Engine removal HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 335 of 1139

VTEC/WC

1.

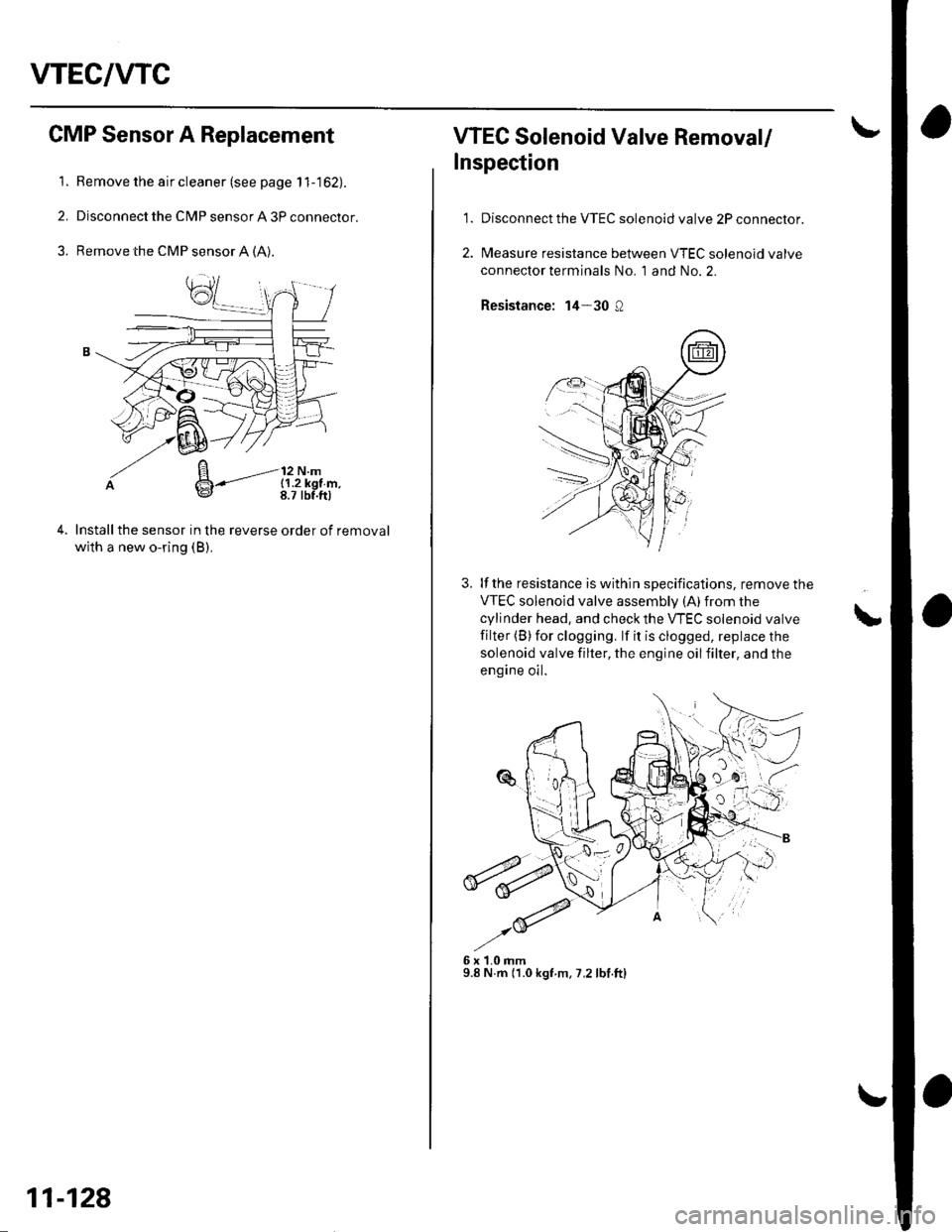

CMP Sensor A Replacement

Remove the air cleaner (see page 1 1-162).

Disconnect the CMP sensor A 3P connector.

Remove the CMP sensor A (A).

Installthe sensor in the reverse order of removal

with a new o-ring (B).

B-'-----'-l:,",14*

11-128

WEC Solenoid Valve Removal/

Inspection

1.Disconnect the VTEC solenoid valve 2P connector.

Measure resistance between VTEC solenoid valve

connector terminals No. 1 and No. 2.

Resistance: 14-30 Q

3. lf the resistance is within specifications, remove the

VTEC solenoid valve assemblv (A)from the

cylinder head, and check the VTEC solenoid valve

filter (B)for clogging. lf it is clogged, replace the

solenoid valve filter, the engine oilfilter, and the

engine oil.

