Front HONDA CIVIC 2003 7.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 421 of 1139

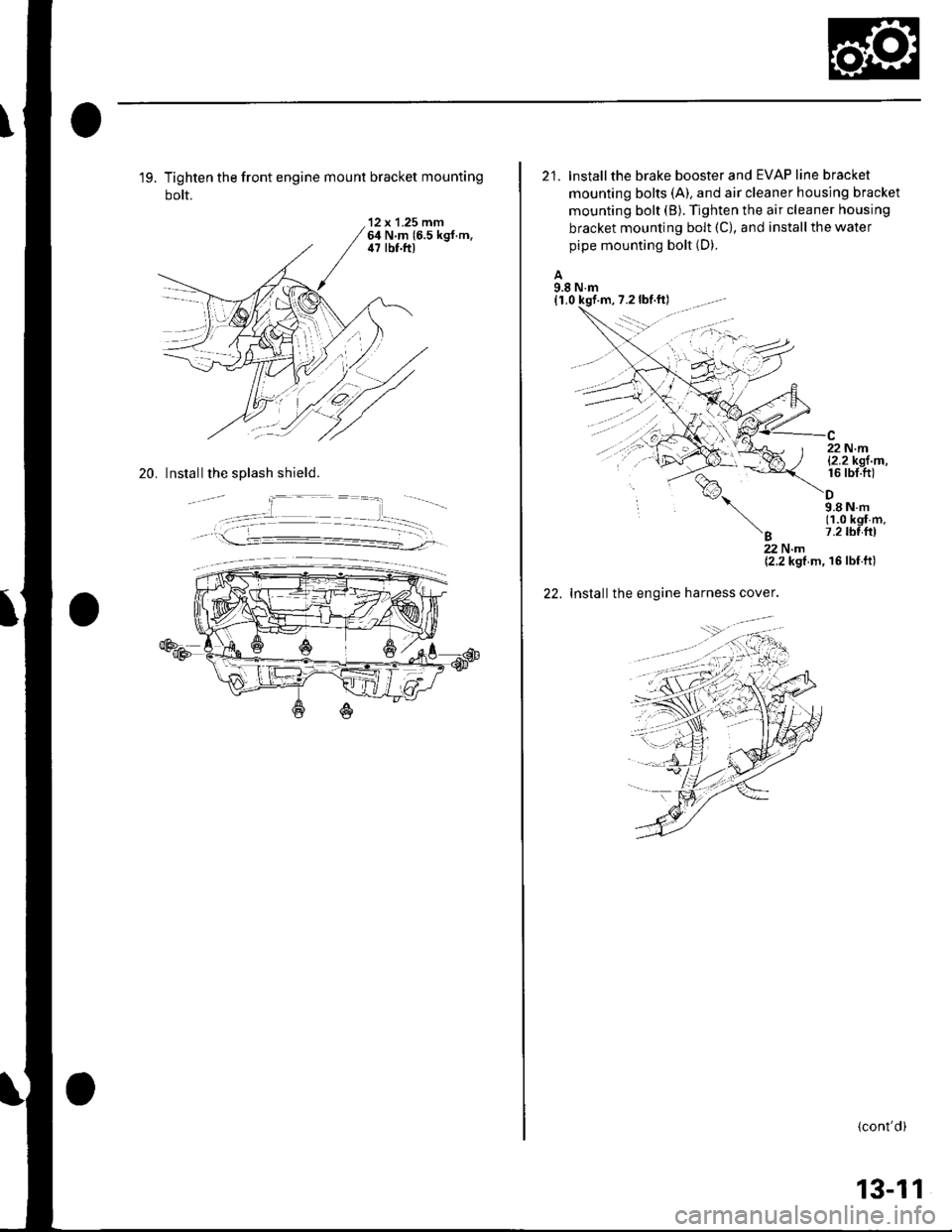

19. Tighten the front engine mount bracket mounting

bolt.

'12 x 1.25 mm64 N.m 16.5 kgf.m,il7 lbf.ft)

20. Install the splash shield.

21. lnstallthe brake booster and EVAP line bracket

mounting bolts (A). and air cleaner housing bracket

mounting bolt (B). Tighten the air cleaner housing

bracket mounting bolt (C), and install the water

pipe mounting bolt (D).

A9.8 N.m(1,0 kqf

%,

'B

22 N.ml2.2kgl m,16 rbt.ft)

9.8Nm(1.0 kgf m.7.2 tbl{rl

22.

22Nm{2.2 kgf m, 16 lbf ft)

Installthe engine harness cover.

(cont'd)

