Front HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 512 of 1139

Service Check Signal Circuit Method:

NOTE: Use this procedure when the PGM Tester

software does not match the yearlmodel vehicle you

are working on.

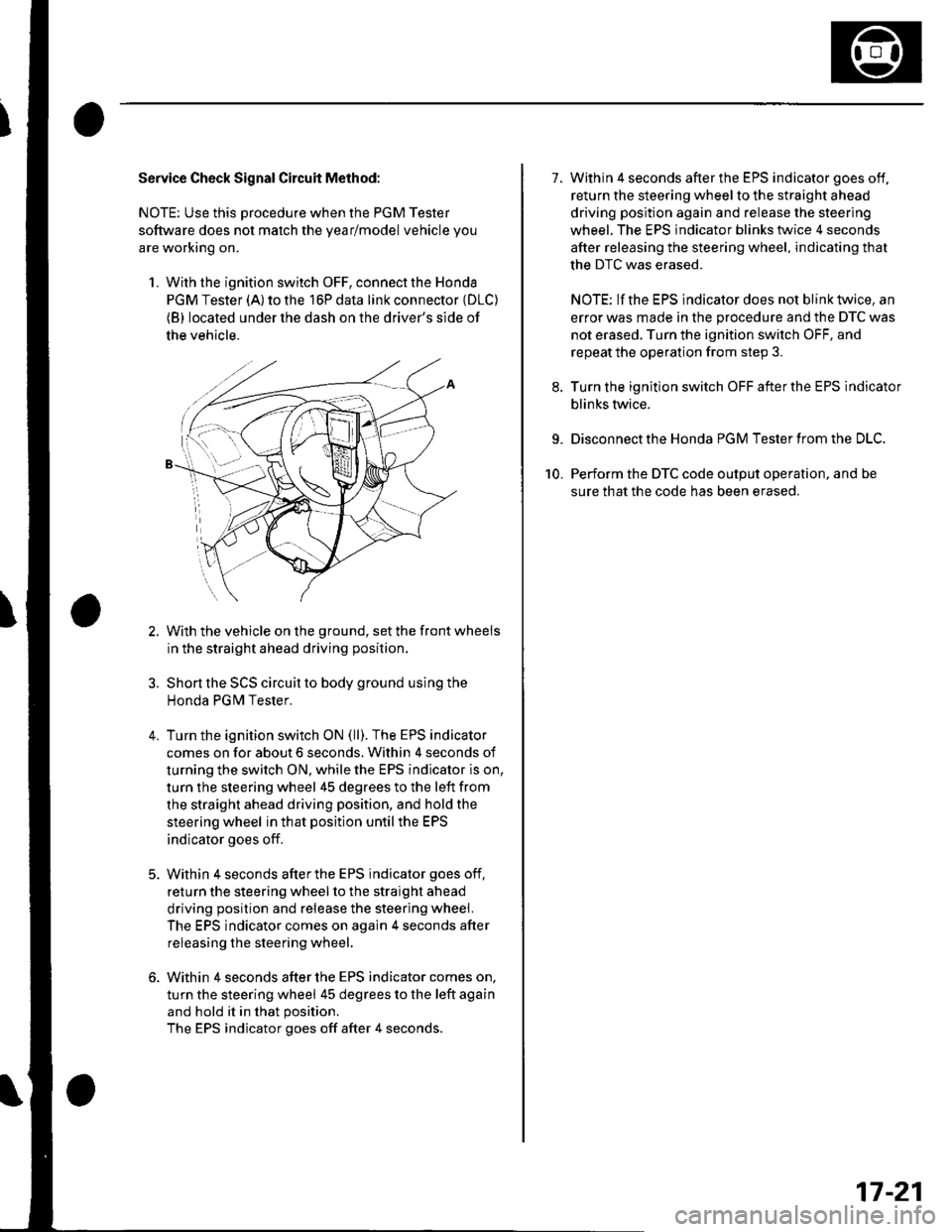

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector {DLC)(B) located under the dash on the driver's side of

the vehicle.

With the vehicle on the ground, set the front wheels

in the straight ahead driving position.

Short the SCS circuit to body ground using the

Honda PGM Tester.

Turn the ignition switch ON (ll). The EPS indicator

comes on for about 6 seconds. Within 4 seconds of

turning the switch ON, while the EPS indicator is on,

turn the steering wheel 45 degrees to the left from

the straight ahead driving position, and hold the

steering wheel in that position until the EPS

indicator goes off.

Within 4 seconds afterthe EPS indicator goes off,

return the steering wheel to the straight ahead

driving position and release the steering wheel.

The EPS indicator comes on again 4 seconds after

releasing the steering wheel,

Within 4 seconds after the EPS indicator comes on,

turn the steering wheel 45 degrees to the left again

and hold it in that position.

The EPS indicator goes off after 4 seconds.

4.

