heater HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 804 of 1139

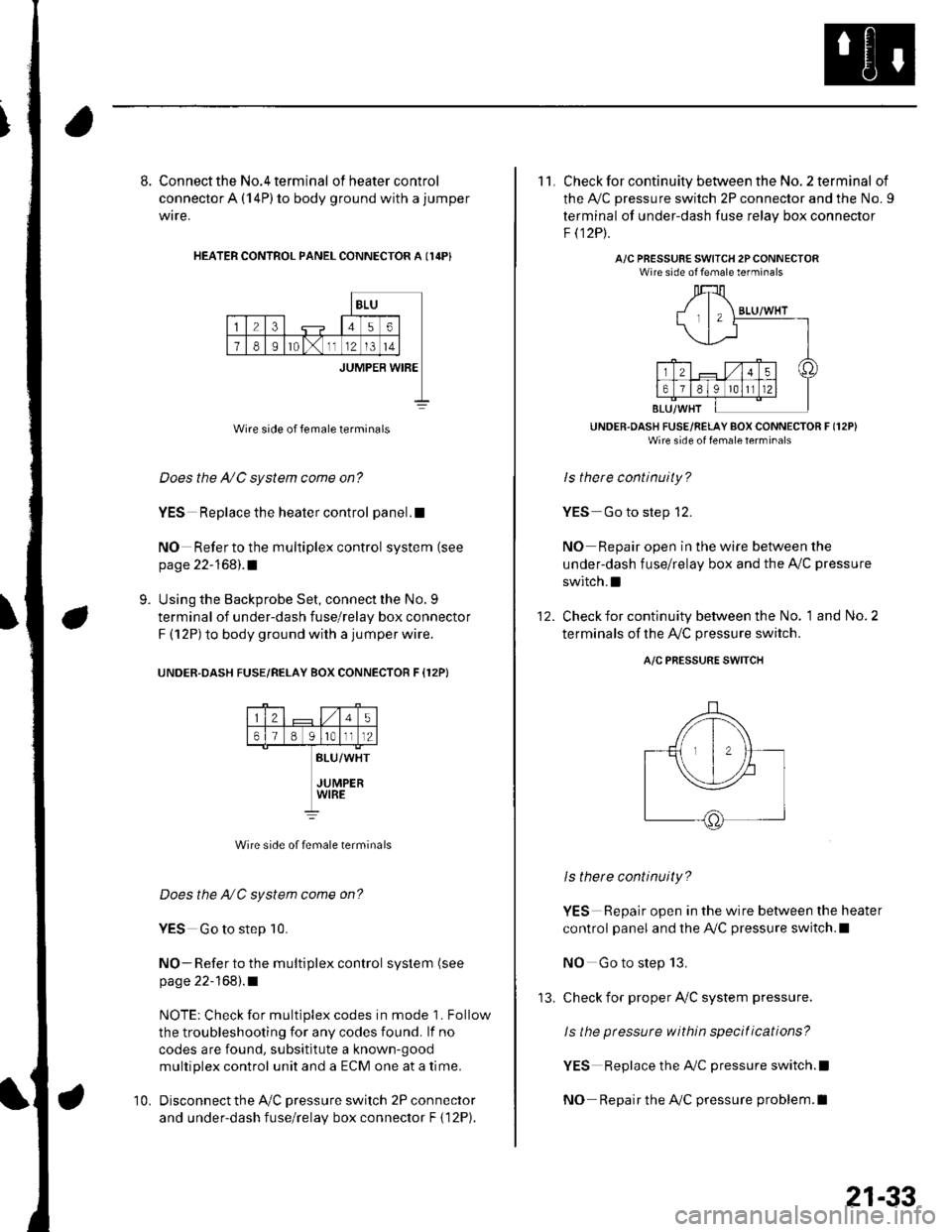

8. Connect the No.4 terminal ofheatercontrol

connector A (14P) to body ground with a jumper

wire,

HEATER CONTROL PANEL CONNECTOR A I14P}

BLU

23456

78Ir0lx1112l3t4

JUMPER WIBE

Wire side of female terminals

Does the A/C system come on?

YES Replace the heater control panel.!

NO Refer to the multiplex control system (see

page 22-168).1

Using the Backprobe Set, connect the No. 9

terminal of under-dash fuse/relay box connector

F (12P) to body ground with a jumper wire.

UNOER.DASH FUSE/RELAY BOX CONNECTOR F {12P}

9.

25

61B g lrotll2

BLU/WHT

JUMPERWIRE

Wire side of female terminals

Does the NC system come on?

YES Go to step 10.

NO- Refer to the multiplex control system (see

page 22-168).1

NOTE: Check for multiplex codes in mode '1. Follow

the troubleshooting {or any codes found. lf no

codes are found, subsititute a known-9ood

multiplex control unit and a ECM one at a time.

Disconnect the Ay'C pressure switch 2P connector

and under-dash fuse/relay box connector F { 12P).

10.

'13.

21-33

11. Check for continuity between the No. 2 terminal of

the A,/C pressure switch 2P connector and the No. 9

terminal of under-dash fuse relav box connector

F t12Pt.

A/C PRESSURE SWITCH 2PCONNECTORWire side of female terminals

UNDER.OASH FUSE/RELAY BOX CONNECTOR F (12P)

Wire side of fenale lerrrinal'

ls there continuity?

YES Go to step 12.

NO Repair open in the wire between the

under-dash fuse/relay box and the A,,/C pressure

switch.I

Check for continuity between the No. 1 and No. 2

terminals of the A,/C pressure switch.

12.

A/C PRESSURE SWITCH

ls there continuity?

YES Repair open in the wire between the heater

control panel and the A,/C pressure switch.l

NO Go to step 13.

check for proper Ay'C system pressure.

ls the pressure within specitications?