6x1.0mm9.8 N.m (1.0 kgf.m, 7,2 lbf.ftl

L

Page 361 of 1139

Fuel Supply System

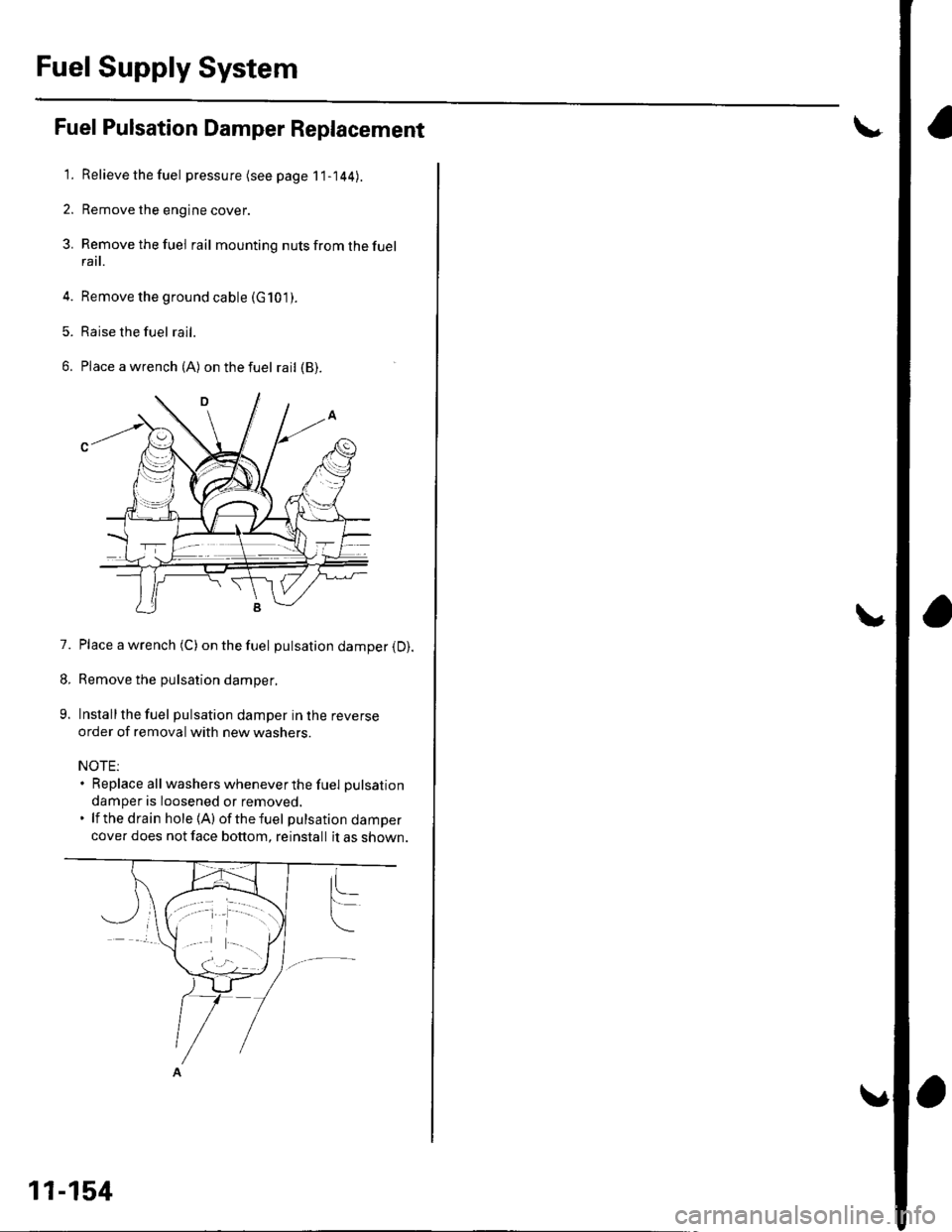

Fuel Pulsation Damper Replacement

1. Relieve the fuel pressure(seepagell-144).

2. Remove the engine cover.

3. Remove the fuel rail mounting nuts from the fuelrail.

4. Remove the ground cable (G 101.

5. Raise the fuel rail.

6. Place awrench (A) onthefuel rail (B).

7. Place a wrench (C) onthefuel pulsation damper (D).

8. Remove the pulsation damper.

9. Installthe fuel pulsation damper in lhe reverse

order of removal with new washers.

NOTE:. Replace all washers wheneve r the fuel pulsation

damper is loosened or removed,. lf the drain hole (A) ofthefuel pulsationdamper

cover does not face bottom, reinstall it as shown.

