check engine HONDA CIVIC 2003 7.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 196 of 1139

Cooling System

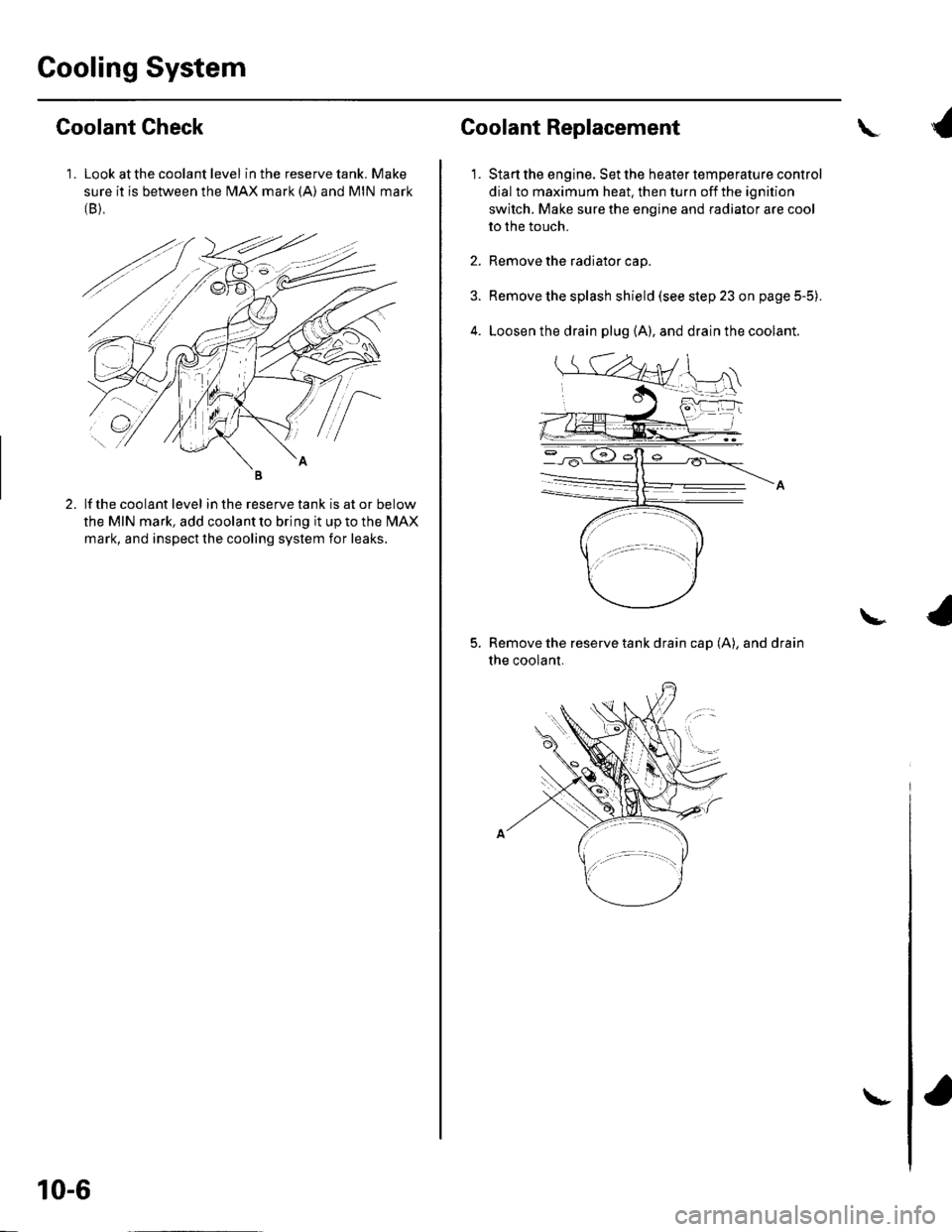

1 . Look at the coolant level in the reserve tank. Make

sure it is between the MAX mark (A) and MIN mark(B),

Goolant Check

lf the coolant level in the reserve tank is at or below

the MIN mark, add coolant to bring it up to the l\4AX

mark, and inspect the cooling system for leaks.

10-6

\-

Coolant Replacement

1.

\

Start the engine. Set the heater temperature control

dial to maximum heat. then turn off the ignition

switch. Make sure the engine and radiator are cool

to the touch.

Remove the radiator cap.

Remove the splash shield (see step 23 on page 5-5).