13-11

Page 423 of 1139

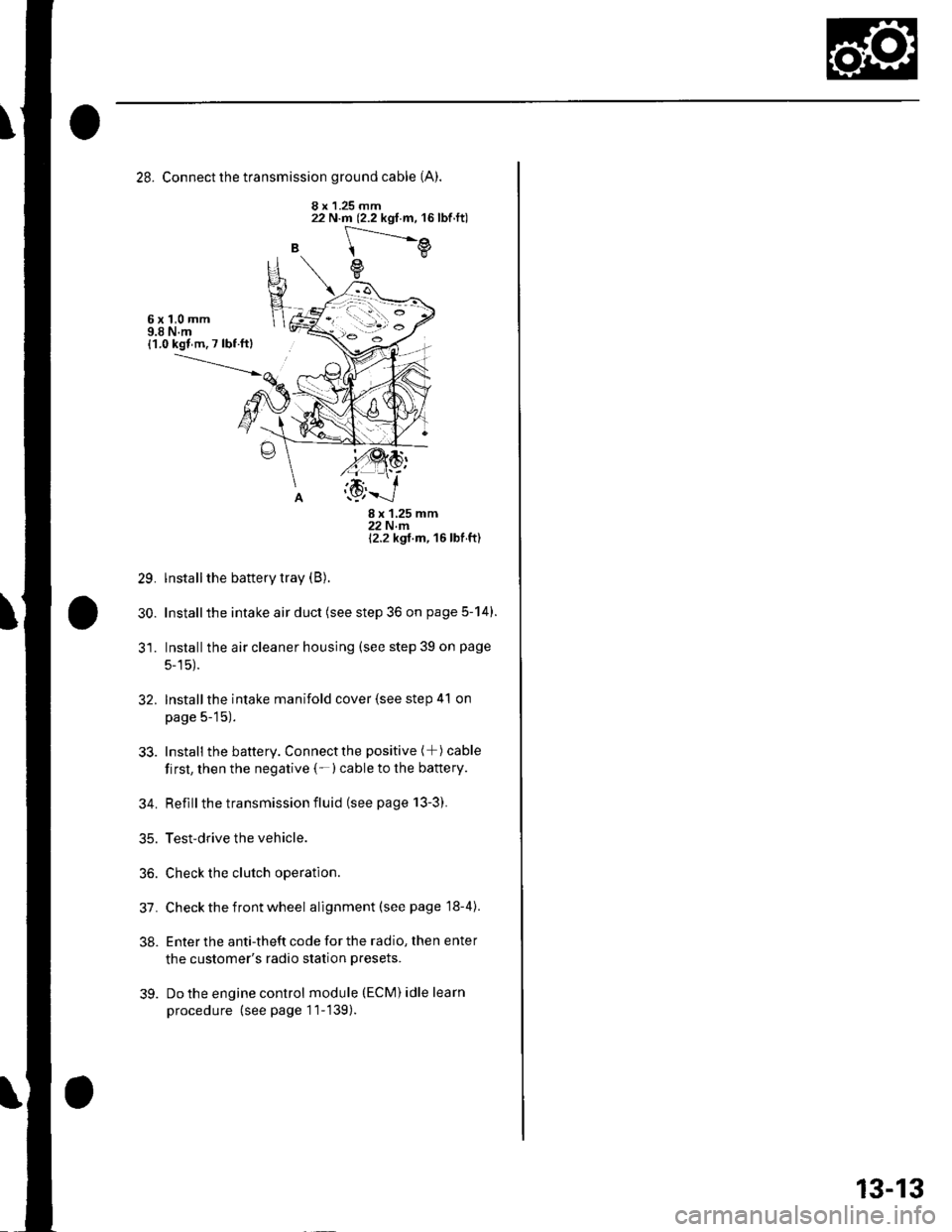

28. Connect the transmission ground cable (A).

8 x 1.25 mm

B

22 N.m (2.2 kgf.m, 16lbf.ft)

[---.-.---e

e

6x1,0mm9.8 N.m{1.0 kgl m. 7 lbf ftl

29.

30.

8x125mm22Nm12.2 kgt m, 16 lbf ft)

lnstall the battery tray (B).

Installthe intake air duct (see step 36 on page 5-14).

Installthe air cleaner housing (see step 39 on page

5-15).

Installthe intake manifold cover (see step 41 on

page 5-15).

Install the battery. Connectthe positive (+) cable

first, then the negative (-)cable to the battery.

Reflllthe transmission fluid (see page 13-3).

Test-drive the vehicle.

Check the clutch operation.

Check the front wheel alignment (see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

32.

33.

34.

35.

36.

31.

38.

39.

