heater HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 254 of 1139

Evaporative Emissions (EVAP) Control

System Monitor and Readiness code

NOTE:

All readiness code are cleared when the batterV is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

The enable criteria must be repeated if the intake air

temperature (lAT) drops lower than 36'F (20"C) from

its value at engine $an up.

Enable Criteria

At engine start up, ECT and IAT are higher than 32'F(0"C) , but lower than 95'F (35"C).

At engine start up, the ECT and IAT are within 12'F(7'C) of each other.

Procedure

1. Connect the scan tool to the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. After about

2.5 miles (1.6 km), the readiness code should

switch f rom incomplete to complete.

4. lf the readinesscode isstill setto incomplete, check

for a temporary DTC. lf there is no DTC, one or

more of the enable criteria were probably not met;

repeat the procedure.

Air Fuel Ratio (A/Fl Sensor Monitor and

Readiness Code

NOTE:. Do not turn the ignition switch off during the

orocedure.. All readiness codes are cleared when the baftery is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

Enable Criteria

ECT at 140'F (60"C) or higher.

Procedure

1. Connect the scan toolto the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. During the

drive, decelerate (wirh the throttle fully closed) for

5 seconds. After about 3.5 miles (2.2 km). the

readiness code should switch from incomDlete to

complete.

4. lfthereadinesscodeisstill set to incomplete, check

for a temporary DTC. lfthere is no DTC, the enable

criteria was probably not meU repeat the procedure.

Air/Fuel Ratio (A/Fl Sensor Heater Monitor

Readiness Code

NOTE; All readiness codes are cleared when the battery

is disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester,

Procedure'1. Connect the scan tool to the vehicle's data link

connector {DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine, and let it idle for 1 minute. The

readiness code should switch from incomplete to

comDlete.

3. lf the readiness code is still set to incomplete, check

for a temporary DTC. lf there is no DTC, repeat theproceoure.

(cont'd)

11-47

Page 275 of 1139

PGM-FISystem

3.

DTC Troubleshooting (cont'dl

DTC P0141: Secondary HO2S (Sensor 2l

Heater Circuit Malfunction

1. Reset the ECM (see page 1 l-4)

2. Start the engine.

ls DTC P0141 indicated?

YES-Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

Turn the ignition switch OFF.

Disconnect the secondary H02S (Sensor 2) 4P

connecror.

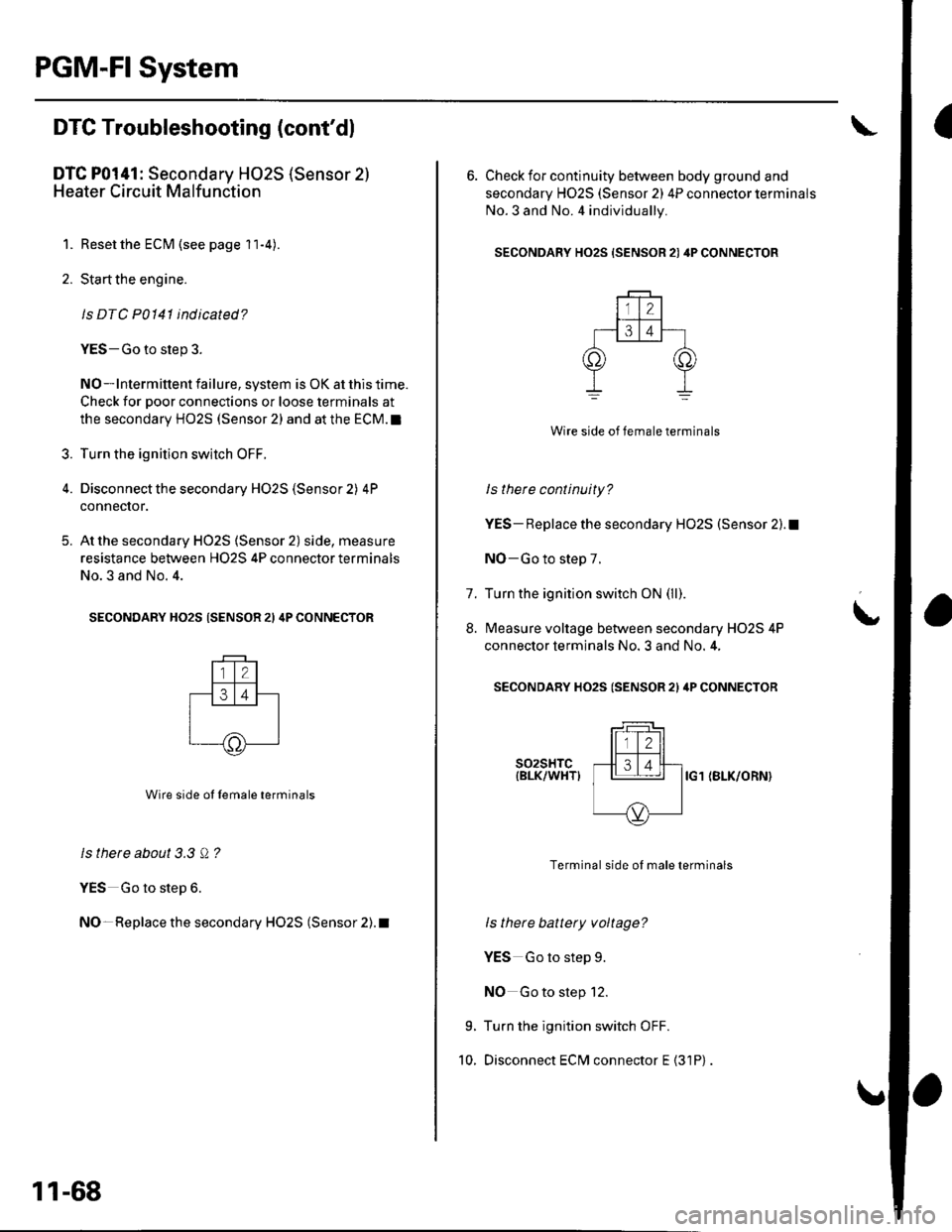

At the secondary HO2S (Sensor 2) side, measure

resistance between H02S 4P connector terminals

No.3 and No. 4.