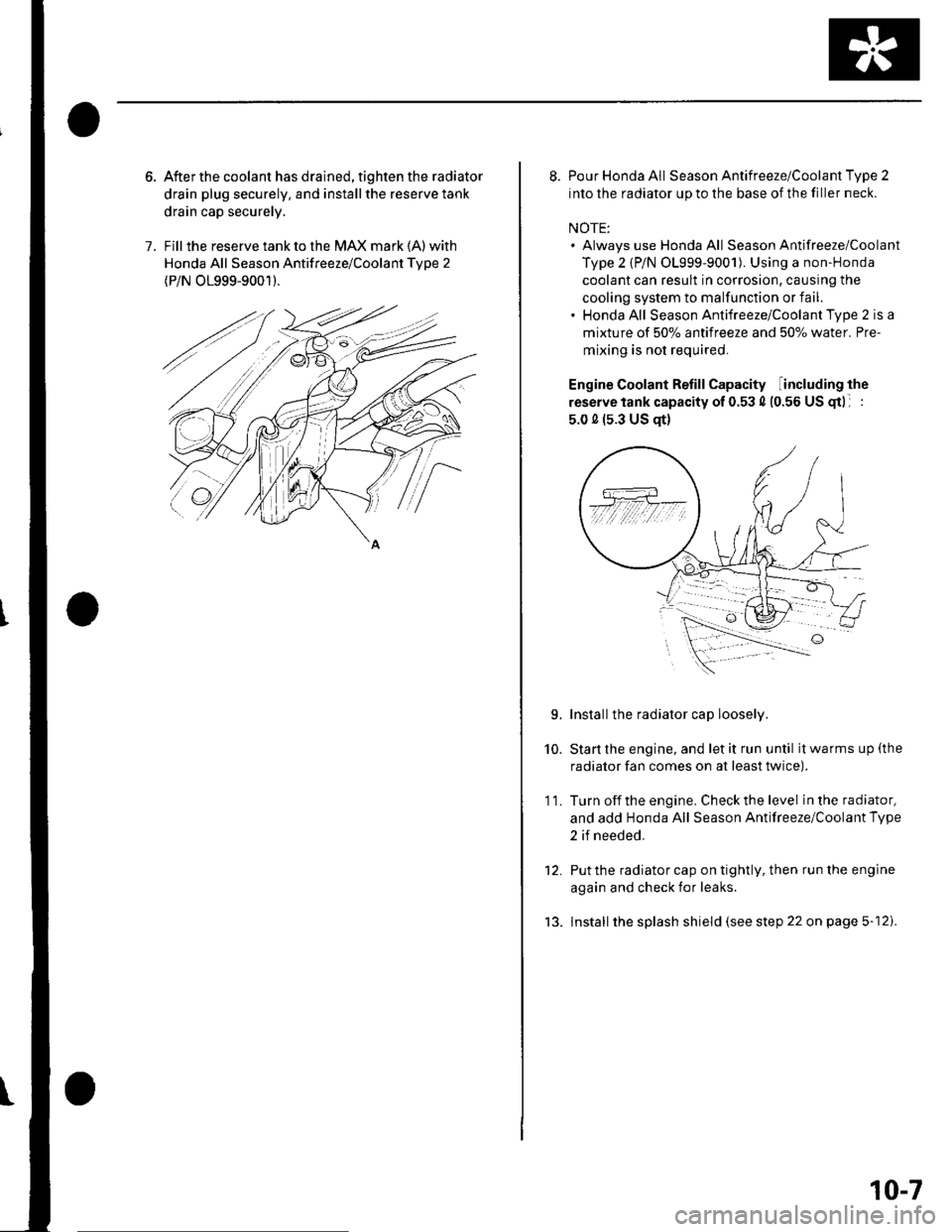

Loosen the drain plug (A), and drain the coolant.

Remove the reserve tank drain cap (A), and drain

the coolant.

\

Page 197 of 1139

1.

After the coolant has drained, tighten the radiator

drain plug securely. and installthe reserve tank

drain cap securely.

Fill the reserve tank to the MAX mark (A) with

Honda All Season Antifreeze/Coolant Tvpe 2

(P/N O1999-9001).

8. Pour Honda All Season Antifreeze/Coolant Type 2

into the radiator up to the base of the filler neck.

NOTE:. Always use Honda All Season Antifreeze/Coolant

Type 2 {P/N 01999-9001). Using a non-Honda

coolant can result in corrosion, causing the

cooling system to malfunction or fail.. Honda All Season Antifreeze/Coolant Type 2 is a

mixture of 50% antifreeze and 507o water. Pre-

mixing is not required.

Engine Coolant Refill Capacity including the

reserve tank capacity of 0.53 4 (0.56 US gtl :

5.0 0 (s.3 US qt)

Installthe radiator cap loosely.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

Turn off the engine. Check the level in the radiator,

and add Honda All Season Antifreeze/Coolant Type

2 if needed.

Put the radiator cap on tightly, then run the engine

again and check for leaks.

lnstall the splash shield (see step 22 on page 5-12).

10.

11.

L

tJ.