11-154

Page 371 of 1139

Intake Air System

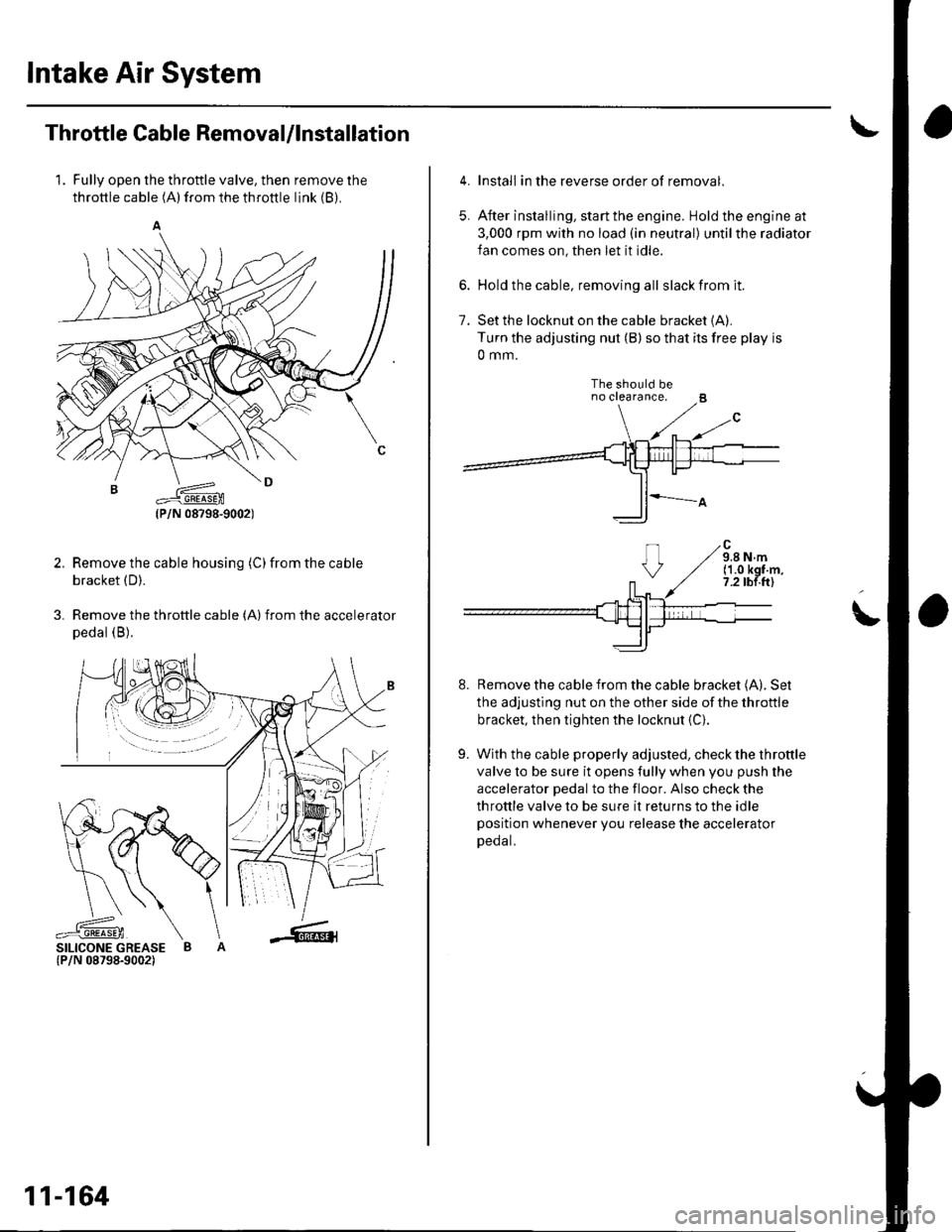

Throttle Cable Removal/lnstallation

1. Fully open the throttle valve, then remove the

throttle cable (A) from the throttle link (B).

Remove the cable housing (C)from the cable

bracket (D).

Remove the throttle cable (A)from the accelerator

pedal (B).

2.

3.

SILICONE GREASE B(P/N 08798-9002)

(P/N 08?98-9002)

11-164

5.

Install in the reverse order of removal.

After installing, start the engine. Hold the engine at

3,000 rpm with no load (in neutral) untilthe radiator

fan comes on, then let it idle.

Hold the cable, removing all slack from it.

Set the locknut on the cable bracket {A).Turn the adjusting nut (B) so that its free play is

0 mm.

The should beno crearance.

Remove the cable from the cable bracket (A). Set

the adjusting nut on the other side of the throttle

bracket, then tighten the locknut {C}.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the

throttle valve to be sure it returns to the idle

position whenever you release the accelerator

Deoat.

7.

!

8.

9.

('1.0 kgf.m,7.2 tbf.ftl

Page 402 of 1139

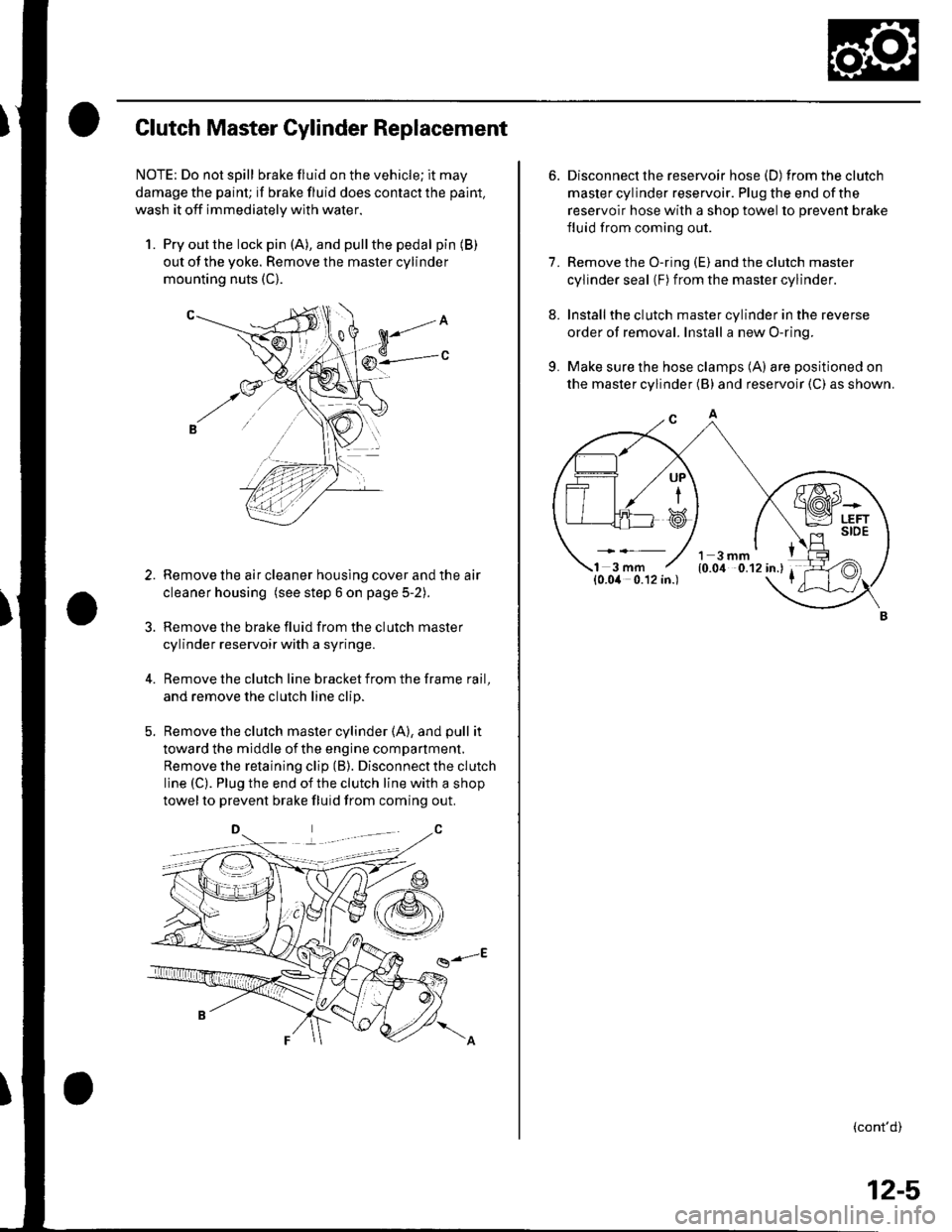

Clutch Master Cylinder Replacement

NOTE: Do not spill brake fluid on the vehicle; it may

damage the paint; if brake fluid does contact the paint,

wash it off immediatelV with water.

1. Pry out the lock pin (A), and pullthe pedal pin (B)

out of the yoke. Remove the master cylinder

mounting nuts (C).