1.Within 4 seconds after the EPS indicator goes off,

return the steering wheel to the straight ahead

driving position again and release the steering

wheel. The EPS indicator blinks twice 4 seconds

after releasing the steering wheel, indicating that

the DTC was erased.

NOTE: If the EPS indicator does not blink twice, an

error was made in the procedure and the DTC was

not erased. Turn the ignition switch OFF, and

repeat the operation from step 3.

Turn the ignition switch OFF afterthe EPS indicator

blinks twice.

9. Disconnect the Honda PGM Tester from the DLC.

10. Perform the DTC code output operation, and be

sure that the code has been erased.

17-21

Page 524 of 1139

DTC 22: Vehicle Speed Sensor Signal

DTC 23: Engine Speed Signal

NOTE:. lf the MIL indicator is ON, troubleshoot the PGIVI-Fl

system first.. Even though the system is operating normally, the

EPS indicator will come on under the following

conditions.

- Condition 1:. The vehicle was traveling at least '12.4 mph(20 km/h), then. A rapld change in vehicle speed was detected,

then. The vehicle (or the vehicle speed sensor signal)

stopped for at least 5 seconds, and. The engine speed was still 1,640 rpm or higher for

at least 5 seconds- Condition 2:

After the vehicle (or the vehicle speed sensor

signal) has stopped for at least 10 seconds, yetthe

engine speed was still 1,640 rpm or higher for at

least 20 seconds.- Condition 3:

When the vehicle speed is 10 km/h (6.2 mph) or

above and the engine is running at 280 rpm or

below for 3 seconds.

1. Start the engine and check the tachometer.

ls the tachometer working correctly?

YES- Go to step 2.

NO-Go to step 9.

2. Test-drive the vehicle above 15 km/h {9.3 mph).

ls the speedometer working correctly?

YES Go to step 3.

NO-Perform the speedometer system

troubleshooting {see page 22-651.a

3.Block the rear wheels and raise the vehicle, and

make sure it is securely supported.

Turn the ignition switch ON (ll).