10-7

Page 202 of 1139

Fan Controls

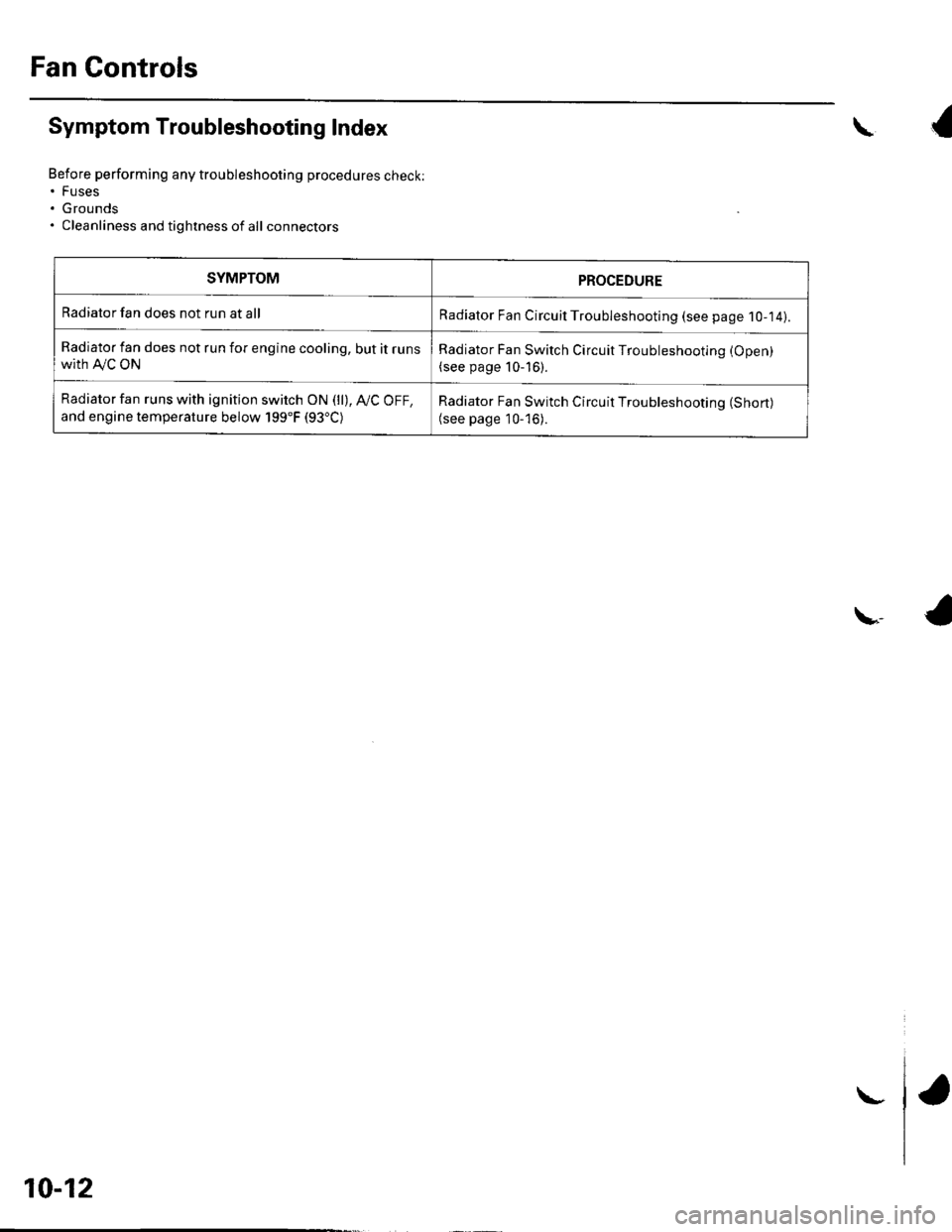

Symptom Troubleshooting Index

Before performing any troubleshooting procedures check:. Fuses. Grounds. Cleanliness and tightness of all connectors

\{

\,4

SYMPTOMPROCEDURE

Radiator fan does not run at allRadiator Fan Circuil Troubleshooting (see page 1O-14).

Radiator fan does not run for engine cooling, but it runswith A,/C ON

Radiator Fan Switch Circuit Troubleshooting (Open)

(see page 10-16).

Radiator fan runs with ignition switch ON (ll), Ay'C OFF,

and engine temperature below 199"F (93"C)Radiator Fan Switch Circuit Troubleshooting (Short)

(see page 10-'16).

10-12

\-

Page 206 of 1139

Fan Controls

Radiator Fan Switch Circuit

Troubleshooting (Openl

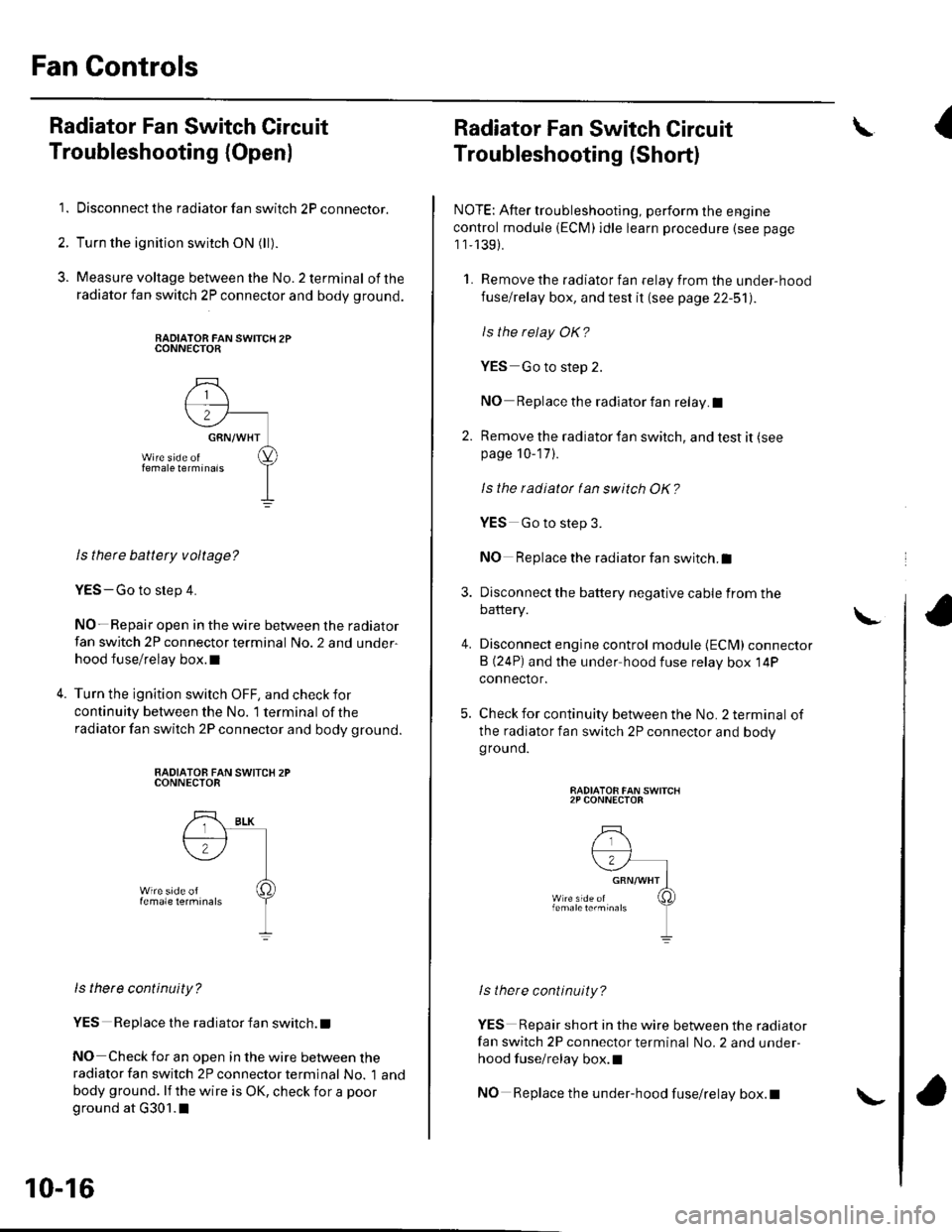

1. Disconnect the radiator fan switch 2P connector.

2. Turn the ignition switch ON (ll).

3. Measure voltage between the No.2 terminal ofthe

radiator fan switch 2P connector and body ground.

RADIATOR FAN SWITCH 2PCONNECTOR

ls there battety voltage?

YES-Go to step 4.

NO- Repair open in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

Turn the ignition switch OFF, and check for

continuity between the No. '1 terminal of the

radiator fan switch 2P connector and body ground.

RADIATOB FAN SWITCX 2PCONNECTOR

ls there continuity?

YES Replace the radiator fan switch. t

NO Check for an open in the wire between theradiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

10-16

\-

Radiator Fan Switch Circuit

Troubleshooting (Short)

NOTE: After troubleshooting, perform the engine

control module (ECM)idle learn procedure (see page

1 1,139).

