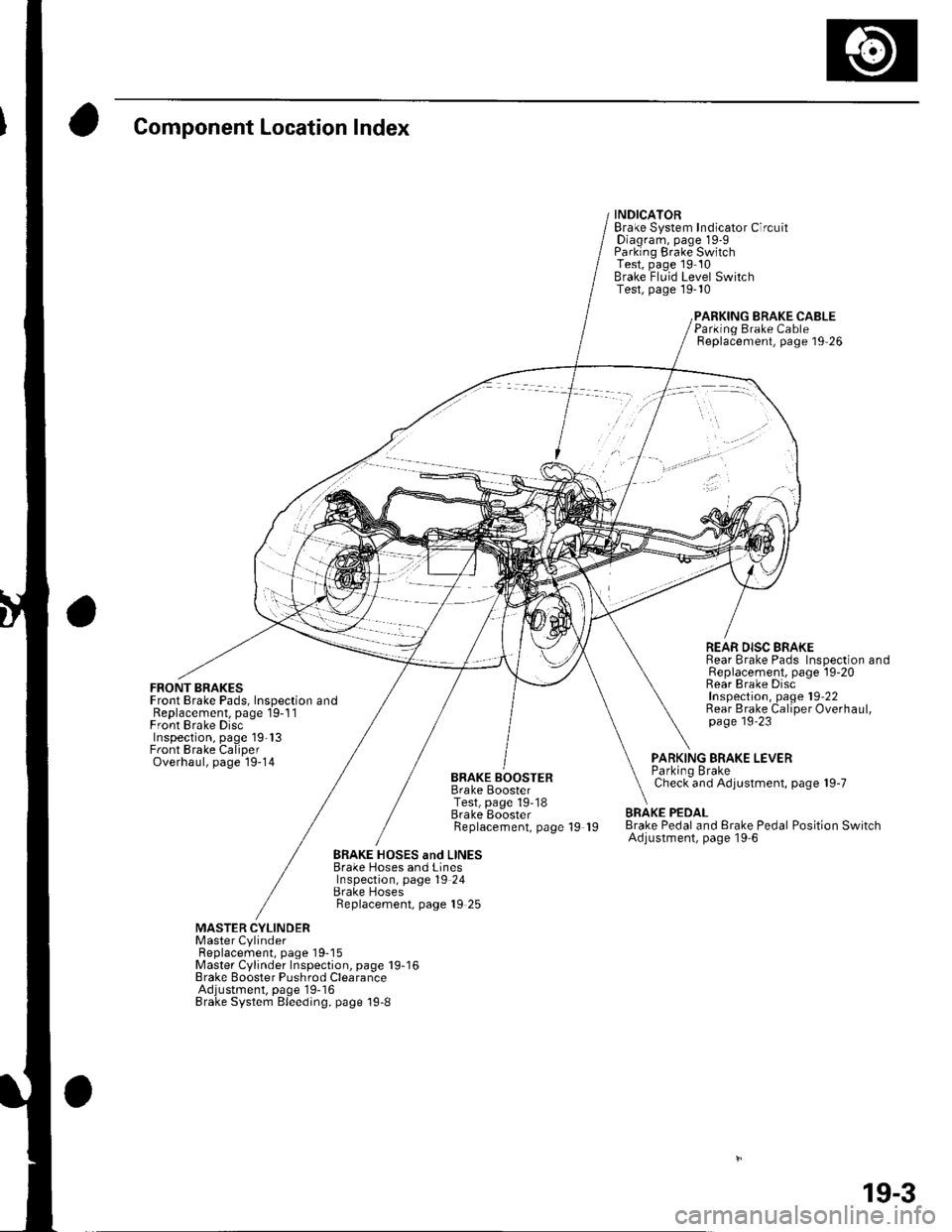

Component Location Index

FRONT BRAKESFront Brake Pads, Inspection andReplacement, page 19-1 1Front Brake DiscInspection, page 19'13Front Brake CaliperOverhaul, page 19-14

INDICATORBrake System Indicator CircuitDiagram, page 19-9Parking Brake SwitchTest, page 19 10Brake Fluid Level SwitchTest, page 19-10

