Engine removal HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 142 of 1139

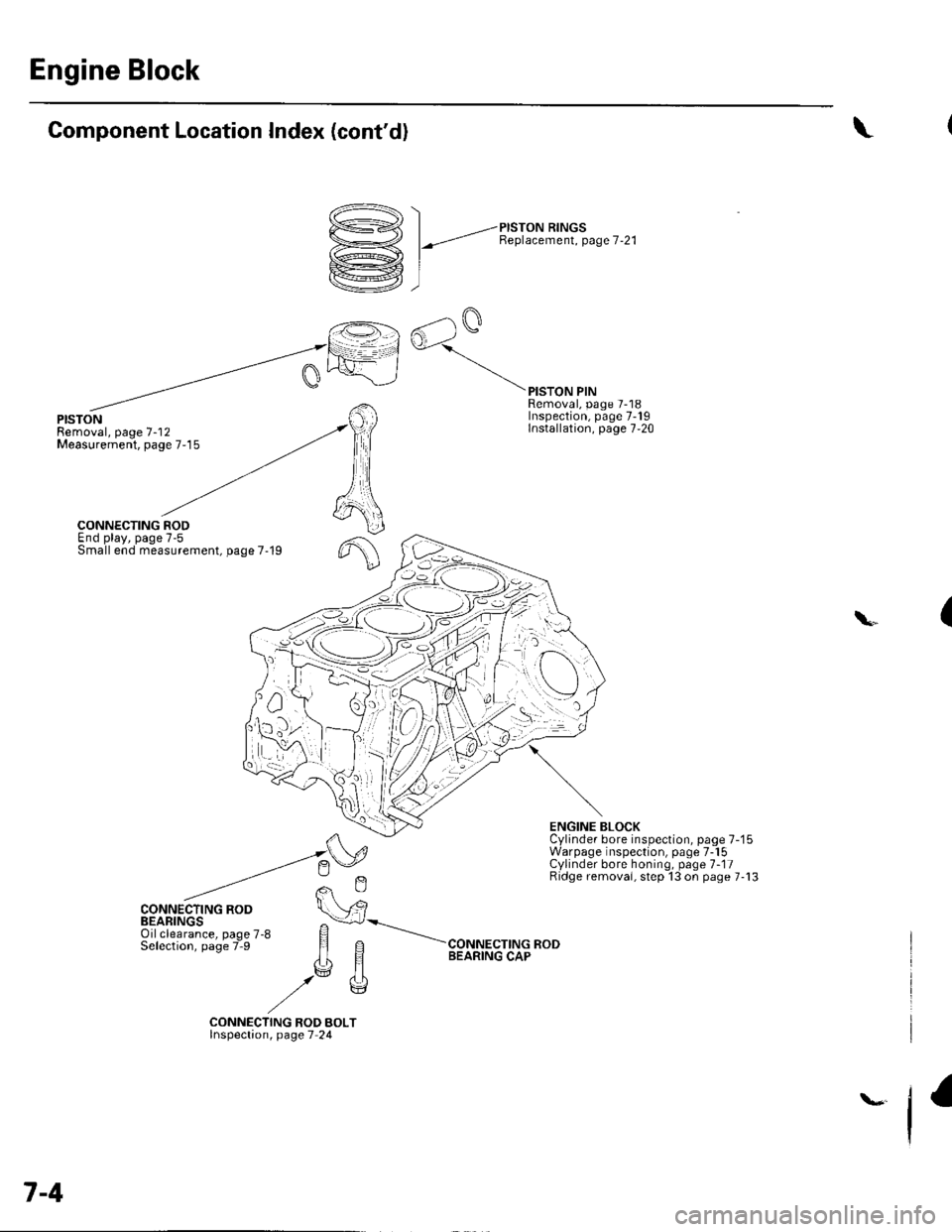

Engine Block

Component Location Index (cont'd)

/^., \

D->< | _,-ersroru nrrucs

Y1 l-"t Benlacement. Page 7-21

rkrej, I

ffil

rG AalQ

[=l^oJ

\

PISTONRemoval, page 7-'12Measurement, page 7-15

PISTON PINRemoval, page 7-18Inspection, page 7-19Installation, page 7,20

f,

6

CONNECTING RODEnd play, page 7-5Small end measurement, page 7-19

CONNECTING ROD

ENGINE BLOCKCylinder bore inspection, page 7-'15Warpage inspection, page 7-15Cylinder bore honing, page 1-11Ridge removai, step 13 on page 7-13

(\

CONNECTING ROD BOLTlnspectaon, page 7 24

7-4

Page 149 of 1139

1.