13-13

Page 470 of 1139

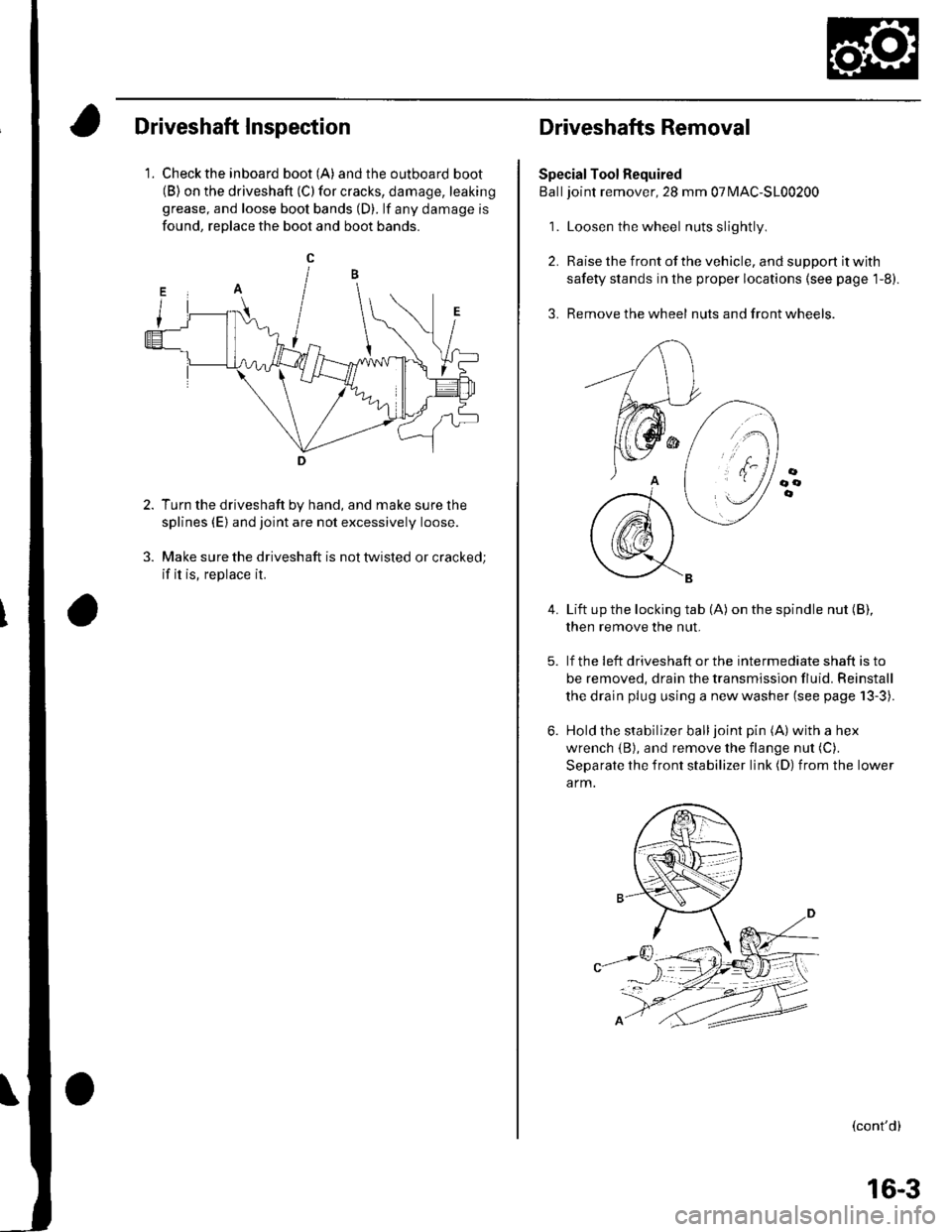

Driveshaft Inspection

1. Check the inboard boot (A) andthe outboard boot(B) on the driveshaft (C) for cracks, damage, leaking

grease, and loose boot bands (D). lf any damage is

found, reDlace the boot and boot bands.

Turn the driveshaft by hand, and make sure the

splines (E) and joint are not excessively loose.

Make sure the driveshaft is not twisted or cracked;

if it is, replace it.

Driveshafts Removal

Special Tool Required

Balljoint remover, 28 mm 07MAC-S100200

1. Loosen the wheel nuts slightly

2. Raise the front of the vehicle, and support it with

safety stands in the proper locations (see page 1-8).

3. Remove the wheel nuts and front wheels.

4.Lift up the locking tab (A) on the spindle nut (B),

then remove the nut.

lf the !eft driveshaft or the intermediate shaft is to

be removed, drain the transmission fluid. Reinstall

the drain plug using a new washer (see page 13-3).

Hold the stabilizer balljoint pin (A) with a hex

wrench {B), and remove the flange nut (C).

Separate the front stabilizer link (D) from the lower

a rm.

(cont'd)

16-3

Page 471 of 1139

Driveline/Axle

Driveshafts Removal (cont'd)

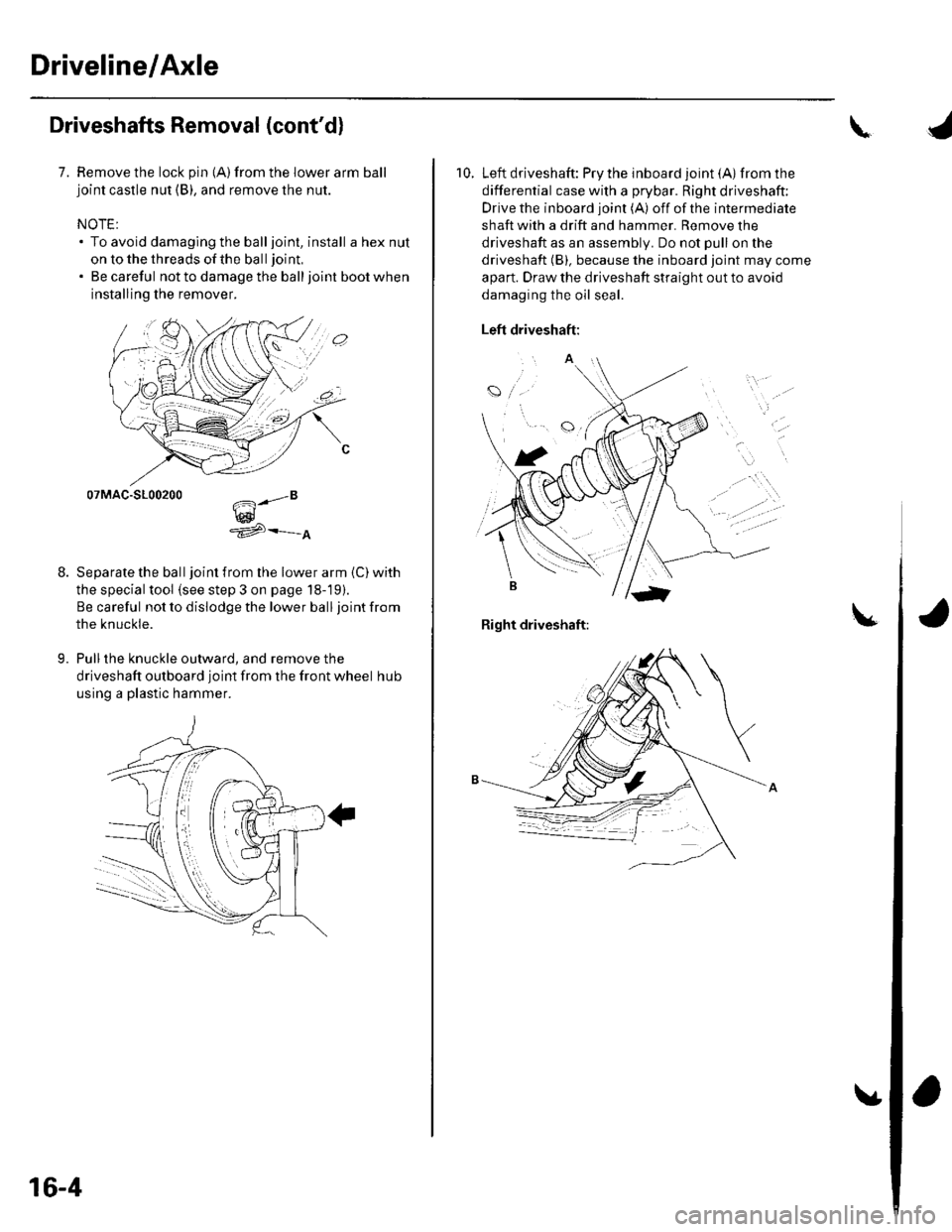

7. Remove the lock pin {A)from the lower arm balljoint castle nut (B), and remove the nut.

NOTE:. To avoid damaging the balljoint, install a hex nut

on to the threads of the ball joint,

. Be careful not to damage the balljoint boot when

installing the remover.