Remove the air cleaner housing cover and the air

cleaner housing (see step 6 on page 5-2).

Remove the brake fluid from the clutch master

cylinder reservoir with a syringe.

Remove the clutch line bracket from the frame rail,

and remove the clutch line clip.

Remove the clutch master cylinder (A), and pull it

toward the middle of the engine compartment.

Remove the retaining clip (B). Disconnect the clutch

line (C). Plug the end of the clutch line with a shop

towelto prevent brake fluid from coming out.

g-E

3.

6. Disconnect the reservoir hose (D) fromtheclutch

master cylinder reservoir. Plug the end of the

reservoir hose with a shop towel to prevent brake

fluid from coming out.

7. Remove the O-ring (E) and the clutch master

cylinder seal (F) from the master cylinder.

8. Installthe clutch master cylinder in the reverse

order of removal. Install a new O-ring.

9. Make sure the hose clamps (A) are positioned on

the master cylinder (B) and reservoir (C) as shown.

(cont'd)

UP

i

12-5

Page 414 of 1139

Manual Transmission

Transmission Removal

SpecialTools Required. Engine hanger adapter.2.0 to 2.4 liter VSB02C000015. Engine hanger VSB02C000018. Engine support hanger, A & Reds AAR'T 12566'. Subframe adaDter EOS02C000011 '

* Available through the Honda Tool and Equipment

Program 888-424-6857

NOTE: Use fender covers to avoid damaging painted

surfaces.

4.

1.

7.

Write down the frequencies for the radio's preset

buttons. Disconnect the negative ( ) cable first,

then the positive ( )cable from the battery.

Remove the battery.

Remove the intake manifold cover {see page g-3).

Remove the air cleaner housing (see page 1 1-162).

Remove the intake air duct {see step 8 on page 5-3).

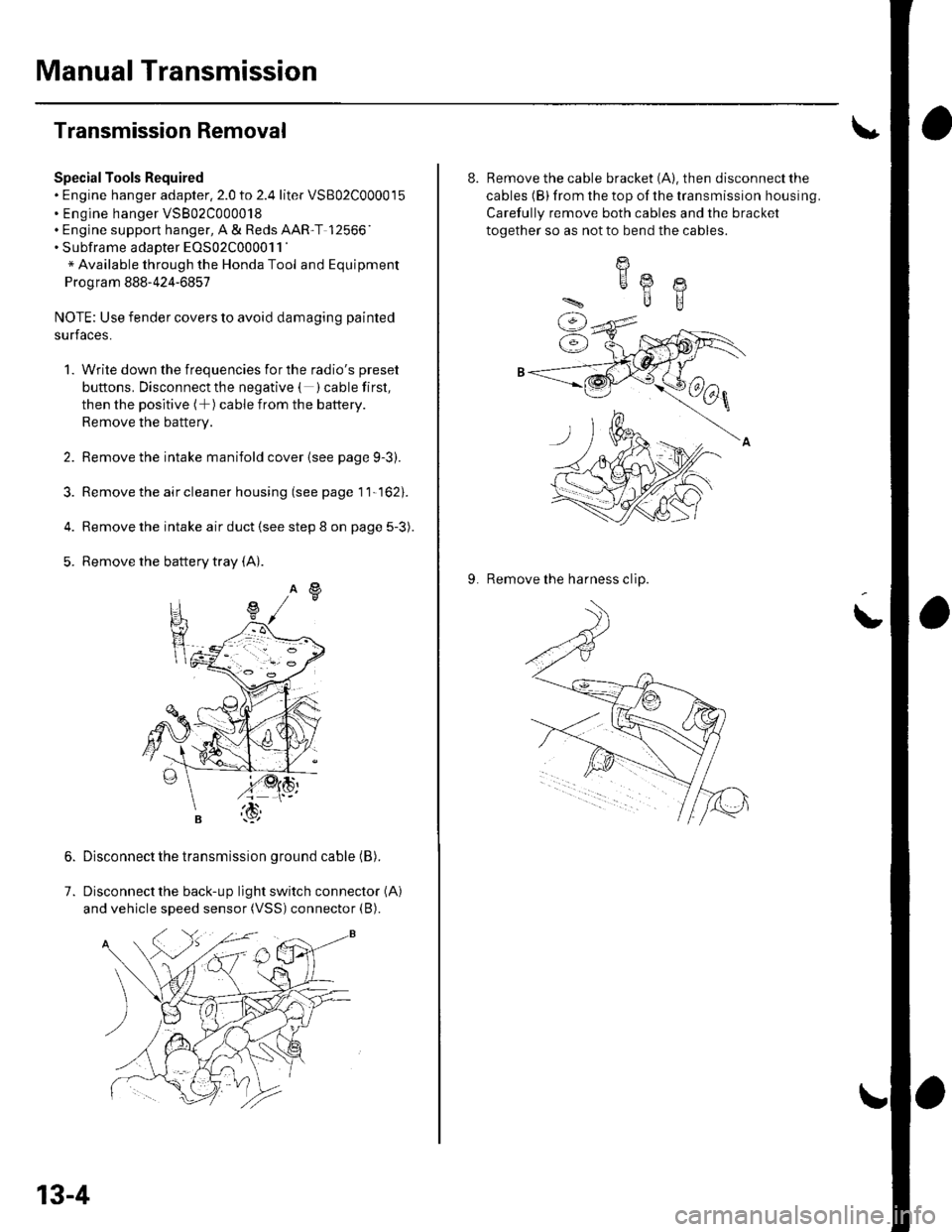

Remove the battery tray (A).

Disconnect the transmission ground cable (B).

Disconnect the back-up light switch connector (A)

and vehicle speed sensor (VSS) connector (B).

13-4

8. Remove the cable bracket (A). then disconnect the

cables (B) from the top of the transmission housing.

Carefully remove both cables and the bracket

together so as not to bend the cables.