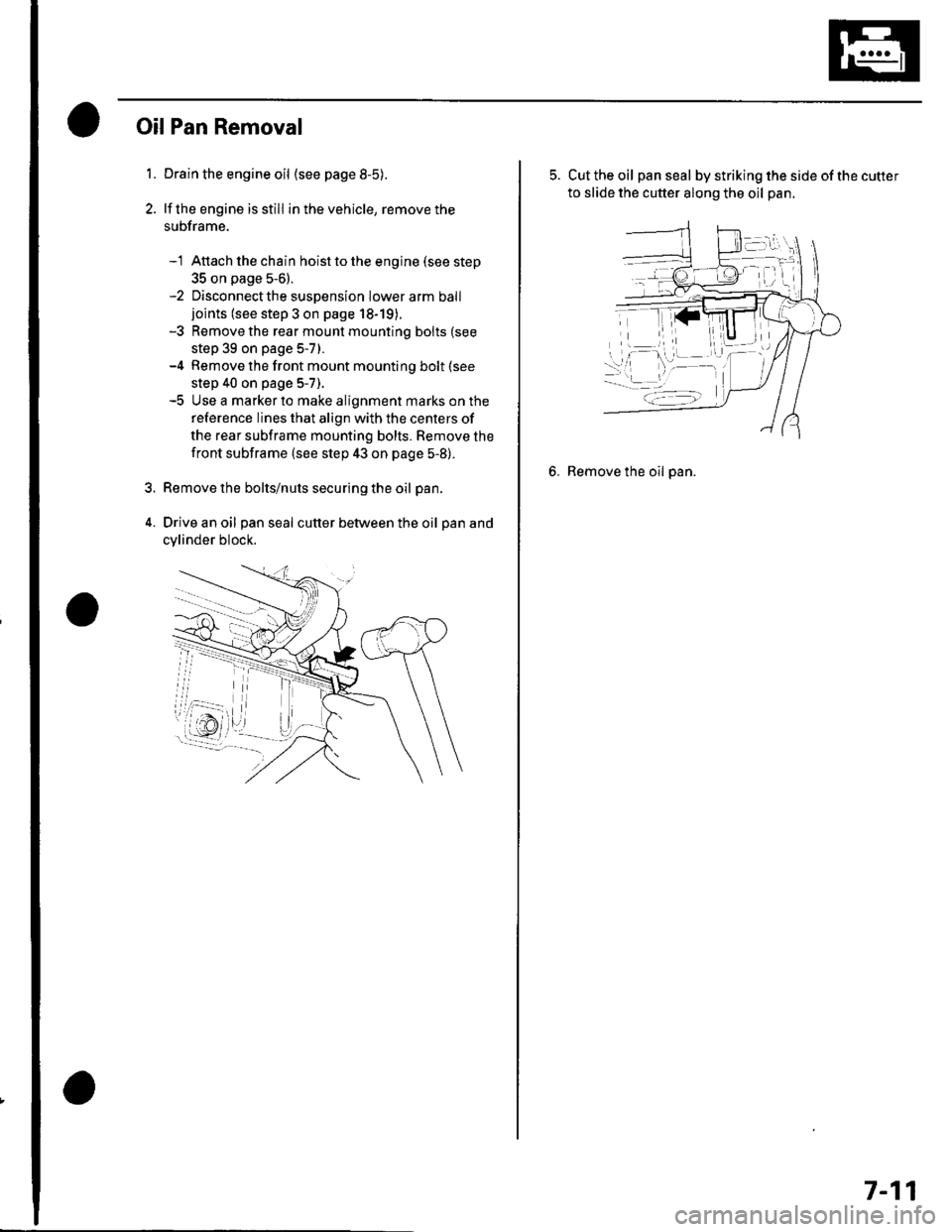

OilPan Removal

Drain the engine oil (see page 8-5).

lf the engine is still in the vehicle, remove the

subframe.

-1 Attach the chain hoist to the engine (see step

35 on page 5-6).-2 Disconnectthe suspension lower arm balljoints (see step 3 on page 18-19).-3 Remove the rear mounl mounting bolts (see

step 39 on page 5-7).-4 Remove the front mount mounting bolt (see

step 40 on page 5-7).-5 Use a marker to make alignment marks on the

reference lines that align with the centers of

the rear subframe mounting bolts. Remove the

front subframe (see step 43 on page 5-8).

Remove the bolts/nuts securing the oil pan.

Drive an oil pan seal cutter between the oil pan and

cylinder block.

5. Cut the oil panseal bystrikingthesideofthecutter

to slide the cutter along the oil pan.