YES Replace the AilC pressure switch.l

NO Repair the AilC pressure problem.I

Page 805 of 1139

Heating and Air Conditioning

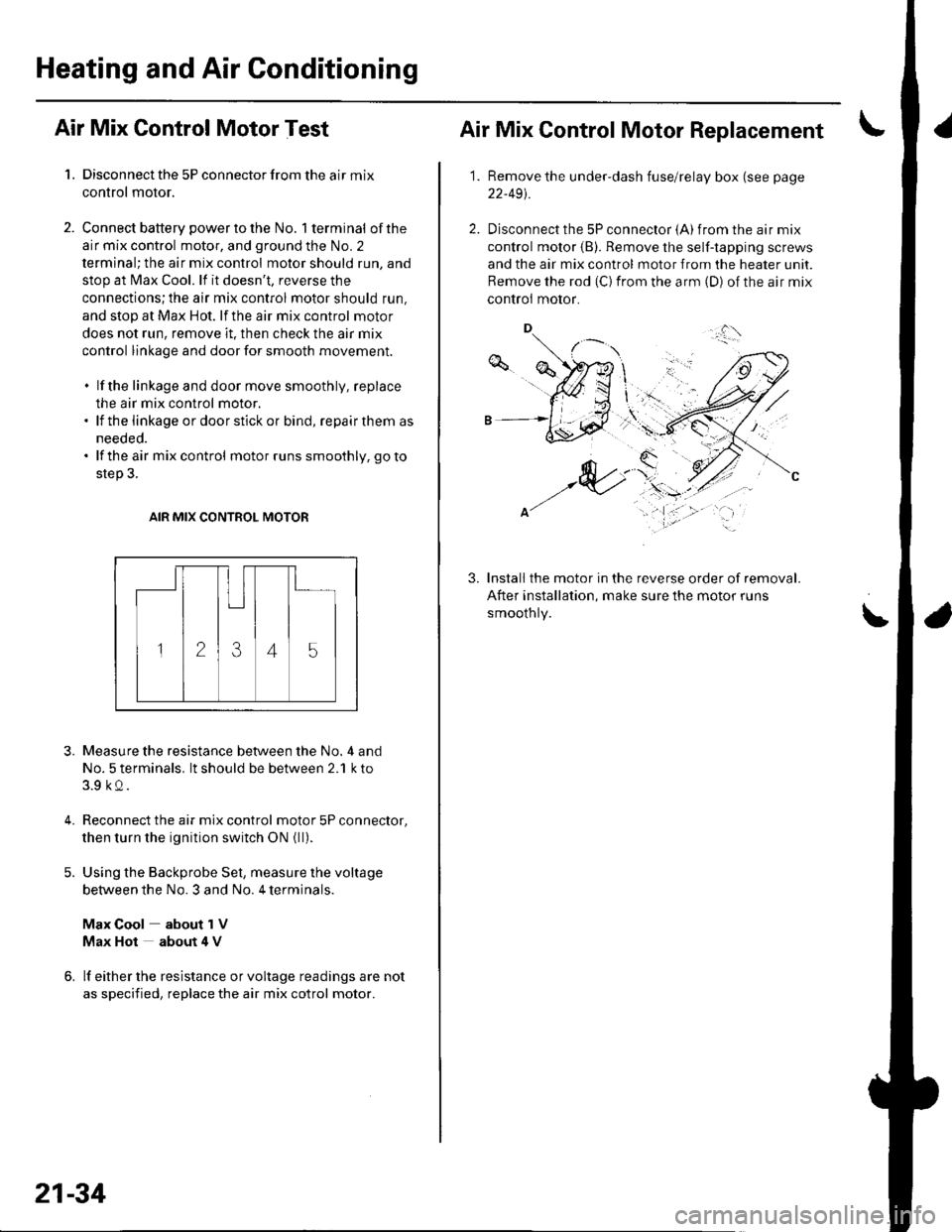

Air Mix Control Motor Test

1. Disconnect the 5P connector from the air mix

control motor.

2. Connect battery powertothe No. l terminal ofthe

air mix control motor, and ground the No. 2

terminal; the air mix control motor should run, and

stop at Max Cool. lf it doesn't, reverse the

connections;the air mix control motor should run,

and stop at Max Hot. lf the air mix control motor

does not run, remove it. then check the air mix

control linkage and door for smooth movement.

. lf the linkage and door move smoothly, replace

the air mix control motor.. lf the linkage ordoorstickor bind, repairthem as

needed.. lf the air mix control motor runs smoothly, go to

step 3.

AIR MIX CONTROL MOTOR

3.

4.

Measure the resistance between the No. 4 and

No. 5 terminals. lt should be between 2.1 k to

3.9 kQ.

Reconnect the air mix control motor 5P connector,

then turn the ignition switch ON {ll).

Using the Backprobe Set, measure the voltage

between the No. 3 and No. 4 terminals.

Max Cool about 1V

Max Hot about 4 V

lf either the resistance or voltage readings are not

as specified, replace the air mix cotrol motor.

21-34

Air Mix Control Motor Replacement

1.Remove the under-dash fuse/relay box (see page

22-491.

Disconnect the 5P connector {A) from the air mix

control motor (B). Remove the self-tapping screws

and the air mix control motor from the heater unit.

Remove the rod (C) from the arm (D) of the air mix

controi motor.

Install the motor in the reverse order of removal.

After installation, make sure the motor runs

smoothly.

3.

\'

,.,:l'