9. Remove the harness clip.

I

HA @

ilB

Page 416 of 1139

Manual Transmission

Transmission Removal (cont'd)

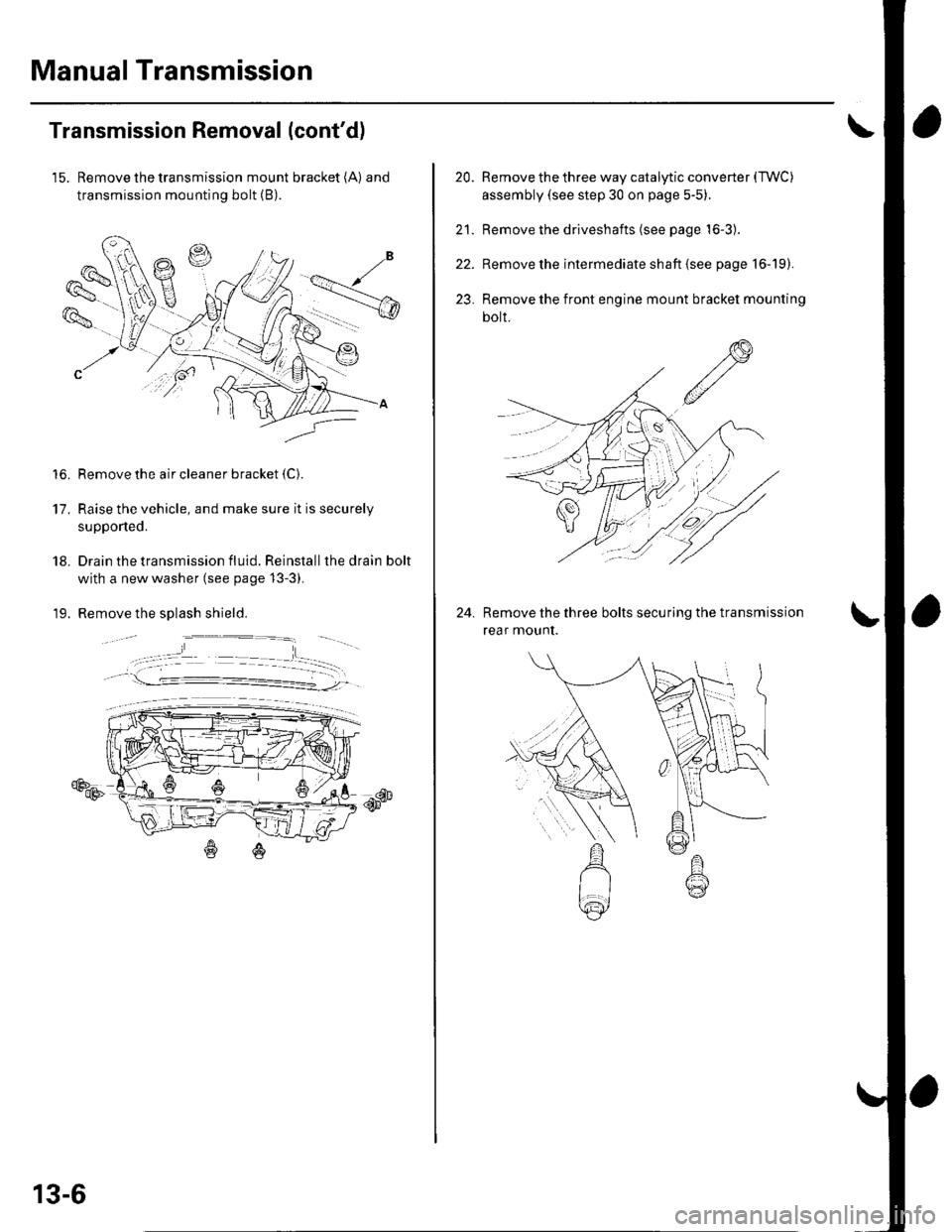

15. Remove the transmission mount bracket (A) and

transmission mounting bolt (B).

Remove the air cleaner bracket {C).

Raise the vehicle, and make sure it is securely

supponed.

Drain the transmission fluid. Reinstall the drain bolt

with a new washer (see page 13-3).

Remove the splash shield.

€Ds

to.

17.

18.

19.

db--qF

13-6

20.

21.

22.

23.

Remove the three way catalytic converter (TWC)

assembly (see step 30 on page 5-5)

Remove the driveshafts (see page 16-3).

Remove the intermediate shaft {see page 16-19).

Remove the front engine mount bracket mounting

bolt.

Remove the three bolts securing the transmission

rear mounI.

24.

Page 418 of 1139

Manual Transmission

\

12 x 1.25 mm64 N.m{6.5 ksf.m,47 tbf.ft)

30.

Transmission Removal (cont'd)