07MAC-S100200

w^'e

Separate the ball joint from the lower arm (C) with

the special tool (see step 3 on page 18-19).

Be careful not to dislodge the lower ball joint from

the knuckle.

Pull the knuckle outward, and remove the

driveshaft outboard joint from the front wheel hub

using a plastic hammer.

9.

.."8

16-4

\

10. Left driveshaft: Pry the inboard joint (A)from the

differential case with a prybar. Right driveshaft:

Drive the inboard joint (A) off of the intermediate

shaft with a drift and hammer. Remove the

driveshaft as an assembly. Do not pull on the

driveshaft (B), because the inboard joint may come

apart. Draw the driveshaft straight out to avoid

damaging the oil seal.

Left driveshaft:

a

t

Right driveshaft:

Page 485 of 1139

Driveline/Axle

Driveshafts Installation (cont'd)

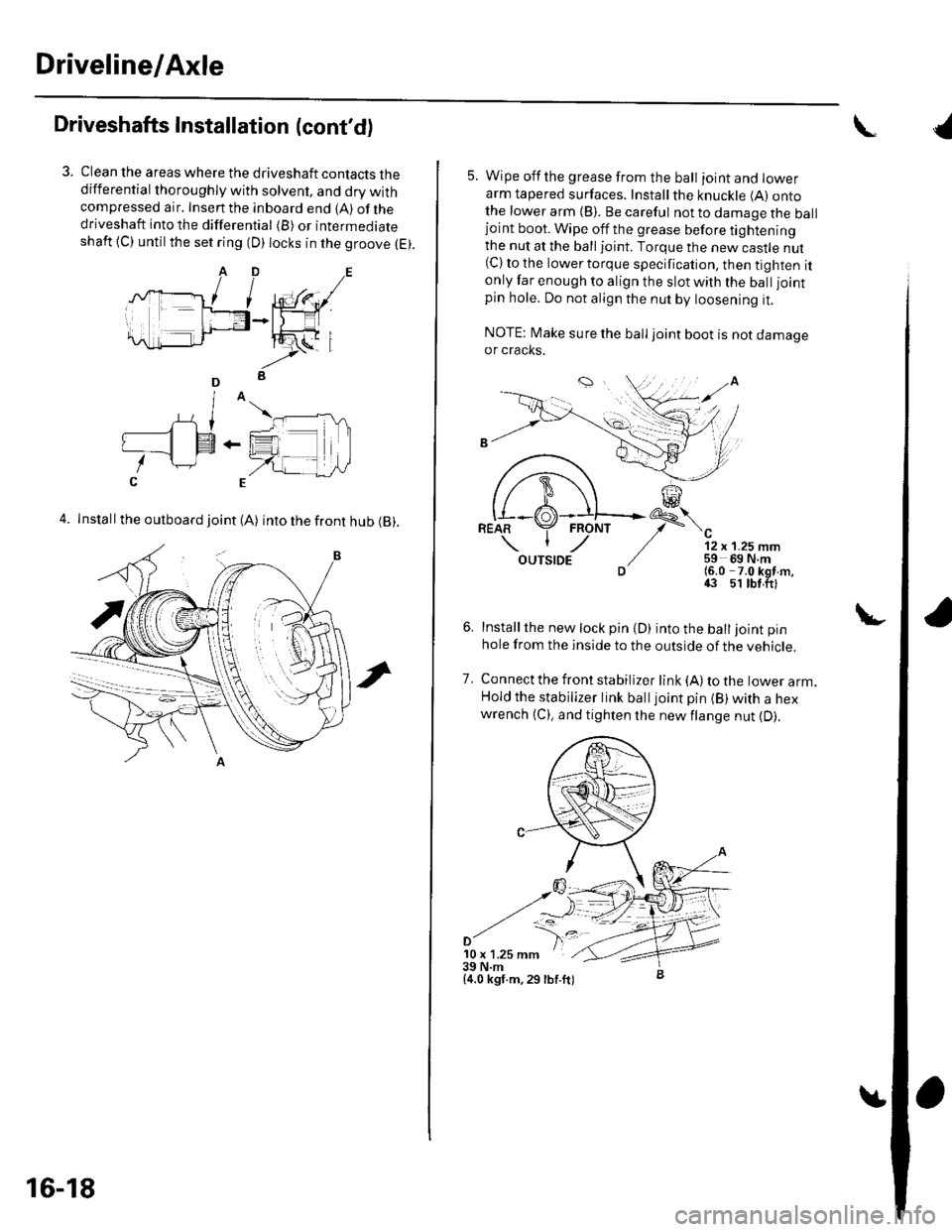

Clean the areas where the driveshaft contacts thedifferential thoroughly with solvent, and dry withcompressed air. Insenthe inboard end {A) ofthedriveshaft into the differential (B) or intermediateshaft {C) until the set ring (D) locks in the groove (E).

4. Install the outboard joint (A) into the front hub (B).

16-18

5. Wipe offthe grease from the ball ioint and lowerarm tapered surfaces. Installthe knuckle (A) ontothe lower arm {B). Be careful not to damage the balljoint boot. Wipe off the grease before tighteningthe nut at the ball joint. Torque the new castle nut(C) to the lower torque specification, then tighten itonly far enough to align the slot with the ball joint

pin hole. Do not align the nut by loosening it.

NOTE: Make sure the ball joint boot is not damageor cracks.

"-'t-

12 x 1.25 mm59 69 N.m(6.0 -7.0 kgf m,43 51 tbt.ftl

Installthe new lock pin {D) into the balljoint pin

hole from the inside to the outside of the vehicle.

Connect the front stabilizer link {A) to the lower arm.Hold the stabilizer link balljoint pin (B) with a hexwrench {C), and tighten the newflange nut {D).

7.