Page 806 of 1139

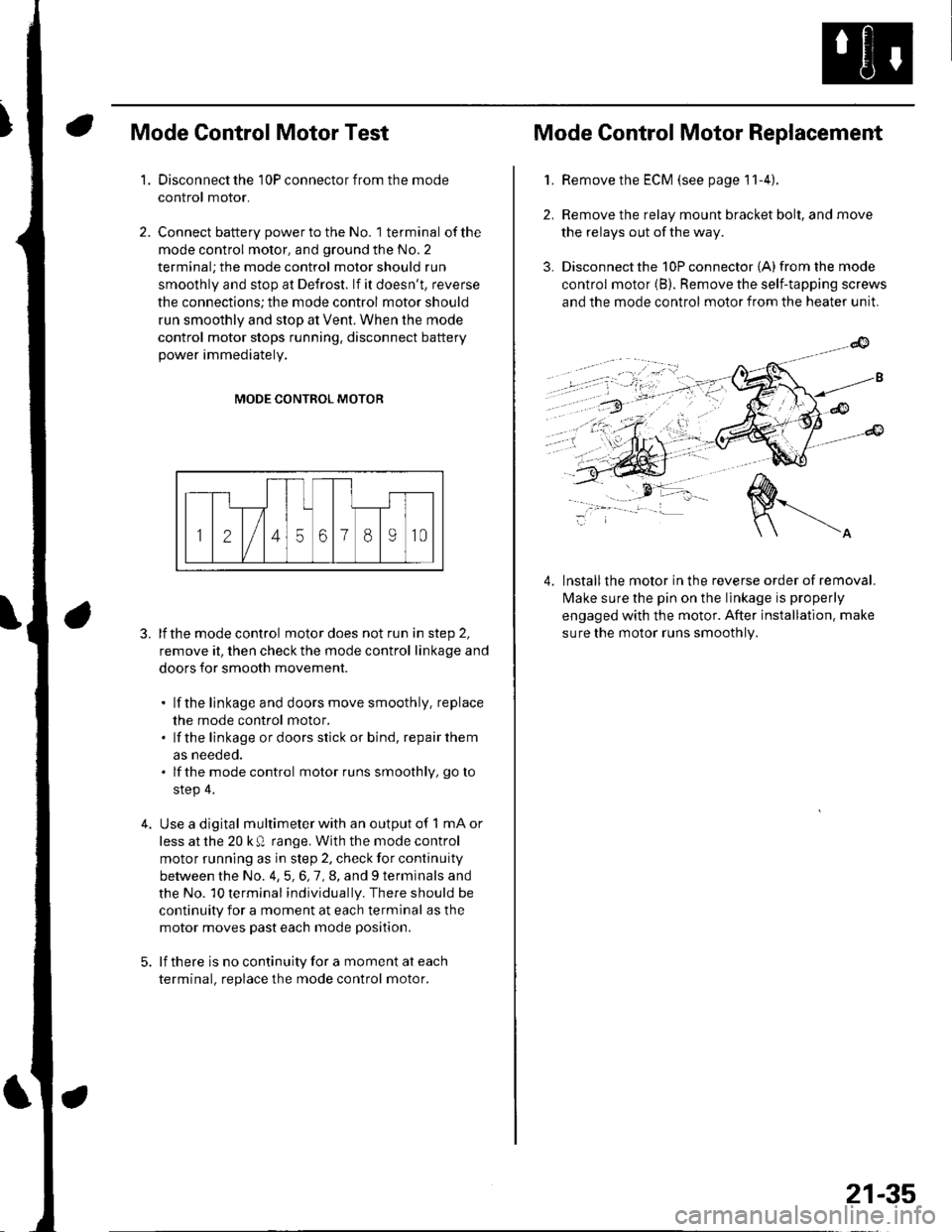

Mode Control Motor Test

Disconnect the 10P connector from the mode

control motor.

Connect battery power to the No. 1 terminal of the

mode control motor, and ground the No. 2

terminal; the mode control motor should run

smoothly and stop at Defrost. lf it doesn't, reverse

the connections; the mode control motor should

run smoothly and stop at Vent. When the mode

control motor stops running, disconnect battery

power immediately.

'1.

4.

MODE CONTROL MOTOR

3. lfthe mode control motor does not run in step 2,

remove it, then check the mode control linkage and

doors for smooth movement.

. lf the linkage and doors move smoothly. replace

the mode control motor.. lf the linkage ordoorsstick or bind, repairthem

as neeoeo.. lfthe mode control motor runs smoothly, go to

step 4.

Use a digital multimeter with an output of 1 mA or

less at the 20 k Q range. With the mode control

motor running as in step 2, check for continuity

between the No. 4,5,6,7,8, and 9 terminals and

the No. 10 terminal individually. There should be

continuity for a moment at each terminal as the

motor moves past each mode position.

lf there is no continuity for a moment at each

terminal. replace the mode control motor.

Mode Control Motor Replacement

2.

3.

1.Remove the ECM (see page 11-4).

Remove the relay mount bracket bolt, and move

the relays out of the way.

Disconnect the 10P connector {A) from the mode

control motor (B). Remove the self-tapping screws

and the mode control motor from the heater unit.

lnstallthe motor in the reverse order of removal.

lvlake sure the pin on the linkage is properly

engaged with the motor. After installation. make

sure the motor runs smoothly.

4.