BRAKE CABLE

BRAKE BOOSTERBrake BoosterTest, page 19-18Brake EoosterReplacement, page 19 19

Parking Brake CableReplacement, page 19 26

REAR DISC BRAKERear Brake Pads Inspection andReplacement, page l9-20Rear Brake DiscInspection, page 19'22Rear Brake Caliper Overhaul,page 19'23

PARKING BRAKE LEVERParkino BrakeCheck and Adjustment, page 19-7

BRAKE PEDALBrake Pedal and Erake Pedal Position SwitchAdjustment, page l9-6

BRAKE HOSES and LINESBrake Hoses and LinesInspection, page 19 24Brake HosesReplacement, page 19 25

MASTER CYLINDERMaster CylinderFl6^1.^6m6nr ^2^o 1O-18Master Cylinder Inspection, page 19-16Brake Booster Pushrod ClearanceAdjustment, page'19-16Brake System Bleeding, page 19-8

19-3

Page 600 of 1139

Rapid brake pad wear. Vehicle vibration {after a long

drivel, or High, hard brake pedal

1. Drive the vehicle until the brakes drag or untilthe

pedal is high and hard. This can take 20 or more

brake pedal applications during an extended test

drive.

2. With the engine running, raise the vehicle on a lift,

and spin all four wheels by hand.

ls there btake drag at any of the wheels?

YES Go to step 3.

NO Look for other causes of the pad wear, high

pedal, or vehicle vibration.I

3. Turn the engine off, pump the brake pedal to

deplete the vacuum in the brake booster, and then

spin the wheels again to check for brake drag.

ls therc brake dtag at any ot the wheels?

YES-Go to step 4.

NO Replace the brake booster.I

4. Without removing the brake lines, unbolt and

separate the master cylinder from the booster, then

spin the wheels lo check for brake drag.

ls there btake drag at any of the wheels?

YES Go to step 5,

NO-Check the brake pedal position switch

adjustment and pedal free play.I

5. Loosen the hydraulic lines at the master cylinder,

then spin the wheels to check for brake drag.

ls there brake drag at any of the wheels?

YES Go to step 6.

NO- Replace the master cylinder.l

6. Loosen the bleeder screws at each caliper, then

spin the wheels to check for brake drag.

Is there brake drag at any of the wheels?

YES Disassemble and repair the caliper on the

wheel(s) with brake drag.l

NO Inspect brake hose (s)/line (s).