1. Remove the radiator fan relay from the under-hood

fuse/relay box, and test it (see page 22-51).

ls the relay OK?

YES Go to step 2.

NO Replace the radiator fan relay.I

2. Remove the radiator fan switch, and test it (see

page 10-17 ).

Is the radiatot tan switch OK?

4.

YES Go to step 3.

NO Replace the radiator fan switch.I

Disconnect the battery negative cable from the

battery.

Disconnect engine control module {ECM) connector

B (24P) and the under hood fuse relay box 14P

connector.

Check for continuity between the No. 2 terminal of

the radiator fan switch 2P connector and bodygrouno.

RADIATOR FAN SWITCH2P CONNECTOR

lstnere continuity?

YES Repair short in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

NO Replace the under-hood fuse/relay box.t

\I

\

Page 210 of 1139

General Troubleshooting Information

Intermittent Failures

The term "intermittent failure" means a svstem mav

have had a failure. but it checks OK now. lf the

Malfunction Indicator Lamp (MlL) on the dash does not

come on, check for Door connections or loose terminals

at all connectors related to the circuit that Vou are

troubleshooting.

Opens and Shorts

"Ooen" and "Short" are common electrical terms. An

open is a break in a wire or at a connection. A short is

an accidental connection of a wire to ground or to

another wire. In simple electronics, this usually means

something won't work at all. With complex electronics(such as ECMs)this can sometimes mean something

works, but not the way it's supposed to.

How to Use the PGM Tester or a Scan Tool

lf the MIL {Malfunction Indicator Lamp} has come on

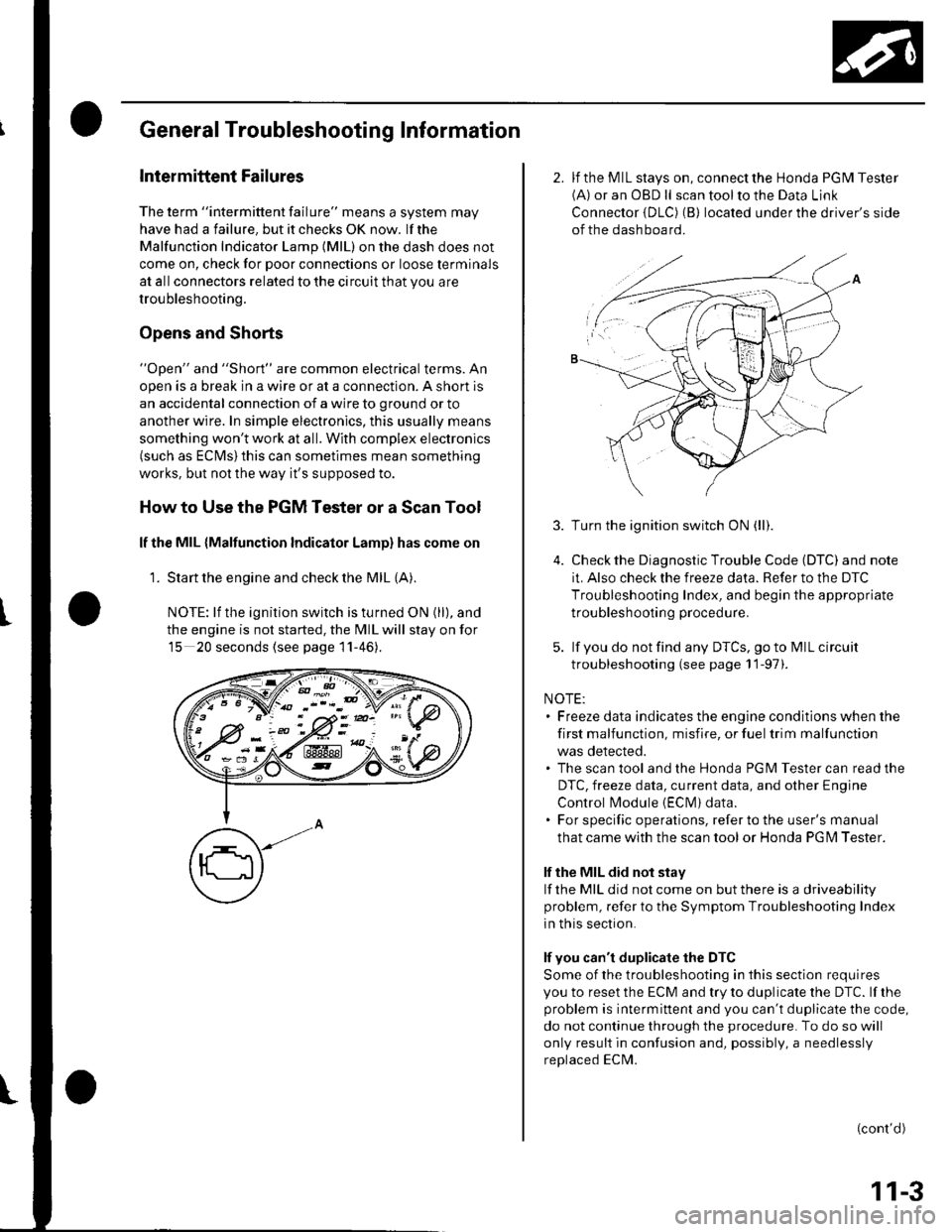

'1. Start the engine and check the MIL {A).

NOTE: lf the ignition switch is turned ON (ll), and

the engine is not started, the MIL will stay on for

15 20 seconds (see page 11-46).

K-> ;"PN/.- -::: - -d V-: !

w:ix&K#

2. lf the MIL stays on, connect the Honda PGM Tester(A) or an OBD ll scan tool to the Data Link

Connector {DLC) (B) located under the driver's side

of the dashboard.

3.

5.

Turn the ignition switch ON (ll).

Check the Diagnostic Trouble Code (DTC) and note

it. Also check the freeze data. Refer to the DTC

Troubleshooting Index, and begin the appropriate

troubleshooting procedure.

lf you do not find any DTCS, go to MIL circuit

troubleshooting (see page 11-97).