21-35

Page 809 of 1139

Heating and Air Gonditioning

a

\

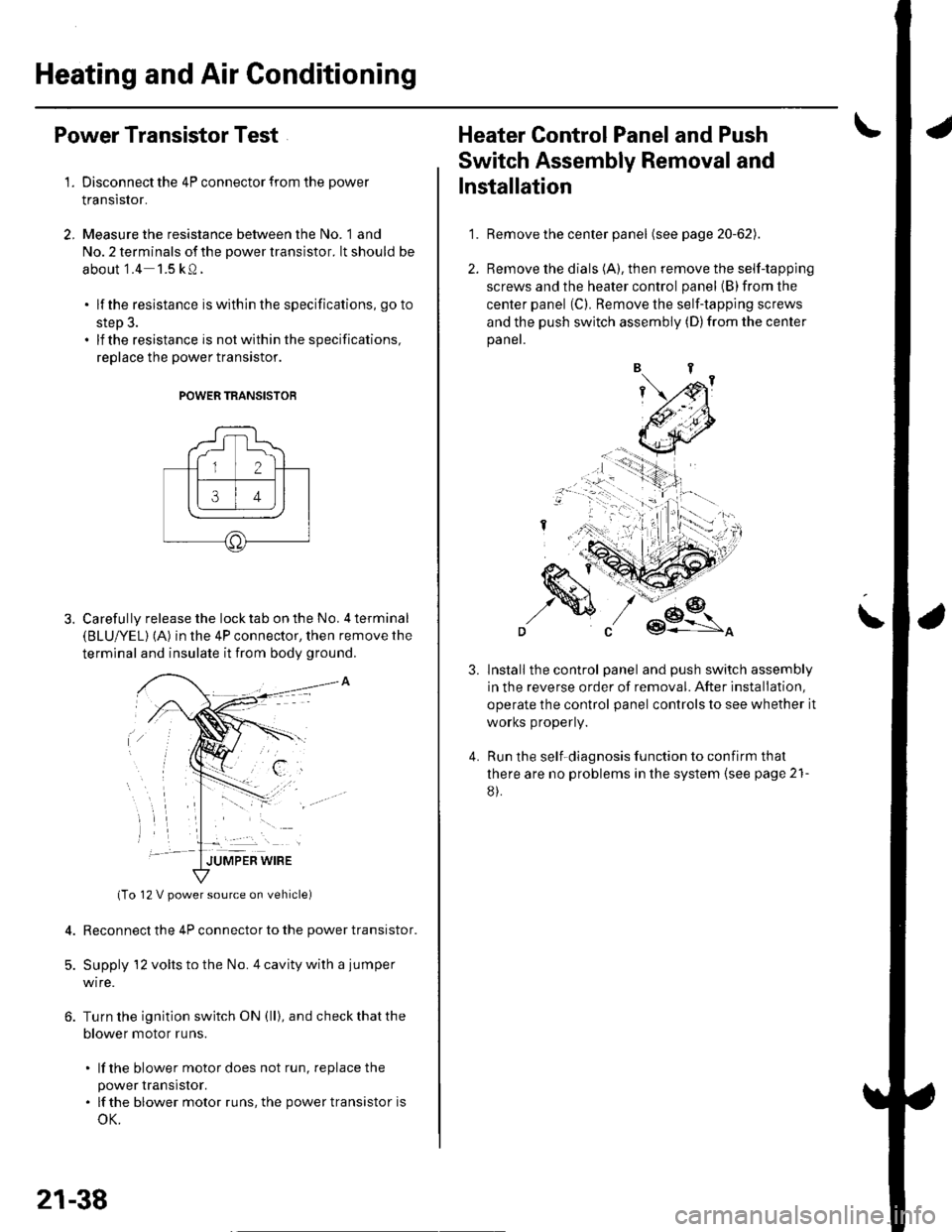

Power Transistor Test

1. Disconnect the 4P connector from the power

Iranslslor.

2, Measure the resistance between the No. 1 and

No. 2 terminals of the power transistor. lt should be

about '1.4 1.5 kQ.

. lf the resistance iswithln the specifications, go to

step 3.. lf the resistance is notwithin the specifications,

replace the power transistor.

POWER TRANSISTOB

Carefully release the lock tab on the No. 4 terminal(BLUI/EL) (A) in the 4P connector, then remove the

terminal and insulate it from body ground.

(To 12 V power source on vehicle)

Reconnect the 4P connector to the power transistor.

Supply 12 volts to the No. 4 cavity with a jumper

wire.

Turn the ignition switch ON (ll), and check that the

blower motor runs.

. lf the blower motor does not run, replace the

power rranstsror.. lf the blower motor runs,the powertransistoris

oK.

12 V power source on vehicle)

21-38

1.

Heater Control Panel and Push

Switch Assembly Removal and

Installation

Remove the center panel (see page 20-62).

Remove the dials (A), then remove the self-tapping

screws and the heater control panel (B)from the

center panel (Cl. Remove the self-tapping screws

and the push switch assembly (D)from the center

panel.

lnstall the control panel and push switch assembly

in the reverse order of removal. After installation,

operate the control panel controls to see whether it

worKs propeny.

Run the self-diagnosis function to confirm that

there are no problems in the system (see page 21-

8).

3.

4.

