Front HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 34 of 1139

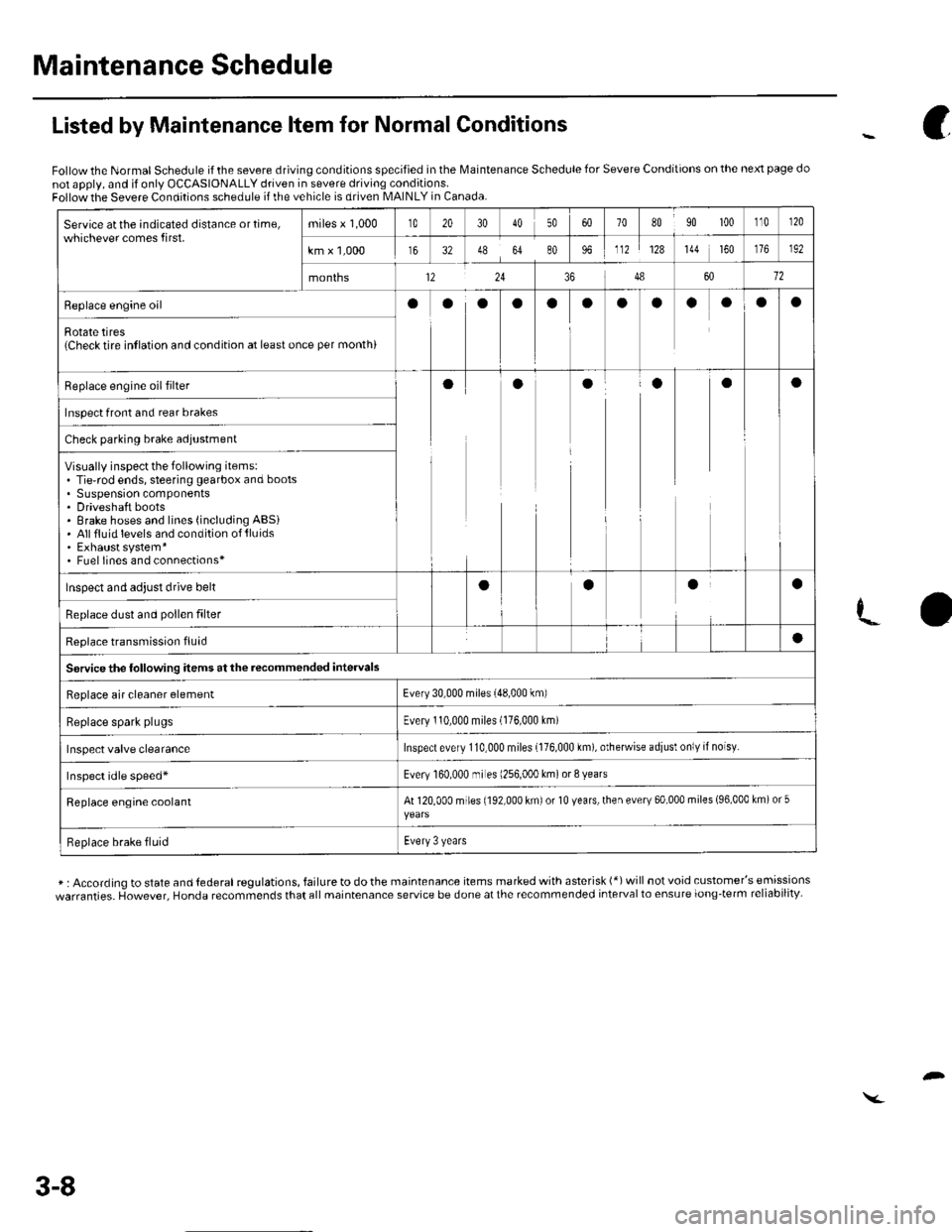

Maintenance Schedule

Service atthe indicated distance ortime,whichever comes first.miles x 1,000t020304050708090 100110r20

km x 1,000163248648096112128144 160192

months12243486012

Replace engine oilooooaooaaoOa

Rotate tires{Check tire intlation and condition at least once per month)

Replace engine oil filterooaaaa

Inspect front and rear brakes

Check parking brake adjustment

Visually inspect the following items:. Tie-rod ends, steering gearbox and boots. Suspension components. Driveshaft boots. Brake hoses and lines (including ABSi. Allfluid levels and condition of{luids. Exhaust system*. Fuel lines and connections*

Inspect and adjust drive beltaaaa

Replace dust and pollen filter

Reolace transmission fluid

Servicethe following items at the recommended intervals

a

Replace air cleaner elementEvery 30,000 miles (48,000 km)

Replace spark plugsEvery 110,000 miles (176,000 Lm)

Inspect valve clearanceInspect every 110,000 miles {176,000 km), otherwise adiusl only if noisy.

Inspect idle speed*Every 160.000 mr es 1256,000 km) or 8 years

Replace engine coolantAt 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (96,000 km) or 5

Replace brake fluidEvery 3 years

Listed by Maintenance ltem for Normal Conditions

Follow the Normal Schedule if the severe driving conditions specified in the lMaintenance Schedule for Severe Conditions on the next page do

not apply, and if only OCCASIONALLY driven in severe driving conditions.Follow the Severe Conditions schedule if the vehicle is driven MAINLY in Canada.