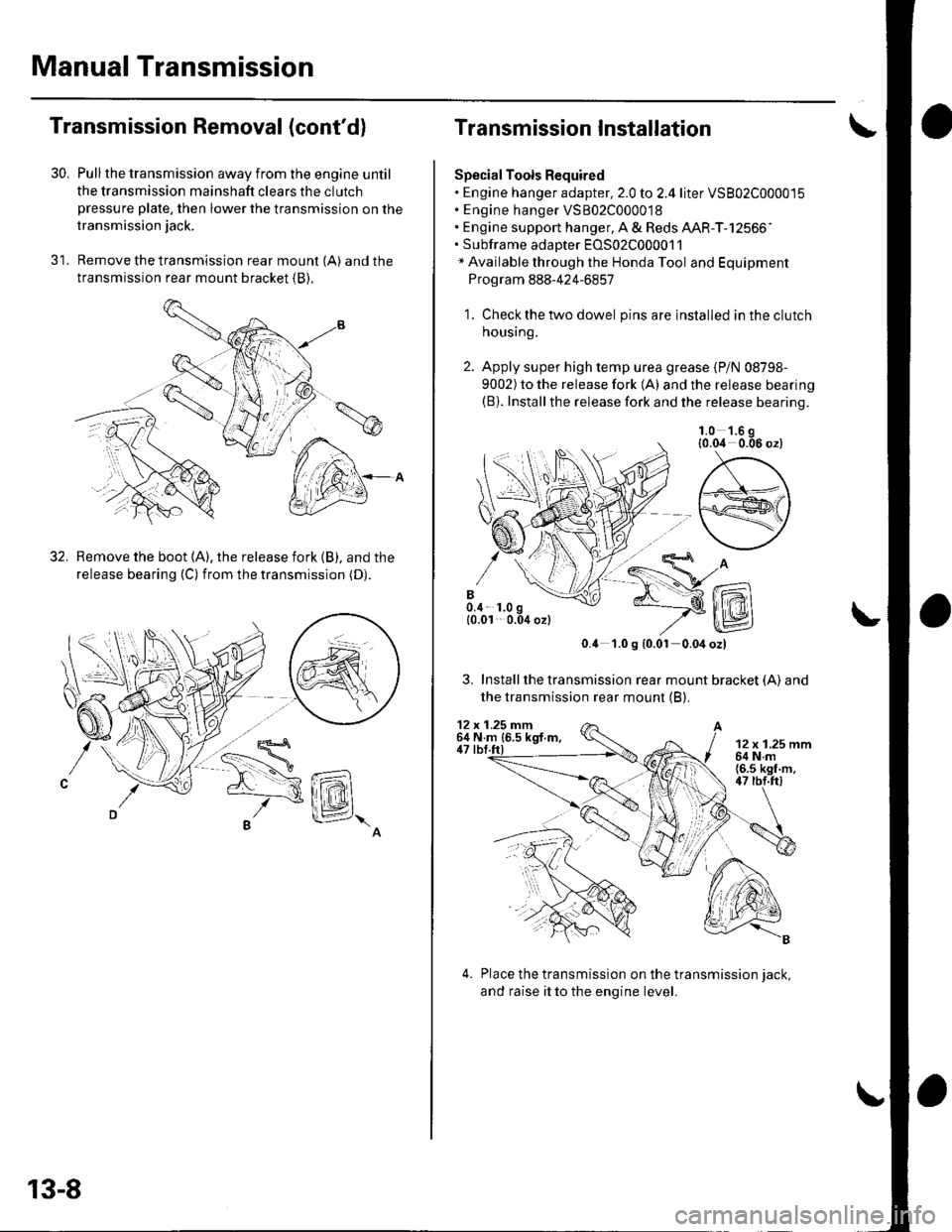

Pull the transmission away from the engine until

the transmission mainshaft clears the clutchpressure plate, then lower the transmission on the

transmission jack.

Remove the transmission rear mount (A) and the

transmission rear mount bracket {B).

Remove the boot (A), the release fork {B). and the

release bearing (C) from the transmission (D).

32.

13-8

Transmission Installation

Special Tools Required. Engine hanger adapter, 2.0 to 2.4 liter VS802C000015. E ngine hanger VS802C000018. Engine support hanger, A & Reds AAR-T-12566". subframe adaDter EoS02c000011* Available through the Honda Tool and Equipment

Program 888-424-6857

1. Check the two dowel pins are installed in the clutch

housr ng.

Apply super high temp urea grease (P/N 08798-

9002) to the release fork (A) and the release bearing(B). Installthe release fork and the release bearing.

0.4 1.0 g {0.01 0.04 ozl

3. Installthe transmission rear mount bracket (A)and

the transmission rear mount (B).

x 1.25 mmN m {6.5 kgf.m,

Place the transmission on the transmission iack.

and raise it to the engine level.

't2

6447

1.0 '1.6 g{0.04 0.06 oz)