SECONDARY HO2S (SENSOR 21 4P CONNECTOR

Wire side ol lemale terminals

ls there about 3.3 Q ?

YES Go to step 6.

NO- Replace the secondary HO2S (Sensor 2). t

5.

11-68

6. Check for continuity between body ground and

secondary H02S (Sensor 2) 4P connector terminals

No.3 and No. 4 individually.

SECONDARY HO2S {SENSOR 21 4P CONNECTOR

Wire side of female terminals

ls there continuity?

YES- Replace the secondary HO2S (Sensor 2).1

NO-Go to step 7.

Turn the ignition switch ON (ll).

Measure voltage between secondary H02S 4P

connector terminals No. 3 and No. 4,

SECONDARY HO2S (SENSOR 2l ilP CONNECTOR

t

7.

8.

9.

10.

s02sHTc{BLK/WHTIIG1 (BLK/ORN}

Terminal side of male terminals

ls there battery voltage?

YES Go to step 9.

NO Go to step 12.

Turn the ignition switch OFF.

Disconnect ECM connector E {31P)

Page 277 of 1139

PGM-FI System

DTC Troubleshooting (cont'dl

DTC P0171: Fuel System Too Lean

DTC P0172: Fuel System Too Rich

NOTE: lf some of the DTCS listed below are stored at

the same time as DfC PO17'l and/ot PO172,

troubleshoot those DTCS first, then recheck for P0171

andlot P0112.

P0107, P0108. P1 128. P1 129: Manifold absolute

pressure (MAP) sensor

P1 162. P1 166, P 1 167: 4,,/F sensor (Sensor 1 ) heater

P0137, P0138: Secondary HO2S (Sensor 2)

P014'l: Secondary HO2S (Sensor 2) heater

P1259: VTEC system

1. Check the fuel pressure (see page 11-'145).

ls luel pressure OK?

YES Go to step 2.

NO Check these items:

. lf the pressure is too high, replace the fuel

pressure regulator (see page 11-152).1. lf the pressure istoo low.checkthefuel pump,