* : According to state and lederal regulations, failure to do the maintenance items marked with asterisk (*) will not void customer's emissions

warranties. However, Honda recommends that all maintenance service be done at the recommended interval to ensure long-term reliability-

c

3-8

Page 35 of 1139

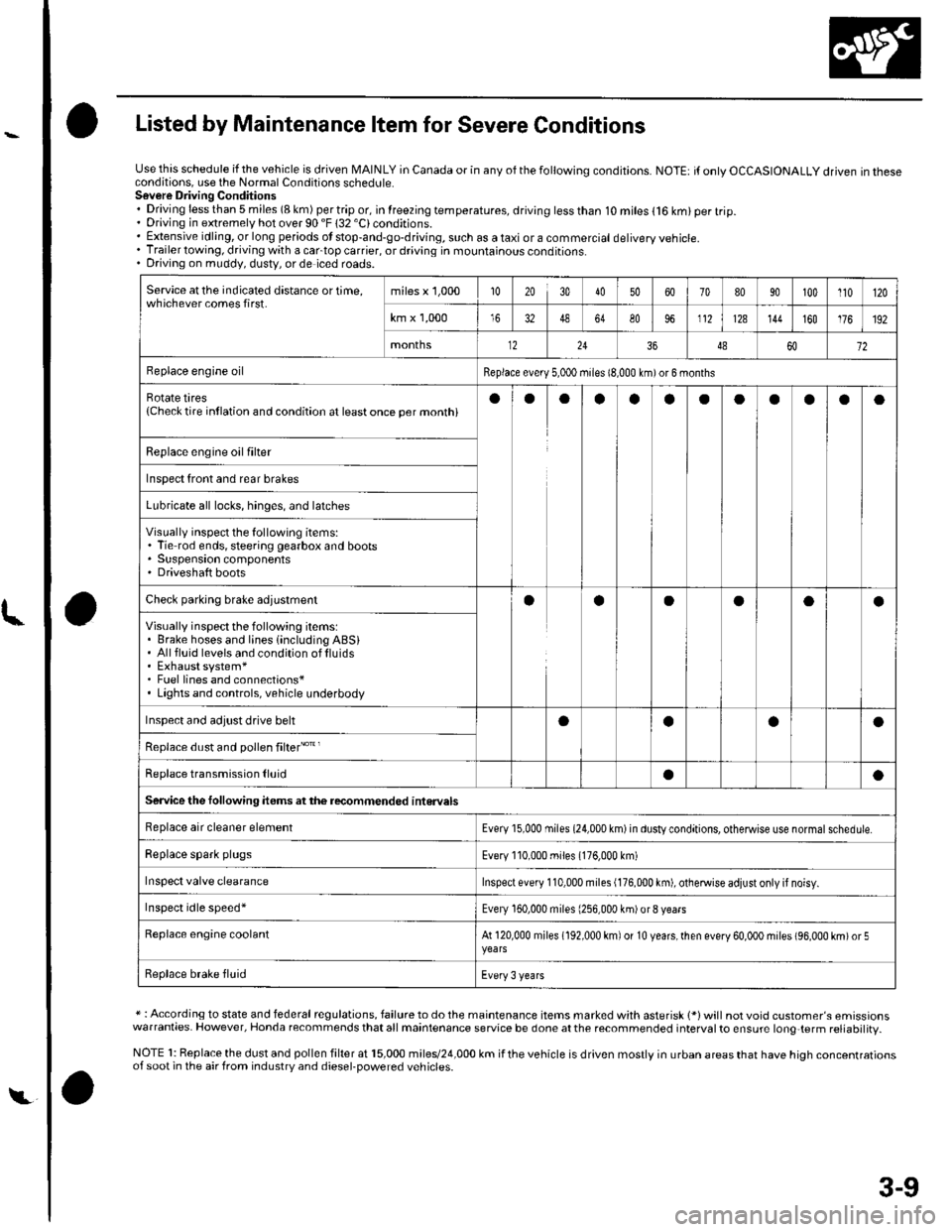

Listed by Maintenance ltem for Severe Conditions

Use this schedule if the vehicle is driven MAINLY in Canada or in anv of the followina conditions.NOTE: it only OCCASIONALLY driven in theseconditions, use the Normal Conditions schedute.Sovere Driving Conditions. Driving less than 5 miles (8 km) per trip or, in lreezing temperatures, driving less than. Driving in extremely hot over 90 "F 132 'C)conditions.10 miles (16 km) per trip.

. Extensive idling, or long periods ot stop-and-go-driving, such as a taxi or a commercial delivery vehicle.. Trailer towing, driving with a cartop carrier, or driving in mountainous conditions.. Driving on muddy, dusty, or de iced roads.

Service at the indicated distance or time,whichever comes first.miles x 1,000102030405060708090100110120

km x 1,0001648648096112128144160176192

months122436486072

Replace engine oilReplace every 5,000 miies 18,000 km)or 6 months

Rotate tires{Checktire intlation and condition at leastonce per monthiaoaaoaaoaaao

Replace engine oil fiher

Inspect front and rear brakes

Lubricate all locks, hinges, and latches

Visually inspect the following items:. Tie rod ends, steering gearbox and boots. Suspension components' Driveshaft boots

Checl parking brale adjuslmentaaOaoa

Visually inspect the following items:. Brake hoses and lines {including ABSi. Allfluid levels and condition oflluids. Exhaust system*. Fuel lines and connections*. Lights and controls, vehicle underbody

Inspect and adjust drive behoaoa

Replace dust and pollen filter"o't'

Replace transmission lluidaa

Service the following items atthe recommended interuals

Replace air cleaner elementEvery 15,000 miies (24,000 km) in dusty conditions, otheMise use normal schedule.

Replace spark plugsEvery 110,000 miles (176,000 km)

Inspect valve clearanceInspect every 110,000 miles (176,000 km), otheMise adiust only if noisy.

Inspect idle speed'Every 160,000 miles (256,000 km)or8 vears

Replace engine coolantAt 120,000 miles (192,000 km) of 10 years,lhen every 60,000 miles (96,000 km)or 5

Replace brake fluidEvery 3 years

* : According to state and federal regulations, failure to do the maintenance items marked with asterisk 1*)will not void customer's emissionswarranties. However, Honda recommends that all maintenance service be done at the recommended interval to ensure long{erm reliabilitv.