Page 419 of 1139

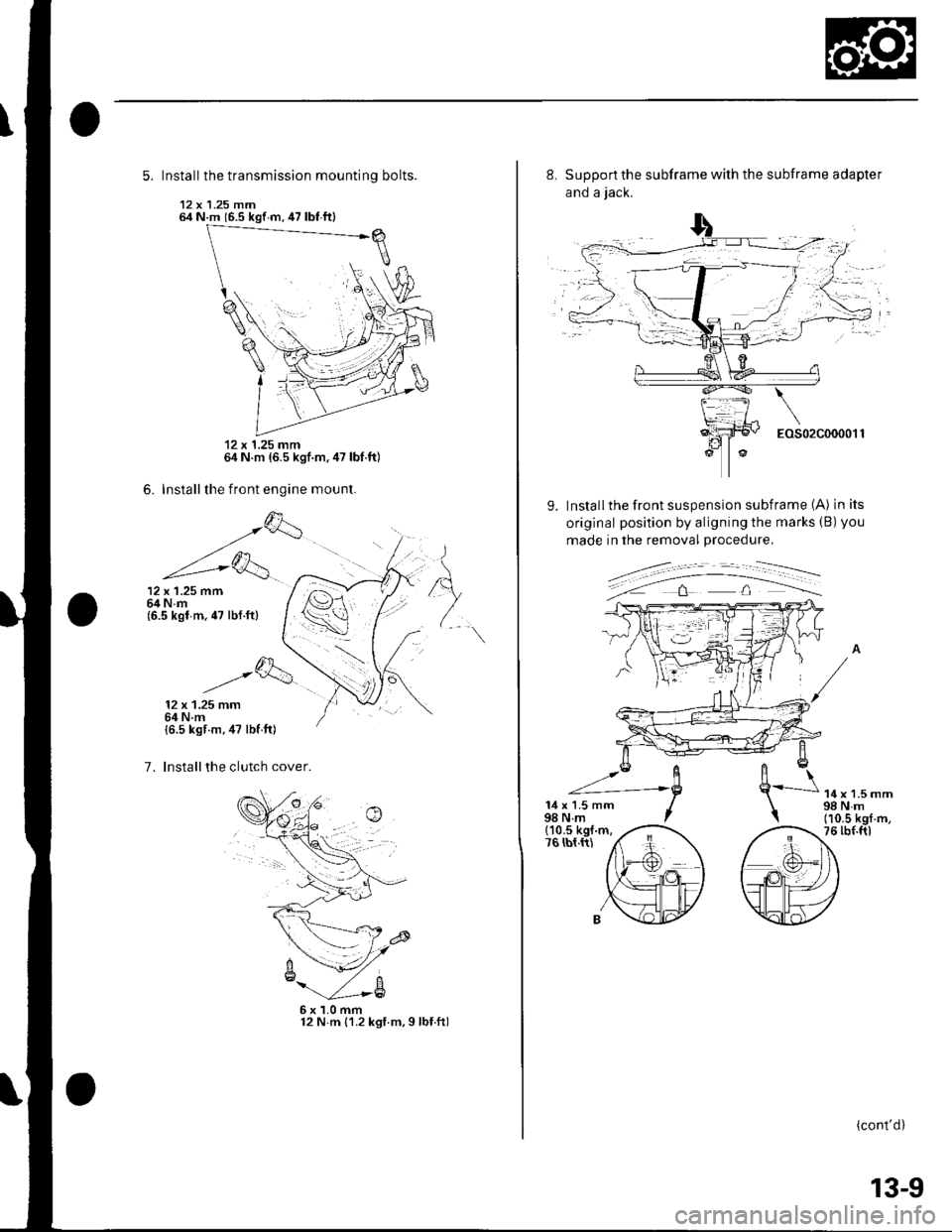

5. Install the transmission mounting

12 x 1.25 mm64 N.m 16.5 kgf m.47 lbt ft)

12 x 1.25 mm64 N.m (6.5 kgf.m,47 lbf.ft)

6. Installthe front engine mount.

12 x 1.25 ftrn64 N.m(6.5 kgf m. 47 lbf.ft)

bolts.

12x 1.25 mm64 N.m(6.5 kst.m,47 lbf ft)

7. lnstallthe clutch cover.

6x1.0mm12 N.m {1.2 kgI.m, 9 lbf ftl

8. Supportthe subframe with the subframe adapter

and a jack.

Installthe front suspension subframe (A) in its

original position by aligning the marks (B) you

made in the removal procedure,

9.

14 x 1.5 mm

(cont'd)

13-9

Page 502 of 1139

Steering

Steering Column Removal

lnstallation

1.

4.

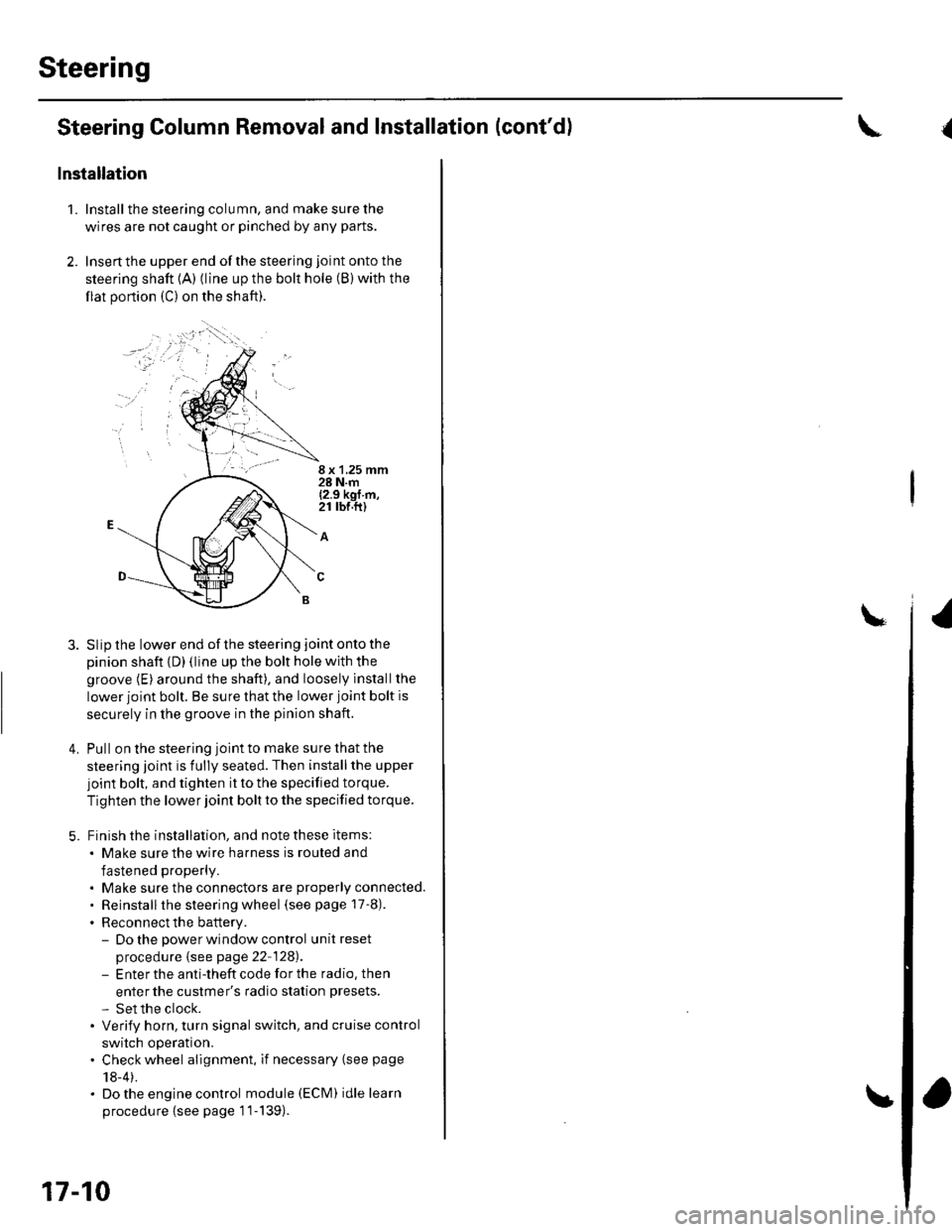

Install the steering column, and make sure the

wires are not caught or pinched by any parts.

Insertthe upper end ofthe steering joint onto the

steering shaft {A) (line up the bolt hole (B) with the

flat portion (C) on the shaft).

8 x 1,25 mm28 N.m{2.9 kgf m,21 rbr.ft)

A

Slip the lower end of the steering joint onto the

pinion shaft {D) (line up the bolt hole with the

groove (E) around the shaft), and loosely lnstallthe

lower joint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft.