6. Remove the oil pan.

7-11

Page 150 of 1139

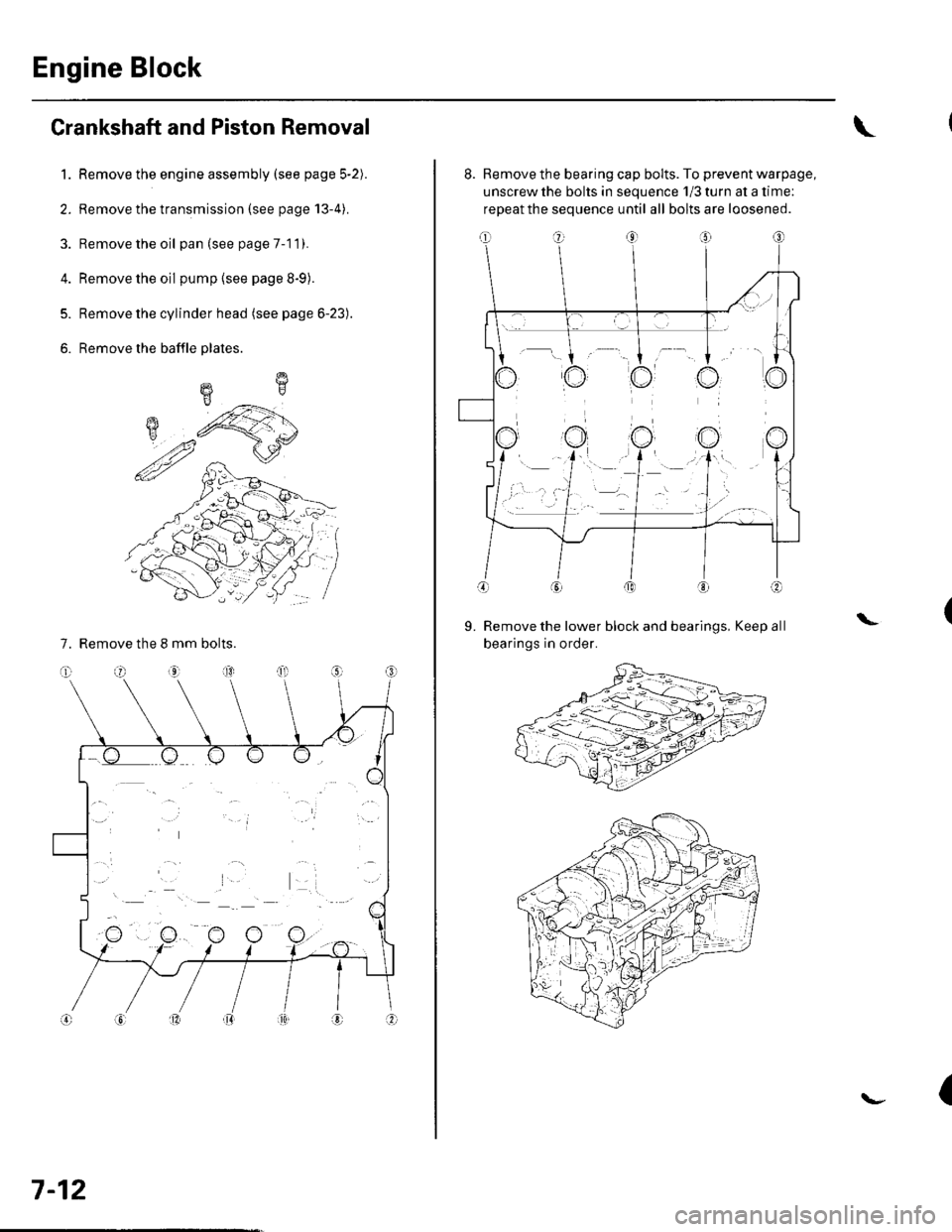

Engine Block

Crankshaft and Piston Removal

1. Remove the engine assembly (see page 5-2).

2. Remove the transmission (see page 13-4).

3. Remove the oil pan (see page 7-1 1).

4. Remove the oil pump {see page 8-9).

5. Remove the cylinder head (see page 6-23).

6. Remove the baffle plates.

7. Remove the 8 mm bolts.

E

7-12

8. Remove the bearing cap bolts. To prevent warpage,

unscrew the bolts in sequence 1/3 turn at a time:

repeat the sequence until all bolts are loosened.

Remove the lower block and bearings, Keep all

bearings in order.