'10 x 1.25 mm39 N.m{4.0 kgf.m,29 lbf.ft)

{

Page 486 of 1139

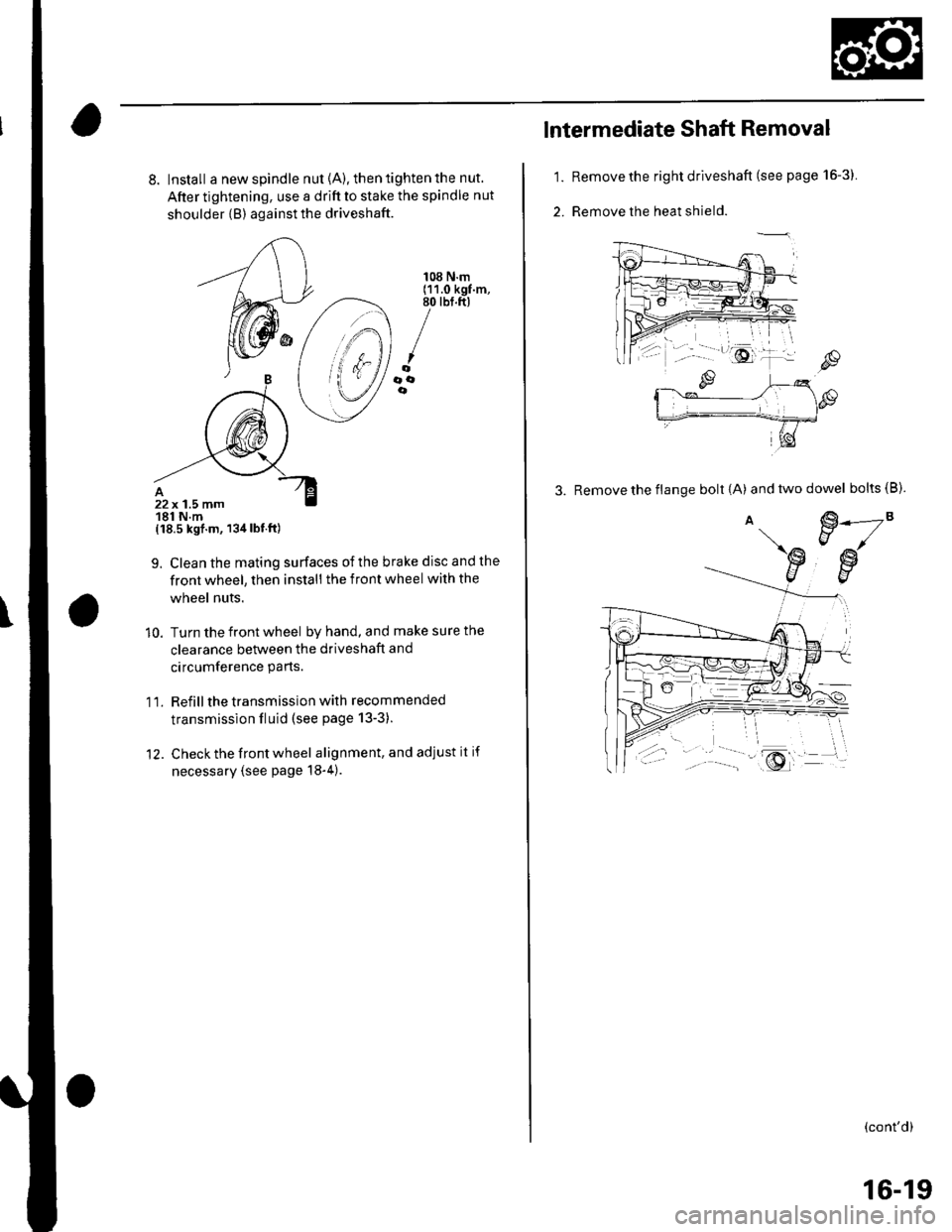

8. Install a new spindle nut {A), then tighten the nut.

After tightening, use a drift to stake the spindle nut

shoulder {B) against the driveshaft.

{18.5 kgf.m, 134lbt.ft)

9. Clean the mating surfaces ofthe brake disc and the

front wheel, then install the front wheel with the

wheel nuts.

10. Turn the front wheel by hand, and make sure the

clearance between the driveshaft and

circumference parts.

1 l. Refill the transmission with recommended

transmission fluid (see page 13-3).

12. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

108 N.m(11.0 kgf.m,80 tbt.ft)

/oooe

22x 1.5 mm181 N.m

1.

2.

lntermediate Shaft Removal

Remove the right driveshaft (see page 16-3).

Remove the heat shield.

3. Remove the flange bolt {A) andtwodowel bolts(B).

€.---2"EJ/

€w

(cont'd)