NOTE 1: Replace the dust and pollen filter at 15,000 miles/24,000 km if the vehicle is driven mostly in urban areas that have high concentrationsof soot in the air from industrv and diesel-Dowered vehicles.

t,

3-9

Page 64 of 1139

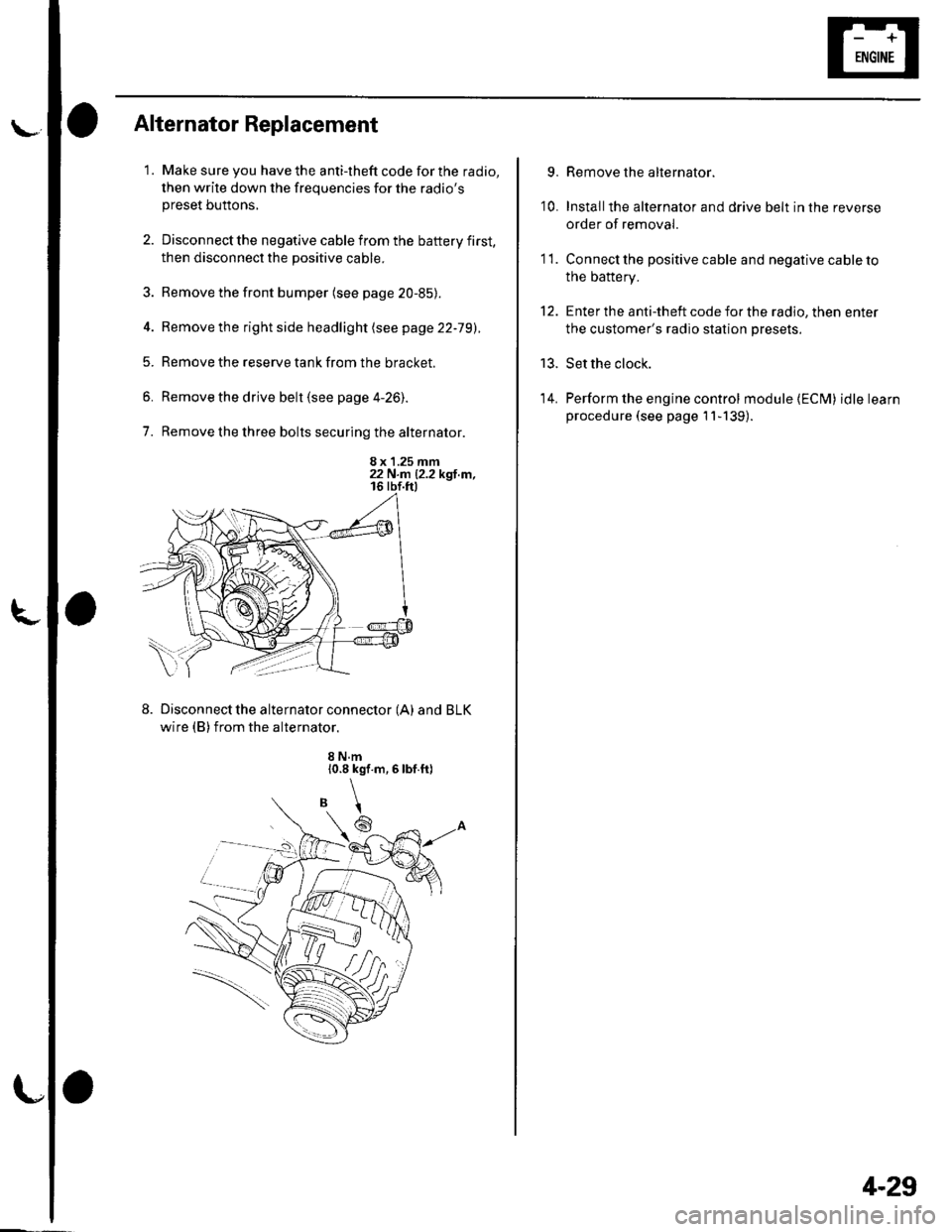

l\-Alternator Replacement

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio'spreset buttons,

2. Disconnect the negative cable from the battery first,

then disconnect the positive cable.

3. Remove the front bumper (see page 20-85).

4. Remove the right side headlight (see page 22-79).

5. Remove the reserve tank from the bracket.

6. Remove the drive belt (see page 4-26).

7. Remove the three bolts securing the alternator.

8 x 1.25 mm22 N.n 12.2 kgl.m,

Disconnect the alternator connector (A) and BLK

wire (B) from the alternator.

8 N.m10.8 kgf.m,6lbf.ft)

\

6

'I 1.

9.

10.

13.

14.

Remove the alternator.

Installthe alternator and drive belt in the reverse

order of removal.

Connect the positive cable and negative cable to

the battery.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

Perform the engine control module {ECM) idle learn

procedure (see page 11-139).

tt.