\L

(

Page 183 of 1139

Engine Mechanical

Intake Manifold and Exhaust System

lntake Manifold Removal and Installation ................. 9-2

Exhaust Manifold Removal and Installation .............. 9-7

Exhaust Pipe and Muffler Replacement ..................... 9-8

r

r-!i!1

Page 186 of 1139

Intake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'dl

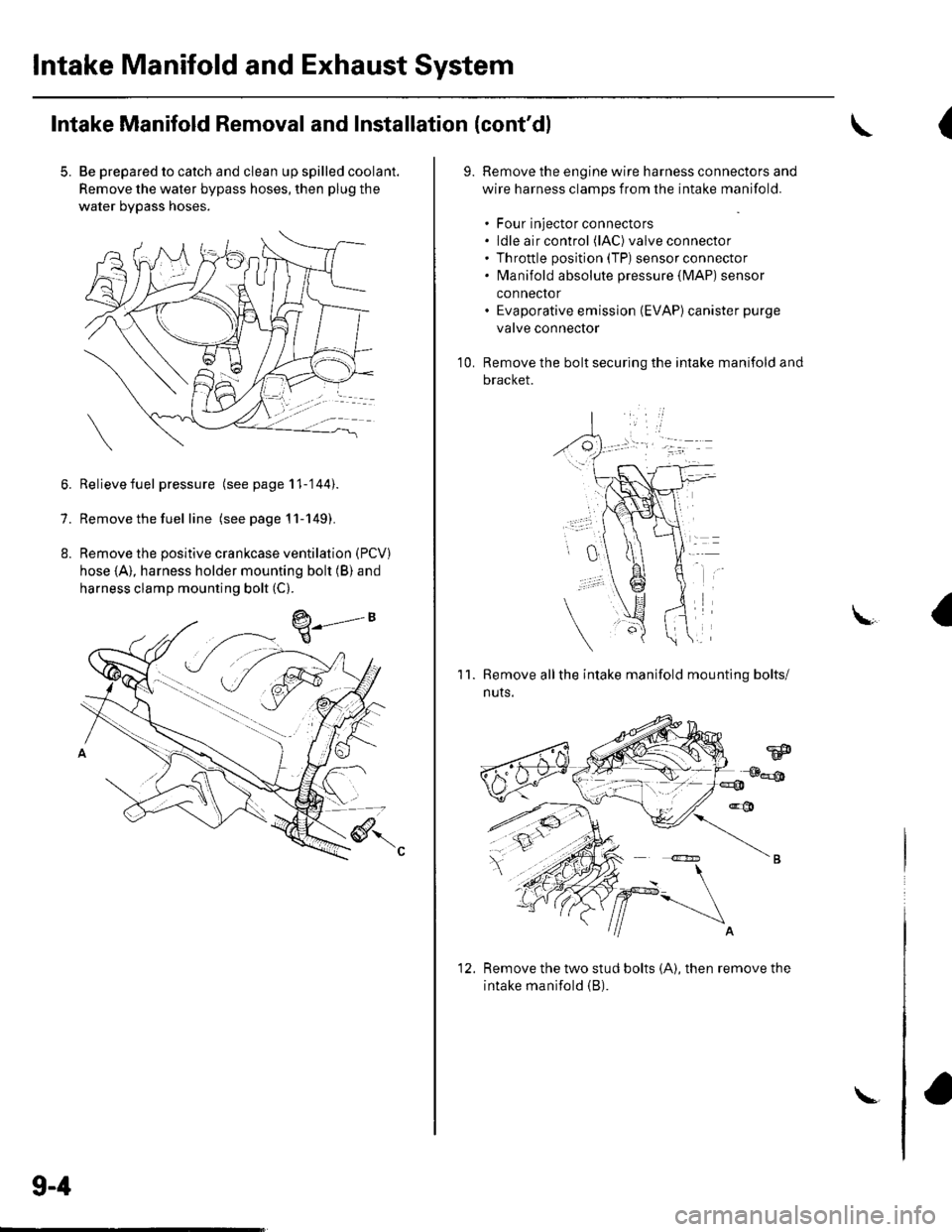

5. Be prepared to catch and clean up spilled coolant.

Remove the water bypass hoses, then plug the

water bypass hoses.

6. Relievefuel pressure (see page 11-'144).

7. Remove the fuel line (seepagell-149).

8. Remove the positive crankcase ventilation (PCV)

hose (A), harness holder mounting bolt (B) and

harness clamp mounting bolt (C).

9-4

\-

(

9.Remove the engine wire harness connectors and

wire harness clamps from the intake manifold.

. Four injector connectors. ldle air control (lAC) valve connector. Throttle position (TP) sensor connector. fvlanifold absolute pressure {lvlAP) sensor

connector. Evaporative emission (EVAP)canister purge

valve connector

Remove the bolt securing the intake manifold and

bracket.

'1 0.

11.Remove allthe intake manifold mounting bolts/

nuts.

Remove the two stud bolts (A), then remove the

intake manifold (B).

1'>

Page 188 of 1139

lntake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'd)