19-5

Page 601 of 1139

Conventional Brake Components

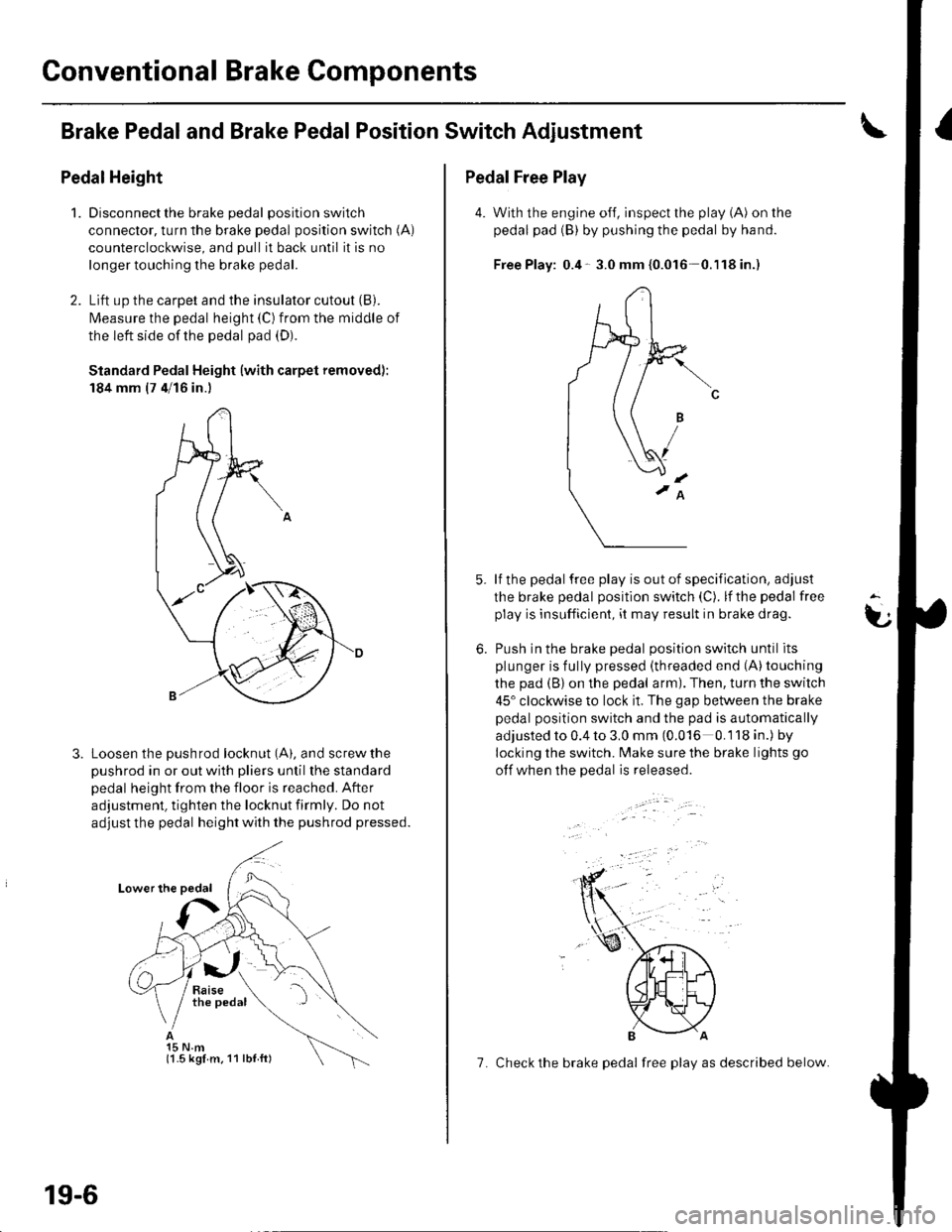

Brake Pedaland Brake PedalPosition Switch Adjustment

Pedal Height

1.Disconnect the brake pedal position switch

connector, turn the brake pedal position switch (A)

counterclockwise, and pull it back until it is no

longer touching the brake pedal.

Lift up the carpet and the insulator cutout (B).

l\4easure the pedal height (C) from the middle of

the left side of the pedal pad (D).

Standard Pedal Height (with carpet removed):

184 mm (7 4/16 in.)

Loosen the pushrod locknut (A), and screw the

pushrod in or out with pliers until the standard

pedal height from the floor is reached. After

adjustment, tighten the locknut firmly. Do not

adjust the pedal height with the pushrod pressed.

15 N.m(1.5 kgl m. 11 lbl ft)

19-6

7. Check the brake pedal free play as described below.

Pedal Free Play

4. With the engine off, inspect the play (A) on the

pedal pad (B) by pushing the pedal by hand.

Free Play: 0.4- 3.0 mm {0.016 0.'l18in.)

lf the pedal free play is out of specification, adjust

the brake pedal position switch (C). lf the pedal free

play is insufficient, it may result in brake drag.

Push in the brake oedal oosition switch until its

plunger is fully pressed (threaded end (A)touching

the pad (B) on the pedal arm). Then, turn the switch

45" clockwise to lock it. The gap between the brake

pedal position switch and the pad is automatically

adjusted to 0.4 to 3.0 mm (0.016 0.118 in.) by

locking the switch. Make sure the brake lights go

otf when the pedal is released.

t

6.