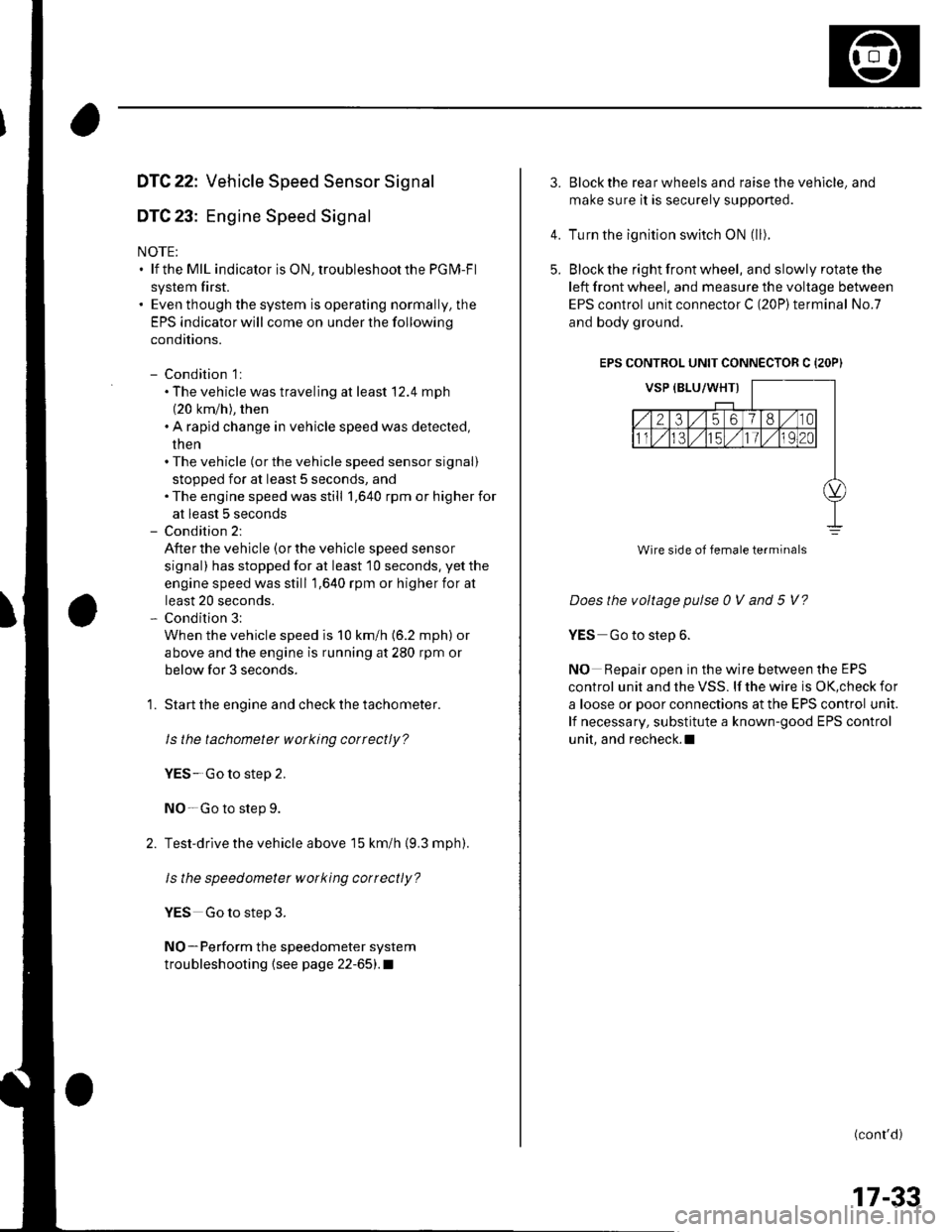

Block the right front wheel, and slowly rotate the

left front wheel, and measure the voltage between

EPS control unit connector C (20P)terminal No.7

and body ground.

EPS CONTROL UNIT CONNECTOR C {2OP)

Does the voltage pulse 0 V and 5 V?

YES Go to step 6.

NO Repair open in the wire between the EPS

control unit and the VSS. lf the wire is OK,check for

a loose or poor connections at the EPS control unit.

lf necessary, substitute a known-good EPS control

unit, and recheck.l

(conr'd)

4.

5.

Wire side of female terminals

17-33

Page 542 of 1139

Steering Gearbox Removal

Special Tool Required

Ball ioint remover,2S mm 0TlvlAC-S100200

1. Raise the front of vehicle, and make sure it is

securely supponed.

2. Remove the front wheels.

Remove the driver's airbag (seepage23-113).

Remove the steering wheel (see page 17-6).

Remove the motor on the steering gearbox (see

page l T-49).

Remove the driver's dashboard lower cover (see

page 20-59) and under cover {see page20-60).