the fuel feed pipe, the fuel filter, and replace the

fuel pressure regulator (see page 11-152).I

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

11-70

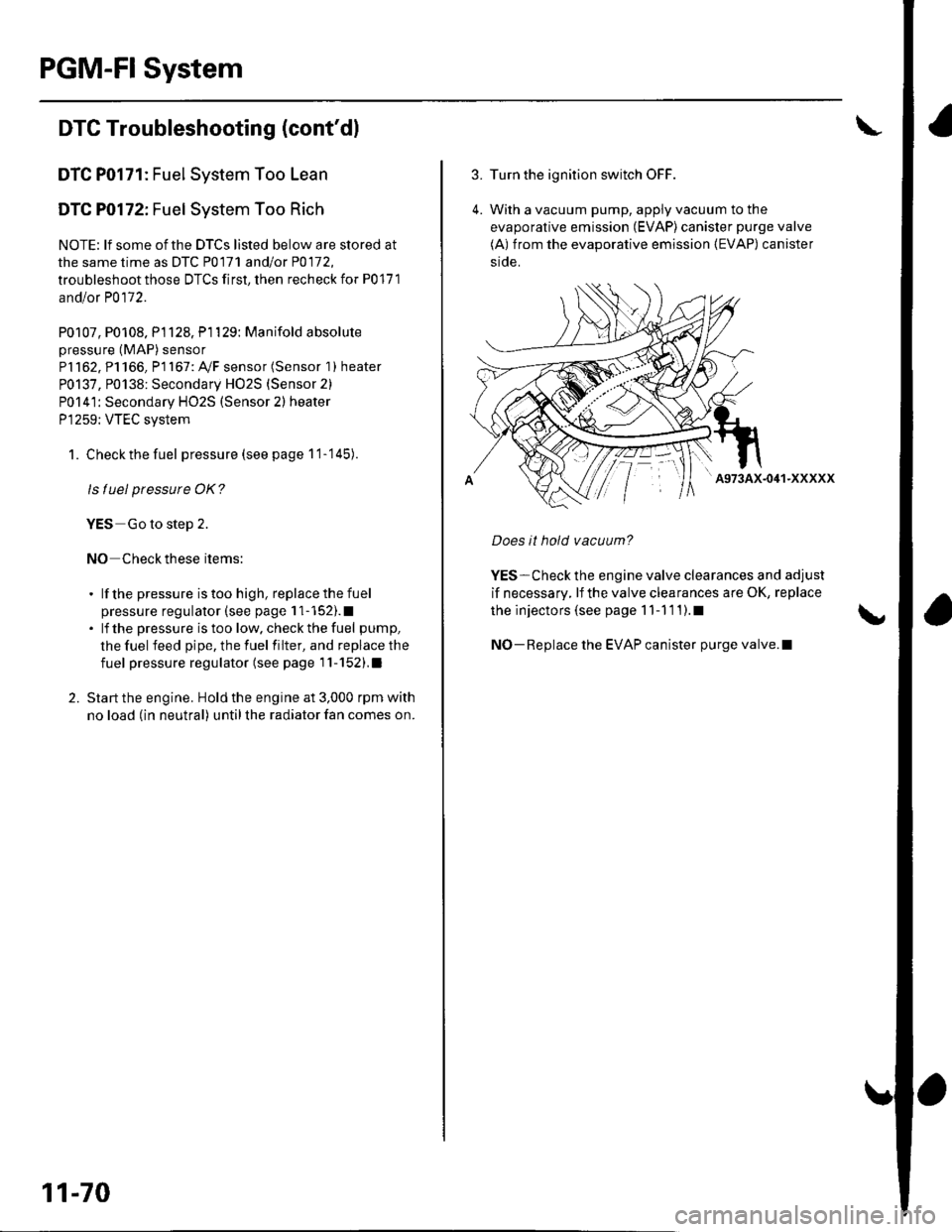

3. Turn the ignition switch OFF.

4. With a vacuum pump, apply vacuum to the

evaporative emission (EVAP) canister purge valve

(A) from the evaporative emission (EVAP) canister

side.

' A973AX-041-XXXXX

Does it hold vacuum?

YES-Check the engine valve clearances and adjust

if necessary, lf the valve clearances are OK, replace

the injectors (see page 1 1-1 1 1).1

NO-Replace the EVAP canister purge valve.l

Page 296 of 1139

DTC Pl166: Ay'F Sensor (Sensor 1) Heater

Circuit Malfunction

1. Resetthe ECM (see page 11-4).

2. Start the engine.

ls DTC P1166 indicated?

YES-Go to step 3.

NO-lntermittent failure, system is OK at this lime.

Check for poor connections or loose terminals at

the Ay'F sensor relay, the A,/F sensor (Sensor 1), and

the EcM. !

3. Check the following fuse:

. No. 14 OPTION (30A)fuse in under-hood fuse/

reray Dox.. No. 2*B LAF (Ay'F) HEATER (20A) fuse in under-

dash fuse/relay box.. No. 4 ACG (10A) in underdash fuse/relay box.

Are any of the fuses blown?

YES Repair short in the wire between the Ay'F

sensor relay and the fuses.I

NO Go to step 4.