16-19

Page 496 of 1139

Steering

Steering Wheel Rotational Play

Check

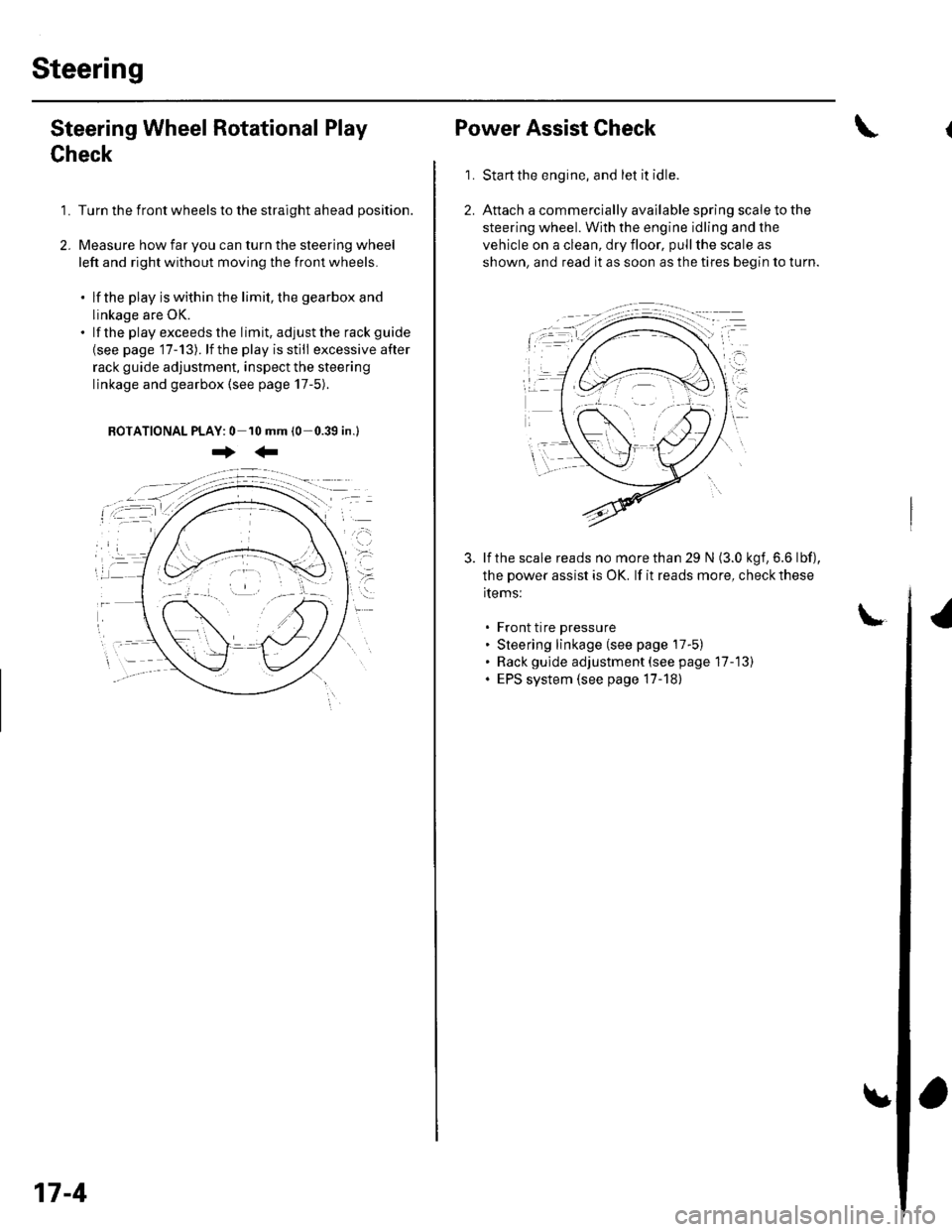

1. Turn the front wheels to the straight ahead position.

2. Measure how far you can turn the steering wheel

left and right without moving the front wheels.

. lf the play is within the limit, the gearbox and

linkage are OK.. lf the playexceedsthe limit, adjustthe rack guide

{see page '17-13). lf the play is still excessive after

rack guide adjustment, inspect the steering

linkage and gearbox {see page 17-5).

BOTATIONAL PLAY: 0 10 mm (0-0.39 in.l

+:

17-4

Power Assist Check

Start the engine, and let it idle.

Attach a commercially available spring scale to the

steering wheel. With the engine idling and the

vehicle on a clean, dry floor, pull the scale as

shown, and read it as soon as the tires begin to turn.

\

1.

3. lf the scale reads no morethan 29 N (3.0 kgf,6.6 lbf),

the power assist is OK. lf it reads more, check these

items:

. Front tire pressure. Steering linkage (see page 17-5). Rack gulde adjustment (see page 17-13). EPS system (see page 17-18)