NOTE:. Freeze data indicates the engine conditions when the

first malfunction, misfire, or fuel trim malfunction

was detected.. The scan tool and the Honda PGM Tester can read the

DTC, freeze data, current data, and other Engine

Control l\4odule {EClvl) data.. For specific operations, refer to the user's manual

that came with the scan tool or Honda PG l\4 Tester.

lf the MIL did not stay

lf the MIL did not come on but there is a driveability

problem, refer to the Symptom Troubleshooting Index

in this section.

lf you can't duplicate the DTC

Some of the troubleshooting in this section requires

you to reset the ECM and try to duplicate the DTC. lf rhe

problem is intermittent and you can't duplicate the code,

do not continue through the procedure. To do so will

only result in confusion and, possibly, a needlessly

replaced ECM.

(cont'd)

11-3

Page 217 of 1139

Fuel and Emissions Systems

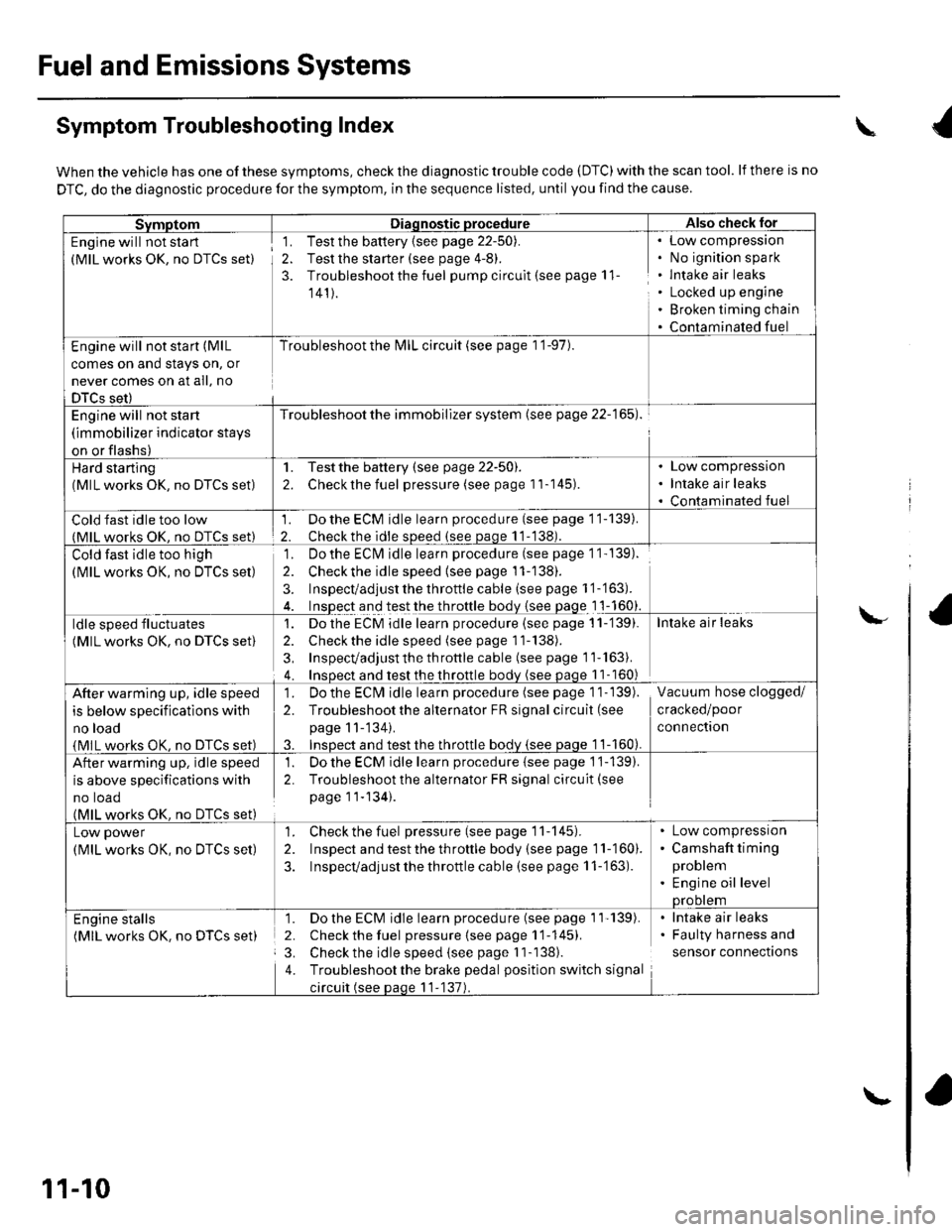

Symptom Troubleshooting Index

When the vehicle has one of these symptoms, check the diagnostic trouble code (DTC) with the scan tool. lf there is no

DTC, do the diagnostic procedure for the symptom, in the sequence listed, until you find the cause.

SvmotomDiaqnostic procedureAlso check lor

Engine will not sta rt

(MlL works OK, no DTCS set)

1. Test the battery {see page 22-50).

2. Test the starter (see page 4-8).

3. Troubleshoot the fuel pump circult (see page 11

141).

Low compressron

No ignition spark

lntake air leaks

Locked up engine

Broken timing chain

Contaminated fuel

Engine will not start (MlL

comes on and stays on, or

never comes on at all, no

DTCS set)

Troubleshoot the l\4lL circuit (see page 1 '1-97).

Engine will not start

(immobilizer indicator stays

on or flashs)

Troubleshoot the immobilizer system (see page 22-165).

Hard starting(MlL works OK, no DTCS set)

1. Testthe battery (see page 22-50).

2. Checkthe fuel pressure (see page 11-145).

Low compression

Intake air leaks

Contaminated fuel

Cold fast idle too low(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 11-139).

2. Checkthe idle sDeed (see paqe 11-138).

Cold fast idle too high

(MlL works OK, no DTCS set)

Do the ECI\4 idle learn procedure (see page 1 1- 139).

Checkthe idle speed {see page 11-138).

Inspect/adjust the throttle cable (see page 1 '1-'163).

Inspect and test the throttle body {see page 1 1-160}.

']�

2.

3.

ldle speed fluctuates

(MlL works OK, no DTCS set)

1. Dothe ECM idle learn procedure (see page 11-'139).

2. Check the idle speed (see page 11-138).

3, Inspecvadjust th e throttle cable (see page 11''163).