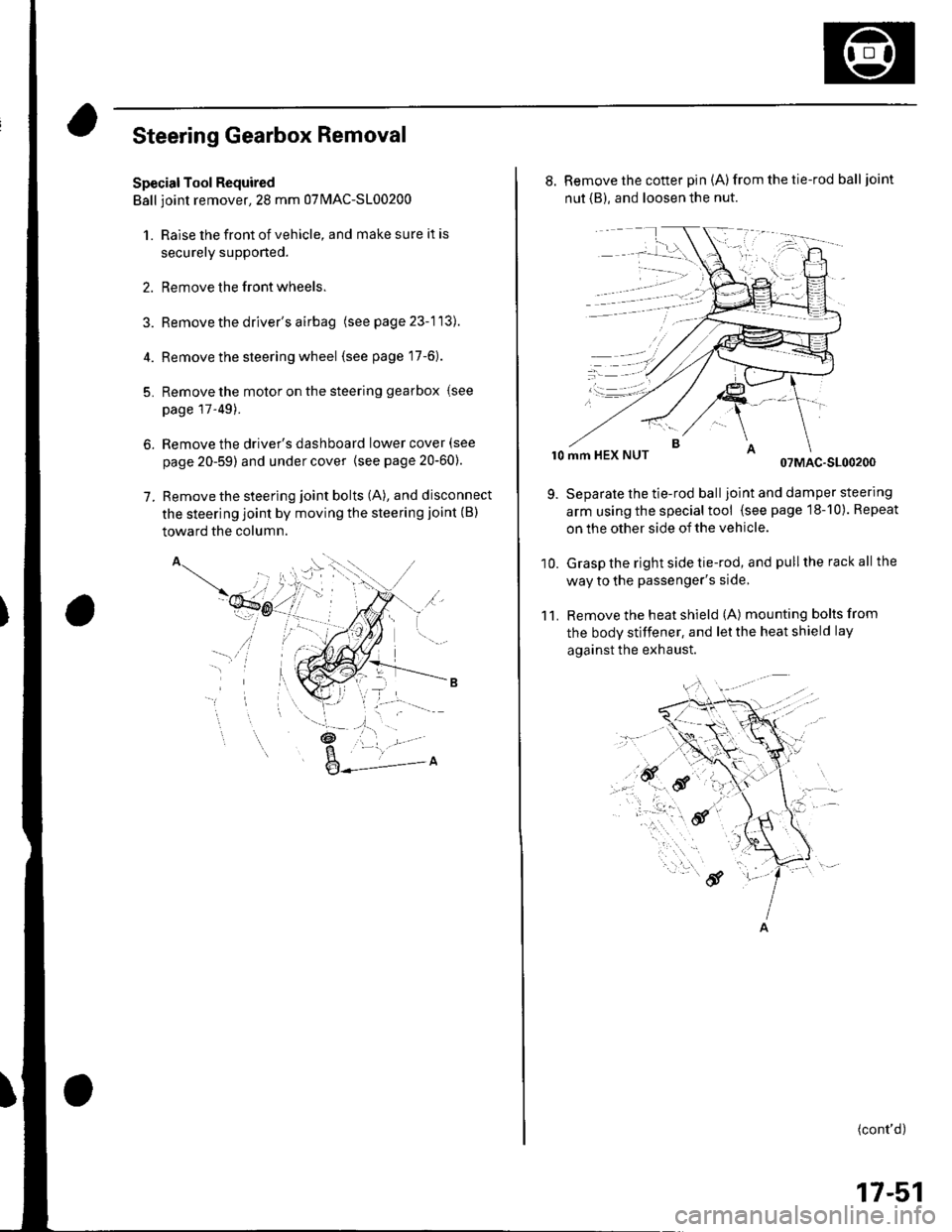

Remove the steering joint bolts (A), and disconnect

the steering joint by moving the steering joint (B)

toward the column.

4.

5.

6.

7.

'il

_t\

l- '/

,a.: --L -

8. Remove the cotter pin (A)from the tie-rod balljoint

nut {B), and loosen the nut.

r0 mm HEX NUT07MAC-S100200

Separate the tie-rod balljoint and damper steering

arm using the special tool (see page 18-10). Repeat

on the other side of the vehicle.

Grasp the right side tie-rod, and pull the rack all the

way to the passenger's side,

Remove the heat shield (A) mounting bolts from

the body stiffener, and let the heat shield lay

against the exhaust.

11.

9.

10.

(cont'd)

17-51

Page 557 of 1139

EPS Components

4

17.

18.

Steering Gearbox Installation (cont'dl

Install the motor on the steering gearbox (see page

17-49).