Page 498 of 1139

Steering

Steering Wheel Removal

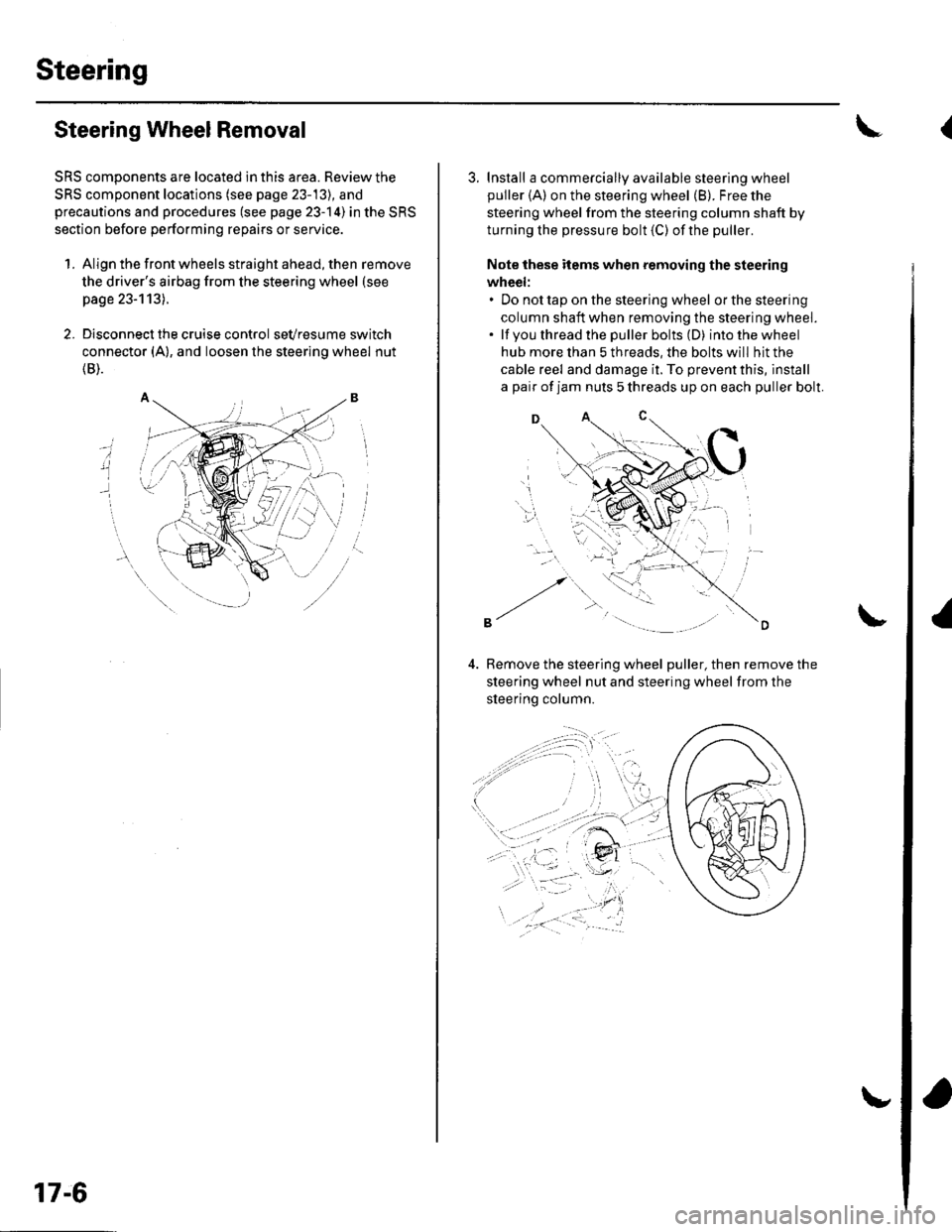

SRS components are located in this area. Review the

SRS component locations (see page 23-13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Align the front wheels straight ahead, then remove

the driver's airbag from the steering wheel (see

page 23-113).

2. Disconnect the cruise control sevresume switch

connector (A), and loosen the steering wheel nut

{B).

i

17-6

3. Install a commercially available steering wheel

puller {A) on the steering wheel (B). Free the

steering wheel from the steering column shaft by

turning the pressure bolt (C) ofthe puller.

Note these items when removing the steering

wheel:. Do not tap on the steering wheel orthesteering

column shaft when removing the steering wheel.. lf you thread the puller bolts (D) intothewheel

hub more than 5 threads, the bolts will hit the

cable reel and damage it. To prevent this, install

a pair of jam nuts 5 threads up on each puller bolt.

D

Bemove the steering wheel puller, then remove the

steering wheel nut and steering wheel from the

sleerino column.

{

Page 500 of 1139

Steering

Steering Wheel Installation

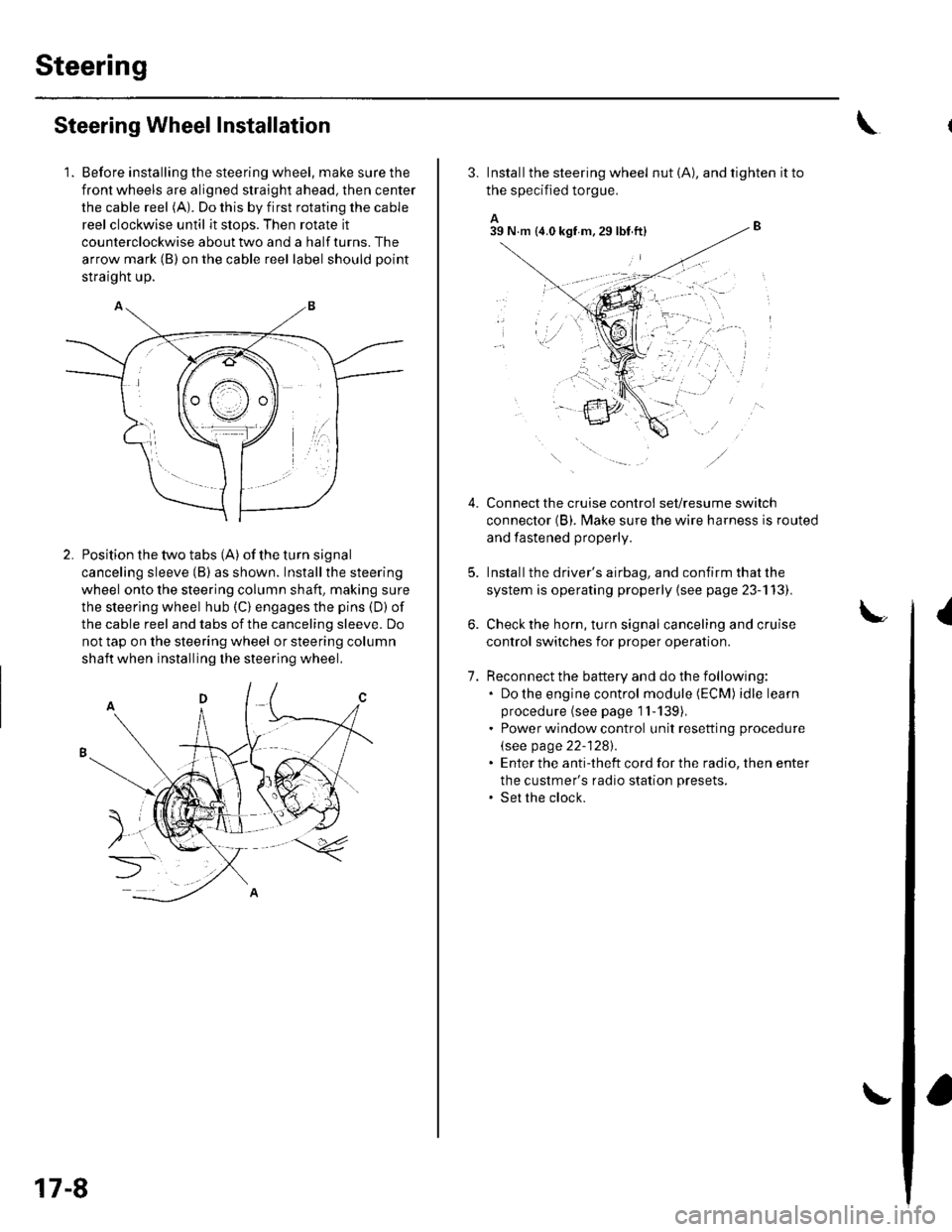

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel (A). Do this by first rotating the cable

reel clockwise until it stops. Then rotate it

counterclockwise about two and a half turns. The

arrow mark (B) on the cable reel label should point

straight up.