4-29

Page 66 of 1139

L

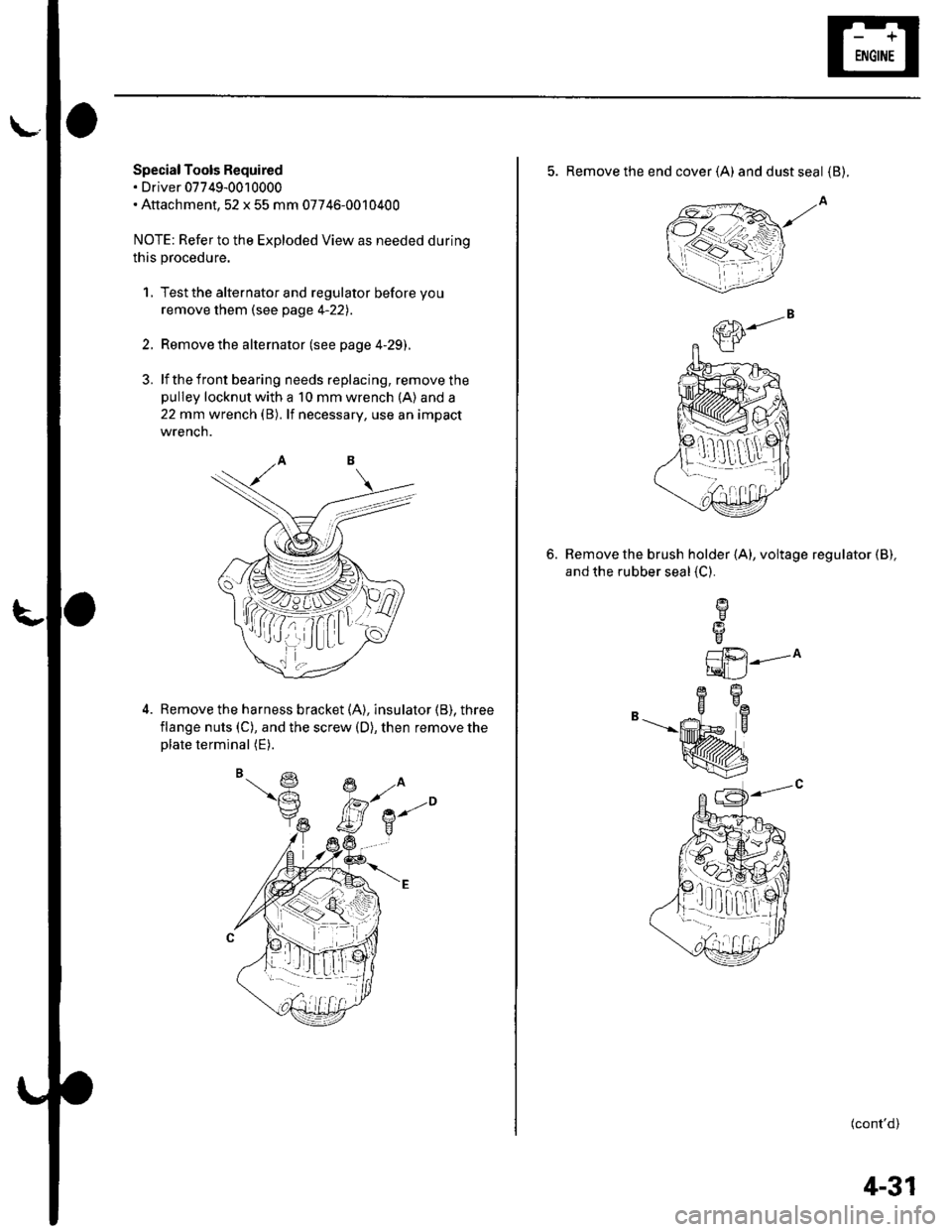

Special Tools Required. Driver 07749-0010000. Attachment,52 x 55 mm 07746-0010400

NOTE: Refer to the Exploded View as needed during

this procedure.

1, Test the alternator and regulator before you

remove them (see page 4-22l,.

2. Remove the alternator (see page 4-29).

3. lf the front bearing needs replacing, remove thepulley locknut with a 10 mm wrench (A) and a

22 mm wrench (B). lf necessary, use an impact

wrencn.

Remove the harness bracket (A), insulator (B). three

flange nuts (C), and the screw (D), then remove theplate terminal (E).

,( ( , tt I;r_ lLt

5. Remove the end cover (A) anddustseal {B).

Remove the brush holder (A), voltage regulator (B),

and the rubber seal {C}.

6.

L1i.21---^

tqLJ

B-"--|.

(cont'd)

1!q[-dr,:l

4-31

Page 67 of 1139

Charging System

Alternator Overhaul (cont'dl

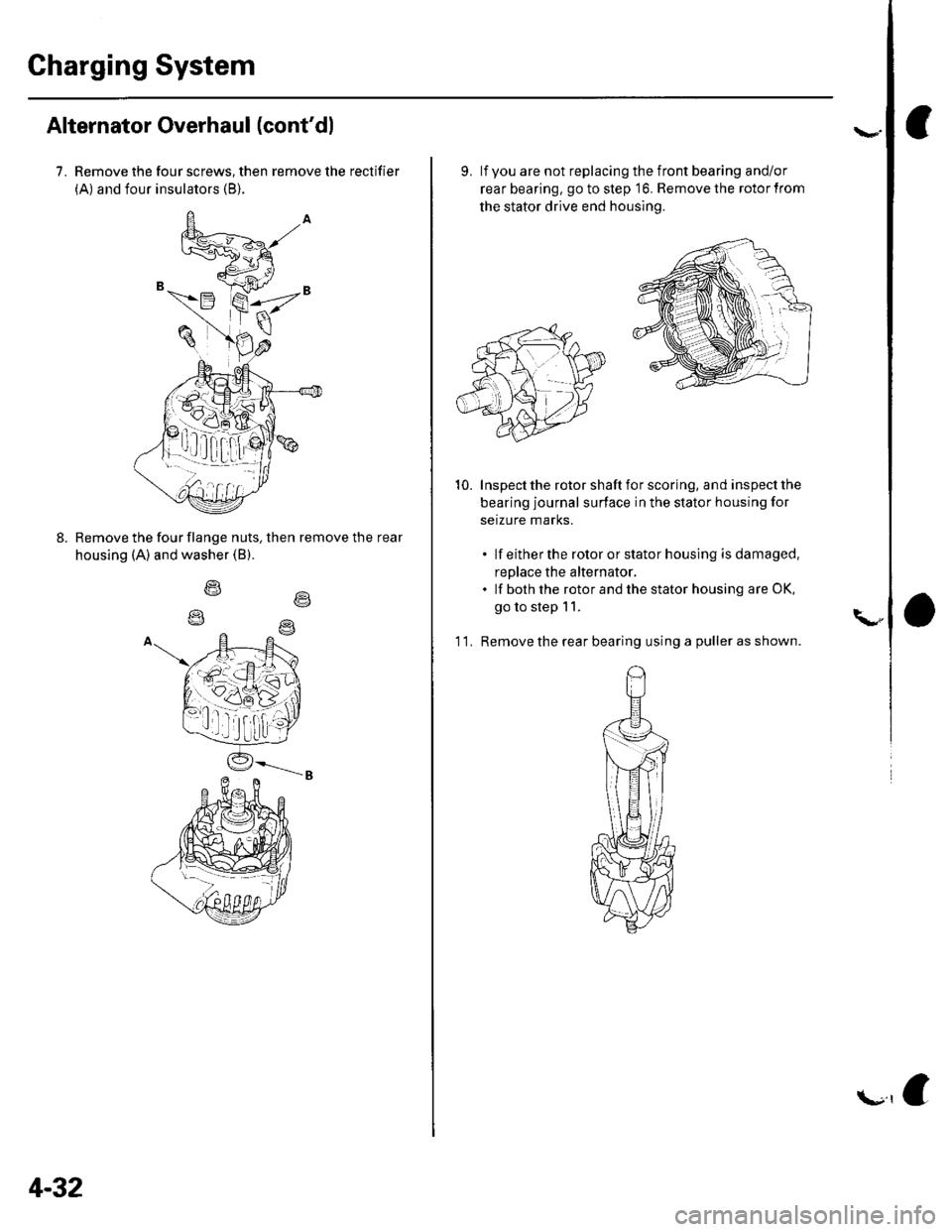

7. Remove the four screws, then remove the rectifier

(A) and four insulators (B).