Page 814 of 1139

Heater Unit/Core Replacement

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

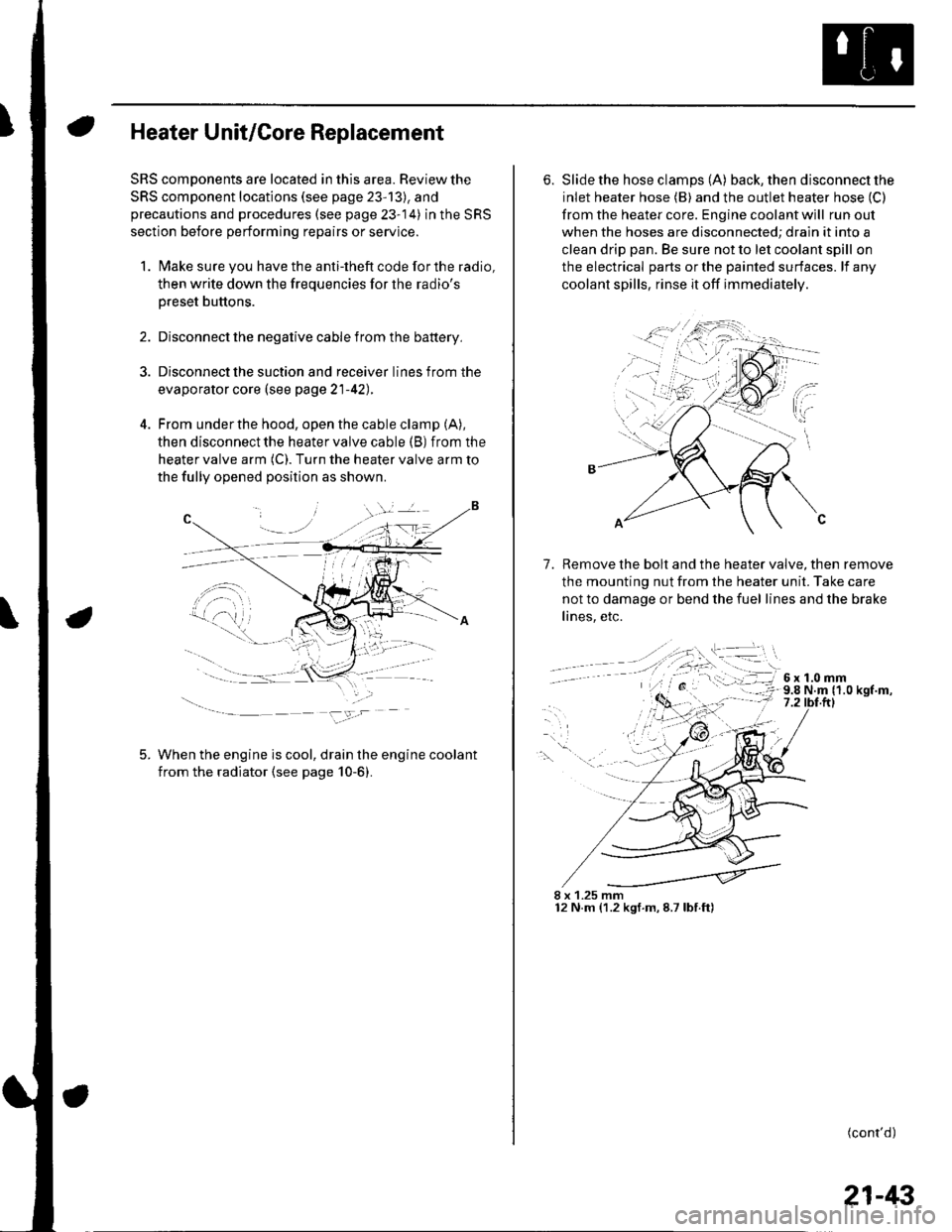

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

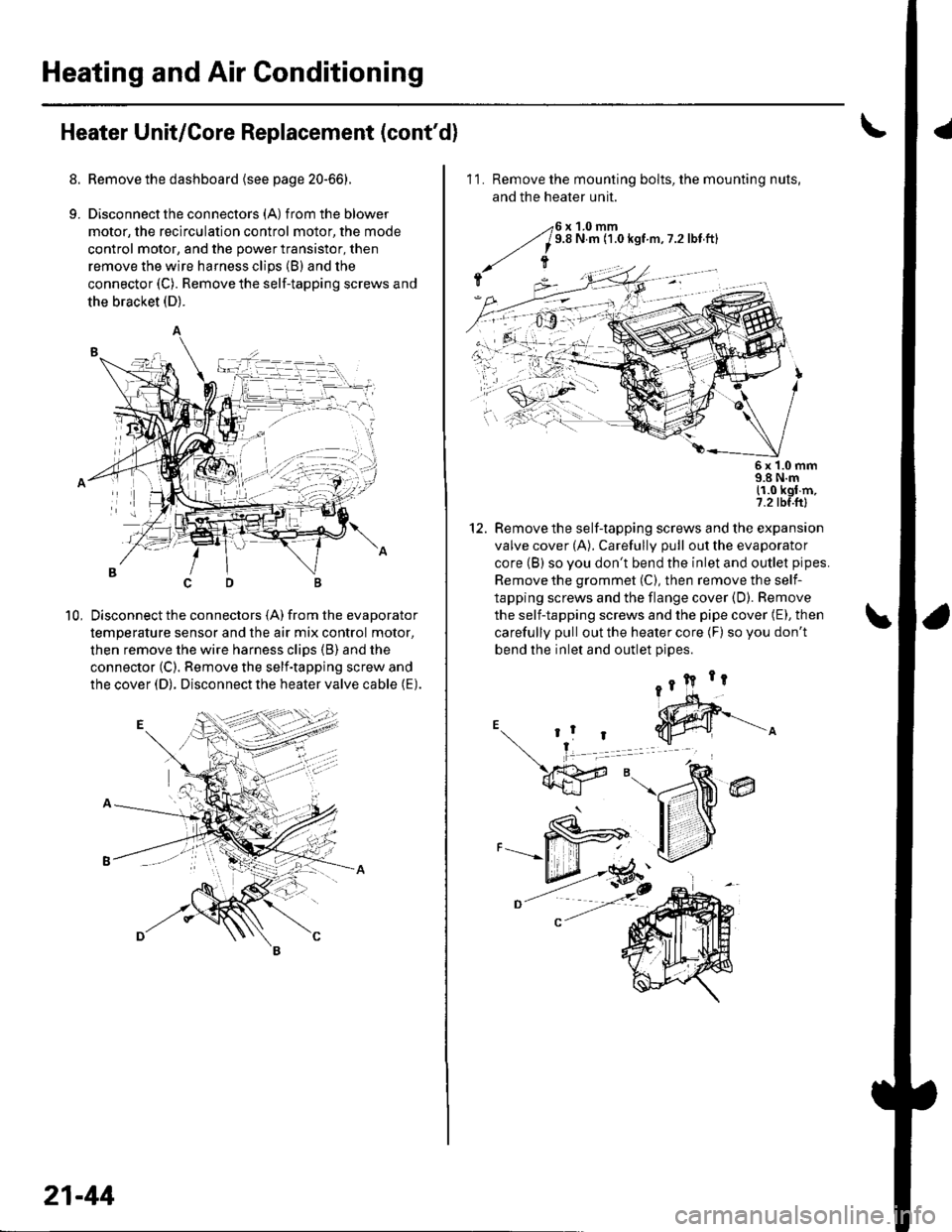

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43

Page 815 of 1139

Heating and Air Conditioning

Heater Unit/Core Replacement (cont'd)

8. Remove the dashboard {see page 20-66).

9. Disconnectthe connectors (A) from the blower

motor, the recirculation control motor, the mode

control motor, and the power transistor, then

remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screws and

the bracket (D).

Disconnect the connectors (A) from the evaporator

temperature sensor and the air mix control motor,

then remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screw and

the cover (D). Disconnect the heater valve cable (E).