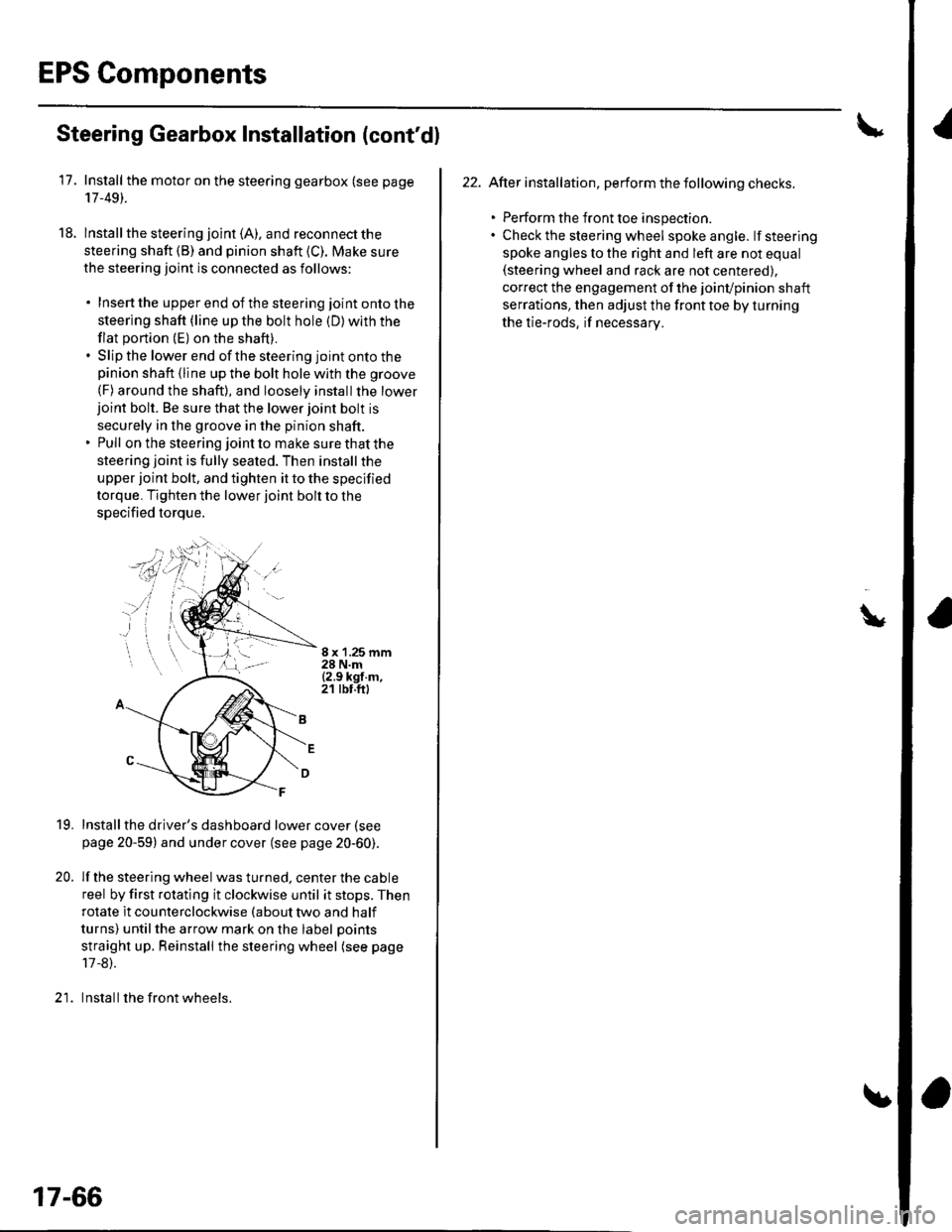

lnstall the steering joint (A). and reconnect the

steering shaft (B) and pinion shaft (C). Make sure

the steering joint is connected as follows:

. Insertthe upperend of thesteering jointontothe

steering shaft (line up the bolt hole (D) with the

flat portion (E) on the shaft).. Slip the lower end of the steering joint onto thepinion shaft (line up the bolt hole with the groove

(F) around the shaft), and loosely installthe lowerjoint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft.. Pull on the steering joint to make sure that the

steering joint is fully seated. Then install the

upper joint bolt, and tighten it to the specified

torque. Tighten the lower joint bolt to the

specified torque.

8 x '1.25 mm28 N.m{2.9 kgf.m,21 tbt.ft)

19.

20.

Installthe driver's dashboard lower cover (see

page 20-59) and under cover (see page 20-60).

lf the steering wheel was turned, center the cable

reel by first rotating it clockwise until it stops. Then

rotate it counterclockwise (about two and half

turns) untilthe arrow mark on the label points

straight up. Reinstall the steering wheel (see page

17 -8).

Install the front wheels.)1

17-66

22. After installation, perform the following checks.

. Perform the front toe inspection.. Check the steering wheel spokeangle. lfsteering

spoke angles to the right and left are not equal(steering wheel and rack are not centered),

correct the engagement of the joinvpinion shaft

serrations, then adjust the front toe by turning

the tie-rods, if necessarv.

\

Page 559 of 1139

Suspension

Front and Rear Suspension

SpecialTools ............. 18-2

Component Location Index ......................................... 18-3

Wheel Alignment ..................... ........... 18-4

Wheel Bearing End Play Inspection ............................ 18-8

Wheel Runout Inspection .................. 18-9

Ball Joint Removal ... 18-10

Front Suspension

Kn uckle/H u bAVheel Bearing Replacement

Ball Joint Boot Reolacement ..................

Stabilizer Bar Rep|acement ....................

Stabilizer Link Removal/lnstallation

LowerArm Removal/lnstallation ...............

Damper/Spring Replacement

Rear Suspension

Hub Bearing Unit Replacement .....................

Knuckle Reolacement

Stabilizer Bar Replacement ....................

Stabilizer Link Removal/lnstallation ..........................

Upper Arm Removal/lnstallation ...............

Trailing Arm Removal/lnstallation

Damper/Spring Replacement

18-1 1

18-16

18-17

18-18

18-19

18-20

18-26

18-28

18-30

18-31

18-32

18-33

18-34

Page 560 of 1139

![HONDA CIVIC 2003 7.G Repair Manual Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly T HONDA CIVIC 2003 7.G Repair Manual Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly T](/img/13/5744/w960_5744-559.png)

Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly Tool

Ball Joint Remover, 28 mm

Attachment, 62 x 68 mm

Driver

Front Hub Dis/Assembly Tool

Support Base

18-2

Page 561 of 1139

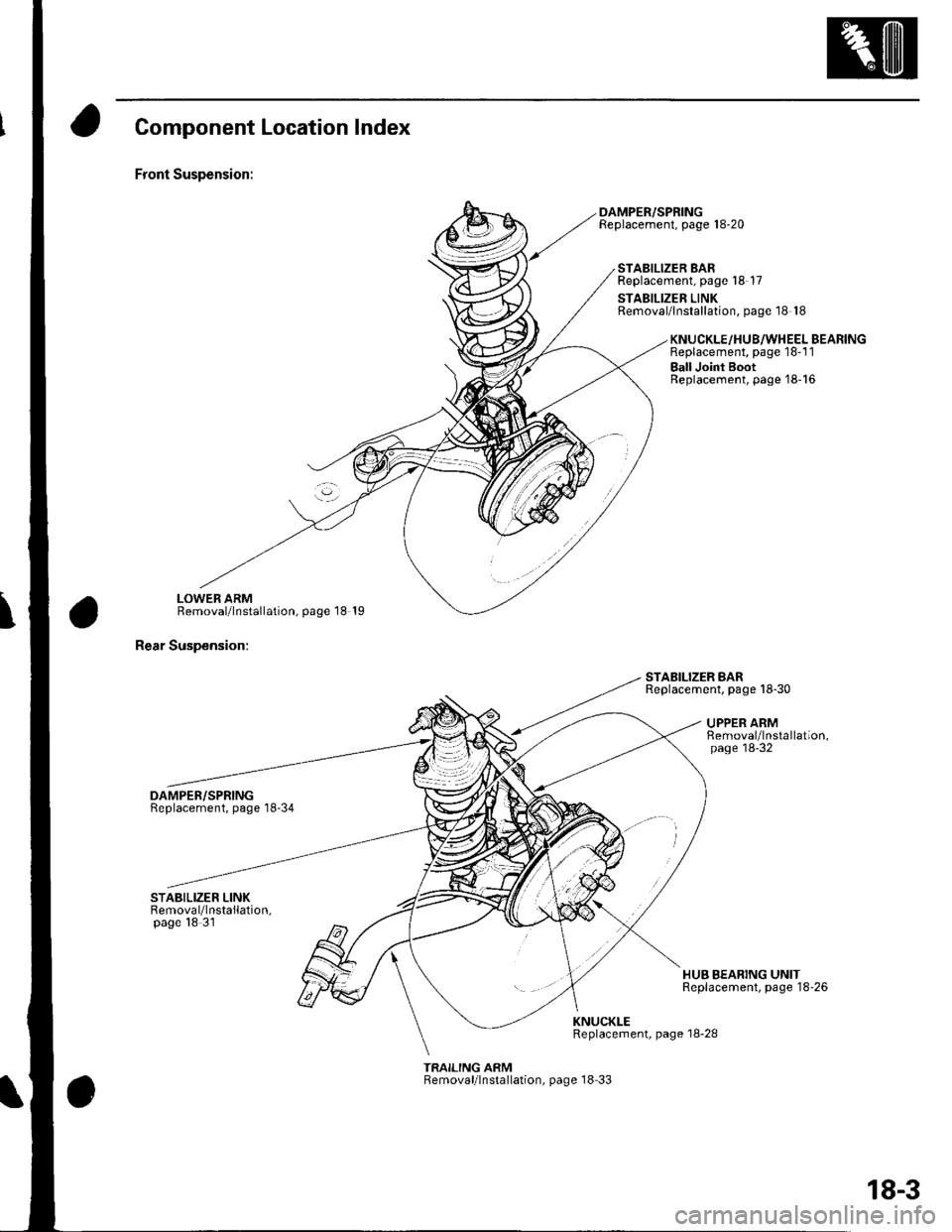

Component Location Index

Front Suspension:

LOWEB ARMRemoval/lnstallation, page 18 19

Rear Suspension:

DAMPER/SPRINGReplacement, page'18-34

DAMPER/SPRINGReplacement, page 18-20

STABILIZER BARReplacement, page 18-17

STABILIZER LINKRemoval/lnstallation, page 18 18

STABILIZER BARReplacement. page 18-30

KNUCKLE/HU8/WHEEL BEARINGReplacement, page 18-1 1

Ball Joint BootReplacement, page'18-16

UPPER ARMRemoval/lnstallation,page'18-32

HUB BEARING UNITReplacement, page 18'26

KNUCKLEReplacement, page 18-28

TRAILING ARMRemoval/lnstallation, page 18 33

18-3

Page 562 of 1139

Front and Rear Suspension

WheelAlignment

The suspension can be adjusted for front camber, front

toe, and rear toe. However, each of these adjustments

are interrelated to each other. For example, when you

adjust the toe, the camber changes. Therefore, you

must adjust the front wheel alignment whenever you

adjust the camber or toe.

Pre-Alignment Checks

For proper inspection and adjustment of the wheel

alignment, do these checks:

1. Release the parking brake to avoid an incorrect

measurement.

Make sure the suspension is not modified.

Check the tire size and tire pressure

Tire size:

Front/rear: 195/60R15

Tire pressure:

Front: 230 kPa {2.3 kgf/cm',33 psil

Rear: 210 kPa |'2.1 kgf/cm', 30 psi)

Check the runout of the wheels and tires.

Check the suspension ball joints. (Hold a wheel

with your hands, and move it up and down and

right and left to check for wobbling),

2.

3.

Bounce the vehicle up and down several times to

stabilize the suspension.

18-4

Front Caster lnspection

Use commerciallv available comDuterized four wheel

alignment equipment to measure wheel alignment

(caster, camber, toe, and turning angle). Follow the

eouioment manufacturer's instructions.

Check the caster angle. lf the caster angle is not within

the specification, check for bent or damaged

susoensron comoonents.