Page 605 of 1139

Conventional Brake Components

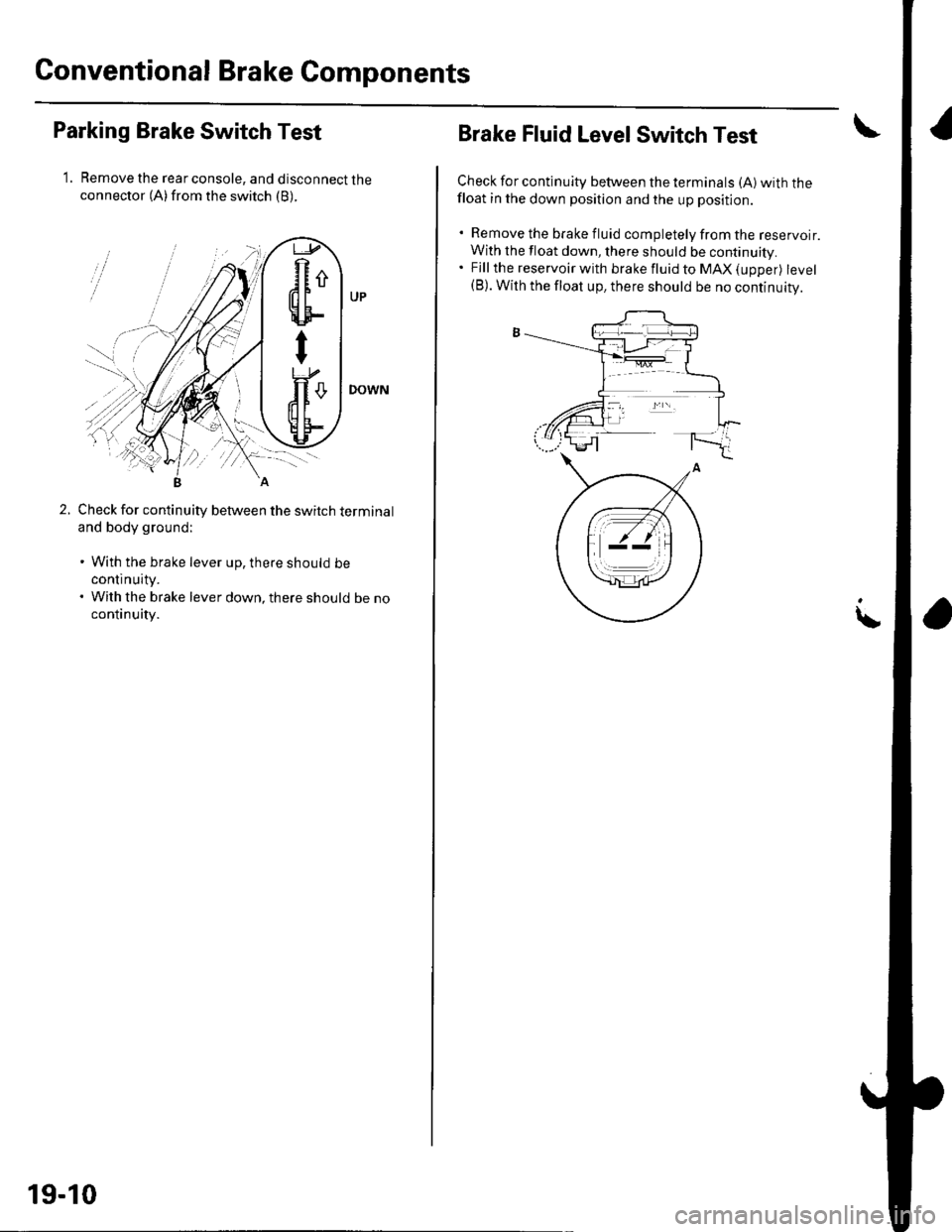

Parking Brake Switch Test

1. Remove the rear console, and disconnect theconnector (A)from the switch (B).

Check for continuity between the switch terminal

and body ground:

. With the brake lever up, there should be

continuity.. With the brake lever down, there should be no

continuity.

R

'dFu\!E!UF-

Y

19-10

Brake Fluid Level Switch Test

Check for continuity between the terminals (A) with thefloat in the down position and the up position.

. Remove the brake fluid completely from the reservoir.

With the float down, there should be continuity.. Fjllthe reservoir with brakefluidto MAX(upper) level(B). With the float up, there should be no continuity.

\

Page 613 of 1139

Gonventional Brake Components

IBrake Booster Test

Functional Test

1. With the engine stopped, press the brake pedal

several times to deplete the vacuum reservoir, thenpress the pedal hard, and hold itfor 15 seconds. lfthe pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines. modulator, or calipers) is leaking.