10,

7t,

21-44

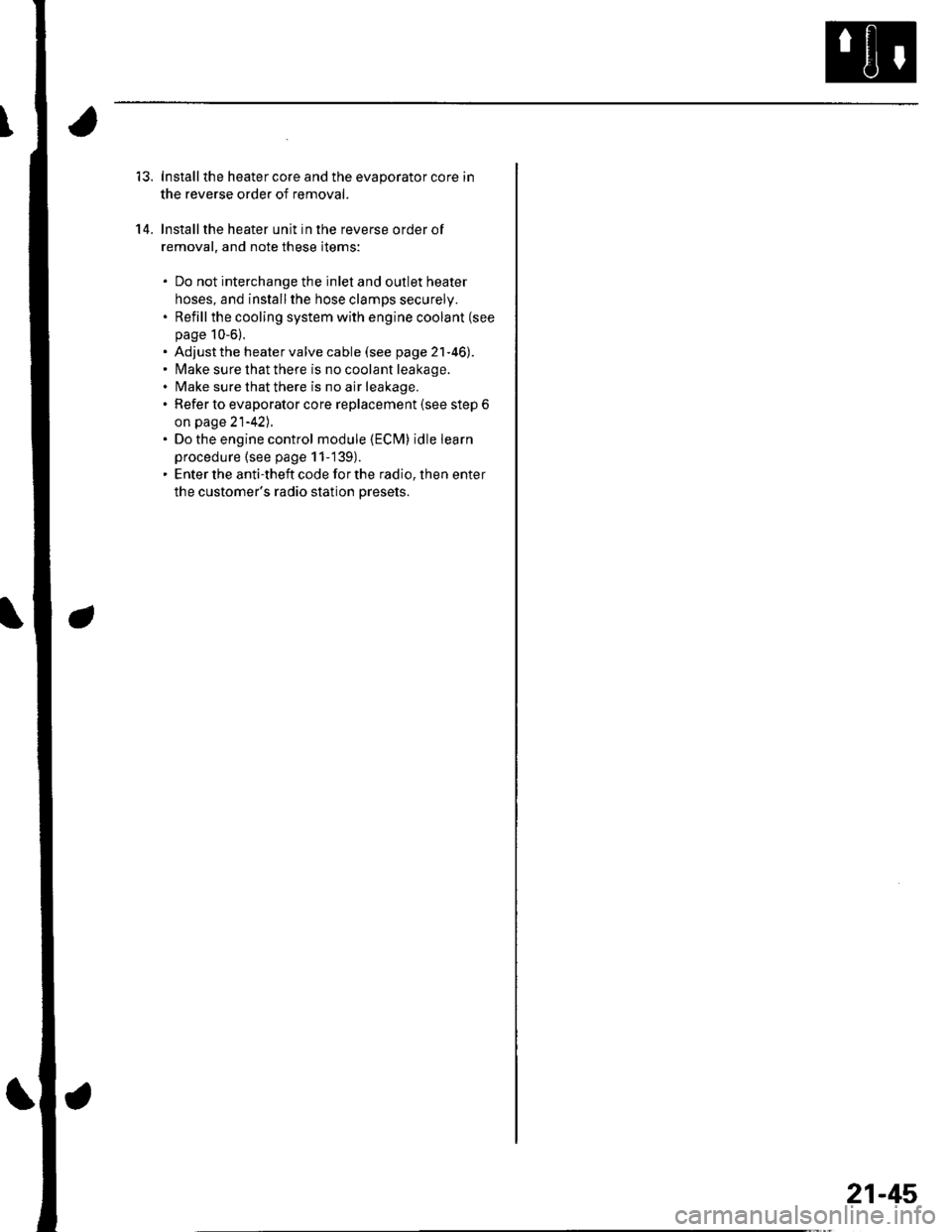

11. Remove the mounting bolts, the mounting nuts,

and the heater unit.

Remove the self-tapping screws and the expansion

valve cover (A). Carefully pull out the evaporator

core (B) so you don't bend the inlet and outlet pipes.

Remove the grommet (C), then remove the self-

tapping screws and the flange cover (D). Bemove

the self-tapping screws and the pipe cover (E), then

carefully pull out the heater core (F) so you don't

bend the inlet and outlet oioes.

@

5x 1.0 mm9.8 N.m11.0 kgl m,7.2 tbf.ftl

12.

Page 816 of 1139

13. Installthe heater core and the evaporator core in

the reverse order of removal.

14. Installthe heater unit in the reverse order of

removal, and note these items:

. Do not interchange the inlet and outlet heater

hoses, and installthe hose clamps securely.. Refillthe cooling system with engine coolant (see

page 10-6).. Adjust the heater valve cable (see page 2'l-461.. Make sure that there is no coolant leakage.. Make sure that there is no air leakage.. Refer to evaporator core replacement {see step 6

on page 21-42).. Do the engine control module (ECl\4) idle learn

procedure (see page 11-139).. Enter the anti-theft code for the radio, then enter

the customer's radio station Dresets.

21-45

Page 817 of 1139

Heating and Air Conditioning

Heater Valve Cable Adjustment

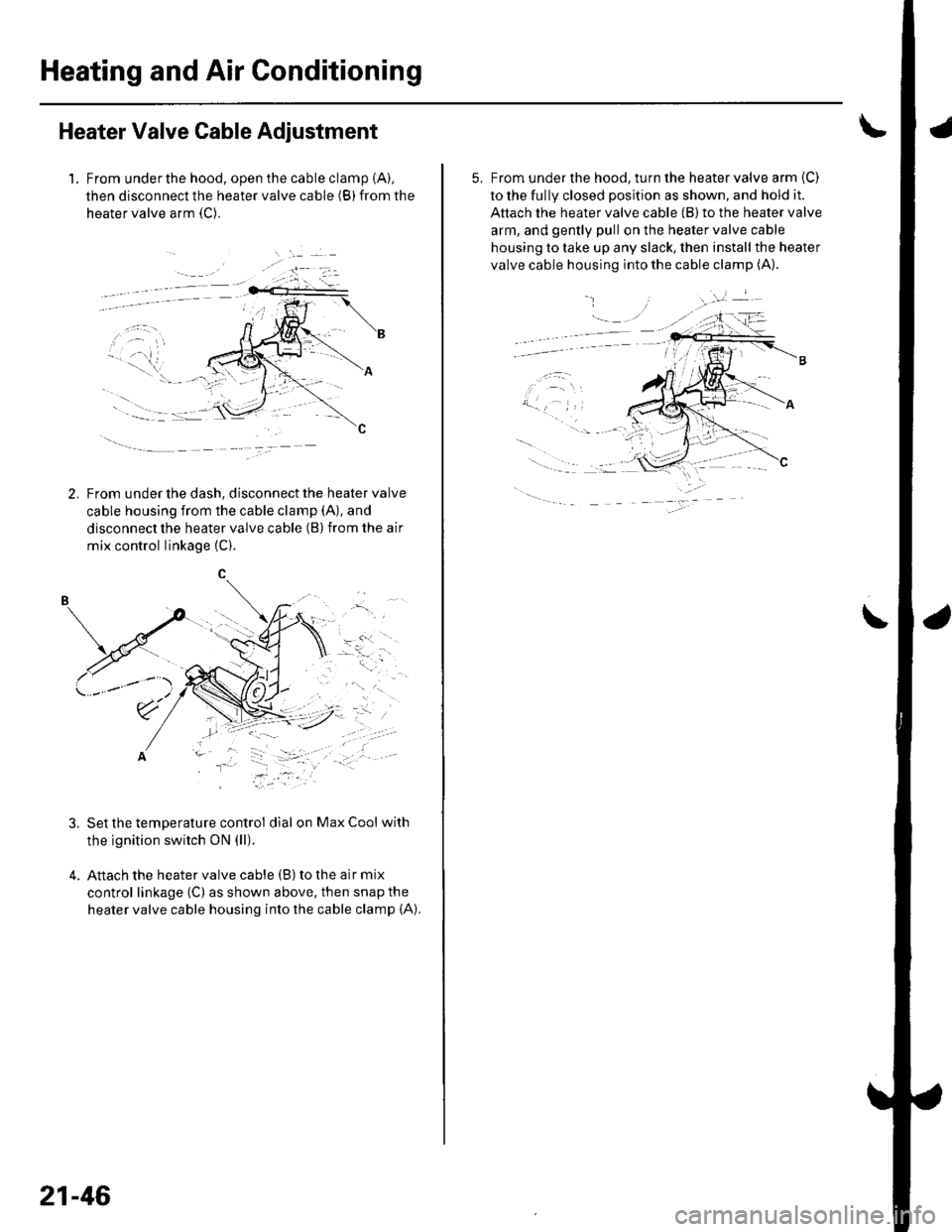

1. From underthe hood, open the cable clamp {A),

then disconnect the heater valve cable (B) from the

heater valve arm {C).

tFrom under the dash, disconnect the heater valve

cable housing from the cable clamp (A), and

disconnect the heater valve cable (B) from the air

mix control linkage {C).