Remove the four flange nuts, then remove the rear

housing (A) and washer (B).

o\

4-32

f.r,e

9. lf you are not replacing the front bearing and/or

rear bearing, go to step '16. Remove the rotor from

the stator drive end housing.

Inspect the rotor shaft for scoring, and inspect the

bearing journal surface in the stator housing for

setzure marks.

. lf eitherthe rotororstatorhousing isdamaged,

replace the alternator,. lf both the rotor and the stator housing are OK,

go to step 11.

'l 1. Remove the rear bearing using a puller as shown.

10.

\"

Page 68 of 1139

\-

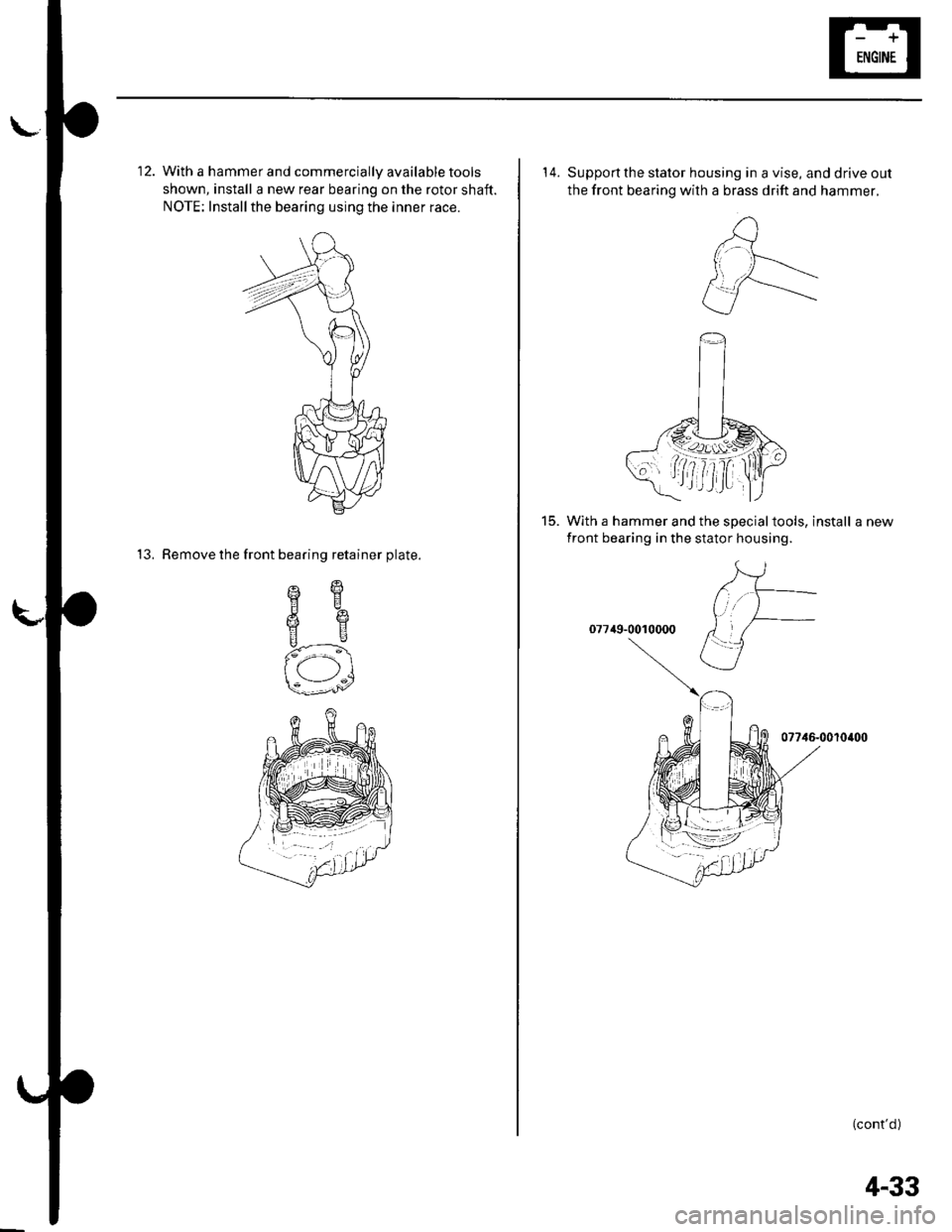

12. With a hammer and commercially available tools

shown, install a new rear bearing on the rotor shaft.

NOTE: Installthe bearing using the inner race.

13. Remove the front bearing retainer plate.

sqHE

6e

us

f-\

-:1s---'^/

14. Supportthe stator housing in a vise, and drive out

the front bearing with a brass drift and hammer.

15. With a hammer and the specialtools, install a new

front bearing in the stator housing.

07749-0010000

07746-0010400

(cont'd )