Front caster angle: 1'40't 1"

\

Page 563 of 1139

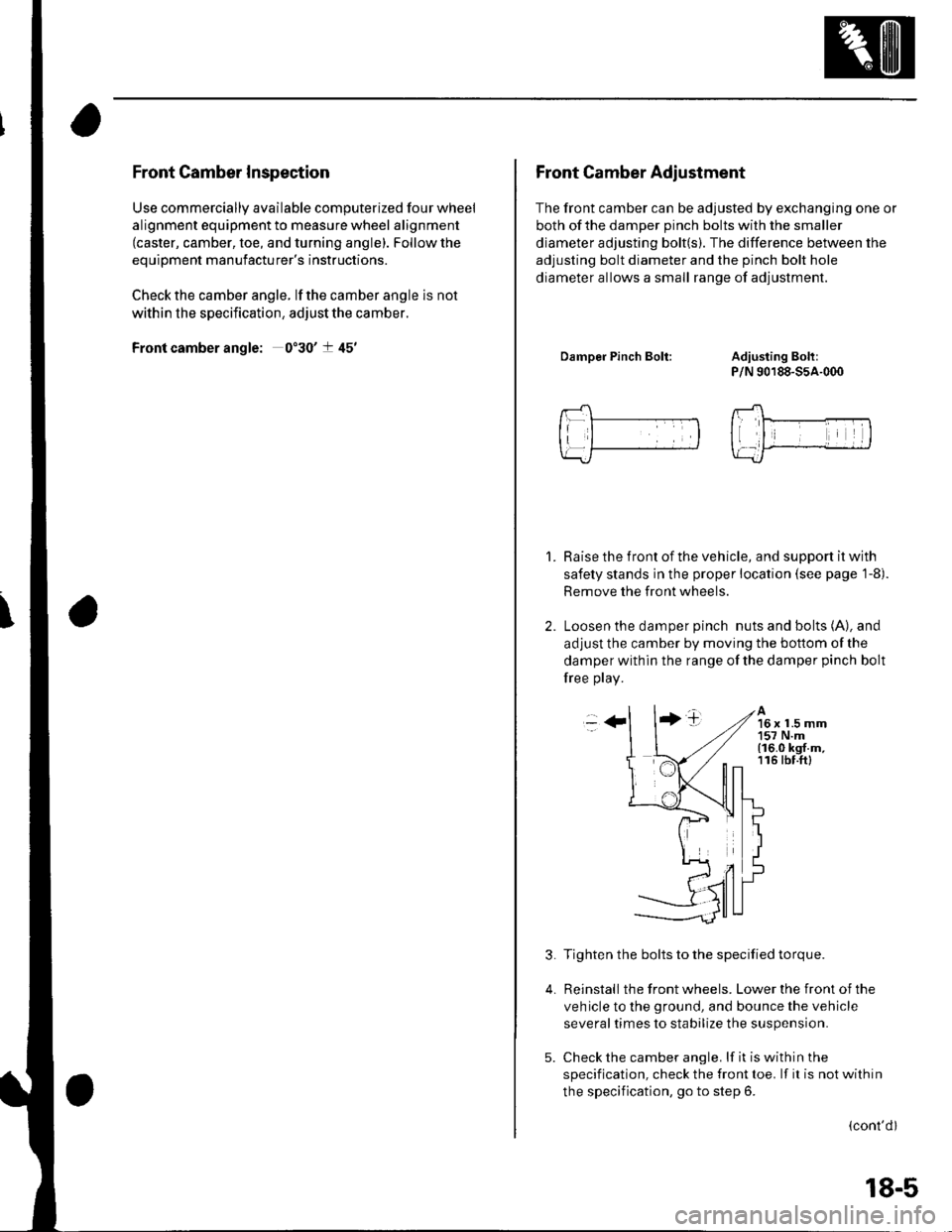

Front Camber Inspection

Use commercially available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions.

Check the camber angle. lf the camber angle is not

within the specification, adjust the camber.

Front camber angle: 0"30' t 45'

Front Camber Adjustment

The front camber can be adjusted by exchanging one or

both of the damDer Dinch bolts with the smaller

diameter adjusting bolt(s). The difference between the

adjusting bolt diameter and the pinch bolt hole

diameter allows a small range of adjustment.

DamDer Pinch Bolt:Adiusting Boh:

P/N 90188-55A-000

Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Loosen the damper pinch nuts and bolts (A), and

adjust the camber by moving the bottom of the

damper within the range of the damper pinch bolt

free play.

1.

-++tA16 x 1.5 mm157 N.m(16.0 kgf.m,116 tbf.ftl

3.

4.

Tighten the bolts to the specified torque.

Reinstall the front wheels. Lower the front of the

veh icle to the ground, and bounce the vehicle

several times to stabilize the suspension.

Check the camber angle. lf it is within the

specification, check the front toe. lf it is not within

the specification, go to step 6.

(cont'dl

5.