, t.- l

\'r2t' ''' '

' ::"'

Set the temperature control dial on Max Cool with

the ignition switch ON (ll).

Attach the heater valve cable (B) to the air mix

control linkage (C) as shown above, then snap the

heater valve cable housing into the cable clamp (A).

.'.-:',,

-"ll

.....-

21-46

5, From under the hood, turn the heater valve arm {C)

to the fully closed position as shown, and hold it.

Attach the heater valve cable (B) to the heater valve

arm, and gently pull on the heater valve cable

housing to take up any slack, then install the heater

valve cable housing into the cable clamp (A).

.

\

Page 857 of 1139

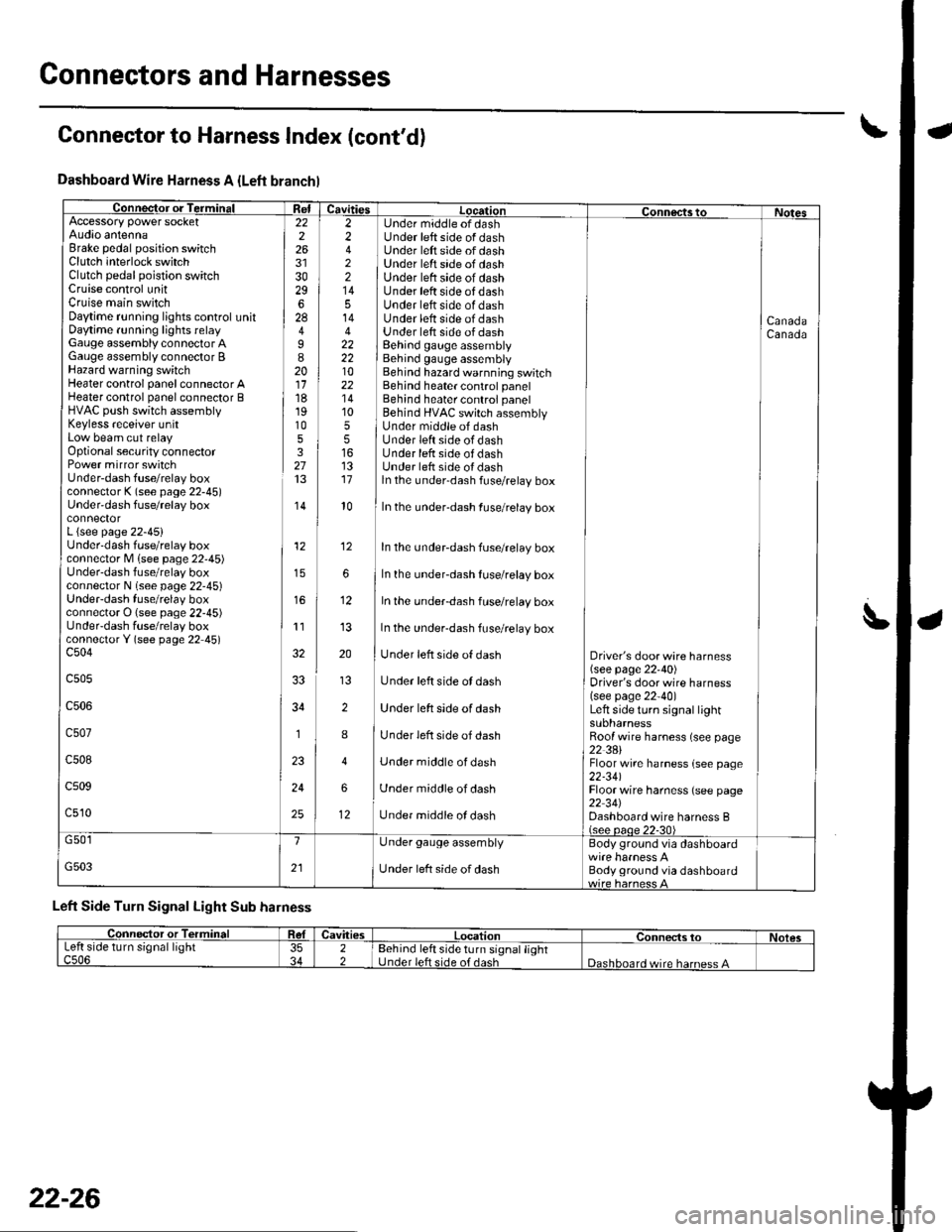

Connectors and Harnesses

Dashboard Wire Harness A {Left branchl

Connector or TerminalffiAccessory power socketAudio antennaBrake pedal position switchClutch interlock switchClutch pedal poistion switchCruise control unitCruise main switchDaytime r!nning lights control unitDaytime running lights relayGauge assembly connector AGauge assembly connector BHazard warning switchHeater control panel connector AHeater control panel connector BHVAC push switch assemblyKeyless receiver unitLow beam cut relayOptional security connectorPower mirror switchUnder-dash fuse/relay boxconnector K (see page 22-45)Under'dash fuse/relay box

L {see page 22-45}Underdash fuse/relay boxconnector M lsee page 22'45)Under-dash fuse/relay boxconnector N (see page 22-45)UndeFdash fuse/relay boxconnector O (see page 22-45)UndeFdash fuse/relay boxconnectorY (see page 22 45)c504

c505

c506

c507

c508

c509

c510

22226

3029628

I820111819105327

,I4

12

11

34

1

24

25

2 Under middle of dash2 Under left side of dash4 ] Under left side of dash2 ] Under left srde of dash2 | Under left side of dash14 I Under left side of dash5 Under left side of dash14 Under lett side of dash4 Under lett side of dash22 I Behind gauge assembly22 i Behind gauge assembly10 Behind hazard warnning switch22 Behind heater control panel'14 Behind heater control panel10 ] Behind HVAC switch assembly5 I Under middle of dash5 lUnderleftsideofdash16 Under lefr side of dash13 Under left side oI dash17 ln the under-dash fuse/relay box

CanadaCanada

l0In the under-dash fuse/relay box

In the undeFdash fuse/relay box

In the underdash fuse/relay box

In the under-dash fuse/relay box

In the under-dash fuse/relay box

Under left side of dash

Under left side ot dash

Under left side of dash

Under left side of dash

Under middle of dash

Under middle of dash

Under middle ol dash

Driver's door wire harness(see page 22'40)Driver's door wire harness(see page 22-40)Left side turo signal lightsuonarnessRoof wire harness (see page22 3AlFloor wire harness {see page22-341Floor wire harness (see page22 34JDashboard wire harness B(see oaoe 22-30)