4. Insoect and test the throttle bodv (see paqe 11- 160)

Intake air leaks

After warming up, idle speed

is below specifications with

no load

{MlL works OK, no DTCS set)

1. Do the ECIVI idle learn procedure (see page 1 1- 139).

2. Troubleshootthe alternator FR signal circuit (see

page 11-'134).

3. InsDect and test the throttle bodv {see paqe 1 1-160).

Vacuum hose clogged/

cracked/poor

connectron

After warming up, idle speed

is above specifications with

no toao(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure {see page 1'j-139).

2. Troubleshoot the alternator FR signal circuit(see

page 11-134).

Low power

(MlL works OK, no DTCS set)

1. Check the fuel pressure(seepagell-145).

2. Inspect and test the th roftle body (see page 11-160).

3. Inspecvadjust the throttle cable (see page 11-'163).

Low compressron

Camshaft timing

problem

Engine oil levelprootem

Engine stalls(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 1'l'139).

2. Check the fuel pressure{seepagell-145).

3. Check the idle speed (see page I 1-138).

4. Troubleshootthe brake pedal position switch signal

circuit (see paqe 11-137).

lntake air leaks

Faulty harness and

sensor connections

\

\-

11-10

\-

Page 219 of 1139

Fuel and Emissions Systems

System Descriptions

Electronic Control System

The functions of the fuel and emlssion control systems are managed by the engine control module (ECM).

Fail-safe Function

When an abnormality occurs in the signal from a sensor, the ECI\4 ignores that signal and assumes a pre-programmed

value for that sensor that allows the enqine to continue to run.

Back-up Function

When an abnormality occurs in the ECM, the injectors are controlled by a back-up circuit independent of the system to

permit minimal driving.

Self-diagnosis

When an abnormality occurs in the signal from a sensor, the ECM supplies ground for the malfunction indicator lamp

{MlL) and stores the diagnostic trouble code {DTC) in erasable memory. When the ignition is first turned on, the EClvl

supplies ground to the l\4lL for 15 to 20 seconds to check the M lL bulb condition.

Two Driving Cycle Detection Method

To prevent false indications, the "two driving cycle detection method" is used for some self-diagnostic functions.

When an abnormality occurs, the ECM stores it in its memory. When the same abnormality recurs afterthe ignition

switch is turned OFF and ON (ll) again, the ECM turns on the MlL.

\

11-12

\.

\{

Page 230 of 1139

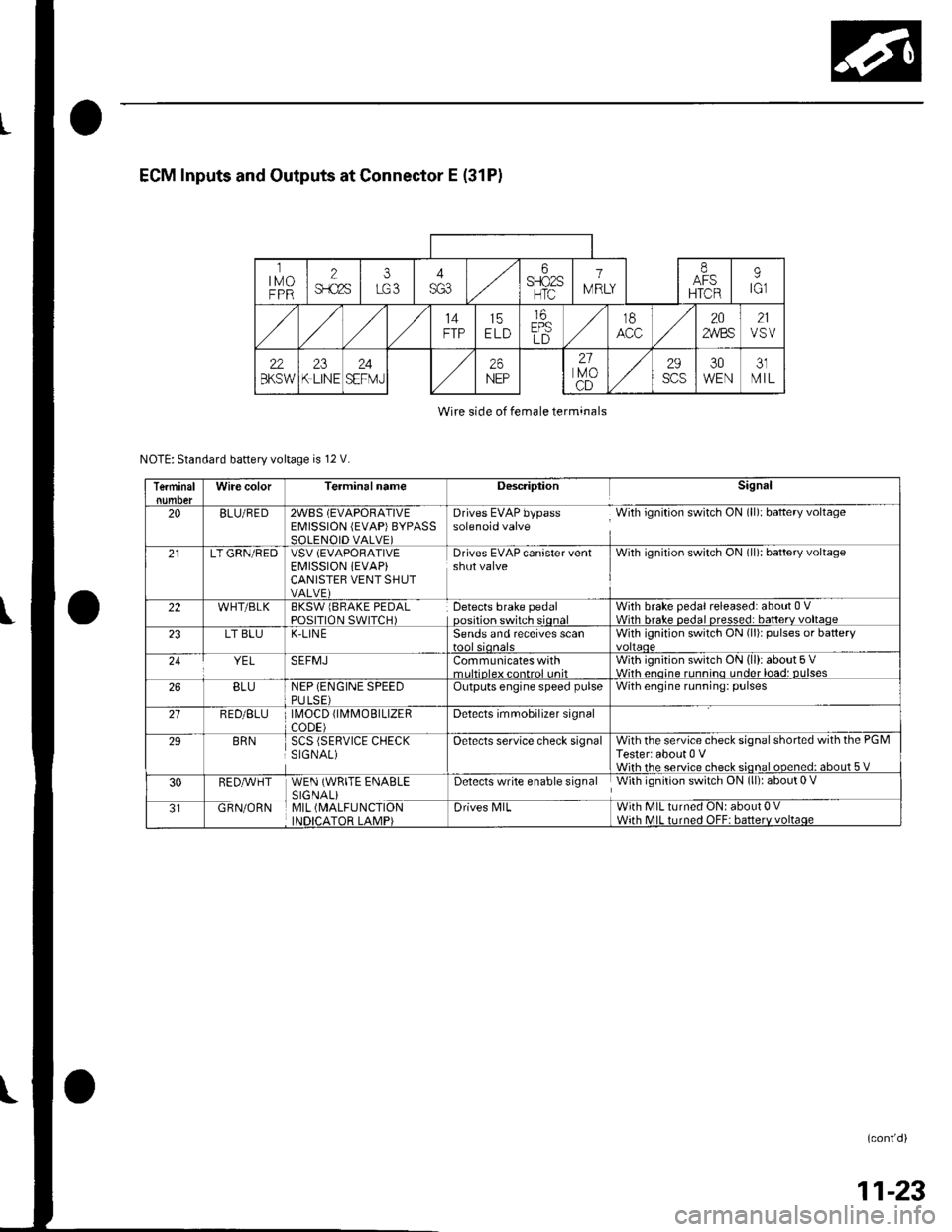

ECM Inputs and Outputs at Connector E (31P)

ltMoFPR

2$.c2s

i6SFIO2SHTC

1

IV RLY

IAFSHTCR

9tGl

14FTP15ELD

16EPSLD

t8202,4/BS21VSV

22BKSW23K LINE24SEFMJ26NEP

21lvoCD

29scs30WEN31MIL

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

TerminalWire colorTerminalnameDescriptionSignal

20BLU/RED2WBS (EVAPORATIVEEMISSION (EVAP)BYPASSSOLENOID VALVE)