4-33

Page 76 of 1139

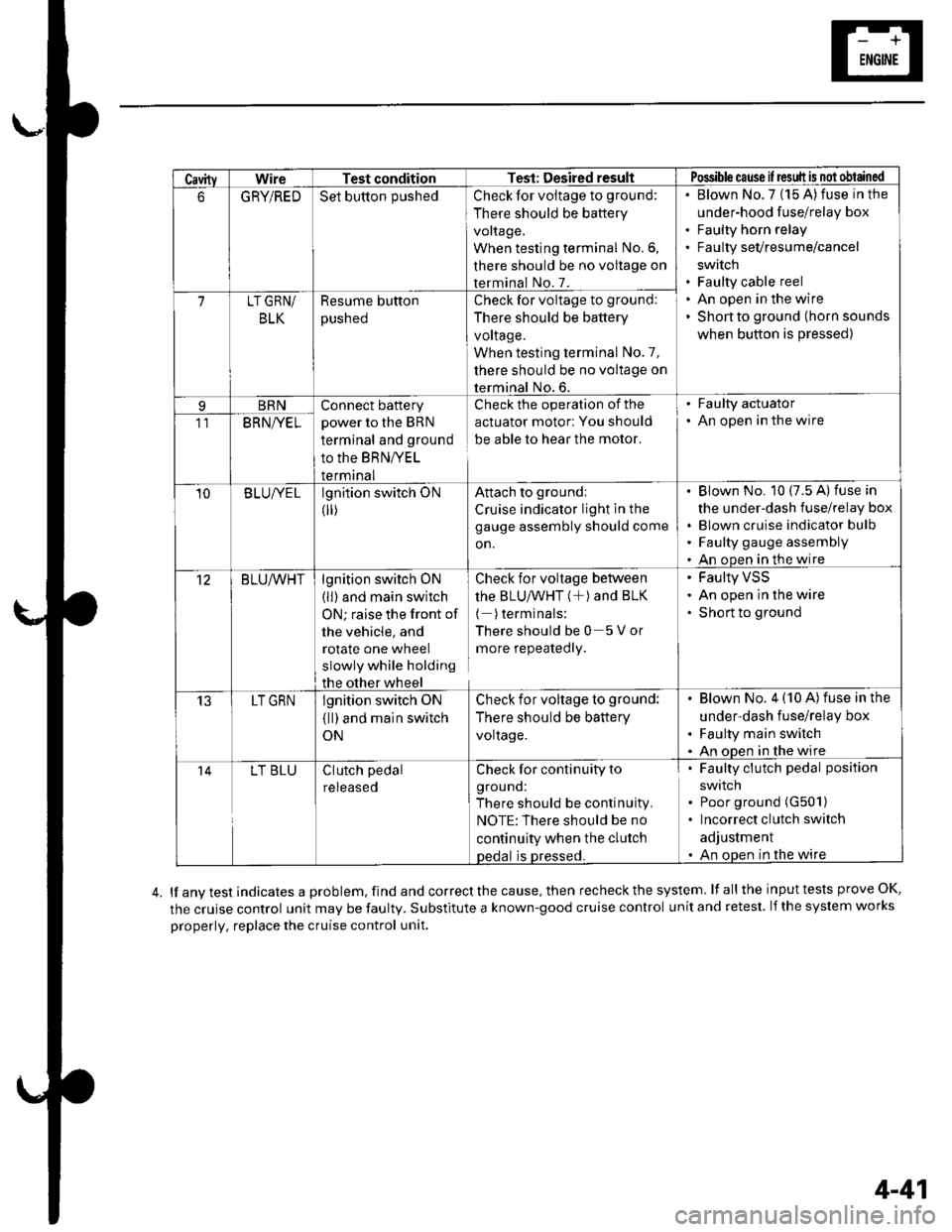

CavityWireTest conditionTest: Desired resultPossible cause il result is not obtained

6GRYiREDSet button pushedCheck for voltage to ground:

There should be battery

voltage,

When testing terminal No.6,

there should be no voltage on

terminal No. 7.

Blown No.7 (15 A)fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume/cancel

swrtch

Faulty cable reel

An open in the wire

Shon to ground (horn sounds

when button is pressed)

7LT GRN/

BLK

Resume button

pusneo

Check for voltage to ground:

There should be battery

voltage.

When testing terminal No.7,

there should be no voltage on

terminal No. 6.

BRNConnect battery

power to the BRN

terminal and ground

to the BRNIVEL

termrnal

Check the operation of the

actuator motor: You should

be able to hear the motor.

. Faulty actuator. An open in the wire11BRNI/EL

10B LUIVE Llgnition switch ON

0r)

Attach to groundi

Cruise indicator light in the

gauge assembly should come

on.

Blown No. 10 (7.5 A) fuse in

the under-dash fuse/relay box

Blown cruise indicator bulfl

Faulty gauge assembly

An open in the wire

12BLU/VVHTlgnition switch ON

(ll) and main switch

ON; raise the front of

the vehicle, and

rotate one wheel

slowly while holding

the other wheel

Check for voltage between

thE BLU/VVHT (+) ANd BLK

( )terminals:

Thereshouldbe0 5Vor

more repeatedly.

Faulty VSS

An open in the wire

Short to ground

13LT GRNlgnition switch oN

{ll) and main switch

ON

Check for voltage to ground:

There should be battery

voltage.

Blown No. 4 (10 A)fuse in the

under-dash fuse/relay box

Faulty main switch

An oDen in the wire

14LT BLUClutch pedal

reteaseo

Check for continuity to

grouno:

There should be continuity.

NOTE:There should be no

continuity when the clutch

oedal is Dressed.

Faulty clutch pedal position

swtlcn

Poor ground (G501)

Incorrect clutch switch

adjustment

An open in the wire

lf any test indicates a problem, find and correct the cause, then recheck the system. lf all the input tests prove OK,

the cruise control unit may be faulty. Substitute a known-good cruise control unit and retest. lf the system works

properly, replace the cruise control unit.