Position the two tabs (A) of the turn signal

canceling sleeve (B) as shown. Installthe steering

wheel onto the steering column shaft, making sure

the steerlng wheel hub (C) engages the pins (D) of

the cable reel and tabs of the canceling sleeve. Do

not tap on the steering wheel or steering column

shaft when installing the steering wheel.

17-8

3. Install the steering wheel nut (A), and tighten it to

the specified torgue.

A_B39 N.m (4.0 kgf m.29lbt ftl

Connect the cruise control set/resume switch

connector (B). fvlake sure the wire harness is routed

and fastened properly.

Install the driver's airbag, and confirm that the

system is operating properly {see page 23-113).

Check the horn, turn signal canceling and cruise

control switches for proper operation.

Reconnect the battery and do the following:. Do the engine control module (ECM) idle learn

procedure (see page 1l-139),. Power window control unit resetting procedure

\see page 22-1281.. Enter the anti-theft cord for the radio, then enter

the custmer's radio station presets.. Set the clock.

{

7.

lr,',,t

;. _,:!

'' '1i::..'.' l

Page 511 of 1139

EPS Components

General Troubleshooting Information (cont'dl

5. The blinking frequency indicates the DTC. DTCS are

indicated by a series of long and short blinks. One

long blink equals 10 short blinks. Add the long and

short blinks together to determine the DTC. After

determining the DTC, refer to the DTC

Troubleshooting Index.

The system will not indicate the DTC unless these

conditions are met:. Set the front wheels in the straight ahead drivingposition.. The ignition switch is turned ON (ll).. The engine is stopped.. The SCS circuit is shorted to body ground before

the ignition switch is turned ON (ll).

Example of DTC 23

Long blinks Short blinks(two times) (three timesl

6.

7.

Turn the ignition switch OFF.

Disconnect the Honda PGM Tester from the DLC.

17-20

How to Clear EPS DTCs

Honda PGM Tesler Method:

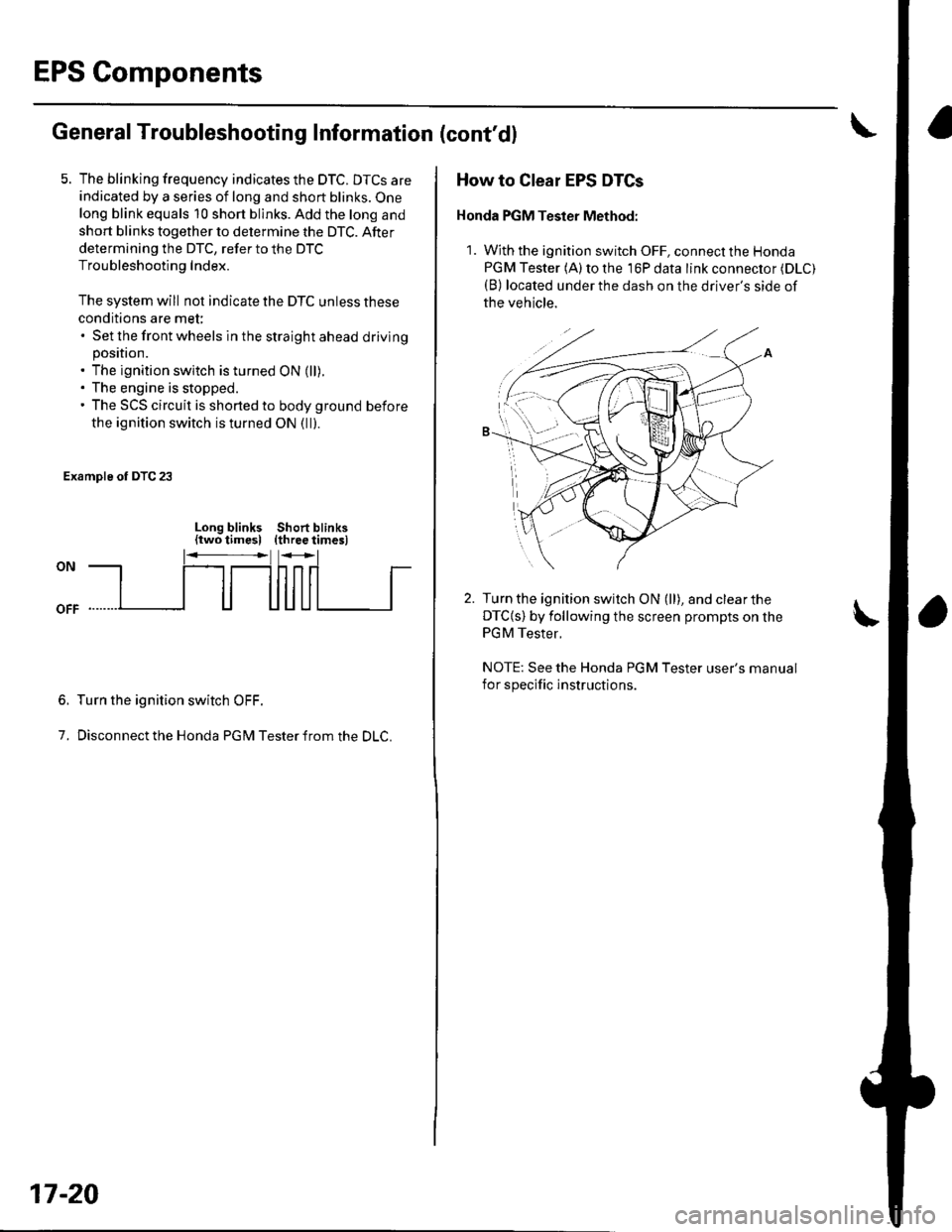

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

Turn the ignition switch ON (ll), and clear the

DTC{s) by following the screen prompts on the

PGM Tester.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.