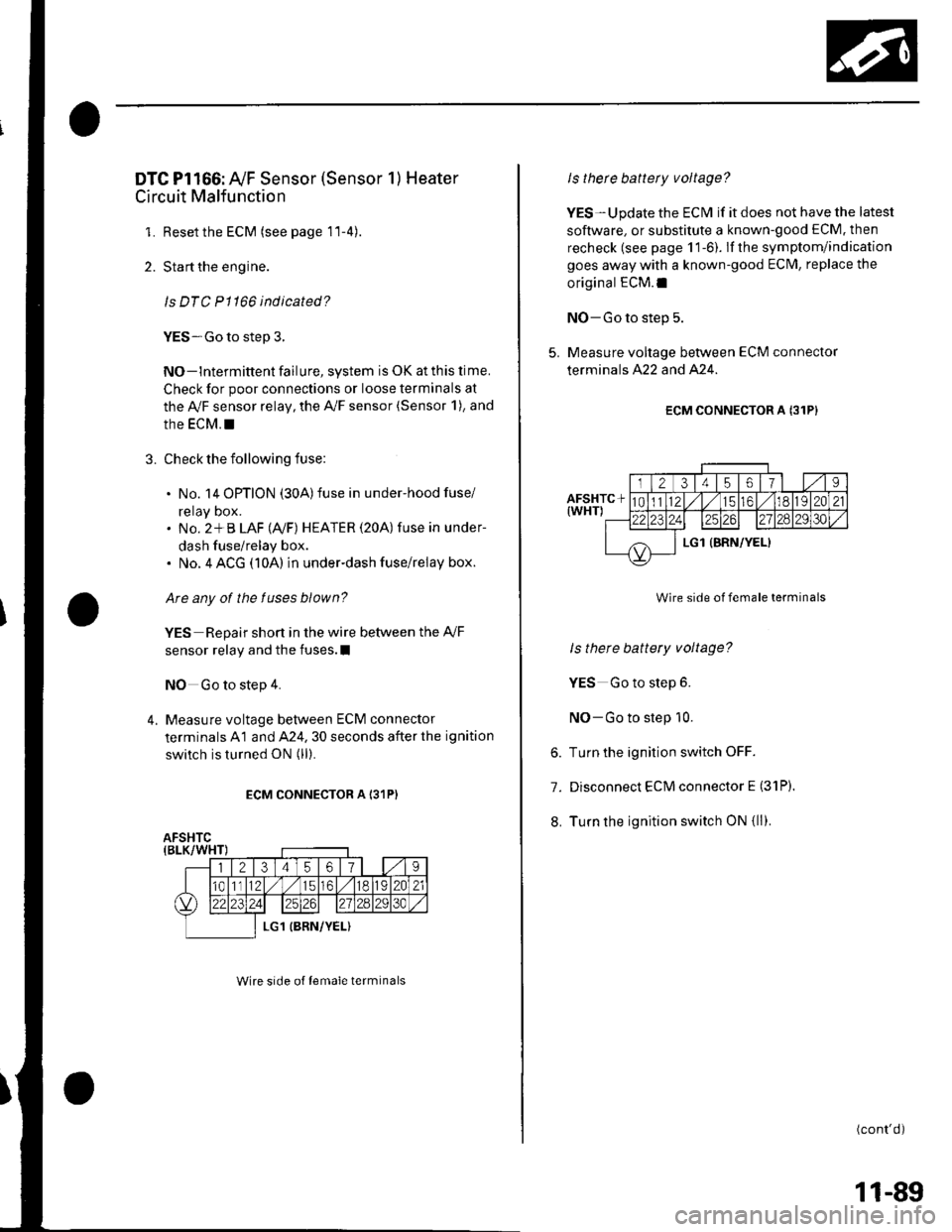

4. Measure voltage between ECM connector

terminals A1 and A24. 30 seconds after the ignition

switch is turned ON (ll).

ECM CONNECTOR A I31P)

Wire srde of lemale terminals

Is therc battery voltage?

YES-Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM. then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO-Go to step 5.

5. Measure voltage between ECM connector

terminals A22 and A24.

ECM CONNECTOR A {31P}

Wire side of female terminals

ls there battery voltage?

YES Go to step 6.

NO-Go to step 10.

6. Turn the ignition switch OFF.

7. Disconnect ECM connector E (31P).

8. Turn the ignition switch ON {ll).

(cont'd)

11-89

Page 298 of 1139

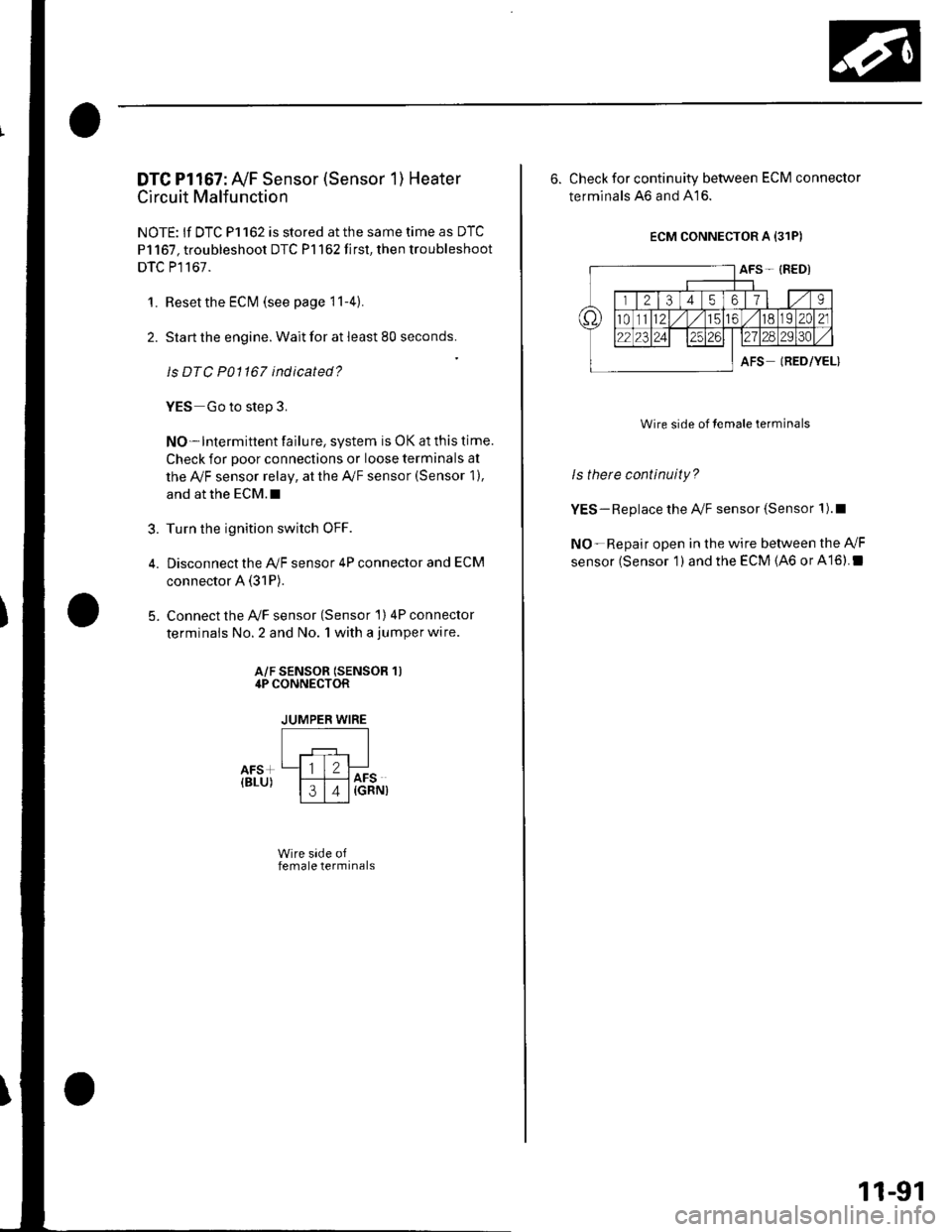

DTC Pl167: Ay'F Sensor (Sensor 1) Heater

Circuit Malfunction

NOTE: lf DTC P1162 is stored at the same time as DTC

P1167, troubleshoot DTC P1162 first, then troubleshoot

DTC P1167.