12

12

G501

G503

1

21

Under gauge assembly

Under left side of dash

Body ground via dashboard

Body ground via dashboard

Left Side Turn Signal Light Sub harness

Connector to Harness Index (cont'd)

L

Connector or TerminalCavitiesLocationConnects toNolesLeft side turn signal lightc506353422Behind left side turn signal lightUnder left side of dashDashboard wire harness A

22-26

Page 878 of 1139

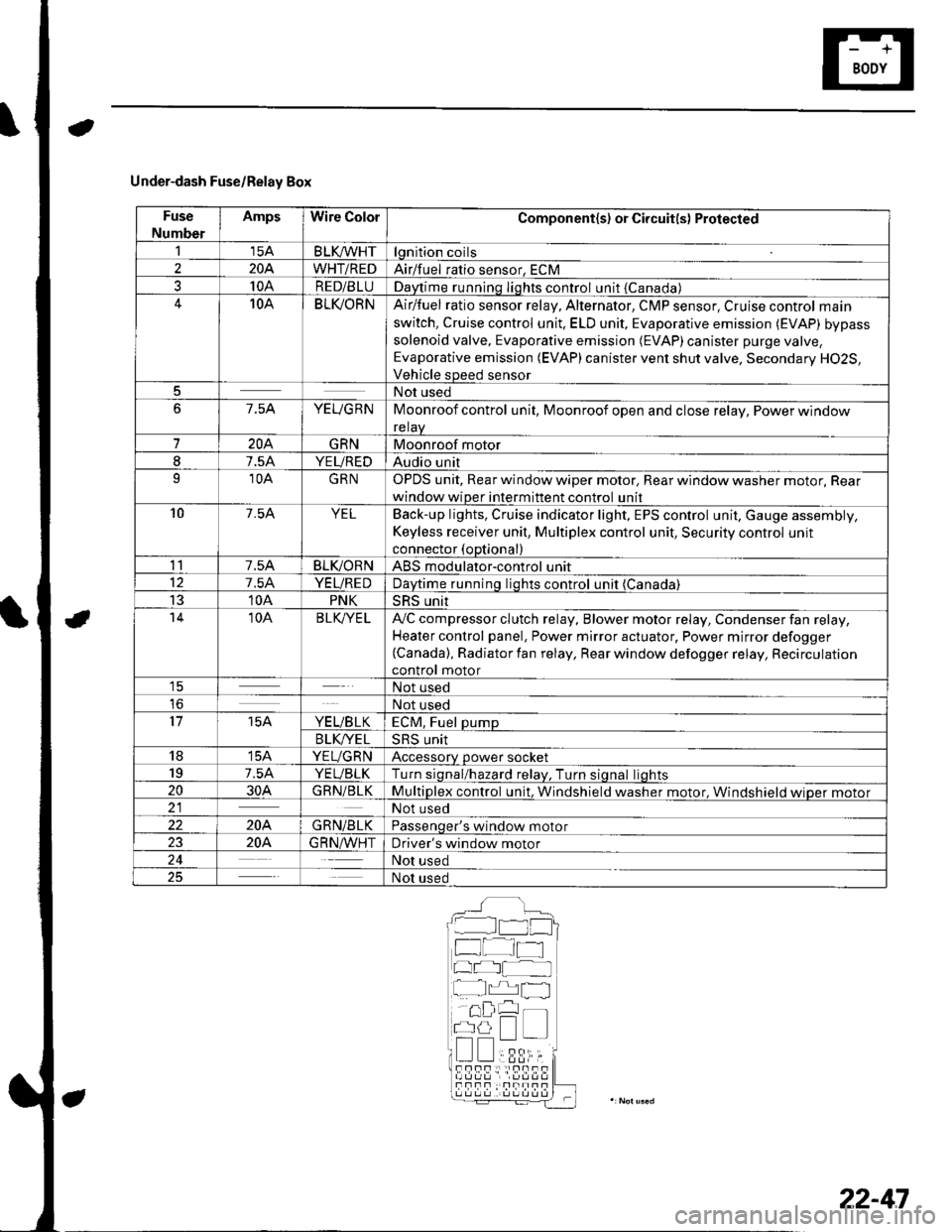

Under-dash Fuse/Relay Box

Fuse

Number

AmpsWire ColorComponent(s) or Circuit(s) Protected

115ABLKA/VHTlgnition coils

2204WHT/REDAirlfuel ratio sensor, ECM

310ARED/BLUDaytime running Iights control unit {Canada)10ABLI(ORNAir/fuel ratio sensor relay, Alternator, CMP sensor, Cruise control main

switch, Cruise control unit. ELD unit, Evaporative emission (EVAP) bypass

solenoid valve, Evaporative emission (EVAP)canister purge valve,

Evaporative emission (EVAP) canister vent shut valve, Secondary H02S,

Vehicle speed sensor

5Not used

67.5AYEUGRNMoonroof control unit, Moonroof open and close relay, Power window

relaV

7204GRNMoonroof motor

I7.5AYEUREDAudio unit

910AGRNOPDS unit, Rear window wiper motor, Rear window washer motor, Rear

window wiper intermittent control unit

107.54YELBack-up lights, Cruise indicator light, EPS control unit, Gauge assembly,

Keyless receiver unit, Multiplex control unit, Security control unit

connector (optional)

117.5ABLIVORNABS modulator-control unit

127.5AYEUREDDaytime runnino liohts control unit (Canada)

1310APNKSRS unit't410ABLK/YE LA,,/C compressor clutch relay, Blower motor relay, Condenser fan relay,

Heater control panel, Power mirror actuator, Power mirror defogger(Canada), Radiator fan relay, Rear window defogger relay, Recirculation

control motor1ENot used

loNot used

1715AYE L/B LKECM, Fuel pump

B LK/YE L>H> Unrr

1815AYEUGRNAccessory power socket

197.5AYEUBLKTurn siqnal/hazard relav, Turn siqnal liohts

2030AGRN/BLKMultiplex control unit, Windshield washer motor. Windshield wioer motor21Not used

22204GRN/BLKPassenqer's window motor

2320A.G R N,A/VHTDriver's window motor

24Not used

25Not used

__^:Hr tl_l

f at-t

at I

r^,rl fl

!!;r -

!339,i;s!!sf Fnf : |rnITf

22-47