Pull on the steering joint to make su re that the

steering joint is fully seated. Then installthe upper

joint bolt, and tighten it to the specified torque.

Tighten the lower joint bolt to the specified torque.

Finish the installation, and note these items:

. Make sure the wire harness is routed and

fastened properly.

. Make sure the connectors are properly connected.. Reinstallthe steering wheel (see page 17-8).

. Reconnect the battery.- Do the power window control unitreset

procedure {see page 22-128).- Enter the anti-theft code for the radio, then

enter the custmer's radio station presets.

- Set the clock.. Verify horn, turn signal switch, and cruise control

switch operation.. Check wheel alignment, if necessary (see page

18-4).. Do the engine control module (ECM) idle learn

procedu re {see page '11-139).

17-10

and Installation (cont'd){

Page 541 of 1139

EPS Components

(Motor RemovaUlnstallation (cont'dl

lnsiallation

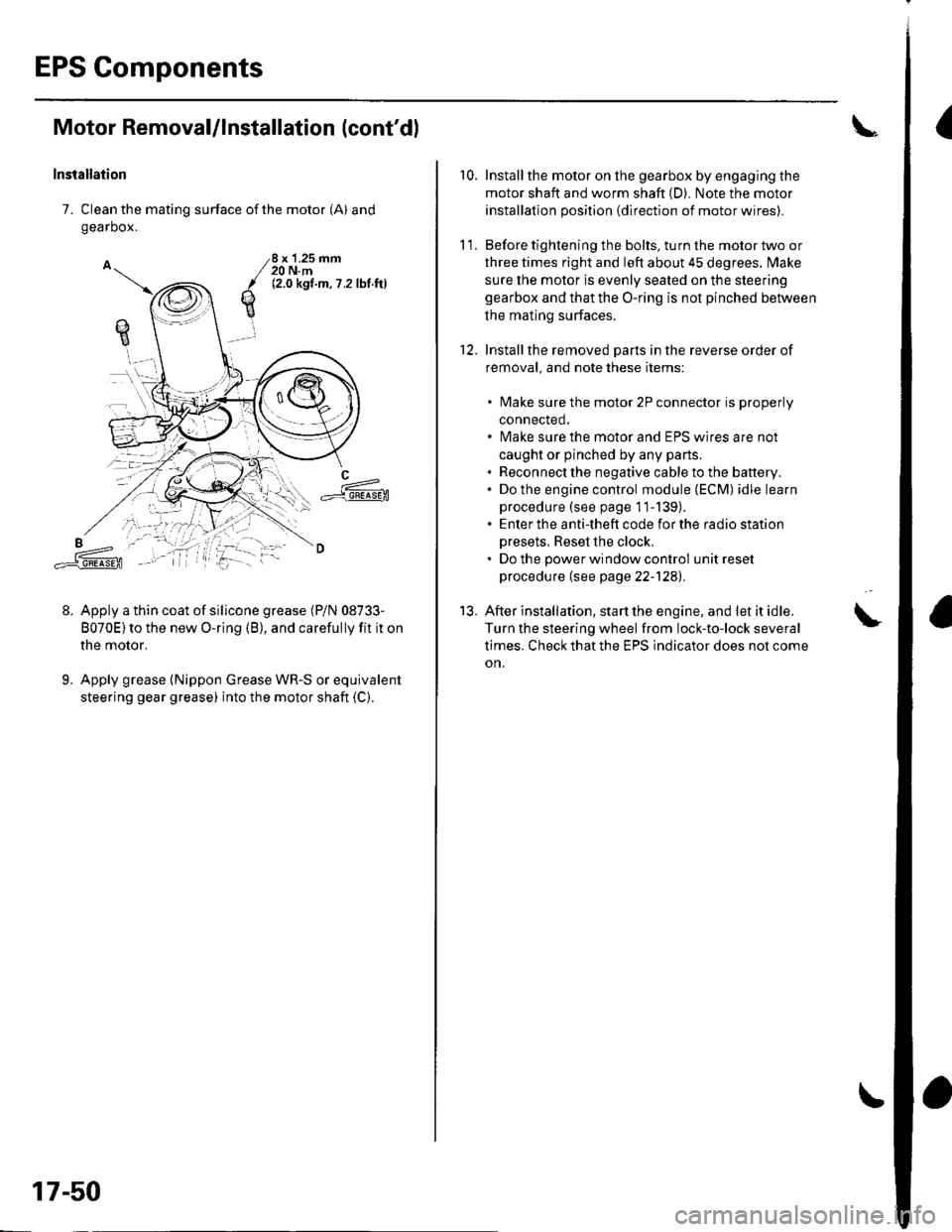

7. Clean the mating surface of the motor (A) and

gearbox.

Apply a thin coat of silicone grease (P/N 08733-

8070E)to the new O-ring (B), and carefully fit it on

the motor.

Apply grease {Nippon Grease WR-S or equivalent

steering gear grease) into the motor shaft (C).

qE

8 x '1.25 mm20 N.m12.0 kgt.m,7 .2lbl ftl

L==-c].E@

9.

17-50

r0.Install the motor on the gearbox by engaging the

motor shaft and worm shaft (D). Note the motor

installation position {direction of motor wires).

Before tightening the bolts, turn the motor two or

three times right and left about 45 degrees. lvlake

sure the motor is evenly seated on the steering

gearbox and that the O-ring is not pinched betlveen

the mating surfaces.

Installthe removed Darts in the reverse order of

removal. and note these items:

lvlake sure the motor 2P connector is properly

connected.

lvlake sure the motor and EPS wires are not

caught or pinched by any parts.

Reconnect the negative cable to the battery.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

Enter the anti-theft code for the radio station

Dresets. Reset the clock,

Do the oower window control unit reset

procedure (see page 22-1241.

After installation, start the engine, and let it idle.

Turn the steering wheel from lock-to-lock several

times. Check that the EPS indicator does not come

on.

11.

12.

13.