1. Resetthe ECI\4 (see page 11-4)

2. Start the engine. Wait for at least 80 seconds.

ls DTC P01167 ind icated?

YES Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the Ay'F sensor relay, at the Ay'F sensor (Sensor 1),

and at the ECM.I

Turn the ignition switch OFF.

Disconnect the A,/F sensor 4P connector and ECM

connector A (31P).

Connect the Ay'F sensor (Sensor 1) 4P connector

terminals No. 2 and No. 1 with a jumper wire.

?

5.

A/F SENSOR (SENSOR 1)4P CONNECTOR

JUMPER WIRE

Wire side offemale terminals

6. Check for continuity between ECM connector

terminals ,46 and 416.

ECM CONNECTOR A {31P)

AFS- {RED)

trTzTil,ils llt9

t82C21

l?rlzsIels

AFSIRED/YEL)

Wire side of lemale terminals

ls thete continuity?

YES-Replace the A/F sensor (Sensor 1).1

NO-Repair open in the wire between the Ay'F

sensor (Sensor 1 ) and the ECM (46 or A16).I

11-91

Page 345 of 1139

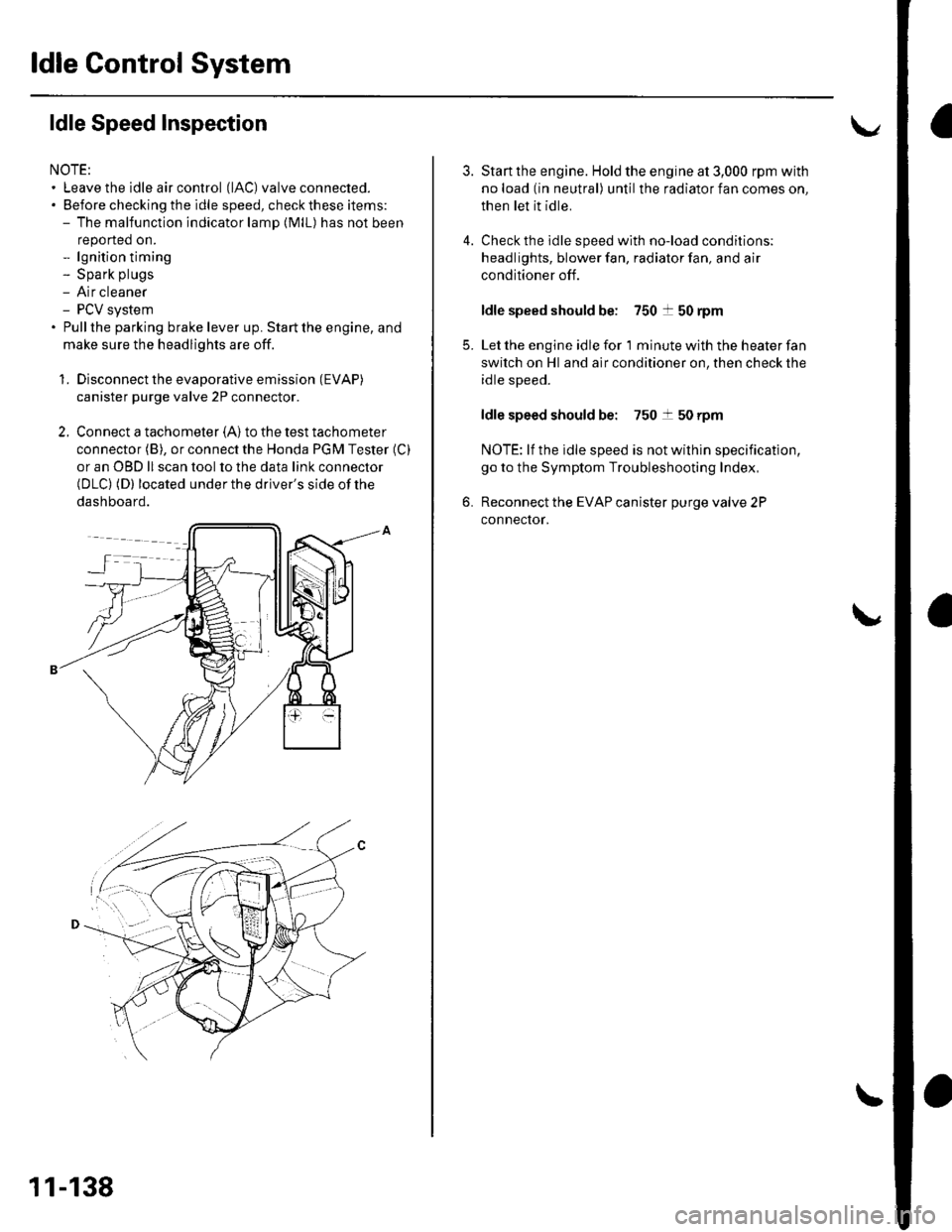

ldle Control System

ldle Speed lnspection

NOTE:' Leave the idle air control (lAC) valve connecled.. Before checking the idle speed, check these items:- The malfunction indicator lamp (MlL) has not been

reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system. Pullthe parking brake lever up. Start the engine, and

make sure the headlights are off.

1. Disconnect the evaporative emission (EVAP)

canister purge valve 2P connector.