2. Start the engine with the brake pedal pressed. lf thepedal sinks slightly, the vacuum booster is workingproperly. lf the pedal height does not vary, thebooster or check valve is faulty.

3. With the engine running, press the brake pedal

lightly. lfthe brake pedal sinks more than 1O mm

{3/8 in, ) in 3 minutes, the master cylinder is faulty.A slight change in pedal height when the Ay'C

compressor cycles on and off is normal. (The A,/C

compressor load changes the vacuum available tothe booster.)

Leak Test

1. Press the brake pedal with the engine running, thenstop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum boosteris OK. lf the pedal rises, the booster is faulty.

2. With the engine stopped, press the brake pedal

several times using normal pressure. When thepedal is first pressed, it should oe row.

On consecutive applications, the pedal height

should gradually rise. lfthe pedal position does notvarv, check the booster check valve.

19-18

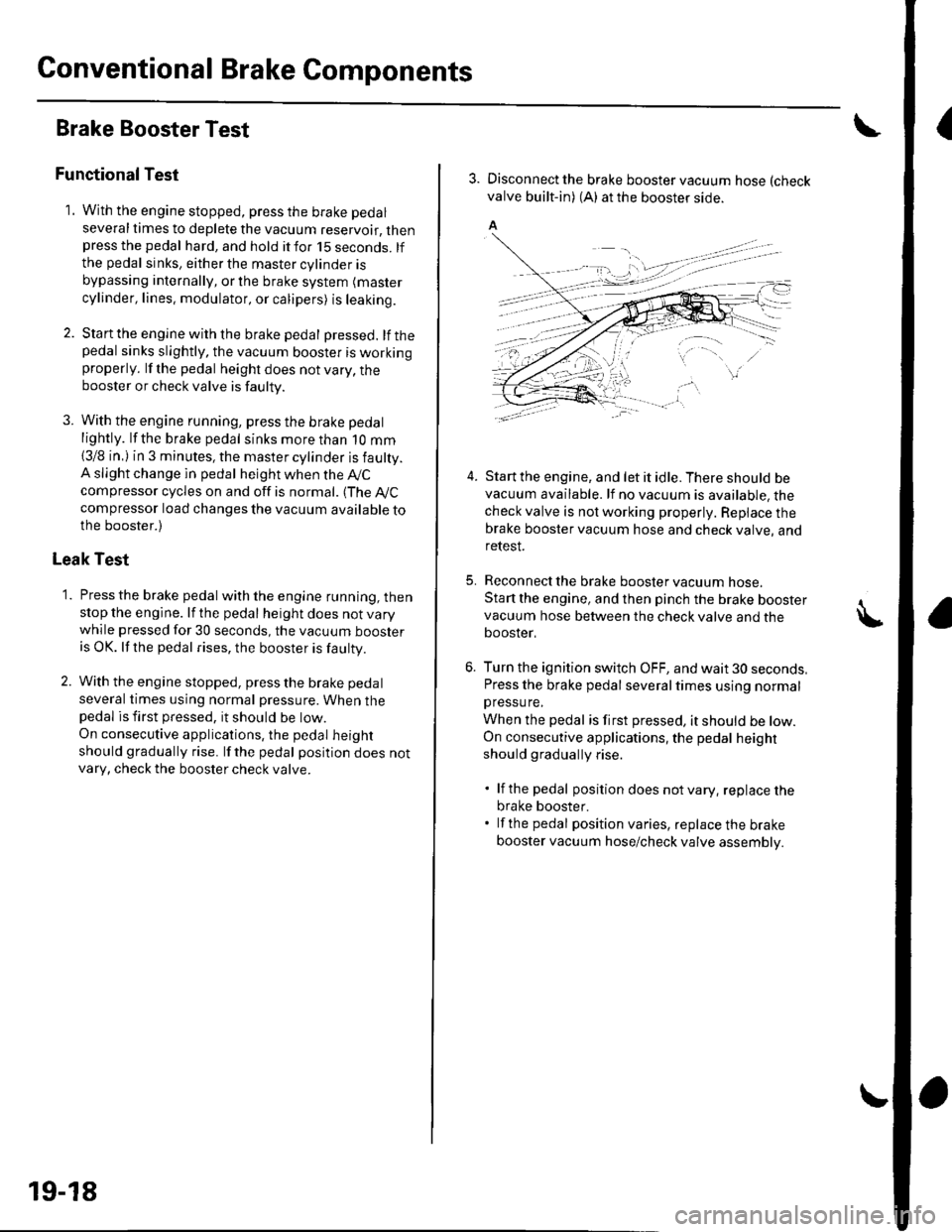

3. Disconnect the brake booster vacuum hose (check

valve built-in) (A) at the booster side.

5.

4.Start the engine, and let it idle. There should bevacuum available. lf no vacuum is available, thecheck valve is not working properly. Repiace thebrake booster vacuum hose and check valve, andrelesI.

Reconnect the brake booster vacuum nose.

Start the engine, and then pinch the brake boostervacuum hose between the check valve and thebooster,

Turn the ignition switch OFF, and wait 30 seconds,Press the brake pedal several times using normalpressu re,

When the pedal is first pressed, it should be low.On consecutive applications, the pedal height

should gradually rise.

. lf the pedal position does notvary, replacethe

brake booster.. lf the pedal position varies, replace the brake

booster vacuum hose/check valve assembly.

Page 625 of 1139

General Troubleshooting Information

ABS Indicator

. lf the system is OK,theABS indicator goes off 2

seconds after turning the ignition switch ON (ll)

without starting the engine, and then comes on again

and goes off 2 seconds later after starting the engine.

This occurs because the ABS control unitisturned

on by the lG2 power source.. The ABS indicator comes on when the ABS control

unit detects a problem in the system. However, even

though the system is operating properly, the indicator