4-41

Page 82 of 1139

Engine Assembly

I

Engine Removal

Special Tools Required

Front subframe adapter EOS02C00001 1

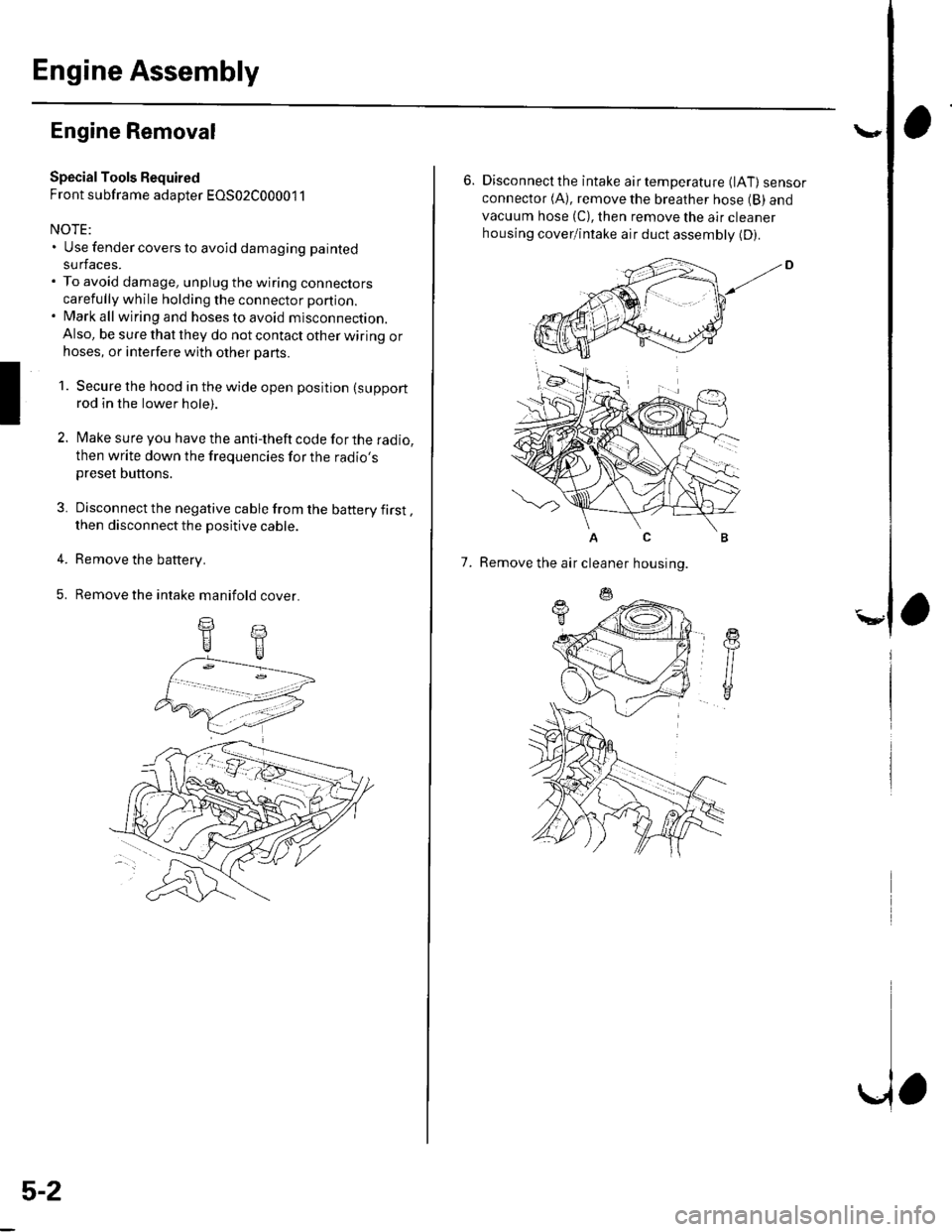

NOTE:. Use fender covers to avoid damaging painted

surfaces.. To avoid damage, unplug the wiring connectors

carefully while holding the connector portion.. Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring orhoses, or interfere with other parts.

1. Secure the hood in the wide open position (support

rod in the lower hole).

2. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio'spreset buttons.

3. Disconnect the negative cable from the battery first,then disconnect the positive cable.

4. Remove the battery.

5. Remove the intake manifold cover.

II

5-2

\,

6. Disconnectthe intake airtemperature (lAT) sensorconnector (A), remove the breather hose (B) and

vacuum hose (C), then remove the air cleaner

housing cover/intake air duct assemblv (D).