Drives EVAP bypass With ignition switch ON (ll): baftery voltagesolenoid valve

21LT GRN/REDVSV (EVAPORATIVE

EI\4ISSION iEVAP)CANISTEB VENT SHUTVALVE)

Drives EVAP canister ventshut valveWith ignilion switch ON (ll): battery voltage

22WHT/BLKBKSW lBRAKE PEDALPOSITION SWITCH)Detects brake pedaloosition switch sionalWith brake pedal released: about 0 VWith hrake nedal nresse.l: batterv voltaoe23LT BLUK-LIN ESends and receives scanWith ignition switch ON (li)r pulses or battery

YELSEFMJCommunicates withmrltinleY eontrol unitWith ignition switch ON (ll): about 5 VWith enoine runnino under load: DUlses26BLUNEP (ENGINE SPEEDPULSE)Outputs engine speed pulseWith engine running: pulses

21RED/BLU \40CD fl\4MOBTLTZERCODE)Detects imrnobilizer signal

29BRNSCS (SERVICE CHECKSIGNAL)Oetects service check signalWith the service check signal shorted with the PGMTester: about 0 VWiih rhe service check sional ooened: about 5 V

30RED,A/VHTWEN (WRITE ENABLESIGNALiDetects write enable signal With ignition switch ON (ll): about 0 V

GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP)Drives N4lLWith MIL turned ON: about 0 VWith MIL turned OFF: batterv voltaqe

(cont'd)

11-23

Page 234 of 1139

lgnition Timing Control

The ECM contains the memory for basic ignition timing

at various engine speeds and manifold absolute

pressure. lt also adjusts the timing according to engine

coolant temperature.

Iniector Timing and Duration

The ECM contains the memory for basic discharge

duration at various engine speeds and manifold

pressures. The basic discharge duration, after being

read out from the memory, is further modified by

signals sent from various sensors to obtain the final

discharge duration.

By monitoring long term fuel trim, the ECM detects long

term malfunctions in the fuel system and sets a

Diagnostic Trouble Code {DTC).

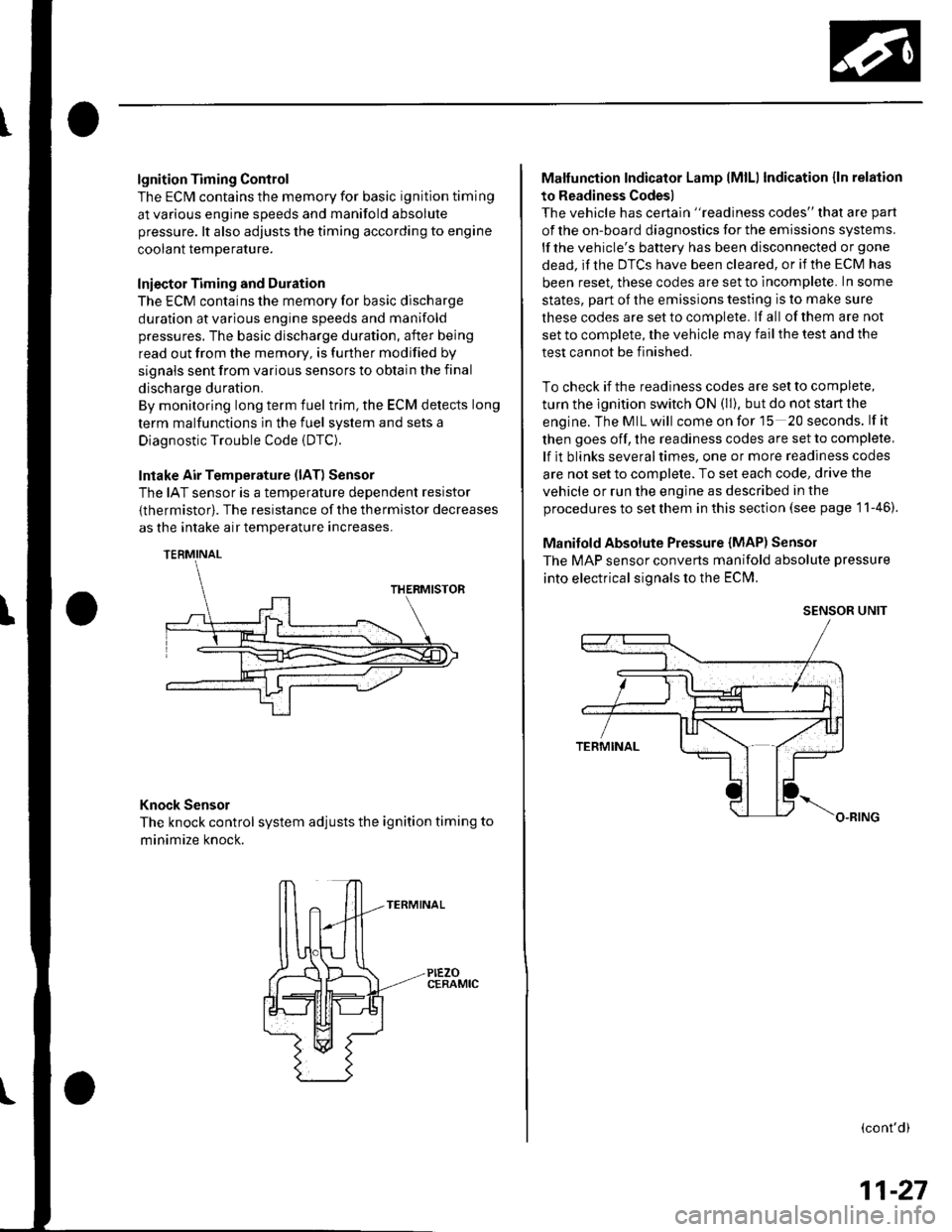

Intake Air Temperature (lAT) Sensor

The IAT sensor is a temperature dependent resistor

{thermistor). The resistance of the thermistor decreases

as the intake air temDerature increases.