will come on under these conditions:- Only the drive wheels rotate- One drive wheel is stuck- The vehicle goes into a spin- The ABS continues to operate for a long time.- The vehicle is subjected to an electrical signal

disturbance

To determine the actual cause of the problem, question

the customer about the problem. taking the above

condilions into consideration.

. When a Droblem is detected and lhe ABS indicator

comes on, there are cases when the indicator stays

on until the ignition switch is turned OFF, and cases

when the indicator goes off automatically when the

sYstem returns to normal.- DTC 61: The ABS indicator goes off automatically

when the system returns to normal.- DTC 11, 13,15,17 ,31,32,33, 34, 35, 36, 37, 38, 54,

or 81: The ABS indicator stays on until the ignition

switch is turned OFF whether or not the system

returns to normal.- DfC 12, 14, 16, 1a,21,51,52, or 53; The ABS

indicator goes off when the vehicle is driven again

and the system is OK after the ignition switch is

turned from OFF to ON {ll}.

Diagnostic Trouble Code {DTCI

. The memory can hold three DTCS. However, when

the same DTC is detected more than once, the more

recent DTC is written over the earlier one.

Therefore, when the same problem is detected

repeatedly, it is memorized as a single DTC.. The DTCs are in the order they occurred, beginning

with the most recent.. The DTCS are memorized in the EEPROM (non-

volatile memory). Therefore. the memorized DTCs

are not cleared when the battery is disconnected, the

ignition switch is turned off, or the system returns to

normal. Do the specified procedures to clear the

DTCs.

Self-diagnosis

. Self-diagnosis can be classified into two categories:- Initial diagnosis:

Done right after the engine starts and until the ABS

indicator goes off- Regular diagnosis:

Done rightafterthe initial diagnosis until the

ignition switch is turned OFF. When a problem is detected by self-diagnosis, the

system does the following:- Turns the ABS indicator on- Memorizes the DTC- Stops ABS control

Kickback

The pump motor operates when the ABS is functioning,

and the fluid in the reservoir is forced out to the master

cylinder, causing kickback at the brake pedal.

Pump Motor

. The pump motor operates when the ABS is

functioning.. The ABS control unit checks the pump motor

operation when the vehicle is started the first time

after the ignition switch is turned ON (ll). You may

hear the motor operate at this time, but it is normal.

(cont'd)

19-31