2. Connect a tachometer (A)to the test tachometer

connector (B), or connect the Honda PGM Tester (C)

or an OBD ll scan tool to the data link connector(DLC) (D) located under the driver's side of the

dashboard.

11-138

4.

3.

5.

6.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

Check the idle speed with no-load conditions;

headlights, blower fan, radiator fan, and air

conditioner off.

ldle speed should be: 750 t 50 rpm

Let the engine idle for 1 minute with the heater fan

switch on Hl and air conditioner on, then check the

idle speed.

ldle speed should be: 750 t 50 rpm

NOTE: lf the idle speed is not wilhin specification,

go to the Symptom Troubleshooting Index,

Reconnect the EVAP canister purge valve 2P

connector.

Page 374 of 1139

Catalytic Converter System

DTC Troubleshooting

DTC P0420: Catalytic System Efficiency

Below Threshold

NOTE: lf some of the DTCS listed below are stored at

the same time as DTC P0420, troubleshoot those DTCS

first, then recheck for DTC P0420.

P0137, P0138: Secondary Heated Oxygen Sensor(secondary HO2S) (Sensor 2)

P0141: Secondary HO2S (Sensor 2) heater

1. Reset the ECM {see page 1'l-4}, then continue to

step 2 through 5 to reset the readiness code.

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) untilthe radiator fan comes on.

Drive for about l0 minutes without stopping. Your

speeo can vary.

With the transmission in 4th gear, drive at a steady

speed between 50 62 mph (80-'100 km/h) for

30 seconds.

Repeat step 4 three times. Between each repetition,

close the throttle completely for 1 2 seconds. lf

the engine is stopped during this part of the

procedure, repeat steps 3, 4 and 5.

Check for a Temporary DTC with the scan tool.

Does the scan tool indicate Temporaty DTC

P0420?

YES Check the TWC. lf necessary, replace the

TWC.I

NO Check for readiness code completion. lfthe

readiness is complete, it was a interminent failure,

and the system is OK at this time. lf the readiness

code is incomplete, repeat steps 2 through 5.1

4.

11-167

Page 543 of 1139

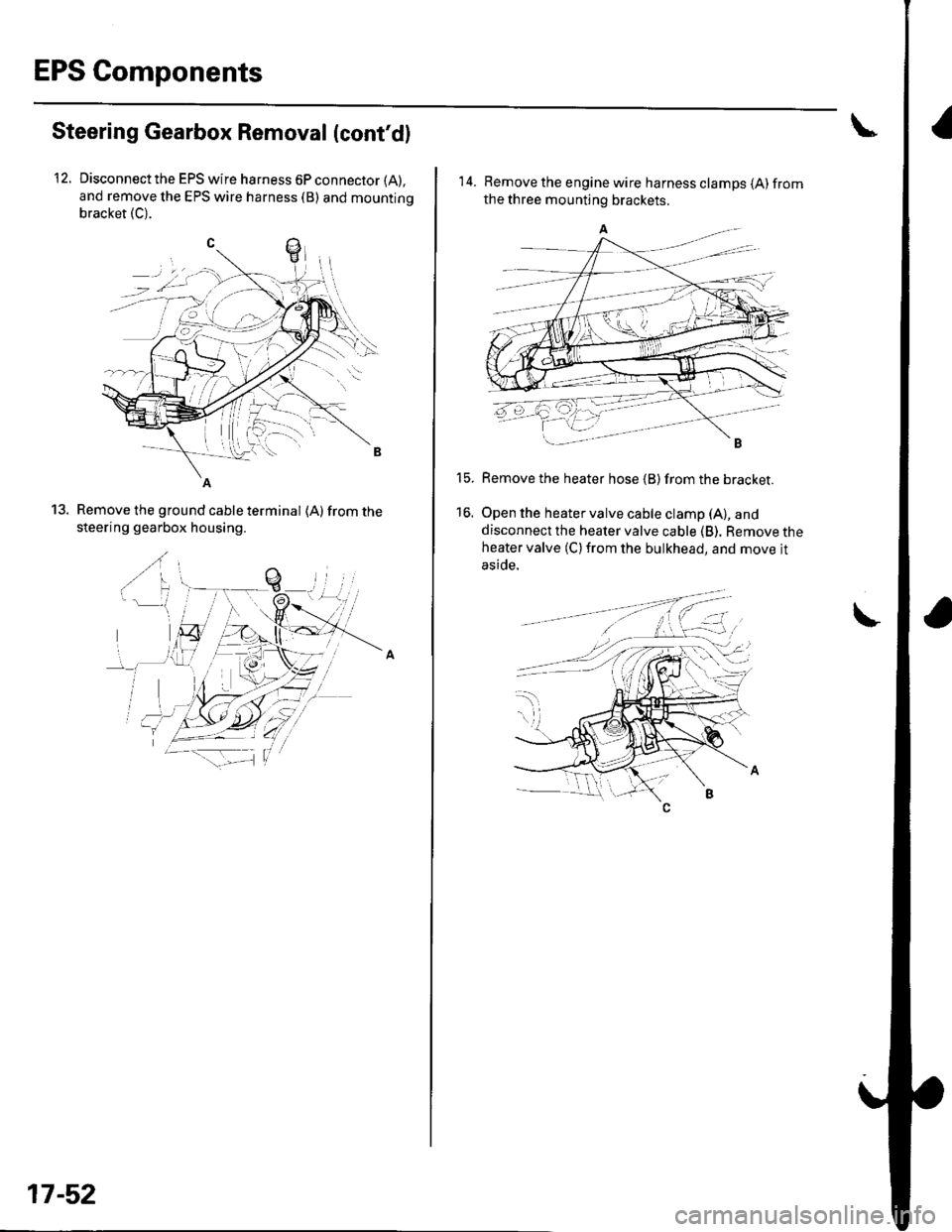

EPS Components

Steering Gearbox Removal (cont'd)

Disconnect the EPS wire harness 6P connector (A),

and remove the EPS wire harness (B) and mountino

bracket (C).