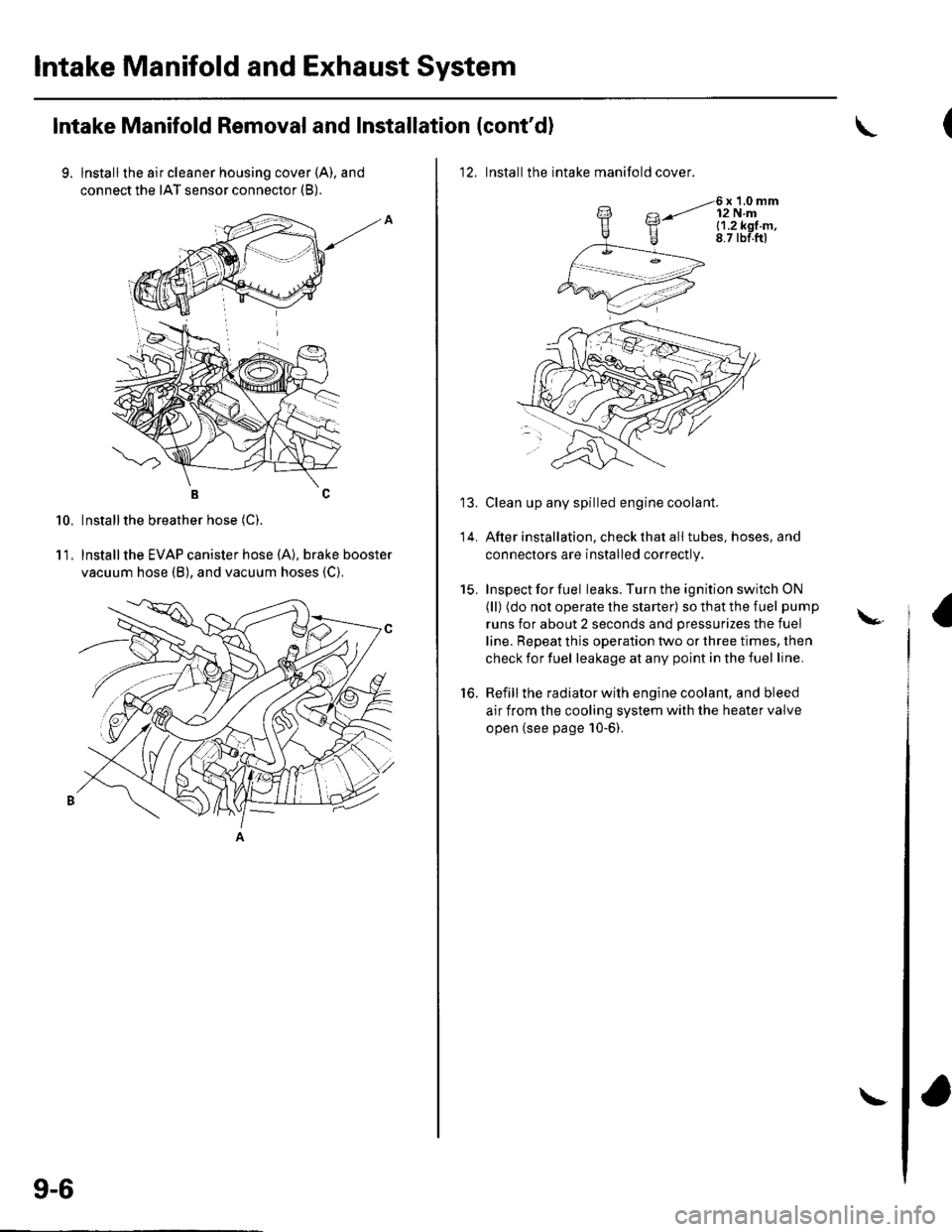

9. lnstallthe air cleaner housing cover (A), and

connect the IAT sensor connector (B).

BC

Installthe breather hose (C).

lnstallthe EVAP canister hose (A), brake booster

vacuum hose (B), and vacuum hoses {C).

10.

11.

9-6

\

12. Installthe intake manifold cover.

6x1.0mm12 N.ml.1.2k91.m,8.7 tbf.ftl

Clean up any spilled engine coolant.

After installation, check that all tubes, hoses, and

connectors are installed correctly.

Inspect for fuel leaks. Turn the ignition switch ON

(ll) (do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

to.

\-

Page 195 of 1139

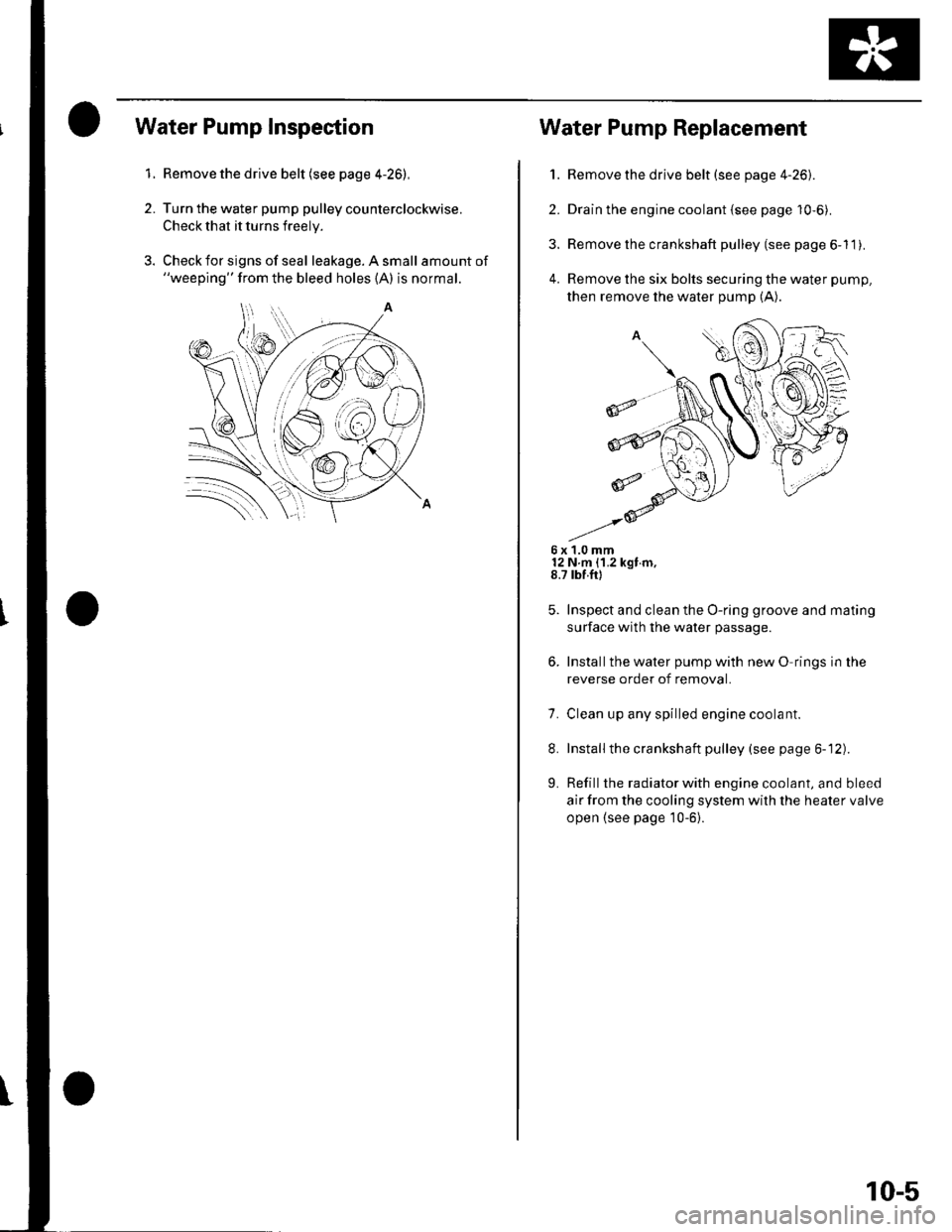

1.