Knock Sensor

The knock control system adjusts the ignition timing to

minimize knock.

PIEZOCERAMIC

Malfunction Indicator Lamp lMlLl Indication {ln relation

to Readiness Codes)

The vehicle has certain "readiness codes" that are part

of the on-board diagnostics for the emissions systems.

lf the vehicle's baftery has been disconnected or gone

dead. if the DTCS have been cleared, or if the ECM has

been reset. these codes are set to incomplete. In some

states, part of the emissions testing is to make sure

these codes are set to comDlete. lf all of them are not

set to complete, the vehicle may fail the test and the

test cannot be finished.

To check if the readiness codes are set to complete,

turn the ignition switch ON (ll). but do not start the

engine.TheMILwill comeonforlS 20seconds. lf it

then goes off, the readiness codes are set to complete,

lf it blinks severaltimes, one or more readiness codes

are not set to comolete. To set each code, drive the

vehicle or run the engine as described in the

procedures to set them in this section (see page 1 1-46).

Manifold Absolute Pressure {MAP) Senso]

The MAP sensor converts manifold absolute pressure

into electrical signals to the ECM.

SENSOR UNIT

(cont'd)

11-27

Page 235 of 1139

Fuel and Emissions Systems

(

(

(

System Descriptions (cont'dl

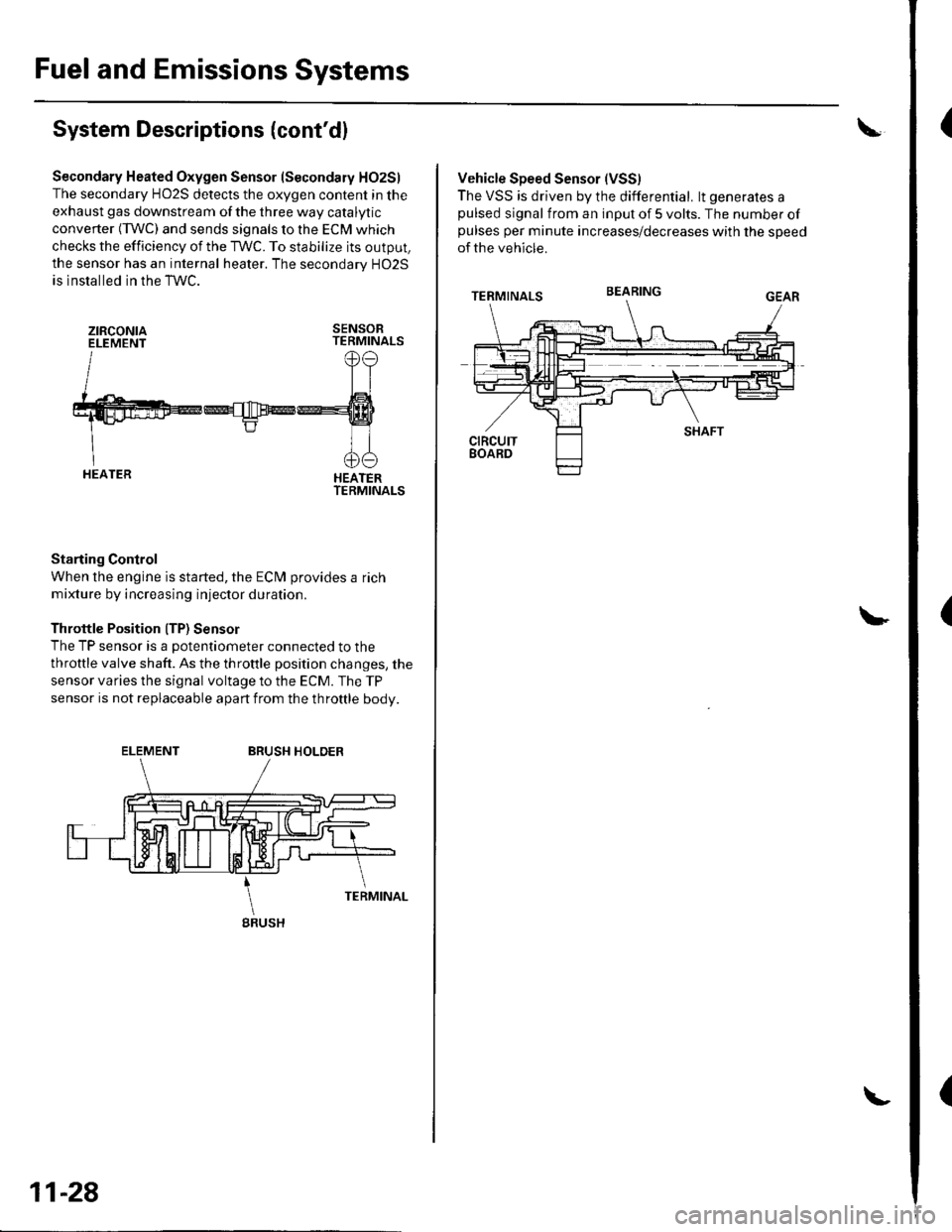

Secondary Heated Oxygen Sensor (Secondary HO2S)

The secondary HO2S detects the oxygen content in the

exhaust gas downstream of the three way catalytic

converter (TWC) and sends signals to the ECM which

checks the efficiency of the TWC. To stabilize its output,

the sensor has an internal heater. The secondarv HO2S

is installed in the TWC.

ztRcoNtaELEMENTSENSORTERMINALS

HEATERTERMINALS

Starting Control

When the engine is started, the ECM provides a rich

mixture by increasing injector duration.

Throttle Position ITP) Sensor

The TP sensor is a potentiometer connected to the

throttle valve shaft. As the throttle position changes, the

sensor varies the signal voltage to the ECM. The TP

sensor is not replaceable apart from the throftle body.

ELEMENTBRUSH HOLDER

gRUSH

11-28

Vehicle Speed Sensor (VSS)

The VSS is driven by the differential. lt generates apulsed signal from an input of 5 volts. The number ofpulses per minute increases/decreases with the speed

of the vehicle.

BEARING