12.

Remove the ground cable terminal (A) from the

steering gearbox housing.

..(

.,/ a

b-H\

ry T,-.lt'^ \

'" \--

13.

_-1..1.-'

-a--zii F--_1

17-52

14. Remove the engine wire harness clamps {A)fromthe three mounting brackets.

Remove the heater hose {B) from the bracket.

Open the heater valve cable clamp (A), and

disconnect the heater valve cable (B). Remove theheater valve (C) from the bulkhead, and move jt

aside.

t5.

16.

I

Page 555 of 1139

EPS Components

Steering Gearbox Installation (cont'd)

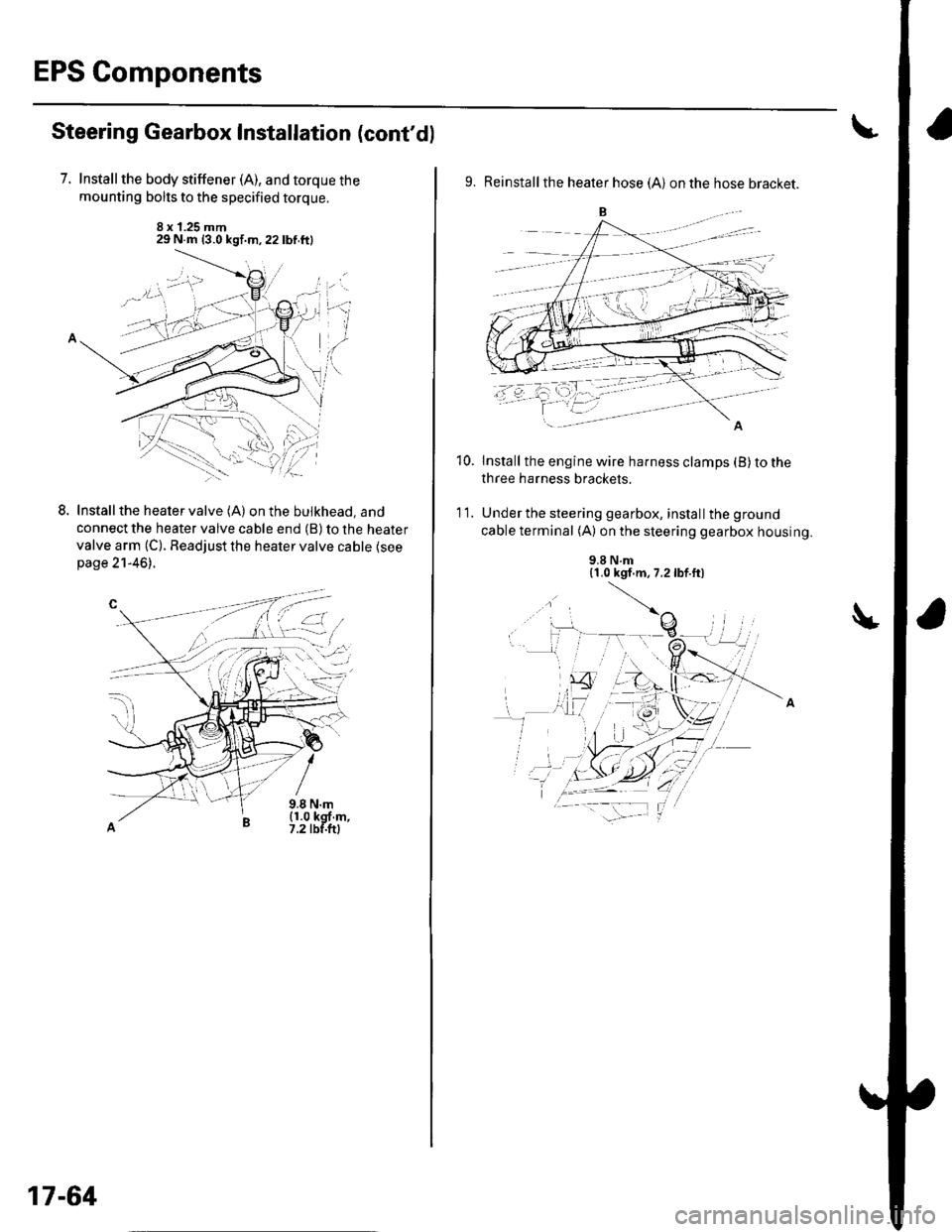

7. Installthe body stiffener (A), and torque the

mounting bolts to the specified torque.

8 x 1.25 mm29 N.m {3.0 kgf.m,22lbf.ftl

LInstall the heater valve (A) on the bulkhead, and

connect the heater valve cable end (B) to the heater

valve arm (C). Readjust the heater valve cable {seepage 21-46).