2.

Water Pump Inspection

Remove the drive belt (see page 4-26),

Turn the water pump pulley counterclockwise.

Check that it turns freely.

Check for signs of seal leakage. A small amount of"weeping" from the bleed holes (A) is normal.

Water Pump Replacement

1. Remove the drive belt (see page 4-26).

2. Drain the engine coolant {see page 10-6).

3. Remove the crankshaft pulley (see page 6-11).

4. Remove the six bolts securing the water pump,

then remove the water pump (A).

6x1.0mm12 N m {1.2 kgt m,8.7 rbf.ft)

Inspect and clean the O-ring groove and mating

surface with the water passage.

Installthe water pump with new O rings in the

reverse order of removal.

7. Clean up any spilled engine coolant.

8. Installthe crankshaft pulley (see page 6-12).

L Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open {see page 10-6}.

10-5

Page 200 of 1139

Cooling System

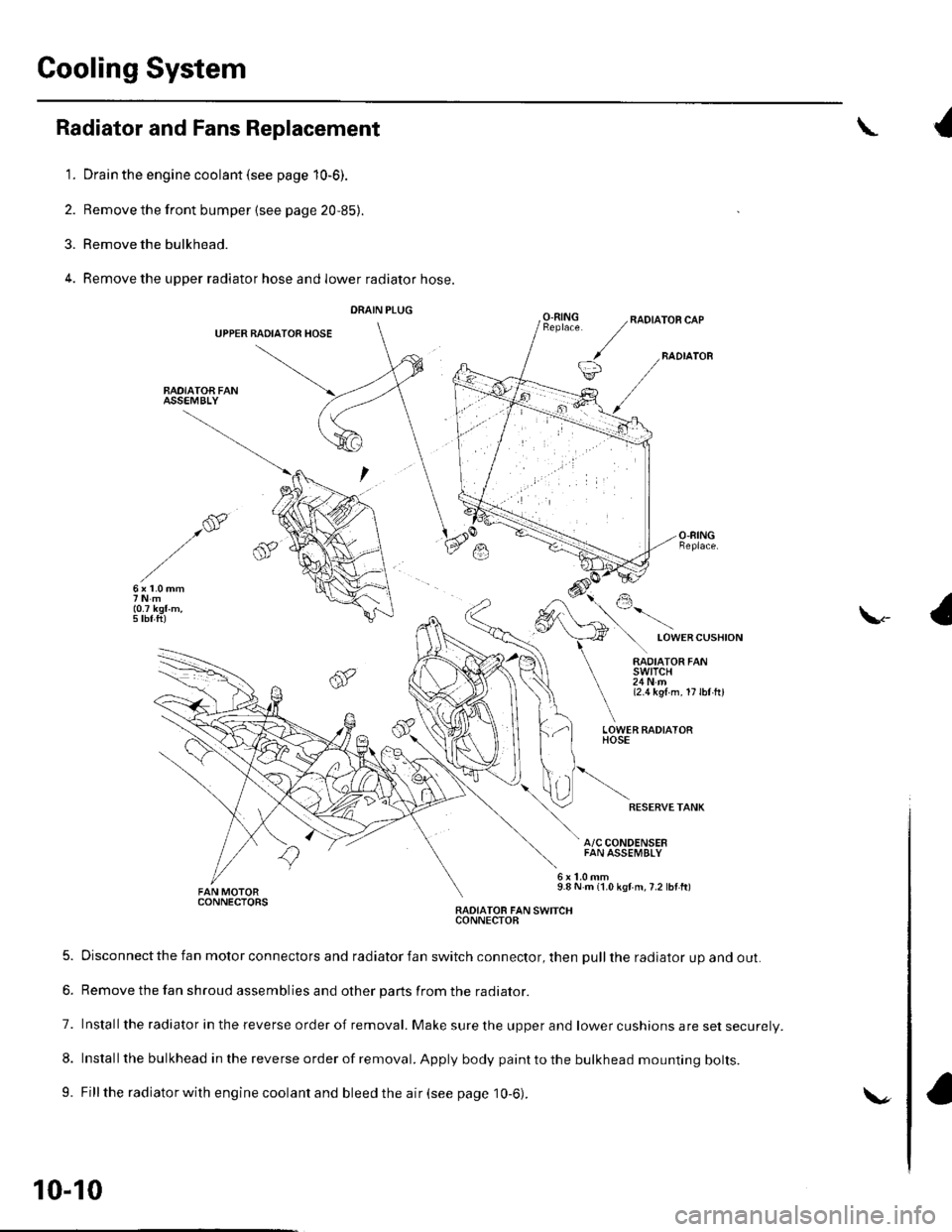

Radiator and Fans Replacement

1. Drain the engine coolant (see page 10-6).

2. Remove the front bumper {see page 20,85).

3. Remove the bulkhead.

4. Remove the upper radiator hose and lower radiator hose.

DRAIN PLUG

UPPER BADIATOR HOSE

BAOIATOA FANASSEMBLY

{

O.RINGRADIATOR CAP

BADIATOB

LOWERCUSHION

\-

RADIATOR FANswtTcH24Nm{2.1t kgl m. 17lbl hl

LOWER FADIATORHOSE

RESERVETANK

A/C CONDENSERFAN ASSEMBLY

9.8 N m {1.0 kgf m,7.2 lbf ft)CONNECTORSRADIATOB FAN SWITCHCONNECTOB

5. Disconnect the fan motor connectors and radiator fan switch connector, then pull the radiator up and out.

6. Remove the fan shroud assemblies and other parts from the radiator.

7. Installthe radiator in the reverse order of removal. Make sure the upper and lower cushions are set securelV.

8. Install the bulkhead in the reverse order of removal. Apply body paint to the bulkhead mounting bolts.

9. Fill the radiator with engine coolant and bleed the air (see page 10-6).

10-10

\.