18-5

Page 564 of 1139

Front and Rear Suspension

Wheel Alignment (cont'd)

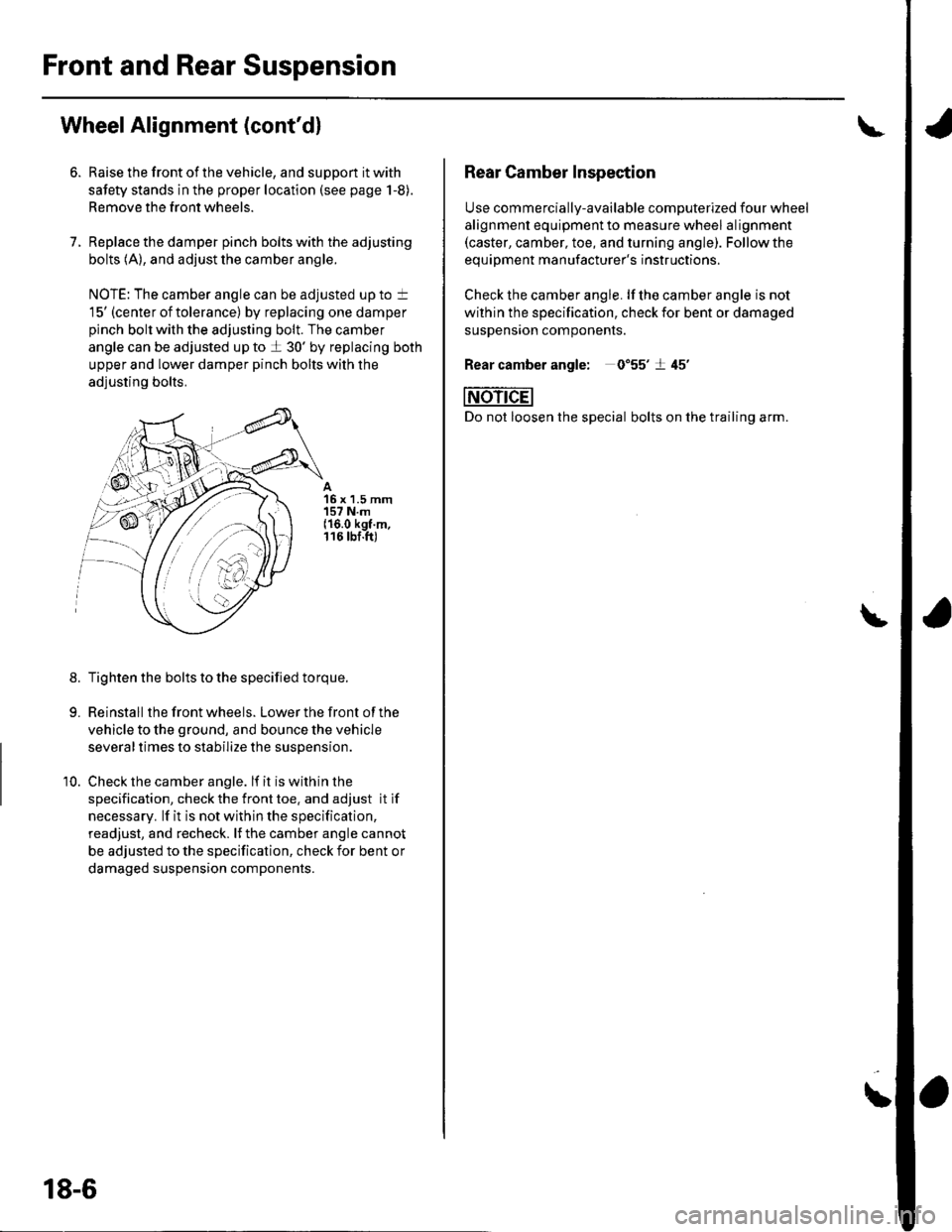

7.

Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Replace the damper pinch bolts with the adjusting

bolts (A), and adjust the camber angle.

NOTE: The camber angle can be adjusted up to t

15' (center of tolerance) by replacing one damper

pinch bolt with the adjusting bolt. The camber

angle can be adjusted up to a 30' by replacing both

upper and lower damper pinch bolts with the

adjusting bolts.

15 x 1.5 mm157 N.m{16.0 kgt.m,116 tbf.ft)

8.Tighten the bolts to the specified torque.

Reinstall the front wheels. Lower the front of the

vehicle to the ground, and bounce the vehicle

several times to stabilize the suspension.

Check the camber angle. lf it is within the

specification, check the front toe. and adjust it if

necessary. lf it is not within the specification,

readjust, and recheck. lJ the camber angle cannot

be adjusted to the specification, check for bent or

damaged suspension components.

10.

'rntr

i,iY. a

.:r,//

18-6

Rear Camber Inspection

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

eouiDment manufacturer's instructions.

Check the camber angle. lf lhe camber angle is not

within the specification, check for bent or damaged

susDenston comoonenrs.

0"55'�t 45'�

bolts on the trailing arm.

Rear camber angle: 0

NOn-dEl

Do not loosen the special

\