AC

7. Remove the air cleaner housing.

Page 85 of 1139

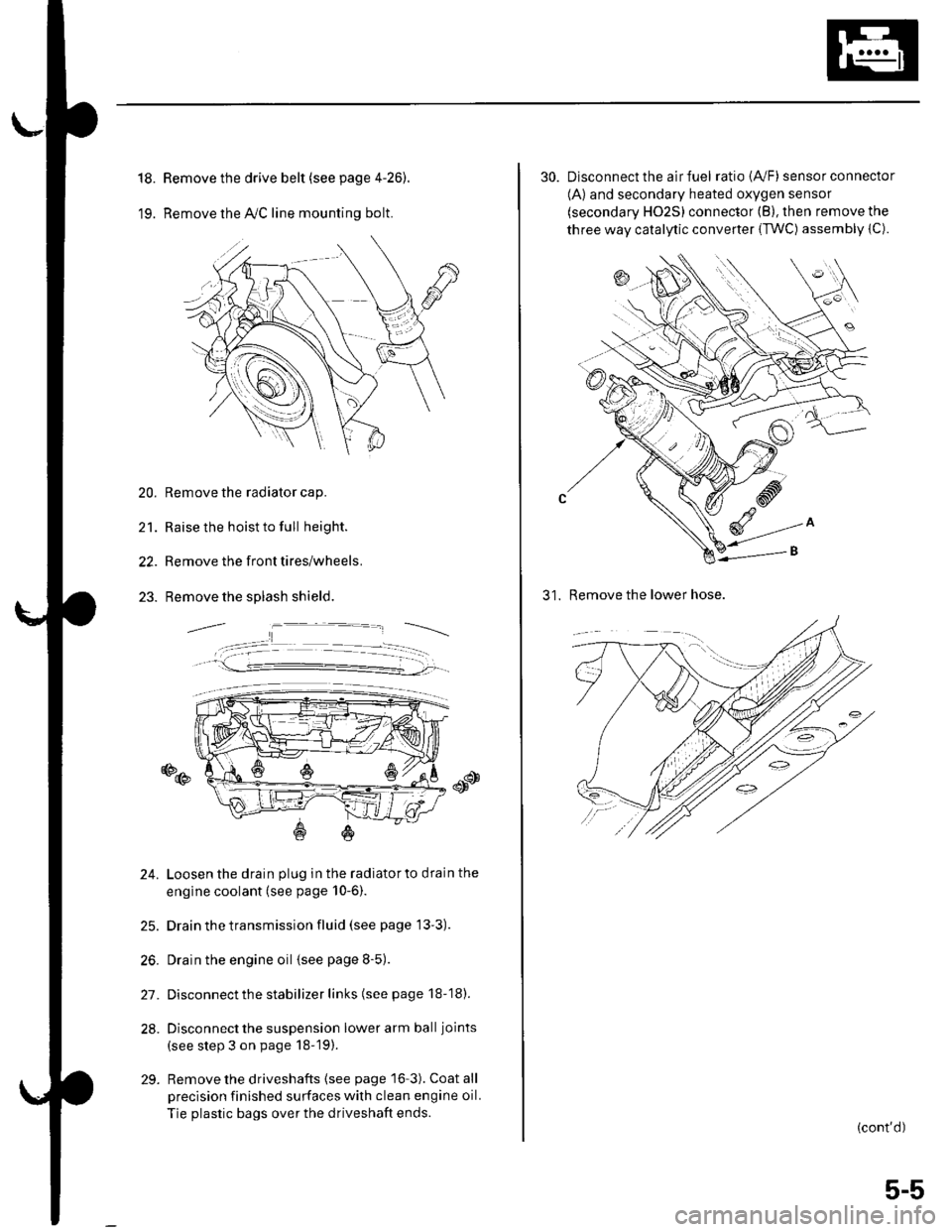

18.

19.

Remove the drive belt (see page 4-26).

Remove the lvC line mounting bolt.

20. Remove the radiator cap.

21. Raise the hoist to full height.

22. Remove the front tires/wheels.

23. Remove the splash shield.

o@

24. Loosen the drain plug in the radiatorto drain the

engine coolant (see page 10-6).

25. Drain the transmission fluid (see page 13'3).

26. Drain the engine oil {see page 8-5).

27. Disconnect the stabilizer links (see page 18-18).

28. Disconnect the suspension lower arm ball joints

(see step 3 on page 18-19).

29. Remove the driveshafts {see page 16-3). Coat all

precision finished surfaces with clean engine oil.

Tie plastic bags over the driveshaft ends.

30. Disconnect the air fuel ratio {4,/F) sensor connector

(A) and secondary heated oxygen sensor

(secondary HO2S) connector (B), then remove the

three way catalytic converter {TWC) assembly {C).

31. Remove the lower hose.

(cont'd)

5-5

Page 87 of 1139

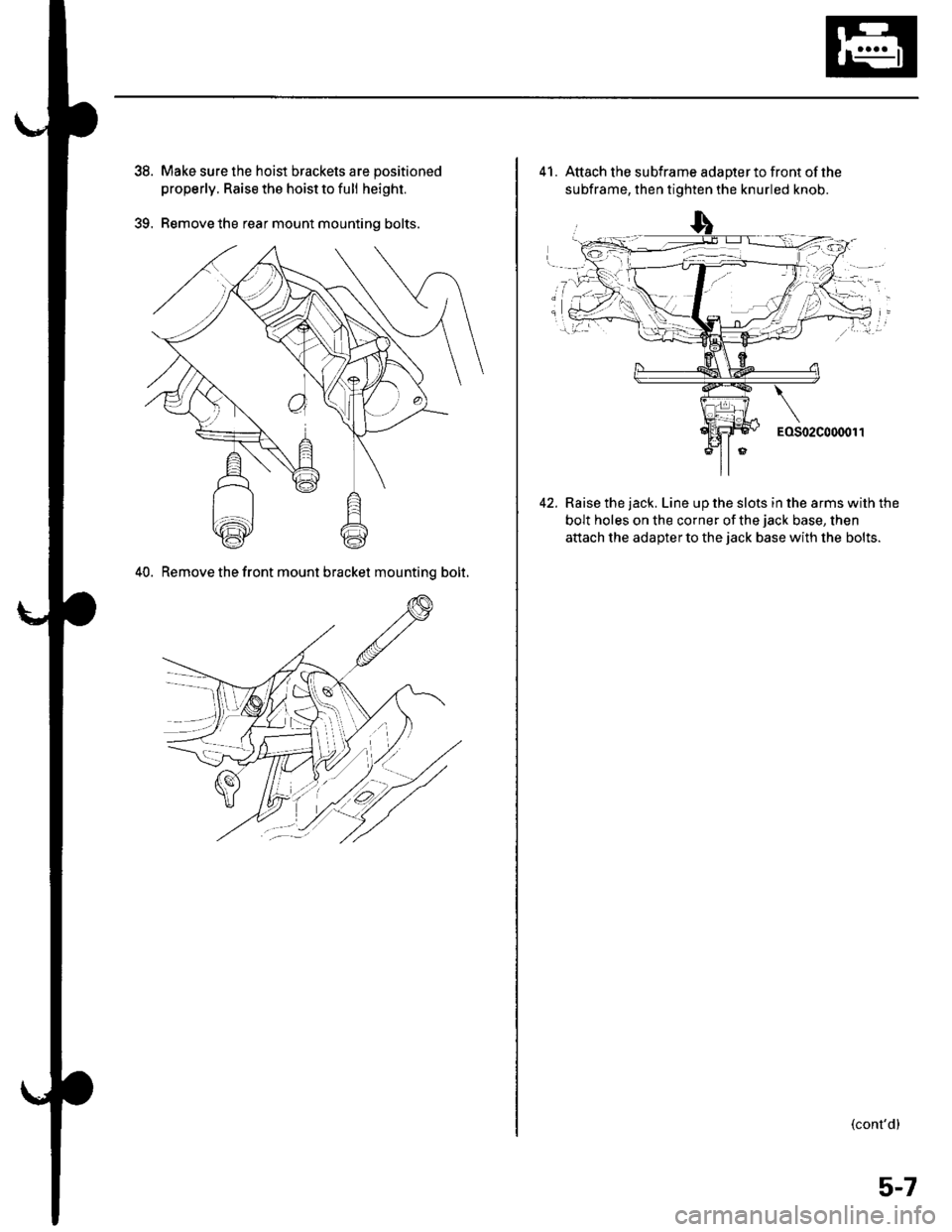

39.

Make sure the hoist brackets are positioned

properly. Raise the hoist to full height.

Remove the rear mount mounting bolts.

40. Remove the front mount bracket mountinq bolt.

41. Attach the subframe adapterto front ofthe

subframe, then tighten the knurled knob.

Raise the jack. Line up the slots in the arms with the

bolt holes on the corner of the jack base, then

attach the adaDter to the iack base with the bolts.

(cont'd)

5-7