Page 211 of 1139

Fuel and Emissions Systems

General Troubleshooting Information (cont'dl

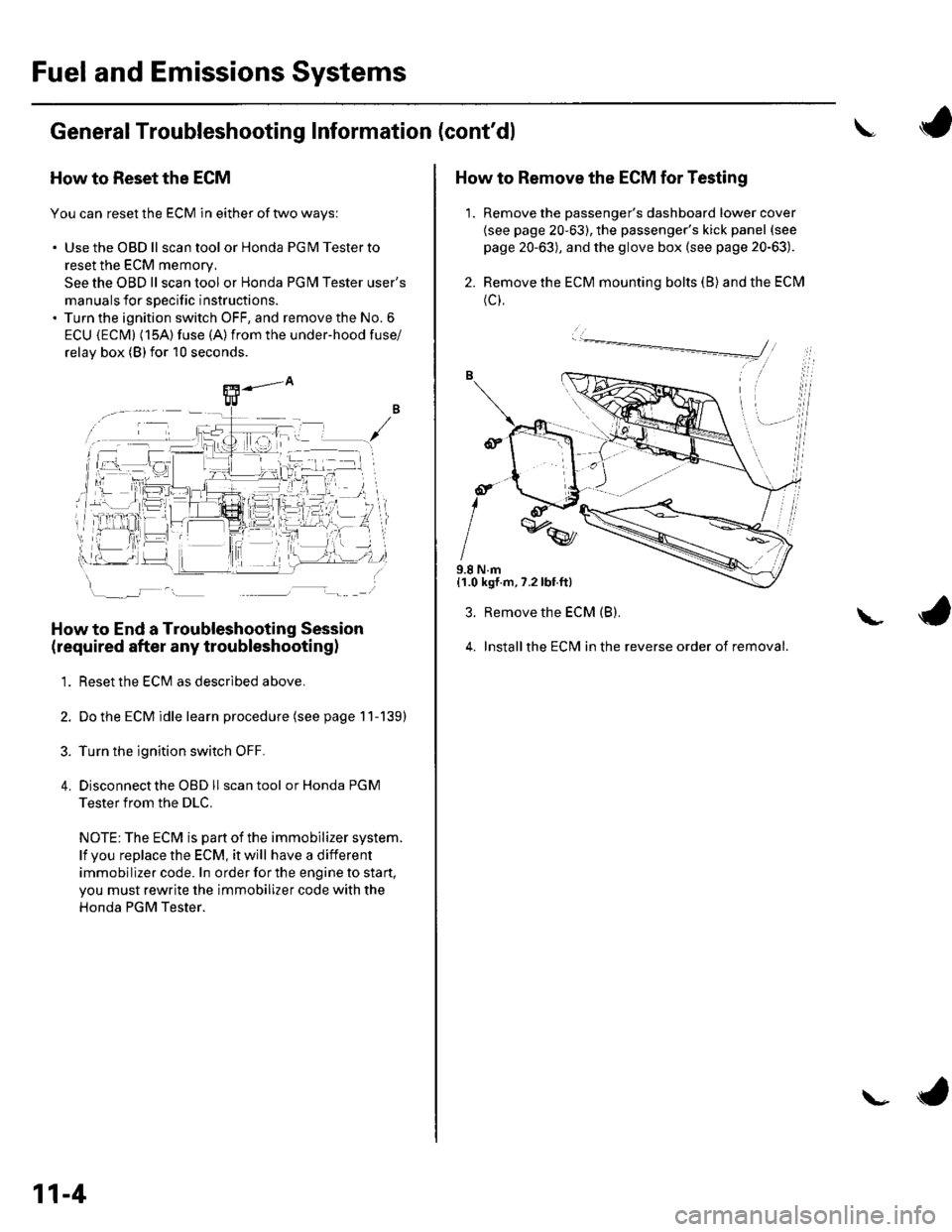

How to Reset the ECM

You can reset the ECM in either of two ways:

. Use the OBD ll scantool or Honda PGMTesterto

reset the ECM memory.

See the OBD ll scan tool or Honda PGI\4 Tester user's

manuals for specific instructions.' Turn the ignition switch OFF, and remove the No. 6

ECU {ECM} (15A) fuse (A)from the under-hood fuse/

relav box (Blfor 10 seconds.

How to End a Troubleshooting Session

(required after any troubleshootingl

1. Reset the ECM as described above.

2. Do the ECM idle learn procedure (see page 11-139)

3. Turn the ignition switch OFF.

4. Disconnectthe OBD ll scan tool or Honda PGM

Tester from the DLC.

NOTE: The ECM is part of the immobilizer system.

lf vou replace the ECM, it will have a different

immobilizer code. In order for the engine to start,

you must rewrite the immobilizer code with the

Honda PGM Tester.