9.8 N.m(1.0 kgf m,7.2 tbf.ftl

L-t ,:.i.t'

17-64

9. Reinstall the heater hose (A) on the hose bracket.

Install the engine wire harness clamps (B) to the

three harness brackets.

Under the steering gearbox, install the ground

cable terminal (A) on the steering gearbox housing.

10.

'I t.

9.8 N.m{1.0 kgf.m, 7.2lbf.ft)

Page 669 of 1139

Power Mirror Replacement

1.

2.

5.

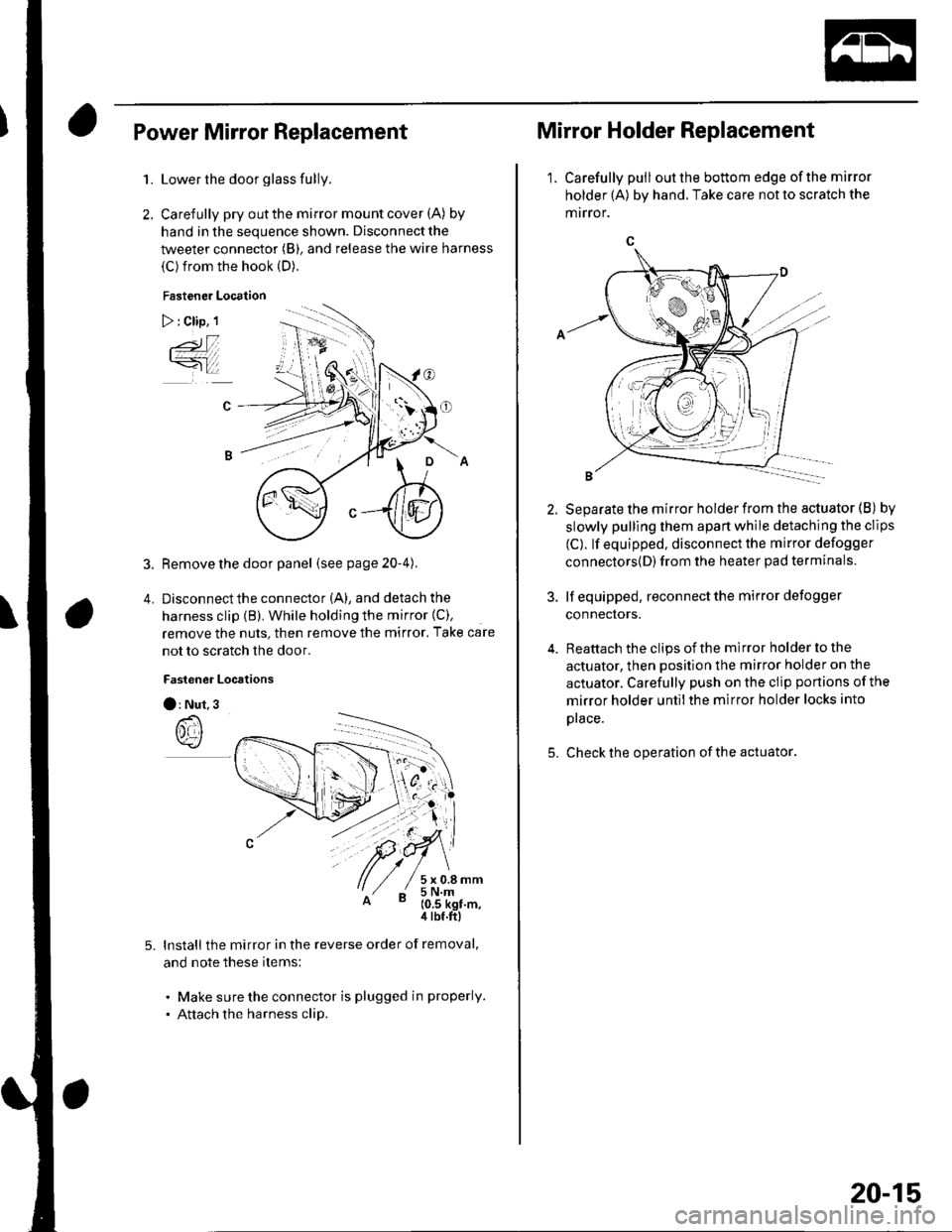

Lower the door glass fully.

Carefully pry out the mirror mount cover (A) by

hand in the sequence shown. Disconnect the

tweeter connector (B), and release the wire harness

(C) from the hook (D).

Fastener Location

) : Clip, 1

3. Remove the door panel (seepage20-4).

4. Disconnectthe connector (A), and detach the

harness clip (B). While holding the mirror {C),

remove the nuts, then remove the mirror. Take care

not to scratch the door.

Fastener Locrtions

O: Nut.3

lnstall the mirror in the reverse order of removal,

and note these items:

. Make sure the connector is plugged in properly.

. Attach the harness clip.

Mirror Holder Replacement

1. Carefully pulloutthe bottom edge ofthe mirror

holder (A) by hand. Take care not to scratch the

mrrror.

5.

Separate the mirror holder from the actuator (B) by

slowly pulling them apart while detaching the clips

(C). lf equipped, disconnect the mirror defogger

connectors{D) from the heater pad terminals.

lf equipped, reconnect the mirror defogger

connectors.

Reattach the clips of the mirror holder to the

actuator, then position the mirror holder on the

actuator. Carefully push on the clip portions of the

mirror holder untilthe mirror holder locks into

prace.

Check the operation of the actuator

20-15