11-4

\- ta

J

How to Remove the ECM for Testing

1. Remove the passenger's dashboard lower cover

{see page 20-63), the passenger's kick panel (see

page 20-63), and the glove box (see page 20-63).

2. Remove the ECM mounting bolts (B) and the ECM

(c),

9.8 N.m{1.0 kgf.m,7.2lbt.ft}

3. Remove the ECM (B).

4. Installthe ECM in the reverse order of removal.

L

Page 334 of 1139

WC OilControl Solenoid Valve Removal/Test

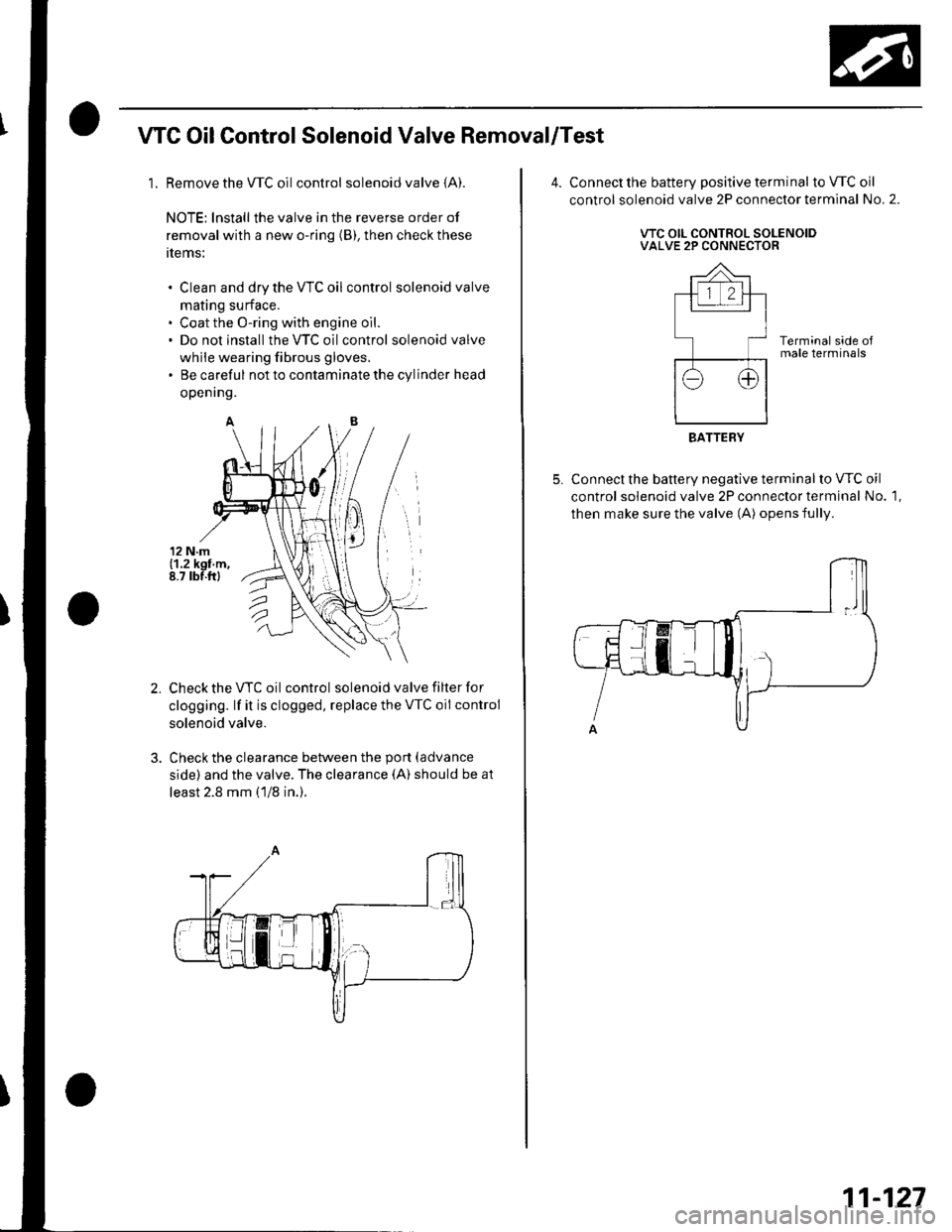

1. Remove the WC oilcontrol solenoid valve (A).

NOTE: lnstall the valve in the reverse order of

removal with a new o-ring (B), then check these

tlems:

Clean and dry the VTC oil control solenoid valve

mating surface.

Coat the O-ring with engine oil.

Do not install the VTC oilcontrol solenoid valve

while wearing fibrous gloves,

Be careful not to contaminate the cylinder head

openrng.

Check the VTC oil control solenoid valve filter for

clogging. lf it is clogged, replace the VTC oil control

solenoid valve.

Check the clearance between the port (advance

side) and the valve. The clearance (A) should be at

least 2.8 mm (1/8 in.).

Connect the battery positive terminal to VTC oil

control solenoid valve 2P connector terminal No. 2.

VTC OIL CONTROL SOLENOIDVALVE 2P CONNECTOR

Terminal side oJmale terminals

Connect the battery negative terminal to VTC oil

control solenoid valve 2P connector terminal No. 1,

then make sure the valve (A) opens fully.

BATTERY

11-127